Design of a Wheelchair-Mounted Robotic Arm for Feeding Assistance of Upper-Limb Impaired Patients

Abstract

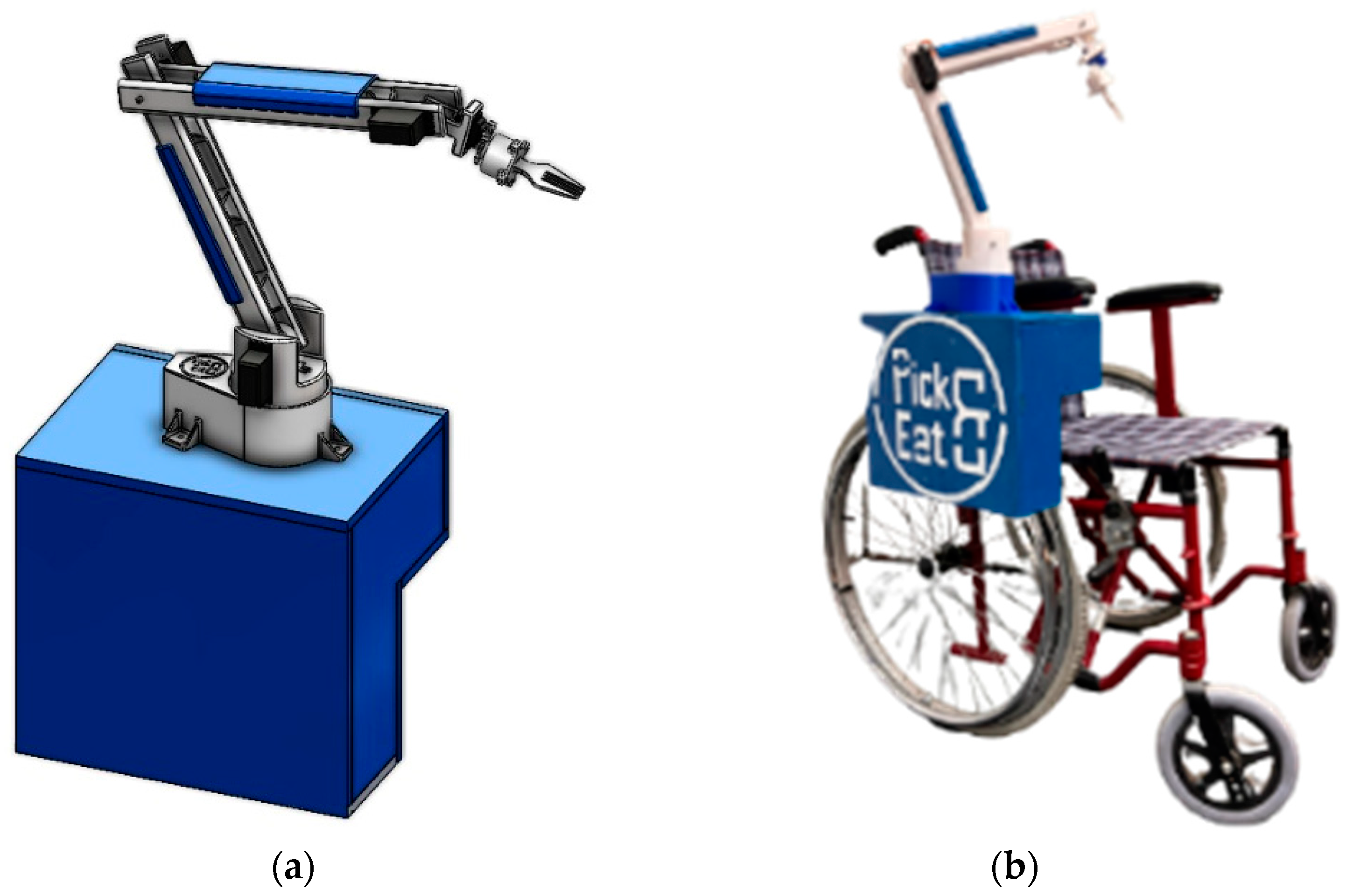

:1. Introduction

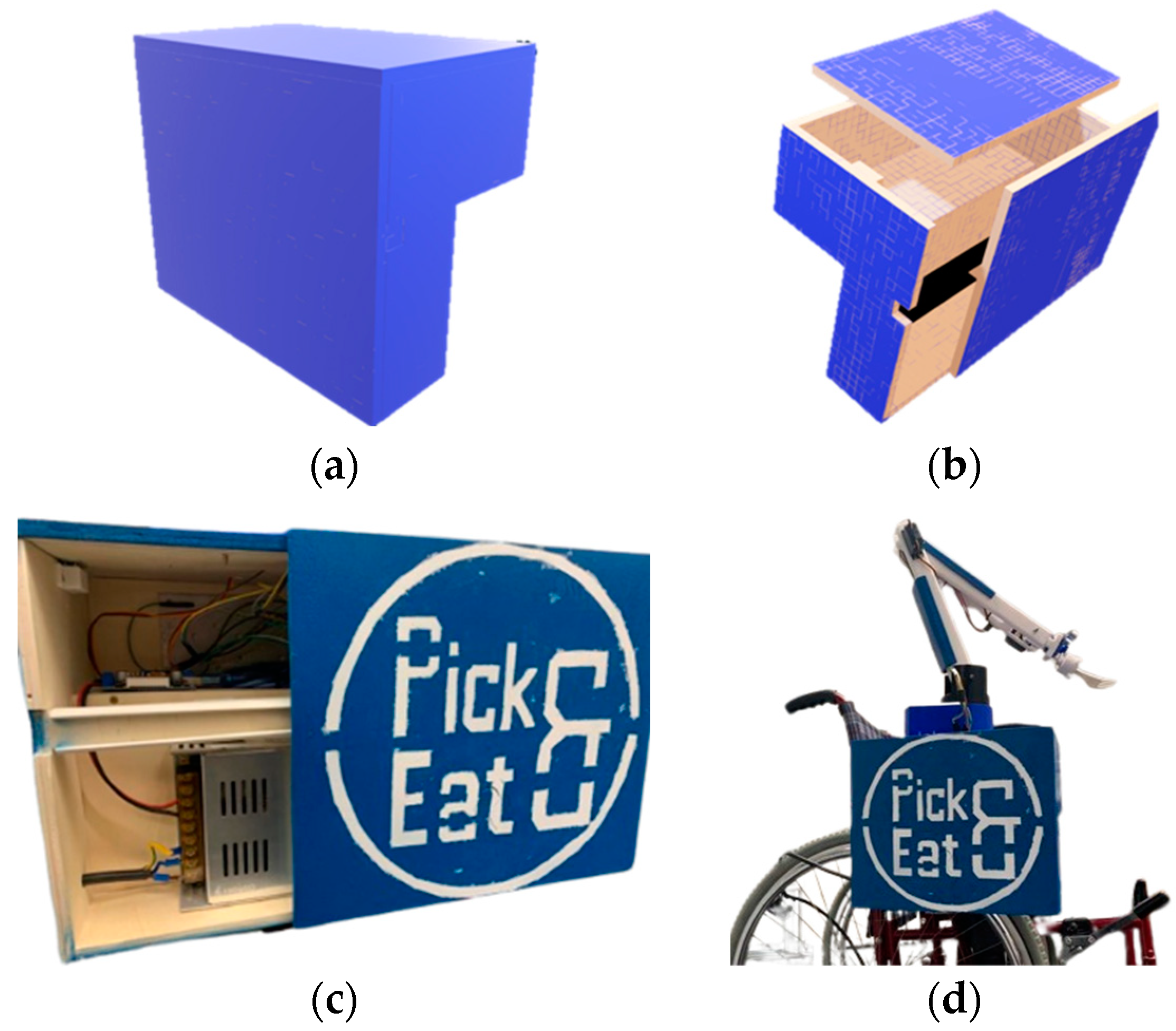

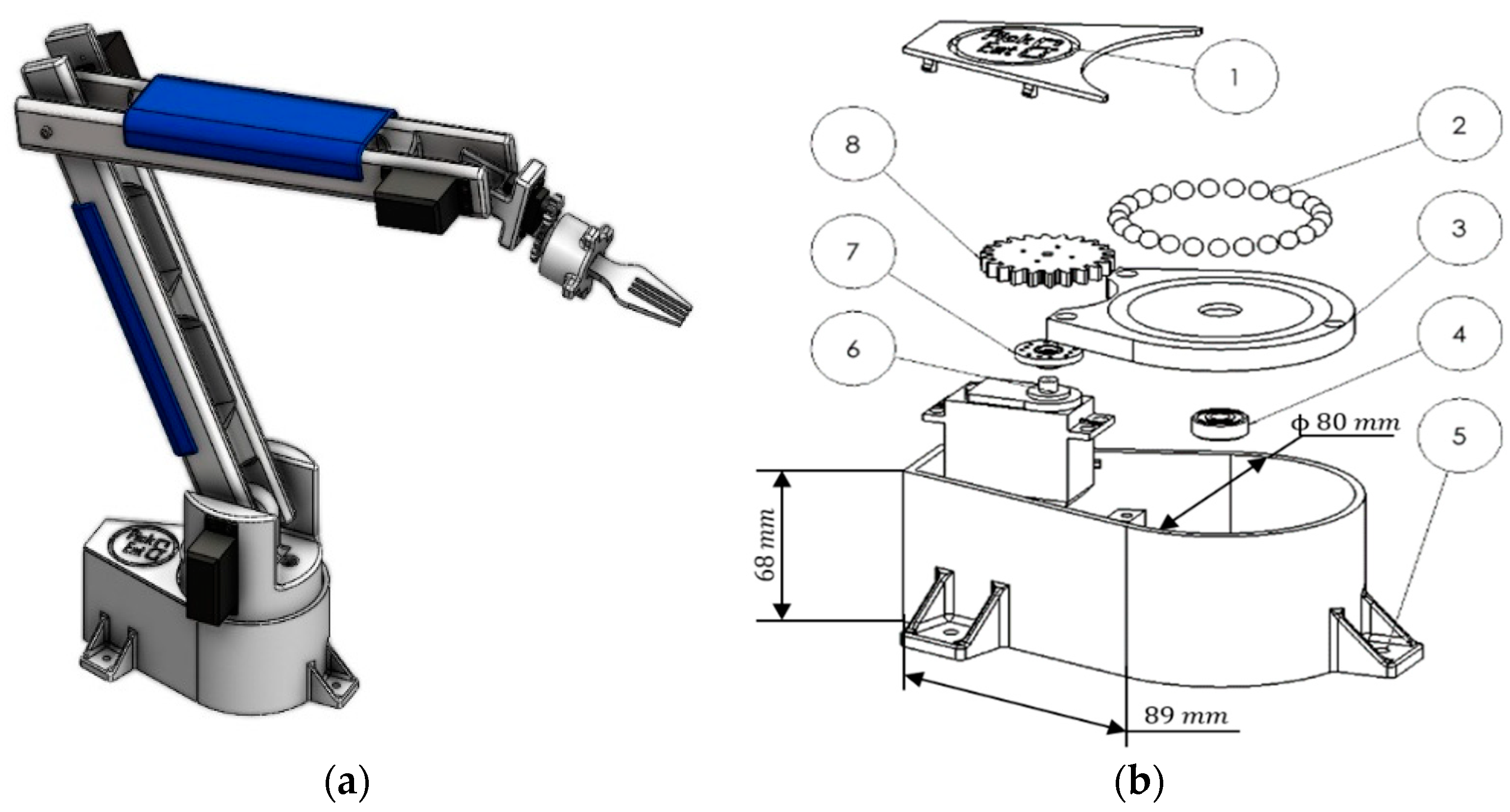

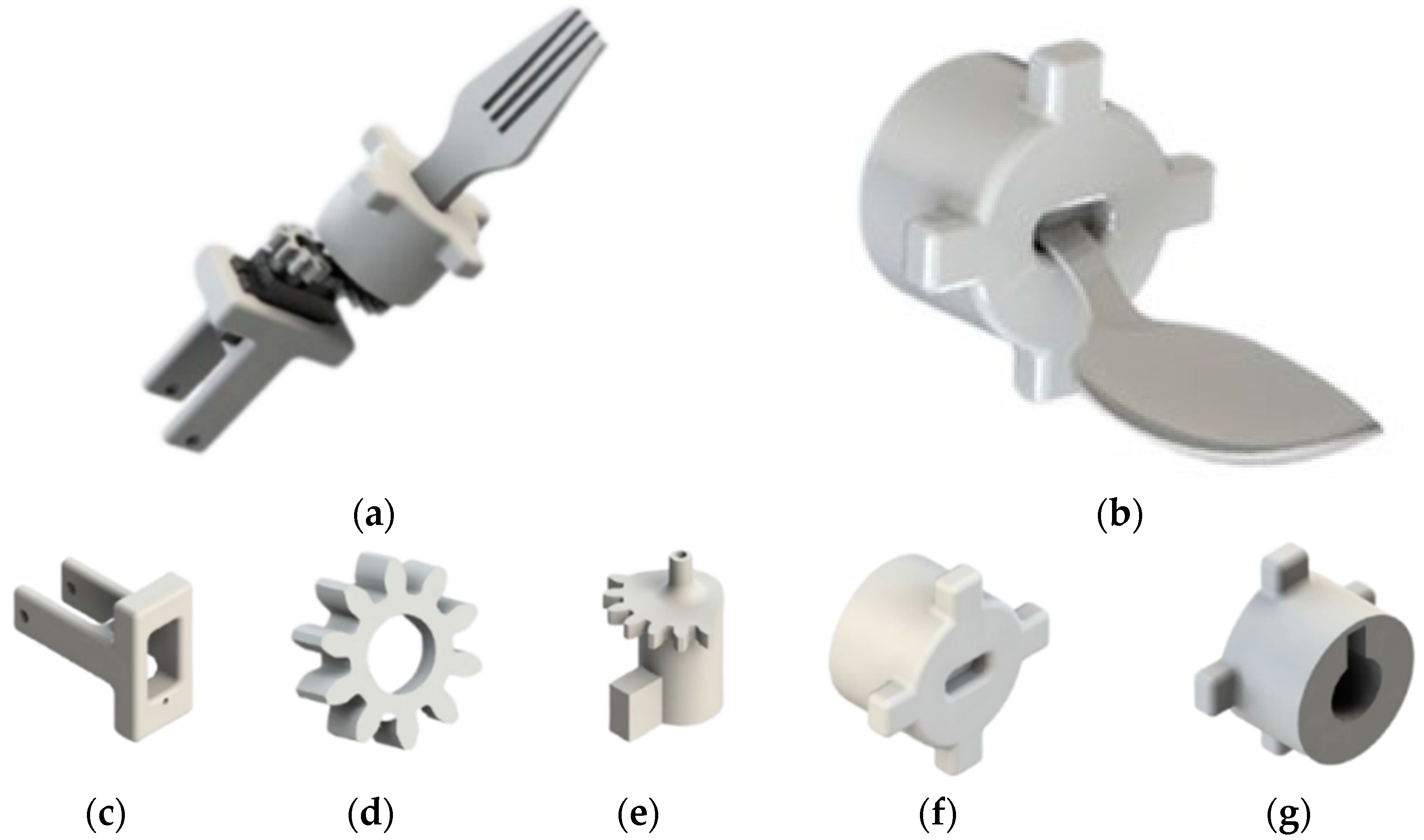

2. Mechanical Design

- Adaptability to different types of wheelchairs.

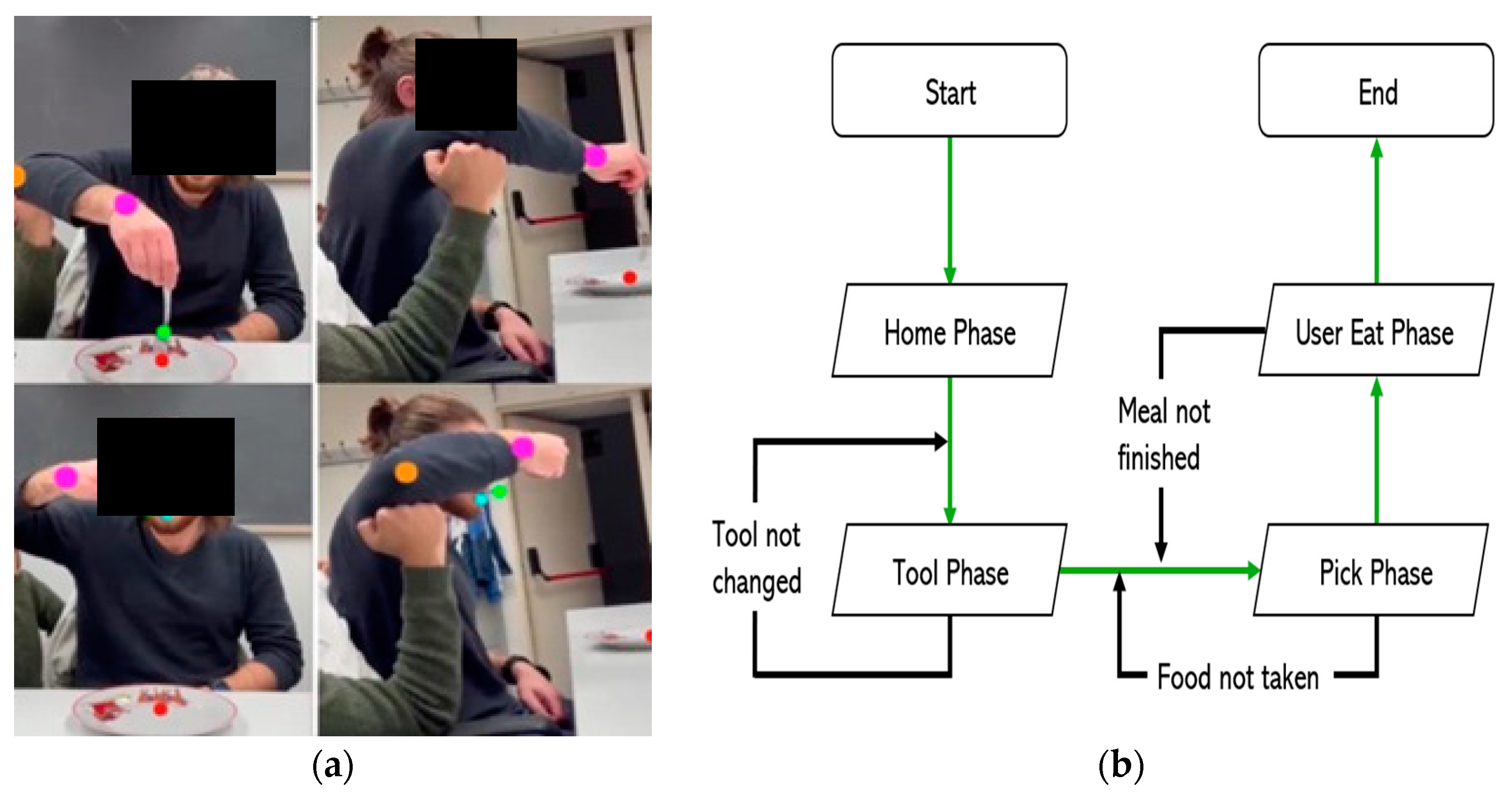

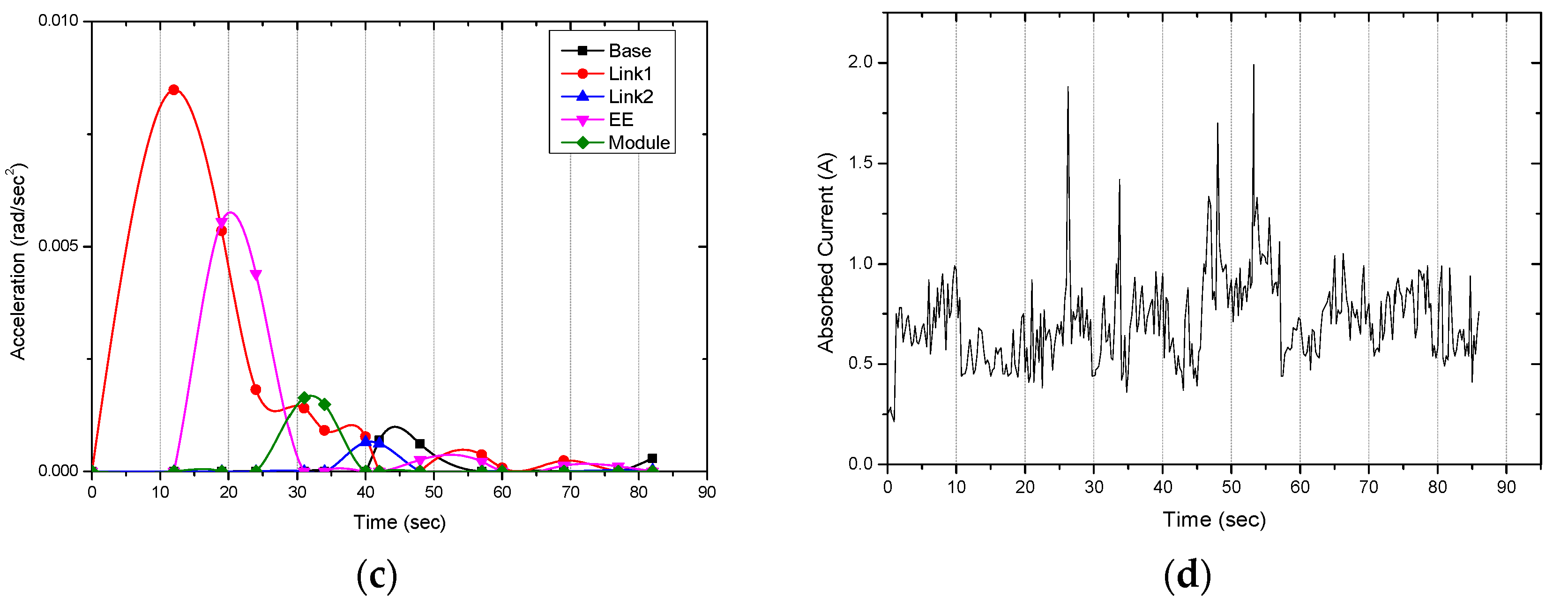

- Device length less than 70 mm (to meet the workspace and necessary manoeuvres without being cumbersome).

- Allow a payload of up to 0.1 Kg (necessary to ensure the lifting of food).

- Interchangeability of the end-effector (ability to use a spoon or fork depending on the dish on the plate).

- DC power supply ranging from 12 to 24 V.

- Manipulator weight less than 1 kg (for portability and to avoid instability).

- Ensure a high level of safety through appropriate sensors (to avoid possible impacts and/or collisions).

- Speed less than 3 cm/s (for proper and timely task execution).

2.1. Preliminary Analysis

2.2. Design Overview

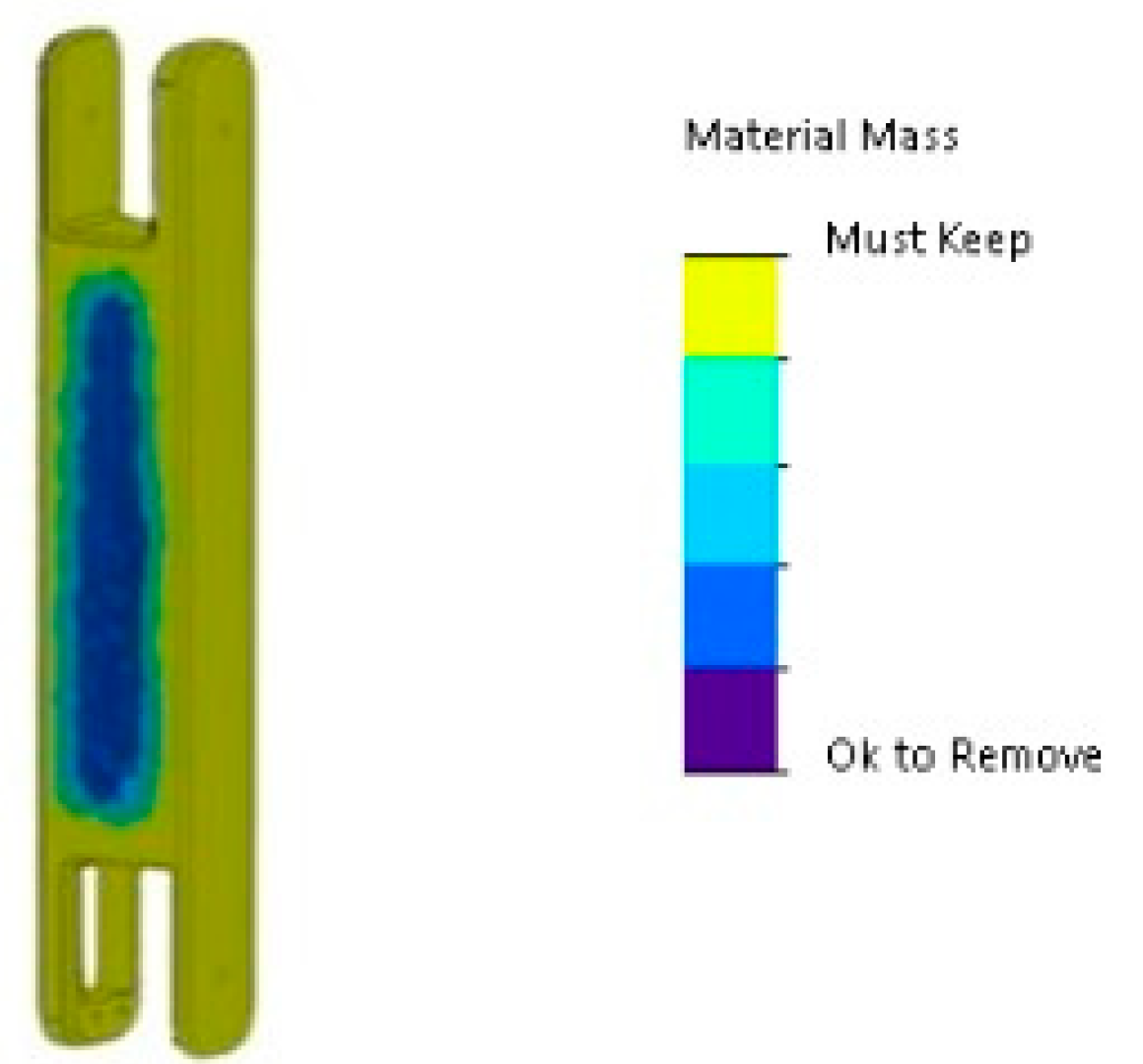

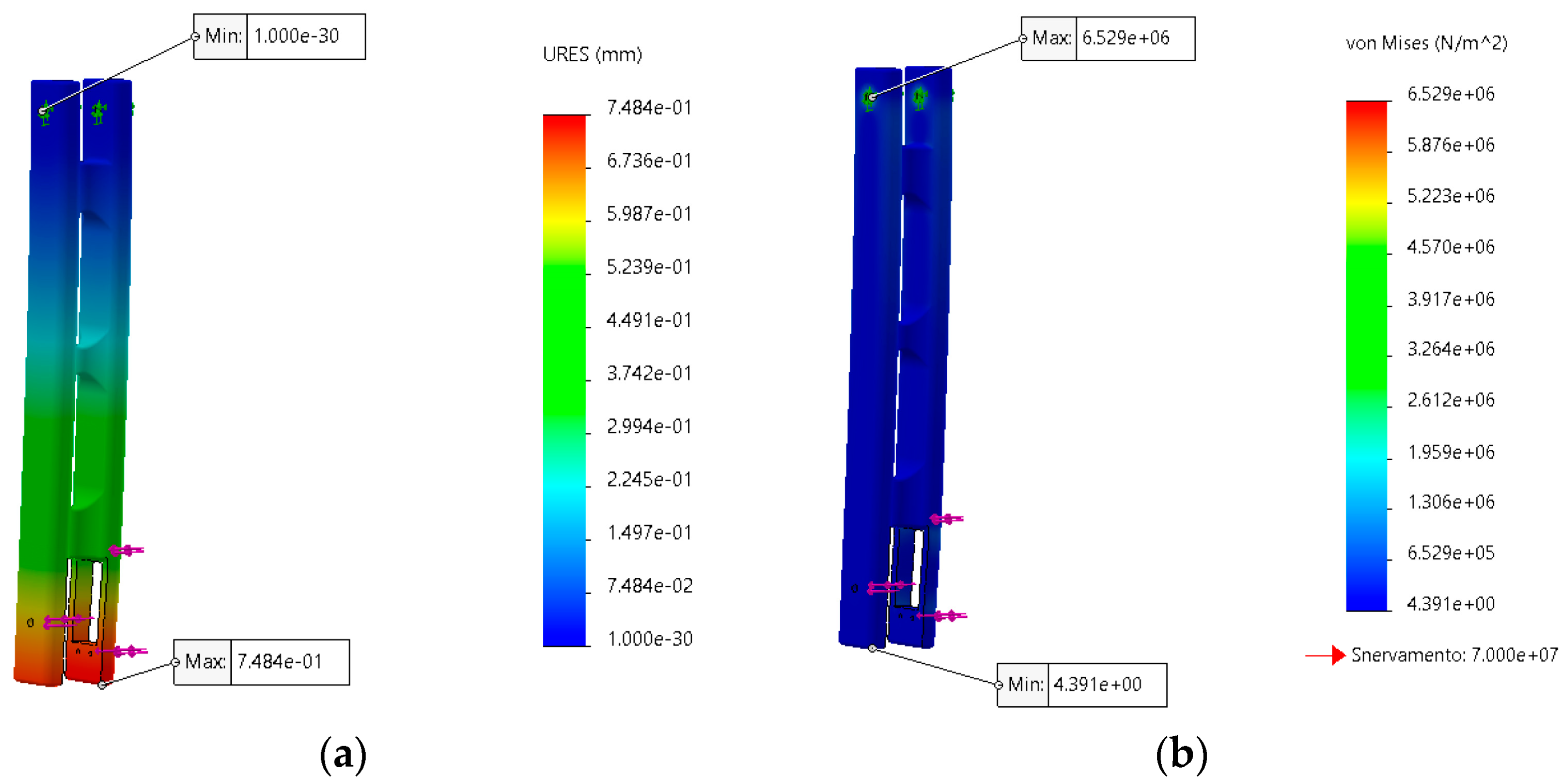

2.3. FEM Simulations

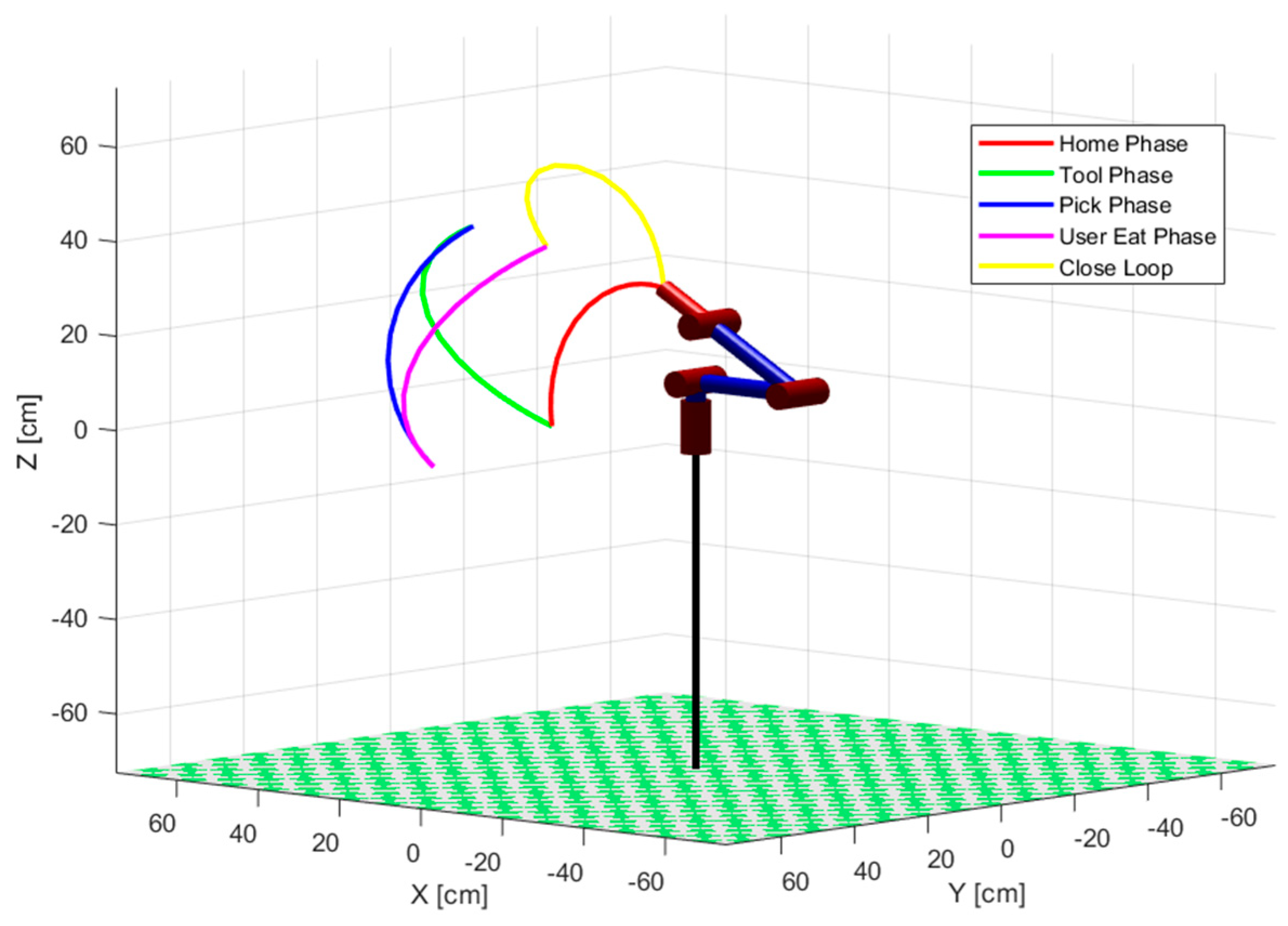

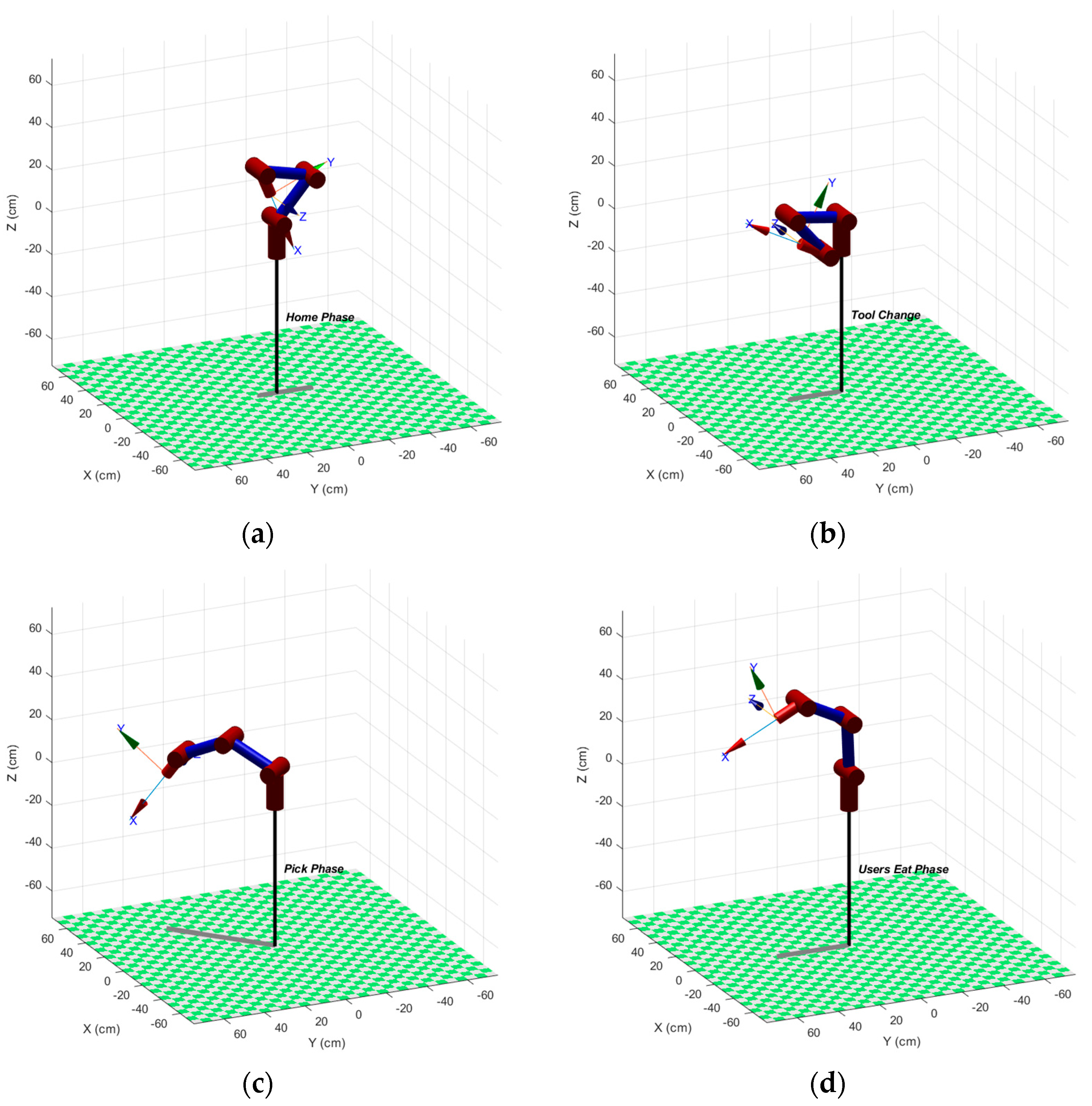

3. Kinematic Analysis

3.1. Forward Kinematic Model

3.2. Inverse Kinematic Model

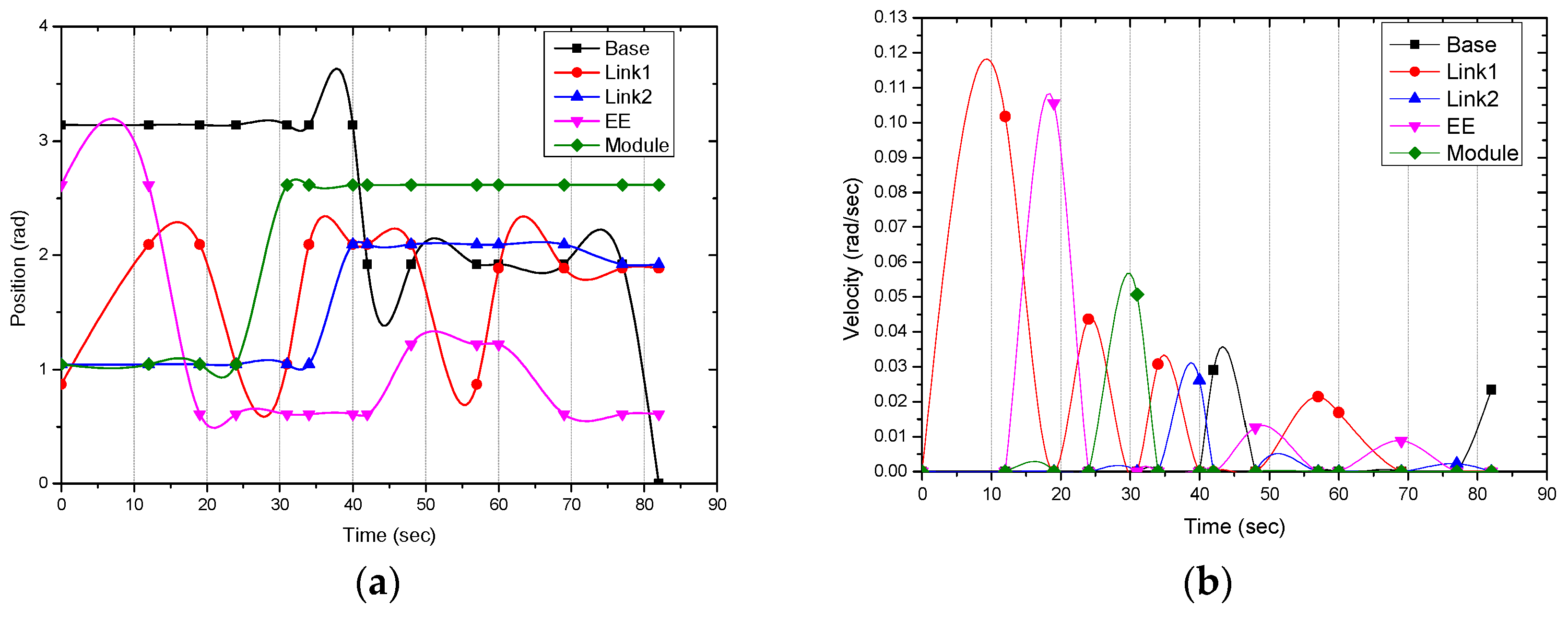

4. Dynamic Analysis

5. Control Architecture

- The values of the servomotor angles are constantly adjusted based on conducted analyses and the described path.

- The sensor is called upon to check, during the movement of the device to bring the food to the mouth, for the presence or absence of obstacles.

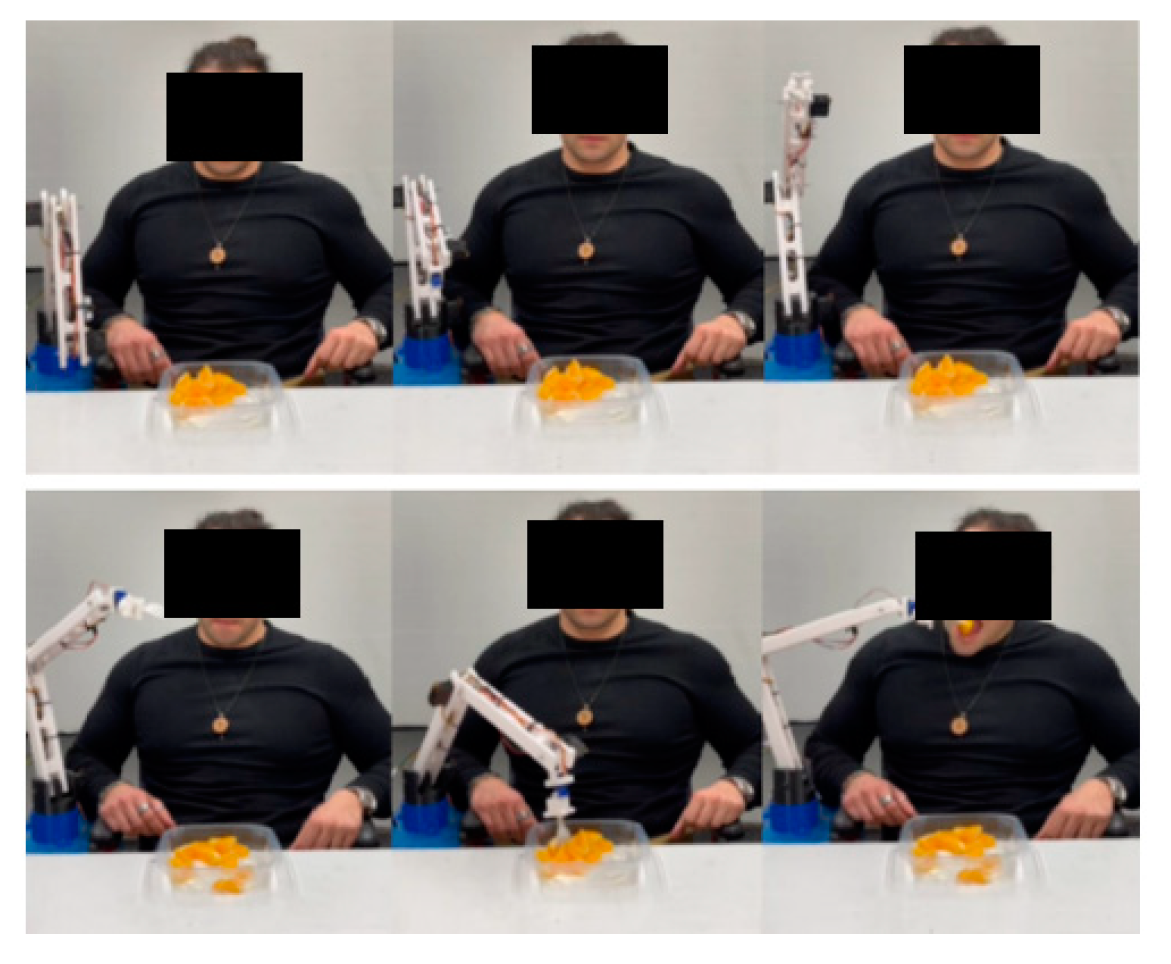

6. Preliminary Tests

- Verification of the stability of the frame placed at the side of the wheelchair.

- Switching on the device, via a close switch, and checking the sensory feedback that is transmitted and stored in a laptop for further investigation.

- Checking the efficiency of the ultrasonic sensor by placing a series of obstacles at different distances and confirming slowing down and/or stopping the motion if the reading gives a distance of between 15 cm and 5 cm, respectively, as visible in the frames in Figure 15.

- Verification of the correct operation of the individual modules, by successively actuating the respective servomotors on the rotation of the device base, the movement of the first link, the second link, and the end-effector.

- Verification of the various functions implemented and the consequent movements to achieve the optimum path, as well as the result of the analyses conducted.

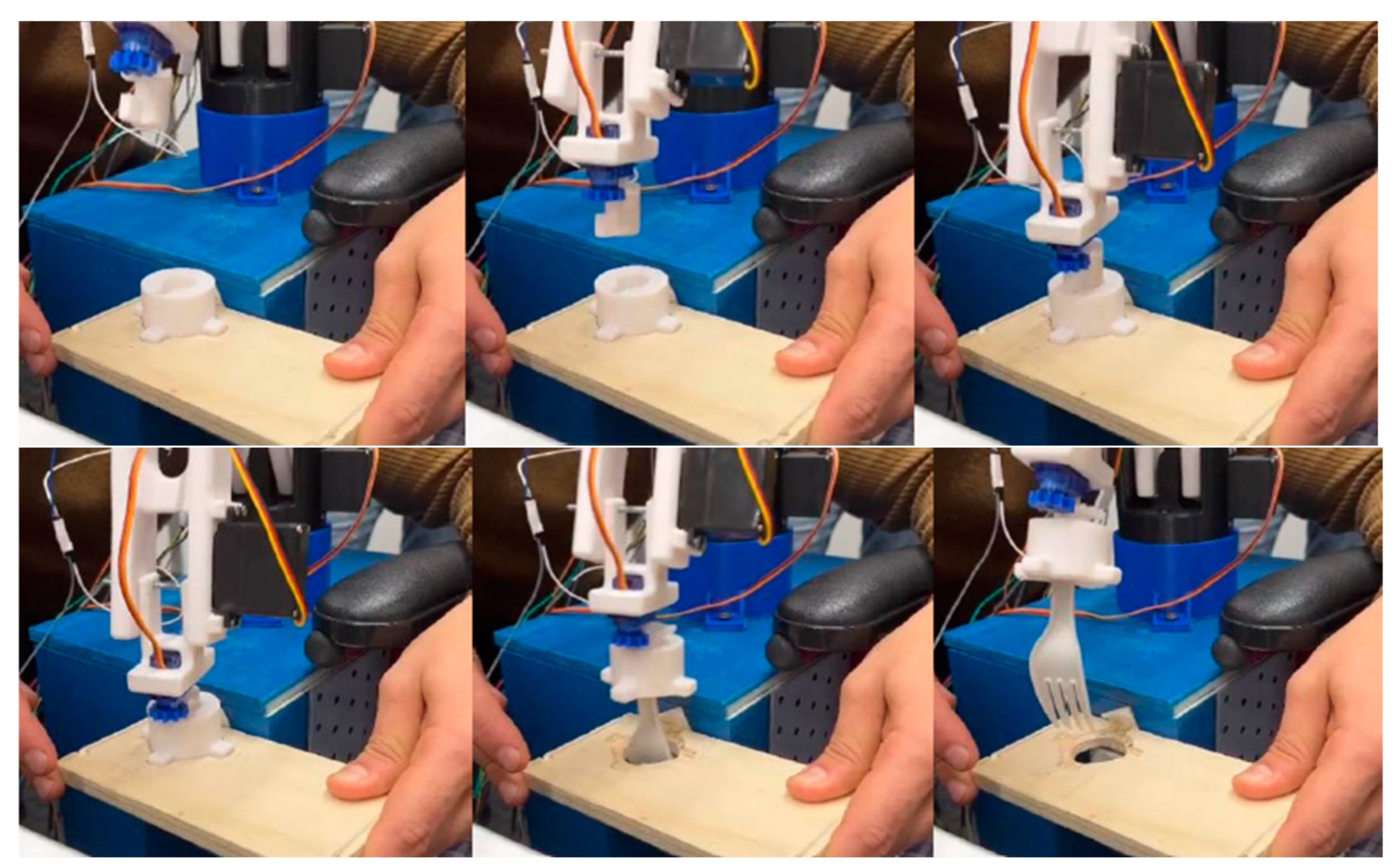

- Check the correct release and/or coupling of the interchangeable tool module, with reference to the detail provided in Figure 16, to ensure the correct execution of the operation.

- Verification of the correct operation of the entire path studied, verifying the effective taking of the food from the plate and the movement required to bring it to the user’s mouth.

- Verification of the correct functioning of the device under different operating conditions.

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharkawy, A.-N. A survey on applications of human-robot interaction. Sens. Transducers 2021, 251, 19–27. Available online: https://www.sensorsportal.com/HTML/DIGEST/P_3221.htm (accessed on 19 September 2023).

- Italian Agency for Development of Cooperation. Available online: https://www.aics.gov.it/home-eng/fields/human-development/disability/ (accessed on 19 September 2023).

- World Health Organization. World Report on Ageing and Health. 2015. Available online: https://apps.who.int/iris/handle/10665/186463 (accessed on 19 September 2023).

- Atashzar, S.F.; Carriere, J.; Tavakoli, M. Review: How Can Intelligent Robots and Smart Mechatronic Modules Facilitate Remote Assessment, Assistance, and Rehabilitation for Isolated Adults with Neuro-Musculoskeletal Conditions? Front. Robot. AI 2021, 8, 610529. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.R.; Wachs, J.P.; Duerstock, B.S.; Pendergast, M. 3D Joystick for Robotic Arm Control by Individuals with High Level Spinal Cord Injuries. In Proceedings of the IEEE International Conference on Rehabilitation Robotics, Seattle, WA, USA, 24–26 June 2013. [Google Scholar]

- Alqasemi, R.M.; McCaffrey, E.J.; Edwards, K.D.; Dubey, R.V. Analysis, Evaluation and Development of Wheelchair-Mounted Robotic Arms. In Proceedings of the IEEE 9th International Conference on Rehabilitation Robotics, Chicago, IL, USA, 28 June–1 July 2005; pp. 469–472. [Google Scholar]

- Eftring, H.; Boschian, K. Technical results from manus user trials. In Proceedings of the ICORR ’99: International Conference on Rehabilitation Robotics, Stanford, CA, USA, 1–2 July 1999; pp. 136–141. [Google Scholar]

- Ranky, G.N.; Adamovich, S. Analysis of a commercial EEG device for the control of a robot arm. In Proceedings of the 2010 IEEE 36th Annual Northeast Bioengineering Conference (NEBEC), New York, NY, USA, 26–28 March 2010. [Google Scholar]

- Hillman, M.; Gammie, A. The Bath institute of medical engineering assistive robot. In Proceedings of the ICORR ’94, Wilmington, DE, USA, 14–15 June 1994; pp. 211–212. [Google Scholar]

- Chaves, E.; Koontz, A.; Garber, S.; Cooper, R.; Williams, A. Clinical Evaluation of a Wheelchair Mounted Robotic Arm. In Proceedings of the RESNA 26th International Annual Conference, Atlanta, GA, USA, 19–23 June 2003. [Google Scholar]

- Maheu, V.; Frappier, J.; Archambault, P.S.; Routhier, F. Evaluation of the JACO robotic arm: Clinico-economic study for powered wheelchair users with upper-extremity disabilities. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011. [Google Scholar]

- Borboni, A.; Maddalena, M.; Rastegarpanah, A.; Saadat, M.; Aggogeri, F. Kinematic performance enhancement of wheelchair-mounted robotic arm by adding a linear drive. In Proceedings of the 2016 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Benevento, Italy, 15–18 May 2016; pp. 1–6. [Google Scholar]

- Song, W.-K.; Lee, H.-Y.; Kim, J.-S.; Yoon, Y.-S. KARES: Intelligent rehabilitation robotic system for the disabled and the elderly. In Proceedings of the 20th Annual International Conference of the IEEE, Hong Kong, China, 1 November 1998. [Google Scholar]

- Volosyak, I.; Ivlev, O.; Graser, A. Rehabilitation robot FRIEND II—The general concept and current implementation. In Proceedings of the 9th International Conference on Rehabilitation Robotics, Chicago, IL, USA, 28 June–1 July 2005. [Google Scholar]

- Hillman, M.; Hagan, K.; Hagan, S.; Jepson, J.; Orpwood, R. The Weston wheelchair mounted assistive robot—The design story. Robotica 2002, 20, 125–132. [Google Scholar] [CrossRef]

- Fridenfalk, M.; Ulf, L.; Gunnar, B. Virtual prototyping and experience of modular robotics design based on user involvement. In Proceedings of the 5th European Conference for the Advancement of Assistive Technology, Düsseldorf, Germany, 1–4 November 1999. [Google Scholar]

- Perera, C.J.; Lalitharatne, T.D.; Kiguchi, K. EEG-controlled meal assistance robot with camera-based automatic mouth position tracking and mouth open detection. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Marina Bay Sands, Singapore, 29 May–3 June 2017; pp. 1760–1765. [Google Scholar]

- Candeias, A.; Rhodes, T.; Marques, M.; Costeira, J.P.; Veloso, M. Vision augmented robot feeding. In Computer Vision—ECCV 2018 Workshops; Lecture Notes in Computer Science; Springer Publishing Company: Cham, Switzerland, 2019; pp. 50–65. [Google Scholar]

- Park, D.; Hoshi, Y.; Mahajan, H.P.; Kim, H.K.; Erickson, Z.; Rogers, W.A.; Kemp, C.C. Active robot-assisted feeding with a general-purpose mobile manipulator: Design, evaluation, and lessons learned. Rob. Auton. Syst. 2020, 124, 103344. [Google Scholar] [CrossRef]

- Song, W.K.; Song, W.J.; Kim, Y.; Kim, J. Usability test of KNRC self-feeding robot. In Proceedings of the 2013 IEEE 13th International Conference on Rehabilitation Robotics (ICORR), Seattle, WA, USA, 24–26 June 2013; pp. 1–5. [Google Scholar]

- Bilyea, A.; Seth, N.; Nesathurai, S.; Abdullah, H.A. Robotic assistants in personal care: A scoping review. Med. Eng. Phys. 2017, 49, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, L.A.; MacKenzie, L. Development and Analysis of a Wheelchair Mounted Robotic Manipulator. In Proceedings of the National Conference on Undergraduate Research (NCUR) 2016, University of Memphis, Memphis, TN, USA, 6–8 April 2017. [Google Scholar]

- Choi, J.; Gu, Z.; Lee, J.; Lee, I. Impedance matching control between a human arm and a haptic joystick for long-term. Robotica 2022, 40, 1880–1893. [Google Scholar] [CrossRef]

- Maciel, G.M.; Pinto, M.F.; da SJúnior, I.C.; Coelho, F.O.; Marcato, A.L.M.; Cruzeiro, M.M. Shared control methodology based on head positioning and vector fields for people with quadriplegia. Robotica 2022, 40, 348–364. [Google Scholar] [CrossRef]

- Calabrò, R.S.; Müller-Eising, C.; Diliberti, M.L.; Manuli, A.; Parrinello, F.; Rao, G.; Barone, V.; Civello, T. Who Will Pay for Robotic Rehabilitation? The Growing Need for a Cost-effectiveness Analysis. Innov. Clin. Neurosci. 2020, 17, 14–16. [Google Scholar]

- Mashrur, T.; Ghulam, Z.; French, G.; Abdullah, H.A. Assistive feeding robot for upper limb impairment—Testing and validation. Int. J. Adv. Robot. Syst. 2023, 20, 17298806231183571. [Google Scholar] [CrossRef]

- Leone, S.; Giunta, L.; Rino, V.; Mellace, S.; Sozzi, A.; Lago, F.; Curcio, E.M.; Pisla, D.; Carbone, G. Design of a Wheelchair-Mounted Arm for Mealtimes Assistance of Upper-Limb-Paralyzed Patients. In Advances in Mechanism and Machine Science; IFToMM WC 2023; Mechanisms and Machine Science; Okada, M., Ed.; Springer: Cham, Switzerland, 2023; Volume 148, pp. 919–927. [Google Scholar] [CrossRef]

- Curcio, E.M.; Carbone, G. Mechatronic design of a robot for upper limb rehabilitation at home. J. Bionic Eng. 2021, 18, 857–871. [Google Scholar] [CrossRef]

- Ye, D.; Yang, C.; Jiang, Y.; Zhang, H. Hybrid impedance and admittance control for optimal robot–environment interaction. Robotica 2023, 42, 510–535. [Google Scholar] [CrossRef]

- Kim, J.; Park, F.C. Active learning of the collision distance function for high-DOF multi-arm robot systems. Robotica 2024, 1–15, published online. [Google Scholar] [CrossRef]

- Yang, D.; Dong, L.; Dai, J.K. Collision avoidance trajectory planning for a dual-robot system: Using a modified APF method. Robotica 2024, 42, 846–863. [Google Scholar] [CrossRef]

- Fu, J.; Yu, Z.; Guo, Q.; Zheng, L.; Gan, D. A variable stiffness robotic gripper based on parallel beam with vision-based force sensing for flexible grasping. Robotica 2023, 1–19, published online. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, J. A review of robotic grasp detection technology. Robotica 2023, 41, 3846–3885. [Google Scholar] [CrossRef]

- Carbone, G.; Gerding, E.C.; Corves, B.; Cafolla, D.; Russo, M.; Ceccarelli, M. Design of a Two-DOFs Driving Mechanism for a Motion-Assisted Finger Exoskeleton. Appl. Sci. 2020, 10, 2619. [Google Scholar] [CrossRef]

- Yao, S.; Ceccarelli, M.; Carbone, G.; Zhan, Q.; Lu, Z. Analysis and optimal design of an underactuated finger mechanism for LARM hand. Front. Mech. Eng. 2011, 6, 332. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leone, S.; Giunta, L.; Rino, V.; Mellace, S.; Sozzi, A.; Lago, F.; Curcio, E.M.; Pisla, D.; Carbone, G. Design of a Wheelchair-Mounted Robotic Arm for Feeding Assistance of Upper-Limb Impaired Patients. Robotics 2024, 13, 38. https://doi.org/10.3390/robotics13030038

Leone S, Giunta L, Rino V, Mellace S, Sozzi A, Lago F, Curcio EM, Pisla D, Carbone G. Design of a Wheelchair-Mounted Robotic Arm for Feeding Assistance of Upper-Limb Impaired Patients. Robotics. 2024; 13(3):38. https://doi.org/10.3390/robotics13030038

Chicago/Turabian StyleLeone, Simone, Luigi Giunta, Vincenzo Rino, Simone Mellace, Alessio Sozzi, Francesco Lago, Elio Matteo Curcio, Doina Pisla, and Giuseppe Carbone. 2024. "Design of a Wheelchair-Mounted Robotic Arm for Feeding Assistance of Upper-Limb Impaired Patients" Robotics 13, no. 3: 38. https://doi.org/10.3390/robotics13030038

APA StyleLeone, S., Giunta, L., Rino, V., Mellace, S., Sozzi, A., Lago, F., Curcio, E. M., Pisla, D., & Carbone, G. (2024). Design of a Wheelchair-Mounted Robotic Arm for Feeding Assistance of Upper-Limb Impaired Patients. Robotics, 13(3), 38. https://doi.org/10.3390/robotics13030038