Practical Design Guidelines for Topology Optimization of Flexible Mechanisms: A Comparison between Weakly Coupled Methods

Abstract

:1. Introduction

2. Cartesian Robot Description

3. Methodology

3.1. Static Optimization Problem

- is the global compliance of the structure and indicated how much the structure deforms when a force is applied: it can also be defined as twice the strain energy;

- is the global displacement vector of the structure nodes;

- is the global stiffness matrix of the structure;

- is the design variable vector;

- is the penalty factor;

- is the element displacement vector;

- is the elemental stiffness matrix;

- is the external load vector for which the optimization is necessary;

- is the volume of the element;

- is the total design volume;

- is the upper bound allowed for the fractional mass, strictly connected to the design purposes.

3.2. Equivalent Static Loads Method

3.2.1. ESL in the Literature

- is the mass matrix;

- is the damping matrix;

- is the stiffness matrix;

- is the displacement vector and its first and second time derivatives, respectively;

- is the load vector that generally contains many null elements.

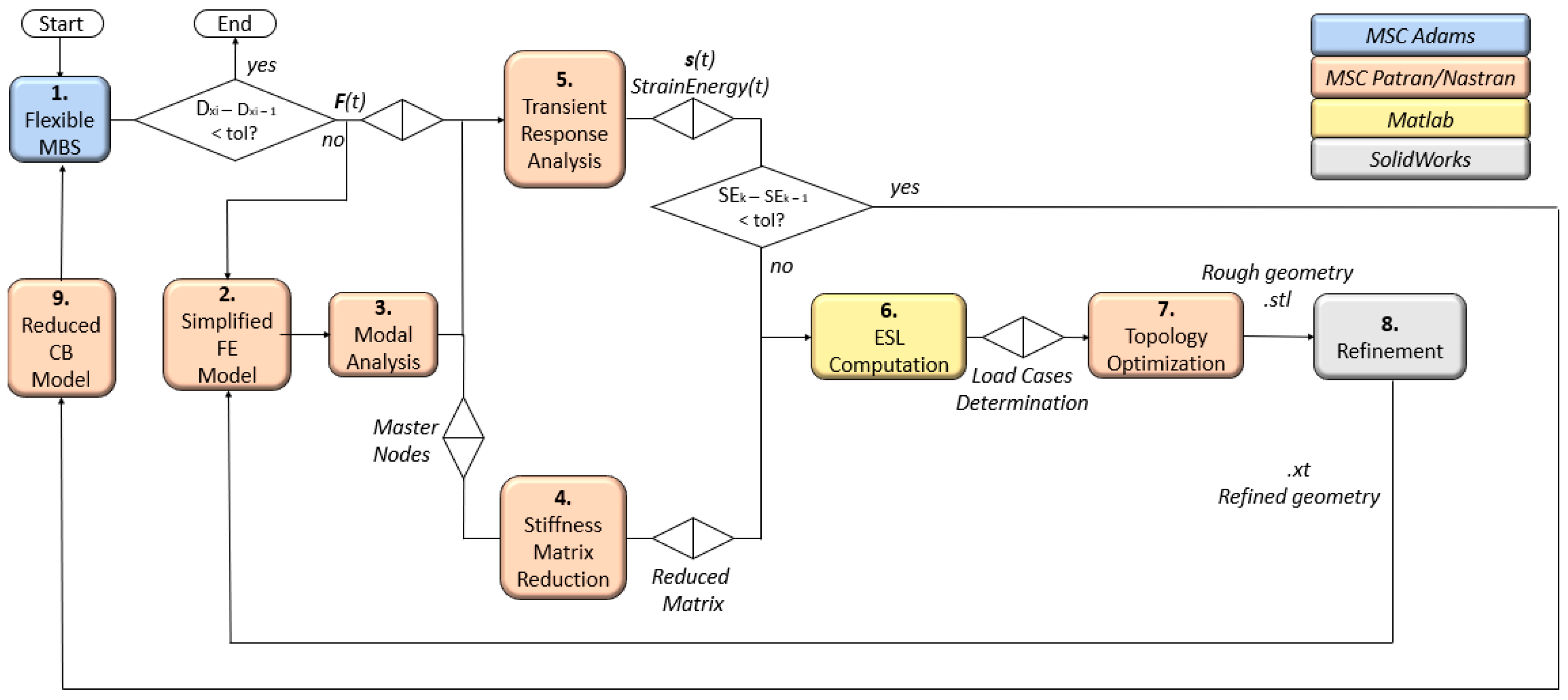

3.2.2. ESL in the Present Work

- the flexible MultiBody Simulation (MBS) is the first necessary step in order to obtain the forces exchanged at the boundary nodes and to assess how the structure flexibility affects the spatial deviation of the TCP from the nominal trajectory. The flexible MBS is the first step of the external analysis and verification cycle.

- A simplified FE model that reproduces the inertial and stiffness properties of specific sub-assembly is created. The simplified FE model contains the real geometry of the component to be optimized (i.e., Z Carriage). The simplified model creation (or updating) represents the first step of the internal optimization cycle.

- An initial modal analysis is suggested to identify the relevant modes for the specific analysis and to understand which are the maximum relative displacement nodes. The maximum relevant displacement nodes for the modes of interest represent the master nodes to use for the Guyan reduction.

- The reduced stiffness matrix related to the specified master nodes is obtained by means of a Guyan reduction.

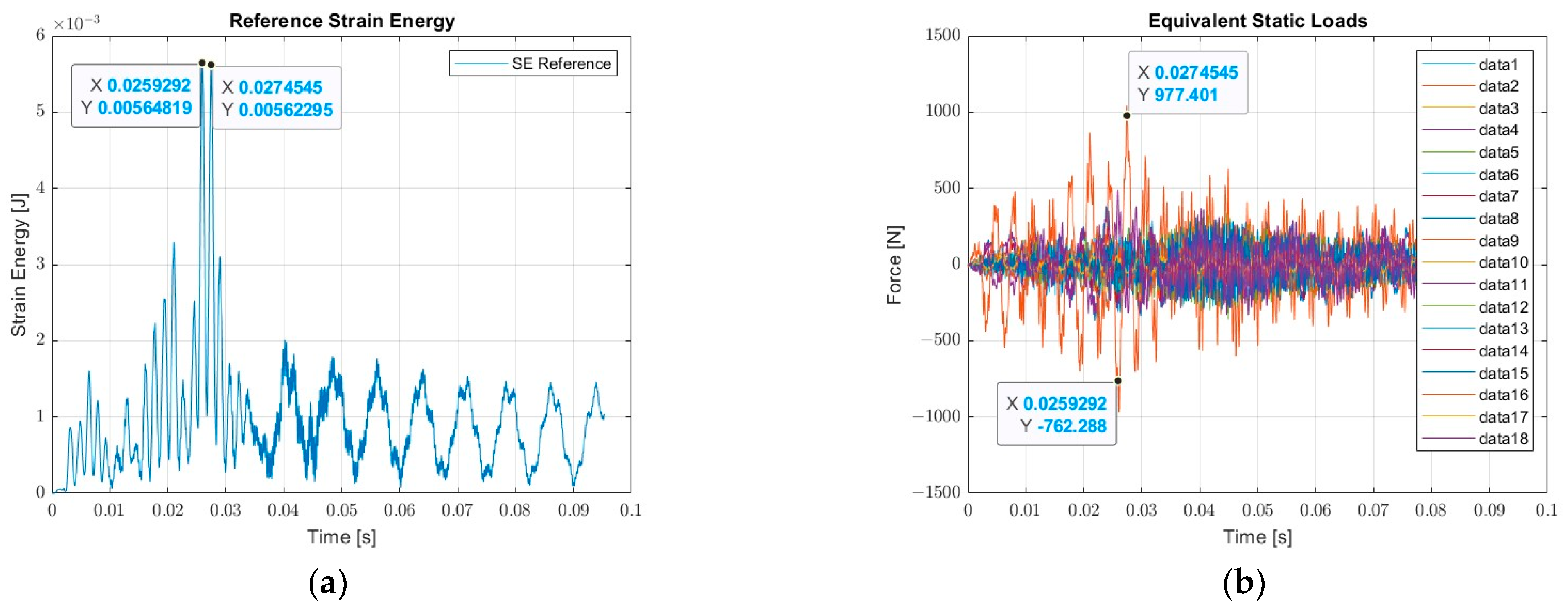

- The dynamic forces computed in the multibody model are provided as input for the transient analysis in the internal optimization cycle. The important outputs of the transient analysis are both the global strain energy over time and the displacements of the master nodes.

- The reduced stiffness matrix and the displacements of the master nodes along three directions are multiplied to obtain the ESL matrix. The matrix represents the ESL for each time step of the simulation. The time instants corresponding to the strain energy peaks are the discriminant parameter for the selection of the most relevant ESL. The main output of this phase is a set of load cases to be applied to the master nodes for the optimization. The number of load cases depends on the strain energy peaks number.

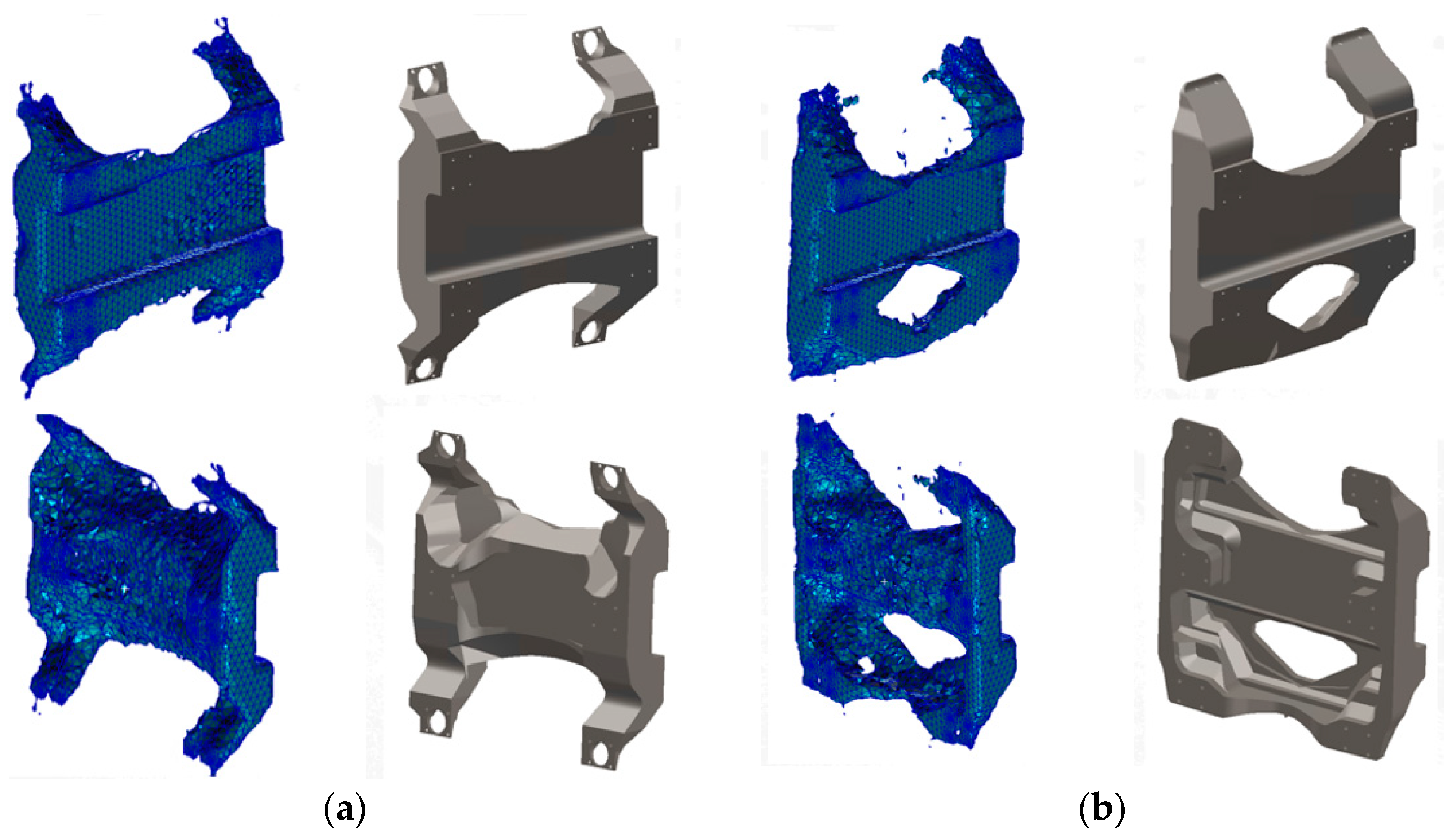

- Once the design volume of the component is specified, the optimization is run. The objective is to find the mass distribution in the available design volume that minimizes the global compliance of the structure, by imposing a constraint on the mass fraction, evaluated according to Equation (3). The value of the upper bound, i.e., in Equation (3), was selected to guarantee the same mass values between the original design and the optimized one.

- The optimization output is then manually post-processed to create a smooth CAD version of the optimized component, i.e., the refinement process. The internal optimization cycle is then repeated (back to 2) until the strain energy peaks minimization is obtained. The output of the cycle is the geometry and, consequently, the mesh of the optimized component.

- The flexible multibody model is updated with the new geometry (a Craig–Bampton reduction is performed), and a new analysis is carried out. For the sake of the optimization procedure, if the TCP accuracy increases, the geometry can be considered feasible, pending manufacturability verification.

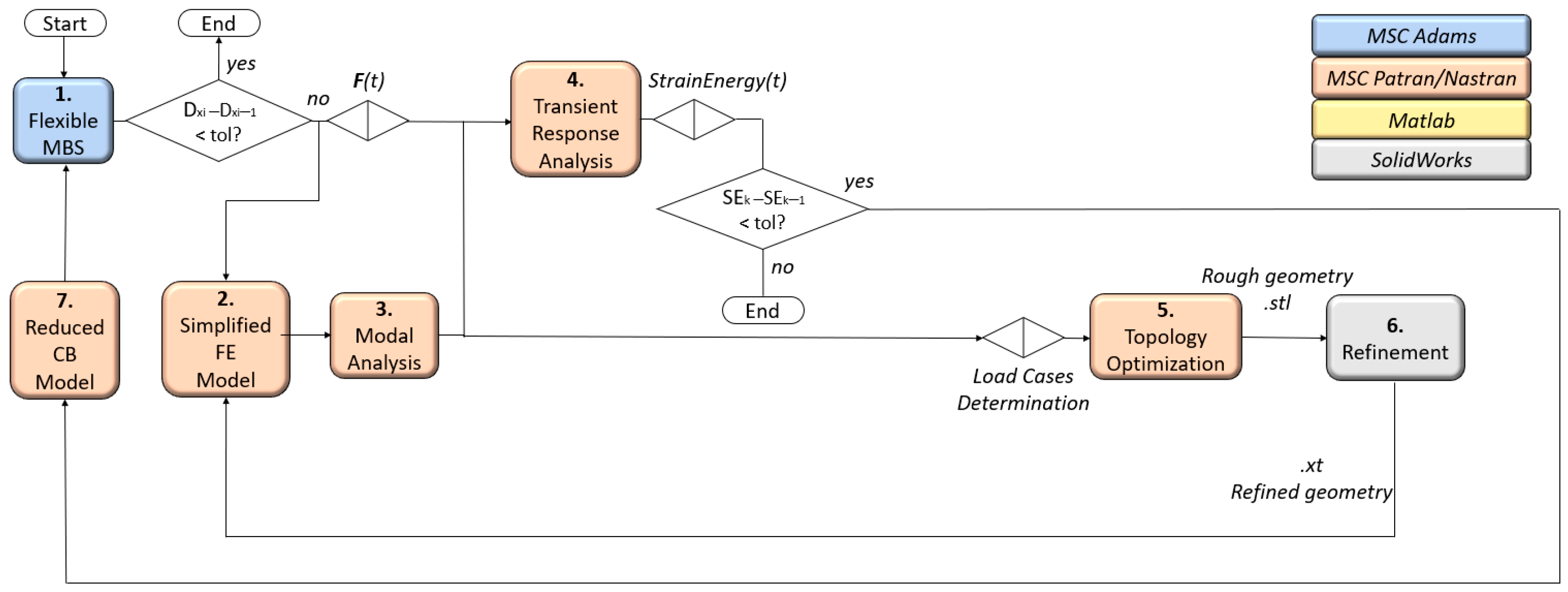

3.3. Quasi-Static Loads method

- A flexible MBS allows for the determination of dynamic loads.

- A simplified FE model reproduces the sub-assembly characteristics.

- A modal analysis is performed to determine the modal characteristics of the structure.

- A transient response analysis is performed to determine the strain energy of the structure before and after optimization.

- The topology optimization is performed, but there are few load cases and the loads are applied only on the boundary nodes (this is not necessarily true in the case of the ESL method).

- A refinement step is carried out after topology optimization to obtain a smooth geometry.

- A reduced CB model is implemented to verify the new geometry, and a final multibody verification is carried out.

4. QSL Method and ESL Method Comparison

4.1. Simple Case—Beam

4.1.1. Cantilever Beam Geometry

4.1.2. Transient Analysis Set-Up

4.1.3. Optimization Output Comparison

4.2. Real Case—Z Carriage

4.2.1. Finite Element Model

4.2.2. Topology Optimization Output Comparison

5. Conclusions

- -

- A system-level flexible multibody analysis to assess the dynamic behavior of the structure.

- -

- A preliminary sensitivity analysis to understand how much the individual component contributes to the overall stiffness of the system. The preliminary analysis should also study the feasibility of the redesign based on the requirements and design phase.

- -

- Modal analysis (before optimization) using the FE model of the subset in which the component to be optimized is present. The advantage of this preliminary modal analysis is twofold: computation of natural frequencies and identification of the nodes with the largest relative displacement to be identified.

- -

- Analysis of the frequency content of the loads applied to the component, before performing the optimization. The ratio between the maximum relevant frequency of the force and the first natural frequency of the component gives an indication for the optimization method selection. The QSL method should be preferred for a frequency ratio about or below 0.15.

- -

- An intermediate Guyan static condensation is suggested when applying the ESL method. The selection of few “smart” nodes allows for the reduction in computation time for the optimization, increasing as well the design volume available for the process.

- -

- Evaluation of the ESL at the time instants of the strain energy peaks rather than blindly selecting the absolute maximum values of the ESL, for the boundary conditions of the optimization process. It is, in fact, not always guaranteed that the highest forces, if applied in few nodes, represent appropriate boundary conditions for the optimization.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tromme, E.; Held, A.; Duysinx, P.; Brüls, O. System-Based Approaches for Structural Optimization of Flexible Mechanisms. Arch. Comput. Methods Eng. 2018, 25, 817–844. [Google Scholar] [CrossRef]

- Min, S.; Kikuchi, N.; Park, Y.C.; Kim, S.; Chang, S. Optimal Topology Design of Structures under Dynamic Loads; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Rong, J.H.; Xie, Y.M.; Yang, X.Y.; Liang, Q.Q. Topology optimization of structures under dynamic response constraints. J. Sound Vib. 2000, 234, 177–189. [Google Scholar] [CrossRef]

- James, K.A.; Waisman, H. Topology optimization of viscoelastic structures using a time-dependent adjoint method. Comput. Methods Appl. Mech. Eng. 2015, 285, 166–187. [Google Scholar] [CrossRef]

- Vanpaemel, S.; Asrih, K.; Vermaut, M.; Naets, F. Topology optimization for dynamic flexible multibody systems using the Flexible Natural Coordinates Formulation. Mech. Mach. Theory 2023, 185, 105344. [Google Scholar] [CrossRef]

- Albers, A. Automated Topology Optimization of Flexible Components in Hybrid Finite Element Multibody Systems Using ADAMS/Flex and MSC. Construct. Available online: https://www.researchgate.net/publication/36452967 (accessed on 18 June 2023).

- Albers, A.; Ottnad, J.; Häußler, P.; Minx, J. Structural Optimization of Components in Controlled Mechanical Systems. 2007. Available online: http://www.asme.org/about-asme/terms-of-use (accessed on 18 June 2023).

- Institute of Electrical and Electronics Engineers; IEEE Robotics and Automation Society. Humanoids ’09: [proceedings]. In Proceedings of the 9th IEEE-RAS International Conference on Humanoid Robots, Paris, France, 7–10 December 2009. [Google Scholar]

- Kang, B.S.; Choi, W.S.; Park, G.J. Structural Optimization under Equivalent Static Loads Transformed from Dynamic Loads Based on Displacement. Available online: www.elsevier.com/locate/compstruc (accessed on 4 July 2023).

- Choi, W.S.; Park, G.J. Structural Optimization Using Equivalent Static Loads at All Time Intervals. Available online: www.elsevier.com/locate/cma (accessed on 4 July 2023).

- Park, G.J.; Kang, B.S.; Choi, K.K. Technical Note Validation of a Structural Optimization Algorithm Transforming Dynamic Loads into Equivalent Static Loads 1. J. Optim. Theory Appl. 2003, 118, 191–200. [Google Scholar] [CrossRef]

- Jang, H.H.; Lee, H.A.; Lee, J.Y.; Park, G.J. Dynamic response topology optimization in the time domain using equivalent static loads. AIAA J. 2012, 50, 226–234. [Google Scholar] [CrossRef]

- Stolpe, M. On the equivalent static loads approach for dynamic response structural optimization. Struct. Multidiscip. Optim. 2014, 50, 921–926. [Google Scholar] [CrossRef]

- Stolpe, M.; Verbart, A.; Rojas-Labanda, S. The equivalent static loads method for structural optimization does not in general generate optimal designs. Struct. Multidiscip. Optim. 2018, 58, 139–154. [Google Scholar] [CrossRef]

- Park, G.J.; Lee, Y. Discussion on the optimality condition of the equivalent static loads method for linear dynamic response structural optimization. Struct. Multidiscip. Optim. 2019, 59, 311–316. [Google Scholar] [CrossRef]

- Olhoff, N.; Taylor, J.E. On Structural Optimization. 1983. Available online: http://asmedigitalcollection.asme.org/appliedmechanics/article-pdf/50/4b/1139/6362856/1139_1.pdf (accessed on 12 January 2023).

- Bendse, M.P.; Kikuchi, N. Generating Optimal Topologies in Structural Design Using a Homogenization Method. Comput. Methods Appl. Mech. Eng. 1988, 71, 197–224. [Google Scholar] [CrossRef]

- MSC Nastran 2022.2 Design Sensitivity and Optimization User’s Guide MSC Nastran Design Sensitivity and Optimization User’s Guide. 1992. Available online: http://msc-documentation.questionpro.com (accessed on 15 February 2023).

- Rozvany, G.I.N. A critical review of established methods of structural topology optimization. Struct. Multidiscip. Optim. 2009, 37, 217–237. [Google Scholar] [CrossRef]

- Rozvany, G.I.N. The Simp Method in Topology Optimization-Theoretical Background, Advantages and New Applications. In Proceedings of the 8th Symposium on Multidisciplinary Analysis and Optimization, Long Beach, CA, USA, 6–8 September 2000. [Google Scholar]

- Sigmund, O. Design of Material Structures using Topology Optimization. Ph.D. Thesis, Technical University of Denmark (DTU), Lyngby, Denmark, 1994. [Google Scholar]

| Parameter | Value |

|---|---|

| D [mm] | 50 |

| b [mm] | 120 |

| h [mm] | 80 |

| t [mm] | 10 |

| l1 [mm] | 350 |

| l2 [mm] | 760 |

| l [mm] | 780 |

| M1 [kg] | 24 |

| M2 [kg] | 15 |

| Parameter | Value |

|---|---|

| E [GPa] | 70 |

| ν [-] | 0.3 |

| ρ [kg/m3] | 2700 |

| Parameter | Reference | ESL Cycle 3 | QSL |

|---|---|---|---|

| Weight [kg] | 13.1 | 13.2 | 13.2 |

| 1st Bending XY [Hz] | 47.4 | 50.7 | 51.0 |

| 1st Bending XZ [Hz] | 66.4 | 81.3 | 81.6 |

| 2nd Bending XY [Hz] | 249 | 240 | 224 |

| 1st Torsion X [Hz] | 318 | 369 | 360 |

| Node 6 Δxmax [m] | 1.23 × 10−6 | 1.57 × 10−6 | 1.94 × 10−6 |

| Node 6 Δymax [m] | 5.94 × 10−6 | 1.07 × 10−5 | 4.88 × 10−6 |

| Node 6 Δzmax [m] | 5.30 × 10−5 | 2.03 × 10−5 | 5.88 × 10−5 |

| Peak SE [J] | 5.65 × 10−3 | 4.30 × 10−3 | 1.02 × 10−2 |

| Trajectory | Deviation | Reference | ESL Cycle 2 | QSL |

|---|---|---|---|---|

| Trajectory 1 | Δx [m] | 0.025700 | −16.30% | −17.69% |

| Δy [m] | 0.007159 | −23.72% | −26.46% | |

| Δz [m] | 0.012687 | −15.75% | −16.02% | |

| Trajectory 2 | Δx [m] | 0.002871 | −16.91% | −18.47% |

| Δy [m] | 0.001037 | −12.41% | −13.52% | |

| Δz [m] | 0.001086 | −12.68% | −13.72% | |

| Trajectory 3 | Δx [m] | 0.002498 | −17.15% | −19.12% |

| Δy [m] | 0.000896 | −14.84% | −16.81% | |

| Δz [m] | 0.00077 | −15.68% | −16.47% | |

| Trajectory 4 | Δx [m] | 0.001898 | −17.35% | −17.88% |

| Δy [m] | 0.000789 | −8.92% | −8.56% | |

| Δz [m] | 0.003128 | −18.53% | −15.25% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Imperio, S.; Berruti, T.M.; Gastaldi, C.; Soccio, P. Practical Design Guidelines for Topology Optimization of Flexible Mechanisms: A Comparison between Weakly Coupled Methods. Robotics 2024, 13, 55. https://doi.org/10.3390/robotics13040055

D’Imperio S, Berruti TM, Gastaldi C, Soccio P. Practical Design Guidelines for Topology Optimization of Flexible Mechanisms: A Comparison between Weakly Coupled Methods. Robotics. 2024; 13(4):55. https://doi.org/10.3390/robotics13040055

Chicago/Turabian StyleD’Imperio, Simone, Teresa Maria Berruti, Chiara Gastaldi, and Pietro Soccio. 2024. "Practical Design Guidelines for Topology Optimization of Flexible Mechanisms: A Comparison between Weakly Coupled Methods" Robotics 13, no. 4: 55. https://doi.org/10.3390/robotics13040055

APA StyleD’Imperio, S., Berruti, T. M., Gastaldi, C., & Soccio, P. (2024). Practical Design Guidelines for Topology Optimization of Flexible Mechanisms: A Comparison between Weakly Coupled Methods. Robotics, 13(4), 55. https://doi.org/10.3390/robotics13040055