Construction of Sensory/Mass Spectrometry Feedback Platform for Seeking Aroma Contributors during the Aroma Enhancement of Congou Black Tea

Abstract

:1. Introduction

2. Material and Methods

2.1. Samples and Chemicals

2.2. Sensory Evaluation

2.3. Quantitative Descriptive Analysis (QDA)

2.4. Tea aroma Extraction by Simultaneous Distillation and Extraction (SDE)

2.5. Compounds Identification by GC-MS

2.6. Statistical Analysis

3. Results and Discussion

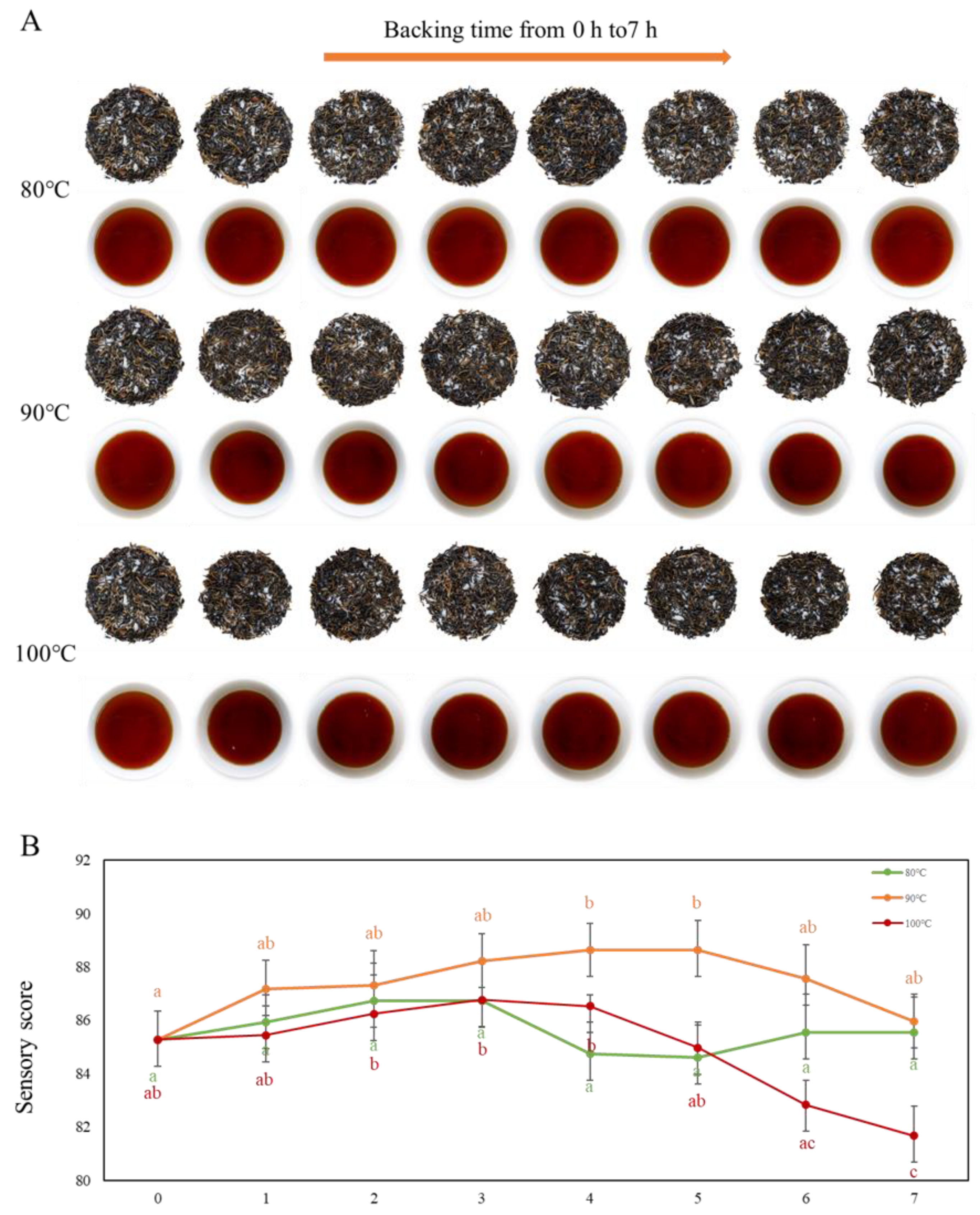

3.1. Sensory Evaluation of Yunnan Congou Black Tea under Different Aroma-Enhancement Conditions

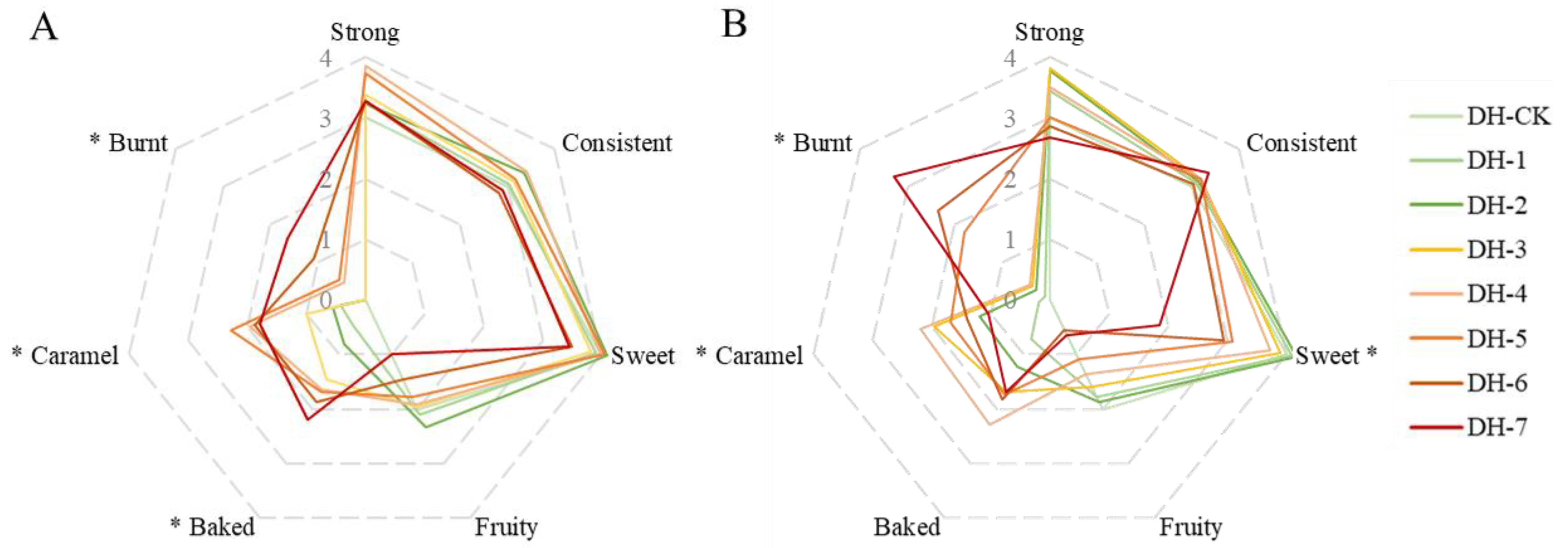

3.2. Aroma Quantitative Descriptive Analysis (QDA) of Yunnan Congou Black Tea under Different Aroma-Enhancement Conditions

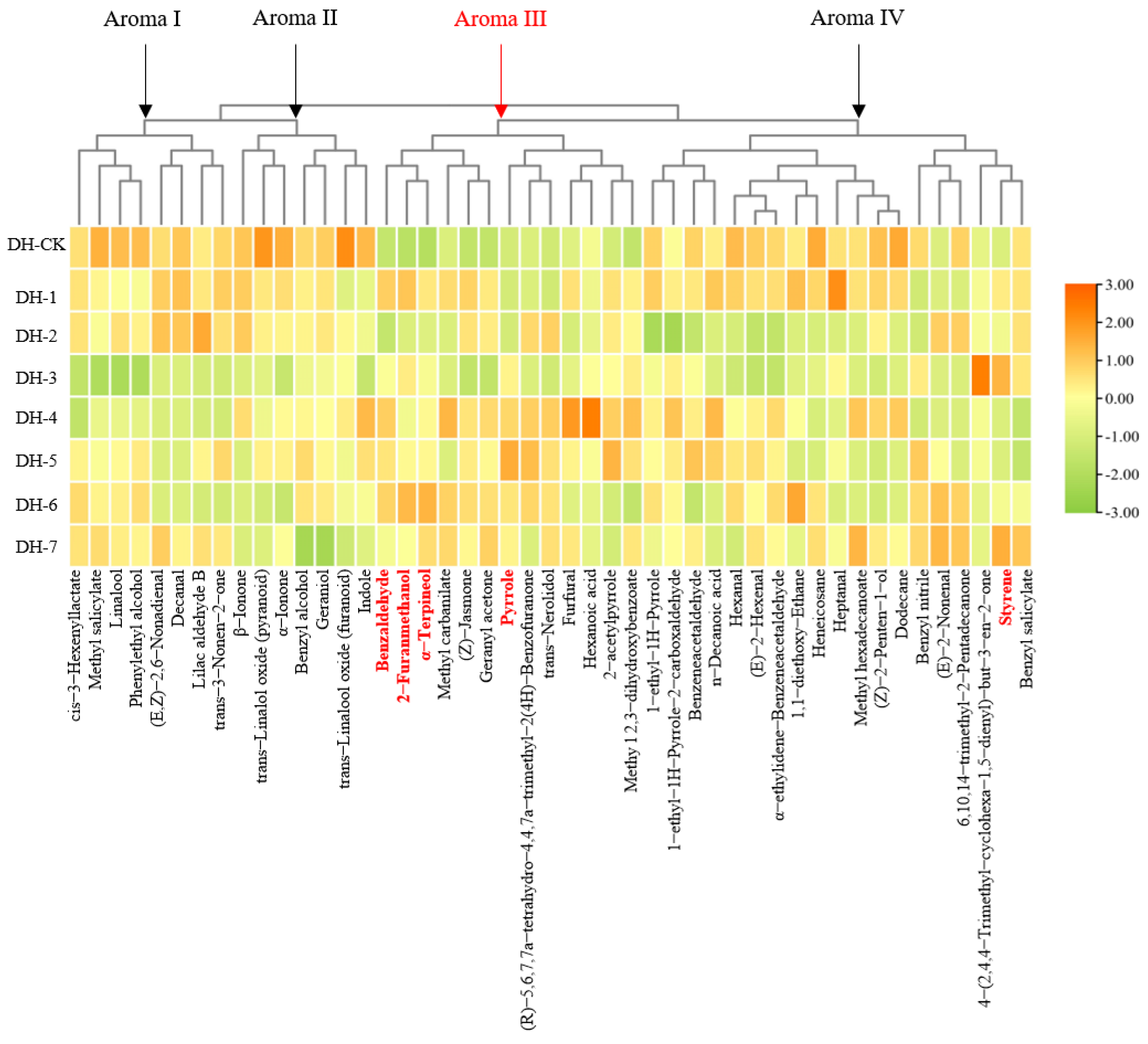

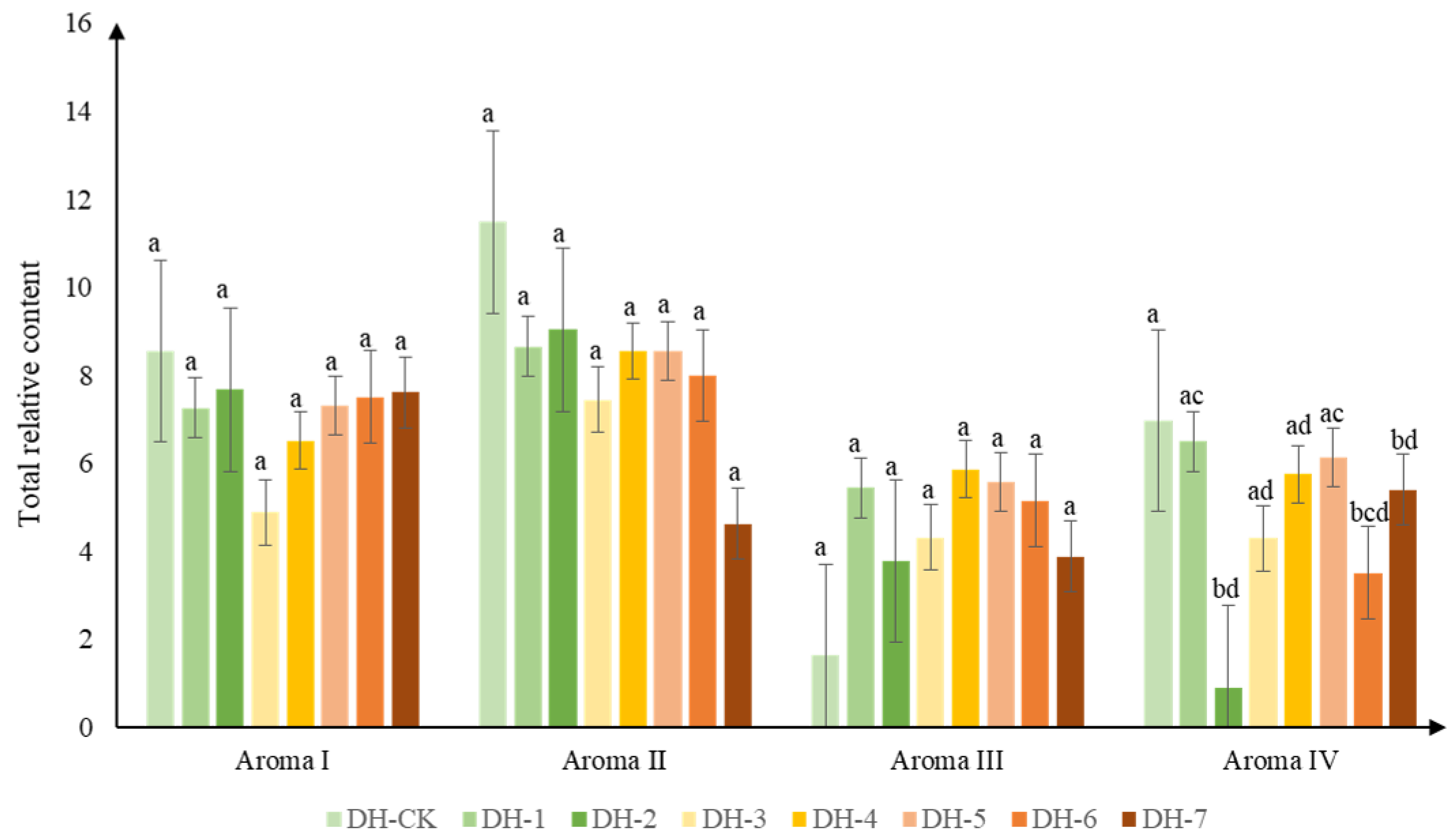

3.3. GC-MS Analysis of Aroma-Enhanced Yunnan Congou Black Tea Baked at 90 °C

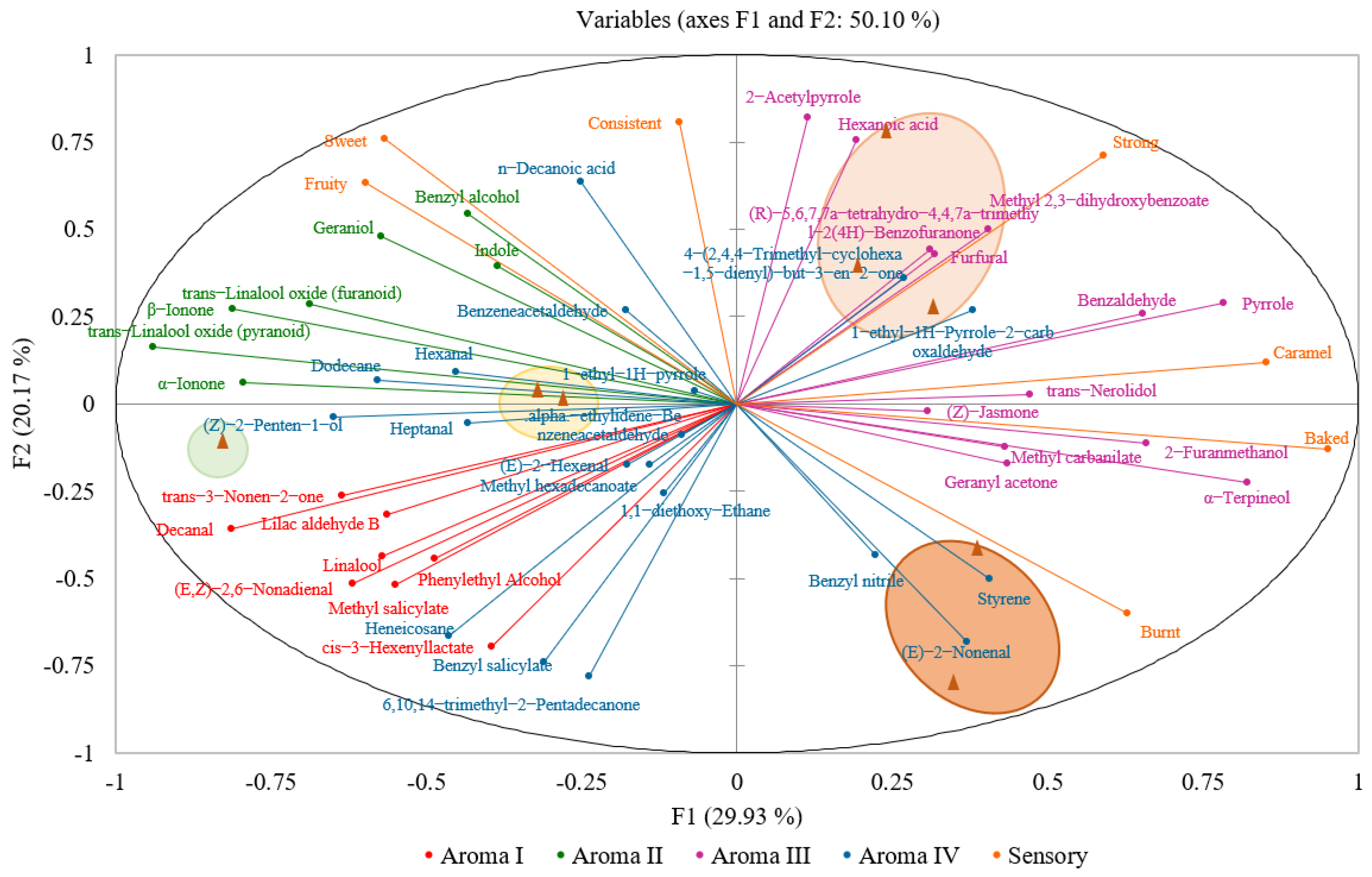

3.4. Multiple Factor Analysis (MFA) of Aroma Attributes and Volatile Compounds of Yunnan Congou Black Tea Baked at 90 °C

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, J.; Wang, Q.S.; Qin, D.D.; Fang, K.X.; Zhu, H.Y.; Jiang, X.H.; Chen, D.; Wu, H.L. Recent progress in black tea quality and related biochemical factors. Food Sci. 2020, 41, 246–253. [Google Scholar] [CrossRef]

- Fu, Y.-Q.; Wang, J.-Q.; Chen, J.-X.; Wang, F.; Yin, J.-F.; Zeng, L.; Shi, J.; Xu, Y.-Q. Effect of baking on the flavor stability of green tea beverages. Food Chem. 2020, 331, 127258. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Sun, W.J. The research advance of baking process in Minnan Oolong tea. J. Food Saf. Qual. 2015, 6, 1525–1529. [Google Scholar] [CrossRef]

- Liu, Q.B. Discussion on Tieguanyin baking technology. Tea Fujian 2014, 36, 23–25. [Google Scholar]

- Guo, X.Y.; Song, C.K.; Ho, C.-T.; Wan, X.C. Contribution of L-theanine to the formation of 2,5-dimethylpyrazine, a key roasted peanutty flavor in Oolong tea during manufacturing processes. Food Chem. 2018, 263, 18–28. [Google Scholar] [CrossRef]

- Guo, X.Y.; Ho, C.-T.; Schwab, W.; Song, C.K.; Wan, X.C. Aroma compositions of large-leaf yellow tea and potential effect of theanine on volatile formation in tea. Food Chem. 2019, 280, 73–82. [Google Scholar] [CrossRef]

- Ma, Y.-Q.; Fang, C.-G.; Xia, L.-F.; Sun, Y.-N.; Tong, J.-Y.; Zhang, Y.-M.; Pam, L.-Y.; Yang, F.-H. Effect of different fermentation degree on aroma components of heavy withered ‘Yunkang No. 10’ black tea. Southwest China J. Agric. Sci. 2020, 33, 760–768. [Google Scholar]

- Peng, Y.; Li, G.; Liu, X.Y.; Lv, C.Y.; Xiong, C.Y. SPME/GC-MS analysis of aroma quality of black tea from different producing areas. Sci. Technol. Food Ind. 2021, 42, 237–244. [Google Scholar] [CrossRef]

- Ren, H.-T.; Zhou, B.; Xia, K.-G.; Qin, T.-F.; Zhang, J.-S. Comparative analysis of aroma compositions in different-grades Yunnan Congou black tea. J. South. Agric. 2012, 43, 489–492. [Google Scholar]

- Su, D.; He, J.-J.; Zhou, Y.-Z.; Li, Y.-L.; Zhou, H.-J. Aroma effects of key volatile compounds in Keemun black tea at different grades: HS-SPME-GC-MS, sensory evaluation, and chemometrics. Food Chem. 2022, 373, 131587. [Google Scholar] [CrossRef]

- Qiu, X.L.; Wang, J.X.; Yu, X.F.; Lv, S.D.; Wu, Y.S.; Wang, C.; Gao, X.M.; Li, J.B.; Zhang, W.R.; Zhao, P.; et al. Aroma formation in Dianhong black tea: Effects of baking. Int. J. Food Prop. 2017, 20, 2724–2735. [Google Scholar] [CrossRef]

- Yang, C.-X.; Wang, Y.; Wang, Y.-J.; Yin, J.-Z.; Wang, S.-M.; Pan, H.-M.; Wu, Z.-S.; Feng, Y.-M.; Wu, S.-X. Changes of aroma and functional components of finished Yunnan black tea under different baking conditions. Mod. Food Sci. Technol. 2021, 37, 242–251. [Google Scholar] [CrossRef]

- Pang, X.L.; Qin, Z.H.; Zhao, L.; Cheng, H.; Hu, X.S.; Song, H.L.; Wu, J.H. Development of regression model to differentiate quality of black tea (Dianhong): Correlate aroma properties with instrumental data using multiple linear regression analysis. Int. J. Food Sci. Technol. 2012, 47, 2372–2379. [Google Scholar] [CrossRef]

- Liu, W.Q.; Zhang, Y.B.; Gong, S.Y.; Chen, P.; Fan, F.Y.; Yang, M.X.; Gu, Z.Q. Effects of different fixatives on fidelity and slow-release of huangjingui tea essential oil aroma. J. Tea Sci. 2016, 36, 372–378. [Google Scholar] [CrossRef]

- Huang, C.S.; Zhou, S.J.; Tong, Y.L.; Lin, Z.C.; Gong, S.Y.; Fan, F.Y. Simultaneous nitrogen-blow distillation extraction: A novel approach for aroma extraction of white tea. LWT-Food Sci. Technol. 2021, 138, 110675. [Google Scholar] [CrossRef]

- Zhou, S.J.; Huang, C.S.; Li, C.L.; Gong, S.Y.; Guo, H.W.; Tong, Y.L.; Fan, F.-Y. Aroma compositions and comparison of their related components of Longjing tea with different aroma types. J. Zhejiang Univ. (Agric. Life Sci.) 2021, 47, 203–211. [Google Scholar]

- Deng, Y.-L.; Yin, J.-F.; Xu, Y.-Q.; Rong-Mei, W.; Chen, G.-S.; Wang, F.; Chen, J.-X.; Yuan, H.-B. Application research of calm-holding temperature-far infrared technology for green tea processing. J. Tea Sci. 2013, 33, 336–344. [Google Scholar] [CrossRef]

- Qiu, F.F.; Zeng, W.C.; Qu, F.F.; Yu, Z.; Chen, Y.Q.; Zheng, S.B.; Ni, D.J. Effect of aroma enhancement methods on the quality of Congou black tea. Food Sci. 2019, 40, 82–87. [Google Scholar]

- Liu, S.-Q.; Yang, J.; Yuan, L.-Y.; Wu, X.-H.; Li, Z.-L. Effect of baking and aroma-improving conditions on the black tea sensory quality and major biochemical components. J. Food Saf. Qual. 2015, 6, 1301–1306. [Google Scholar] [CrossRef]

- Alasalvar, C.; Topal, B.; Serpen, A.; Bahar, B.; Pelvan, E.; Gokmen, V. Flavor characteristics of seven grades of black tea produced in Turkey. J. Agric. Food Chem. 2012, 60, 6323–6332. [Google Scholar] [CrossRef]

- Schuh, C.; Schieberle, P. Characterization of the key aroma compounds in the beverage prepared from Darjeeling black tea: Quantitative differences between tea leaves and infusion. J. Agric. Food Chem. 2006, 54, 916–924. [Google Scholar] [CrossRef]

- Xiao, Z.B.; Wang, H.L.; Niu, Y.W.; Liu, Q.; Zhu, J.C.; Chen, H.X.; Ma, N. Characterization of aroma compositions in different Chinese congou black teas using GC-MS and GC-O combined with partial least squares regression. Flavour Fragr. J. 2017, 32, 265–276. [Google Scholar] [CrossRef]

- Zhang, M.M.; Yang, Y.Q.; Yuan, H.B.; Hua, J.J.; Deng, Y.L.; Jiang, Y.W.; Wang, J.J. Contribution of addition theanine/sucrose on the formation of chestnut-like aroma of green tea. LWT-Food Sci. Technol. 2020, 129, 109512. [Google Scholar] [CrossRef]

- Feng, Z.H.; Li, M.; Li, Y.f.; Wan, X.C.; Yang, X.G. Characterization of the orchid-like aroma contributors in selected premium tea leaves. Food Res. Int. 2020, 129, 108841. [Google Scholar] [CrossRef] [PubMed]

- He, Y.-f.; Cao, B.-B.; Liang, M.-M.; Fu, D.-H. Research on the changes of aroma constituents in fragrant green tea during processing. China Tea Processing 2016, 51–56. [Google Scholar] [CrossRef]

- Guo, X.Y.; Ho, C.-T.; Wan, X.C.; Zhu, H.; Liu, Q.; Wen, Z. Changes of volatile compounds and odor profiles in Wuyi rock tea during processing. Food Chem. 2021, 341, 128230. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.-M.; Dong, J.-J.; Jin, J.; Liu, J.-H.; Zheng, X.-Q.; Lu, J.-L.; Liang, Y.-R.; Ye, J.-H. Roasting process shaping the chemical profile of roasted green tea and the association with aroma features. Food Chem. 2021, 353, 129428. [Google Scholar] [CrossRef] [PubMed]

- Kuo, P.-C.; Lai, Y.-Y.; Chen, Y.-J.; Yang, W.-H.; Tzen, J.T.C. Changes in volatile compounds upon aging and drying in oolong tea production. J. Sci. Food Agric. 2011, 91, 293–301. [Google Scholar] [CrossRef] [PubMed]

- Chetschik, I.; Granvogl, M.; Schieberle, P. Quantitation of key peanut aroma compounds in raw peanuts and pan-roasted peanut meal. Aroma reconstitution and comparison with commercial peanut products. J. Agric. Food Chem. 2010, 58, 11018–11026. [Google Scholar] [CrossRef]

- Du, L.P.; Wang, C.; Zhang, C.X.; Ma, L.J.; Xu, Y.Q.; Xiao, D.G. Characterization of the volatile and sensory profile of instant Pu-erh tea using GC × GC-TOFMS and descriptive sensory analysis. Microchem. J. 2019, 146, 986–996. [Google Scholar] [CrossRef]

- Zhu, Y.; Shao, C.-Y.; Lv, H.-P.; Zhang, Y.; Dai, W.-D.; Guo, L.; Tan, J.-F.; Peng, Q.-H.; Lin, Z. Enantiomeric and quantitative analysis of volatile terpenoids in different teas (Camellia sinensis). J. Chromatogr. A 2017, 1490, 177–190. [Google Scholar] [CrossRef] [PubMed]

- Feng, C.Z. Multiple factor analysis and its application in integrating university evaluation indicators. Renmin Univ. China Educ. J. 2013, 42–53. [Google Scholar]

- Fang, W.Y.; Chen, P. Comparative study on characteristic aroma components of black teas from different regions. J. Tea 2014, 40, 8. [Google Scholar]

| Categories | Alcohols | Aldehydes | Ketones | Acids | Esters | Nitrogenous Compounds | Oxygen-Containing Compounds | Hydrocarbons |

|---|---|---|---|---|---|---|---|---|

| DH-CK | 11.63 ± 0.79 a | 4.44 ± 0.31 a | 0.39 ± 0.14 a | 0.10 ± 0.06 a | 1.90 ± 0.08 a | 1.42 ± 0.28 a | 8.05 ± 0.84 a | 0.35 ± 0.26 abc |

| DH-1 | 12.48 ± 1.93 a | 3.95 ± 0.31 a | 0.56 ± 0.11 a | 0.09 ± 0.08 a | 1.75 ± 0.17 a | 2.37 ± 0.39 a | 5.05 ± 0.93 a | 0.31 ± 0.20 abc |

| DH-2 | 9.50 ± 6.03 a | 0.45 ± 0.13 c | 0.62 ± 0.28 a | 0.01 ± 0.01 a | 1.54 ± 0.48 a | 0.60 ± 0.41 a | 4.11 ± 3.34 a | 0.04 ± 0.01 b |

| DH-3 | 7.32 ± 3.49 a | 2.31 ± 0.74 abc | 0.19 ± 0.17 a | 0.11 ± 0.10 a | 1.19 ± 0.52 a | 1.43 ± 1.15 a | 4.71 ± 2.51 a | 0.20 ± 0.11 abc |

| DH-4 | 10.94 ± 0.26 a | 3.61 ± 0.18 a | 0.51 ± 0.09 a | 0.61 ± 0.53 a | 1.57 ± 0.07 a | 2.36 ± 0.87 a | 5.97 ± 0.60 a | 0.03 ± 0.02 bc |

| DH-5 | 12.14 ± 1.77 a | 4.61 ± 0.51 a | 0.47 ± 0.05 a | 0.14 ± 0.08 a | 1.50 ± 0.05 a | 2.40 ± 0.71 a | 5.77 ± 0.20 a | 0.00 ± 0.00 c |

| DH-6 | 12.79 ± 1.74 a | 1.29 ± 0.08 bd | 0.37 ± 0.05 a | 0.00 ± 0.00 a | 1.57 ± 0.19 a | 1.09 ± 0.65 a | 5.52 ± 1.69 a | 0.29 ± 0.21 abc |

| DH-7 | 7.11 ± 5.17 a | 3.11 ± 2.07 acd | 0.34 ± 0.18 a | 0.00 ± 0.00 a | 1.39 ± 1.06 a | 1.33 ± 0.84 a | 4.78 ± 2.36 a | 0.47 ± 0.05 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, S.; Cao, Y.; Zhang, G.; Zhou, S.; Wang, Y.; Gong, S.; Chu, Q.; Chen, P. Construction of Sensory/Mass Spectrometry Feedback Platform for Seeking Aroma Contributors during the Aroma Enhancement of Congou Black Tea. Plants 2022, 11, 823. https://doi.org/10.3390/plants11060823

Mei S, Cao Y, Zhang G, Zhou S, Wang Y, Gong S, Chu Q, Chen P. Construction of Sensory/Mass Spectrometry Feedback Platform for Seeking Aroma Contributors during the Aroma Enhancement of Congou Black Tea. Plants. 2022; 11(6):823. https://doi.org/10.3390/plants11060823

Chicago/Turabian StyleMei, Sifan, Yanyan Cao, Gang Zhang, Su Zhou, Yi Wang, Shuying Gong, Qiang Chu, and Ping Chen. 2022. "Construction of Sensory/Mass Spectrometry Feedback Platform for Seeking Aroma Contributors during the Aroma Enhancement of Congou Black Tea" Plants 11, no. 6: 823. https://doi.org/10.3390/plants11060823

APA StyleMei, S., Cao, Y., Zhang, G., Zhou, S., Wang, Y., Gong, S., Chu, Q., & Chen, P. (2022). Construction of Sensory/Mass Spectrometry Feedback Platform for Seeking Aroma Contributors during the Aroma Enhancement of Congou Black Tea. Plants, 11(6), 823. https://doi.org/10.3390/plants11060823