Let-Us Investigate; A Meta-Analysis of Influencing Factors on Lettuce Crop Yields within Controlled-Environment Agriculture Systems

Abstract

1. Introduction

2. Results

2.1. Systematic Search Results

2.2. Description of the Dataset

2.3. Lettuce Yield Results: Global Analysis Results

2.4. Subgroup Analysis and Meta-Regression Results

2.4.1. Vertically Grown Crops (n = 144)

2.4.2. Impact of Time (n = 957)

2.4.3. Impact of Different Lettuce Varieties (n = 979)

2.4.4. Impact of Building Type (n = 979) and Season (n = 417)

2.4.5. Impact of Lighting Types (n = 979)

2.4.6. Impact of Water and Nutrient Delivery Technologies (n = 967)

2.4.7. Evaluating the Fit of the Model

2.5. Key Results

- About 121 papers were evaluated, totaling 979 observations within those studies.

- About 85% of all papers were from between 2017 and 2022.

- Mean yield from the global analysis was 3.68 kg m−2, much higher than the global FAO field value of 1.88 kg m−2 [14].

- Mean yield from vertically grown lettuce was 6.88 kg m−2.

- Average time to harvestable size for this study was 40 days, with 94% of papers having trial periods of 70 days or less. The time needed is considerably lower than typical field-based cultivation (60 to 120 days) and will be discussed [13].

- Iceberg lettuce was found to be the highest-yielding variety, reaching on average 7.45 kg m−2. Variety will be discussed as there are many varieties of lettuce, but the variety is an independent variable; it does not drive the different changes, even if its characteristics do influence yield.

- Greenhouses were found to be the highest-yielding building type (5.11 kg m−2), with the season of winter also yielding the highest (8.93 kg m−2).

- Aquaponics was the highest-yielding system (6.73 kg m−2). For comparison, the most common watering type of hydroponics yielded 3.43 kg m−2.

- Ebb and Flow was discovered as the highest-yielding subgroup watering/nutrient delivery method (8.12 kg m−2).

3. Discussion

3.1. Systematic Search and Study Descriptions

3.2. Sub-Group Analysis Discussion

3.2.1. Impact of Time and Season

3.2.2. Impact of Water and Nutrient Delivery Systems

3.2.3. Impact of Lighting

3.2.4. Other Influencing Factors

4. Materials and Methods

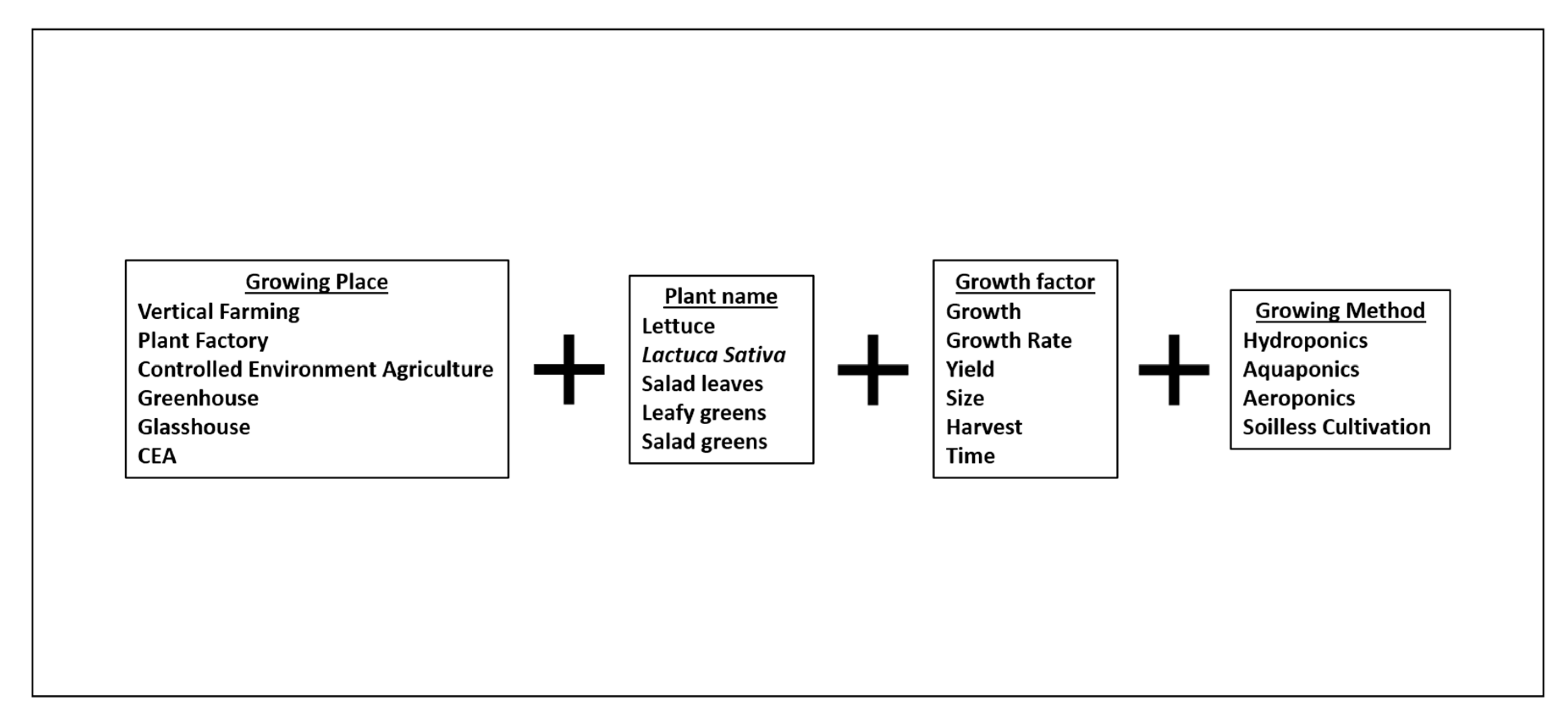

4.1. Systematic Search

- The metrics necessary for meta-analysis: mean, sample size and error term (standard deviation);

- Studies from 2009 to 2022 (12 February 2022 acceptance date);

- Papers containing primary quantitative data;

- From a scientific, peer-reviewed journal;

- Studies must be in English or translated into English.

4.2. Meta-Analysis

5. Challenges Faced and Future Study Recommendations

6. Conclusions

- Lettuce from CEA systems yields on average double that of field-based cultivation and has quicker production rates (50% faster in summer periods and up to 300% faster in winter).

- Different cultivars of the same plant need different conditions, which all must be individually accounted for. There is not a ‘one size fits all’ recipe for lettuce growth within these systems. Detailed research into the conditions needed by each cultivar is required. Aquaponic systems resulted in the highest yields, with their organic nutrient solutions able to achieve similar plant yields but at lower nutrient concentrations, pHs and conductivities.

- Model selection has revealed that the season, nutrient delivery method, cultivar and lighting type are the most influential variables within this model, explaining ~70% of the observed variation in the data. Building type and time were also found to be influencing variables, yet the nutrient delivery method contributed most towards explaining heterogeneity, having the largest influence on lettuce yields in this meta-analysis. More research into nutrient delivery methods is needed, but understanding seasonal impacts is also necessary, especially for greenhouse or protected outdoor production.

- Ebb & Flow was discovered as being the highest-yielding nutrient delivery system, but from reviewing the literature and analysing the efficacy of individual nutrient delivery systems in this meta-analysis, there is little difference in the efficacy of these nutrient delivery technologies; it comes down to preference. Supplementary lighting is beneficial for plant growth, but there is still no consensus on which spectrum is most beneficial for increasing yields in CEA systems.

- Greenhouse yields were the highest of any building type, with natural lighting as its primary light source producing some of the highest yields in this meta-analysis. Greenhouse cultivation is beneficial, especially when considering the environmental impact of fully controlled-environment systems whose artificial lighting and climate control systems necessitate considerable energy input.

- Vertical growth provides much higher yields per area than horizontal single-layer cultivation and field-based cultivation (6.88 kg m−2). Further research into commercial vertical farms is needed, as many studies have used two-layered growth chambers, which are not truly representative of the potential vertical farming has for increasing yields per area.

- Aeroponics is a promising technology, but a lack of data has limited this study’s ability to infer its efficacy and potential. More research is needed to understand its yield potential against other water/nutrient delivery technologies.

- Other factors, such as taste and appearance, are just as important to consumers and need to be considered for lettuce growth as well. The environmental impact of CEA systems also must be considered, as without renewable energy sources, the impacts can be higher than those of conventional, field-based systems.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- United Nations. The Global Land Outlook, Second Edition. 2022. Available online: https://www.unccd.int/sites/default/files/2022-04/UNCCD_GLO2_low-res_2.pdf (accessed on 6 July 2023).

- Webb, N.P.; Marshall, N.A.; Stringer, L.C.; Reed, M.S.; Chappell, A.; Herrick, J.E. Land degradation and climate change: Building climate resilience in agriculture. Front. Ecol. Environ. 2017, 15, 450–459. [Google Scholar] [CrossRef]

- United Nations. Growing at a Slower Pace, World Population is Expected to Reach 9.7 Billion in 2050 and Could Peak at Nearly 11 Billion Around 2100|UN DESA|United Nations Department of Economic and Social Affairs. United Nations Department of Economic and Social Affairs. Available online: https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html (accessed on 17 December 2021).

- United Nations. Around 2.5 Billion More People Will Be Living in Cities by 2050, Projects New UN Report|United Nations. United Nations Department of Economic and Social Affairs. Available online: https://www.un.org/en/desa/around-25-billion-more-people-will-be-living-cities-2050-projects-new-un-report (accessed on 17 December 2021).

- Benke, K.; Tomkins, B. Future food-production systems: Vertical farming and controlled-environment agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–26. [Google Scholar] [CrossRef]

- Ting, K.C.; Lin, T.; Davidson, P.C. Integrated Urban Controlled Environment Agriculture Systems. In LED Lighting for Urban Agriculture; Springer: Berlin, Germany, 2016; pp. 19–36. [Google Scholar] [CrossRef]

- Kozai, T.; Niu, G. Chapter 1-Introduction. In Plant Factory; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: San Diego, CA, USA, 2016; pp. 3–5. [Google Scholar] [CrossRef]

- Gruda, N.; Bisbis, M.; Tanny, J. Impacts of protected vegetable cultivation on climate change and adaptation strategies for cleaner production—A review. J. Clean. Prod. 2019, 225, 324–339. [Google Scholar] [CrossRef]

- OEC. Lettuce (HS: 0705) Product Trade, Exporters and Importers|OEC—The Observatory of Economic Complexity. OEC. Available online: https://oec.world/en/profile/hs92/lettuce (accessed on 17 December 2021).

- Shatilov, M.V.; Razin, A.F.; Ivanova, M.I. Analysis of the world lettuce market. IOP Conf. Series Earth Environ. Sci. 2019, 395, 012053. [Google Scholar] [CrossRef]

- Nicholson, C.F.; Harbick, K.; Gómez, M.I.; Mattson, N.S. An Economic and Environmental Comparison of Conventional and Controlled Environment Agriculture (CEA) Supply Chains for Leaf Lettuce to US Cities. In Food Supply Chains in Cities; Springer: Berlin, Germany, 2020; pp. 33–68. [Google Scholar] [CrossRef]

- Lee, Y.H. Strengths and Limitations of Meta-Analysis. Korean J. Med. 2019, 94, 391–395. [Google Scholar] [CrossRef]

- UoA. Lettuce—Crop Management. Arizona Pest Management Center—The University of Arizona. Available online: https://acis.cals.arizona.edu/agricultural-ipm/vegetables/lettuce/crop-management (accessed on 1 December 2022).

- FAOSTAT. FAOSTAT. FAO. Available online: https://www.fao.org/faostat/en/#data/QCL (accessed on 7 October 2022).

- Harrer, M.; Cuijpers, P.; Furukawa, T.A.; Ebert, D.D. Doing Meta-Analysis With R: A Hands-On Guide; CRC PRESS: Boca Raton, FL, USA, 2021; p. 474. [Google Scholar]

- Gobierno de Espana. Analisis Provincial de Superficie, Rendimiento y Produccion 2021; 2021; Vol. 1. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/superficies-producciones-anuales-cultivos/ (accessed on 6 February 2023).

- Touliatos, D.; Dodd, I.C.; McAinsh, M. Vertical farming increases lettuce yield per unit area compared to conventional horizontal hydroponics. Food Energy Secur. 2016, 5, 184–191. [Google Scholar] [CrossRef]

- Li, Q.; Gao, H.; Zhang, X.; Ni, J.; Mao, H. Describing Lettuce Growth Using Morphological Features Combined with Nonlinear Models. Agronomy 2022, 12, 860. [Google Scholar] [CrossRef]

- Shimizu, H.; Kushida, M.; Fujinuma, W. A Growth Model for Leaf Lettuce under Greenhouse Environments. Environ. Control. Biol. 2008, 46, 211–219. [Google Scholar] [CrossRef]

- Scaife, M.A.; Jones, D. The relationship between crop yield (or mean plant weight) of lettuce and plant density, length of growing period, and initial plant weight. J. Agric. Sci. 1976, 86, 83–91. [Google Scholar] [CrossRef]

- Subbarao, K.V.; Davis, R.M.; Gilbertson, R.L.; Raid, R.N. Compendium of Lettuce Diseases and Pests, 2nd ed.; CABI: Wallingford, UK, 2017. [Google Scholar] [CrossRef]

- Rusu, T.; Moraru, P.I.; Mintas, O.S. Influence of environmental and nutritional factors on the development of lettuce (Lactuca sativa L.) microgreens grown in a hydroponic system: A review. Not. Bot. Horti Agrobot. Cluj-Napoca 2021, 49, 12427. [Google Scholar] [CrossRef]

- Djidonou, D.; Leskovar, D.I. Seasonal Changes in Growth, Nitrogen Nutrition, and Yield of Hydroponic Lettuce. Hortscience 2019, 54, 76–85. [Google Scholar] [CrossRef]

- Chaudhary, S.; Devi, P.; HanumanthaRao, B.; Jha, U.C.; Sharma, K.D.; Prasad, P.V.V.; Kumar, S.; Siddique, K.H.M.; Nayyar, H. Physiological and Molecular Approaches for Developing Thermotolerance in Vegetable Crops: A Growth, Yield and Sustenance Perspective. Front. Plant Sci. 2022, 13, 878498. [Google Scholar] [CrossRef] [PubMed]

- Carotti, L.; Graamans, L.; Puksic, F.; Butturini, M.; Meinen, E.; Heuvelink, E.; Stanghellini, C. Plant Factories Are Heating Up: Hunting for the Best Combination of Light Intensity, Air Temperature and Root-Zone Temperature in Lettuce Production. Front. Plant Sci. 2021, 11, 592171. [Google Scholar] [CrossRef] [PubMed]

- Carini, F.; Filho, A.C.; Kleinpaul, J.A.; Neu, I.M.M.; Silveira, D.L.; Pacheco, M.; Andriolo, J.L. Agronomic performance of lettuce cultivars in different seasons and shading conditions. Idesia (Arica) 2020, 38, 47–58. [Google Scholar] [CrossRef]

- Castillo-Castellanos, D.; Zavala-Leal, I.; Ruiz-Velazco, J.M.; Radilla-García, A.; Nieto-Navarro, J.T.; Romero-Bañuelos, C.A.; González-Hernández, J. Implementation of an experimental nutrient film technique-type aquaponic system. Aquac. Int. 2015, 24, 637–646. [Google Scholar] [CrossRef]

- Ayipio, E.; Wells, D.E.; McQuilling, A.; Wilson, A.E. Comparisons between Aquaponic and Conventional Hydroponic Crop Yields: A Meta-Analysis. Sustainability 2019, 11, 6511. [Google Scholar] [CrossRef]

- Monsees, H.; Suhl, J.; Paul, M.; Kloas, W.; Dannehl, D.; Würtz, S. Lettuce (Lactuca sativa, variety Salanova) production in decoupled aquaponic systems: Same yield and similar quality as in conventional hydroponic systems but drastically reduced greenhouse gas emissions by saving inorganic fertilizer. PLoS ONE 2019, 14, e0218368. [Google Scholar] [CrossRef]

- Majid, M.; Khan, J.N.; Shah, Q.M.A.; Masoodi, K.Z.; Afroza, B.; Parvaze, S. Evaluation of hydroponic systems for the cultivation of Lettuce (Lactuca sativa L., var. Longifolia) and comparison with protected soil-based cultivation. Agric. Water Manag. 2020, 245, 106572. [Google Scholar] [CrossRef]

- Sundar, L.S.; Chen, G.S. Study on the Growth Performance of Lettuce (Lactuca sativa) and Pak Choi (Brassica chinensis) in Different Aquaponic Growing Systems. Horticulturae 2020, 6, 69. [Google Scholar] [CrossRef]

- Goddek, S.; Vermeulen, T. Comparison of Lactuca sativa growth performance in conventional and RAS-based hydroponic systems. Aquac. Int. 2018, 26, 1377–1386. [Google Scholar] [CrossRef]

- Goddek, S.; Joyce, A.; Kotzen, B.; Burnell Editors, G.M. Aquaponics Food Production Systems Combined Aquaculture and Hydroponic Production Technologies for the Future; Open Access: London, UK, 2019. [Google Scholar]

- Gopinath, P.; Vethamoni, P.I.; Gomathi, M. Chemical Science Review and Letters Aeroponics Soilless Cultivation System for Vegetable Crops. Chem. Sci. Rev. Lett. 2017, 6, 838–849. [Google Scholar]

- Loconsole, D.; Cocetta, G.; Santoro, P.; Ferrante, A. Optimization of LED Lighting and Quality Evaluation of Romaine Lettuce Grown in An Innovative Indoor Cultivation System. Sustainability 2019, 11, 841. [Google Scholar] [CrossRef]

- Rahman, M.; Field, D.L.; Ahmed, S.M.; Hasan, T.; Basher, M.K.; Alameh, K. LED Illumination for High-Quality High-Yield Crop Growth in Protected Cropping Environments. Plants 2021, 10, 2470. [Google Scholar] [CrossRef] [PubMed]

- Ohtake, N.; Ishikura, M.; Suzuki, H.; Yamori, W.; Goto, E. Continuous Irradiation with Alternating Red and Blue Light Enhances Plant Growth While Keeping Nutritional Quality in Lettuce. Hortscience 2018, 53, 1804–1809. [Google Scholar] [CrossRef]

- Li, L.; Tong, Y.-X.; Lu, J.-L.; Li, Y.-M.; Yang, Q.-C. Lettuce Growth, Nutritional Quality, and Energy Use Efficiency as Affected by Red–Blue Light Combined with Different Monochromatic Wavelengths. Hortscience 2020, 55, 613–620. [Google Scholar] [CrossRef]

- Azad, M.O.K.; Kjaer, K.H.; Adnan, M.; Naznin, M.T.; Lim, J.D.; Sung, I.J.; Park, C.H.; Lim, Y.S. The Evaluation of Growth Performance, Photosynthetic Capacity, and Primary and Secondary Metabolite Content of Leaf Lettuce Grown under Limited Irradiation of Blue and Red LED Light in an Urban Plant Factory. Agriculture 2020, 10, 28. [Google Scholar] [CrossRef]

- Zou, J.; Zhou, C.-B.; Xu, H.; Cheng, R.-F.; Yang, Q.-C.; Li, T. The effect of artificial solar spectrum on growth of cucumber and lettuce under controlled environment. J. Integr. Agric. 2020, 19, 2027–2034. [Google Scholar] [CrossRef]

- Meng, Q.; Runkle, E.S. Far-red radiation interacts with relative and absolute blue and red photon flux densities to regulate growth, morphology, and pigmentation of lettuce and basil seedlings. Sci. Hortic. 2019, 255, 269–280. [Google Scholar] [CrossRef]

- Frąszczak, B.; Kula-Maximenko, M. The Preferences of Different Cultivars of Lettuce Seedlings (Lactuca sativa L.) for the Spectral Composition of Light. Agronomy 2021, 11, 1211. [Google Scholar] [CrossRef]

- Yan, Z.; He, D.; Niu, G.; Zhou, Q.; Qu, Y. Growth, nutritional quality, and energy use efficiency in two lettuce cultivars as influenced by white plus red versus red plus blue LEDs. Int. J. Agric. Biol. Eng. 2020, 13, 33–40. [Google Scholar] [CrossRef]

- Miller, A.; Langenhoven, P.; Nemali, K. Maximizing Productivity of Greenhouse-grown Hydroponic Lettuce during Winter. Hortscience 2020, 55, 1963–1969. [Google Scholar] [CrossRef]

- Kang, J.H.; KrishnaKumar, S.; Atulba, S.L.S.; Jeong, B.R.; Hwang, S.J. Light intensity and photoperiod influence the growth and development of hydroponically grown leaf lettuce in a closed-type plant factory system. Hortic. Environ. Biotechnol. 2013, 54, 501–509. [Google Scholar] [CrossRef]

- Kelly, N.; Choe, D.; Meng, Q.; Runkle, E.S. Promotion of lettuce growth under an increasing daily light integral depends on the combination of the photosynthetic photon flux density and photoperiod. Sci. Hortic. 2020, 272, 109565. [Google Scholar] [CrossRef]

- Pennisi, G.; Orsini, F.; Landolfo, M.; Pistillo, A.; Crepaldi, A.; Nicola, S.; Fernández, J.; Marcelis, L.; Gianquinto, G. Optimal photoperiod for indoor cultivation of leafy vegetables and herbs. Eur. J. Hortic. Sci. 2020, 85, 329–338. [Google Scholar] [CrossRef]

- Zhang, X.; He, D.; Niu, G.; Yan, Z.; Song, J. Effects of Environment Lighting on the Growth, Photosynthesis, and Quality of Hydroponic Lettuce in a Plant Factory. Int. J. Agric. Biol. Eng. 2018, 11, 33–40. [Google Scholar] [CrossRef]

- Shultz, R.C.; Coyle, S.D.; Bright, L.A.; Hager, J.V.; Tidwell, J.H. Evaluation of different artificial light technologies for indoor aquaponic production of Bibb lettuce, Lactuca sativa var. capitata, and compact basil, Ocimum basilicum var. Genovese. J. World Aquac. Soc. 2021, 53, 703–713. [Google Scholar] [CrossRef]

- Hernandez, E.; Timmons, M.B.; Mattson, N.S. Quality, Yield, and Biomass Efficacy of Several Hydroponic Lettuce (Lactuca sativa L.) Cultivars in Response to High Pressure Sodium Lights or Light Emitting Diodes for Greenhouse Supplemental Lighting. Horticulturae 2020, 6, 7. [Google Scholar] [CrossRef]

- Dannehl, D.; Schwend, T.; Veit, D.; Schmidt, U. LED versus HPS Lighting: Effects on Water and Energy Consumption and Yield Quality in Lettuce Greenhouse Production. Sustainability 2021, 13, 8651. [Google Scholar] [CrossRef]

- Voutsinos, O.; Mastoraki, M.; Ntatsi, G.; Liakopoulos, G.; Savvas, D. Comparative Assessment of Hydroponic Lettuce Production Either under Artificial Lighting, or in a Mediterranean Greenhouse during Wintertime. Agriculture 2021, 11, 503. [Google Scholar] [CrossRef]

- Weaver, G.; van Iersel, M. Photochemical Characterization of Greenhouse-grown Lettuce (Lactuca sativa L. ‘Green Towers’) with Applications for Supplemental Lighting Control. Hortscience 2019, 54, 317–322. [Google Scholar] [CrossRef]

- Graamans, L.; Baeza, E.; van den Dobbelsteen, A.; Tsafaras, I.; Stanghellini, C. Plant factories versus greenhouses: Comparison of resource use efficiency. Agric. Syst. 2018, 160, 31–43. [Google Scholar] [CrossRef]

- Moreno-Pérez, E.D.C.; Castillo, S.D.; Gutiérrez-Tlaque, J.; González-Molina, L.; Pineda-Pineda, J. Producción de Lechuga En Invernadero Con y Sin Recirculación de La Solución Nutritiva. Rev. Chapingo Ser. Hortic. 2015, 21, 43–55. [Google Scholar] [CrossRef]

- Delaide, B.; Goddek, S.; Gott, J.; Soyeurt, H.; Jijakli, M.H. Lettuce (Lactuca sativa L. var. Sucrine) Growth Performance in Complemented Aquaponic Solution Outperforms Hydroponics. Water 2016, 8, 467. [Google Scholar] [CrossRef]

- Frasetya, B.; Harisman, K.; Ramdaniah, N.A.H. The effect of hydroponics systems on the growth of lettuce. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1098, p. 042115. [Google Scholar] [CrossRef]

- Casey, L.; Freeman, B.; Francis, K.; Brychkova, G.; McKeown, P.; Spillane, C.; Bezrukov, A.; Zaworotko, M.; Styles, D. Comparative environmental footprints of lettuce supplied by hydroponic controlled-environment agriculture and field-based supply chains. J. Clean. Prod. 2022, 369, 133214. [Google Scholar] [CrossRef]

- Akobeng, A.K. Understanding systematic reviews and meta-analysis. Arch. Dis. Child. 2005, 90, 845–848. [Google Scholar] [CrossRef]

- Koutsos, T.M.; Menexes, G.C.; Dordas, C.A. An efficient framework for conducting systematic literature reviews in agricultural sciences. Sci. Total. Environ. 2019, 682, 106–117. [Google Scholar] [CrossRef]

- Pullin, A.S.; Stewart, G.B. Guidelines for systematic review in conversation and environmental management. Conserv Biol. 2006, 20, 1647–1656. [Google Scholar] [CrossRef]

- Mengist, W.; Soromessa, T.; Legese, G. Method for conducting systematic literature review and meta-analysis for environmental science research. MethodsX. 2020, 7, 100777. [Google Scholar] [CrossRef]

- PlotDigitizer. Available online: https://plotdigitizer.com/ (accessed on 6 November 2022).

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021; Available online: https://www.r-project.org/ (accessed on 21 December 2021).

- Balduzzi, S.; Rücker, G.; Schwarzer, G. How to perform a meta-analysis with R: A practical tutorial. BMJ Ment. Health 2019, 22, 153–160. [Google Scholar] [CrossRef]

- Viechtbauer, W. Conducting Meta-Analyses in R with the meta for Package. J. Stat. Softw. 2010, 36, 1–48. [Google Scholar] [CrossRef]

| Parameter | |

| Paper ID | Yield per plant (g) |

| Study | SD (g) |

| DOI | Area (m2) |

| Title | Time (days) |

| Author | Planting density (plants m−2) |

| Year | Lettuce Variety |

| Season | Overall watering system (i.e., Hydroponic, Aeroponic, Aquaponic) |

| Country | Nutrient delivery system (i.e., Ebb & Flow, Deep water culture) |

| N | Building type |

| Mean (kg m−2) | Lighting type |

| SD (kg m−2) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gargaro, M.; Murphy, R.J.; Harris, Z.M. Let-Us Investigate; A Meta-Analysis of Influencing Factors on Lettuce Crop Yields within Controlled-Environment Agriculture Systems. Plants 2023, 12, 2623. https://doi.org/10.3390/plants12142623

Gargaro M, Murphy RJ, Harris ZM. Let-Us Investigate; A Meta-Analysis of Influencing Factors on Lettuce Crop Yields within Controlled-Environment Agriculture Systems. Plants. 2023; 12(14):2623. https://doi.org/10.3390/plants12142623

Chicago/Turabian StyleGargaro, Michael, Richard J. Murphy, and Zoe M. Harris. 2023. "Let-Us Investigate; A Meta-Analysis of Influencing Factors on Lettuce Crop Yields within Controlled-Environment Agriculture Systems" Plants 12, no. 14: 2623. https://doi.org/10.3390/plants12142623

APA StyleGargaro, M., Murphy, R. J., & Harris, Z. M. (2023). Let-Us Investigate; A Meta-Analysis of Influencing Factors on Lettuce Crop Yields within Controlled-Environment Agriculture Systems. Plants, 12(14), 2623. https://doi.org/10.3390/plants12142623