Minor Variety of Campania Olive Germplasm (“Racioppella”): Effects of Kaolin on Production and Bioactive Components of Drupes and Oil

Abstract

:1. Introduction

2. Results

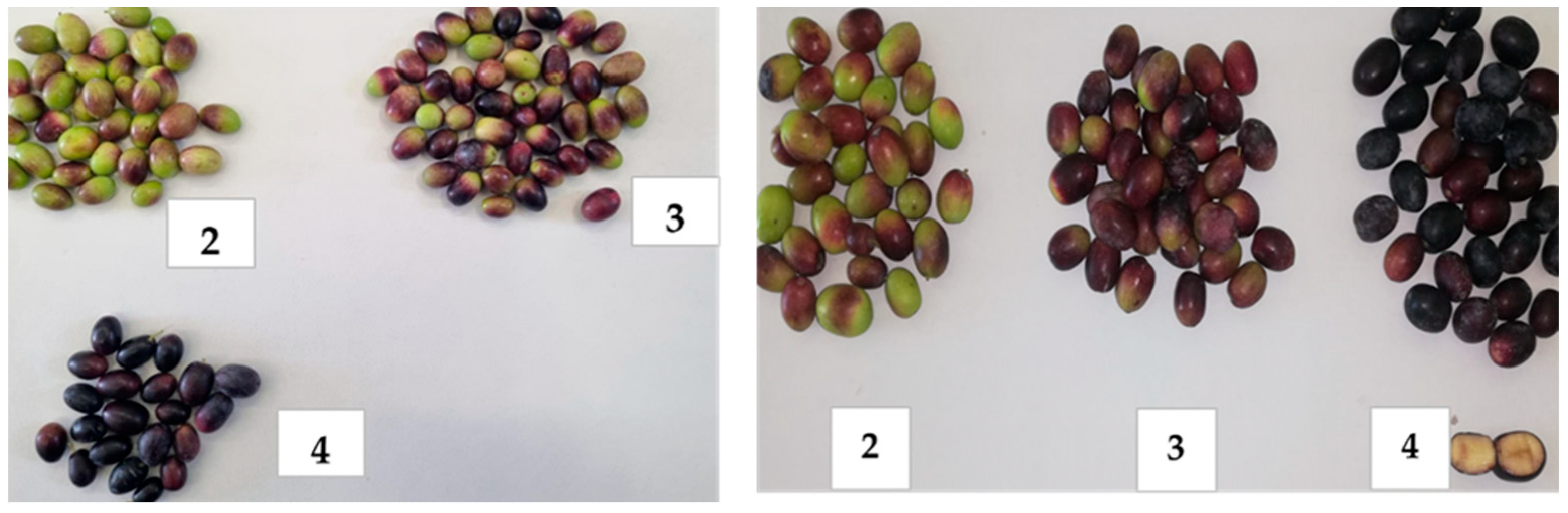

2.1. Effects of Kaolin on Drupe Characteristics

2.2. Polyphenolic Compounds Analysis by UHPLC-Q-Orbitrap HRMS and Antioxidant Activity of Olive Drupes

2.3. Effects of Kaolin on Oil Quality

2.4. Fatty Acids Composition of Olive Oil

2.5. Polyphenols Content of Olive Oil

3. Discussion

3.1. Effects of Kaolin on Drupe Bioactive Characteristics

3.2. Effects of Kaolin on Olive Oil Quality

4. Materials and Methods

4.1. Experimental Design and Plant Materials

- (1)

- Control (C) plants were only treated with water.

- (2)

- Kaolin (K): the product used was Manisol (kaolin + copper 5%) from Manica S.p.a (Rovereto, Italy), which was used by foliar application with 3.5 kg/hL.

4.2. Harvest, Production/Plants, Maturation Index, and Oil Extraction

4.3. Fat Extraction by Drupes

4.4. Carotenoids and Chlorophylls Determination of the Drupes

4.5. Anthocyanins Determination of the Drupes

4.6. Ultrasound-Assisted Extraction of Polyphenolic Compounds from Drupes

4.7. UHPLC-HRMS Analysis of Polyphenolic Compounds and Antioxidant Activity Evaluation of the Drupes

4.8. Polyphenols Determination by HPLC and Total Polyphenols Content (TPC) of the Oil (FOLIN Assay)

4.9. Quality Indices of Olive Oil

4.10. Fatty Acid Profile of the oil

4.11. Statistical Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Famiani, F.; Farinelli, D.; Rollo, S.; Camposeo, S.; Di Vaio, C.; Inglese, P. Evaluation of Different Mechanical Fruit Harvesting Systems and Oil Quality in Very Large Size Olive Trees. Span. J. Agric. Res. 2014, 12, 960. [Google Scholar] [CrossRef] [Green Version]

- Clodoveo, M.L.; Camposeo, S.; De Gennaro, B.; Pascuzzi, S.; Roselli, L. In the Ancient World, Virgin Olive Oil Was Called “Liquid Gold” by Homer and “the Great Healer” by Hippocrates. Why Has This Mythic Image Been Forgotten? Food Res. Int. 2014, 62, 1062–1068. [Google Scholar] [CrossRef]

- Muzzalupo, I.; Lombardo, N.; Salimonti, A.; Perri, E. Molecular Characterization of Italian Olive Cultivars by Microsatellite Markers. In Advances in Horticultural Science; Firenze University Press: Firenze, Italy, 2008. [Google Scholar]

- Muzzalupo, I.; Vendramin, G.G.; Chiappetta, A. Genetic Biodiversity of Italian Olives (Olea europaea) Germplasm Analyzed by SSR Markers. Sci. World J. 2014, 2014, 296590. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Di Vaio, C.; Nocerino, S.; Paduano, A.; Sacchi, R. Characterization and Evaluation of Olive Germplasm in Southern Italy: Olive Germplasm in Southern Italy. J. Sci. Food Agric. 2013, 93, 2458–2462. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Besnard, G.; Baradat, P.; Bervillé, A. Genetic Relationships in the Olive (Olea europaea L.) Reflect Multilocal Selection of Cultivars. Appl. Genet. 2001, 102, 251–258. [Google Scholar] [CrossRef]

- Angiolillo, A.; Reale, S.; Pilla, F.; Baldoni, L. Molecular Analysis of Olive Cultivars in the Molise Region of Italy. Genet. Resour. Crop Evol. 2006, 53, 289–295. [Google Scholar] [CrossRef]

- Bracci, T.; Sebastiani, L.; Busconi, M.; Fogher, C.; Belaj, A.; Trujillo, I. SSR Markers Reveal the Uniqueness of Olive Cultivars from the Italian Region of Liguria. Sci. Hortic. 2009, 122, 209–215. [Google Scholar] [CrossRef]

- Marra, F.P.; Caruso, T.; Costa, F.; Di Vaio, C.; Mafrica, R.; Marchese, A. Genetic Relationships, Structure and Parentage Simulation among the Olive Tree (Olea europaea L. Subsp. Europaea) Cultivated in Southern Italy Revealed by SSR Markers. Tree Genet. Genomes 2013, 9, 961–973. [Google Scholar] [CrossRef]

- Rao, R.; La Mura, M.; Corrado, G.; Ambrosino, O.; Foroni, I.; Perri, E.; Pugliano, G. Molecular Diversity and Genetic Relationships of Southern Italian Olive Cultivars as Depicted by AFLP and Morphological Traits. J. Hortic. Sci. Biotechnol. 2009, 84, 261–266. [Google Scholar] [CrossRef]

- Di Vaio, C.; Graziani, G.; Gaspari, A.; De Luca, L.; Aiello, A.; Cirillo, A.; Bruno, A.; Romano, R.; Ritieni, A. Drupe Characters, Fatty Acids, Polyphenolic and Aromatic Profile of Olive Oil Obtained from “Oliva Bianca”, Minor Autochthonous Cultivar of Campania. Plants 2021, 10, 1119. [Google Scholar] [CrossRef]

- Flamminii, F.; Marone, E.; Neri, L.; Pollastri, L.; Cichelli, A.; Di Mattia, C.D. The Effect of Harvesting Time on Olive Fruits and Oils Quality Parameters of Tortiglione and Dritta Olive Cultivars. Eur. J. Lipid Sci. Technol. 2021, 123, 2000382. [Google Scholar] [CrossRef]

- Barranco, D.; Rallo, L. Olive Cultivars in Spain. HortTechnology 2000, 10, 107–110. [Google Scholar] [CrossRef]

- Ouazzani, N.; Lumaret, R.; Villemur, P.; Giusto, F.D. Leaf Allozyme Variation in Cultivated and Wild Olive Trees (Olea europaea L.). J. Hered. 1993, 84, 34–42. [Google Scholar] [CrossRef]

- Belaj, A.; Satovic, Z.; Cipriani, G.; Baldoni, L.; Testolin, R.; Rallo, L.; Trujillo, I. Comparative Study of the Discriminating Capacity of RAPD, AFLP and SSR Markers and of Their Effectiveness in Establishing Genetic Relationships in Olive. Appl. Genet. 2003, 107, 736–744. [Google Scholar] [CrossRef]

- Iovane, M.; Izzo, L.G.; Cirillo, A.; Romano, L.E.; Di Vaio, C.; Aronne, G. Flowering and Pollen Resilience to High Temperature of Apricot Cultivars. Sci. Hortic. 2022, 304, 111261. [Google Scholar] [CrossRef]

- Chartzoulakis, K.; Patakas, A.; Bosabalidis, A.M. Changes in Water Relations, Photosynthesis and Leaf Anatomy Induced by Intermittent Drought in Two Olive Cultivars. Environ. Exp. Bot. 1999, 42, 113–120. [Google Scholar] [CrossRef]

- Bacelar, E.A.; Correia, C.M.; Moutinho-Pereira, J.M.; Goncalves, B.C.; Lopes, J.I.; Torres-Pereira, J.M.G. Sclerophylly and Leaf Anatomical Traits of Five Field-Grown Olive Cultivars Growing under Drought Conditions. Tree Physiol. 2004, 24, 233–239. [Google Scholar] [CrossRef]

- Sebastiani, L.; Minnocci, A.; Tognetti, R. Genotypic Differences in the Response to Elevated CO2 Concentration of One-Year-Old Olive Cuttings (Olea europaea L. Cv. Frantoio and Moraiolo). Plant Biosyst.—Int. J. Deal. All Asp. Plant Biol. 2002, 136, 199–207. [Google Scholar] [CrossRef]

- Fraga, H.; Pinto, J.G.; Viola, F.; Santos, J.A. Climate Change Projections for Olive Yields in the Mediterranean Basin. Int. J. Climatol. 2020, 40, 769–781. [Google Scholar] [CrossRef] [Green Version]

- Cirillo, A.; Conti, S.; Graziani, G.; El-Nakhel, C.; Rouphael, Y.; Ritieni, A.; Di Vaio, C. Mitigation of High-Temperature Damage by Application of Kaolin and Pinolene on Young Olive Trees (Olea europaea L.): A Preliminary Experiment to Assess Biometric, Eco-Physiological and Nutraceutical Parameters. Agronomy 2021, 11, 1884. [Google Scholar] [CrossRef]

- Cantore, V.; Pace, B.; Albrizio, R. Kaolin-Based Particle FIlm Technology Affects Tomato Physiology, Yield and Quality. Environ. Exp. Bot. 2009, 10, 279–288. [Google Scholar] [CrossRef]

- Lombardini, L.; Harris, M.K.; Glenn, D.M. Effects of Particle Film Application on Leaf Gas Exchange, Water Relations, Nut Yield, and Insect Populations in Mature Pecan Trees. HortScience 2005, 40, 5. [Google Scholar] [CrossRef] [Green Version]

- Sacchi, R.; Ambrosino, M.L.; Della Medaglia, D.; Paduano, A.; Spagna Musso, S. Gli Oli della Campania; Se.S.I.R.C.A.: Regione Campania, Italy, 1999. [Google Scholar]

- Criado, M.N.; Motilva, M.J.; Goñi, M.; Romero, M.P. Comparative Study of the Effect of the Maturation Process of the Olive Fruit on the Chlorophyll and Carotenoid Fractions of Drupes and Virgin Oils from Arbequina and Farga Cultivars. Food Chem. 2007, 100, 748–755. [Google Scholar] [CrossRef]

- Saour, G.; Makee, H. Effects of Kaolin Particle Film on Olive Fruit Yield, Oil Content and Quality. Adv. Hortic. Sci. 2023, 17, 204–206. [Google Scholar]

- Arafat, S.M.; Sayed, M.E.E. Maximizing the Productivity of Olives by Using Some Materials and Its Impacts on the Quality Indices of Picual Olive Oil. J. Food Technol. Res. 2014, 1, 96–110. [Google Scholar] [CrossRef]

- Kozukue, N.; Friedman, M. Tomatine, Chlorophyll, β-Carotene and Lycopene Content in Tomatoes during Growth and Maturation. J. Sci. Food Agric. 2003, 83, 195–200. [Google Scholar] [CrossRef]

- Romano, R.; De Luca, L.; Aiello, A.; Rossi, D.; Pizzolongo, F.; Masi, P. Bioactive Compounds Extracted by Liquid and Supercritical Carbon Dioxide from Citrus Peels. Int. J. Food Sci. Technol. 2022, 57, 3826–3837. [Google Scholar] [CrossRef]

- Wang, Y.; Xue, T.; Han, X.; Guan, L.; Zhang, L.; Wang, H.; Li, H. Kaolin Particle Film Affects Grapevine Berry Quality in Cv. Meili in Humid Climate Conditions. HortScience 2020, 55, 1987–2000. [Google Scholar] [CrossRef]

- Brillante, L.; Belfiore, N.; Gaiotti, F.; Lovat, L.; Sansone, L.; Poni, S.; Tomasi, D. Comparing Kaolin and Pinolene to Improve Sustainable Grapevine Production during Drought. PLoS ONE 2016, 11, e0156631. [Google Scholar] [CrossRef]

- Khavari, M.; Fatahi, R.; Zamani, Z. Salicylic Acid and Kaolin Effects on Pomological, Physiological, and Phytochemical Characters of Hazelnut (Corylus Avellana) at Warm Summer Condition. Sci. Rep. 2021, 11, 4568. [Google Scholar] [CrossRef]

- Brito, C.; Dinis, L.-T.; Moutinho-Pereira, J.; Correia, C. Kaolin, an Emerging Tool to Alleviate the Effects of Abiotic Stresses on Crop Performance. Sci. Hortic. 2019, 250, 310–316. [Google Scholar] [CrossRef]

- Motilva, M.-J.; Romero, M.-P. The Effect of the Ripening Process of the Olive Fruit on the Chlorophyll and Carotenoid Fractions of Drupes and Virgin Oils. In Olives and Olive Oil in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2010; pp. 59–68. ISBN 978-0-12-374420-3. [Google Scholar]

- Roussos, P.A.; Denaxa, N.-K.; Damvakaris, T.; Stournaras, V.; Argyrokastritis, I. Effect of Alleviating Products with Different Mode of Action on Physiology and Yield of Olive under Drought. Sci. Hortic. 2010, 12, 700–711. [Google Scholar] [CrossRef]

- Scarmeas, N.; Stern, Y.; Tang, M.-X.; Mayeux, R.; Luchsinger, J.A. Mediterranean Diet and Risk for Alzheimer’s Disease. Ann. Neurol. 2006, 59, 912–921. [Google Scholar] [CrossRef] [Green Version]

- Brito, C.; Dinis, L.-T.; Luzio, A.; Silva, E.; Gonçalves, A.; Meijón, M.; Escandón, M.; Arrobas, M.; Rodrigues, M.Â.; Moutinho-Pereira, J.; et al. Kaolin and Salicylic Acid Alleviate Summer Stress in Rainfed Olive Orchards by Modulation of Distinct Physiological and Biochemical Responses. Sci. Hortic. 2019, 246, 201–211. [Google Scholar] [CrossRef] [Green Version]

- Graziani, G.; Cirillo, A.; Giannini, P.; Conti, S.; El-Nakhel, C.; Rouphael, Y.; Ritieni, A.; Di Vaio, C. Biostimulants Improve Plant Growth and Bioactive Compounds of Young Olive Trees under Abiotic Stress Conditions. Agriculture 2022, 12, 227. [Google Scholar] [CrossRef]

- Hagagg, L.F.; Merwad, M.A.; Shahin, M.M.; El-Hady, E.S. Ameliorative effect of foliar application of calcium on vege-tative growth and mineral contents of olive trees Kalmata and Manzanillo cultivars irrigated with saline water. Bull. Natl. Res. Cent. 2022, 44, 128. [Google Scholar] [CrossRef]

- Dinis, L.-T.; Bernardo, S.; Conde, A.; Pimentel, D.; Ferreira, H.; Félix, L.; Gerós, H.; Correia, C.M.; Moutinho-Pereira, J. Kaolin Exogenous Application Boosts Antioxidant Capacity and Phenolic Content in Berries and Leaves of Grapevine under Summer Stress. J. Plant Physiol. 2016, 191, 45–53. [Google Scholar] [CrossRef]

- Ćosić, M. The Effect of Kaolinite on Improved Water Use Efficiency in Different Irrigation Treatments of Peppers (Capsicum annuum, L.). Ph.D. Thesis, Faculty of Agriculture, University of Belgrade, Belgrade, Serbia, 2015. [Google Scholar]

- Cabo, S.; Aires, A.; Carvalho, R.; Vilela, A.; Pascual-Seva, N.; Silva, A.P.; Gonçalves, B. Kaolin, Ascophyllum nodosum and Salicylic Acid Mitigate Effects of Summer Stress Improving Hazelnut Quality. J. Sci. Food Agric. 2021, 101, 459–475. [Google Scholar] [CrossRef]

- Hamdy, A.E.; Abdel-Aziz, H.F.; El-khamissi, H.; AlJwaizea, N.I.; El-Yazied, A.A.; Selim, S.; Tawfik, M.M.; AlHarbi, K.; Ali, M.S.M.; Elkelish, A. Kaolin Improves Photosynthetic Pigments, and Antioxidant Content, and Decreases Sunburn of Mangoes: Field Study. Agronomy 2022, 12, 1535. [Google Scholar] [CrossRef]

- Jimenez-Lopez, C.; Carpena, M.; Lourenço-Lopes, C.; Gallardo-Gomez, M.; Lorenzo, J.M.; Barba, F.J.; Prieto, M.A.; Simal-Gandara, J. Bioactive Compounds and Quality of Extra Virgin Olive Oil. Foods 2020, 9, 1014. [Google Scholar] [CrossRef]

- Brito, C. Kaolin Particle Film Modulates Morphological, Physiological and Biochemical Olive Tree Responses to Drought and Rewatering. Plant Physiol. Biochem. 2018, 11, 29–39. [Google Scholar] [CrossRef] [PubMed]

- Rotondi, A.; Bertazza, G.; Faccini, B.; Ferretti, G.; Morrone, L. Effect of Different Foliar Particle Films (Kaolin and Zeolitite) on Chemical and Sensory Properties of Olive Oil. Agronomy 2022, 12, 3088. [Google Scholar] [CrossRef]

- Perri, E.; Iannotta, N.; Muzzalupo, I.; Russo, A.; Caravita, M.A.; Pellegrino, M.; Parise, A.; Tucci, P. Kaolin Protects Olive Fruits from Bactrocera oleae (Gmelin) Infestations Unaffecting Olive Oil Quality. IOBC/WPRS Bull. 2006; in press. [Google Scholar]

- Rotondi, A.; Morrone, L.; Facini, O.; Faccini, B.; Ferretti, G.; Coltorti, M. Distinct Particle Films Impacts on Olive Leaf Optical Properties and Plant Physiology. Foods 2021, 10, 1291. [Google Scholar] [CrossRef] [PubMed]

- Moghaddam, G.; Heyden, Y.V.; Rabiei, Z.; Sadeghi, N.; Oveisi, M.R.; Jannat, B.; Araghi, V.; Hassani, S.; Behzad, M.; Hajimahmoodi, M. Characterization of Different Olive Pulp and Kernel Oils. J. Food Compos. Anal. 2012, 28, 54–60. [Google Scholar] [CrossRef]

- Tura, D.; Gigliotti, C.; Pedò, S.; Failla, O.; Bassi, D.; Serraiocco, A. Influence of Cultivar and Site of Cultivation on Levels of Lipophilic and Hydrophilic Antioxidants in Virgin Olive Oils (Olea europea L.) and Correlations with Oxidative Stability. Sci. Hortic. 2007, 112, 108–119. [Google Scholar] [CrossRef]

- Sakar, E.H.; Khtira, A.; Aalam, Z.; Zeroual, A.; Gagour, J.; Gharby, S. Variations in Physicochemical Characteristics of Olive Oil (Cv ‘Moroccan Picholine’) According to Extraction Technology as Revealed by Multivariate Analysis. AgriEngineering 2022, 4, 59. [Google Scholar] [CrossRef]

- Khaleghi, E.; Arzani, K.; Moallemi, N.; Barzegar, M. The Efficacy of Kaolin Particle Film on Oil Quality Indices of Olive Trees (Olea europaea L.) Cv ‘Zard’ Grown under Warm and Semi-Arid Region of Iran. Food Chem. 2015, 166, 35–41. [Google Scholar] [CrossRef]

- Piscopo, A.; De Bruno, A.; Zappia, A.; Ventre, C.; Poiana, M. Characterization of Monovarietal Olive Oils Obtained from Mills of Calabria Region (Southern Italy). Food Chem. 2016, 213, 313–318. [Google Scholar] [CrossRef] [Green Version]

- Torić, J.; Brozovic, A.; Baus Lončar, M.; Jakobušić Brala, C.; Karković Marković, A.; Benčić, Đ.; Barbarić, M. Biological Activity of Phenolic Compounds in Extra Virgin Olive Oils through Their Phenolic Profile and Their Combination with Anticancer Drugs Observed in Human Cervical Carcinoma and Colon Adenocarcinoma Cells. Antioxidants 2020, 9, 453. [Google Scholar] [CrossRef]

- Murkovic, M.; Lechner, S.; Pietzka, A.; Bratacos, M.; Katzogiannos, E. Analysis of Minor Components in Olive Oil. J. Biochem. Biophys. Methods 2004, 61, 155–160. [Google Scholar] [CrossRef]

- Oğraş, Ş.Ş. Comparative Study of Phenolic Compounds in Olive Oils from Differentgeographic Regions. Turk. J. Agric. For. 2022, 46, 318–326. [Google Scholar] [CrossRef]

- Sanz-Cortes, F.; Martinez-Calvo, J.; Badenes, M.L.; Bleiholder, H.; Hack, H.; Llacer, G.; Meier, U. Phenological Growth Stages of Olive Trees (Olea europaea). Ann. Appl. Biol. 2002, 140, 151–157. [Google Scholar] [CrossRef]

- Gonçalves, A.; Silva, E.; Brito, C.; Martins, S.; Pinto, L.; Dinis, L.; Luzio, A.; Martins-Gomes, C.; Fernandes-Silva, A.; Ribeiro, C.; et al. Olive Tree Physiology and Chemical Composition of Fruits Are Modulated by Different Deficit Irrigation Strategies. J. Sci. Food Agric. 2020, 100, 682–694. [Google Scholar] [CrossRef] [Green Version]

- Aiello, A.; Pizzolongo, F.; Scognamiglio, G.; Romano, A.; Masi, P.; Romano, R. Effects of Supercritical and Liquid Carbon Dioxide Extraction on Hemp (Cannabis Sativa L.) Seed Oil. Int. J. Food Sci. Technol. 2020, 55, 2472–2480. [Google Scholar] [CrossRef]

- Raj, A.; Ahmad, F. Evaluation of anthocyanin content in the fruits of different Russian olive (Elaeagnus angustifolia) genotypes of Ladakh. Prog. Hortic. 2013, 45, 298–301. [Google Scholar]

- Talhaoui, N.; Taamalli, A.; Gómez-Caravaca, A.M.; Fernández-Gutiérrez, A.; Segura-Carretero, A. Phenolic Compounds in Olive Leaves: Analytical Determination, Biotic and Abiotic Influence, and Health Benefits. Food Res. Int. 2015, 77, 92–108. [Google Scholar] [CrossRef]

- Dini, I.; Graziani, G.; Fedele, F.L.; Sicari, A.; Vinale, F.; Castaldo, L.; Ritieni, A. Effects of Trichoderma Biostimulation on the Phenolic Profile of Extra-Virgin Olive Oil and Olive Oil By-Products. Antioxidants 2020, 9, 284. [Google Scholar] [CrossRef] [Green Version]

- Graziani, G.; Gaspari, A.; Di Vaio, C.; Cirillo, A.; Ronca, C.L.; Grosso, M.; Ritieni, A. Assessment of In Vitro Bioaccessibility of Polyphenols from Annurca, Limoncella, Red Delicious, and Golden Delicious Apples Using a Sequential Enzymatic Digestion Model. Antioxidants 2021, 10, 541. [Google Scholar] [CrossRef]

- Genovese, A.; Caporaso, N.; De Luca, L.; Paduano, A.; Sacchi, R. Influence of Olive Oil Phenolic Compounds on Headspace Aroma Release by Interaction with Whey Proteins. J. Agric. Food Chem. 2015, 63, 3838–3850. [Google Scholar] [CrossRef]

| C | K | Significance | |

|---|---|---|---|

| Jaen index | 2.87 | 3.91 | |

| Production/plant (kg) | 25.00 ± 0.95 a | 25.30 ± 0.44 a | ns |

| Oil content (% f.w.) | 14.30 ± 0.14 b | 14.78 ± 0.02 a | * |

| Anthocyanins (mg/kg) | 428.03 ± 4.57 b | 531.06 ± 2.13 a | *** |

| Carotenoids (mg/kg) | 6.78 ± 0.08 a | 4.17 ± 0.10 b | *** |

| Total chlorophyll (mg/kg) | 15.88 ± 0.18 a | 12.52 ± 0.38 b | ** |

| C | K | Significance | |

|---|---|---|---|

| Hydroxytyrosol glucoside | 4.85 ± 0.47 b | 9.05 ± 0.51 a | *** |

| Hydroxytyrosol (3,4-DHPEA) | 73.18 ± 7.10 b | 153.07 ± 22.05 a | * |

| Tyrosol (4-HPEA) | 8.26 ± 1.12 b | 13.75 ± 1.82 a | * |

| Vanillic acid | 7.52 ± 1.03 b | 16.66 ± 3.40 a | * |

| Rutin | 56.35 ± 16.64 b | 95.61 ± 22.83 a | ** |

| Elenolic acid | 20.25 ± 2.17 a | 18.61 ± 1.29 a | ns |

| Verbascoside | 7078.61 ± 618.05 b | 10,872.06 ± 482.56 a | ** |

| DHPEA-EDA | 284.12 ± 133.34 a | 300.93 ± 18.25 a | ns |

| Ligstroside | 47.00 ± 23.97 b | 98.03 ± 25.04 a | ** |

| Oleuropeina | 442.56 ± 97.58 a | 559.36 ± 103.44 a | ns |

| p HPEA-EDA | 10.51 ± 1.35 b | 16.89 ± 0.59 a | *** |

| Hydroxy–Oleuropein–aglycon | 5.52 ± 1.66 a | 6.79 ± 0.89 a | ns |

| Luteolin | 14.92 ± 0.90 b | 38.91 ± 8.05 a | * |

| 3,4-DHPEA-AC | 12.27 ± 1.84 b | 41.02 ± 3.16 a | *** |

| DHPEA-EA | 471.32 ± 288.33 b | 718.48 ± 213.55 a | ** |

| p-HPEA-EA | 7.60 ± 2.82 b | 29.99 ± 4.55 a | ** |

| Total polyphenols | 8102.26 ± 679.24 b | 12,989.23 ± 241.28 a | *** |

| Oil Quality Index | C | K | Significance |

|---|---|---|---|

| Acidity (% oleic acid) | 0.28 ± 0.01 a | 0.29 ± 0.02 a | ns |

| Peroxide value (meq O2/kg) | 5.34 ± 0.03 b | 6.86 ± 0.01 a | *** |

| K270 | 0.20 ± 0.00 b | 0.21 ± 0.00 a | * |

| K232 | 1.46 ± 0.00 b | 1.64 ± 0.01 a | *** |

| ΔK | 0.00 ± 0.00 a | 0.00 ± 0.00 a | ns |

| Panel Test | C | K |

|---|---|---|

| Fruity | 7.2 | 5.4 |

| Bitter | 3.6 | 3 |

| Spicy | 4.6 | 2.4 |

| Heating/sludge | 0 | 0 |

| Winey/acid/acidic/sour | 0 | 0 |

| Rancid | 0 | 0 |

| Mold/moisture/ground | 0 | 0 |

| Frozen olive | 0 | 0 |

| % Fatty Acids | C | K | Significance |

|---|---|---|---|

| Palmitic (C16:0) | 13.90 ± 0.06 a | 12.56 ± 0.02 b | *** |

| Palmitoleic (C16:1) | 1.10 ± 0.01 a | 0.91 ± 0.04 b | * |

| Heptadecanoic (C17:0) | 0.20 ± 0.00 a | 0.19 ± 0.00 a | ns |

| Stearic (C18:0) | 2.90 ± 0.02 a | 2.64 ± 0.01 b | ** |

| Oleic (C18:1) | 66.23 ± 0.00 b | 70.22 ± 0.05 a | *** |

| Linoleic (C18:2) | 14.06 ± 0.04 a | 11.82 ± 0.00 b | *** |

| Arachidic (C20:0) | 0.39 ± 0.00 a | 0.36 ± 0.00 b | ** |

| Linolenic (C18:3) | 1.08 ± 0.00 b | 1.19 ± 0.01 a | ** |

| Behenic (C22:0) | 0.14 ± 0.00 a | 0.13 ± 0.00 a | ns |

| MUFA | 67.34 ± 0.01 b | 71.13 ± 0.02 a | ** |

| PUFA | 15.14 ± 0.04 a | 13.01 ± 0.01 b | *** |

| SFA | 17.53 ± 0.04 a | 15.87 ± 0.00 b | *** |

| MUFA/PUFA | 4.38 ± 0.01 b | 5.40 ± 0.01 a | *** |

| MUFA/SFA | 3.78 ± 0.01 b | 4.43 ± 0.00 a | *** |

| Oleic/linoleic | 4.71 ± 0.01 b | 5.94 ± 0.01 a | *** |

| Polyphenols (mg/kg) | C | K | Significance |

|---|---|---|---|

| Tyrosol | 8.17 ± 0.11 b | 9.85 ± 0.10 a | *** |

| p-coumaric acid | 4.31 ± 0.01 b | 4.55 ± 0.00 a | *** |

| Ferulic acid | 0.81 ± 0.01 a | 0.76 ± 0.01 b | * |

| Vanillic acid | 0.42 ± 0.01 a | 0.31 ± 0.01 b | ** |

| Oleuropein | <LOD | <LOD | |

| TPC (mg GAE/kg) | 442.31 ± 10.77 b | 489.80 ± 0.02 a | ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cirillo, A.; Graziani, G.; De Luca, L.; Cepparulo, M.; Ritieni, A.; Romano, R.; Di Vaio, C. Minor Variety of Campania Olive Germplasm (“Racioppella”): Effects of Kaolin on Production and Bioactive Components of Drupes and Oil. Plants 2023, 12, 1259. https://doi.org/10.3390/plants12061259

Cirillo A, Graziani G, De Luca L, Cepparulo M, Ritieni A, Romano R, Di Vaio C. Minor Variety of Campania Olive Germplasm (“Racioppella”): Effects of Kaolin on Production and Bioactive Components of Drupes and Oil. Plants. 2023; 12(6):1259. https://doi.org/10.3390/plants12061259

Chicago/Turabian StyleCirillo, Aurora, Giulia Graziani, Lucia De Luca, Marco Cepparulo, Alberto Ritieni, Raffaele Romano, and Claudio Di Vaio. 2023. "Minor Variety of Campania Olive Germplasm (“Racioppella”): Effects of Kaolin on Production and Bioactive Components of Drupes and Oil" Plants 12, no. 6: 1259. https://doi.org/10.3390/plants12061259

APA StyleCirillo, A., Graziani, G., De Luca, L., Cepparulo, M., Ritieni, A., Romano, R., & Di Vaio, C. (2023). Minor Variety of Campania Olive Germplasm (“Racioppella”): Effects of Kaolin on Production and Bioactive Components of Drupes and Oil. Plants, 12(6), 1259. https://doi.org/10.3390/plants12061259