Tuning the Ballistic Performance of a Single-Burning-Rate Grain Solid Rocket Motor via New Discontinuous Embedded Metal Wires

Abstract

1. Introduction

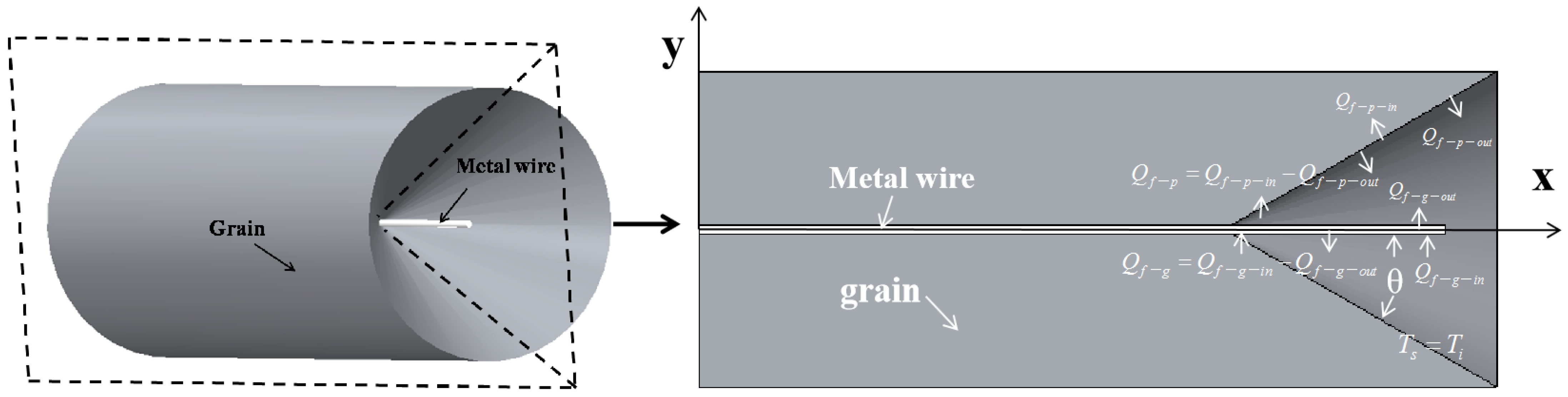

2. Numerical Model

2.1. Basic Hypothesis

- (1)

- The heat transfer mode between silver–nickel alloy metal wires and the combustion gas of the propellant is heat convection and radiation; the heat transfer mode between silver–nickel alloy metal wires and grains is heat conduction; the heat transfer mode between combustion gas and grains is heat convection and radiation.

- (2)

- The burning of grains which are far away from the silver–nickel alloy metal wires abides by the parallel burning law. The grain close to silver–nickel alloy metal wires is ignited when the grain temperature rises to ignition temperature and the burning rate of the grains close to the metal wires differs depending on the position.

- (3)

- The silver–nickel alloy metal wires break when the temperature rises to the melting temperature. These broken silver–nickel alloy metal wires are useless for grains and combustion gas, and there is no heat convection or heat radiation between each other.

- (4)

- When the diameter of silver–nickel alloy metal wires is relatively smaller, namely less than one millimeter, the temperature diversity in the radial direction is ignored and the temperature gradient only exists in the axial direction.

- (5)

- Combustion gas is uniform everywhere. The flow of combustion gas has no influence on the heat convection among gas and silver–nickel alloy metal wires and grains.

2.2. Governing Equations

- (1)

- Governing equation for pressure

- (2)

- Heat transfer equations

- (3)

- Burning rate ratio

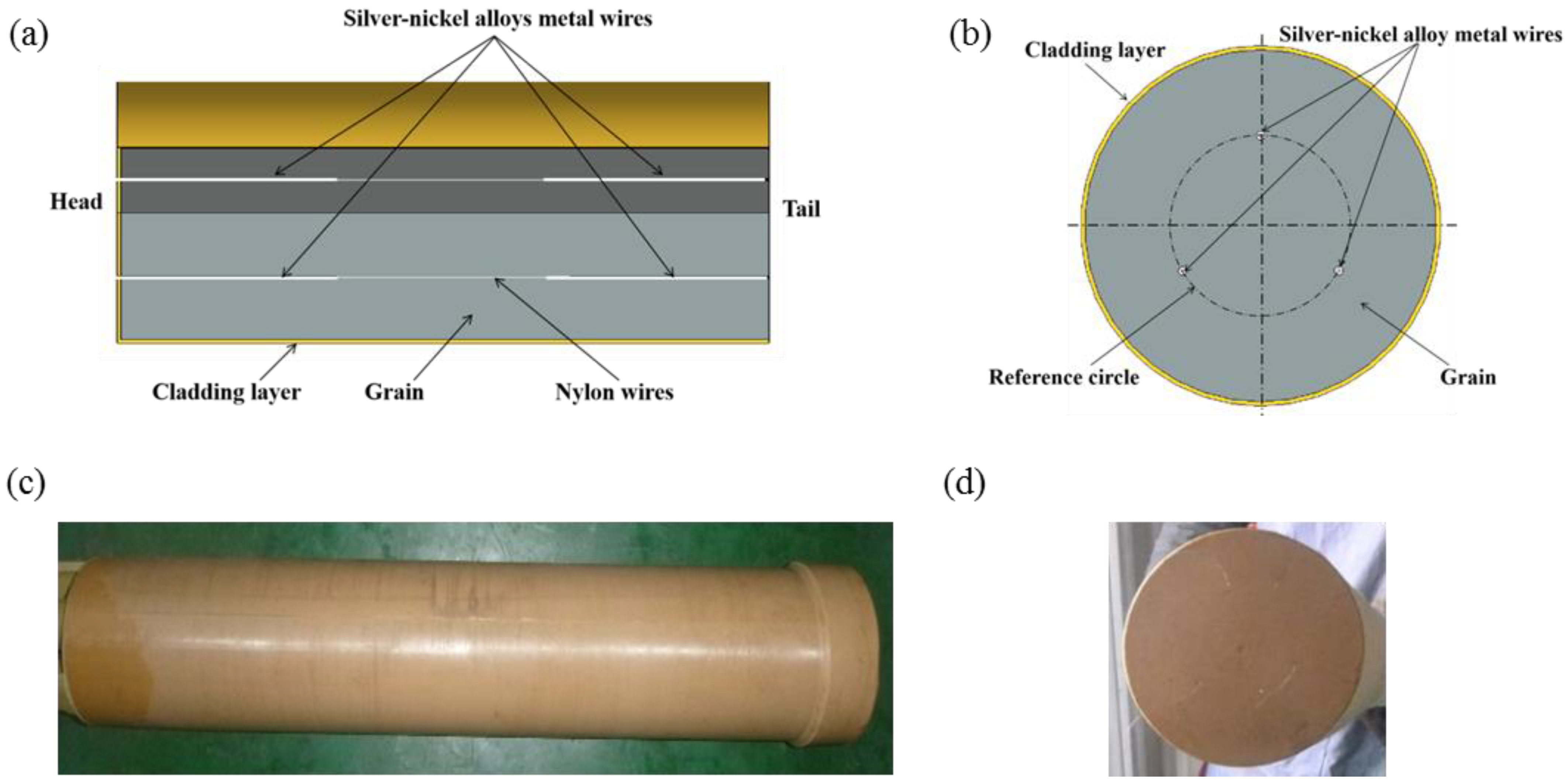

3. Experimental Methods

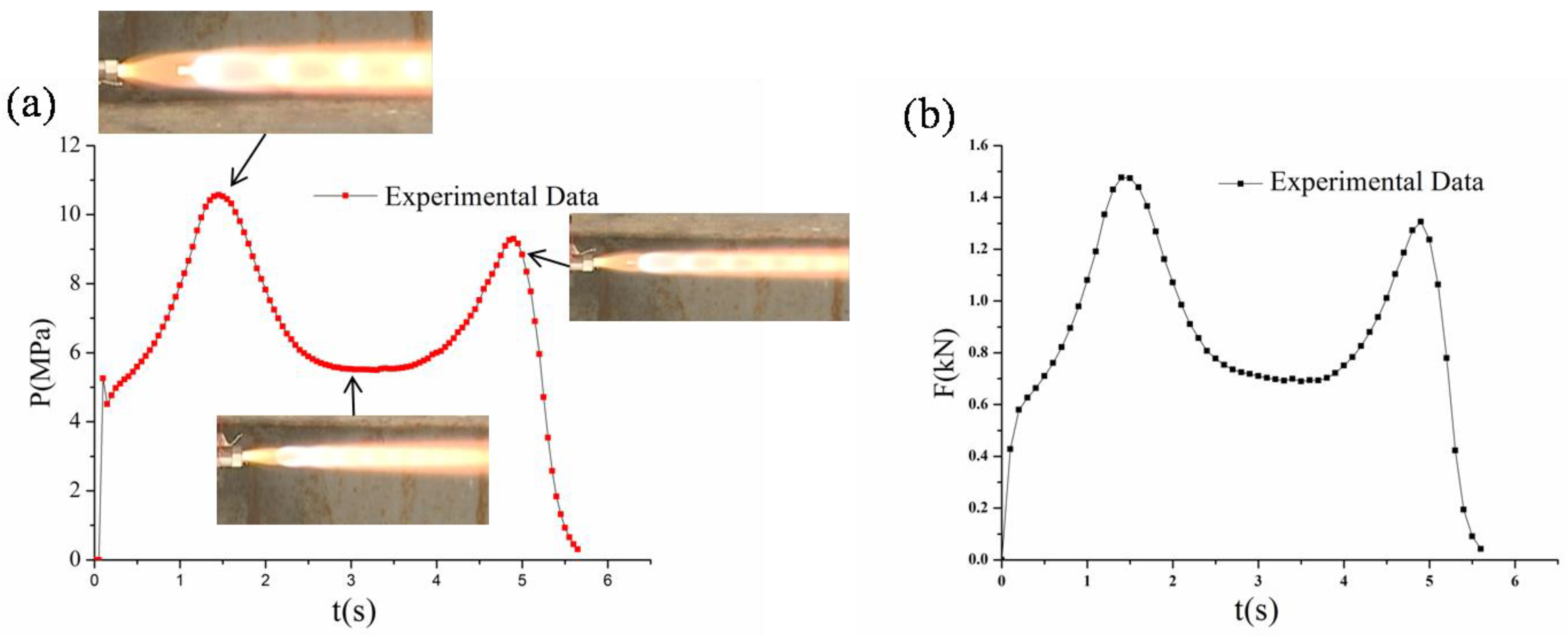

4. Results and Discussion

4.1. Solid Rocket Motor Firing Verification of Discontinuous Embedded Metal Wires (GNEMWs)

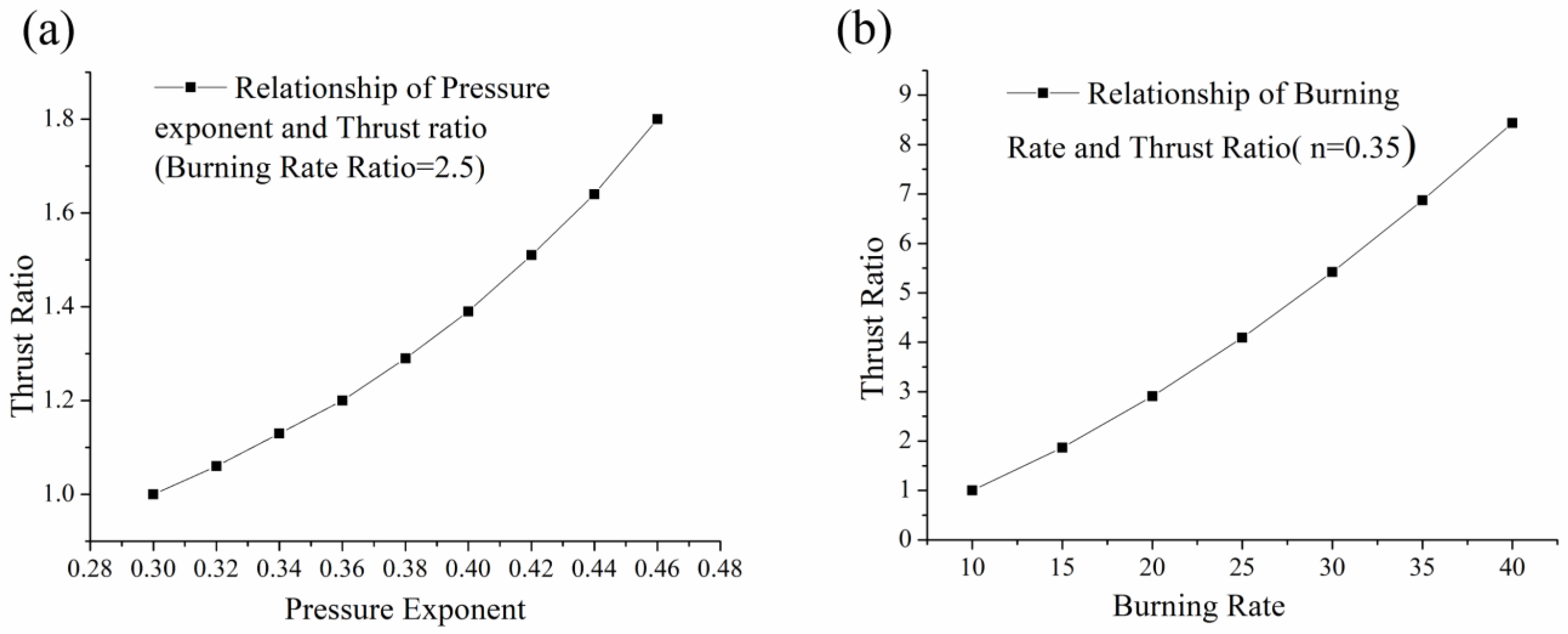

4.2. Thrust Ratio Prediction in Different Propellants of Discontinuous Embedded Metal Wires (GNEMWs)

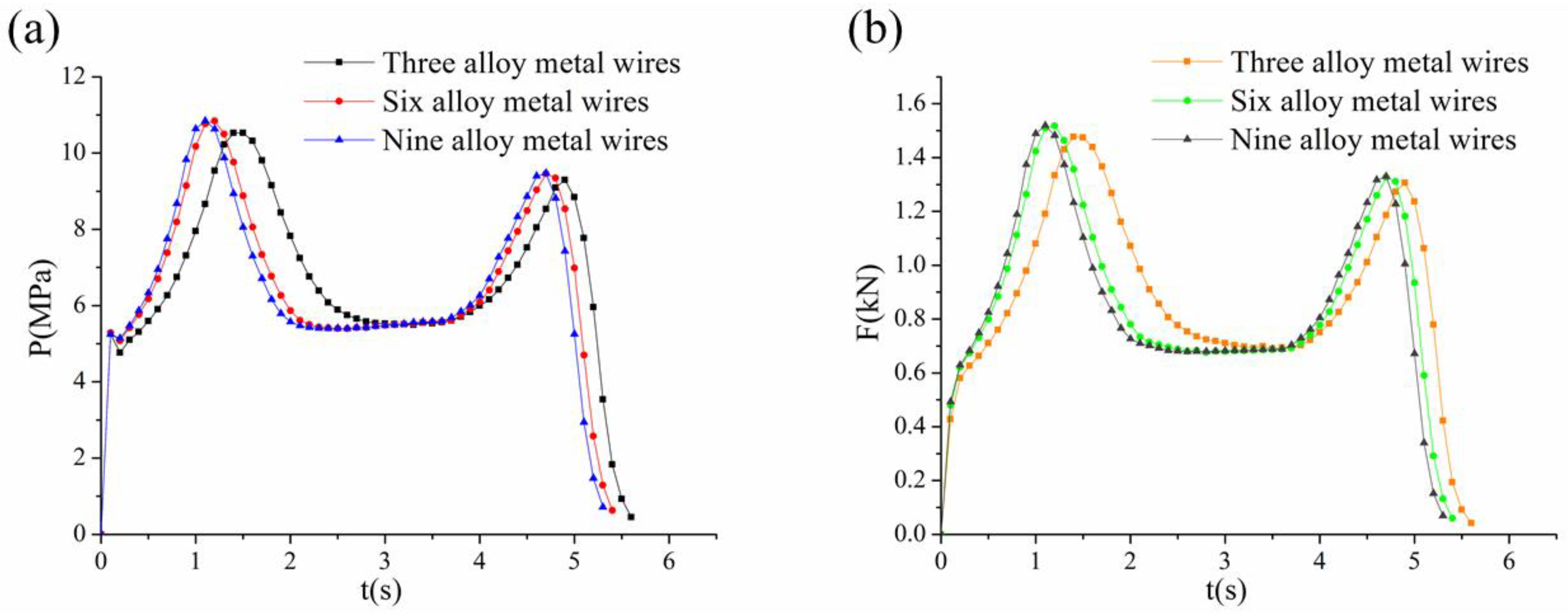

4.3. Thrust Ratio Prediction in Different Metal Wire Materials and Numbers of Discontinuous Embedded Metal Wires (GNEMWs)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

Terms and Definition

| : | Burning surface of the grain, m2 |

| : | Nozzle throat area, m2 |

| : | Cross-section area of the metal wire, m2 |

| : | Burning surface of grain without any embedded metal wire, m2 |

| : | Characteristic velocity, m/s |

| : | Specific heat capacity of the metal wire, J/(kg·K) |

| : | Specific heat capacity of the grain, J/(kg·K) |

| : | Thrust coefficient |

| : | Thrust of the solid rocket motor, N |

| : | Heat convection coefficient between combustion gas and the metal wire, W/(m2·K) |

| : | Heat convection coefficient between combustion gas and the grain, W/(m2·K) |

| : | Perimeter of the metal wire, m |

| : | Pressure exponent |

| : | Normal direction of grain burning surface |

| : | Combustion chamber pressure, Pa |

| : | Heat transfer between the metal wire and combustion gas |

| : | Heat transfer from combustion gas to the metal wire |

| Heat transfer from the metal wire to combustion gas | |

| : | Heat transfer between the metal wire and the grain |

| : | Heat transfer from the grain to the metal wire |

| : | Heat transfer from the metal wire to the grain |

| Heat transfer density between combustion gas and the metal wire, W/m2 | |

| : | Heat transfer density between the grain and the metal wire, W/m2 |

| : | Gas constant, J/(mol·K) |

| : | Operation time, s |

| : | Combustion gas temperature, K |

| : | Temperature of the metal wire, K |

| : | The head-exposed temperature of the metal wire, K |

| : | Melting temperature of the metal wire, K |

| : | Ignition temperature of the grain, K |

| : | Burning surface temperature of the grain, K |

| : | Temperature of the grain, K |

| : | Chamber’s free volume, m3 |

| x | Axial direction, m |

| y | Radial direction, m |

| : | Coefficient of burning rate |

| : | Heat diffusion coefficient between combustion gas and the metal wire, W/(m2·K) |

| : | Heat diffusion coefficient between the metal wire and the grain, W/(m2·K) |

| : | Blackening of the metal wire |

| : | Blackening of the grain |

| : | Taper angle of the grain close to the metal wire, ° |

| : | Heat conduction coefficient of the metal wire, W/(m·K) |

| : | Heat conduction coefficient of the grain, W/(m·K) |

| : | Metal wire density, kg/m3 |

| : | Propellant destiny, kg/m3 |

| Combustion gas destiny of propellant, kg/m3 | |

| : | Boltzmann constant, J/K |

| : | Burning rate ratio |

References

- Lee, S.; Oh, J.; Lee, H.; Khil, T.; Kim, M. Study on combustion characteristics of thermoplastic solid propellants embedded with metal wires. J. Korean Soc. Propuls. Eng. 2022, 26, 21–27. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Y.; Li, X.; Cong, J. Using the impulse method to determine high-pressure dynamic burning rate of solid propellants. Aerospace 2023, 10, 818. [Google Scholar] [CrossRef]

- Lee, H.; Oh, J.; Yang, H.; Lee, S.; Khil, T. Burn-back analysis for propellant grains with embedded metal wires. J. Korean Soc. Propuls. Eng. 2022, 26, 12–19. [Google Scholar] [CrossRef]

- Cha, J.; de Oliveira, É.J. Performance comparison of control strategies for a variable-thrust solid-propellant rocket motor. Aerospace 2022, 9, 325. [Google Scholar] [CrossRef]

- Dunn; Stuart, S. 3-D grain design and ballistic analysis using the SPP97 code. In Proceedings of the 33th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Seattle, WA, USA, 6–9 July 1997. [Google Scholar]

- Greatrix, D.R. Transient burning rate model for solid rocket motor internal ballistic simulations. Int. J. Aerosp. Eng. 2008, 5, 826070. [Google Scholar] [CrossRef]

- Hejl, R.J.; Heister, S.D. Solid rocket motor grain burnback analysis using adaptive grids. J. Propuls. Power 1995, 11, 1006–1011. [Google Scholar] [CrossRef]

- Willcox, M.A.; Brewster, M.Q.; Tang, K.C.; Stewart, D.S. Solid propellant grain design and burnback simulation using a minimum distance function. J. Propuls. Power 2007, 23, 465–475. [Google Scholar] [CrossRef]

- Sun, D.; Li, Y.; Liu, P.; Chen, B.; Fan, W. Numerical investigation on the effect of ammonium perchlorate content and position on the combustion characteristics of an ammonium perchlorate/hydroxyl-terminated polybutadiene propellant. Aerospace 2023, 10, 692. [Google Scholar] [CrossRef]

- Yue, S.; Liu, L.; Liu, H.; Jiang, Y.; Liu, P.; Pang, A.; Zhang, G.; Ao, W. Agglomerate size evolution in solid propellant combustion under high pressure. Aerospace 2023, 10, 515. [Google Scholar] [CrossRef]

- Isert, S.; Lane, C.D.; Gunduz, I.E.; Son, S.F. Tailoring burning rates using reactive wires in composite solid rocket propellants. Proc. Combust. Inst. 2016, 36, 2283–2290. [Google Scholar] [CrossRef]

- King, M.K. Analytical modeling of effects of wires on solid motor ballistics. J. Propuls. Power 1991, 7, 312–321. [Google Scholar] [CrossRef]

- Song, M.; Ye, D. Study of a new kind of multipulse rocket motor. J. Propuls. Power 2001, 17, 380–384. [Google Scholar] [CrossRef]

- Kubota, N.; Ichida, M.; Fujisawa, T. Combustion processes of propellants with embedded metal wires. AIAA J. 1982, 20, 116–121. [Google Scholar] [CrossRef]

- Yoo, J. Burning characteristics of nitramine propellant embedded with metal wires. J. Korean Soc. Propuls. Eng. 2000, 4, 50–58. [Google Scholar]

- Hsing, Y.; Wu, S.; Kuo, J. Burning rate of HTPB composite propellant grains with embedded metal wires. In Proceedings of the 28th AIAA Aerospace Sciences Meeting, Reno, NV, USA, 8–11 January 1990. [Google Scholar]

- Xiong, W.; Liu, Y. Burning surface calculation for grain embedded metal wires based on solid work API. J. Beijing Univ. Aeronaut. Astronaut. 2007, 33, 1400–1403. [Google Scholar]

- Gossant, B.; Godfroy, F.; Robert, P. Theoretical calculus of burning rate ratio in grain with embedded Metal Wires. In Proceedings of the 24th Joint Propulsion Conference, Boston, MA, USA, 11–13 July 1988. [Google Scholar]

- Zhang, Y.; Wang, X.; Yang, J. Numerical study of end-burning solid motor embedded with wire. J. Propuls. Technol. 2008, 28, 4–8. [Google Scholar]

- Wei, R.; Bao, F.; Liu, Y.; Hui, W. Combined acceleration methods for solid rocket motor grain burn back simulation based on the level set method. Int. J. Aerosp. Eng. 2018, 2, 4827810. [Google Scholar]

- Li, W.; Wei, Z. Fundamental of Solid Propellant Rocket Motor; Beijing Institute of Technology Publishing: Beijing, China, 2023. [Google Scholar]

- Paul, B. Tactical Missile Performance for Single and Multi-Wire Embedded Propellant Configurations with Discontinuities; Department of the Air Force, Air University: Montgomery, AL, USA, 2019. [Google Scholar]

| Structure | Main Material |

|---|---|

| Ignition case | Carbon steel |

| Ignition charge | Black gunpowder |

| Case | Carbon steel |

| Combustion insulation | Nitrile–butadiene rubber |

| Propellant | HTPB |

| Nozzle case | Carbon steel |

| Nozzle throat insert | Copper-infiltrated tungsten (W-7Cu) |

| Insulation of nozzle convergent section | Silica phenolic resin molded |

| Insulation of nozzle extend section | Silica phenolic resin molded |

| Parameter | Unit | Value |

|---|---|---|

| Metal wire diameter | mm | Φ0.4 |

| Blackening of metal wire | - | 0.8 |

| Blackening of the grain | - | 0.9 |

| Melting temperature of the metal wire | K | 1, 700 |

| Initial temperature of the metal wire | K | 293 |

| Standard burning rate motor (6.0 MPa, 20 °C) | mm/s | 29 |

| Heat conduction coefficient of the grain | W/(m·K) | 1 |

| Grain density | kg/m3 | 1, 800 |

| Grain combustion heat | kJ/kg | 2, 600 |

| Ignition temperature of the grain | K | 650 |

| Initial temperature of the grain | K | 293 |

| Specific heat ratio of the grain | - | 1.22 |

| Environment pressure | MPa | 0.1 |

| Gas constant | J/(kg·K) | 287.4 |

| Heat convection coefficient between combustion gas and the metal wire | W/(m2·K) | 50 |

| Heat convection coefficient between combustion gas and the grain | W/(m2·K) | 2.4 |

| Pressure exponent of the propellant | - | 0.35 |

| Temperature sensitivity coefficient | /°C | 0.0015 |

| Characteristic velocity | m/s | 1520 |

| Nozzle throat diameter | mm | 10.5 |

| Ablation rate of nozzle throat insert | mm/s | 0 |

| Grain diameter | mm | Φ84 |

| Grain length | mm | 210 |

| Heat conduction coefficient of the silver–nickel alloy | W/(m·k) | 305 |

| Specific heat capacity of the silver–nickel alloy | J/(kg·K) | 276 |

| Density of the silver–nickel alloy | kg/m3 | 10,200 |

| Combustion gas temperature | K | 3500 K |

| Chamber’s free volume | mm3 | 1.1 × 105 |

| Combustion gas destiny of propellant | kg/m3 | 5.2 |

| Boltzmann constant | J/K | 1.38 × 10−23 |

| Specific heat capacity of the grain | J/(kg·K) | 1200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Q.; Ren, Q. Tuning the Ballistic Performance of a Single-Burning-Rate Grain Solid Rocket Motor via New Discontinuous Embedded Metal Wires. Aerospace 2024, 11, 308. https://doi.org/10.3390/aerospace11040308

Wu Q, Ren Q. Tuning the Ballistic Performance of a Single-Burning-Rate Grain Solid Rocket Motor via New Discontinuous Embedded Metal Wires. Aerospace. 2024; 11(4):308. https://doi.org/10.3390/aerospace11040308

Chicago/Turabian StyleWu, Qiu, and Quanbin Ren. 2024. "Tuning the Ballistic Performance of a Single-Burning-Rate Grain Solid Rocket Motor via New Discontinuous Embedded Metal Wires" Aerospace 11, no. 4: 308. https://doi.org/10.3390/aerospace11040308

APA StyleWu, Q., & Ren, Q. (2024). Tuning the Ballistic Performance of a Single-Burning-Rate Grain Solid Rocket Motor via New Discontinuous Embedded Metal Wires. Aerospace, 11(4), 308. https://doi.org/10.3390/aerospace11040308