A Review of Recent Developments in Hybrid Rocket Propulsion and Its Applications

Abstract

:1. Introduction of Hybrid Rocket Propulsion

1.1. Historical Perspective

1.2. Fundamental Principles of Chemical Bi-Propellant Rocket Thrusters

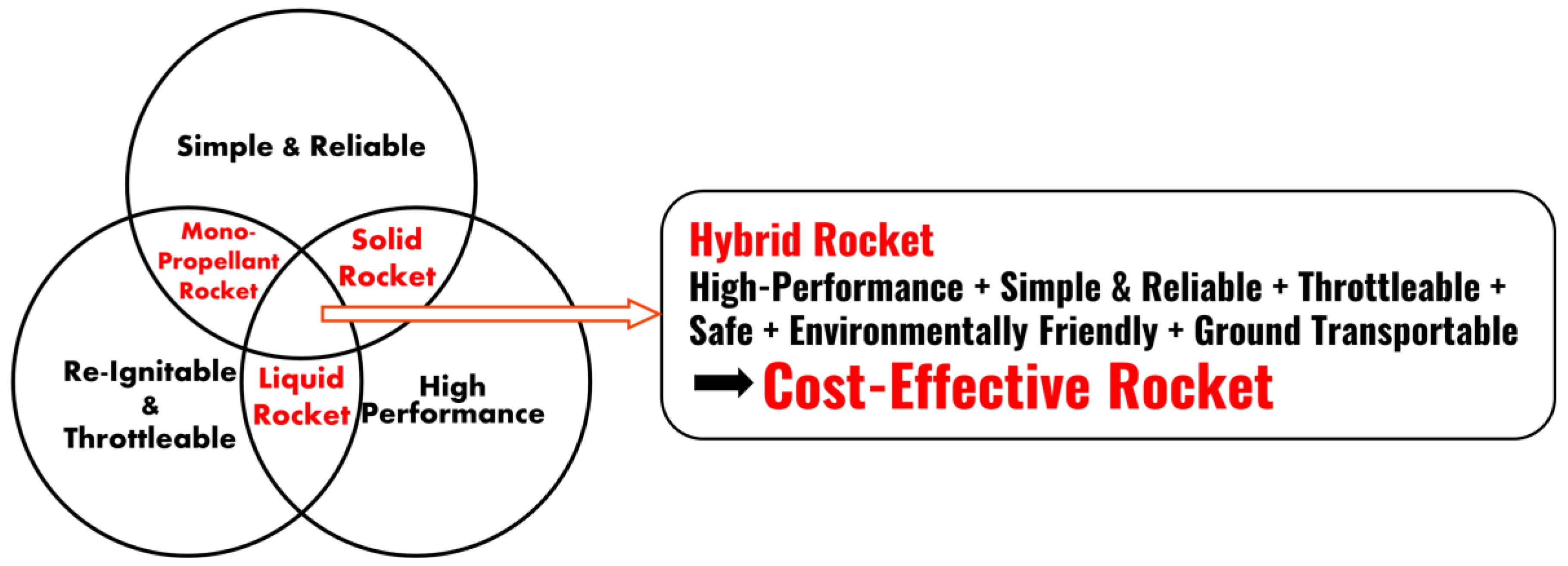

1.3. Characteristics, Advantages, and Disadvantages of HREs

1.3.1. Specific Impulse as Propulsion Performance Indicator

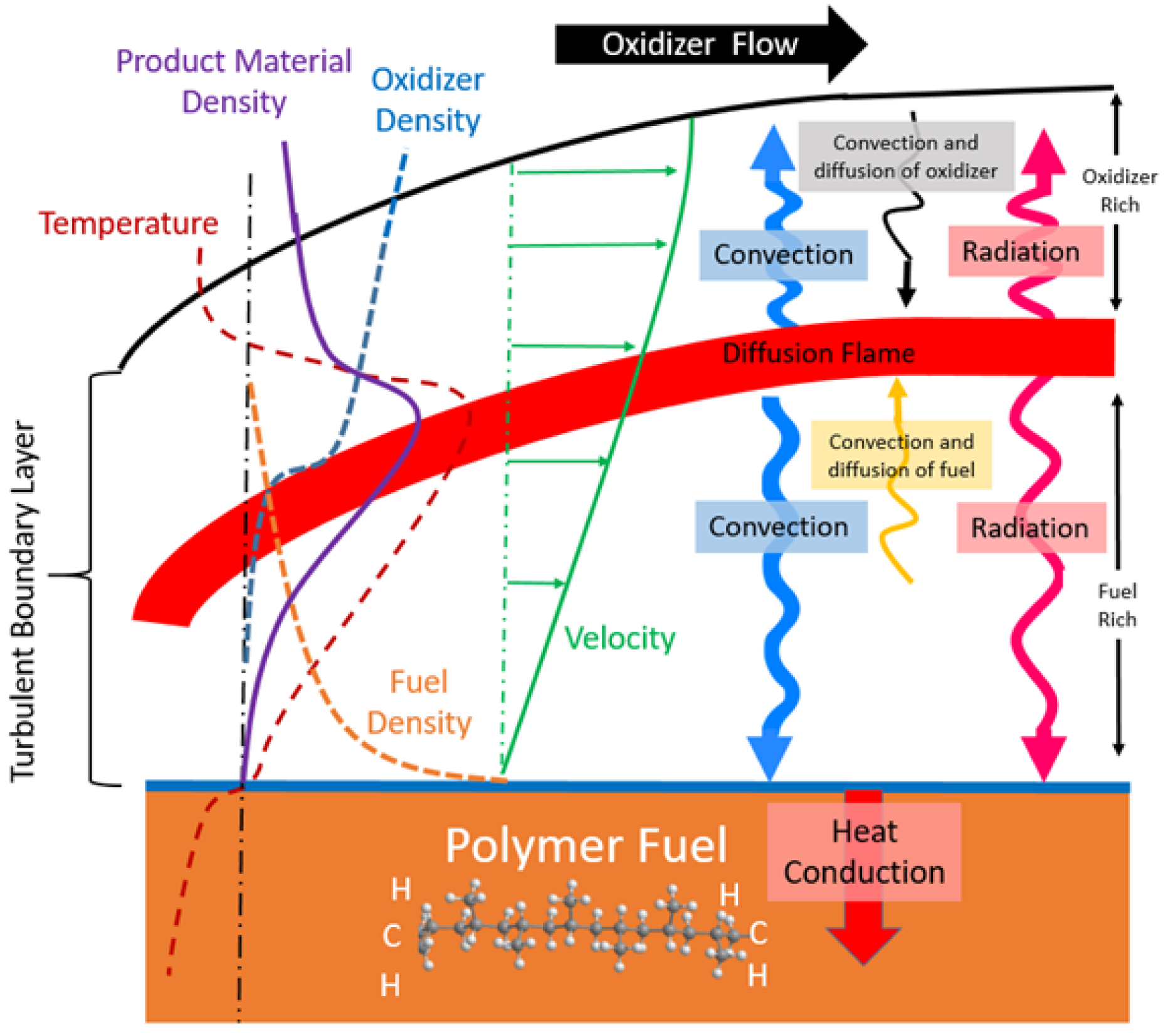

1.3.2. Combustion Characteristics

1.3.3. Propellant Storage and Handling Safety

1.3.4. Throttling and Re-Ignition Capability

1.3.5. Cost-Effectiveness

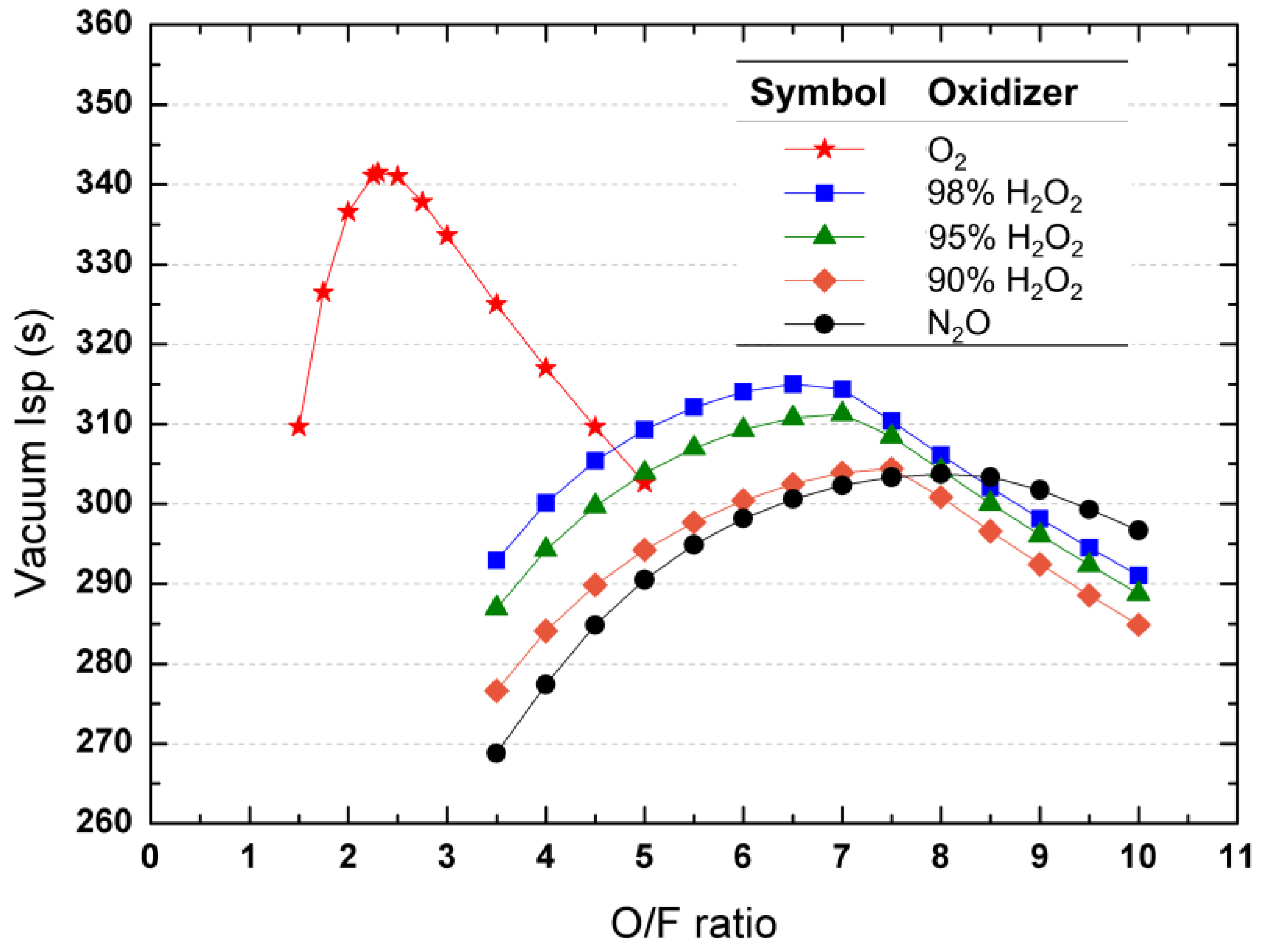

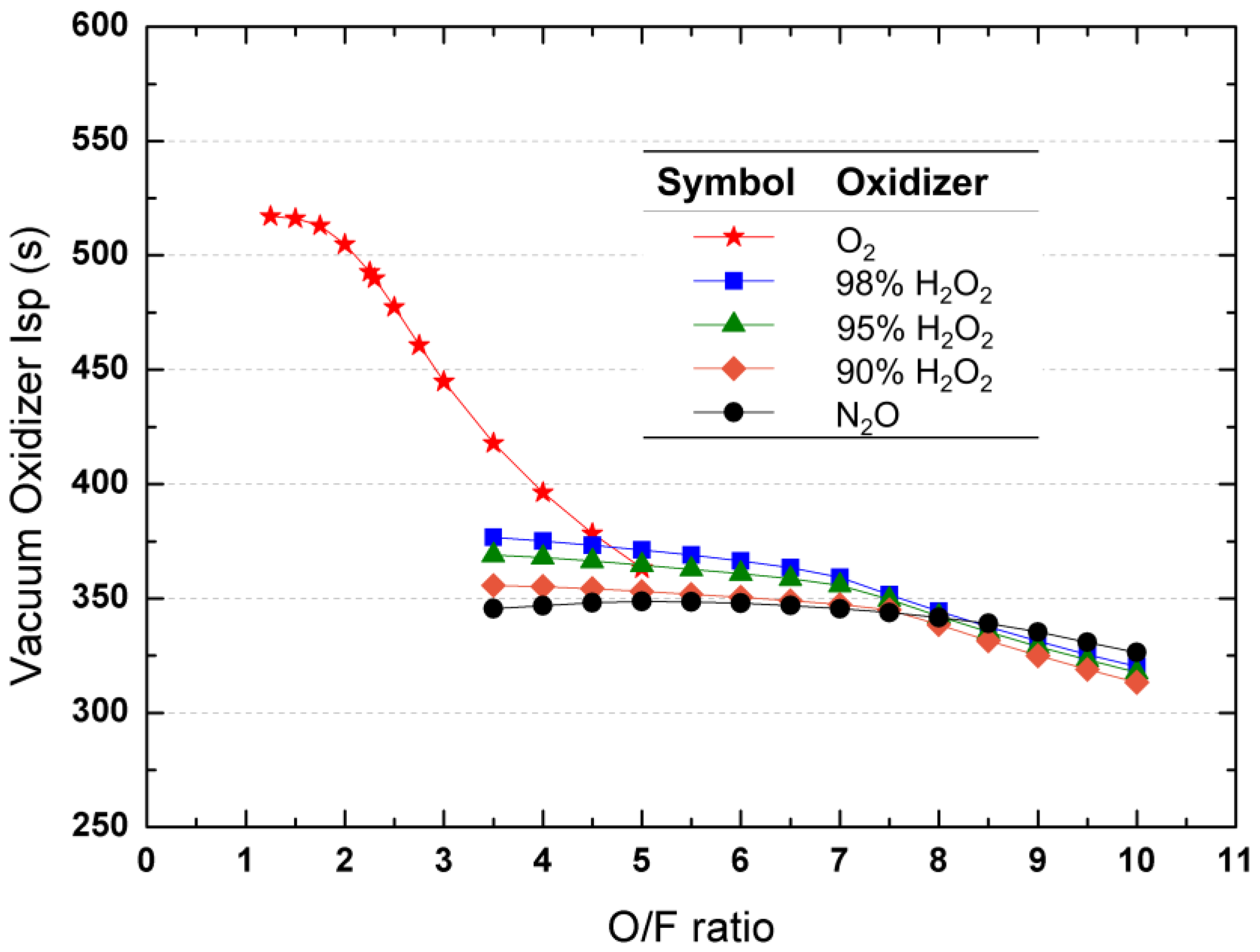

1.4. Theoretical Propulsion Performances for Different Fuel–Oxidizer Combinations

1.4.1. Typical Fuels and Oxidizers

- Affordability (Cost)

- b.

- System performance

- c.

- Survivability (Safety)

- d.

- Reliability

- e.

- Controllability

- f.

- Maintainability

- g.

- Geometric constraints

- h.

- Operability

- i.

- Producibility

- j.

- Environmental acceptability

1.4.2. Density-Specific Impulse

1.5. The Challenge for Hybrid Rocket Space Transportation

2. Oxidizers and Fuels for Hybrid Rocket Propulsion

2.1. Oxygen (O2)

2.2. Hydrogen Peroxide (H2O2)

2.3. Nitrous Oxide (N2O)

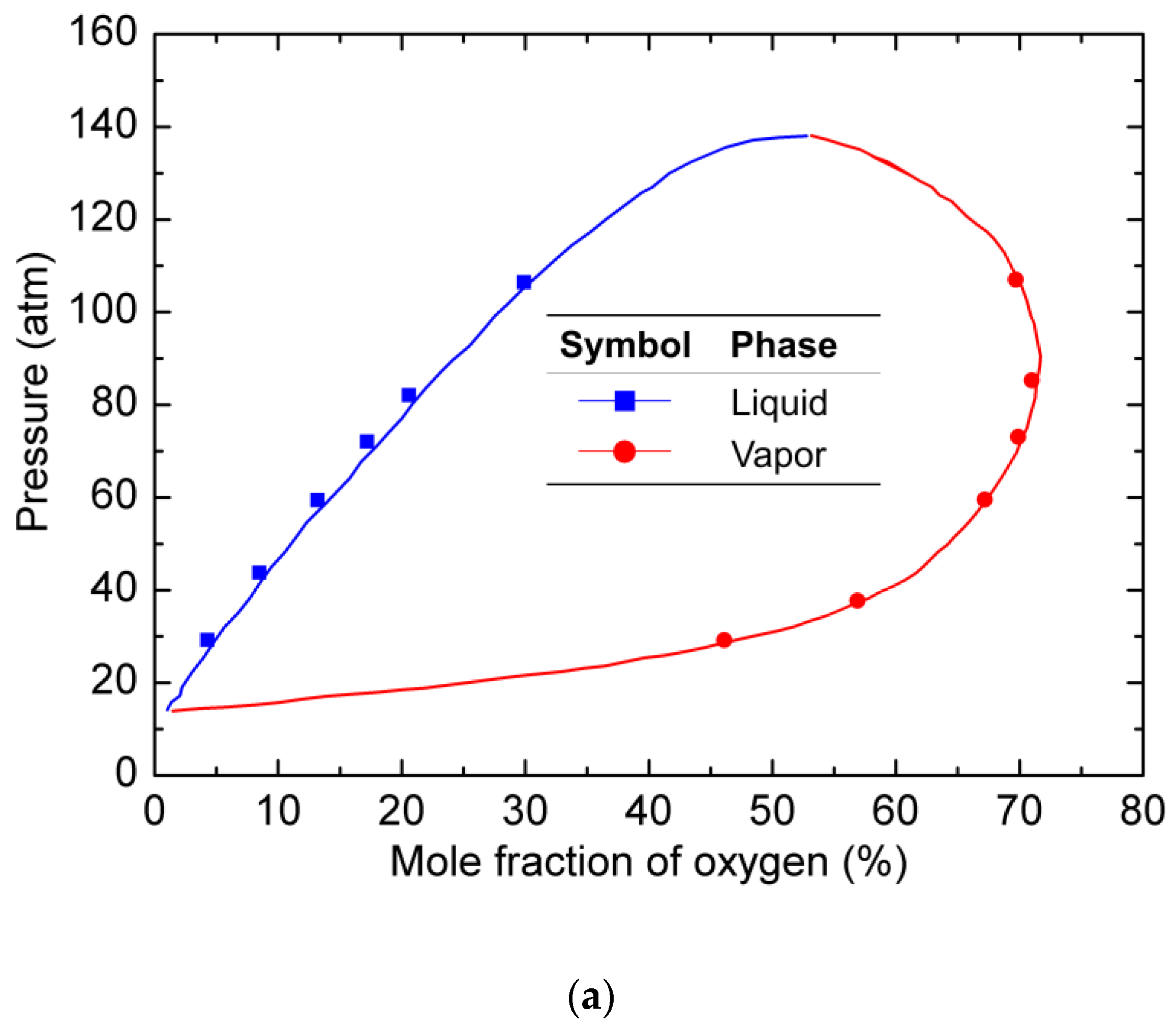

2.4. Nytrox

2.5. Thermoplastic and Thermoset Fuel

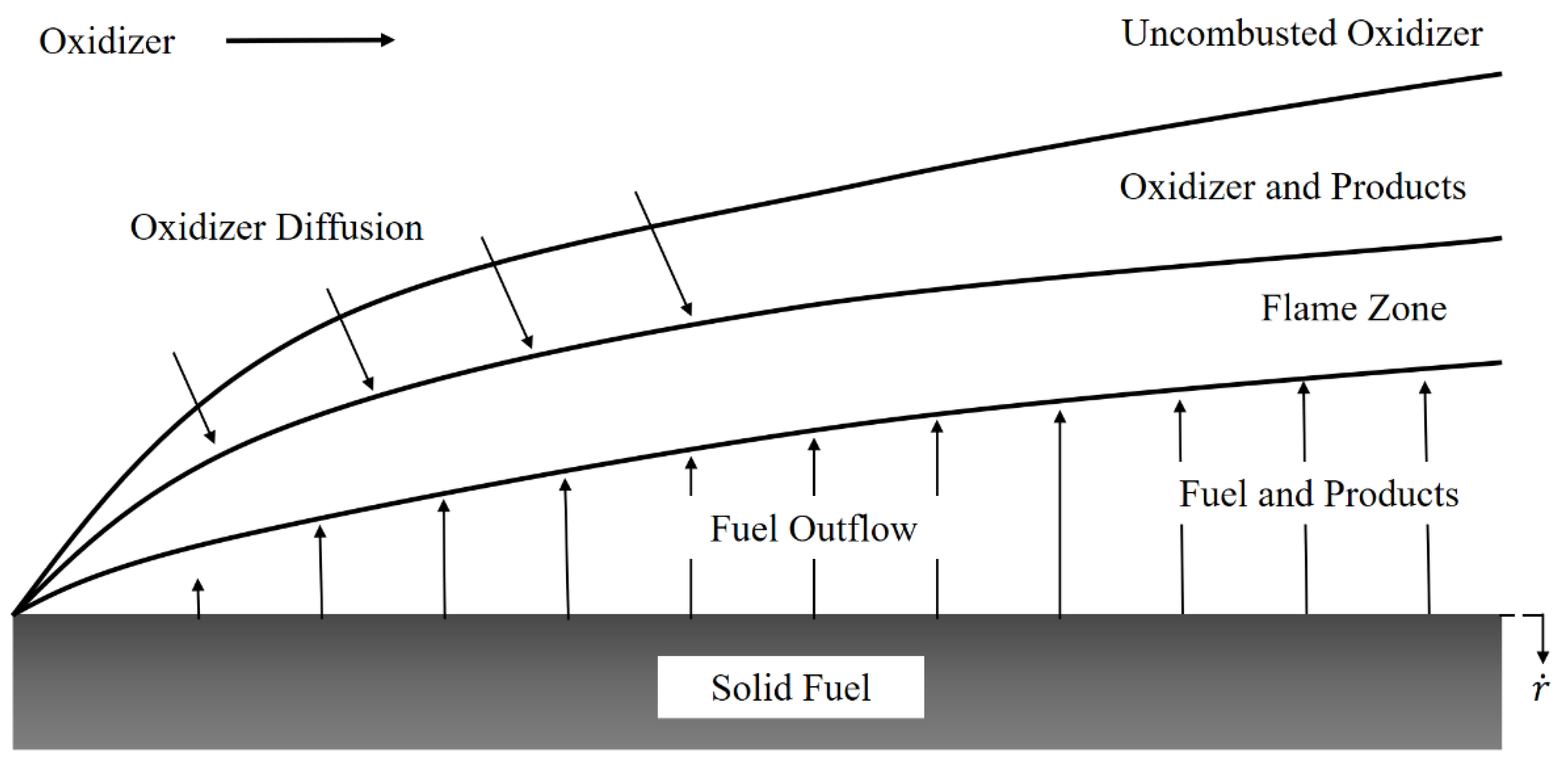

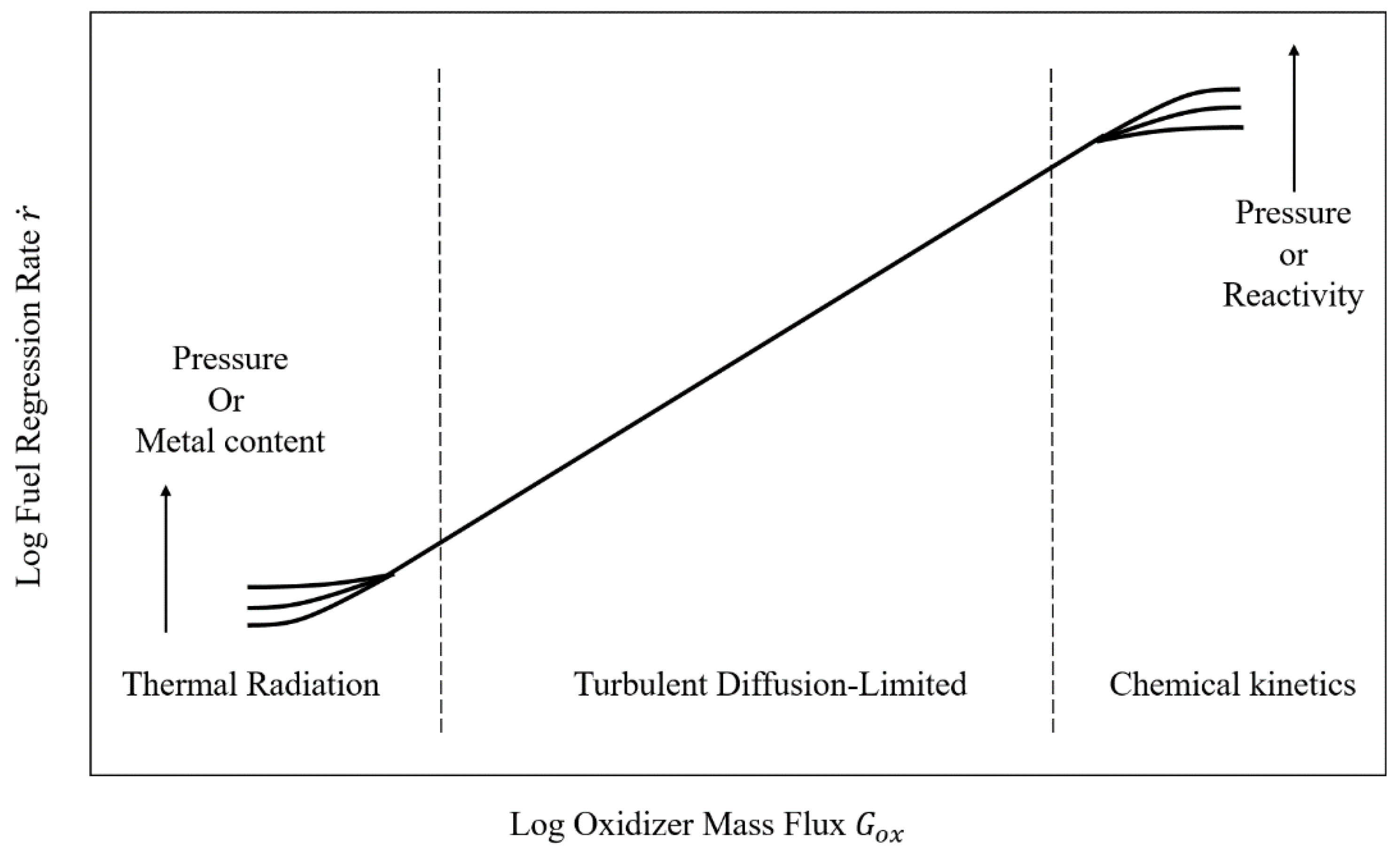

2.6. Fuel Regression Rate

3. Specific Issues for Hybrid Rocket Propulsion

3.1. Solid-Fuel Grain Design for Enhancing Fuel Mass Flow Rate

3.1.1. Star-Port Design

3.1.2. Multi-Port Design

3.1.3. Helical-Port Design and 3D-Printed Fuel Grains

3.1.4. Special Fuel Grain Geometry Design

3.1.5. Other Mixing Enhancement Mechanisms

3.1.6. Mixture Fuel

3.1.7. Composite Fuel with Additives

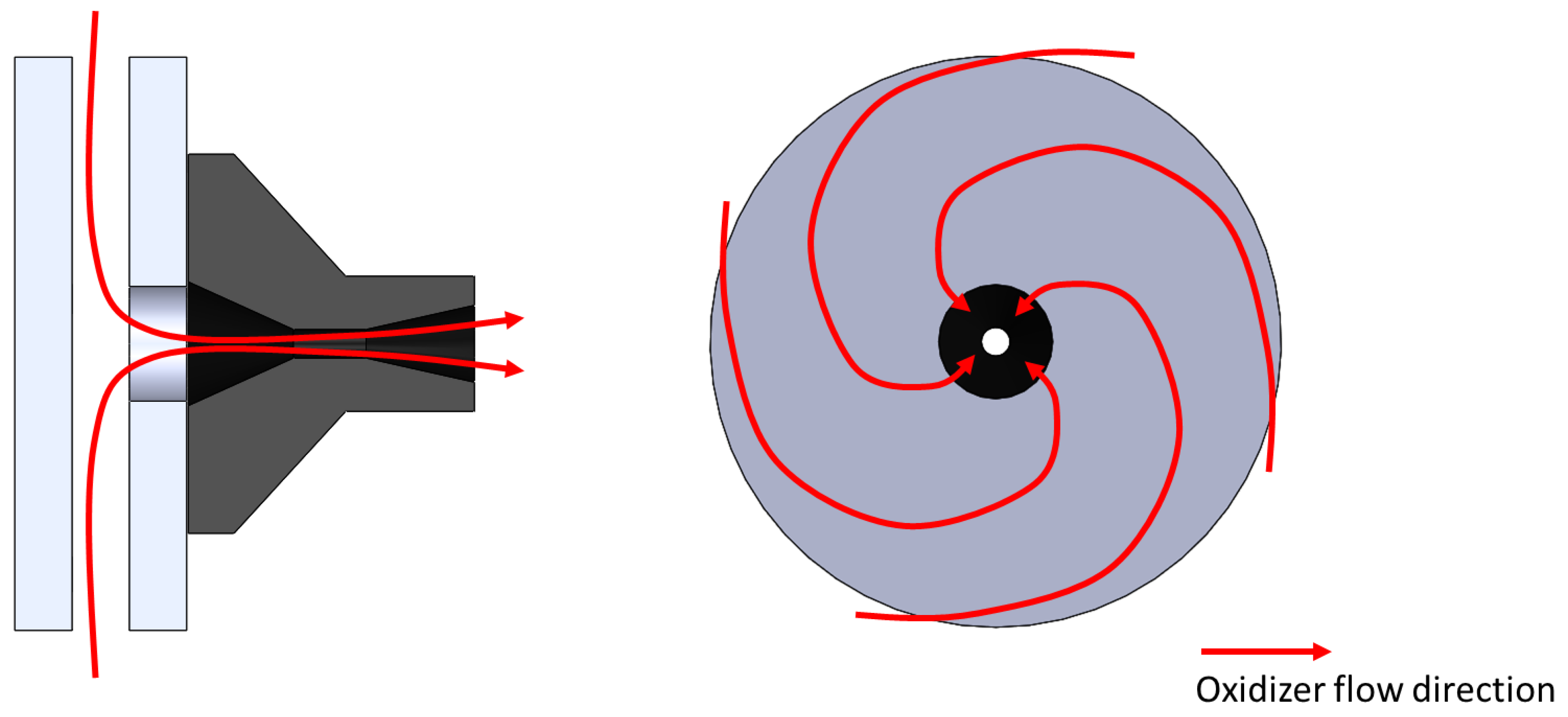

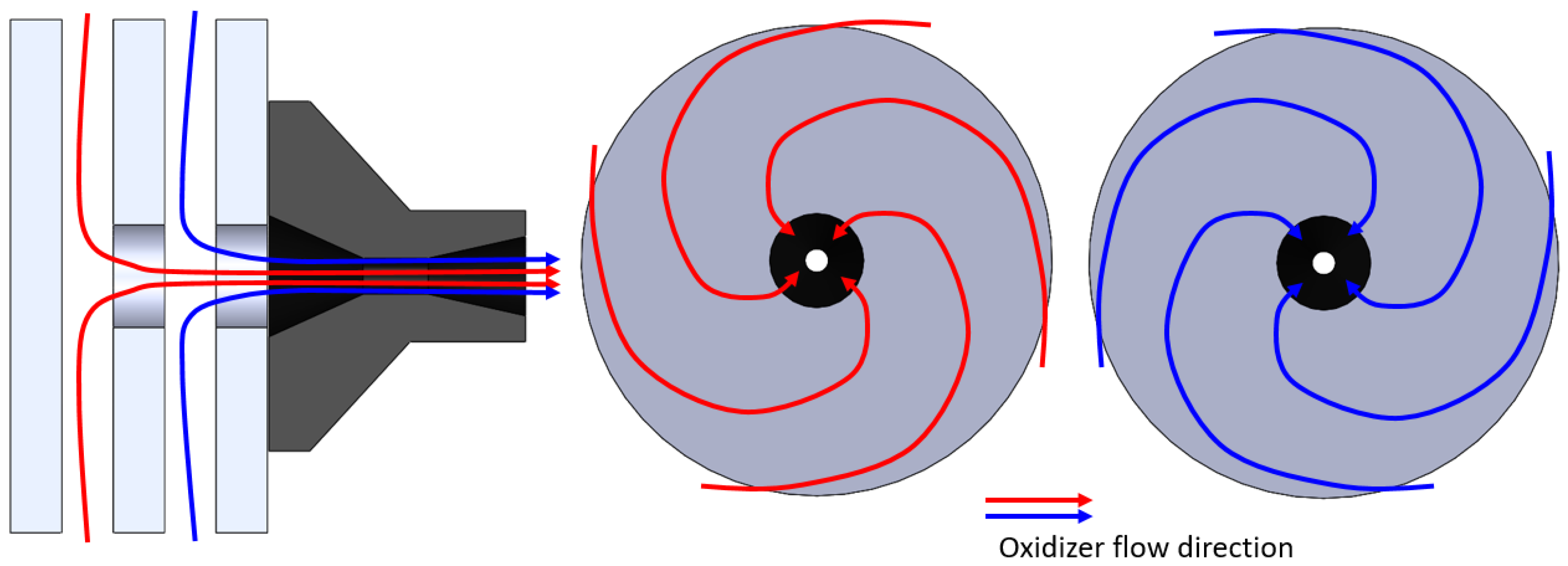

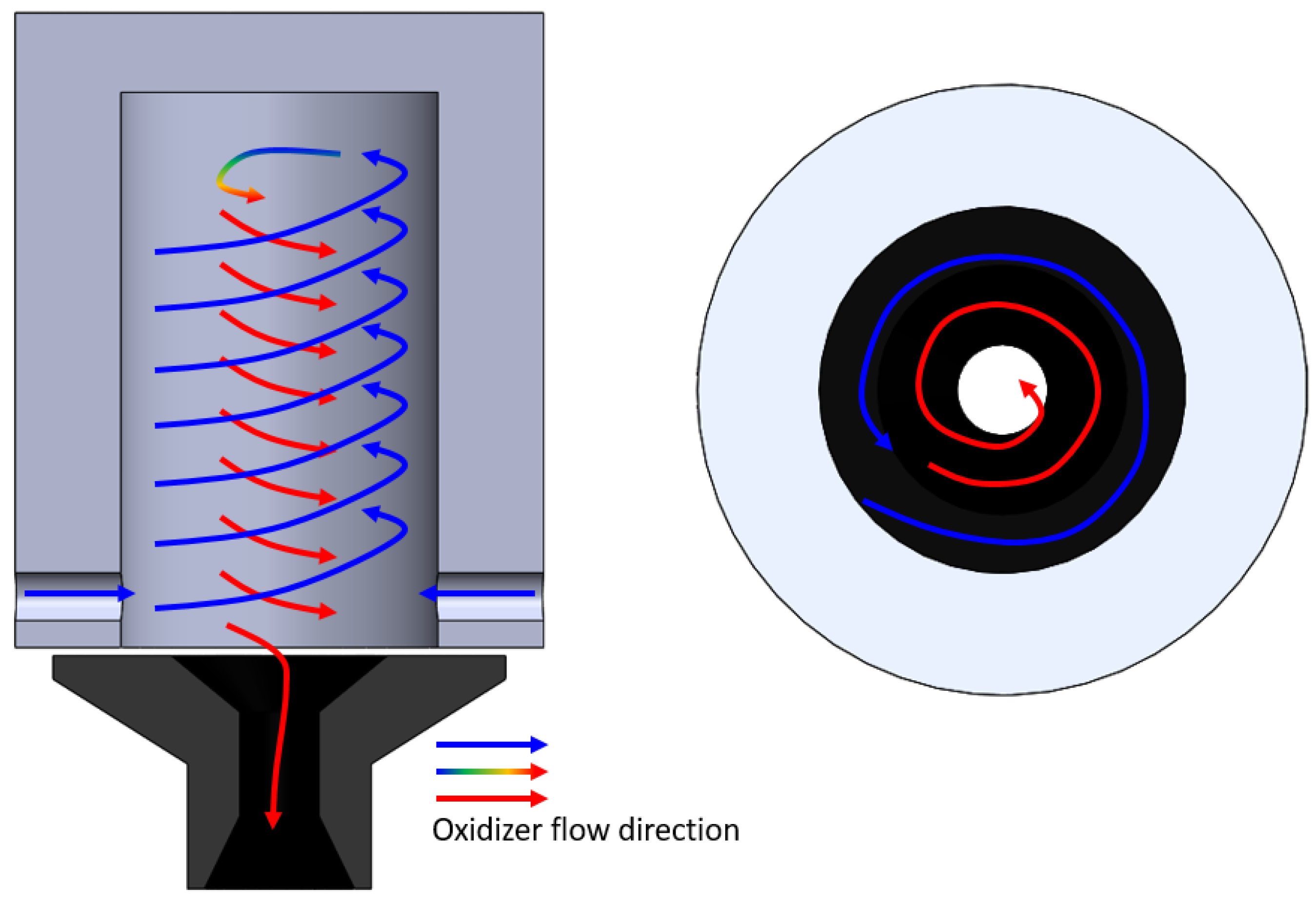

3.2. Swirl Oxidizer Injection

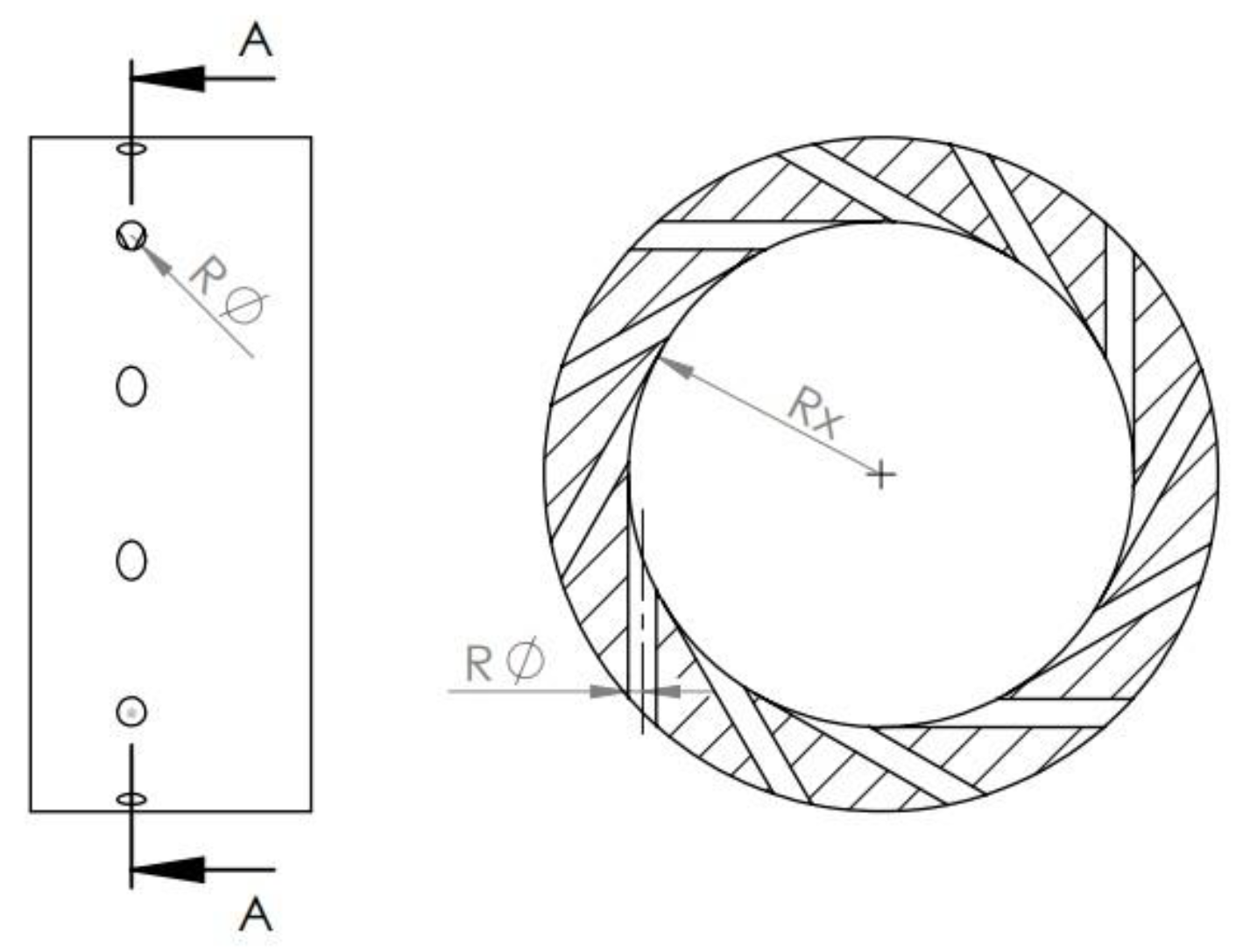

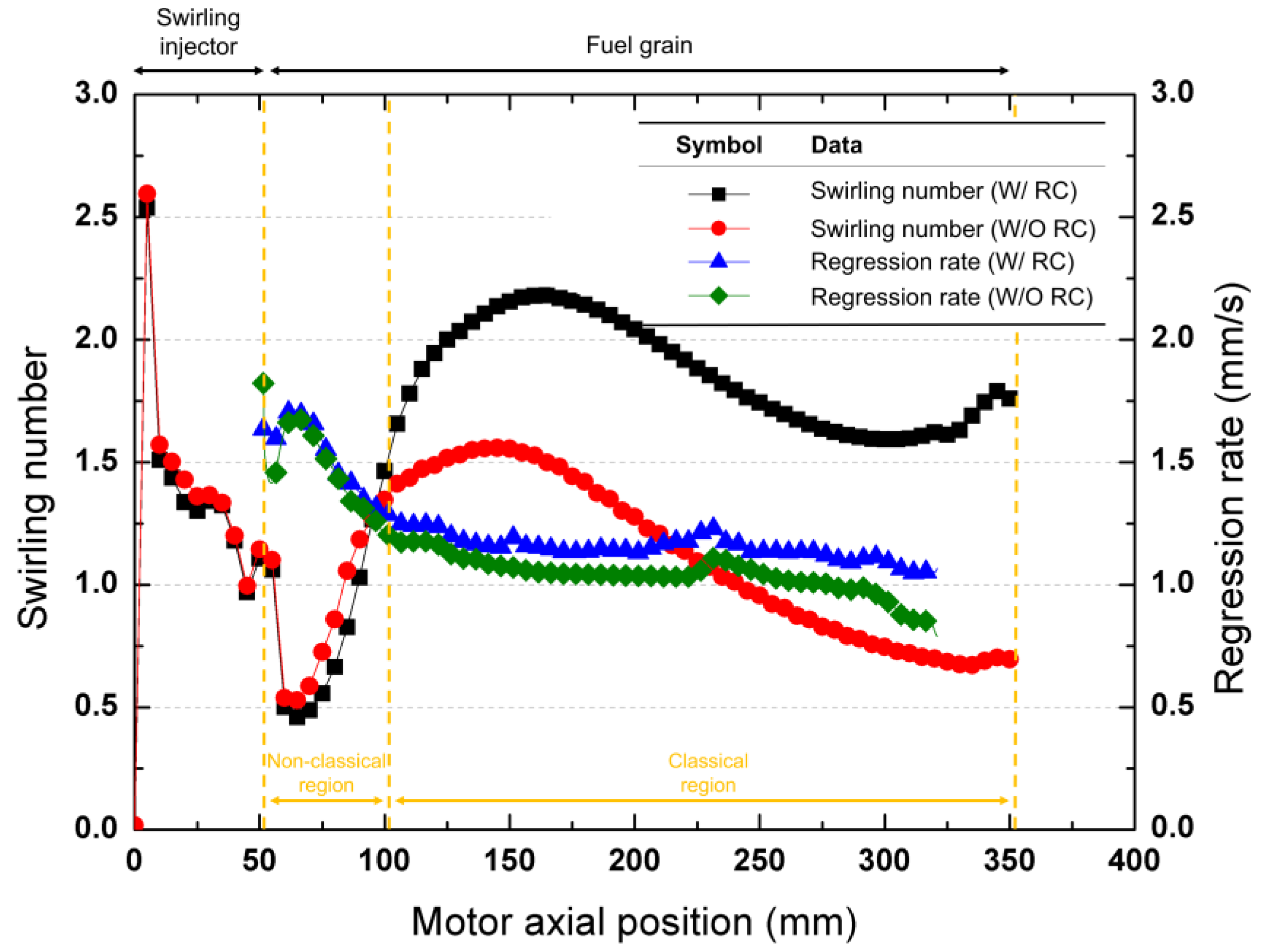

3.2.1. Experimental Studies on Swirl Injection

3.2.2. Numerical Investigations of Swirl Oxidizer Injection

3.3. O/F Ratio Shift and Propellant Residue

3.4. Low-Frequency Instability

3.5. Ignitor Design

3.6. Scaling-Up Methods

4. Advanced Studies of Hybrid Rocket Engines and Applications

4.1. Throttling Capacity of Hybrid Rocket Engine

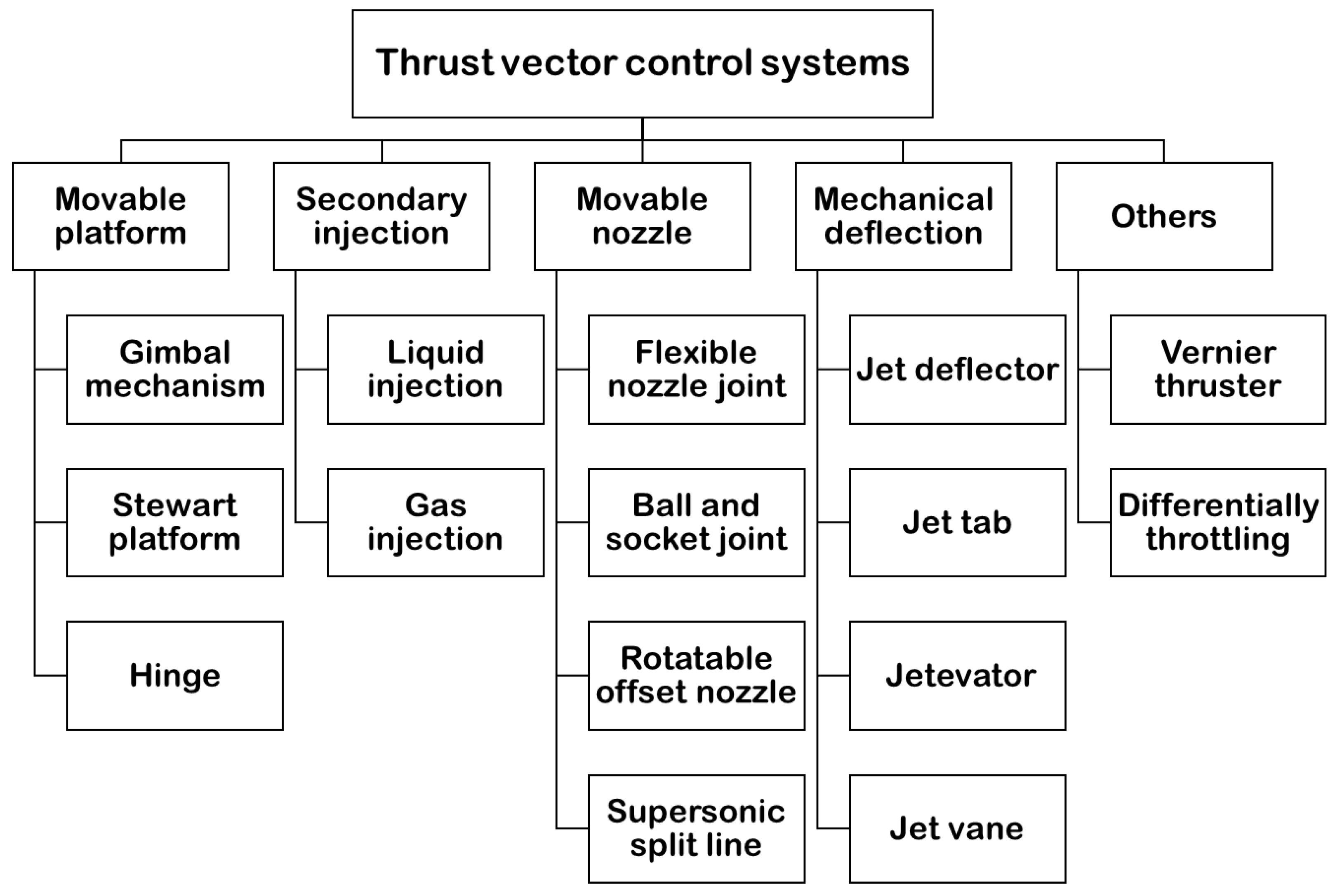

4.2. Thrust Vector Control for Hybrid Rocket Engine

4.3. Insulation Material for Chamber Casing and Nozzle Material

4.3.1. Temperature Distribution

4.3.2. Efficiency Enhancement Structure

4.3.3. Oxidizer and Fuel Distribution

4.3.4. Residual Fuel

4.4. 3D Metal Printing for Complicated Chamber Design

4.4.1. Powder Bed Fusion

4.4.2. Directed Energy Deposition

4.4.3. Binder Jetting (Li et al., 2020) [243]

4.4.4. Fused Filament Fabrication (FFF)

4.4.5. Sheet Lamination (Zhang et al., 2018) [245]

4.5. Recent Status of Hybrid Sounding Rockets and Launch Vehicles

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Surmacz, P.; Rarata, G. Hybrid Rocket Propulsion Development and Application. Prog. Astronaut. 2009, 3, 123–137. [Google Scholar]

- Ordhl, D.D.; Rains, W.A. Recent Developments and Current Status of Hybrid Rocket Propulsion. J. Spacecr. Rocket. 1965, 2, 923–926. [Google Scholar] [CrossRef]

- Okninski, A.; Kopacz, W.; Kaniewski, D.; Sobczak, K. Hybrid Rocket Propulsion Technology for Space Transportation Revisited-Propellant Solutions and Challenges. FirePhysChem 2021, 1, 260–271. [Google Scholar] [CrossRef]

- Altman, D.; Holzman, A. Overview and History of Hybrid Rocket Propulsion. In Fundamentals of Hybrid Rocket Combustion and Propulsion; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2007; pp. 1–36. [Google Scholar]

- Amos, J. Virgin Galactic: Sir Richard Branson Rockets to the Edge of Space. BBC, [Online]. Available online: https://www.bbc.com/news/science-environment-57797297 (accessed on 4 September 2024).

- INNOSPACE. About INNOSPACE Company. [Online]. Available online: http://www.innospc.com/page/sub03_01 (accessed on 4 September 2024).

- Hyimpusle. Mission. Hyimpusle, [Online]. Available online: https://www.hyimpulse.de/en/mission (accessed on 4 September 2024).

- Riley, J. Countdown: Gilmour’s Long Wait for a Launch Permit. [Online]. Available online: https://www.innovationaus.com/countdown-gilmours-long-wait-for-a-launch-permit/ (accessed on 4 September 2024).

- Sutton, G.P.; Biblarz, O. Rocket Propulsion Elements, 9th ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2019. [Google Scholar]

- Kuo, K.K.; Chiaverini, M.J. Fundamentals of Hybrid Rocket Combustion and Propulsion; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007; p. 627. [Google Scholar]

- Altman, D. Hybrid Rocket Development History. In Proceedings of the AIAA/SAE/ASME/ASEE 27th Joint Propulsion Conference, Sacramento, CA, USA, 24–27 June 1991. [Google Scholar]

- Bennett, D.P., Jr. Inverse Hybrid Rocket. U.S. Patent 3,555,826, 18 January 1971. [Google Scholar]

- Saraniero, M.A.; Caveny, L.H.; Summerfield, M. Restart transients of hybrid rocket engines. J. Spacecr. Rocket. 1973, 10, 215–217. [Google Scholar] [CrossRef]

- Karabeyoglu, M.A.; Altman, D.; Bershader, D. Transient combustion in hybrid rockets. In Proceedings of the Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995. [Google Scholar]

- Aerospace Notes. Selection Criteria of Rocket Propulsion System. [Online]. Available online: https://aerospacenotes.com/selection-criteria-of-rocket-propulsion-system/ (accessed on 4 September 2024).

- Humble, R.W.; Henry, G.N.; Larson, W.J. Space Propulsion Analysis and Design; The McGraw-Hill Companies, Inc.: New York, NY, USA, 1995. [Google Scholar]

- Gordon, S.; McBride, B.J. Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications. NASA Glenn Research Center, 1996. [Online]. Available online: https://cearun.grc.nasa.gov/intro.html (accessed on 4 September 2024).

- ProPep 3. Propellant Performance Evaluation Program 3, Ver. 1.0.1; NASSA: Las Vegas, NV, USA, 2018. [Google Scholar]

- Tugnoli, M.; Sarret, M.; Aliberti, M. European Access to Space: Bussiness and Policy Perspectives on Micro Launchers; Springers: New York, NY, USA, 2019. [Google Scholar]

- Niederstrasser, C. Small Launchers in a Pandemic Worl—2021 Edition of the Annual Industry Survey. In Proceedings of the 35th Annual AIAA/USU Conference on Small Satellites, Logan, UT, USA, 6–11 August 2021. [Google Scholar]

- Kulu, E. Small Launchers—2023 Industry Survey and Market Analysis. In Proceedings of the 74th International Astronautical Congress (IAC 2023), Baku, Azerbaijan, 2–6 October 2023. [Google Scholar]

- Casalino, L.; Masseni, F.; Pastrone, D. Optimal Design of Hybrid Rocket Small Satellite LaunchersL Ground Versus Airbone Launch. J. Spacecr. Rocket. 2022, 59, 2084–2093. [Google Scholar] [CrossRef]

- Marquadft, T.; Majdalani, J. Advanced Manufacturing Extends Operational Boundaries of Hybrids. Aeros Am. 2019, 57, 50. Available online: https://aerospaceamerica.aiaa.org/year-in-review/advanced-manufacturing-extends-operational-boundaries-of-hybrids/ (accessed on 4 September 2024).

- bluShift Aerospace. BluShift. [Online]. Available online: https://www.blushiftaerospace.com/ (accessed on 4 September 2024).

- Vaya Space. About Vaya Space. [Online]. Available online: https://www.vayaspace.com/about (accessed on 4 September 2024).

- Firehawk Aerospace, About Firehawk Aerospace. [Online]. Available online: https://firehawkaerospace.com/about/ (accessed on 4 September 2024).

- Chen, Y.S. Development of Hapith Small Launch Vehicle Based on Hybrid Rocket Propulsion. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- SpaceRyde. Available online: https://spaceryde.webflow.io/ (accessed on 4 September 2024).

- Reaction Dynamics. Reaction Dynamics Technology. [Online]. Available online: https://www.reactiondynamics.space/ (accessed on 4 September 2024).

- Letara. About Letara. [Online]. Available online: https://www.letara.space/about (accessed on 4 September 2024).

- Elliott, T.S.; Majdalani, J. Advancements in Laser Ignition Systems, Active Controls, Hybrid Biofuels and Suborbital Sounding Rockets. Aeros Am. 2022, 55. Available online: https://aerospaceamerica.aiaa.org/year-in-review/advancements-in-laser-ignition-systems-active-controls-hybrid-biofuels-and-suborbital-sounding-rockets/ (accessed on 4 September 2024).

- Majdalani, J. A Defining Year for Hybrid Rocket Innovation. Aeros Am. 2021, 53. Available online: https://aerospaceamerica.aiaa.org/year-in-review/a-defining-year-for-hybrid-rocket-innovation/ (accessed on 4 September 2024).

- Hillion, L.; Parisse, J.-D.; Mangeot, A. Preliminary sizing and study of a hybrid rocket based combined cycle. Front. Space Technol. 2023, 4, 1103981. [Google Scholar] [CrossRef]

- Karabeyoglu, A. Challenges in the Development of Large-Scale Hybrid Rockets. Int. J. Energetic Mater. Chem. Propuls. 2017, 16, 243–261. [Google Scholar] [CrossRef]

- Mazetti, A.; Merotto, L.; Pinarello, G. Paraffin-Based Hybrid Rocket Engines Applications: A Review and a Market Perspective. Acta Astronaut. 2016, 126, 286–297. [Google Scholar] [CrossRef]

- McFarlane, J.S.; Kniffen, R.J.; Lichatowich, J. Design and Testing of AMROC’s 250,000 Pound Thrust Hybrid Motor. In Proceedings of the 29th AIAA Joint Propulsion Conference, Monterey, CA, USA, 28–30 June 1993. [Google Scholar]

- Greiner, B.; Frederick, R.A. Experimental Investigation of Labscale Hybrid Instability. In Proceedings of the 30th AIAA Joint Propulsion Conference, Indianapolis, IN, USA, 27–29 June 1994. [Google Scholar]

- Ventura, M.C.; Heister, S.D. Hydrogen Peroxide as an Alternate Oxidizer for a Hybrid Rocket Booster. J. Propuls. Power 1995, 11, 562–565. [Google Scholar] [CrossRef]

- Yuasa, S.; Shimada, O.; Imamura, T.; Tamura, T.; Yamoto, K. A Techique for Improving the Performance of Hybrid Rocket Engines. In Proceedings of the 35th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 1999. [Google Scholar]

- Quadros, F.D.A.; Lacava, P.T. Swirl Injection of Gaseous Oxygen in a Lab-Scale Paraffin Hybrid Rocket Motor. J. Propuls. Power 2019, 35, 896–905. [Google Scholar] [CrossRef]

- Bianchi, D.; Betti, B.; Nasuti, F. Simulation of Gaseous Oxygen/Hydroxyl-Terminated Polybutadiene Hybrid Rocket Flowfields and Comparison with Experiments. J. Propuls. Power 2015, 31, 919–929. [Google Scholar] [CrossRef]

- Story, G. Large-Scale Hybrid Motor Testing. In Fundamentals of Hybrid Rocket Combustion and Propulsion; AIAA Inc.: Reston, VA, USA, 2006; pp. 513–552. [Google Scholar]

- Walter, H. Experience with the Application of Hydrogen Peroxide for Production of Power. J. Jet Propuls. 1954, 24, 166–171. [Google Scholar] [CrossRef]

- Wernimont, E.J.; Heister, S.D. Characterization of Fuel Regression in Hybrid Rockets Utiling Hydrogen Peroxide Oxidizer. In Proceedings of the 31st Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 10–12 July 1995. [Google Scholar]

- Hannum, J.A.E. Hazards of Chemical Rockets and Propellants Handbook; Chemical Propulsion Information Agency: Laurel, MD, USA; Sprindfield, VA, USA, 1972; Volume 1. [Google Scholar]

- Constantine, M.T.; Cain, E.F. Hydrogen Peroxide Handbok; Rocket Canoga Park CA Chemical and Material Sciences Dept.: Canogn Park, CA, USA, 1967. [Google Scholar]

- Faenza, M.G.; Boiron, A.J.; Haemmerli, B.; Verberne, O. The Nammo Nucleus Launch: Norwegian Hybrid Sounding Rocket over 100km. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Wei, S.S.; Lee, M.C.; Huang, J.W.; Kang, C.H.; Kao, S.T.; Lu, S.J.; Huang, C.H.; Zhan, J.J.; Chen, Z.R.; Wang, A.; et al. Demonstration of Tethered Hovering Flight of HTTP-3AT Hybrid Rocket. Acta Astronaut. 2022, 191, 279–292. [Google Scholar] [CrossRef]

- Marciniak, B.; Okninski, A.; Bartkowiak, B.; Pakosz, M.; Sobczak, K.; Florczuk, W.; Kaniewski, D.; Matyszewski, J.; Nowakowski, P.; Cieslinski, D.; et al. Development of the ILR-33 “Amber” Sounding Rocket for Microgravity Experimentation. Aerosp. Sci. Technol. 2018, 73, 19–31. [Google Scholar] [CrossRef]

- Okninski, A.; Surmacz, P.; Bartkowiak, B.; Mayer, T.; Sobczak, K.; Pakosz, M.; Kaniewski, D.; Matyszewski, J.; Rarata, G.; Wolanski, P. Development of Green Storable Hybrid Rocket Propulsion Technology Using 98% Hydrogen Peroxide as Oxidizer. Aerospace 2021, 8, 234. [Google Scholar] [CrossRef]

- Parsonson, A. ILR-33 Amber 2K Makes History as Poland’s First Rocket to Reach Space. European Spaceflight, [Online]. Available online: https://europeanspaceflight.com/ilr-33-amber-2k-makes-history-as-polands-first-rocket-to-reach-space/ (accessed on 4 September 2024).

- Kelly, J.W.; Rogers, C.E.; Brierly, G.T.; Martin, J.C.; Murphy, M.G. Motivation for Air-Launch: Past, Present, and Future. In Proceedings of the AIAA SPACE and Astronautics Forum and Exposition, Orlando, FL, USA, 12–14 September 2017. [Google Scholar]

- Thicksten, Z.; Macklin, F.; Campbell, J. Handling Considerations of Nitrous Oxide in Hybrid Rocket. In Proceedings of the 44th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Hartford, CT, USA, 21–23 July 2008. [Google Scholar]

- Kobald, M.; Schmierer, C.; Fischer, U.; Tomilin, T.; Petrarolo, A.; Rehberger, M. The HyEnD Stern Hybrid Sounding Rocket Project. Prog. Propuls. Phys. 2019, 11, 25–64. [Google Scholar]

- Dyer, J.; Doran, E.; Dunn, Z.; Lohner, K.; Bayart, C.; Sadhwani, A. Design and Development of a 100 km Nitrous Oxide/Paraffin Hybrid Rocket Vehicle. In Proceedings of the 43rd AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Cincinnati, OH, USA, 8–11 July 2007. [Google Scholar]

- Zakirov, V.; Sweeting, M.; Lawrence, T.; Sellers, J. Nitrous Oxide as a Rocket Propellant. Acta Astronaut. 2001, 48, 353–362. [Google Scholar] [CrossRef]

- Arves, J.P.; Jones, H.S.; Kline, K.; Smith, K.; Slack, T.; Bales, T. Development of a N2O/HTPB Hybrid Rocket Motor. In Proceedings of the 33rd Joint Propulsion Conference and Exhubit, Seattle, WA, USA, 6–9 July 1997. [Google Scholar]

- Hennemann, L.; Andrade, J.C.; Costa, F.D.S. Experimental Investigation of a Monopropellant Thruster Using Nitrous Oxide. J. Aerosp. Technol. Manag. 2014, 6, 363–372. [Google Scholar] [CrossRef]

- Saripalli, P.S.; Sedwick, R.J. Nitrous Oxide Decomposition Using Inductively Heated Heat Exchangers. J. Propuls. Power 2020, 36, 887–900. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Peterson, Z.W.; Eilers, S.D. Deep Throttle of a Nitrous Oxide and Hydroxyl-Terminated Polybutadiene Hybrid Rocket Motor. J. Propuls. Power 2014, 30, 78–86. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Peterson, Z.W.; Eilers, S.D. Closed-Loop Precision Throttling of a Hybrid Rocket Motor. J. Propuls. Power 2014, 30, 325–336. [Google Scholar] [CrossRef]

- Karabeyoglu, A. Mixtures of Nitrous Oxide and Oxygen (Nytrox) as Oxidizers for Rocket Propulsion Applications. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Denver, CO, USA, 2–5 August 2009. [Google Scholar]

- Karabeyoglu, A. Nitrous Oxide and Oxygen Mixtures (Nytrox) as Oxidizers for Rocket Propulsion Applications. J. Propuls. Power 2014, 30, 696–706. [Google Scholar] [CrossRef]

- Stoddard, R.L. Experimental Investigation of N2O/O2 Mixtures as Volumetrically Efficient Oxidizers for Small Spacecraft Hybrid Propulsion Systems. Master’s Thesis, Utah State University, Old Main Hill, Logan, UT, USA, 2019. [Google Scholar]

- Whitmore, S.A.; Stoddard, R.L. Medical Grade N2O/O2 Mixtures as Inexpensive and Volumetrically Efficient Oxidizers for Small Spacecraft Hybrid Propulsion Systems. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Whitmore, S.A. Nytrox as “Drop-in” Replacement for Gaseous Oxygen in SmallSat Hybrid Propulsion Systems. Aerospace 2020, 7, 43. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Stoddard, R.L. N2O/O2 blends safe and volumetrically efficient oxidizers for small spacecraft hybrid propulsion. Aeronaut. Aerosp. Open Access J. 2019, 3, 171–196. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Frischkorn, C.I. Analyzing and Reducing Ignition Latency of a Nytrox/ABS Hybrid Propulsion System. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar]

- Sella, V.; Larkey, A.; Majumder, A.; Rao, A.; Abidi, Z.; Rasmont, N.; Randeo, A.; Liu, M.; Moore, A.; Lembeck, M.F. Development of a Nytrox-Paraffin Hybrid Rocket Engine. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar]

- Kumar, R.; Thamizarasan, K. Use of N2O–O2 as the Oxidizer for the Hybrid Rocket Application. In Proceedings of the National Aerospace Propulsion Conference; Sivaramakrishna, G., Kumar, S.K., Raghunandan, B.N., Eds.; Springer: Singapore, 2023; pp. 273–289. [Google Scholar]

- Paravan, C.; Hashish, A.; Santolini, V. Test Activities on Hybrid Rocket Engines: Combustion Analyses and Green Storable Oxidizers—A Short Review. Aerospace 2023, 10, 572. [Google Scholar] [CrossRef]

- Lysien, K.; Stolarczyk, A.; Jarosz, T. Solid Propellant Formulations: A Review of Recent Progress and Utilized Components. Materials 2021, 14, 6657. [Google Scholar] [CrossRef]

- Wingborg, N. Increasing the Tensile Strength of HTPB with Different Isocyanates and Chain Extenders. Polym. Test. 2002, 2, 283–287. [Google Scholar] [CrossRef]

- DeSain, J.; Brady, B.; Metzler, K.; Curtiss, T.; Albright, T. Tensile Tests of Paraffin Wax for Hybrid Rocket Fuel Grains. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Denver, CO, USA, 2–5 August 2009. [Google Scholar]

- Davenas, A. Development of Modern Solid Propellants. J. Propuls. Power 2003, 19, 1108–1128. [Google Scholar] [CrossRef]

- Villar, L.D.; Cicaglioni, T.; Diniz, M.F.; Takahashi, M.F.K.; Rezende, L.C. Thermal Aging of HTPB/IPDI-Based Polyurethane as a Function of NCO/OH Ratio. Mater. Res. 2011, 14, 372–375. [Google Scholar] [CrossRef]

- Karabeyoglu, A.; Zilliac, G.; Cantwell, B.J.; DeZilwa, S.; Castellucci, P. Scale-Up Tests of High Regression Rate Paraffin-Based Hybrid Rocket Fuels. J. Propuls. Power 2004, 20, 1037–1045. [Google Scholar] [CrossRef]

- Barato, F. Review of Alternative Sustainable Fuels for Hybrid Rocket Propulsion. Aerospace 2023, 10, 643. [Google Scholar] [CrossRef]

- Marquardt, T.; Majdalani, J. Review of Classical Diffusion-Limited Regression Rate Models in Hybrid Rockets. Aerospace 2019, 6, 75. [Google Scholar] [CrossRef]

- Marxman, G.; Gilbert, M. Turbulent Boundary Layer Combustion in the Hybrid Rocket. Symp. (Int.) Combust. 1963, 9, 371–383. [Google Scholar] [CrossRef]

- Lees, L. Convective Heat Transfer with Mass Addition and Chemical Reactions. In Combustion and Propulsion, Proceedings of the Third AGARD Colloquium, Palermo, Sicily, Italy, 17–21 March 1958; Pergamon Press: Oxford, UK, 1958. [Google Scholar]

- Zilliac, G.; Karabeyoglu, M. Hybrid Rocket Fuel Regression Rate data and Modeling. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar]

- Chiaverini, M.J.; Serin, N.; Johnson, D.K.; Lu, Y.C.; Kuo, K.K.; Risha, G.A. Regression Rate Behavior of Hybrid Rocket Solid Fuels. J. Propuls. Power 2000, 16, 125–132. [Google Scholar] [CrossRef]

- Miller, E. Hybrid Rocket Combustion Regression Rate Model. AIAA J. 1966, 4, 725–753. [Google Scholar] [CrossRef]

- Smoot, L.D.; Price, C.F. Pressure Dependence of Hybrid Fuel Regression Rates. AIAA J. 1967, 5, 102–106. [Google Scholar] [CrossRef]

- Kumar, R.N.; Stickler, D.B. Polymer-Degradation Theory of Pressure-Sensitive Hybrid Combustion. Symp. (Int.) Combust. 1971, 13, 1059–1072. [Google Scholar] [CrossRef]

- Pal, Y.; Mahottamananda, S.N.; Palateerdham, S.K.; Subha, S.; Ingenito, A. Review on the Regression Rate-Improvement Techniques and Mechanical Performance of Hybrid Rocekt Fuels. FirePhysChem 2021, 1, 272–282. [Google Scholar] [CrossRef]

- Heeg, F.; Kilzer, L.; Seitz, R.; Stoll, E. Design and Test of a Student Hybrid Rocket Engine with an External Carbon Fiber Composite Structure. Aerospace 2020, 7, 57. [Google Scholar] [CrossRef]

- Tian, H.; Jiang, X.; Lu, Y.; Liang, Y.; Zhu, H.; Cai, G. Numerical Investigation on Hybrid Rocket Motors with Star-Segmented Rotation Grain. Aerospace 2022, 9, 585. [Google Scholar] [CrossRef]

- Kim, S.; Lee, J.; Moon, H.; Kim, J.; Sung, H.; Kwon, O.C. Regression Characteristics of the Cylindrical Multiport Grain in Hybrid Rockets. J. Propuls. Power 2013, 29, 578–581. [Google Scholar] [CrossRef]

- Tian, H.; Li, X.; Zeng, P.; Yu, N.; Cai, G. Numerical and Experimental Studies of the Hybrid Rocket Motor with Multi-Port Fuel Grain. Acta Astronaut. 2014, 96, 267–268. [Google Scholar] [CrossRef]

- Ahn, B.; Kang, H.; Lee, E.; Yun, Y.; Kwon, S. Design of Multiport Grain with Hydrogen Peroxide Hybrid Rocket. J. Propuls. Power 2018, 34, 1189–1197. [Google Scholar] [CrossRef]

- Yun, Y.; Huh, J.; Kwon, S. Port Diameter Design of Multiport Solid Fuel in Hydrogen Peroxide Hybrid Rocekts. Aerosp. Sci. Technol. 2021, 110, 106485. [Google Scholar] [CrossRef]

- Boardman, T.A.; Abel, T.M.; Claflin, S.E.; Shaffer, C.W. Design and Test Planning for a 250-klbf-Thrust Hybrid Rocket Motor under the Hybrid Propulsion. In The JANNAF, Proceedings of Propulsion and Joint Subcommittee Meetings, Albuquerque, New Mexico, 9–13 December 1996; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2012. [Google Scholar]

- Story, G.; Zoladz, T.; Arves, J.; Kearney, D.; Abel, T.; Park, O. Hybrid Propulsion Demonstration Program 250K Hybrid Motor. In Proceedings of the 39th AAIA/ASME/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. [Google Scholar]

- Lee, C.; Na, Y.; Lee, J.W.; Byun, Y.H. Effect of Induced Swirl Flow on Regression Rate of Hybrid Rocket Fuel by Helical Grain Configuration. Aerosp. Sci. Technol. 2007, 11, 68–76. [Google Scholar] [CrossRef]

- Oztan, C.; Coverstone, V. Utilization of Additive Manufacturing in Hybrid Rocket Technology: A Review. Acta Astronaut. 2021, 1180, 130–140. [Google Scholar] [CrossRef]

- Yu, X.; Yu, H.; Zhang, W.; DeLuca, L.T.; Shen, R. Effect of Penetrative Combustion on Regression Rate of 3D Printed Hybrid Rocket Fuel. Aerospace 2022, 9, 696. [Google Scholar] [CrossRef]

- Yu, X.; Yu, H.; Gao, H.; Zhang, W.; DeLuca, L.T.; Shen, R. 3D printed different polymer fuel grains for hybrid rocket engine. FirePhysChem 2024, 4, 139–145. [Google Scholar] [CrossRef]

- Whitmore, S.A.; Marshall, J. Thrust-Augmented Nozzle for a Hybrid Rocket with a 3-D Printed Helical Fuel Grain. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Marshall, J.H.; Whitmore, S.A.; Heiner, M.C. Thrust Augmentation of an Additively Manufactured Hybrid Rocket System Using Secondary H2O2 Injection. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Dinisman, S.; Eisen, N.E.; Gany, A. Enhancing Hybrid Motor Thrust by A Helical-Port Fuel Grain. Int. J. Energetic Mater. Chem. Propuls. 2024, 23, 69–84. [Google Scholar] [CrossRef]

- Fuller, J.K.J.; Ehrlich, D.A.; Lu, P.C.; Jansen, R.P.; Hoffman, J.D. Advantages of Rapid Prototyping for Hybrid Rocket Motor Fuel Grain Fabrication. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Armold, D.; Boyer, J.E.; Kuo, K.K.; DeSain, J.D.; Curtiss, T.J.; Fuller, J.K. Test of Hyrbid Rocket Fuel Grains with Swirl Patterns Fabricated Using Rapid Prototyping Technology. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Conference, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Whitmore, S.A.; Walker, S.D.; Merkley, D.P.; Sobbi, M. High Regression Rate Hybrid Rocket Fuel Grains with Helical Port Structures. J. Propuls. Powers 2015, 31, 1727–1738. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Li, F.; Yu, X. Combustion Performance of a Novel Hybrid Rocket Fuel Grain with a Nested Helical Structure. Aerosp. Sci. Technol. 2020, 97, 105613. [Google Scholar] [CrossRef]

- Bisin, R.; Paravan, C. A new strategy for the reinforcement of paraffin-based fuels based on cellular structures: The armored grain—Ballistic characterization. Acta Astronaut. 2023, 206, 284–298. [Google Scholar] [CrossRef]

- Saito, Y.; Yokoi, T.; Yasukochi, H.; Soeda, K.; Totani, T.; Wakita, M.; Nagata, H. Fuel Regression Characteristics of a Novel Axial-Injection End-Burning Hybrid Rocket. J. Propuls. Power 2018, 34, 247–259. [Google Scholar] [CrossRef]

- Okuda, R.; Komizu, K.; Tsuji, A.; Miwa, T.; Fukada, M.; Yokobori, S.; Soeda, K.; Kamps, L.; Nagata, H. Fuel Regression Characteristics of Axial-Injection End-Burning Hybrid Rocket Using Nitrous Oxide. J. Propuls. Power 2022, 38, 759–770. [Google Scholar] [CrossRef]

- Hirai, S.; Kamps, L.T.; Nobuhara, Y.; Nagata, H. Demonstration of Axial-Injection End-Burning Hybrid Rocket using FDM 3D Printer. In Proceedings of the AIAA SCITECH 2023 Forum, National Harbor, MD, USA, 23–27 January 2023. [Google Scholar]

- Gibbon, D.; Haag, G. Investigating of an Alternative Geometry Hybrid Rocket for Small Spacecraft Orbit Transfer; Defense Technical Information Center: Fort Belvoir, VA, USA, 2001. [Google Scholar]

- Paravan, C.; Glowacki, J.; Carlotti, S.; Maggi, F.; Galfetti, L. Vortex Combustion in a Hybrid Rocket Motor. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Lai, A.; Lin, Y.C.; Wei, S.S.; Chou, T.H.; Lin, J.W.; Wu, J.S.; Chen, Y.S. Numerical Investigation of a N2O/HTPB Hybrid Rocket Motor with a Dual-Vortical-Flow (DVF) Design. J. Mech. 2017, 33, 853–862. [Google Scholar] [CrossRef]

- Lai, A.; Chou, T.H.; Wei, S.S.; Lin, J.W.; Wu, J.S.; Chen, Y.S. Investigation of Dual-Vortical-Flow Hybrid Rocket Enigne without Flame Holding Mechanism. Int. J. Aerosp. Eng. 2018, 2018, 6513084. [Google Scholar]

- Nagata, H.; Ito, M.; Maeda, T.; Watanabe, M.; Uematsu, T.; Totano, T.; Kudo, I. Development of CAMUI Hybrid Rocket to Create a Market for Small Rocket Experiments. Acta Astronaut. 2006, 59, 253–258. [Google Scholar] [CrossRef]

- Viscor, T.; Kamps, L.; Yonekura, K.; Isochi, H.; Nagata, H. Large-Scale CAMUI Type Hybrid Rocket Motor Scaling, Modeling, and Test Results. Aerospace 2022, 9, 1. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, A.; Chou, T.H.; Wu, J.S. N2O-HTPB Hybrid Rocket Combustion Modeling with Mixing Enhancement Designs. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Zilliac, G.; Story, G.T.; Karp, A.C.; Jens, E.T.; Whittinghill, G. Combustion Efficiency in Single-Port Hybrid Rocket Engines. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar]

- Tian, H.; Tain, X.; Yu, N.; Cai, G. Numerical and Experimental Investigation on the Effects of Aft Mixing Chamber Diaphragm in Hybrid Rocket Motor. Sci. China Technol. Sci. 2013, 56, 2721–2731. [Google Scholar] [CrossRef]

- Kim, H.; Kim, S.; Woo, K.; Lee, J.; Moon, H.; Sung, H.; Kim, J. Investigation on the Effect of Liquefying Diaphragm in Hybrid Rocket Motors using Paraffin-Based Fuel. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Lee, J.; Rhee, S.; Kim, J.; Moon, H. Combustion Instability Mechanism in Hybrid Rocket Motors with Diaphragm. J. Propuls. Power 2022, 38, 309–318. [Google Scholar] [CrossRef]

- Karabeyoglu, M.; Cantwell, B.; Altman, D. Development and Testing of Paraffin-Based Hybrid Rocket Fuels. In Proceedings of the 37th Joint Propulsion Conference and Exhibit, Salt Lake City, UT, USA, 8–11 July 2001. [Google Scholar]

- Leccese, G.; Cavallini, E.; Pizzarelli, M. State of Art and Current Challenges of the Paraffin–Based Hybrid Rocket Technology. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Kobald, M.; Ciezki, H.K.; Schlechtriem, S.; Toson, E.; De Luca, L. Evaluation of Paraffin-based Fuels for Hybrid Rocket Engines. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Maruyama, S.; Ishiguro, T.; Shinohara, K.; Nakagawa, I. Study on Mechanical Characteristics of Paraffin-Based Fuel. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Kim, S.; Moon, H.; Kim, J.; Cho, J. Evaluation of Paraffin–Polyethylene Blends as Novel Solid Fuel for Hybrid Rockets. J. Propuls. Power 2015, 31, 1750–1760. [Google Scholar] [CrossRef]

- Pal, Y.; Kumar, K.H.; Li, Y.H. Ballistic and Mechanical Characteristics of Paraffin-Based Solid Fuels. CEAS Space J. 2019, 11, 317–327. [Google Scholar] [CrossRef]

- Mengu, D.; Kumar, R. Development of EVA-SEBS Based Wax Fuel for Hybrid Rocket Applications. Acta Astronaut. 2018, 152, 325–334. [Google Scholar] [CrossRef]

- Thomas, J.C.; Paravan, C.; Stahl, J.M.; Tykol, A.J.; Rodriguez, F.A.; Galfetti, L.; Petersen, E.L. Experimental evaluation of HTPB/paraffin fuel blends for hybrid rocket applications. Combust. Flame 2021, 229, 111386. [Google Scholar] [CrossRef]

- De Zilwa, S.; Zilliac, G.; Karabeyoglu, A.; Reinath, M. Combustion Oscillations in High Regression Rate Hybrid Rockets. In Proceedings of the 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Huntsville, AL, USA, 20–23 July 2003. [Google Scholar]

- Galfetti, L.; Merotto, L.; Boiocchi, M.; Maggi, F.; De Luca, L. Ballistic and Rheological Characterization of Paraffin-Based Fuels for Hybrid Rocket Propulsion. In Proceedings of the 47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, San Diego, CA, USA, 31 July–3 August 2011. [Google Scholar]

- Veale, K.; Adali, S.; Pitot, J.; Brooks, M. A Review of The Performance and Structural Considerations of Paraffin Wax Hybrid Rocket Fuels with Additives. Acta Astronaut. 2017, 141, 196–208. [Google Scholar] [CrossRef]

- Cantwell, B.; Karabeyoglu, A.; Altman, D. Recent Advances in Hybrid Propulsion. Int. J. Energeic Mater. Chem. Propuls. 2010, 9, 305–326. [Google Scholar] [CrossRef]

- Carmicino, C.; Scaramuzzino, F.; Sorge, A.R. Trade-off between paraffin-based and aluminium-loaded HTPB fuels to improve performance of hybrid rocket fed with N2O. Aerosp. Sci. Technol. 2014, 37, 81–92. [Google Scholar] [CrossRef]

- Elanjickal, S.; Gany, A. Enhancement of the Fuel Regression Rate in Hybrid Propulsion by Expandable Graphite Additive. Combust. Sci. Technol. 2020, 192, 1253–1273. [Google Scholar] [CrossRef]

- Karakas, H.; Kahraman, B.; Ozkol, I.; Karabeyoglu, A. Hybrid Rocket Nozzle Erosion with Microaluminum-Added Fuel. J. Propuls. Power 2022, 38, 901–910. [Google Scholar] [CrossRef]

- Farbar, E.; Louwers, J.; Kaya, T. Investigation of Metallized and Nonmetallized Hydroxyl Terminated Polybutadiene/Hydroge Peroxide Hybrid Rockets. J. Propuls. Power 2007, 23, 476–486. [Google Scholar] [CrossRef]

- Paravan, C. Nano-Sized and Mechanically Activated Composites: Perspectives for Enhanced Mass Burning Rate in Aluminized Solid Fuels for Hybrid Rocket Propulsion. Aerospace 2019, 6, 127. [Google Scholar] [CrossRef]

- Thomas, J.C.; Rodriguez, F.A.; Petersen, E.L. Metallic Additives for Solid-Fuel Propulsion Applications. Combust. Sci. Technol. 2021, 195, 1279–1298. [Google Scholar] [CrossRef]

- Wright, A.; Teague, W.; Hudson, M.; Wright, A.B.; Foley, P. A Thrust and Impulse Study of Guanidinium Azo-Tetrazolate as a Fuel Additive for Hybrid Rocket Motors. J. Pyrotech. 2005, 22, 44–51. [Google Scholar]

- Shark, S.C.; Zaseck, C.R.; Pourpoint, T.L.; Son, S.F.; Heister, S.D. Visualization and Performance of Hybrid Rocket Solid Fuels in an Optical Cylindrical Combustor. In Proceedings of the 49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, San Jose, CA, USA, 14–17 July 2013. [Google Scholar]

- Shark, S.C.; Zaseck, C.R.; Pourpoint, T.L.; Son, S.F.; Heister, S.D. Performance and Flame Visualization of Dicyclopentadiene Rocket Propellants with Metal Hydride Additives. J. Propuls. Power 2016, 32, 869–881. [Google Scholar] [CrossRef]

- Karakas, H.; Kara, O.; Ozkol, I.; Karabeyoglu, A. Performance Enhancing Additives for Hybrid Rockets. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Hawassa, A.; Churchillb, D.G.; Kwon, S. Enhancement in hypergolic properties of paraffin wax hybrid rocket fuel. Egypt. J. Chem. 2024, 67, 195–201. [Google Scholar] [CrossRef]

- Karabeyoglu, A.; Arkin, U. Evaluation of Fuel Additives for Hybrid Rockets and SFRJ Systems. In Proceedings of the 50th AIAA/ASME/SAE/ASEE Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Matsumoto, Y.; Takahashi, K.; Kinoshita, K.; Nakajima, K. Characteristics of a Polymeric as an Additive in WAX-Based Hybrid Rocket Fuel. In Proceedings of the 2018 Joint Propulsion Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Carmicino, C.; Sorge, A.R. Role of Injection in Hybrid Rockets Regression Rate Behaviour. J. Propuls. Power 2005, 21, 606–612. [Google Scholar] [CrossRef]

- Bouziane, M.; Bertoldi, A.E.M.; Milova, P.; Hendrick, P.; Lefebvre, M. Performance comparison of oxidizer injectors in a 1-kN paraffin-fueled hybrid rocket motor. Aerosp. Sci. Technol. 2019, 89, 392–406. [Google Scholar] [CrossRef]

- Jones, C.C.; Myre, D.D.; Cowart, J.S. Performance and Analysis of Vortex Oxidizer Injeciton in a Hybrid Rocket Motor. In Proceedings of the 45th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Denver, CO, USA, 2–5 August 2009. [Google Scholar]

- Bellomo, N.; Barato, F.; Faenza, M.; Lazzarin, M.; Bettella, A.; Pavarin, D. Numerical and Experimental Investigation of Unidirectional Vortex Injection in Hybrid Rocket Engines. J. Propuls. Power 2013, 29, 1097–1113. [Google Scholar] [CrossRef]

- Franco, M.; Barato, F.; Paccagnella, E.; Santi, M.; Battiston, A.; Comazzetto, A.; Pavarin, D. Regression Rate Design Tailoring through Vortex Injection in Hybrid Rocket Motors. J. Spacecr. Rocket. 2020, 57, 278–290. [Google Scholar] [CrossRef]

- Stella, M.; Zeni, L.; Nichelini, L.; Bellomo, N.; Pavarin, D.; Migliorino, M.T.; Fabiani, M.; Bianchi, D.; Nasuti, F.; Paravan, C. Experimental Investigation of a H2O2 Hybrid Rocket with Different Swirl Injections and Fuels. Appl. Sci. 2024, 14, 5625. [Google Scholar] [CrossRef]

- Knuth, W.H.; Gramer, D.J.; Chiaverini, M.J.; Sauer, J.A. Development and Testing of a Vortex-Driven, High-Regression Rate Hybrid Rocket Engine. In Proceedings of the 34th AIAA/ASME/SAE/ASEE Joint Conference and Exhibit, Cleveland, OH, USA, 13–15 July 1998. [Google Scholar]

- Knuth, W.H.; Chaverini, M.J.; Gramer, D.J.; Sauer, J.A. Experimental Investigation of a Vortex-Driven High-Regression Rate Hybrid Rocket Engine. In Proceedings of the 34th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Cleveland, OH, USA, 13–15 July 1998. [Google Scholar]

- Knuth, W.H.; Chaverini, M.J.; Gramer, D.J.; Sauer, J.A. Solid-Fuel Regression Rate Behavior of Vortex Hybrid Rocket Engines. J. Propuls. Power 2002, 18, 600–609. [Google Scholar] [CrossRef]

- Lestrade, Y.-J.; Anthoine, J.; Musker, J.A.; Lecossais, A. Experimental demonstration of an end-burning swirling flow hybrid rocket engine. Aerosp. Sci. Technol. 2019, 92, 1–8. [Google Scholar] [CrossRef]

- Lee, J.; Woo, K.; Kim, S. Effect of swirl intensity variation on combustion characteristics in end-burning hybrid rocket engines. Acta Astronaut. 2024, 217, 302–311. [Google Scholar] [CrossRef]

- Cai, G.; Zhao, Z.; Zhao, B.; Liu, Y.; Yu, N. Regression Rate and Combustion Performance Investigation on Hybrid Rocket Motor with Head-End Swirl Injection under High Geometric Swirl Number. Aerosp. Sci. Technol. 2020, 103, 105922. [Google Scholar] [CrossRef]

- Kumar, C.P.; Kumar, A. Effect of Swirl on the Regression Rate in Hybrid Rocket Motors. Aerosp. Sci. Technol. 2013, 29, 92–99. [Google Scholar] [CrossRef]

- Paccagnella, E.; Barato, F.; Pavarin, D.; Karabeyoglu, A. Scaling of Hybrid Rocket Motors with Swirling Oxidizer Injection. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- Paccagnella, E.; Barato, F.; Pavarin, D.; Karabeyoğlu, A. Scaling of Hybrid Rocket Motors with Swirling Oxidizer Injection-Part 2. In Proceedings of the 52nd AIAA/SAE/ASEE Joint Propulsion Conference, AIAA 2016-4750, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar]

- Paccagnella, E.; Barato, F.; Pavarin, D.; Karabeyoglu, A. Scaling Parameters of Swirling Oxidizer Injection in Hybrid Rocket Motors. J. Propuls. Power 2017, 33, 1378–1394. [Google Scholar] [CrossRef]

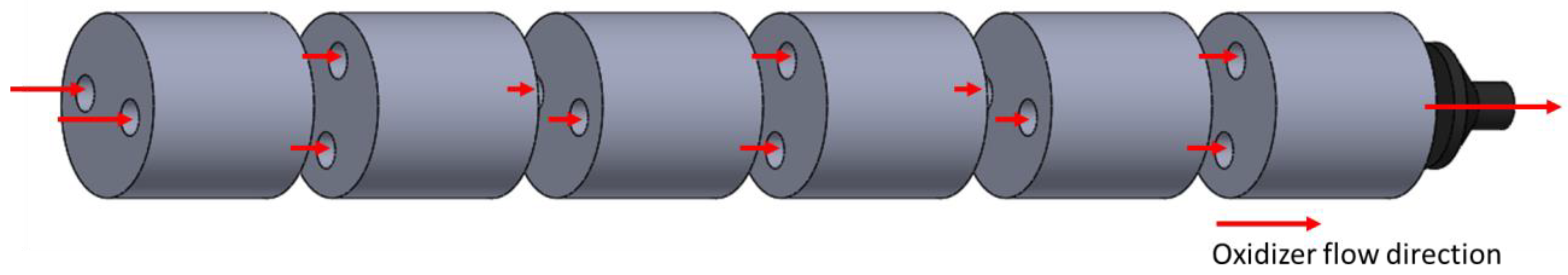

- Li, C.; Cai, G.; Tian, H. Numerical Analysis of Combustion Characteristics of Hybrid Rocket Motor with Multi-Section Swirl Injection. Acta Astronaut. 2016, 123, 26–36. [Google Scholar] [CrossRef]

- Barato, F.; Paccagnella, E.; Venturelli, G.; Pavarin, D.; Picano, F.; Lestrade, J.Y. Numerical Simulations of an Isochoric Hybrid Rocket Combustion Chamber and Comparison with Tests. In Proceedings of the 8th European Conference for Aeronautics and Space Sciences (EUCASS), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Li, M.C.; Wei, S.S.; Hung, C.H.; Wu, J.S. Experimental and Numerical Investigation of Swirling H2O2 and Polyprolene Hybrid Rocket Motor with Regenerartive Cooling. Acta Astronaut. 2022, 190, 283–298. [Google Scholar] [CrossRef]

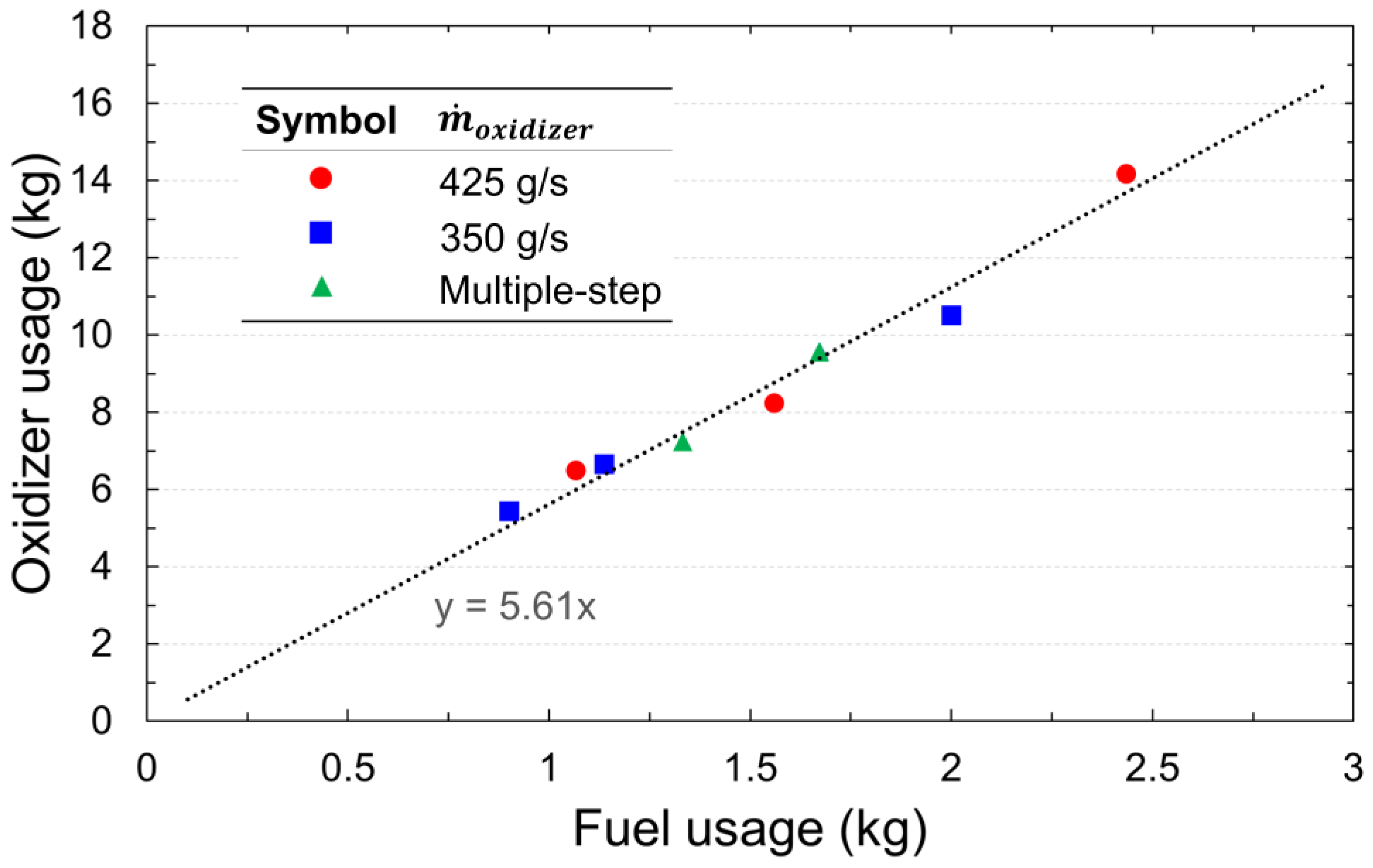

- Li, M.C.; Chang, C.S.; Wei, S.S.; Wu, J.S. Experimental Investigation of Throttleable H2O2 and Polypropylene Hybrid Rocket Motor. J. Propuls. Power 2023, 39, 63–70. [Google Scholar] [CrossRef]

- Kamps, L.; Hirai, S.; Nagata, H. Hybrid Rockets as Post-Boost Stages and Kick Motors. Aerospace 2021, 8, 253. [Google Scholar] [CrossRef]

- Wei, S.S.; Lee, M.C.; Chien, Y.H.; Chou, T.H.; Wu, J.S. Experimental Investigation of the Effect of Nozzle Throat Diameter on the Performance of a Hybrid Rocket Motor with Swirling Injection of Hight-Concentration Hydrogen Peroxide. Acta Astronaut. 2019, 164, 334–344. [Google Scholar] [CrossRef]

- Karabeyoglu, A.; Toson, E.; Evans, B. “O/F Shift” in Hybrid Rockets. In Proceedings of the 50th AIAA/ASME/SAE/ASSS Joint Propulsion Conference, Cleveland, OH, USA, 28–30 July 2014. [Google Scholar]

- Ozawa, K.; Shimada, T. Effect of O/F Shifts on Flight Performance of Vertically Launched Hybrid Sounding Rockets. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Barato, F.; Toson, E.; Pavarin, D. Variations and Control of Thrust and Mixture Ratio in Hybrid Rocket Motors. Adv. Astronaut. Sci. Technol. 2021, 4, 56–76. [Google Scholar] [CrossRef]

- Ozawa, K.; Neki, T.; Tsuboi, N. Visualization of the physical destruction process of additive-manufactured regression sensor structures. Sci. Technol. Energetic Mater. 2023, 83, 24–31. [Google Scholar]

- Evans, B.; Favorito, N.A.; Kuo, K.K. Study of Solid Fuel Burning-Rate Enhancement Behavior in an X-ray Translucent Hybrid Rocket Motor. In Proceedings of the 41st AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Tucson, AZ, USA, 10–13 July 2005. [Google Scholar]

- Karabeyoglu, A.; Altman, D. Dynamics Modeling of Hybrid Rocket Combustion. J. Propuls. Power 1999, 15, 562–571. [Google Scholar] [CrossRef]

- Park, K.; Lee, C. Low Frequency Instability in Laboratory-Scale Hybrid Rocket Motors. Aerosp. Sci. Technol. 2015, 42, 148–157. [Google Scholar] [CrossRef]

- Messineo, J.; Lestrade, Y.-J.; Hijlkema, J.; Anthoine, J. Hydrodynamic Instabilities Modeling in Hybrid Rocket Engines. J. Spacecr. Rocket. 2019, 56, 1371–1382. [Google Scholar] [CrossRef]

- Kobald, M.; Verri, I.; Schlechtriem, S. Theoretical and Experimental Analysis of Liquid Layer Instability in Hybrid Rocket Engines. CEAS Space J. 2015, 7, 11–22. [Google Scholar] [CrossRef]

- Petrarolo, A.; Kobald, M.; Schlechtriem, S. Understanding Kelvin–Helmholtz Instability in Paraffin-Based Hybrid Rocket Fuels. Exp. Fluids 2018, 59, 62. [Google Scholar] [CrossRef]

- Jo, S.; Jang, D.; An, S.; Kwon, S. Chugging Instability of H2O2 Monopropellant Thrusters with Catalyst Reactivity and Support Sizes. J. Propuls. Power 2011, 27, 920–924. [Google Scholar] [CrossRef]

- Kim, J.; Lee, C. Transition of Combustion Instability in Hybrid Rocket by Swirl Injection. Acta Astronaut. 2019, 158, 323–333. [Google Scholar] [CrossRef]

- Kim, J.; Lee, C. Equivalence Ratio Variation and Combustion Instability in Hybrid Rocket. J. Mech. Sci. Technol. 2019, 33, 5033–5042. [Google Scholar]

- Kim, J.; Lee, C. Low Frequency Instability and Oscillating Boundary Layer in Hybrid Rocket Combustion. J. Mech. Sci. Technol. 2020, 34, 4831–4839. [Google Scholar] [CrossRef]

- Hyun, W.; Kim, J.; Chae, H.; Lee, C. Passive Control of Low-Frequency Instability in Hybrid Rocket Combustion. Aerospace 2021, 8, 204. [Google Scholar] [CrossRef]

- Morlan, P.W.; Wu, P.K.; Ruttle, D.W. Catalyst Development for Hydrogen Peroxide Rocket Engines. In Proceedings of the 35th AIAA Joint Propulsion Conference and Exhibit, Los Angeles, CA, USA, 20–24 June 1999. [Google Scholar]

- Dennis, J.D.; Clubb, J. Investigation of Reduced Toxicity Hypergolic Fuels Renewed Efforts in the Development of the Navy. In Proceedings of the USA 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016. [Google Scholar]

- Lawver, B.R.; Nadlg, E.W.; Tkachendo, E.; Breen, B.P. A Mathematical Model of Random Wave Phenomena in Hypergolic Propellant Combustion. In Proceedings of the 3rd Propulsion Joint Specialist Conference, Washington, DC, USA, 17–21 July 1967. [Google Scholar]

- Chuen, R.L.; Wilber, P.C. Ignition of Hypergolic Propellants at Low Pressure and Low Temperature in a Space Enviroment Simulation Chamber. In Proceedings of the Space Simulation Conference, Houston, TX, USA, 7–9 September 1966. [Google Scholar]

- Bhosale, V.K.; Kim, K.S.; Kwon, S.; Churchill, D.G. Sodium Iodide: A Trigger for Hypergolic Ignition of Non-toxic Fuels with Hydrogen Peroxide. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar]

- Kang, H.; Kim, H.; Kwon, S. Difficulties in Dual-Mode Operation of Nontoxic Hypergolic Thruster Using Decomposition of H2O2. J. Propuls. Power 2019, 35, 780–786. [Google Scholar] [CrossRef]

- Kang, H.; Lee, E.; Kwon, S. Suppression of Hard Start for Nontoxic Hypergolic Thruster Using H2O2 Oxidizer. J. Propuls. Power 2017, 33, 1111–1117. [Google Scholar] [CrossRef]

- Jeong, J.; Kim, K.S.; Bhosale, V.K.; Kwon, S. Demonstration of Ammonia Borane-Based Hypergolic Ignitor for Hybrid Rocket. Acta Astronaut. 2022, 196, 85–93. [Google Scholar] [CrossRef]

- Castaneda, D.A.; Natan, B. Experimental investigation of the hydrogen peroxide-solid hydrocarbon hypergolic ignition. Acta Astronaut. 2019, 158, 286–295. [Google Scholar] [CrossRef]

- Nath, S.; Laso, I.; Leftkowitx, J.K. Ignition Study of a Metal-Hydride Based Non-Toxic Hypergolic Hybrid Rocket Propellant. In Proceedings of the AIAA SCITECH 2022 Forum, San Diego, CA, USA, 3–7 January 2022. [Google Scholar]

- Whitmore, S.A.; Mathias, S.; Harvey, R. High Voltage Breakdown and Arc-Tracking Mechanism of Thermoplastics with Applications to Hybrid Rocket Arc-Ignition. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, CA, USA, 10–12 July 2017. [Google Scholar]

- Lee, S.; Noh, K.; Lim, J.; Yoon, W. A Steam-Plasma Igniter for Aluminum Powder Combustion. Plasma Sci. Technol. 2015, 17, 392. [Google Scholar] [CrossRef]

- Dyrda, D.M.; Korneyeva, V.; Cantwell, B.J. Diode Laser Ignition Mechanism for Hybrid Propulsion Systems. J. Propuls. Power 2020, 36, 901–911. [Google Scholar] [CrossRef]

- Marxman, G.A. Combustion in the Turbulent Boundary Layer on a Vaporing Surface. Symp. (Int.) Combust. 1965, 10, 1337–1349. [Google Scholar] [CrossRef]

- Marxman, G.A. Boundary-Layer Combustion in Propulsion. Symp. (Int.) Propuls. 1967, 11, 269–289. [Google Scholar] [CrossRef]

- Yun, Y.; Huh, J.; Kim, Y.; Heo, S.; Kim, H.; Kwon, S. Scale-Up Validation of Hydrogen Peroxide/High-Density Polyethylene Hybrid Rocket with Multiport Solid Fuel. J. Spacecr. Rocket. 2021, 58, 552–565. [Google Scholar] [CrossRef]

- Cai, G.; Zeng, P.; Li, X.; Tian, H.; Yu, N. Scale Effect of Fuel Regression Rate in Hybrid Rocket Motor. Aerosp. Sci. Technol. 2013, 24, 141–146. [Google Scholar] [CrossRef]

- Kim, H.; Kang, H.; Kwon, S. A Feasibility Study of Using Pintle Injector as Sole-Throttling Device for Shallow Throttling Condition. Acta Astronaut. 2020, 167, 272–279. [Google Scholar] [CrossRef]

- Casiano, M.J.; Hulka, J.R.; Yang, V. Liquid-Propellant Rocket Engine Throttling: A Comprehensive Review. J. Propuls. Power 2010, 26, 897–923. [Google Scholar] [CrossRef]

- Vergez, P.L. Tactical Missile Guidance with Passive Seekers Under High Off-Boresight Launch Conditions. J. Guid. Control Dyn. 1998, 21, 465–470. [Google Scholar] [CrossRef]

- Xiao, M.; Hao, Z.; Ziyan, D.; Gao, Y.; Tian, H.; Cai, G. Design Optimization of Velocity-Controlled Cruise Vehicle Propelled by Throttleable Hybrid Rocket Motor. Aerosp. Sci. Technol. 2021, 115, 106784. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, N.; Liu, Y.; Zeng, P.; Wang, J. Unsteady Simulation and Experimental Study of Hydrogen Peroxide Throttleable Catalyst Hybrid Rocket Motor. Aerosp. Sci. Technol. 2018, 76, 27–36. [Google Scholar] [CrossRef]

- Zhao, S.; Cai, G.; Tian, H.; Yu, N. Experimental Tests of Throttleable H2O2/PE Hybrid Rocket Motors. In Propulsion and Energy Forum, Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, AIAA 2015-3831, Orlando, FL, USA, 27–29 July 2015; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2015. [Google Scholar]

- Ruffin, A.; Santi, M.; Paccagnella, E.; Barato, F.; Bellomo, N.; Miste, G.A.; Venturelli, G.M.; Pavarin, D. Development of a Flow Control Valve for a Throttleable Hybrid Rocket Motor and Throttling Fire Tests. In Proceedings of the 2018 Joint Propulsion Conference, AIAA 2018-4664, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Ruffin, A.; Paccagnella, E.; Santi, M.; Barato, F.; Pavarin, D. Real-Time Deep Throttling Tests of a Hydrogen Peroxide Hybrid Rocket Motor. J. Propuls. Power 2022, 38, 833–848. [Google Scholar] [CrossRef]

- Wang, Z.; Jia, Y.; Jin, L.; Duan, J. Thrust Vector Control of Upper Stage with a Gimbaled Thruster During Orbit Transfer. Acta Astronaut. 2016, 127, 359–366. [Google Scholar] [CrossRef]

- Sackheim, R.L. Spacecraft Chemical Propulsion. Encycl. Phys. Sci. Technol. 2003, 403–430. [Google Scholar] [CrossRef]

- Penchuk, A.; Croopnick, S. Digital Autopilot for Thrust Vector Control of the Shuttle Orbital Maneuvering System. J. Guid. Control Dyn. 1983, 6, 436–441. [Google Scholar] [CrossRef]

- Redmill, K.; Ozguner, U.; Musgrave, J.; Merril, W. Intelligent Hierarchical Thrust Vector Control for a Space Shuttle. IEEE Control Syst. Mag. 1994, 4, 13–23. [Google Scholar]

- Zmijanovic, V.; Lago, V.; Sellam, M.; Choun, A. Thrust Shock Vector Control of an Axisymmetric Conical Supersonic Nozzle Via Secondary Transverse Gas Injection. Shock Waves 2014, 24, 97–111. [Google Scholar] [CrossRef]

- Green, C.J.; McCullough, F., Jr. Liquid Injection Thrust Vector Control. AIAA J. 1963, 1, 573–578. [Google Scholar] [CrossRef]

- Zeamer, R.J. Liquid-Injection Thrust Vector Control. J. Spacecr. 1977, 14, 321–322. [Google Scholar] [CrossRef]

- Waithe, K.A.; Deere, K.A. Experimental and Computational Investigation of Multiple Injection Ports in a Convergent-Divergent Nozzle for Fluidic Thrust Vectoring. In Proceedings of the 21st Applied Aerodynamics Conference, Orlando, FL, USA, 23–26 June 2003. [Google Scholar]

- Chen, J.L.; Liao, Y.L. Parametric Study on Thrust Vectoring with a Secondary Injection in a Convergent-Divergent Nozzle. J. Aerosp. Eng. 2020, 33, 04020020. [Google Scholar] [CrossRef]

- Lee, E.; Kang, H.; Kwon, S. Demonstration of Thrust Vector Control by Hydrogen Peroxide Injection in Hybrid Rockets. J. Propuls. Power 2019, 35, 109–114. [Google Scholar] [CrossRef]

- Miloš, P.; Davidović, N.; Jojić, B.; Miloš, M.; Todić, I. A novel 6 DOF thrust vector control test stand. Tech. Gaz. 2015, 22, 1247–1254. [Google Scholar]

- Berdoyes, M. Snecma Propulsion Solide Advanced Technology SRM Nozzles. History and Future. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar]

- Yağmur, H.; Şen, S.; Bayar, C.; Serbest, K. Design of A 3-DOF Thrust Control System for Rocket Engines. J. Smart Syst. Res. 2022, 3, 30–48. [Google Scholar]

- Larkin, D.; Singh, H. Thrust Vector Control. 2011. Available online: https://digitalcommons.calpoly.edu/mesp/73/ (accessed on 4 September 2024).

- Orbekk, E. SuperSonic Split Line TVC Technology and Testing at Nammo Raufoss AS. In Proceedings of the 42nd AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit, Sacramento, CA, USA, 9–12 July 2006. [Google Scholar]

- Mechentel, F.S.; Cantwell, B.J. Experimental Findings on Pre-and Post-combustion Chamber Effects in a Laboratory-scale Motor. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Gomes, S.R.; Junior, L.; Rocco, J. Swirl Injection Effects on Hybrid Rocket Motors. J. Aerosp. Technol. Manag. 2015, 7, 418–424. [Google Scholar] [CrossRef]

- Lazzarin, M.; Faenza, M.; Barato, F.; Bettella, A.; Pavarin, D. Computational Fluid Dynamics Simulation of Hybrid Rockets of Different Scales. J. Propuls. Power 2015, 31, 1458–1469. [Google Scholar] [CrossRef]

- Mechentel, F.S.; Hord, B.R.; Cantwell, B.J. Optically Resolved Fuel Regression of a Clear Polymethylmethacrylate Hybrid Rocket Motor. J. Propuls. Power 2020, 36, 763–772. [Google Scholar] [CrossRef]

- Natali, M.; Kenny, J.M.; Torre, L. Science and Technology of Polymeric Ablative Materials for Thermal Protection Systems and Propulsion Devices: A Review. Prog. Mater. Sci. 2016, 84, 192–275. [Google Scholar] [CrossRef]

- Milhomem, G.; Nunes, A.P.; Andrianov, A.; Shynkarenko, O.; Lee, J. Experimental Studies of Heat Insulation Materials for Hybrid Propellant Rocket Motors. In Proceedings of the 24th ABCM International Congress of Mechanical Engineering, Curitiba, Brazil, 3–8 December 2017. [Google Scholar]

- Kim, E.S.; Lee, T.H.; Shin, S.H. Effect of Incorporation of Carbon Fiber and Silicon Carbide Powder into Silicone Rubber on the Ablation and Mechanical Properties of the Silicone Rubber-Based Ablation Material. J. Appl. Polym. Sci. 2011, 120, 831–838. [Google Scholar] [CrossRef]

- Vaka, P.R.; Rathi, N.; Ramakrishna, P.A. Experimental Investigation of Erosion Rate of Insulation Materials Using Hybrid Rockets. FirePhysChem 2021, 1, 222–230. [Google Scholar] [CrossRef]

- Barato, F.; Paccagnella, E.; Franco, M.; Pavarin, D. Numerical Analyses of Thermal Protection Design in Hybrid Rocket Motors. In Proceedings of the AIAA Propulsion and Energy Forum, Online, 24–28 August 2020. [Google Scholar]

- Barato, F. Challenges of Ablatively Cooled Hybrid Rockets for Satellites or Upper Stages. Aerospace 2021, 8, 190. [Google Scholar] [CrossRef]

- Kahraman, B.; Karakas, H.; Eren, B.N.; Karabeyoglu, A. Erosion Rate Investigation of Various Nozzle Materials in Hybrid Rocket Motors. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar]

- Whitmore, S.A.; Babb, R.; Stephens, J.C.; Horlacher, J.D. Further Development of Low-Erosion Nozzle Materials for Long-Duration Hybrid Rocket Burns. In Proceedings of the AIAA Propulsion and Energy Forum, Online, 9–11 August 2021. [Google Scholar]

- Gallo, G.; Kojima, H.; Kamps, L.; Nagata, H. Experimental investigation of regenerative cooling performance in hybrid rocket engines. Therm. Sci. Eng. Prog. 2024, 49, 102481. [Google Scholar] [CrossRef]

- Rotondi, M.; Migliorino, M.T.; Bianchi, D.; Kamps, L.; Nagata, H. Computational Analysis and Regression Laws for Nozzle Erosion Prediction in Hybrid Rockets. J. Propuls. Power 2024, 40, 439–459. [Google Scholar] [CrossRef]

- Kerstens, F.; Cervone, A.; Gradl, P. End to End Process Evaluation for Additively Manufactured Liquid Rocket Engine Thrust Chambers. Acta Astronaut. 2021, 182, 454–465. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufaturing: A Review of Common Processes Industrial Applications, Current Challenges. J. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- ABL Space System. ABL Space System RS1 Website. [Online]. Available online: https://ablspacesystems.com/rs1/ (accessed on 4 September 2024).

- Lee, K.O.; Lima, B.; Kimb, D.J.; Hpngc, M.; Lee, K. Technology Trends in Additively Manufactured Small Rocket Engines for Launcher Applications. J. Korean Soc. Propuls. Eng. 2020, 24, 73–82. [Google Scholar] [CrossRef]

- Gradl, P.R.; Portz, C.; Fikes, J.; Ellis, D.; Evans, L.; Clark, A.; Miller, S.; Hudson, T. Lightweight Thrust Chamber Assemblies Using Multi-Alloy Additive Manufacturing and Composite Overwra. In Proceedings of the AIAA Propulsion and Energey Forum, Online, 24–28 August 2020. [Google Scholar]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Wagner, M.A.; Hadian, A.; Sebastian, T.; Clements, F.; Schweizer, T.; Rodriguez-Arbaizar, M.; Carreno-Morelli, E.; Spolenak, R. Fused Filament Fabrication of Stainless Steel Structures-from Binder Development to Sintered Properties. Addit. Manuf. 2022, 49, 102472. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L.; Guo, X.; Kane, S.; Deng, Y.; Jung, Y.G.; Lee, J.H.; Zhang, J. Additive Manufacturing of Metallic Materials: A Review. J. Mater. Eng. Perform. 2018, 27, 1–13. [Google Scholar] [CrossRef]

- Kellner, T. 3D-Printed ‘Bionic’ Parts Could Revolutionize Aerospace Design; General Electric Reports: Boston, MA, USA, 2017. [Google Scholar]

- Rocket Lab. Rocket Lab Website. [Online]. Available online: https://www.rocketlabusa.com/ (accessed on 4 September 2024).

- Clark, A.; Tyler, H. Rapid Analysis and Manufacturing Propulsion Technology (RAMPT). 2021. [Online]. Available online: https://ntrs.nasa.gov/citations/20210019482 (accessed on 4 September 2024).

- Ossola, E.; Borgonia, J.P.; Hendry, M.; Sunada, E.; Brusa, E.; Sesana, R. Design of Isogrid Shells for Venus Surface Probes. J. Spacecr. Rocket 2021, 58, 643–652. [Google Scholar] [CrossRef]

- Musker, A.J.; Lestrade, J.Y.; Anthoine, J.; Lécossais, A. Catalytic Injectors for an Isochoric Hybrid Rocket Motor. In Proceedings of the Space Propulsion 2018, Seville, Spain, 14–18 May 2018. [Google Scholar]

- Quigley, N.; Lyne, J.E. Development of a Three-Dimensional Printed, Liquid-Cooled Nozzle for a Hybrid Rocket Motor. J. Propuls. Power 2014, 30, 1726–1727. [Google Scholar] [CrossRef]

- Ercole, G.; Garofalo, E.; Lemieux, P.; Maglie, M.M.; Pastrone, D. N2O-Cooled Aerospike for a Hybrid Rocket Motor: Nitrous Oxide Characterization and Additive Manufacturing. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Estey, P.; Whittinghill, G.R. Hybrid Rocket Motor Propellant Selection Alternatives. In Proceedings of the 28th Joint Propulsion Conference and Exhibit, Nashville, TN, USA, 6–8 July 1992. [Google Scholar]

- Cecil, O.; Majdalani, J. Several Hybrid Rocket Technologies Hit Advanced Test Stages. Aerosp. Am. 2016, 54. Available online: https://aerospaceamerica.aiaa.org/year-in-review/several-hybrid-rocket-technologies-hit-advanced-test-stages/ (accessed on 4 September 2024).

- Kobald, M.; Fischer, U.; Tomilin, K.; Petrarolo, A.; Kysela, P.; Schmierer, A.P.; Gauger, J.; Breitinger, J.; Hertel, F.; Hochheimer, B. Sounding Rocket “HEROS”—A Low-Cost Hybrid Rocket Technology Demonstrator. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanda, GA, USA, 10–12 July 2017. [Google Scholar]

- Oechsle, M.; Dobusch, J.; Gritzka, M.; Jochum, P.; Merz, F.; Rodinger, R. Design and Launch of the Hybrid Rocket Demonstrator Compass. In Proceedings of the 2nd International Conference on Flight Vehicles, Aerothermodynamics and Re-entry Missions and Engineering (FAR), Heilbronn, Germany, 19–23 June 2022. [Google Scholar]

- Hybrid Engine Development. First Results of the N₂ORTH Post Flight Analysis. [Online]. Available online: https://hyend.de/index.php/2023/07/18/first-results-of-the-n2orth-post-flight-analysis/ (accessed on 4 September 2024).

- HyImpulse. German Space Company Successfully Launches First Commercially Viable Launch Vehicle. 2024. Available online: https://www.hyimpulse.de/Press_Release/03052024_Press%20Release_HyImpulse%20-%20German%20space%20company%20successfully%20launches%20first%20commercially%20viable%20launch%20vehicle.pdf (accessed on 4 September 2024).

- Genevieve, B.; Pitot, J.; Brooks, M.J.; Chowdhury, S.; Veale, K.L.; Leverone, F.; Balmogin, U.; Mawbey, R. Flight Test of the Phoenix-1A Hybrid Rocket. In Proceedings of the 51st AIAA/SAE/ASEE Joint Propulsion Conference, Orlando, FL, USA, 27–29 July 2015. [Google Scholar]

- Messinger, T.; Hill, C.; Quinn, D.; Stannard, D.; Doerksen, G.; Johansen, C.T. Development and Test Flight of the Atlantis Nitrous Oxide/Paraffin-based Hybrid Rocket. In Proceedings of the AIAA Propulsion and Energy Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar]

- Kniffen, R.J.; Mckinney, B.; Estey, P. Hybrid Rocket Development at the America Rocket Company. In Proceedings of the 26th Joint Propulsion Conference, Orlando, FL, USA, 6–18 July 1990. [Google Scholar]

- Schmierer, C.; Konald, M.; Tomilin, K.; Fischer, U.; Schlechtriem, S. Low Cost Small-Satellite Access to Space Using Hybrid Rocket Propulsion. Acta Astronaut. 2019, 159, 579–583. [Google Scholar] [CrossRef]

- Sotto, E.D.; Mollinedo, L.; Portero, R.; Milhano, T.; D’Ambrogio, M.; Pessana, M.; Ronningen, J.E. GNC and Avionics Assembly Integration and Validation for SPARTAN Technology Demonstrator. In Proceedings of the 6th European Conference for Aerospace Sciences (EUCASS), Krakow, Poland, 29 June–3 July 2015. [Google Scholar]

- Story, G.T.; Karp, A.C.; Nakazono, B.; Zilliac, G.; Evans, B.J.; Whittinghill, G. Mars Ascent Vehicle Hybrid Propulsion Effort. In Proceedings of the AIAA Propulsion and Energy 2020 Forum, Online, 24–28 August 2020. [Google Scholar]

| Propellant Combination (Fuel + Oxidizer) | Optimum O/F | Sea Level Isp (s) | C* (m/s) | Remarks |

|---|---|---|---|---|

| Carbon, Air | 11.3 | 184 | 1224 | |

| Carbon, Lox | 1.9 | 249 | 1599 | Cryogenic |

| Carbon, N2O | 6.3 | 236 | 1522 | |

| Cellulose, Gox | 1.0 | 247 | 1572 | |

| CH4(s), Lox | 3 | 291 | 1871 | Cryogenic |

| CH4(s)/Be(36%), Lox | 1.3 | 306 | 1918 | Cryogenic |

| HTPB, F2 + Lox | 3.3 | 314 | 2045 | Cryogenic |

| HTPB, IRFNA | 4.3 | 247 | 1591 | |

| HTPB, Lox | 1.9 | 280 | 1820 | Cryogenic |

| HTPB, N2O | 7.1 | 247 | 1604 | |

| HTPB, N2O4 | 3.5 | 258 | 1663 | |

| HTPB/Al(40%), Lox | 1.1 | 274 | 1757 | Cryogenic |

| HTPB/Al(40%), N2O | 3.5 | 252 | 1637 | |

| HTPB/Al(40%), N2O4 | 1.7 | 261 | 1679 | |

| HTPB/Al(60%), F2 + Lox | 2.5 | 312 | 2006 | Cryogenic |

| Li/LiH/HTPB, F2 + Lox | 2.8 | 326 | 2118 | Cryogenic |

| NH3(s)/Be(26%), Lox | 0.47 | 307 | 1967 | Cryogenic |

| Paraffin, Lox | 2.5 | 281 | 1804 | Cryogenic |

| Paraffin, N2O | 8.0 | 248 | 1606 | |

| Paraffin, N2O4 | 4.0 | 259 | 1667 | |

| Pentance(s), Lox | 2.7 | 279 | 1789 | Cryogenic |

| PE, N2O | 8.0 | 247 | 1600 | |

| PE, Lox | 2.5 | 279 | 1791 | Cryogenic |

| PMMA, Lox | 1.5 | 259 | 1661 | Cryogenic |

| JP-4, AN | 17.0 | 216 | 1418 | Reverse HRE |

| JP-4, AP | 9.1 | 235 | 1526 | Reverse HRE |

| JP-4, NP | 3.6 | 259 | 1669 | Reverse HRE |

| Feature | Lox | N2O | Nytrox |

|---|---|---|---|

| Density | 4 | 2 | 4 |

| Isp Performance | 5 | 3 | 4 |

| Impulse Density | 4 | 1 | 3 |

| Self-Pressurization Capability | 1 | 5 | 3 |

| Performance Tuning Capability | 1 | 2 | 5 |

| Chemical Compatibility | 5 | 5 | 5 |

| Chemical Stability | 5 | 4 | 4 |

| Gas-Phase Combustion | 1 * | 3 | 5 |

| Hypergolicity | 1 | 1 | 1 |

| Motor Stability/Efficiency | 2 | 5 | 4 |

| Performance Tuning Capability | 1 | 2 | 5 |

| Storability | 1 | 5 | 3 |

| Toxicity | 5 | 4 | 4 |

| Ease of handling | 3 | 5 | 4 |

| Material Cost | 5 | 4 | 4 |

| Overall Safety | 3 | 2 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, S.-S.; Li, M.-C.; Lai, A.; Chou, T.-H.; Wu, J.-S. A Review of Recent Developments in Hybrid Rocket Propulsion and Its Applications. Aerospace 2024, 11, 739. https://doi.org/10.3390/aerospace11090739

Wei S-S, Li M-C, Lai A, Chou T-H, Wu J-S. A Review of Recent Developments in Hybrid Rocket Propulsion and Its Applications. Aerospace. 2024; 11(9):739. https://doi.org/10.3390/aerospace11090739

Chicago/Turabian StyleWei, Shih-Sin, Meng-Che Li, Alfred Lai, Tzu-Hao Chou, and Jong-Shinn Wu. 2024. "A Review of Recent Developments in Hybrid Rocket Propulsion and Its Applications" Aerospace 11, no. 9: 739. https://doi.org/10.3390/aerospace11090739

APA StyleWei, S.-S., Li, M.-C., Lai, A., Chou, T.-H., & Wu, J.-S. (2024). A Review of Recent Developments in Hybrid Rocket Propulsion and Its Applications. Aerospace, 11(9), 739. https://doi.org/10.3390/aerospace11090739