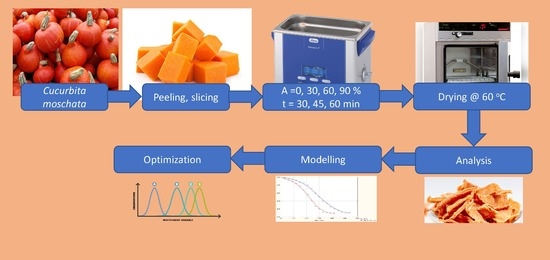

Mathematical Modeling and Optimization of Ultrasonic Pre-Treatment for Drying of Pumpkin (Cucurbita moschata)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Ultrasound Pretreatment

2.3. Drying Experiment

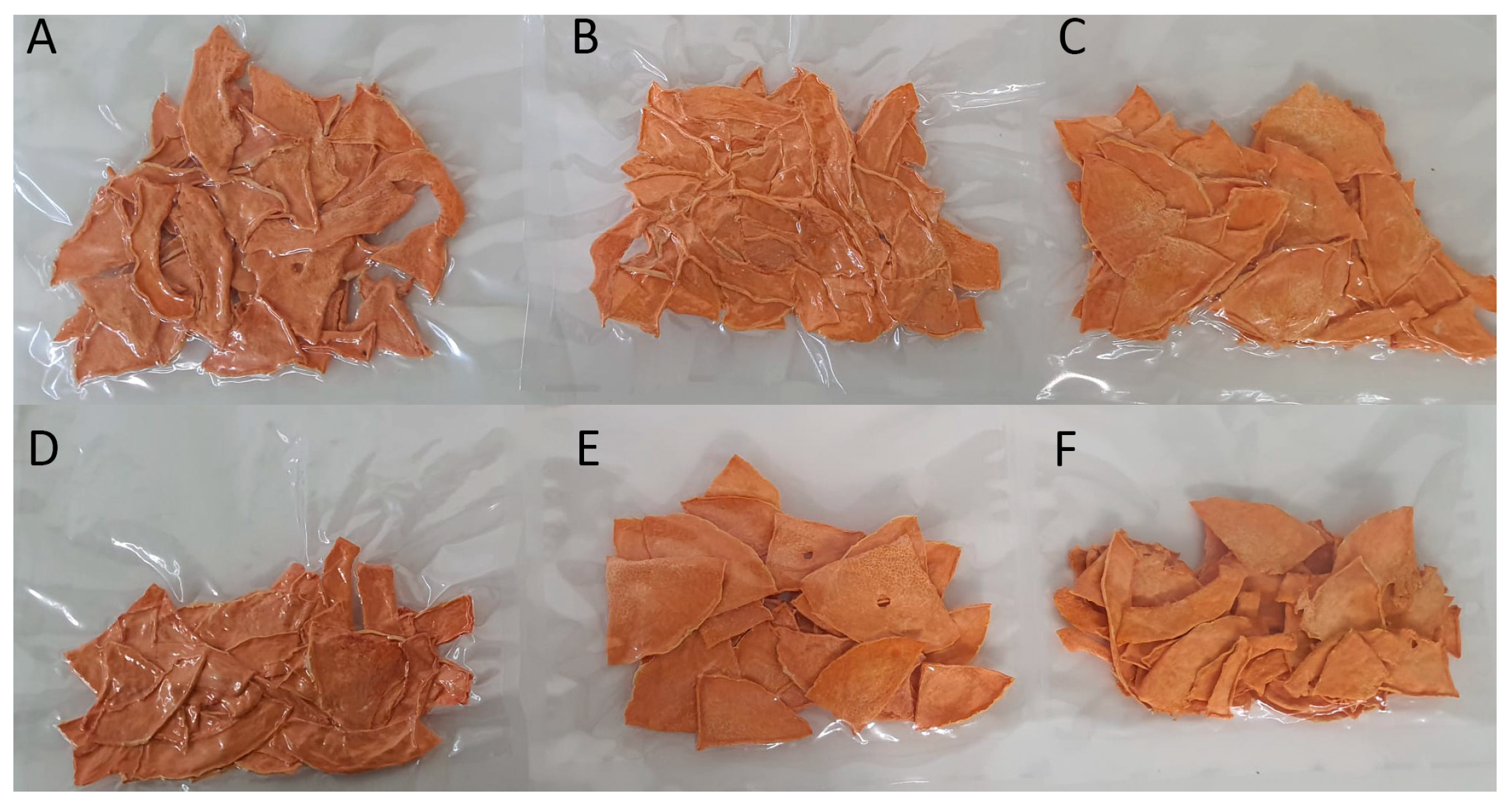

2.4. Color Measurement

2.5. Mathematical Modeling

2.6. Data Analysis

3. Results and Discussion

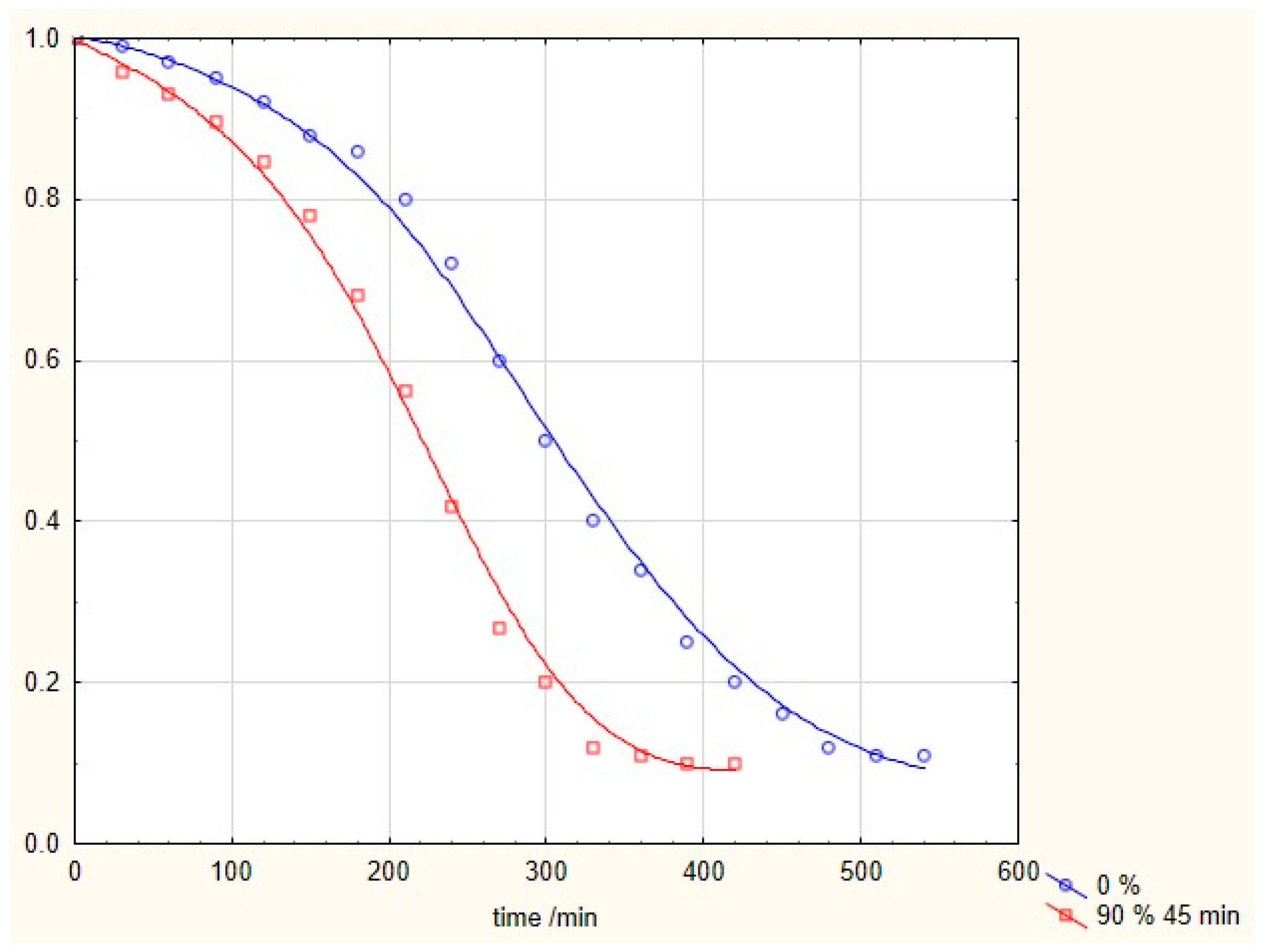

3.1. Modeling

3.2. Optimal Pre-Treatment Parameters

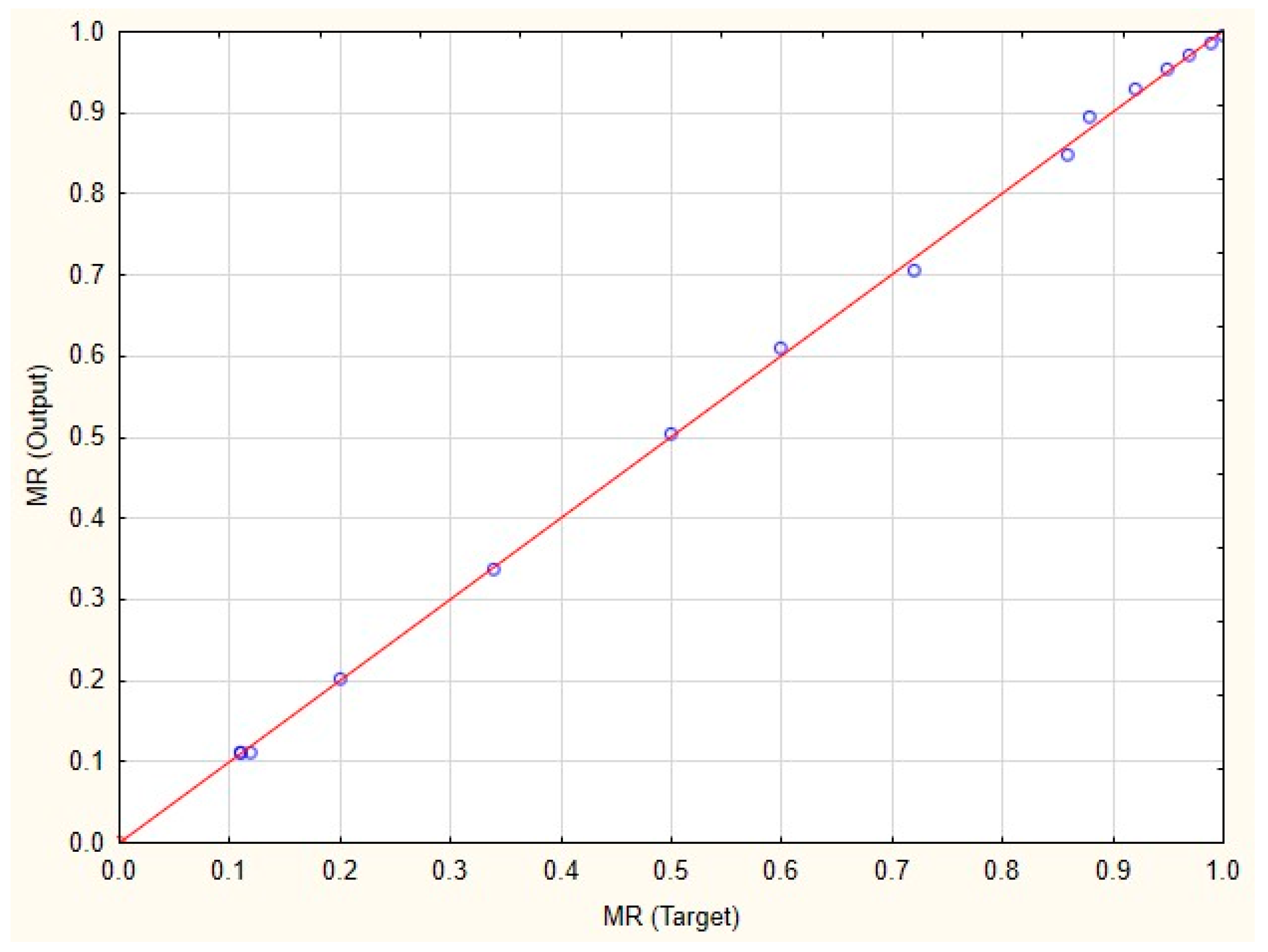

3.3. Artificial Neural Networks

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussain, A.; Kausar, T.; Sehar, S.; Sarwar, A.; Ashraf, A.; Jamil, M.; Noreen, S.; Rafique, A.; Iftikhar, K.; Quddoos, M.; et al. A Comprehensive review of functional ingredients, especially bioactive compounds present in pumpkin peel, flesh and seeds, and their health benefits. Food Chem. Adv. 2022, 1, 100067. [Google Scholar] [CrossRef]

- Lee, Y.; Chung, W.; Ezura, H. Efficient plant regeneration via organogenesis in winter squash (Cucurbita maxima Duch). Plant Sci. 2003, 164, 413–418. [Google Scholar] [CrossRef]

- FAO. Food and Agriculture Organization of the United Nation; FAOSTAT: Rome, Italy, 2019; Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 2 December 2022).

- Chao, E.; Tian, J.; Fan, L.; Zhang, T. Drying methods influence the physicochemical and functional properties of seed-used pumpkin. Food Chem. 2022, 369, 130937. [Google Scholar] [CrossRef] [PubMed]

- Oloyede, F.; Agbaje, G.; Obuotor, E.; Obisesan, I. Nutritional and antioxidant profiles of pumpkin (Cucurbita pepo Linn.) immature and mature fruits as influenced by NPK fertilizer. Food Chem. 2012, 135, 460–463. [Google Scholar] [CrossRef] [PubMed]

- Xia, T.; Wang, Q. Hypoglycaemic role of Cucurbita ficifolia (Cucurbitaceae) fruit extract in streptozotocin-induced diabetic rats. J. Sci. Food Agric. 2007, 87, 1753–1757. [Google Scholar] [CrossRef]

- Pérez-Álvarez, J.; Botella-Martínez, C.; de Vera, C.N.-R.; Sayas-Barberá, E.; Viuda-Martos, M.; Fernández-López, J.; Sánchez-Zapata, E. A Preliminary Study on the Incorporation of Quinoa Flour in Organic Pumpkin Creams: Effect on the Physicochemical Properties. In Proceedings of the 1st International Electronic Conference on Food Science and Functional Foods, Online, 10–25 November 2020; Available online: https://foods_2020.sciforum.net/ (accessed on 20 September 2021).

- Hussain, A.; Kausar, T.; Din, A.; Murtaza, M.; Jamil, M.; Noreen, S.; Rehman, H.; Shabbir, H.; Ramzan, M. Determination of total phenolic, flavonoid, carotenoid, and mineral contents in peel, flesh, and seeds of pumpkin (Cucurbita maxima). J. Food Process. Preserv. 2021, 45, e15542. [Google Scholar] [CrossRef]

- Fang, Z.; Xiao, B.; Jiang, W.; Hao, X.; Tan, J.; Lu, A.; Li, J.; Wang, W.; Wang, G.; Zhang, Y. The antioxidant capacity evaluation of polysaccharide hydrolyzates from pumpkin using Caenorhabditis elegans model. J. Food Biochem. 2021, 45, e13275. [Google Scholar] [CrossRef] [PubMed]

- Kulczyński, M.; Gramza, K. Optimization of Extraction Conditions for the Antioxidant Potential of Different Pumpkin Varieties (Cucurbita maxima). Sustainability 2020, 12, 1305. [Google Scholar] [CrossRef]

- Ahmad, G.; Khan, A.A. Pumpkin: Horticultural Importance and Its Roles in Various Forms: A Review. Int. J. Hortic. Agric. 2019, 4, 1–6. [Google Scholar] [CrossRef]

- Sharma, M.; Bhat, R. Extraction of Carotenoids from Pumpkin Peel and Pulp: Comparison between Innovative Green Extraction Technologies (Ultrasonic and Microwave-Assisted Extractions Using Corn Oil). Foods 2021, 10, 787. [Google Scholar] [CrossRef]

- Ježek, D.; Tripalo, B.; Brncic, M.; Karlovic, D.; Brncic, S.; Vikic-Topic, D.; Karlovic, S. Dehydration of celery by infrared drying. Croat. Chem. Acta 2008, 81, 325–331. [Google Scholar]

- Dujmić, F.; Brncic, M.; Karlovic, S.; Bosiljkov, T.; Jezek, D.; Tripalo, B.; Mofardin, I. Ultrasound-Assisted Infrared Drying of Pear Slices: Textural Issues. J. Food Process Eng. 2013, 36, 397–406. [Google Scholar] [CrossRef]

- Onwude, D.; Hashim, N.; Janius, R.; Nawi, N.; Abdan, K. Modeling the Thin-Layer Drying of Fruits and Vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Zlabur, J.; Zutic, I.; Radman, S.; Plesa, M.; Brncic, M.; Barba, F.; Rocchetti, G.; Lucini, L.; Lorenzo, J.; Dominguez, R.; et al. Effect of Different Green Extraction Methods and Solvents on Bioactive Components of Chamomile (Matricaria chamomilla L.). Flowers. Mol. 2020, 25, 810. [Google Scholar] [CrossRef]

- Herceg, Z.; Brnčić, M.; Jambrak, A.R.; Brnčić, S.R.; Badanjak, M.; Sokolić, I. Possibility of application high intensity ultrasound in milk industry. Mljekarstvo 2009, 59, 65–69. [Google Scholar]

- Dujmic, F.; Ganic, K.K.; Curic, D.; Karlovic, S.; Bosiljkov, T.; Jezek, D.; Vidrih, R.; Hribar, J.; Zlatic, E.; Prusina, T.; et al. Non-Thermal Ultrasonic Extraction of Polyphenolic Compounds from Red Wine Lees. Foods 2020, 9, 472. [Google Scholar] [CrossRef] [PubMed]

- Sokac, T.; Gunjevic, V.; Pusek, A.; Tusek, A.; Dujmic, F.; Brncic, M.; Ganic, K.; Jakovljevic, T.; Uher, D.; Mitric, G.; et al. Comparison of Drying Methods and Their Effect on the Stability of Grasevina Grape Pomace Biologically Active Compounds. Foods 2022, 11, 112. [Google Scholar] [CrossRef] [PubMed]

- Voučko, B.; Novotni, D.; Balbino, S.; Mustač, N.; Drakula, S.; Dujmić, F.; Habuš, M.; Jarni, K.; Ćurić, D. Utilization of pumpkin seed oil cake and proso millet flour in enhancing gluten-free bread quality. J. Food Process. Preserv. 2022, 46, e17070. [Google Scholar] [CrossRef]

- Lukić, K.; Brnčić, M.; Ćurko, N.; Tomašević, M.; Valinger, D.; Denoya, I.; Barba, J.; Ganić, K.K. Effects of high power ultrasound treatments on the phenolic, chromatic and aroma composition of young and aged red wine. Ultrason. Sonochem. 2019, 59, 104725. [Google Scholar] [CrossRef]

- Madhavan, J.; Theerthagiri, J.; Balaji, D.; Sunitha, S.; Choi, M.; Ashokkumar, M. Hybrid Advanced Oxidation Processes Involving Ultrasound: An Overview. Molecules 2019, 24, 3341. [Google Scholar] [CrossRef]

- Abramova, A.; Abramov, V.; Bayazitov, V.; Nikonov, R.; Fedulov, I.; Stevanato, L.; Cravotto, G. Ultrasound-Assisted Cold Pasteurization in Liquid or SC-CO2. Processes 2021, 9, 1457. [Google Scholar] [CrossRef]

- Rodríguez, Ó.; Bona, S.; Stäbler, A.; Rodríguez-Turienzo, L. Ultrasound-Assisted Extraction of Polyphenols from Olive Pomace: Scale Up from Laboratory to Pilot Scenario. Processes 2022, 10, 2481. [Google Scholar] [CrossRef]

- Theerthagiria, J.; Madhavanb, J.; Leea, S.; Choi, M.; Ashokkumarc, M.; Polletd, B. Sonoelectrochemistry for energy and environmental applications. Ultrason. Sonochem. 2020, 63, 104960. [Google Scholar] [CrossRef] [PubMed]

- Andaluz-Mejía, L.; Anda, D.R.-D.; Ozuna, C. Non-Thermal Technologies Combined with Antimicrobial Peptides as Methods for Microbial Inactivation: A Review. Processes 2022, 10, 995. [Google Scholar] [CrossRef]

- Vanga, S.K.; Wang, J.; Jayaram, S.; Raghavan, V. Effects of Pulsed Electric Fields and Ultrasound Processing on Proteins and Enzymes: A Review. Processes 2021, 9, 722. [Google Scholar] [CrossRef]

- Karlović, S.; Bosiljkov, T.; Brnčić, M.; Semenski, D.; Dujmić, F.; Tripalo, B.; Ježek, D. Reducing Fat Globules Particle-Size in Goat Milk: Ultrasound and High Hydrostatic Pressures Approach. Chem. Biochem. Eng. Q. 2014, 28, 499–507. [Google Scholar] [CrossRef]

- Santos, K.; Guedes, J.; Rojas, M.; Carvalho, G.; Augusto, P. Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrason. Sonochem. 2021, 70, 105304. [Google Scholar] [CrossRef]

- Tao, Y.; Li, D.; Chai, W.S.; Show, P.; Yang, X.; Manickam, S.; Xie, G.; Han, Y. Comparison between airborne ultrasound and contact ultrasound to intensify air drying of blackberry: Heat and mass transfer simulation, energy consumption and quality evaluation. Ultrason. Sonochem. 2021, 72, 105410. [Google Scholar] [CrossRef]

- Žlabur, J.Š.; Colnar, D.; Voća, S.; Lorenzo, J.; Munekata, P.; Barba, F.; Dobričević, N.; Galić, A.; Dujmić, F.; Pliestić, S.; et al. Effect of ultrasound pre-treatment and drying method on specialized metabolites of honeyberry fruits (Lonicera caerulea var. kamtschatica). Ultrason. Sonochem. 2019, 56, 372–377. [Google Scholar] [CrossRef]

- Ozuna, C.; Carcel, J.; Garcia-Perez, J.; Mulet, A. Improvement of water transport mechanisms during potato drying by applying ultrasound. J. Sci. Food Agric. 2011, 91, 2511–2517. [Google Scholar] [CrossRef]

- Szadzińska, J.; Łechtańska, J.; Pashminehazar, R.; Kharaghani, A.; Tsotsas, E. Microwave- and ultrasound-assisted convective drying of raspberries: Drying kinetics and microstructural changes. Dry. Technol. 2018, 37, 1–12. [Google Scholar] [CrossRef]

- Mothibe, K.; Zhang, M.; Mujumdar, A.; Wang, Y.; Cheng, X. Effects of Ultrasound and Microwave Pretreatments of Apple Before Spouted Bed Drying on Rate of Dehydration and Physical Properties. Dry. Technol. 2014, 32, 1848–1856. [Google Scholar] [CrossRef]

- Aregbesola, O.; Ogunsina, B.; Sofolahan, A.; Chime, N. Mathematical modeling of thin layer drying characteristics of dika (Irvingia gabonensis) nuts and kernels. Niger. Food J. 2015, 33, 83–89. [Google Scholar] [CrossRef]

- Akpinar, E.; Sarsılmaz, C.; Yildiz, C. Mathematical modelling of a thin layer drying of apricots in a solar energized rotary dryer. Int. J. Energy Res. 2004, 28, 739–752. [Google Scholar] [CrossRef]

- Diamante, L.; Ihns, R.; Savage, G.; Vanhanen, L. A new mathematical model for thin layer drying of fruits. Int. J. Food Sci. Technol. 2010, 45, 1956–1962. [Google Scholar] [CrossRef]

- Raut, S.; Saleh, R.M.; Kirchhofer, P.; Kulig, B.; Hensel, O.; Sturm, B. Investigating the Effect of Different Drying Strategies on the Quality Parameters of Daucus carota L. using dynamic process control and measurement techniques. Food Bioprocess Technol. 2021, 14, 1067–1088. [Google Scholar] [CrossRef]

- Chikpah, S.; Korese, J.; Sturm, B.; Hensel, O. Colour change kinetics of pumpkin (Cucurbita moschata) slices during convective air drying and bioactive compounds of the dried products. J. Agric. Food Res. 2022, 10, 100409. [Google Scholar] [CrossRef]

- Association Official. Analytical Chemists Official Methods of Analysis of AOAC International, 21st ed.; AOAC International: Gaithersburg, MD, USA, 2019; Volume 927, Volume I Method, p. 5. [Google Scholar]

- Kek, S.; Chin, N.; Yusof, Y. Direct and indirect power ultrasound assisted pre-osmotic treatments in convective drying of guava slices. Food Bioprod. Process. 2013, 91, 495–506. [Google Scholar] [CrossRef]

- Roongruangsri, W.S.; Bronlund, J. Effect of air-drying temperature on physico-chemical, powder properties and sorption characteristics of pumpkin powders. Int. Food Res. J. 2016, 23, 962–972. [Google Scholar]

- Bhattacharya, M.; Srivastav, P.; Mishra, H. Thin-layer modeling of convective and microwave-convective drying of oyster mushroom (Pleurotus ostreatus). J. Food Sci. Technol. 2015, 52, 2013–2022. [Google Scholar] [CrossRef]

- Midilli, A.; Kucuk, H. Mathematical modeling of thin layer drying of pistachio by using solar energy. Energy Convers. Manag. 2003, 44, 1111–1122. [Google Scholar] [CrossRef]

- Buzrul, S. Reassessment of Thin-Layer Drying Models for Foods: A Critical Short Communication. Processes 2022, 10, 118. [Google Scholar] [CrossRef]

- Yunhong, L.; Yue, S.; Huichun, Y.; Yong, Y.; Xin, L.; Xu, D. Hot air drying of purple-fleshed sweet potato with contact ultrasound assistance. Dry. Technolol. 2017, 35, 564–576. [Google Scholar]

- Erpeng, C.; Jinwei, L.; Liuping, F. Enhancing drying efficiency and quality of seed-used pumpkin using ultrasound, freeze-thawing and blanching pretreatments. Food Chem. 2022, 384, 132496. [Google Scholar]

- Soquetta, M.B.; Schmaltz, S.; Righes, F.W.; Salvalaggio, R.; de Marsillac Terra, L. Effects of pretreatment ultrasound bath and ultrasonic probe, in osmotic dehydration, in the kinetics of oven drying and the physicochemical properties of beet snacks. J. Food Process Preserv. 2018, 42, e13393. [Google Scholar] [CrossRef]

- Jarahizadeh, H.; Dinani, S.T. Influence of applied time and power of ultrasonic pretreatment on convective drying of potato slices. Food Sci. Biotechnol. 2019, 28, 365–376. [Google Scholar] [CrossRef]

- Fernandes, F.; Rodrigues, S. Ultrasound as pre-treatment for drying of fruits: Dehydration of banana. J. Food Eng. 2007, 82, 261–267. [Google Scholar] [CrossRef]

- Khoshhal, A.; Dakhel, A.; Etemadi, A.; Zereshki, S. Artificial Neural Network Modeling Of Apple Drying Process. J. Food Process Eng. 2010, 33, 298–313. [Google Scholar] [CrossRef]

- Murthy, T.K.; Manohar, B. Microwave drying of mango ginger (Curcuma amada Roxb): Prediction of drying kinetics by mathematical modelling and artificial neural network. Int. J. Food Sci. Technol. 2012, 47, 1229–1236. [Google Scholar] [CrossRef]

| Model | Equation | References |

|---|---|---|

| Page | MR = exp(−ktn) | [35,36] |

| Modified Page | MR = exp(−(kt)n)) | |

| Weibull | MR = exp((−t/α)β) | |

| Modified two-term | MR = a*exp(−k*t) + (1 − a)*exp (−k*a*t) |

| Model | US Power/% | R2 | RMSE |

|---|---|---|---|

| Page | 0 | 0.9995 | 0.0010 |

| 30 | 0.9623 | 0.0056 | |

| 60 | 0.9784 | 0.0051 | |

| 90 | 0.9442 | 0.0078 | |

| Modified Page | 0 | 0.9990 | 0.0015 |

| 30 | 0.9624 | 0.0062 | |

| 60 | 0.9790 | 0.0060 | |

| 90 | 0.9457 | 0.0083 | |

| Weibull | 0 | 0.9990 | 0.0006 |

| 30 | 0.9917 | 0.0011 | |

| 60 | 0.9974 | 0.0020 | |

| 90 | 0.9940 | 0.0019 | |

| Modified two-term | 0 | 0.9997 | 0.0018 |

| 30 | 0.9602 | 0.0035 | |

| 60 | 0.9762 | 0.0029 | |

| 90 | 0.9418 | 0.0054 |

| Model | US Power/% | R2 | RMSE |

|---|---|---|---|

| Page | 30 | 0.9981 | 0.0018 |

| 60 | 0.9675 | 0.0044 | |

| 90 | 0.9334 | 0.0178 | |

| Modified Page | 30 | 0.9957 | 0.0014 |

| 60 | 0.9652 | 0.0033 | |

| 90 | 0.9314 | 0.0081 | |

| Weibull | 30 | 0.9991 | 0.0015 |

| 60 | 0.9933 | 0.0025 | |

| 90 | 0.9978 | 0.0042 | |

| Modified two-term | 30 | 0.9929 | 0.0030 |

| 60 | 0.9635 | 0.0187 | |

| 90 | 0.9373 | 0.0231 |

| Model | US Power/% | R2 | RMSE |

|---|---|---|---|

| Page | 30 | 0.9801 | 0.0029 |

| 60 | 0.9860 | 0.0043 | |

| 90 | 0.9421 | 0.0082 | |

| Modified Page | 30 | 0.9759 | 0.0033 |

| 60 | 0.9814 | 0.0027 | |

| 90 | 0.9373 | 0.0195 | |

| Weibull | 30 | 0.9952 | 0.0019 |

| 60 | 0.9906 | 0.0014 | |

| 90 | 0.9968 | 0.0034 | |

| Modified two-term | 30 | 0.9747 | 0.0034 |

| 60 | 0.9816 | 0.0027 | |

| 90 | 0.9288 | 0.0109 |

| US Power/% | Sonication Time/min | Total Color Change/ΔE |

|---|---|---|

| 30 | 30 | 3.95 ± 0.98a |

| 30 | 45 | 4.11 ± 1.19b |

| 30 | 60 | 3.87 ± 0.55a |

| 60 | 30 | 4.26 ± 0.12b |

| 60 | 45 | 4.18 ± 1.07b |

| 60 | 60 | 4.17 ± 1.12b |

| 90 | 30 | 3.63 ± 0.58a |

| 90 | 45 | 3.40 ± 0.57c |

| 90 | 60 | 3.35 ± 0.52c |

| US Power/% | Sonication Time/min | Drying Time/min |

|---|---|---|

| 0 | 0 | 451.67 ± 7.64a |

| 30 | 30 | 361.67 ± 2.89b |

| 30 | 45 | 356.66 ± 2.89c |

| 30 | 60 | 351.67 ± 2.89c |

| 60 | 30 | 358.33 ± 2.89b |

| 60 | 45 | 346.67 ± 2.89c |

| 60 | 60 | 343.33 ± 2.89c |

| 90 | 30 | 349.00 ± 5.00d |

| 90 | 45 | 322.33 ± 2.89e |

| 90 | 60 | 320.67 ± 2.89e |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karlović, S.; Dujmić, F.; Brnčić, S.R.; Sabolović, M.B.; Ninčević Grassino, A.; Škegro, M.; Šimić, M.A.; Brnčić, M. Mathematical Modeling and Optimization of Ultrasonic Pre-Treatment for Drying of Pumpkin (Cucurbita moschata). Processes 2023, 11, 469. https://doi.org/10.3390/pr11020469

Karlović S, Dujmić F, Brnčić SR, Sabolović MB, Ninčević Grassino A, Škegro M, Šimić MA, Brnčić M. Mathematical Modeling and Optimization of Ultrasonic Pre-Treatment for Drying of Pumpkin (Cucurbita moschata). Processes. 2023; 11(2):469. https://doi.org/10.3390/pr11020469

Chicago/Turabian StyleKarlović, Sven, Filip Dujmić, Suzana Rimac Brnčić, Marija Badanjak Sabolović, Antonela Ninčević Grassino, Marko Škegro, Marko Adrian Šimić, and Mladen Brnčić. 2023. "Mathematical Modeling and Optimization of Ultrasonic Pre-Treatment for Drying of Pumpkin (Cucurbita moschata)" Processes 11, no. 2: 469. https://doi.org/10.3390/pr11020469

APA StyleKarlović, S., Dujmić, F., Brnčić, S. R., Sabolović, M. B., Ninčević Grassino, A., Škegro, M., Šimić, M. A., & Brnčić, M. (2023). Mathematical Modeling and Optimization of Ultrasonic Pre-Treatment for Drying of Pumpkin (Cucurbita moschata). Processes, 11(2), 469. https://doi.org/10.3390/pr11020469