1. Introduction

With the rapid advancement of nano-technologies, the number of chips used in devices is continuously increasing and leading to high circuit complexity. This increases the requirement of heat dissipation in a very small area of electronic devices such as processors. That leads to an overheating problem which is one of the main reasons for electronic chip damage. As a result, using liquid (water), air, and hybrid air-water cooling systems become necessary. However, these types of cooling systems are not effective in the cooling process due to rapid more in technology development. In addition, it is necessary to explore an alternative and effective method rather than conventional ones to remove a significant amount of heat transfer. Tuckerman and Pease [

1], in 1981, first proposed the MCHS, which is one of the most convenient methods for effective cooling electronic devices. In the very beginning, pure water in a single phase is used as a coolant, and a significant heat transfer enhancement was achieved. For instance, the generated heat flux reaching 790 W/cm

2 is dissipated. Additionally, it is reported that decreasing the width of the microchannel leads to improving convective heat transfer. On the contrary, due to more technological improvements, the usage of pure water as a coolant in MCHS has not become effective. Therefore, it is important to find alternative ways to improve heat transfer dissipation that can compete with quick technology improvements.

The most common channel is the straight rectangular MCHS, which is inadequate to absorb the total heat generated by micro-scale chip devices. Therefore, Chen et al. [

2] studied numerically different configurations of microchannels, such as the rectangular, trapezoidal, and triangular microchannels, and their effect on heat transfer characteristics. The average Nusselt number, Poiseuille number, temperature, and thermal efficiency are the key parameters of this study. It is revealed that the Nusselt number has the highest value at the microchannel inlet and then significantly decreases to be a fully developed constant value for all configurations, while the triangular shape achieves the maximum thermal efficiency (thermal efficiency: heat transfer rate to the rate of power consumption) among the three configurations. The effect of different microchannel configurations on heat transfer characteristics and laminar flow was numerically investigated for a low range of Reynolds numbers from 100–1000 by Gunnasegaran et al. [

3]. Rectangular, trapezoidal, and triangular are the main shapes in this study. It is found that at the smallest hydraulic diameter, better uniformities in the temperature and heat transfer coefficient can be achieved. Additionally, the smallest hydraulic diameter offers lower pressure drop as well as power consumption. The highest heat transfer coefficient and Poiseuille number are achieved for a rectangular microchannel, while the lowest values are for the triangular configuration. The pressure drop is studied at different heat fluxes of 100, 500, and 1000 W/m

2, and it is found that increasing heat flux leads to increased pressure drop.

A 3-D numerical simulation of laminar water flow through a grooved microchannel aluminum heat sink is studied by Ahmed and Ahmed [

4]. A constant wall heat flux forced convection heat transfer, and different cavity shapes (rectangular, triangular, and trapezoidal) are used as key parameters under investigation. It is found that a trapezoidal groove with a groove pitch ratio of 3.334, tip length ratio of 0.5, and groove depth ratio of 0.4 gives a significant improvement in flow and heat transfer characteristics. For example, Nusselt number improvement is 51.59% while the friction factor enhancement is 2.35%.

On the other hand, the thermal conductivity of the coolant is a crucial parameter that affects the improvement of the heat transfer characteristics [

5]. Choi and Eastman [

6] explored a new type of coolant that is called nanofluid, which can be formed by mixing nanoparticles of metallic substance with traditional heat transfer base fluids, such as pure water. This mixture produces nanofluids with new and good thermal properties (such as thermal conductivity) compared with those of base fluids. Godson et al. [

7] reported that the increase of nanofluid thermal conductivity leads to significant enhancement of the cooling process. In addition, Tokit et al. [

8] mentioned that the Brownian motion, which plays a vital role in helping the nanoparticle cluster formation, is considered the main reason for high thermal conductivity. In addition, Das et al. [

9] showed that using CuO-H

2O leads to an increase the thermal conductivity from 14% to 36%, which causes a significant effect on heat transfer characteristics.

Salman et al. [

10] studied the effect of mixing different types of nanoparticles (CuO, Al

2O

3, ZnO, and SiO

2) mixed with ethylene glycol as a base fluid at different volume concentrations, sizes, and Reynolds numbers. Salman et al. reported that increasing the volume fraction of nanoparticles leads to improvement in the cooling process while increasing the nanoparticle diameters inversely affects the heat transfer for all cases. Additionally, Nguyen et al. [

11] found that using a 6.8% volume fraction of Al

2O

3–H

2O nanofluid leads to an increase in the coefficient of heat transfer by 40% compared with base fluid (pure water). The same nanofluid of Nguyen et al.’s study is used by Elbadawy and Fayed [

12] to study the effect of Al

2O

3–H

2O flow through single and double-stack MCHS. Constant heat flux (q = 10

6 W/m

2), laminar flow (Re = 200–1500), and different nanoparticle concentrations (φ = 1–5%) are the main parameters under investigation. Elbadawy and Fayed [

12] evaluate how much volume reduction is obtained caused by the improvement in nanofluid thermal conductivity as well as the characteristics of heat transfer. It is reported that a 62.6% size reduction was achieved for a single channel row at a 5% nanoparticle concentration. Mohamed et al. [

13] investigated the effect of different nanoparticles (Al

2O

3, diamond, TiO

2, SiO

2, Ag, and CuO) with base fluid (pure water) and triangular microchannel on fluid flow and heat transfer characteristics. Heat transfer coefficient, pressure drop, power, and thermal resistance are used as key parameters. Diamond-H

2O leads to the lowest temperature and highest heat transfer coefficient, while the highest and lowest pressure drop occurred for SiO

2–H

2O and Ag–H

2O, respectively. Finally, it is worth mentioning that nanofluids and hybrid nanofluids have been investigated for different geometries along with the impact of different physical parameters; these include the porous media effect, rarefied flows, and magnetohydrodynamics [

14,

15,

16,

17,

18,

19,

20,

21,

22,

23].

Through an extensive survey of the literature, it is aimed that prior work related to the computational investigation of nanofluids, the heat transfer, and flow through MCHS using different nanofluids and different MCHS configurations are carefully and extensively investigated. Therefore, Al

2O

3–H

2O, SiO

2–H

2O, and TiO

2–H

2O and different MCHS configurations (rectangular, trapezoidal, triangular, and circular) are numerically investigated. In addition, the different volume fractions of nanoparticles (1% to 7%) and laminar flow (Re = 890 to 1500) are used. The heat transfer coefficient, pressure drop along the channel, and thermal efficiency are used as key parameters using the CFD software (ANSYS-Fluent 18.2) [

24].

3. Results and Discussion

The coolant temperature along the centerline is used as a key parameter to investigate the mesh sensitivity. Three different mesh levels (Mesh 1, Mesh 2, and Mesh 3) of cell volumes (20, 40, and 60 μm

3, respectively) are used. Pure water at constant heat flux, q = 10

6 W/m

2, and Re = 890 are applied in this study.

Figure 5 indicates that the predicted center line temperature is mesh-independent. The figure indicates that the centerline temperature results are very close for all meshes, with the differences in local temperature being less than 0.5%. Additionally, due to small differences in the run time for all cases, all reported subsequent results have been obtained using the smallest cell volume (Mesh 1) to increase the accuracy and resolution of the results. On the other hand, the experimental data obtained by Qu and Mudawar [

33] and Arulprakasajothi et al. [

34] are used to examine the current numerical results’ validity for pure water [

33] and TiO

2/water nanofluids [

34]. The heatsink temperature distribution along the line that is parallel to the microchannel centerline is used for validity purposes using Qu and Mudawar’s data. While Nusselt number variation with Reynolds number is used for verification purposes using Arulprakasajothi et al.’s data [

34]. In the validation study, the model is a rectangular MCHS configuration with channel height, width, hydraulic diameter, and length of 713 μm, 231 μm, 348.9 μm, and 44.764 mm, respectively. The experimental data [

33] for a temperature measured by thermocouples along an x-y plane and four different locations at the height of 3175 μm, shown in

Figure 6a, are obtained at a constant heat flux of q = 10

6 W/m

2, T

in = 288 k, and Re = 890.

Figure 6 indicates an acceptable agreement between the CFD (current work) and the experimental data [

33,

34]. Thus, the current model is trusted and can be applied to investigate different nanofluids as a coolant and different microchannel configurations and their effects on the flow and heat transfer characteristics of an MCHS.

3.1. Different Nanofluid

Various nanofluids, such as Al

2O

3–H

2O, SiO

2–H

2O, and TiO

2–H

2O, are investigated using rectangular MCHS. The volume concentration of different nanoparticles ranging from 1% to 7% at Reynolds numbers ranging from 890 to 1500 is studied.

Figure 7 shows the effect of Re on the heat transfer coefficient for different concentrations of Al

2O

3 nanoparticles. The heat transfer coefficient (represented values are in 10 thousand) for all concentrations increased with increasing Reynolds number and was significantly higher than the pure water. The results showed that the larger percentage of Al

2O

3 nanoparticles contributes to the higher heat transfer coefficient. For example, at Re = 1500 and

, the heat transfer coefficient reached the highest value with an increment of 8.58% compared to pure water. In

Figure 8, the effect of both Re and

on the average heat transfer coefficient “h” is more conventionally shown by plotting the normalized heat transfer coefficient that is a non-dimensional quantity,

, with Re, where

and

represent the average heat transfer coefficient of both nanofluid and base fluid (water), respectively. The normalized heat transfer coefficient significantly increased with nanofluid concentration and was nearly constant with Re numbers. As observed, a greater normalized heat transfer coefficient improvement is achieved at the higher concentration. For instance, at Re = 890 and

7%, a 9.89% increase in heat transfer coefficient improvement was indicated. This means that adding more nanoparticles leads to a better cooling process.

The pressure drop profile for different concentrations of Al

2O

3 nanoparticles is shown in

Figure 9. From this figure, the relation between pressure drop and Reynolds number at different concentrations can be observed. The figure indicates that the pressure drop rises linearly with the Reynolds number. It is also observed that the pressure drop increases with increasing nanoparticle concentration. For example, the maximum pressure drop occurred at

and Re = 1500. The percentage of pressure drop increment at

compared with pure water is 12.4%. This increment is due to the increase of nanofluid dynamic viscosity compared with the corresponding value for pure water.

A comparison between different nanofluids is drawn for Al

2O

3–H

2O, SiO

2–H

2O, and TiO

2–H

2O at different Re numbers and nanoparticle concentrations.

Figure 10a,b shows the heat transfer coefficient variation of Al

2O

3–H

2O, SiO

2–H

2O, and TiO

2–H

2O at different Re for

1% and

7%. It can be inferred that all nanoparticles have the same linear increasing trend with Re. Comparing the heat transfer coefficient of pure water at Re = 890 and nanofluids at

1%, it was found that the heat transfer coefficients for Al

2O

3, TiO

2, and SiO

2 increased by 1.48%, 1.33%, and 0.81%, respectively. While the corresponding heat transfer coefficient increment at Re = 890 and

7%, shown in

Figure 10b, are 9.82%, 8.87%, and 5.04% for Al

2O

3, TiO

2, and SiO

2, respectively. As a result, the maximum heat transfer coefficient is obtained by Al

2O

3–H

2O at all concentrations.

Figure 11a,b shows the relationship between the pressure drop and Re for the three different nanofluids mentioned above, at

1% and

7%, respectively. It is found that by increasing the Reynolds number, the pressure drop increases with the maximum pressure drop for SiO

2 compared with pure water. Additionally, both figures indicate that there is a slight difference between the pressure drop for both Al

2O

3 and TiO

2. In more detail, the increment of pressure drops for SiO

2, TiO

2, and Al

2O

3 are estimated to be 3.67%, 1.84%, and 2.02% compared with pure water, respectively. The corresponding increments of pressure drop at

7%, shown in

Figure 11b, are 21.45%, 14.22%, and 12.99% for SiO

2, Al

2O

3, and TiO

2, respectively. As a result, an increase in the concentration of nanoparticles leads to an increase in the viscosity of the nanofluids as well as the friction factor and pressure drop.

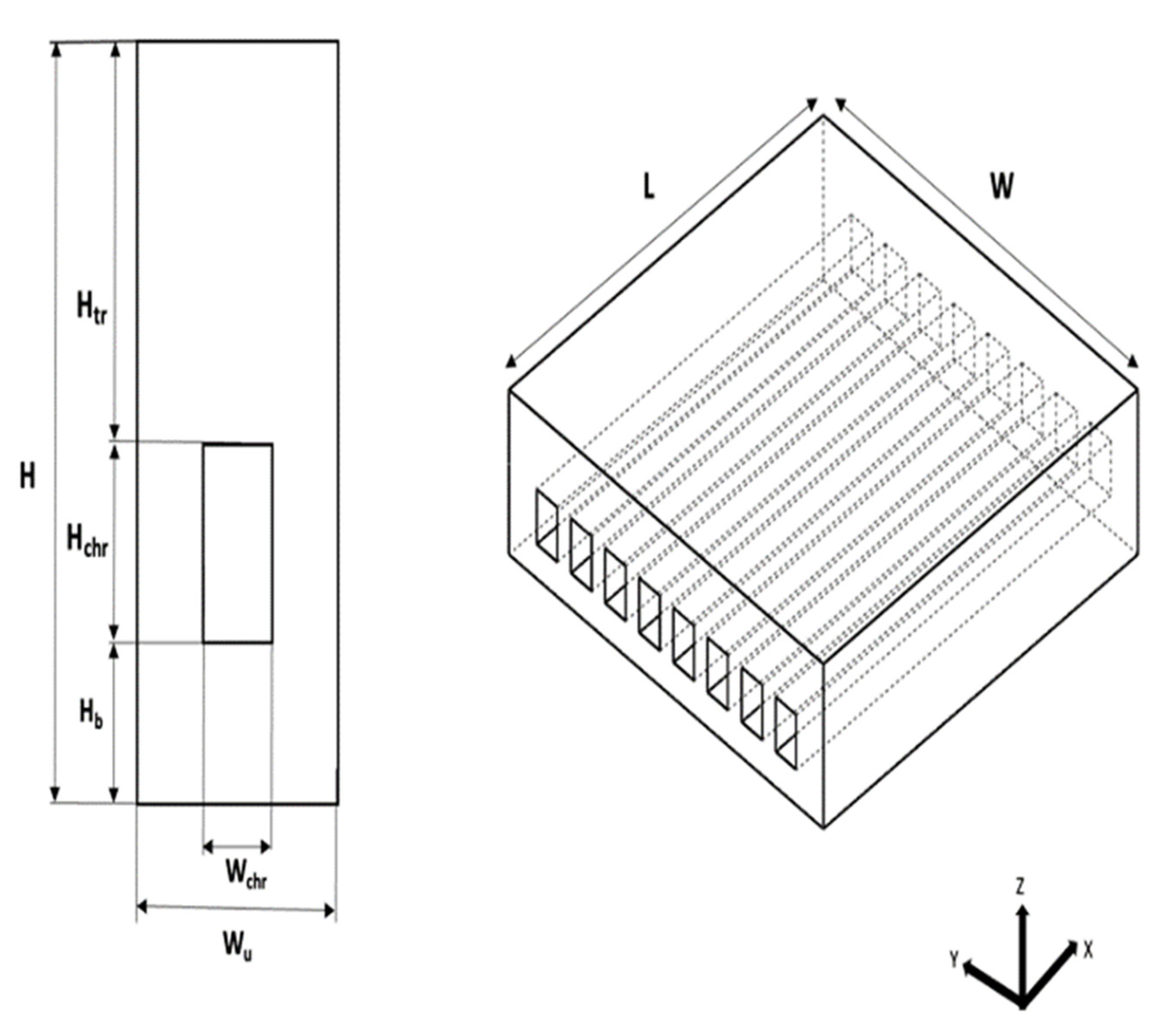

3.2. Different MCHS Configurations

As discussed in

Section 3.1, the Al

2O

3–H

2O achieves the highest average heat transfer coefficient; therefore, this type of nanofluid is used to investigate the different configurations of MCHS, shown in

Figure 1,

Figure 2,

Figure 3 and

Figure 4. The average heat transfer coefficient, pressure drop, and thermal efficiency are used as key parameters to evaluate the suitable configuration that achieves the best heat transfer rate.

Figure 12 represents the effect of both Re and different MCHS configurations (rectangular, trapezoidal, triangular, and circular) on the average heat transfer for (a)

= 1% and (b)

= 7%. The pure water (

= 0%) results are shown in

Figure 12 as solid lines for clear comparison and evaluation. The heat transfer coefficient for all geometrical configurations increases with both Re and

. According to the figure, the maximum and minimum heat transfer coefficients are obtained for triangular and circular configurations, respectively, while the trapezoidal and rectangular are sandwiched between triangular and circular geometry. For example, at Re = 890 and

7%, the heat transfer coefficient increments of triangular, rectangular, trapezoidal, and circular increases by 7.473%, 9.889%, 8.941%, and 10.951% compared with pure water of the same configurations, respectively. As a result, different MCHS configurations significantly affected the heat transfer properties. The triangular configuration is considered the best configuration that results in the greatest heat transfer coefficient.

Figure 13 shows the variation of pressure drop across the MCHS for different configurations and different Reynolds numbers at (a)

1% and (b)

7%. It is clearly shown that the pressure drop rises with both Re and

. Triangular MCHS causes the highest pressure drop compared to the other configurations. The pure water flows through the rectangular MCHS and is used as a reference value to evaluate the other configurations and nanofluids. For example, at Re = 890 and

1%, the pressure drop increase of the triangular domain was 2.3 times more than that of pure water in the rectangular MCHS. On the contrary, the circular domain at Re = 890 showed an increase of 0.52 times more than that of the same reference. While at

7%, indicated in

Figure 13b, the pressure drops of triangular and circular MCHS increased by 2.72 and 0.46 times compared with the pure water of the rectangular MCHS, respectively. The reason for the above results can be due to the hydraulic diameter, where the hydraulic diameter (Equation (12)) of a triangular shape is smaller than the circular one.

In order to give a clear understanding of the effect of different configurations of MCHS on the heat transfer and flow characteristics, the thermal efficiency (Equation (14)), which is the ratio between the heat transfer rate and the power consumption, is introduced as follows:

Figure 14 shows the thermal efficiency of all configurations. As shown in the figure, the maximum and minimum thermal efficiency are achieved by the circular and triangular MCHS, respectively. However, triangular MCHS leads to the maximum heat transfer coefficient, but at the same time, it has a maximum hydraulic diameter that leads to a high-pressure drop. According to these results, it is very important to understand that nanofluids have advantages related to heat transfer and disadvantages related to power consumption. In summary, the higher the volume of nanoparticle concentration, the higher the heat transfer coefficient and the higher the pressure drop.