Abstract

Olive cake, the solid byproduct of three-phase centrifugation olive oil production, has a high organic and polyphenol content, rendering it an environmental threat when landfilled as well as limiting its animal feed potential. This residue can be a good candidate for biomethane production due to its rich polysaccharide content (pectin, hemicellulose, and cellulose). Two strategies were compared to maximize biomethane production: destoning (i.e., removal of the seed fragments via mechanical means) and enzymatic pretreatment of the pulp. After 30 days of batch anaerobic digestion at 35 °C, both enzymatically pretreated and destoned olive cakes produced similar amounts of methane (~295 mL CH4/g volatile solids (VS)), 42% more than the control. A comparison of olive cake’s biomethane yields with a broad range of agricultural residues in the literature demonstrated its suitability for biomethane production. Additionally, the digestate recovered from the anaerobic digestion of olive cake had high Kjeldahl nitrogen contents (3.6%, db) and low polyphenol concentrations (0.02 mg gallic acid equivalent (GAE)/g), qualifying it as an ingredient for soil amendment. This study demonstrated olive cake can be diverted from landfills for second-generation biofuel production, and that the resulting digestate may have value for soil amendment.

1. Introduction

In the past 60 years, global olive oil production has tripled, reaching 3,010,000 metric tons in the 2020/2021 season [1]. This growing consumer interest can be attributed to the population’s awareness of the possible health benefits of olive oil consumption including, but not limited to, the improvement of cardiometabolic markers and decreased instances of cardiovascular disease [2]. However, this steady increase in demand and production heralds major environmental challenges. While many large olive oil producers utilize the more environmentally friendly two-phase centrifugation systems, the older three-phase systems are widely used owing to the prohibitive cost of upgrading [3]. Under a three-phase centrifugation system, every ton of raw olives (including leaves which are removed in the process) produces approximately 170 kg of olive oil, leaving 480 kg of olive cake (solid waste consisting of pulp and stone from the olive fruit) and 290 kg of olive mill wastewater (liquid waste rich in residual oil and polyphenols) to be disposed of [4].

The disposal of the solid waste that results from three-phase centrifugation, olive cake, can be challenging. The olive cake has little value as an animal feed due to its high polyphenol content and the presence of highly lignified olive stones. Olive cake is also challenging to use as a sole composting source due to its phytotoxicity and phenolic content, which considerably impedes its degradation [5]. Its disposal in landfills not only contributes to GHG emissions but can also be costly for olive oil processors due to hauling and tipping fees. Thus, it is common in Mediterranean countries to combust the solid waste for heat and energy. High in calorific power (400 kcal/kg) [6], dried olive cake produces a gas rich in carbon and carbon monoxide when burned to recover energy, contributing to greenhouse gas (GHG) emissions [7].

The quest for sustainable energy remains unsolved and one of the most challenging issues of the 21st century. Production of biogas through anaerobic digestion is one potential path that is being investigated. Anaerobic digestion is a millennia-old biofuel production method that uses a mixture of microorganisms in four sequential steps (hydrolysis, acidogenic fermentation, acetogenesis, and methanogenesis) to treat and convert organic substrates into biogas. The produced biogas primarily consists of carbon dioxide and biomethane [8]. Biomethane can then be upgraded to renewable natural gas or be burned for heat and electricity, offsetting energy costs and producing carbon credits (tradable permits that allow a certain amount of carbon emissions). Anaerobic digestion is capable of offsetting 28% of the GHG emissions from olive oil production compared to combusting olive cake for energy to aid in the solvent extraction of olive pomace oil, a common activity in the Mediterranean olive oil industry, which only offsets 17% [9]. Furthermore, the stabilized digestate produced from the anaerobic digestion of various byproducts including, but not limited to municipal waste, agricultural residues, and manures, is a liquid effluent rich in nitrogen and fiber that has applications in agriculture as fertilizer [10].

Anaerobic digestion of both first- and second-generation biomasses has been previously investigated. Agricultural residues and food wastes, such as olive cake, belong to the second generation. Generally, second-generation biomasses have high concentrations of lignin in the form of lignocellulose. Lignocellulose content is inversely proportional to a substrate’s methane potential [11]. One advantage olive cake has over traditional second-generation biofuel feedstocks such as corn stover is the fruit’s phytotomy. A drupe, olive fruit is characterized by a thin epicarp, a fleshy mesocarp that holds the oil, and a highly lignified endocarp (stone) that contains the seed [12]. Thus, the indigestible lignin in olives is concentrated in the endocarp, which can be physically removed. Conversely, corn stover often requires chemical pretreatment to solubilize the lignin. In addition, enzymes have been reported to be a powerful tool to solubilize hemicellulose and cellulose into simpler, fermentable carbohydrates [13]. Based on olive cake’s rich composition of polysaccharides, such as arabinans, cellulose, and hemicellulose, olive cake from a three-phase olive mill is a suitable candidate for enzymatic pretreatment to supplement anaerobic digestion.

As the presence of stones has no effect on the olive oil quality and aids oil extraction during crushing, stones are removed from the cake after oil extraction, if at all. They can be used for energy recovery, carbon sequestration, and as an additive for cement lime mortar or heavy metal sorption [14,15,16]. The last three options represent a more sustainable alternative for their use. The separation of the stones is conducted by gravitational methods, using cyclones that separate the lighter pulp from the heavier stone fragments [17]. Large and costly, cyclones represent an additional financial investment that can be a pitfall for small olive producers.

The objectives of this study were two-fold. The first was to perform a biomethane potential (BMP) assay, a batch test used to evaluate the biogas volume and composition generated from the anaerobic digestion of olive cake to yield a specific methane yield (SMY) of the agricultural residue. Biomethane potential assays allow for comparisons to be made between the SMY of various feedstocks. The value of batch tests may seem confirmatory at first as olive mill wastes have already made great strides as a potential biofuel feedstock with many studies focusing on co-digestion with traditional feedstocks [18,19] and other studies already moving towards continuous systems [3]. Such experiments utilize parameters that are not standardized and are difficult to replicate laboratory to laboratory, leaving possible comparisons of biomethane yields between olive cake and other agricultural residues with much to be desired. Batch digestions are not yet completely precluded from a lack of standardization and reproducibility [20], but the amount of control one has over the experiment makes the BMP assay the best option in evaluating a feedstock’s biomethane potential. The second objective was to investigate whether the mechanical removal of the stones and an enzymatic pretreatment would increase the biomethane potential of olive cake. It was hypothesized that a higher SMY would be obtained by (1) the mechanical removal of the stone fragments, which would decrease the lignin content and increase the relative volume of pulp loaded into the digestion vessel compared to olive cake that still contained stones; and (2) enzymatic hydrolysis of the pulp with a carbohydrase cocktail to convert polysaccharides into fermentable sugars.

First, the destoning efficiency (the mass percentage of stones separated from the olive cake) of a centrifuge was compared to the one of a horizontal screw press (HSP) equipped with a mesh screen to determine which destoning method would be utilized for the anaerobic digestion experiments. The SMY of four types of olive cake were assayed: olive cake diluted with tap water (DOC) representing the control, an enzymatically pretreated diluted olive cake (EDOC), a destoned diluted olive cake (DDOC), and diluted olive cake that was destoned and then enzymatically pretreated (DEDOC). Co-digestion with other residues was not considered as the objective of this study was to determine the biomethane potential of olive cake from three-phase systems, so it could be compared with literature values of agricultural residues, in particular, olive pomace from a two-phase centrifuge. To our knowledge, this is the first BMP assay of enzymatically pretreated olive solid waste originating from a three-phase centrifuge.

2. Materials and Methods

2.1. Substrate and Inoculum

The olive cake was obtained from a processing plant located in Santa Margarita (CA, USA), which utilized a three-phase centrifuge and came from Arbosana olives. The cake was stored in the dark at −20 °C until further processed. The inoculum used for anaerobic digestion was digested wastewater sludge (35 °C, 60-day hydraulic residence time) from a municipal wastewater treatment facility (San Luis Obispo Water Resource Recovery Facility (SLO WRRF), CA, USA). The inoculum was stored in an incubator at 35 °C until used.

2.2. Experimental Design

2.2.1. Enzymatic Pretreatments

The olive cake (pH 4.3) was first diluted with 56 °C tap water at a 2:3 w/w, tap water/olive cake (as is) ratio. The enzymatic pretreatment involved a cocktail of four enzymes for a total of 1.6% w/w (db, each): 0.4% w/w cellulase (powder; activity 100,000 CU/g; optimum pH 4–6.5, temperature 30–70 °C), 0.4% w/w hemicellulase (powder; activity 400,000 HCU/g; optimum pH 2–8, temperature 25–90 °C), 0.4% w/w xylanase (powder; activity 100,000 XU/g; optimum pH 3.5–6.5, temperature 40–65 °C), and 0.4% w/w pectinase (powder; activity 8000 ENDO-PG/g; optimum pH 2–4, temperature 30–60 °C), from BIO-CAT (Troy, VA, USA). Enzymatic activities were provided by the manufacturer along with assay protocols: locust bean gum assay for hemicellulase activity, viscosimetric determination of carboxymethyl cellulose for cellulase activity, a turbidometric assay for xylanase activity following the protocol established in Bailey and Poutanen (1989) [21], and an endo-polygalacturonase assay for pectinase activity.

After enzyme addition, diluted samples (2.5 kg) were shaken in a MaxQ 5000 Floor-Model Shaker (Thermo Fisher Scientific, Waltham, MA, USA) for 24 h at 56 °C and 150 rpm. After shaking, enzymatically pretreated cakes (EDOC) were stored in the dark at −20 °C or immediately destoned.

2.2.2. Destoning by Horizontal Screw Press (HSP) and Centrifugation

To determine the destoning (seed and pit removal) method for subsequent experiments, diluted, enzymatically pretreated olive cakes (EDOC) were centrifuged or submitted to mechanical stone removal via a HSP equipped with a mesh screen.

For the preparation of the centrifuged samples, 950 ± 25 mL of EDOC was centrifuged in a 1 L bottle (JLA—9.1, Beckman Coulter, Brea, CA, USA) at 100, 200, or 3000× g for 5 min. The supernatant, which was poured off, was called destoned and enzymatically pretreated diluted olive cake by centrifugation (DEDOC-C).

Mechanical stone removal consisted of immediately processing EDOC through a HSP (Leeson Model C145T17FB60D) equipped with a 0.71 mm mesh screen and running at 500 rpm. The liquid stream was collected and run through the HSP two more times. The resulting slurry was called destoned, enzymatically pretreated diluted olive cake by HSP (DEDOC-H). The stream that contained the stones was collected and stored away.

Total solids (TS) of the pretreated olive cakes were determined using standard techniques [22]. Determination of the percentage of stones removed was calculated by decanting a 200 g (as is) aliquot of DEDOC-C100, DEDOC-C200, DEDOC-C3000, DEDOC-H, or EDOC (the control). Stones were collected from the bottom of the container and dried for 72 h at 100 °C. For the comparison of centrifugation and HSP, the percentage of stones removed was calculated as:

2.3. Anaerobic Digestion

2.3.1. Mechanical and Enzymatic Pretreatment of Olive Cake

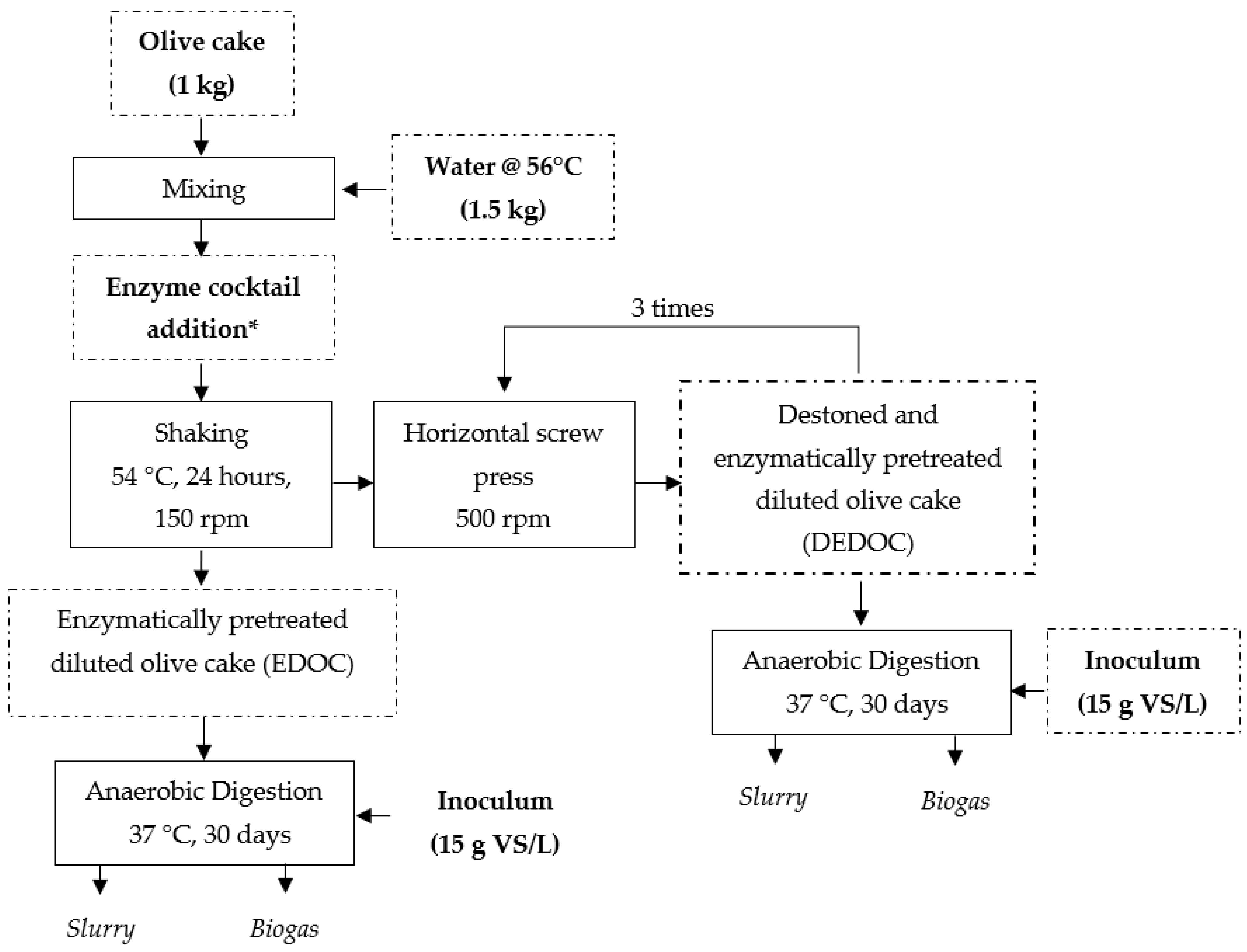

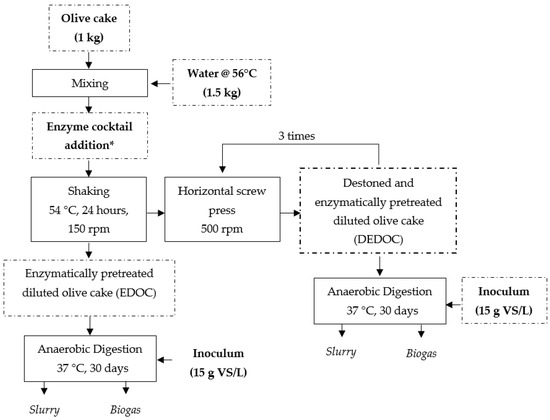

Figure 1 summarizes the pretreatment process for the olive cakes that underwent anaerobic digestion. The method described in 2.2.1 was used to produce the EDOC and the HSP was used to obtain the DEDOC. Control (DOC) and destoned olive cakes (DDOC) were similarly prepared but without the addition of the enzyme cocktail. For the DDOC, after the shaking process, the olive cakes were immediately submitted to mechanical stone removal by HSP according to the method laid out in Section 2.2.2. All the pretreated olive cakes were stored in the dark at −20 °C and thawed overnight at 4 °C before use. The abbreviations used and a summary of the pretreatment applied to the olive cakes for the anaerobic digestion experiment can be found in Table 1.

Figure 1.

Experimental flow chart. * Diluted olive cake (DOC, control) and destoned diluted olive cake (DDOC) were obtained without enzymatic addition. Bold and dashed lines indicate feed and intermediate products; italics indicates end products.

Table 1.

Abbreviation guide for the pretreated olive cakes.

2.3.2. Olive Cake Characterization

Total solids (TS) and volatile solids (VS) of the pretreated olive cakes (DOC, DDOC, EDOC, DEDOC) and inoculum were determined using standard techniques [22]. The pH was measured with an EW-59500-81 pH electrode (Oakton, IL, USA). The method described in Section 2.2.2 was followed to determine the mass percentage of stones removed. In this case, the control was the diluted olive cake (DOC). The effect of extended hydration on the mass percentage of stones removed was also studied. Before destoning by HSP, the DOC was either left in the shaker for either 1 h (DDOC T1) or 24 h (DDOC T24).

The olive cakes were freeze-dried in an HR7000-M freeze dryer (Harvest Right, North Salt Lake, UT, USA). Kjeldahl nitrogen was measured with a Kjeltec 8200 (FOSS, Eden Prairie, MN, USA). Lipid content was determined with a Soxtec 2043 (FOSS, Eden Prairie, MN, USA). Cellulose, hemicellulose, and lignin were determined using the Van Soest method with lignin expressed as acid detergent lignin (ADL) [23]. The reducing sugar content of the supernatant was measured after centrifugation at 8000 rpm for 30 min at room temperature with the dinitrosalicylic acid (DNS) method. Glucose was used to obtain a standard curve ranging from 0.8–4.0 mg/mL.

Phenolic compounds were extracted from the olive cakes using an 80% w/v methanol solution. The extract was then defatted with hexane before analysis. Total phenol content of the defatted extract was determined with the Folin-Ciocalteu method and expressed as mg gallic acid equivalent (GAE)/g of extract, as described by Obied et al. (2007) [24]. A standard curve was produced using gallic acid (0.0–5.0 mg/mL).

2.3.3. Biochemical Methane Potential Substrate and Inoculum Loadings

Biochemical methane potential (BMP) assays followed the procedures established by Angelidaki et al. (2009) [25]. Assays were conducted in 165 mL serum bottle digesters, which were filled to a working volume of 100 mL. Triplicate control blanks containing only the inoculum accounted for residual methane production due to the inoculum’s biodegradation. The glucose control determined the upper limit for methane yield. The substrate VS loading for the glucose control and all olive cakes was 7.5 g VS/L, which corresponded to a substrate: inoculum (S:I) ratio of 0.5 by VS. No nutrients or buffers were added and digesters were flushed with N2 gas for a minute before being sealed with butyl septa. The digesters were incubated at 37 ± 2 °C and manually shaken for one minute every day for 30 days. Digesters were prepared in sets of three.

2.3.4. Biogas Analysis

The biogas yield for each digester was volumetrically measured with a liquid displacement method using a graduated cylinder (mL biogas/day). The headspace gas was collected and analyzed with a gas chromatograph (SRI 8610, Torrance, CA, USA) equipped with a thermal conductivity detector (TCD) and a 1.8 m concentric packed column with a 3.18 mm inner column, filled with a proprietary porous polymer mixture and a 6.35 mm diameter molecular sieve outer column (Alltech CTR1, Deerfield, IL, USA). Argon was used as a carrier gas at a flow rate of 16 mL/min. The operating temperature was 55 °C, and 1 mL of the sample was injected in duplicate [22]. The percentage of CH4, CO2, N2, and O2 in the biogas was determined by comparison to standard gases of known purity.

2.3.5. Carbohydrate Profile of Olive Cake and Digestate

Characterization and quantification of the carbohydrate monomers were performed before digestion and on days 0, 15, and 30 with HPLC. To allow for this, one serum bottle in each set of triplicates was taken apart at the mid-point, i.e., after 15 days. The Prominence ultra-fast liquid chromatograph (UFLC) was equipped with an Aminex HPX-87H column (Bio-Rad, Hercules, CA, USA) and the detector used was an Agilent 1200 series refractive index (RI) detector (Santa Clara, CA, USA).

The mobile phase was 0.005 M sulfuric acid running at an isocratic flow rate of 0.6 mL/min. Glucose, xylose, galactose, and arabinose at concentrations of 0.125, 0.25, 0.5, and 1 mg/mL were used as standards. Galactose and xylose had the same retention time [19]. Supernatants were collected from the pretreated olive cakes and were diluted at a 1:9 vol/vol supernatant: nanopure water ratio (Thermo Fischer Scientific, Waltham, MA, USA). Supernatants collected after the olive cake had been combined with the inoculum on days 0, 15, and 30 were not diluted. All the samples were filtered through a 1 mL syringe with a 25 mm, 0.45 µm polyvinylidene fluoride membrane (Thermo Fischer Scientific, Waltham, MA, USA) before 10 µL was injected into the UFLC in duplicate. Peaks were integrated with the LabSolutions Analysis Data System (Shimadzu, Kyoto, Japan).

2.3.6. Digestate Analysis

At the end of the 30-day digestion, the pH and alkalinity of the digestates for all the olive cakes were measured [22]. The digestate of the destoned olive cake (DDOC) and enzymatically pretreated olive cake (EDOC) were dried in a convection oven at 50 ± 5 °C for 72 h. Kjeldahl nitrogen, lipid content, sequential fiber, and total phenolic determinations were performed as described in Section 2.3.2. The gross heat of combustion was measured using a Parr 1241 Oxygen Bomb Calorimeter and 1180 Oxygen Combustion Bomb (Moline, IL, USA) following methods N°203M [26].

2.4. Calculations

The Buswell formula (Equations (1) and (2)) was used to calculate the theoretical methane yield (TMY, mL CH4/g VS) for the glucose control with N, a, and b equal to 6, 12, and 6, respectively [27]:

CnHaOb + (n − a/4 − b/2) H2O → (n/2 − a/8 + b/4) CO2 + (n/2 + a/8 − b/4) CH4

TMY = (22.4 × 1000 × (n/2 + a/8 − b/4))/(12n + a +16b)

Using Equation (2), the TMY of glucose is 373.5 mL CH4/g VS at standard temperature and pressure.

The specific methane yield (mL CH4/g VS), the normalized amount of methane produced by the substrate, was calculated by subtracting the methane yield of the inoculum blank (mL CH4 inoculum) from the methane yield of each substrate (mL CH4 substrate). The resulting value was divided by the mass of the substrate VS added to the digester (Equation (4)).

SMY = (mL CH4 substrate − mL CH4 inoculum)/(g VS substrate added)

2.5. Statistical Analysis

Proximate analysis of the olive cakes and the comparison between stone removal by HSP and centrifuge were performed in triplicate. All the other experiments were run in at least duplicate. Average values were reported. JMP software (Cary, NC, USA) was used for the analysis of variance (ANOVA) and to perform Tukey’s honest significant different (HSD) test with a critical significance level of 0.05.

3. Results and Discussion

3.1. Stone Removal, and Total Solid Distribution with Horizontal Screw Press (HSP) or Centrifugation

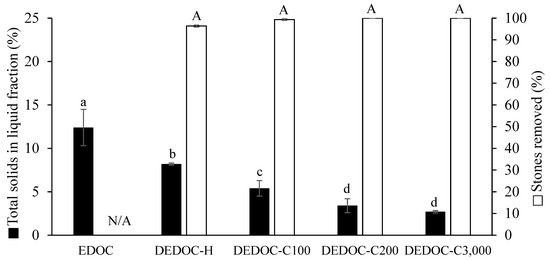

The comparison of destoning by an HSP equipped with a mesh screen versus a centrifuge was performed on the enzymatically pretreated diluted olive cake (EDOC). The purpose of mechanical pretreatment was to remove as many of the stone fragments as possible while retaining the maximum amount of the digestible solids in the liquid fraction for subsequent anaerobic digestion.

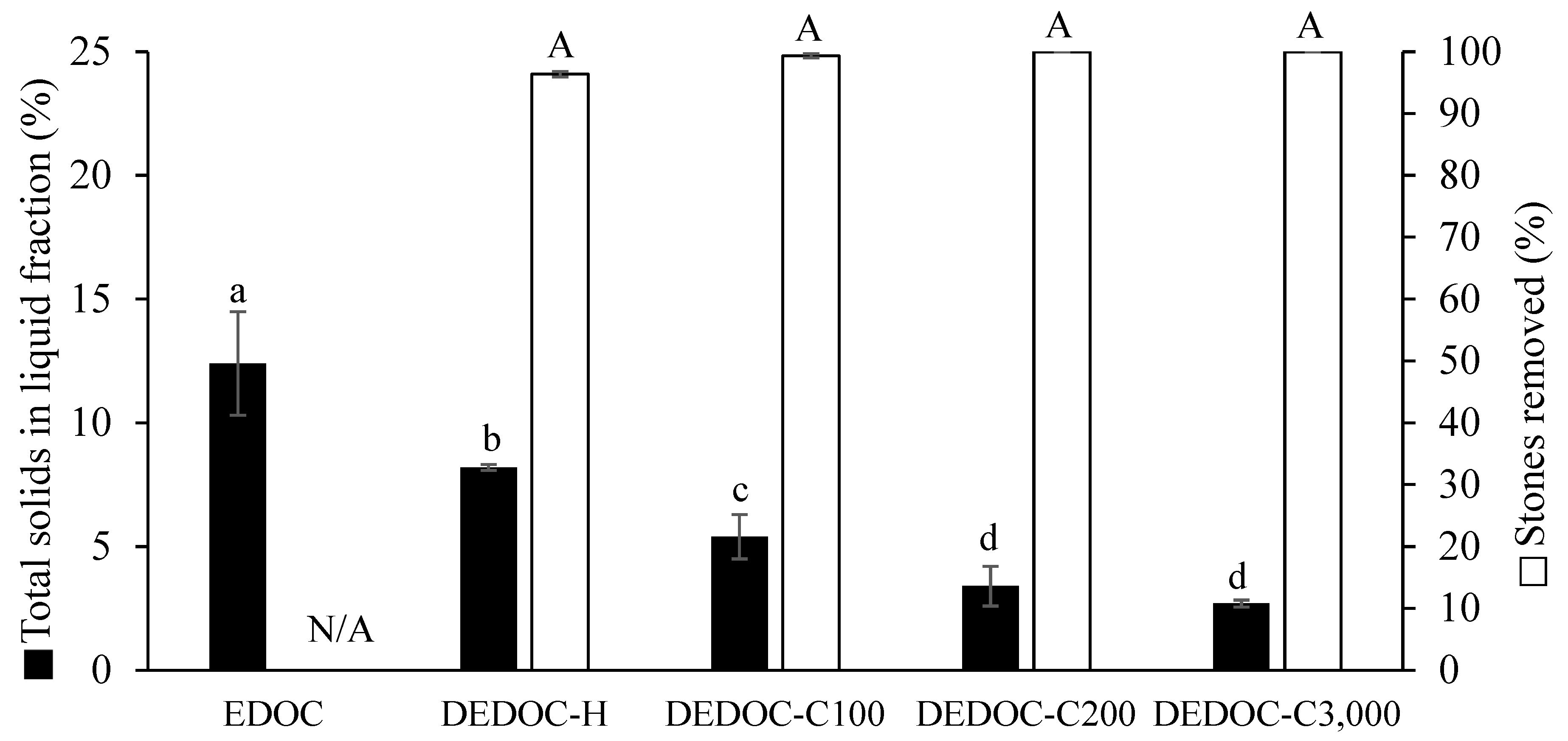

Both HSP and centrifuge, regardless of centrifugal speed, removed over 95% of the stones (Figure 2). A lower stone removal percentage of 84% was reported after steam treatment for 135 s at 234 °C or 193 °C [28]. In addition to removing a lower percentage of stones from the olive cake, HSP and centrifugation have the advantage of requiring less thermal energy than steam explosion.

Figure 2.

Comparison of the percentage of stones removed with a centrifuge and a horizontal screw press on enzymatically pretreated diluted olive cake. Control for stones removed (%) was EDOC. Enzymatically pretreated diluted olive cake (EDOC); destoned enzymatically pretreated diluted olive cake by horizontal screw press (DEDOC-H); destoned enzymatically pretreated diluted olive cake by centrifugation at 100× g (DEDOC-C100); destoned enzymatically pretreated diluted olive cake by centrifugation at 200× g (DEDOC-C200); destoned enzymatically pretreated diluted olive cake by centrifugation at 3000× g (DEDOC-C3000). Different letters within a group indicate significant differences. Capital letters = Stones removed; lower case letters = Total solids in liquid fraction.

While the HSP and centrifuge removed similar amounts of olive stones, the TS, i.e., dry matter remaining after stone removal, significantly differed between the two destoning methods. Less than a quarter (21%) of TS was recovered in the supernatant for DEDOC-C3000 (Figure 2). This result is in agreement with 18% TS recovered when two-phase olive mill waste (2POMW) was pretreated at 170 °C for 60 min and then centrifuged at 4700× g [29]. When the olive cakes were centrifuged, pulp partitioned with the stones, becoming part of the pellet. This is reflected in the lower %TS in the supernatant (Figure 2). It is important to note that although such a centrifugal speed is easily achievable with laboratory centrifuges, it is higher than most centrifuges used in the olive oil industry. At a centrifugal speed of 200× g, the destoned supernatant contained 27% of the TS (Figure 2). Lowering the speed to 100× g significantly increased the TS in the destoned supernatant to 43%. The use of a HSP for destoning olive cake resulted in the greatest retention of TS (66%) in the destoned fraction. Therefore, all subsequent destoning was conducted with the use of the HSP.

3.2. Olive Cake Destoning Efficiency of a Horizontal Screw Press (HSP) Compared to Enzymatic Pretreatment

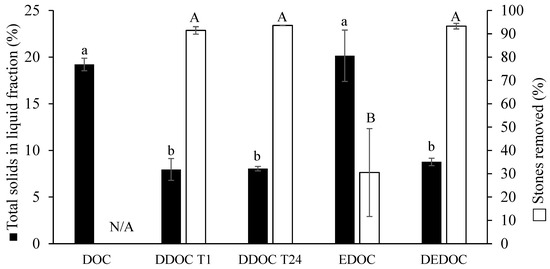

After comparing mechanical stone fragment removal methods, olive cakes were diluted (DOC), diluted and destoned with the HSP (DDOC), diluted and enzymatically treated (EDOC), diluted, enzymatically treated, and then destoned with the HSP (DEDOC) in preparation for the batch anaerobic digestion.

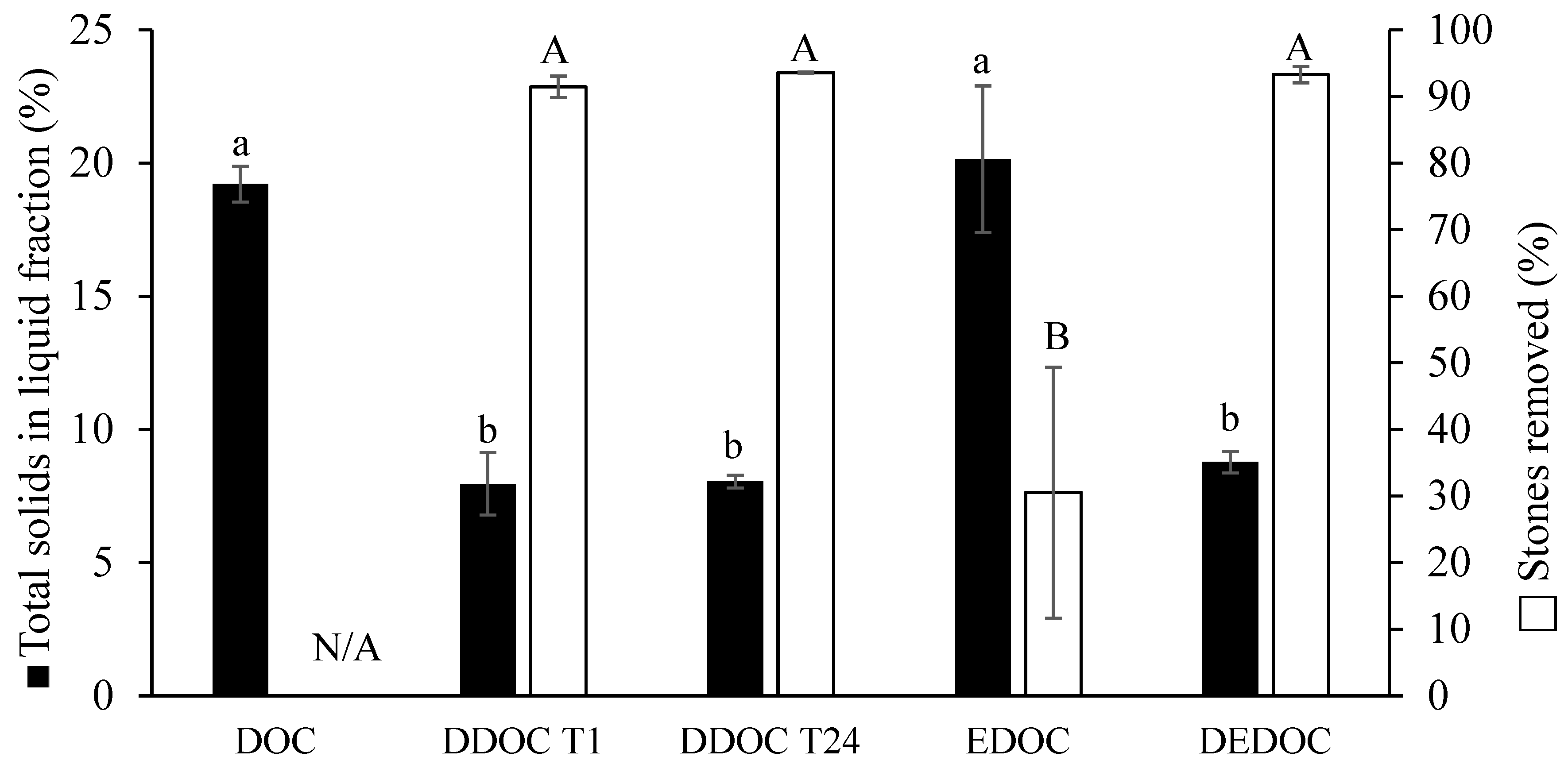

Figure 3 describes the mass percentage of stones removed and %TS recovered in the liquid fraction of the pretreated olive cakes. When the HSP was used to destone olive cake (DDOC), 94% of stones were removed when compared to the stone content of the control (DOC). Interestingly, even though the enzymatically pretreated olive cake (EDOC) was not submitted to the destoning process, the stone content was 31% lower than the control (DOC). This observed mass reduction was attributed to the removal of hemicellulose and cellulose from the stones due to enzymatic hydrolysis. The TS content of the DOC (19.2%) and EDOC (20.1%) not being significantly different (p > 0.05) reinforces the previous hypothesis. Total solids are defined as the sum of the dissolved, suspended, and settleable solids, i.e., the material minus the water. As enzymes catalyze reactions and do not remove material from the system, the TS between DOC and EDOC should not be significantly different. As mentioned above this was shown to be the case.

Figure 3.

Percentage of stones removed with a horizontal screw press on the diluted olive cake and enzymatically pretreated diluted olive cake. N/A = not applicable. Control for stones removed (%) was DOC. Diluted olive cake (DOC, control); destoned diluted olive cake soaked for 1 h and 24 h (DDOC T1 and DDOC T24, respectively); enzymatically pretreated diluted olive cake (EDOC); destoned and enzymatically pretreated diluted olive cake (DEDOC). Different letters within a group indicate significant differences. Capital letters = Stones removed; lower case letters = Total solids in liquid fraction.

Extended hydration at an elevated temperature (56 °C) was expected to cause the insoluble fiber to swell and loosen from the stone fragments (Figure 3). Unexpectedly, soaking the olive cake (DOC) at 56 °C for an additional 23 h before destoning had no significant effect on the TS or % mass stones removed. Although a slightly puzzling result, achieving optimal destoning after 1 h of hydration at 56 °C in a shaker saves olive mills interested in destoning technology a large amount of time and energy that would go towards an extended soak.

3.3. Impact of Pretreatment on Olive Cake Characteristics

Table 2 summarizes the physical and chemical properties of the olive cakes used as a substrate for anaerobic digestion.

Table 2.

Characteristics of various olive cakes and inoculum.

Olive cake from three-phase systems is known to have a low protein content (3.3–9.6%, db) [30,31]. The solid waste obtained from the Arbosana olives processed with a three-phase centrifuge belongs in this range (4.6% (db)). The removal of stones concentrated the pulp, increasing the amount of protein to 8.9%, which confirmed results reported in previous studies when commercially destoned cake was compared to crude ones [30,32].

Residual oil content in olive cakes is dependent on the efficiency of olive oil extraction. Olive mill waste lipid content can be as low as 7.3% (db) or as high as 22.1% (db) [30,33]. In our study, the diluted olive cake (DOC) contained 8.3% lipid (db). Both destoning and enzymatic pretreatment increased lipid content.

The reducing sugar content was increased by a factor of almost three after enzymatic pretreatment, increasing the amount of digestible substrate immediately available for conversion to methane (DOC, 10.0 mg/mL vs. EDOC, 27.9 mg/mL). Carbohydrates were not lost in the destoning process as the amount of reducing sugar in the destoned olive cakes (DDOC, DEDOC) did not significantly decrease after destoning (Table 2).

Total phenol concentrations (0.7–1.0 mg GAE/g) of all four olive cakes was well below the demonstrated inhibitory level of 1.7 mg GAE/g total phenol concentration for methanogenic microorganisms [34].

Acid detergent lignin in olive cake ranges from 12–30% (db) depending on the variety of the olives [30,31]. As expected, after destoning by HSP, lignin content decreased more than 50% (DOC, 29.0% vs. DDOC, 12.1%). This result demonstrated that the HSP was more efficient at destoning than densimetry methods. For comparison, densimetry has been shown to reduce the lignin content in olive cake by 25% [5]. A large reduction in lignin after destoning can be explained by the phytotomy of olives. Classical lignocellulosic biomasses such as corn stover have cellulose in a crystalline form that is cross-linked with hemicellulose and lignin polymers. Lignin acts as a cement, restricting enzyme access to the cellulose. Such a decrease in the enzymatic accessibility of polysaccharides is less of a hindrance in olive cake from three-phase systems as a large portion of the lignin is localized in the kernel and stone [13], while the flesh is composed of a cellulose matrix. In short, destoning reduced the mass percentage of lignin-dense stones, resulting in a lower percentage of TS. In return, there is a higher volume of nutrient-rich pulp per gram (db) of olive cake.

3.4. Methane Yields

Biochemical methane potential (BMP) assays are a standard, batch protocol used to estimate the volume and quality of methane generated from the anaerobic digestion of agricultural residues, including olive cake [35].

The addition of the inoculum to the enzymatically pretreated olive cakes (EDOC, DEDOC) resulted in pH > 7 in the serum bottle digesters. The near-neutral pH was due to the low S:I volume ratio (1:9 v/v) to achieve the S:I VS ratio of 0.5. This pH was outside of the pH optimal range of all enzymes used, except the hemicellulose; so, some residual enzyme activity was expected. Enzymes were not inactivated before anaerobic digestion in hopes residual enzymatic activity would promote greater biogas production.

The SMY of the glucose control on Day 30 displayed 92% of the theoretical methane yield (TMY) of glucose (373.5 mL CH4/g VS). Microcrystalline cellulose is often used as a positive control for BMP assays involving lignocellulosic agricultural byproducts [36]; however, enzymatic pretreatment with cellulase is expected to degrade the cellulose in the olive cake into quantities of readily digestible glucose [13]. Thus, a glucose control was chosen over cellulose as a positive control to serve as a ceiling to compare the SMY’s of the pretreated olive cakes.

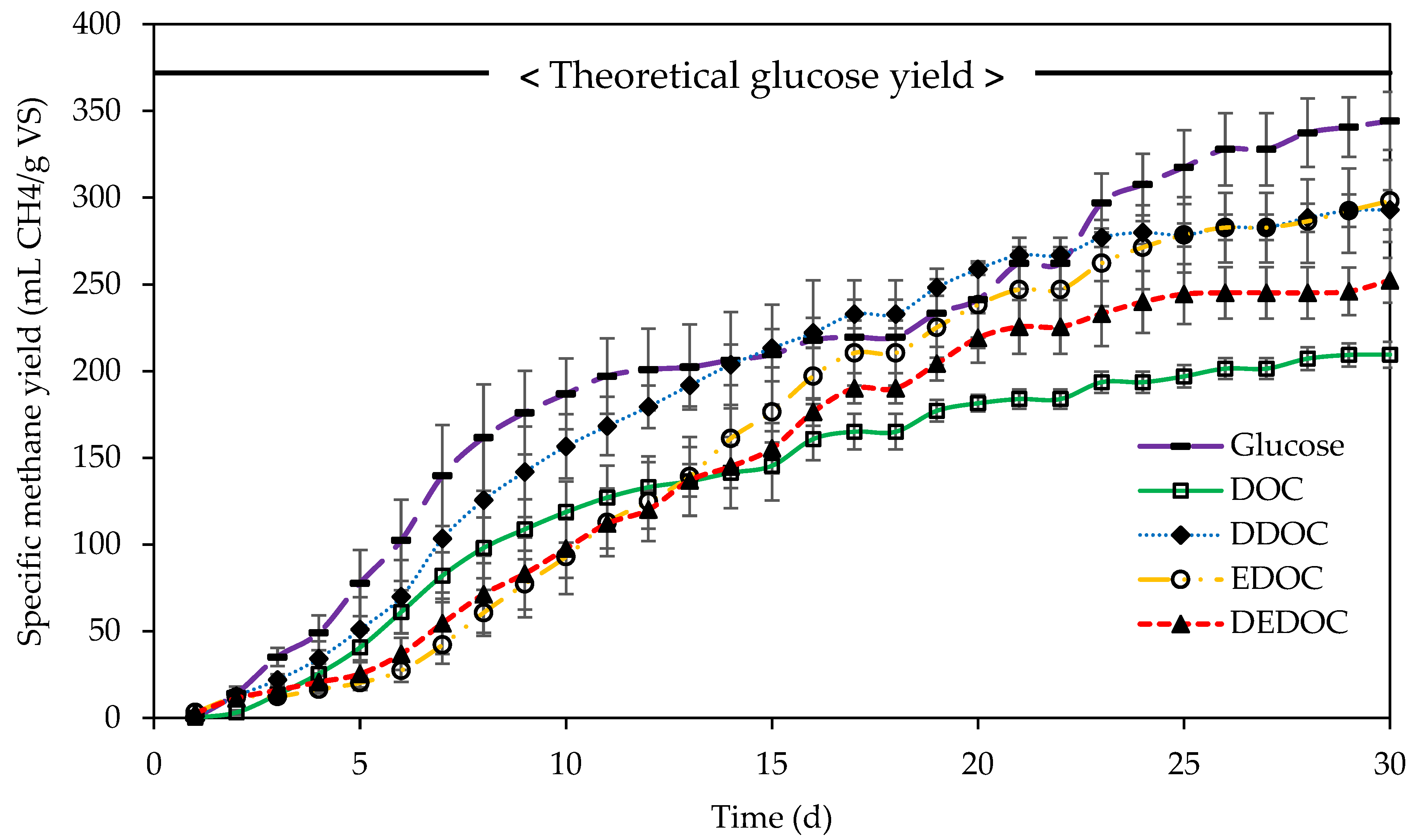

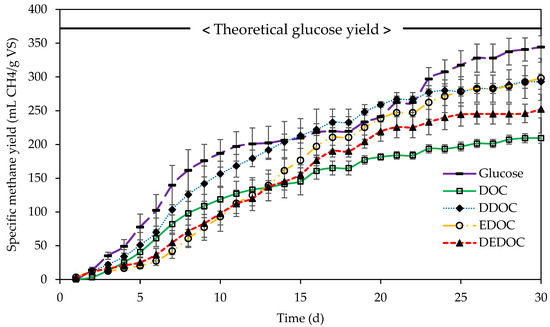

For all the olive cakes, the kinetics of biomethane production were similar; the anaerobic digestion started with a short lag phase, followed by a steady production of methane, before plateauing on Day 23 (<5% total methane production between day 23 and day 30) (Figure 4). As expected, the control (DOC) displayed the lowest SMY value (209.5 mL CH4/g VS). The enzymatically pretreated olive cake (EDOC, 298.1 mL CH4/g VS) and the destoned olive cake (DDOC, 293.1 mL CH4/g VS) produced the highest amount of methane, 42% higher than that of the control (DOC) and just 14% lower than the glucose control. There was no statistical difference between the two samples, suggesting that destoning was as effective as the enzymatic pretreatment in increasing SMY.

Figure 4.

Effect of enzyme and destoning on specific methane yield (SMY). DDOC and EDOC are not statistically different on day 30. A plateau started on Day 23 (<5% increase for 7 days). Glucose, dash; diluted olive cake (DOC, control), open square; destoned diluted olive cake (DDOC), closed diamond; enzymatically pretreated diluted olive cake (EDOC), open circle; destoned and enzymatically pretreated diluted olive cake (DEDOC), closed triangle.

The higher methane yield for the destoned, diluted olive cake (DDOC) was due to the increased amount of digestible substrate loaded into the digester (which replaced the stones to keep the VS loading constant), whereas the higher yield after enzymatic pretreatment can be explained by the increased amount of fermentable sugars available (Table 2). When destoning and enzymatic pretreatments were combined, i.e., the DEDOC samples, 252.3 mL CH4/g VS was obtained. This value represented a SMY that was 20% higher than the control, but lower than the one obtained with olive cake that was submitted to either a destoning (DDOC) or enzymatic pretreatment (EDOC). Interestingly, the methane production of the DEDOC followed that of the EDOC from Day 5 to 14, suggesting the inhibition occurred after the readily available monosaccharides had been completely digested.

One possible hypothesis for the lower SMY of destoned and enzymatically pretreated olive cake (DEDOC) compared to the olive cakes that underwent a single pretreatment (DDOC and EDOC) is the profile of polyphenols within the digester. Oleuropein is the main polyphenol in olive and is known to have antimicrobial properties. Hydroxytyrosol, one of oleuropein’s degradation products, has a higher antimicrobial activity [37]. Polyphenols form complexes with polysaccharides in olives, which can be degraded during enzymatic treatment involving carbohydrases [38]. The enzymatic hydrolysis of carbohydrates complexed with polyphenols can release the polyphenols into the matrix where they can be further degraded. Our biomethane potential results (Figure 4) suggest that a combination of destoning and enzymatic pretreatment led to conditions promoting the formation of a higher antimicrobial activity in the sample, which had a detrimental impact on methane production. Due to the closed nature of a batch system, it was not possible to follow phenolic profile and content throughout the digestion process.

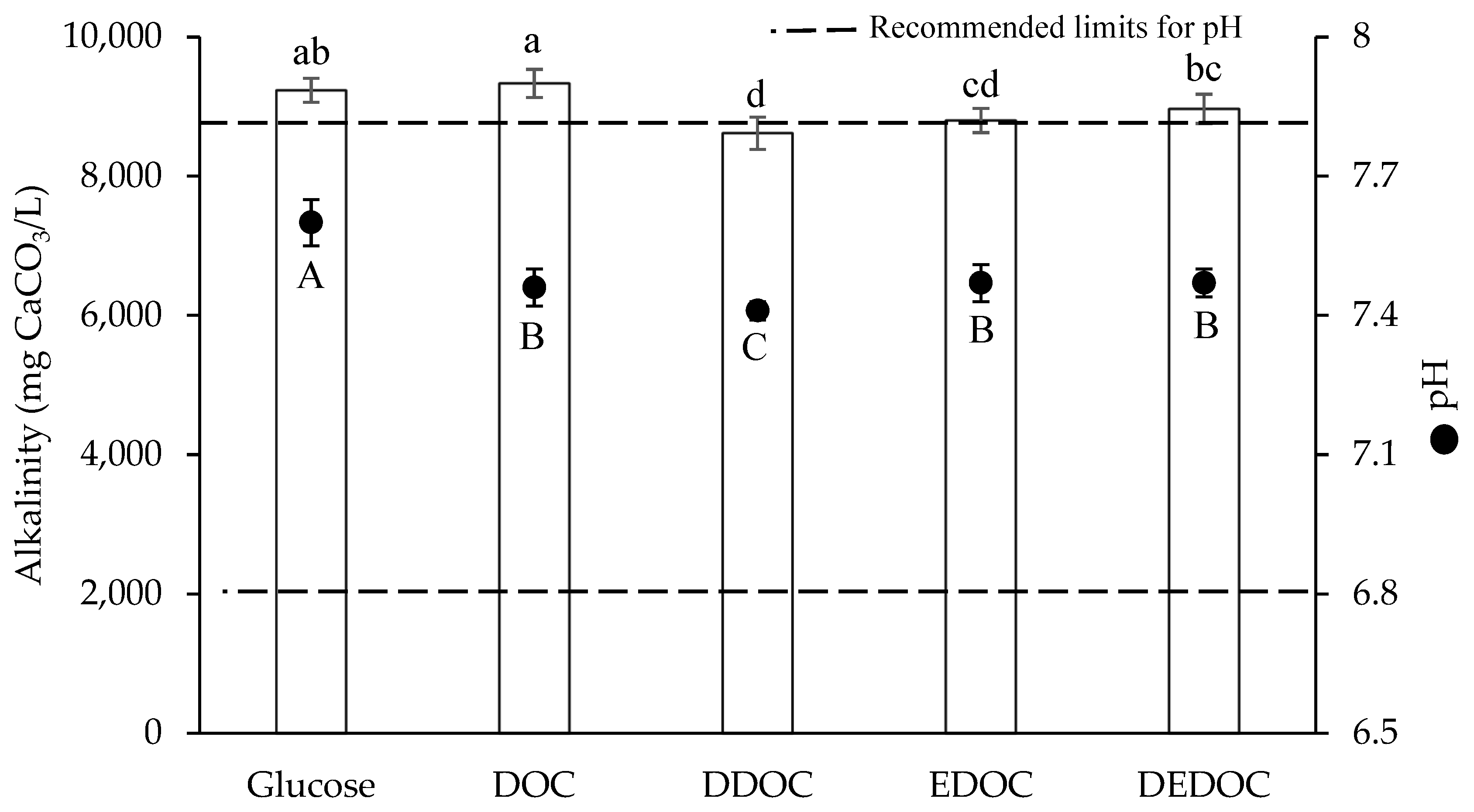

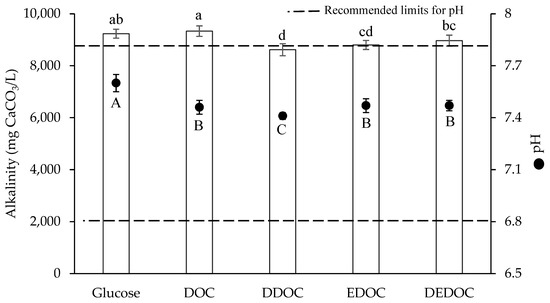

Acidification of the anaerobic fermentation medium over time is often a factor in impeding optimal biomethane production. To evaluate the stability of the anaerobic digestion process, endpoint (Day 30) pH, and alkalinity were measured (Figure 5). With the applied S:I ratio of 0.5, the pH value of all digesters was within the recommended bounds for methanogenic activity (pH 6.8–7.8) [29]. Alkalinity ranging from 8800 to 9333 mg CaCO3/L was measured in all the digesters, indicating an excess of buffering capacity was present. With a high alkalinity and a pH within the recommended limits of anaerobic digestion, there was no evidence of inhibition due to acidification.

Figure 5.

Anaerobic digester conditions at the end of the biochemical methane potential (BMP) assay; different lower-case letters represent significant statistical differences in alkalinity. Different uppercase letters represent significant differences in pH. Diluted olive cake (DOC); destoned diluted olive cake (DDOC); enzymatically pretreated diluted olive cake (EDOC); destoned and enzymatically pretreated olive cake (DEDOC).

Comparisons to the SMY of other BMP assays are difficult to make when the S:I ratio between experiments varies. For instance, at an S:I ratio of 2 by VS, olive pomace (in this case the solid waste produced after solvent extraction of olives that had already been cold-pressed) digested for 14 days yielded 21 mL CH4/g VS [39]. Their low SMY using a high S:I ratio can be explained by the build-up of toxic metabolites due to the presence of excess substrate inhibiting the induction of microbial enzymes, leading to the build-up of toxic metabolites. Furthermore, residues from pomace oil production have low-lipid contents. Solid olive mill wastes have a considerable amount of residual lipids, which contributes to their suitability as a candidate for anaerobic digestion.

Table 3 compares the limited number of BMP assays in the literature performed in mesophilic conditions with an S:I ratio of 0.5. The TMY for carbohydrates, proteins, and lipids were also included. Without any pretreatment, olive cake from a three-phase system was found to be a reasonable candidate for anaerobic digestion, producing similar amounts of methane to 2POMW (213.1 mL CH4/g VS) and cotton gin waste (235.7 mL CH4/g VS). Substrates with traditionally high amounts of lignocellulosic material are generally inefficient at producing methane (e.g., pine, 59 mL CH4/g VS). After enzymatic pretreatment or destoning, the olive cake displayed similar yields to nitrogen-rich substrates such as chicken manure (295 mL CH4/g VS) and higher yields than that of corn stover (241 mL CH4/g VS).

Table 3.

Specific methane yields for different substrates.

Co-digestion is often presented as a powerful tool to improve methane yield through selecting substrates that have complementary properties. For olive mill wastes that originate from a three-phase centrifuge, it is possible to co-digest the wastewater with the solid olive mill waste (olive cake). When conducted at an S:I ratio of 8.7 by VS for 60 days, 1.8 mL CH4/g VS was reported [43]. This SMY is ~100 times lower than what was obtained with the control diluted olive cake (DOC) in this study (145 mL CH4/g VS, S:I ratio 0.5). After diluting the OMWW and olive cake blend with tap water, and adding buffering agents, an SMY of 193.4 mL CH4/g VS was reported demonstrating the suitability of the pairing. Although the SMY of three-phase olive cake co-digested with OMWW is lower than the SMY of the diluted olive cake alone, co-digestion simultaneously converts olive cake and OMWW, which is another environmentally detrimental byproduct of olive oil production. One future consideration could be extracting the polyphenols from OMWW and then co-digesting the resulting liquor with enzymatically pretreated olive cakes. One severe limitation to this approach is the high organic load (and therefore VS) of olive mill waste products such as olive cake and OMWW. As seen in this study, to achieve a S:I (VS) of 0.5, which is quite regular to BMP studies, a low S:I volume ratio was required, which is undesirable from a waste management standpoint. The higher the S:I ratio, the more of the byproduct that can be used for anaerobic digestion.

3.5. Carbohydrate Content and Profile

Table 4 describes the carbohydrate profile of the olive cake pre-digestion, after the inoculum was added (Day 0), during the midpoint of digestion (Day 15), and at the end (Day 30). The control, diluted olive cake (DOC) had a similar amount of glucose and xylose/galactose (each ~5.3 mg/mL). After enzymatic pretreatment, concentrations of glucose in the EDOC (9.9 mg/mL) and the destoned enzymatically pretreated olive cake (DEDOC, 10.4 mg/mL) significantly increased, while the xylose/galactose content remained the same.

Table 4.

Carbohydrate profile of digestate at Day 0, 15, and 30; and olive cake supernatant.

Glucuronoxylans, which can be degraded into xylose, are commonly found in the lignified fraction of the olive pulp or the stones [44,45]. Due to the crystalline structure of the lignin, our results suggested that the xylanase was unable to convert those xylans into xylose under the conditions used in the experiment. The results of this study suggested that at the present conditions, the presence of xylanase does not seem to contribute to xylan degradation. Arabinose was not detected in the DOC and DDOC; however, 2.5 mg/mL was found in both EDOC and DEDOC, demonstrating hemicellulase and pectinase activity.

After the inoculum was added to the olive cakes in preparation for anaerobic digestion (Day 0), an expected decrease in total sugar content was observed due to the dilution. After 15 days of digestion, no monosaccharides were detected, which confirmed the consumption of glucose. The hydrolysis rate of cellulose is lower than the rate of fermentation of its monomeric product, meaning that the accumulation of glucose was non-existent. Our results were comparable to the ones observed at the end of a 22-day digestion period of a 2POMW. In that study, the total carbohydrate remaining in the digestate supernatant was found to be negligible (0.025–0.050 mg/mL) [29]. Other substrates converted during digestion were lipids and proteins which produce more methane per g of VS [8].

3.6. Valorization Potential of the Olive Cake Digestate

Because of their high caloric value, illustrated by a gross heat of combustion up to 21 kJ/g TS [31], untreated solid olive mill wastes are currently used for energy recovery. The digestates recovered after anaerobic digestion of the olive cake which produced the highest amounts of methane, the destoned diluted olive cake (DDOC), and the enzymatically pretreated olive cake (EDOC), were further analyzed to determine potential applications (Table 5). The olive cake digestates displayed gross heat of combustion values of 3.3–3.5 kJ/g TS, which were significantly lower than untreated olive cakes, limiting their value for energy recovery. These lower values were expected as the samples were diluted with wastewater sludge and were digested.

Table 5.

Characteristics of digestate after 30 days of anaerobic digestion.

Protein content is another important characteristic for determining the potential use of agricultural by-products. Both the destoned and enzymatically pretreated olive cake digestates (DDOC and EDOC) had a Kjeldahl nitrogen content of 3.6% TS (Table 5), which was higher than the undigested olive cake (1.4% TS) (Table 2) and slightly lower than the one reported for cow manure’s digestate (4.3% TS) [10]. The high Kjeldahl nitrogen content in the digested olive cakes could qualify them as good substrates for soil amendment. Indeed, nitrogen is the main limiting factor for plant growth, and using olive cake digestate as a soil amendment would lower the use of artificial fertilizers commonly produced with fossil fuels. Furthermore, olive cake digestate could be an attractive fertilizer for organic farmers when digested, as long as neither human nor animal wastes are incorporated. Another advantage of using olive cake digestate as a soil amendment instead of directly applying olive cake is the negligible phenolic load (~0.020 mg GAE/g), which is not expected to have a phytotoxic effect.

Another important parameter in determining potential applications for digestate is fiber content. Van Soest sequential fiber analysis showed about 17% hemicellulose and 12% lignin remained in both DDOC and EDOC digestates. High-fiber dairy digestates have been sold as a peat substitute for potting mixes [46].

4. Conclusions

Olive cake, solid olive mill waste originating from a three-phase centrifuge, is a suitable candidate for anaerobic digestion. Batch BMP assays indicated the two pretreatments applied, destoning by HSP and the hydrolysis of polysaccharides by a fiber-degrading enzymatic treatment, improved the SMY. The destoned (DDOC) and enzymatically pretreated (EDOC) olive cakes produced 24 and 17% more methane than corn stover and vinegar residue, respectively, under similar conditions. These results provide evidence that olive cake can be diverted from landfills and converted into second-generation biofuels with the resulting digestate having value as a soil amendment due to its high nitrogen content and low polyphenol concentration.

Energy production in the form of biomethane is only one aspect of the olive mill waste biorefinery. The biorefinery concept has been gaining traction as an approach that integrates waste management and valorization [47,48]. If the polyphenols can be extracted, the wastewater from the three-phase centrifugation system can be used to substitute tap water for olive cake dilution. We are currently exploring this approach and how the removal of the polyphenols impacts the production of biomethane from the olive pomace. Furthermore, the ability to easily separate the digestible pulp from the olive stones with a mechanical screen engenders various avenues of research centering on the physical properties of olive stones. For example, the potential of the olive stone for biochar production is currently being evaluated, and a techno-economic and life-cycle analysis will determine the feasibility of implementing a biorefinery concept to olive pomace.

Author Contributions

P.T.: conceptualization, all areas; methodology, all areas; writing—original draft preparation, and review and editing; investigation, all areas; formal analysis, all areas. R.S.: conceptualization, biomethane potential assay; methodology, biomethane potential assay; writing—review and editing. J.C.: conceptualization, HPLC; methodology, HPLC; writing—review and editing. S.J.: funding acquisition, supervision, project administration, conceptualization, all areas; methodology, characterization and destoning; writing—review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by California State University Agricultural Research Institute (ARI#16-03-016) and the California Polytechnic State University Center for Applied Biotechnology (#67490-115100-CU014).

Data Availability Statement

All data is available upon request.

Acknowledgments

Gross heat of combustion and fiber analysis were conducted in the Animal Nutrition Laboratory at California Polytechnic State University, San Luis Obispo with guidance from Mark Edwards. Olive cake samples were kindly donated by La Panza Ranch, California. Enzymes were donated by BioCat.

Conflicts of Interest

The authors would like to declare that there were no conflict of interest.

References

- International Olive Council. Olive Oil Dashboard. 2023. Available online: https://www.internationaloliveoil.org/wp-content/uploads/2021/12/IOC-Olive-Oil-Dashboard-1.html#production-2 (accessed on 14 February 2023).

- Guasch-Ferré, M.; Liu, G.; Li, Y.; Sampson, L.; Manson, J.E.; Salas-Salvadó, J.; Martínez-González, M.A.; Stampfer, M.J.; Willett, W.C.; Sun, Q.; et al. Olive Oil Consumption and Cardiovascular Risk in U.S. Adults. J. Am. Coll. Cardiol. 2020, 75, 1729–1739. [Google Scholar] [CrossRef] [PubMed]

- Al Afif, R.; Linke, B. Biogas Production from Three-Phase Olive Mill Solid Waste in Lab-Scale Continuously Stirred Tank Reactor. Energy 2019, 171, 1046–1052. [Google Scholar] [CrossRef]

- Dammak, I.; Neves, M.; Souilem, S.; Isoda, H.; Sayadi, S.; Nakajima, M. Material Balance of Olive Components in Virgin Olive Oil Extraction Processing. FSTR 2015, 21, 193–205. [Google Scholar] [CrossRef]

- Hachicha, R.; Rigane, H.; Khodher, M.B.; Nasri, M.; Medhioub, K. Effects of Partial Stone Removal on the Co-composting of Olive-oil Processing Solid Residues with Poultry Manure and the Quality of Compost. Environ. Technol. 2003, 24, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An Overview on Olive Mill Wastes and Their Valorisation Methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef]

- Masghouni, M.; Hassairi, M. Energy Applications of Olive-Oil Industry by-Products: I. The Exhaust Foot Cake. Biomass Bioenergy 2000, 18, 257–262. [Google Scholar] [CrossRef]

- Wilkie, A.C. Biomethane from Biomass, Biowaste, and Biofuels. In Bioenergy; Wall, J.D., Harwood, C.S., Demain, A., Eds.; ASM Press: Washington, DC, USA, 2014; pp. 195–205. [Google Scholar]

- Alonso-Fariñas, B.; Oliva, A.; Rodríguez-Galán, M.; Esposito, G.; García-Martín, J.F.; Rodríguez-Gutiérrez, G.; Serrano, A.; Fermoso, F.G. Environmental Assessment of Olive Mill Solid Waste Valorization via Anaerobic Digestion Versus Olive Pomace Oil Extraction. Processes 2020, 8, 626. [Google Scholar] [CrossRef]

- Makádi, M.; Tomócsik, A.; Orosz, V. Digestate: A New Nutrient Source–Review. In Biogas; Kumar, S., Ed.; Intech: Rijeka, Croatia, 2012; pp. 295–310. [Google Scholar]

- Triolo, J.M.; Sommer, S.G.; Møller, H.B.; Weisbjerg, M.R.; Jiang, X.Y. A New Algorithm to Characterize Biodegradability of Biomass during Anaerobic Digestion: Influence of Lignin Concentration on Methane Production Potential. Bioresour. Technol. 2011, 102, 9395–9402. [Google Scholar] [CrossRef]

- Guo, Z.; Jia, X.; Zheng, Z.; Lu, X.; Zheng, Y.; Zheng, B.; Xiao, J. Chemical Composition and Nutritional Function of Olive (Olea europaea L.): A Review. Phytochem. Rev. 2018, 17, 1091–1110. [Google Scholar] [CrossRef]

- Miranda, I.; Simões, R.; Medeiros, B.; Nampoothiri, K.M.; Sukumaran, R.K.; Rajan, D.; Pereira, H.; Ferreira-Dias, S. Valorization of Lignocellulosic Residues from the Olive Oil Industry by Production of Lignin, Glucose and Functional Sugars. Bioresour. Technol. 2019, 292, 121936. [Google Scholar] [CrossRef]

- Fernández-Lobato, L.; López-Sánchez, Y.; Blejman, G.; Jurado, F.; Moyano-Fuentes, J.; Vera, D. Life Cycle Assessment of the Spanish Virgin Olive Oil Production: A Case Study for Andalusian Region. J. Clean. Prod. 2021, 290, 125677. [Google Scholar] [CrossRef]

- Barreca, F.; Fichera, C.R. Use of Olive Stone as an Additive in Cement Lime Mortar to Improve Thermal Insulation. Energy Build. 2013, 62, 507–513. [Google Scholar] [CrossRef]

- Fiol, N.; Villaescusa, I.; Martínez, M.; Miralles, N.; Poch, J.; Serarols, J. Sorption of Pb(II), Ni(II), Cu(II) and Cd(II) from Aqueous Solution by Olive Stone Waste. Sep. Purif. Technol. 2006, 50, 132–140. [Google Scholar] [CrossRef]

- Sánchez Moral, P.; Ruiz Méndez, M.V. Production of Pomace Olive Oil. Grasas y Aceites 2006, 57, 47–55. [Google Scholar] [CrossRef]

- Carlini, M.; Castellucci, S.; Moneti, M. Anaerobic Co-Digestion of Olive-Mill Solid Waste with Cattle Manure and Cattle Slurry: Analysis of Bio-Methane Potential. Energy Procedia 2015, 81, 354–367. [Google Scholar] [CrossRef]

- de la Lama-Calvente, D.; Fernández-Rodríguez, M.J.; Llanos, J.; Mancilla-Leytón, J.M.; Borja, R. Enhancing Methane Production from the Invasive Macroalga Rugulopteryx Okamurae through Anaerobic Co-Digestion with Olive Mill Solid Waste: Process Performance and Kinetic Analysis. J. Appl. Phycol. 2021, 33, 4113–4124. [Google Scholar] [CrossRef]

- Holliger, C.; Alves, M.; Andrade, D.; Angelidaki, I.; Astals, S.; Baier, U.; Bougrier, C.; Buffière, P.; Carballa, M.; de Wilde, V.; et al. Towards a Standardization of Biomethane Potential Tests. Water Sci. Technol. 2016, 74, 2515–2522. [Google Scholar] [CrossRef]

- Bailey, M.J.; Poutanen, K. Production of Xylanolytic Enzymes by Strains of Aspergillus. Appl. Microbiol. Biotechnol. 1989, 30, 5–10. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 16th ed.; American Public Health Association: Washington DC, USA, 1985. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 18th ed.; Association of Officiating Analytical Chemists: Gaithersburg, MD, USA, 2005. [Google Scholar]

- Obied, H.K.; Bedgood, D.R.; Prenzler, P.D.; Robards, K. Bioscreening of Australian Olive Mill Waste Extracts: Biophenol Content, Antioxidant, Antimicrobial and Molluscicidal Activities. Food Chem. Toxicol. 2007, 45, 1238–1248. [Google Scholar] [CrossRef]

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; van Lier, J.B. Defining the Biomethane Potential (BMP) of Solid Organic Wastes and Energy Crops: A Proposed Protocol for Batch Assays. Water Sci. Technol. 2009, 59, 927–934. [Google Scholar] [CrossRef]

- Parr Instrument Company. 203M 1241 Oxygen Bomb Calorimeter Operating Instructions. 2013. Available online: https://www.parrinst.com/products/oxygen-bomb-calorimeters/previous-calorimeter-models/ (accessed on 29 March 2018).

- Yan, H.; Zhao, C.; Zhang, J.; Zhang, R.; Xue, C.; Liu, G.; Chen, C. Study on Biomethane Production and Biodegradability of Different Leafy Vegetables in Anaerobic Digestion. AMB Expr. 2017, 7, 27. [Google Scholar] [CrossRef] [PubMed]

- Felizón, B.; Fernández-Bolaños, J.; Heredia, A.; Guillén, R. Steam-Explosion Pretreatment of Olive Cake. J. Amer. Oil Chem. Soc. 2000, 77, 15–22. [Google Scholar] [CrossRef]

- Serrano, A.; Fermoso, F.G.; Alonso-Fariñas, B.; Rodríguez-Gutierrez, G.; Fernandez-Bolaños, J.; Borja, R. Olive Mill Solid Waste Biorefinery: High-Temperature Thermal Pre-Treatment for Phenol Recovery and Biomethanization. J. Clean. Prod. 2017, 148, 314–323. [Google Scholar] [CrossRef]

- Chiofalo, B.; Liotta, L.; Zumbo, A.; Chiofalo, V. Administration of Olive Cake for Ewe Feeding: Effect on Milk Yield and Composition. Small Rumin. Res. 2004, 55, 169–176. [Google Scholar] [CrossRef]

- Ferrer, P.; García-Rebollar, P.; Cerisuelo, A.; Ibáñez, M.A.; Rodríguez, C.A.; Calvet, S.; De Blas, C. Nutritional Value of Crude and Partially Defatted Olive Cake in Finishing Pigs and Effects on Nitrogen Balance and Gaseous Emissions. Anim. Feed Sci. Technol. 2018, 236, 131–140. [Google Scholar] [CrossRef]

- Sadeghi, H.; Yansari, A.T.; Ansari-Pirsarai, Z. Effects of Different Olive Cake by Products on Dry Matter Intake, Nutrient Digestibility and Performance of Zel Sheep. Int. J. Agric. Biol. 2009, 11, 6. [Google Scholar]

- Vlyssides, A.; Loizidou, M.; Gimouhopoulos, K.; Zorpas, A. Olive Oil Processing Wastes Production and Their Characteristics in Relation to Olive Oil Extraction Methods. Fresenius Enivr. Bull. 1998, 7, 308–311. [Google Scholar]

- Akassou, M.; Kaanane, A.; Crolla, A.; Kinsley, C. Statistical Modelling of the Impact of Some Polyphenols on the Efficiency of Anaerobic Digestion and the Co-Digestion of the Wine Distillery Wastewater with Dairy Cattle Manure and Cheese Whey. Water Sci. Technol. 2010, 62, 475–483. [Google Scholar] [CrossRef]

- Messineo, A.; Maniscalco, M.P.; Volpe, R. Biomethane Recovery from Olive Mill Residues through Anaerobic Digestion: A Review of the State of the Art Technology. Sci. Total Environ. 2020, 703, 135508. [Google Scholar] [CrossRef]

- Koch, K.; Hafner, S.; Astals, S.; Weinrich, S. Evaluation of Common Supermarket Products as Positive Controls in Biochemical Methane Potential (BMP) Tests. Water 2020, 12, 1223. [Google Scholar] [CrossRef]

- Yuan, J.-J.; Tu, J.-L.; Qin, F.G.F.; Xu, Y.-J.; Li, B. Phenolic Composition of Oleuropein Extract after Enzymatic Process by HPLC-MS and Their Antioxidant and Antibacterial Activities. J. Food Biochem. 2018, 42, e12517. [Google Scholar] [CrossRef]

- Bermúdez-Oria, A.; Rodríguez-Juan, E.; Rodríguez-Gutiérrez, G.; Fernández-Prior, Á.; Fernández-Bolaños, J. Effect of the Olive Oil Extraction Process on the Formation of Complex Pectin–Polyphenols and Their Antioxidant and Antiproliferative Activities. Antioxidants 2021, 10, 1858. [Google Scholar] [CrossRef] [PubMed]

- Tekin, A.R.; Dalgıç, A.C. Biogas Production from Olive Pomace. Resour., Conserv. Recycling 2000, 30, 301–313. [Google Scholar] [CrossRef]

- Chynoweth, D.P.; Turick, C.E.; Owens, J.M.; Jerger, D.E.; Peck, M.W. Biochemical Methane Potential of Biomass and Waste Feedstocks. Biomass Bioenergy 1993, 5, 95–111. [Google Scholar] [CrossRef]

- Pellera, F.-M.; Gidarakos, E. Effect of Substrate to Inoculum Ratio and Inoculum Type on the Biochemical Methane Potential of Solid Agroindustrial Waste. J. Environ. Chem. Eng. 2016, 4, 3217–3229. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Liu, G.; Chen, C.; He, Y.; Liu, X. Comparison of Methane Production Potential, Biodegradability, and Kinetics of Different Organic Substrates. Bioresour. Technol. 2013, 149, 565–569. [Google Scholar] [CrossRef]

- Ruggeri, B.; Battista, F.; Bernardi, M.; Fino, D.; Mancini, G. The Selection of Pretreatment Options for Anaerobic Digestion (AD): A Case Study in Olive Oil Waste Production. Chem. Eng. J. 2015, 259, 630–639. [Google Scholar] [CrossRef]

- Coimbra, M.A.; Waldron, K.W.; Selvendran, R.R. Isolation and Characterisation of Cell Wall Polymers from the Heavily Lignified Tissues of Olive (Olea Europaea) Seed Hull. Carbohydr. Polym. 1995, 27, 285–294. [Google Scholar] [CrossRef]

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolaños, J. Olive Stone an Attractive Source of Bioactive and Valuable Compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef]

- Pelaez-Samaniego, M.R.; Hummel, R.L.; Liao, W.; Ma, J.; Jensen, J.; Kruger, C.; Frear, C. Approaches for Adding Value to Anaerobically Digested Dairy Fiber. Renew. Sustain. Energy Rev. 2017, 72, 254–268. [Google Scholar] [CrossRef]

- Orive, M. Integrated Biorefinery Process for Olive Pomace Valorisation. Biomass Bioenergy 2021, 149, 106079. [Google Scholar] [CrossRef]

- Najafi, E.; Castro, E.; Karimi, K. Biorefining for Olive Wastes Management and Efficient Bioenergy Production. Energy Convers. Manag. 2021, 244, 114467. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).