Abstract

New environmentally friendly methods for extracting vegetable oils are in development, with a focus on pressurized liquid extraction (PLE) in an intermittent process. Ethanol, a renewable and generally recognized as safe (GRAS) solvent, is gaining prominence in this process. It is crucial for these methods to maintain the physicochemical characteristics of the extracted oils and be economically viable on a large scale. Using SuperPro Design software v 8.5, a simulation of PLE scaled up to industrial levels was conducted. Measurements of oils extracted with pressurized hexane and ethanol showed minimal density variations, with slightly higher viscosity for ethanol-extracted oil. Accelerated oxidative degradation revealed a longer induction period for hexane-extracted oil, indicating that ethanol-extracted oil degrades more easily. The antioxidant activity of the oil extracted with hexane was lower than that with ethanol. In the differential scanning calorimetry analysis, the oils extracted with hexane and ethanol presented onset melting point temperatures of −43.2 and −36.1 °C, respectively. The economic assessment considered 16 scenarios, showing a return on investment ranging from 9.0 to 133.5% in the first year and payback times from 0.7 to 11.1 years. Scenario 8, involving two 5000 L extractors, ethanol recycling, and an annual production of 3,325,300 L of soybean oil at USD 1.25/L, demonstrated the best return on investment (133.5%) in less than one year. Overall, this study suggests that industrial-scale soybean oil extraction via PLE in an intermittent process can be more cost-effective than conventional methods, making implementation feasible.

1. Introduction

In the search for less toxic and environmentally safe extraction technologies, new extraction methods have been devised for obtaining vegetable oils. Among these techniques is pressurized liquid extraction (PLE) in an intermittent process [1,2,3,4,5,6].

PLE has been consolidated as an alternative for the extraction of vegetable oils using less solvent than conventional methods or substituting solvents that are less harmful to the environment and less toxic to humans. This process allows for decreased solvent viscosity and increased diffusivity into the matrix (seeds, leaves, grains, etc.), thus enhancing the efficiency of mass transfer [7]. This results in shorter extraction times and smaller amounts of solvents compared with conventional extraction methods [8,9,10,11].

The pursuit of new processes for extracting vegetable oils, as a substitute for the conventional method that uses hexane, an unsustainable solvent that leaves toxic residues in the product, has been accompanied by the search for other solvents that are less toxic and less harmful to the environment, such as ethanol. Considered a generally recognized as safe (GRAS) solvent, ethanol can be a substitute for hexane in PLE, since it has shown a similar extraction efficiency to that of conventional oil extraction using hexane [1,12,13,14,15].

However, regardless of such efficiency, it is expected that oils extracted using alternative methods will exhibit the same physicochemical characteristics as oils extracted by conventional methods. In addition, the economic feasibility of using new processes and different solvents in extraction should also be assessed to ensure that the obtained oil can be competitive in terms of the production cost, return on investment, and future profits.

In addition to the products’ properties, the study of implementing new processes is fundamental for new technologies to replace conventional ones. There is a need to demonstrate that the obtained product, in addition to being free from toxic residues of organic solvents, can be economically feasible and industrially produced. Process optimization at the laboratory scale, scale-up studies, and implementation analyses are interconnected. Successful scale-up requires identically replicating a smaller-scale process [16,17].

Several parameters must be taken into account for a scale-up study of PLE equipment in an intermittent process, such as the extraction kinetics, economic factors (construction and operation costs), and the energy consumption involved. When scaling up a high-pressure process, maintaining the ratio between the solvent mass (S) used and the mass of the matrix (F) (S/F ratio), as well as the solvent’s residence time, are considered to be efficient criteria for process scaling [18,19,20].

Experimental data at the laboratory or pilot scale can be used to calculate the construction cost of the equipment at the beginning of the process; however, the cost of manufacturing is what determines whether the process is profitable or not. Demonstrating that a process is lucrative is the only way to attract investments for the implementation of new processes with few or no references on an industrial scale. Therefore, a scientific nature must be combined with economic awareness, as the cost aspects are fundamental to the process’s design [16,17].

Thus, the present study aimed to characterize crude soybean oil, without any refining process, extracted by PLE in an intermittent process using two different solvents (hexane and ethanol). Additionally, economic feasibility was assessed to demonstrate different configurations of possible industrial processes.

2. Material and Methods

2.1. Materials

The reagents used in the extraction processes were hexano 98.5% (Dinâmica Química Contemporânea Ltda, Indaiatuba, Brazil), ethanol 99.5% (Dinâmica Química Contemporânea Ltda., Indaiatuba, Brazil), ABTS+ (Sigma Aldrich, São Paulo, SP, Brazil), sodium persulfate (Synth, Diadema, SP, Brazil), and Trolox (Sigma Aldrich, São Paulo, SP, Brazil. Commercial oil (Soya Bunge, Jaguaré, SP, Brazil) and soybean (Soya Bunge, Jaguaré, SP, Brazil) were also used.

2.2. Extraction of Soybean Oil by Pressurized Liquid Extraction

The optimized soybean oil extraction conditions in PLE for hexane, in an intermittent process, occurred at a temperature of 85 °C, with a contact time between the solvent and the matrix (static time) of 13 min, and a rinse solvent volume of 60% of the extraction cell’s volume, corresponding to a total of 60 mL and 20 mL in each cycle (C), fixed at 3 cycles. When ethanol was used as solvent, the optimal extraction point was observed at a temperature of 80 °C, a static time of 12 min, with a rinse solvent volume (SV) of 60% of the extraction cell’s volume, implying 60 mL or 20 mL in each cycle (C), fixed at 3 cycles. The pressure of the system was maintained at 10.34 MPa. In a previous study by our research group, soybean oil extracted using hexane and ethanol was characterized by its refractive index; determination of the non-lipid fraction, β-sitosterol, the free fatty acid content, and the fatty acid profile; and estimation of the triacylglycerols [7].

2.3. Characterization of the Soybean Oil

2.3.1. Density and Viscosity

A benchtop digital density meter (DMA 4500, Anton Paar, Graz, Austria) was used for the density analysis. The equipment provided density values with an uncertainty of 5 × 10−5 g/cm3. Readings of the oils extracted with hexane and ethanol and of the commercial oil were taken to compare the obtained results. Approximately 3.0 g of soybean oil was injected directly into the equipment using a syringe, and the analyses were conducted in triplicate at temperatures of 25 and 40 °C.

Viscosity was determined using an automated falling ball micro-viscometer (AMVn, Anton Paar, Graz, Austria). The readings were performed in triplicate at temperatures of 25 and 40 °C and inclination angles of 50, 60, and 70°.

2.3.2. Differential Scanning Calorimetry (DSC)

The obtained soybean oils were analyzed using a differential scanning calorimeter (DSC TA2010, TA Instruments, New Castle, DE, USA) in the range of −150 to 150 °C, with a heating rate of 10 °C/min. For each analysis, a small amount of each sample (approximately 7.0 mg) of the oils extracted using different methods and solvents was placed in sealed crucibles and inserted into the equipment under a nitrogen-inert atmosphere (45 mL N2/min). These curves enabled the identification of heat flow peaks (W/g), the onset and end melting temperatures, and the enthalpies of fusion for each oil.

2.3.3. Oxidative Stability by the Enhanced Electrical Conductivity Method

The analysis of accelerated oxidative degradation using the enhanced electrical conductivity method was carried out using Rancimat equipment (Metrohm, Switzerland) at temperatures of 120 °C and an airflow rate of 15 L/h. Approximately 5.0 mL of soybean oil was inserted in a Rancimat glass tube with a constant flow of atmospheric air (15 L/h at 25 °C) bubbled into the oil. Gases from the oil/air mixture were collected in a vial with deionized water and an electrode to monitor electrical conductivity. As free radicals formed in the mixture, they dissolved in the water, causing a gradual increase in conductivity. A sudden change in this conductivity indicated the induction period (IP), marking the point of complete oil oxidation [21].

Using the Arrhenius equation (Equation (1)) and the obtained values of the oxidative induction period (IP), it is possible to calculate the activation energy (Ea) [22]

where K is the oxidation reaction rate constant for a specific temperature, A0 represents the initial conductivity, Ea is the activation energy, R is the ideal gas constant, and T (K) is the temperature used in the process.

2.3.4. Antioxidant Activity by the ABTS Method

In total, 5.0 mL of ABTS+(2,2-azino-bis(3-ethylbenzothiazoline-6-sulfonate)) solution (7 mM) was mixed with 88 μL of a sodium persulfate solution (140 mM) in a volumetric flask and stored in the dark for 16 h (Solution A). After the reaction period, 500 μL of Solution A was diluted in ethanol to achieve an absorbance reading on a spectrophotometer (Thermo Fisher Scientific, G10S UV-Vis, Waltham, Massachusetts, USA) of 0.70 ± 0.05 nm at a wavelength of 734 nm, thus originating Solution B. A total of 30 μL of the oil sample was diluted in 3.0 mL of Solution B and read with the spectrophotometer.

For preparation of the standard curve to be used in the antioxidant activity analysis, 25 mg of Trolox was diluted in 50 mL of ethanol. Subsequently, in a Falcon tube, the solution was further diluted in ethanol in proportions of 0.5:9.5, 2.5:7.5, 5.0:5.0, 7.5:2.5, and 10.0:0.0 in a total volume of 30 μL (Trolox:ethanol v/v). A total of 3.0 mL of Solution B was mixed in a vortex for 6 min and read on the spectrophotometer at λ = 734 nm, a wavelength that exhibits minimal influence on turbidity and lower sample interference [23]. With the obtained wavelength values, the equation for determining antioxidant activity was derived (R2 = 0.9991) (Equation (2)). This equation enabled us to determine the values in terms of Trolox equivalent antioxidant capacity (TEAC) [9,11,24,25,26].

2.4. Scale-Up and Economic Viability of Implementation

2.4.1. Pressurized Liquid Extraction in Pilot-Scale Equipment Using Ethanol as Solvent

The pilot-scale PLE equipment, built in Brazil, consists of a 2.0 L jacketed stainless-steel extractor, heated by circulating silicone oil maintained in a bath with electrical resistance. A Shimadzu pump supplies the solvent to the extractor, while a back-pressure pump maintains a pressure of 10 MPa. The system includes block, safety, and pressure relief valves, and is manually operated with an intermittent process, including a final nitrogen purge. The solvent reservoir holds 10 L, the collector holds 5.0 L, and the system is equipped with manometers and thermocouples for pressure and temperature monitoring.

The pilot-scale equipment was used after optimizing the extraction process at the laboratory scale for both solvents (hexane and ethanol) [7]. During the scale-up, the ratio between the solvent mass (ethanol) and laminated soybean mass (S/F) was maintained (2.5).

The experiment used only ethanol to develop an industrial-scale method for vegetable oil extraction with a green, sustainable solvent that leaves no toxic residues. This contrasts with hexane, which is neither environmentally sustainable nor free from toxic residues.

A total of 900 g of soybeans was placed in the extractor and filled with approximately 1050 mL of ethanol. The first extraction cycle began when the temperature reached 80 °C and the pressure was at 10 MPa. The solvent stayed in contact with the soybeans for 12 min, followed by a 400 mL solvent rinse and partial extract collection. During the process, pressure and temperature were kept stable, though minor temperature fluctuations occurred during the solvent’s entry and purging of the extract, which needed correction. Subsequent cycles repeated the 12 min contact time and 400 mL rinse while collecting the extract.

The adopted number of cycles (C) was 3. After the end of the third cycle, the system was completely emptied by purging the remaining micelle in the extractor with nitrogen, thus ensuring that the entire oil/solvent mixture was collected. The micelle was placed in a rotary evaporator and the solvent was recovered, leaving only the crude oil.

2.4.2. Economic Analysis and Cost of Industrial-Scale Implementation/Production

The pilot-scale experiments, replicating the laboratory-scale process, were essential for estimating the fixed capital investment (FCI) of a PLE system in an intermittent process. The FCI calculation included installation financing and working capital. The cost of manufacturing (COM) was based on the raw material costs, including soybeans, ethanol, hexane, and nitrogen. The operating cost (OC) was estimated using recent labor cost data from the chemical and food industries, including wages and associated hiring expenses.

The cost of manufacturing (COM) is influenced by several factors and can be divided into direct costs, fixed costs, and overall expenses. Direct costs are related to the costs with raw materials, services, labor, and energy consumption. Fixed costs, on the other hand, involve taxes and the equipment’s insurance and depreciation, costs that are independent of the production rate. Finally, the overall expenses are related to maintenance, research and development, and administrative costs, among others [17,27,28,29]

Using SuperPro Design® (8.5) software, the implementation cost, operation cost, and return-on-investment time for scales beyond the pilot were estimated. These calculations considered the investment costs for constructing the pilot PLE and the operating costs (Table 1), raw material prices, and 2023 product selling prices. Table 2 outlines the costs for constructing, maintaining, and operating the PLE in an intermittent process.

Table 1.

Price of the pilot-scale components of PLE in an intermittent process.

Table 2.

Sales prices and construction, maintenance, and processing costs of PLE on a pilot scale.

In the experiment, we used laminated soybeans provided by Bunge® (Jaguaré, Brazil), and the price of a soybean bushel was considered to be the value of this raw material, with a cost of USD 0.43/kg of soybeans. The ethanol used was purchased for USD 3.92/L for small scales and USD 0.78/L for larger scales (Table 2).

The total cost of construction and implementation of the pilot-scale PLE was USD 32,732.79 for equipment consisting of a 2.0-L extractor. The values of the equipment’s components (Table 1) were adjusted (in August 2023) for inflation during the period, which was 5.31%.

The cost of waste treatment was disregarded, since the ethanol used in the extraction process could be recovered. Moreover, soybean meal without oil can be utilized as a raw material for new products, such as a protein source in animal feed and human foods.

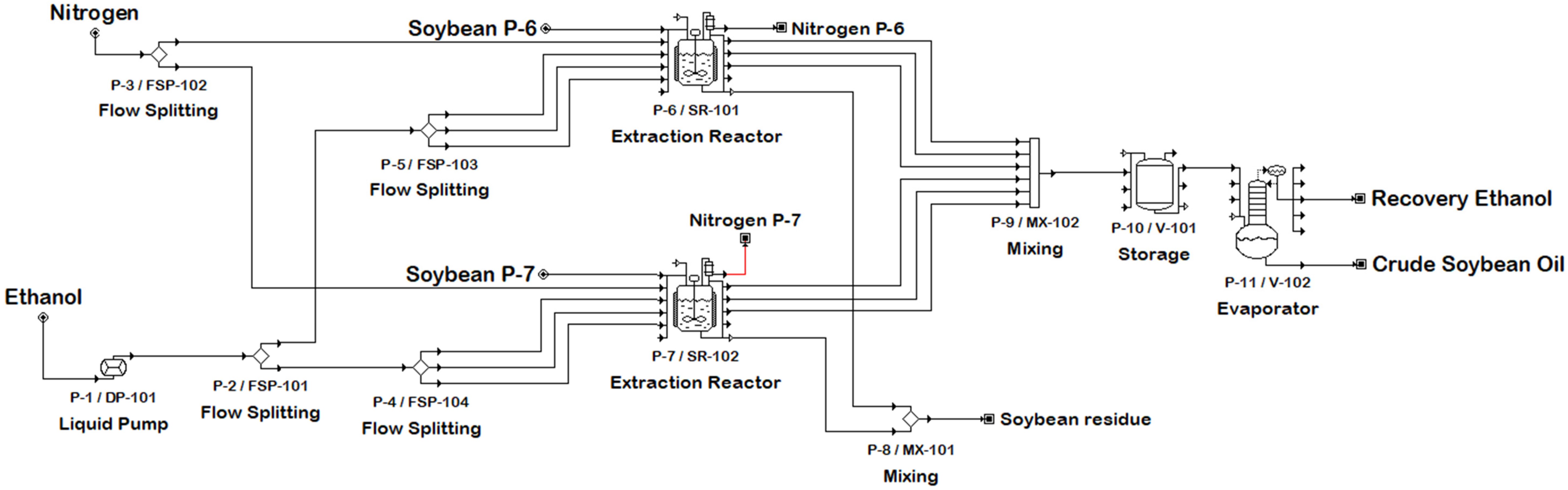

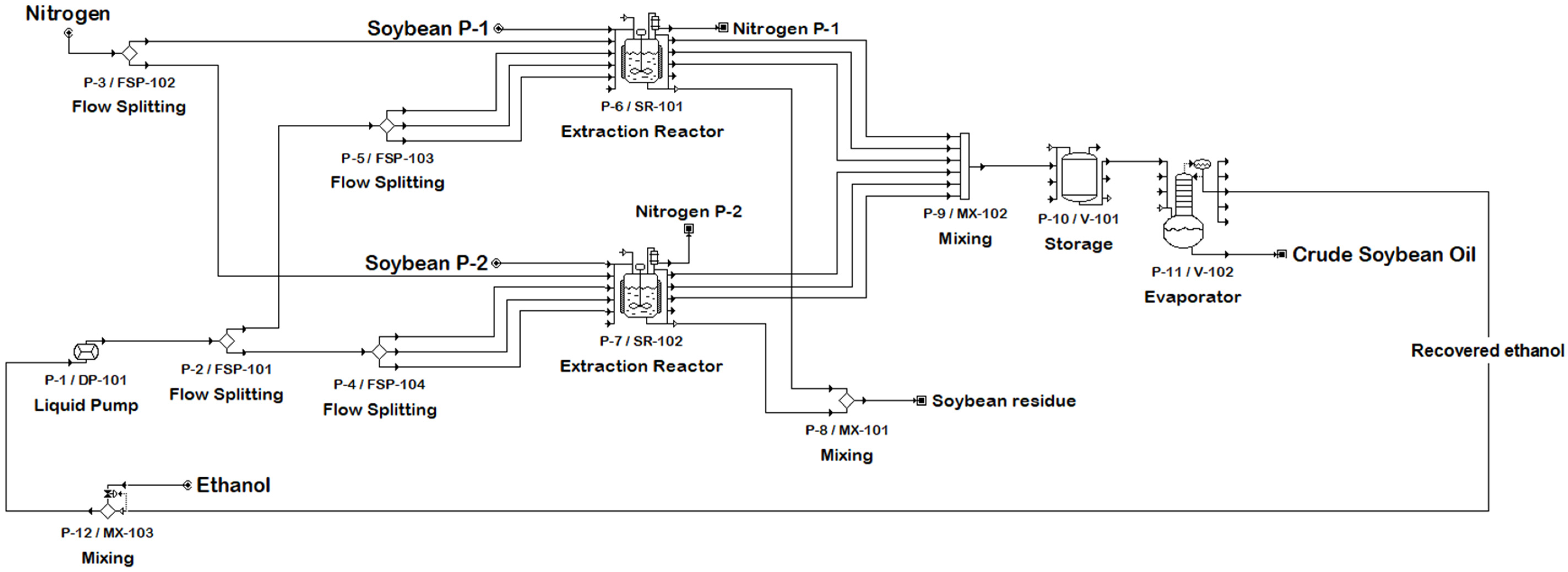

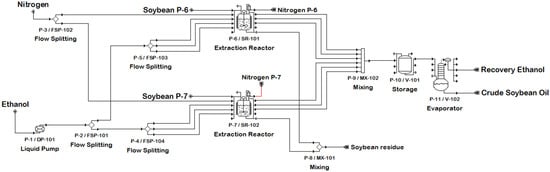

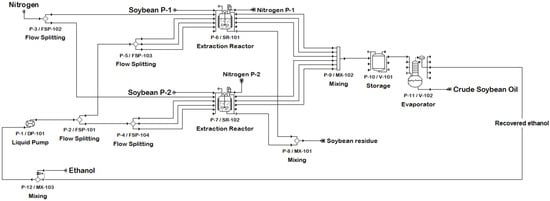

To simulate the implementation and operation costs of the industrial-scale PLE, two processing models were considered; the first was without ethanol recycling and the second was with ethanol recycling, both involving the preheating of ethanol before entering the extractor. The two processes’ flowchart models are shown in Figure 1 and Figure 2, obtained with the assistance of the SuperPro Design® program. Figure 1 illustrates the flowchart without ethanol recycling, while Figure 2 shows the flowchart with ethanol recycling.

Figure 1.

Flowchart model of the extraction process with pressurized ethanol without solvent recycling.

Figure 2.

Flowchart model of the extraction process with pressurized ethanol with solvent recycling.

Two extractors were considered in industrial production, since the system operates in batches. Having two extractors ensured that there was no idle time between operations. While one extractor operated, the other was unloaded, cleaned, and loaded again with laminated soybeans. The processing parameters were kept constant under the optimized condition identified in previous experiments at the laboratory scale [7] (SV equal to 60% of the extractor volume, 60 mL or 20 mL of rinse volume per cycle, C equal to 3, T of extraction of 80 °C, and St of 12 min).

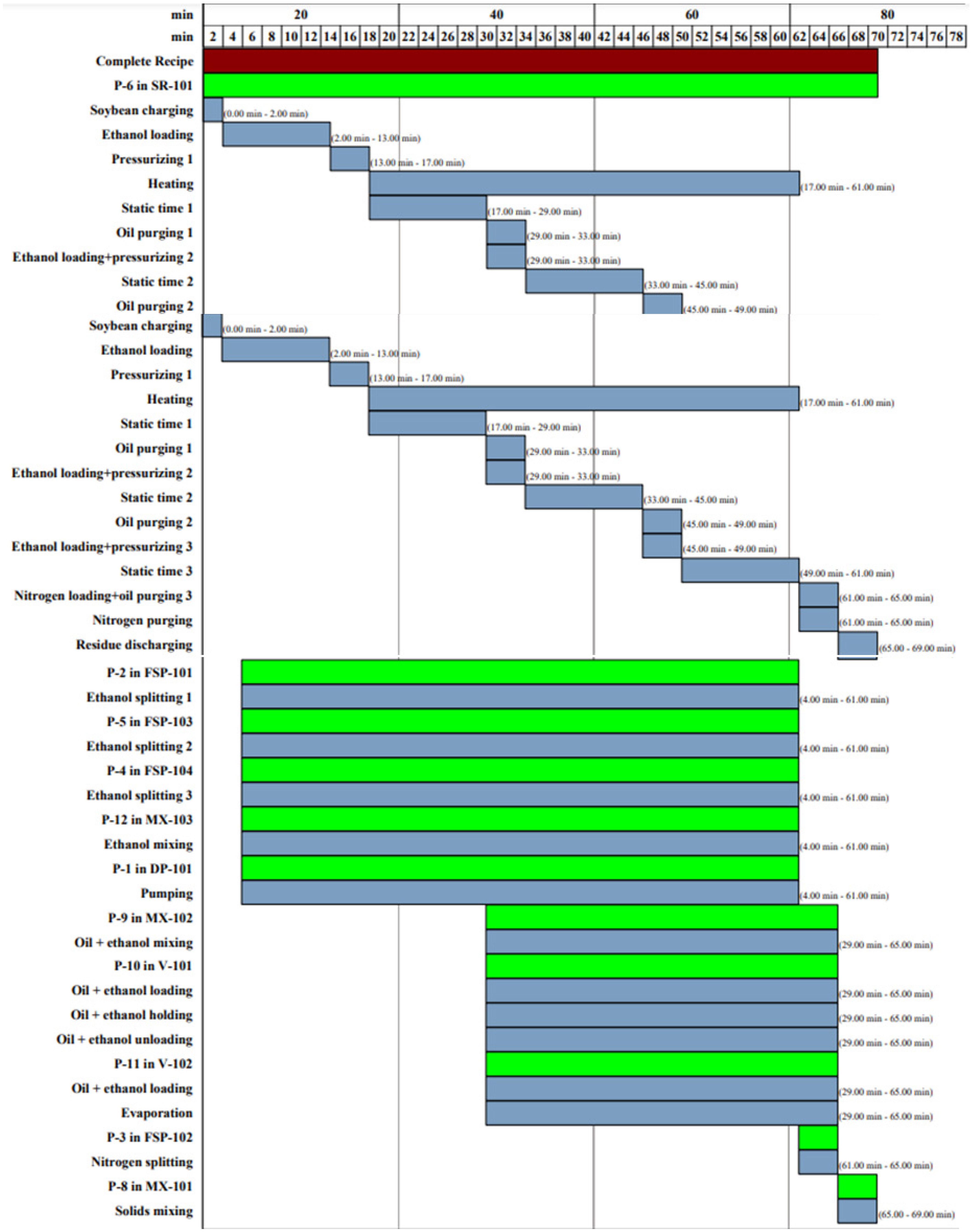

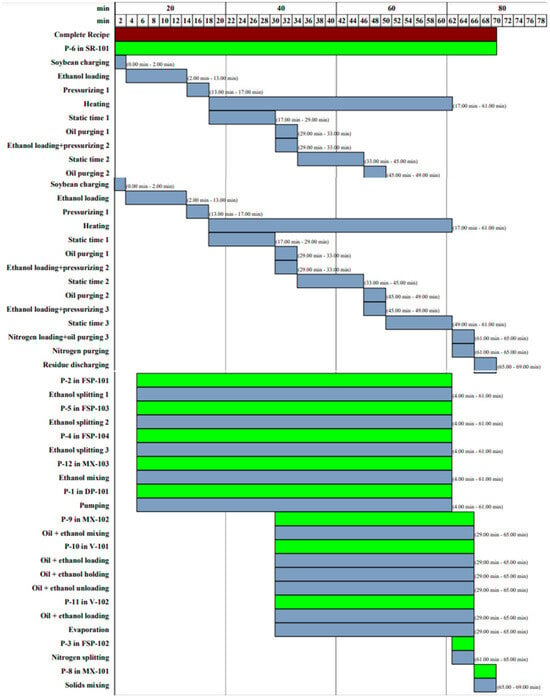

The simulated scenarios were proposed, based on the process flowcharts presented in the form of a Gantt diagram (Figure 3) and also simulated using experimental data at the pilot scale in SuperPro Design® software. From the evaluation of the pilot-scale PLE scenario, the capacity was gradually increased to achieve a potential positive return. In this simulation, the key components affecting economic parameters were taken into account (Table 3).

Figure 3.

Gantt diagram of the pressurized ethanol extraction process.

Table 3.

Variables used in each scenario to simulate the scale-up of the extraction process with pressurized ethanol in an intermittent process.

The equipment costs for some capacities were commonly obtained from suppliers, while for other equipment sizes or capacities, estimates were necessary due to the absence of consistent trading on the desired scale or the unavailability of values from suppliers. As a result, the estimated costs of the equipment used in the study for the required capacities were calculated using the power law (Equation (3)) [28,30,31,32]. Here, C1 represents the cost of equipment with a capacity of Q1, C2 represents the cost of equipment with a capacity of Q2, and M is a constant that depends on the types of equipment. It was assumed that the yield would remain consistent at larger scales when compared with the experimental results at the laboratory scale.

The COM and the percentage contribution of the itemized costs (fixed capital investment, FCI; cost of raw materials, CRM; cost of operational labor, COL; cost of utilities, CUT) were evaluated using the typical default models provided by the SuperPro Design® simulator. The economic return scenarios considered the gross margin (GM), return on investment (ROI), payback time (PT), net present value at 7% interest (NPV), and gross profit (GP).

3. Results and Discussion

3.1. Characterization of the Soybean Oil

In the development of the process, the characterization of the products generated using different solvents was necessary for process optimization and in simulating the estimation of oil production costs and economic competitiveness

3.1.1. Density and Viscosity

Table 4 shows the density and viscosity values for the soybean oils extracted with hexane and ethanol, and the values of these properties for a commercial oil for comparison. For both temperatures, 25 and 40 °C, the density did not show a significant variation among the oils extracted with the different solvents and remained very close to the value observed in the commercial oil, even though it was refined. The highest density value at 25 °C was identified in the oil extracted with hexane (0.9174 ± 0.0002 g/cm3). The oil extracted with ethanol exhibited a density of 0.9025 ± 0.0001 g/cm3, and the commercial oil had a density value of 0.9155 ± 0.0001 g/cm3. For this property, there was a significant difference due to the solvents or the extraction method. The oil extracted with ethanol had a lower density, differing from the oil extracted with hexane and the refined oil.

Table 4.

Density and viscosity of soybean oil extracted with different solvents at 25 and 40 °C and physicochemical parameters obtained by DSC analysis.

The increase in temperature resulted in decreased density, as observed in the measurements taken at 40 °C. The values for the oil extracted with hexane were 0.9072 ± 0.0002 g/cm3, while the oil extracted with ethanol presented a density of 0.9092 ± 0.0015 g/cm3, and the commercial oil, a density of 0.9059 ± 0.0005 g/cm3. Increased temperatures led to the oils’ expansion (even if slightly), causing an increase in volume and, consequently, a decrease in density. Moreover, at this temperature, there was a significant difference between the soybean oils obtained with ethanol and hexane and the commercial oil. This difference may be due to the extraction methods used, as the commercial oil was extracted under atmospheric pressure using hexane.

Shahid et al. [33] demonstrated that the density of soybean oil at 20 °C ranges from 0.9165 to 0.9261 g/cm3 and decreases drastically to the range of 0.000643 to 0.000668 g/cm3 with an increase in temperature to 63 °C. At room temperature, in this case, 20 °C, the density values were of the same order of magnitude as those found in the present study, and, as expected, the increase in temperature to 63 °C caused a considerable change in density. Meanwhile, Gad et al. [34] observed a decrease in viscosity from 7.5 to 2.0 mPA·s and also in density, from 0.916 g/cm3 to 0.870 g/cm3, in jatropha seed oil when the temperature was increased from 15 to 105 °C.

The viscosity exhibited identical behavior concerning temperature, regardless of the solvent or process used; the values decreased with the temperature increase. This behavior was expected because vegetable oils demonstrate Newtonian behavior, and their viscosity decreases with rising temperatures. According to Brock et al. [35], soybean oil has a viscosity of 59 mPa·s at 20 °C and 29.5 at 40 °C. Other studies reported that the viscosity of oil at 20 °C can range from 58.5 to 62.2 mPa·s [33].

In this study, the viscosity values for the soybean oil extracted with hexane were 47.8 ± 0.0 mPa·s and 27.3 ± 0.0 mPa·s at 25 and 40 °C, respectively. For the oil extracted with ethanol, the viscosity values at 25 °C were 53.7 ± 1.6 mPa·s and 30.4 ± 0.8 mPa·s at 40 °C. The analyzed commercial oil, used for comparison, exhibited a viscosity of 49.5 ±0.0 mPa·s at 25 °C and 28.4 ± 0.1 mPa·s at 40 °C (Table 4). The viscosity values of the soybean oil at both temperatures (25 and 40 °C) were similar for the oil extracted with hexane and the commercial oil. The oil extracted with ethanol showed slightly higher viscosity than the other two oils (Table 4). The divergent viscosity value for the oil extracted with ethanol can be explained by the fact that ethanol, being a polar solvent, may have extracted other compounds along with lipids, and these polar soybean compounds could be influencing the interactions and intermolecular forces in the oil, causing a slight increase in its viscosity.

Wang et al. [36] reported that unrefined oils present high viscosity and low mobility. According to Bhattacharya et al. [37] and Jia et al. [38], lecithin, a protein found in soybeans, can increase the viscosity of vegetable oils when added or extracted from the matrix during solvent extraction processes with polarities compatible with this compound, such as ethanol.

3.1.2. Differential Scanning Calorimetry (DSC)

The thermal analysis showed that the oil extracted with hexane had a peak at a temperature of −43.2 °C, the oil extracted with ethanol had a peak at −36.1 °C, and the commercial oil had a peak at −34.2 °C. The melting temperature (Tm) of the crude oil varied depending on the solvent used in the extraction or the extraction method, with values of 6.1 °C (hexane), 0 °C (ethanol), and 6.8 °C (commercial oil). The oil extraction method and the solvent used influenced these physical properties.

Physical properties such as the melting temperature (Tm) and the variation in fusion enthalpy (ΔHfus) also characterize the composition of oils and fats. The melting temperature (Tm) of the oil extracted with hexane via PLE in an intermittent process and the commercial oil showed values of −21.95 and −26.50 °C, respectively, values that were very similar to those observed in the soybean oil extracted with ethanol (−26.54 °C) (Table 4). The analysis of the thermal profile of oils obtained using different organic solvents and extraction methods showed that in the oil extracted with ethanol, the melting temperature (Tm) was lower than in the oils extracted with hexane and the commercial oil. Thus, it can be inferred that the oil extracted with ethanol had its characteristics altered.

The melting temperature of soybean oils can vary according to their degree of refinement, with values ranging from −23 to −6.0 [39,40], and is dependent on the triacylglycerol composition of the oil. Therefore, different concentrations of specific acids or the degree of oil degradation, even if small, can influence the melting point [41].

The variation in the fusion enthalpy of oils extracted with hexane and ethanol also showed very close values. The ΔHfus was equal to 54.39 J/g and 53.70 J/g, indicating that the amount of heat absorbed by the oil during phase transition was not affected by the extraction solvent.

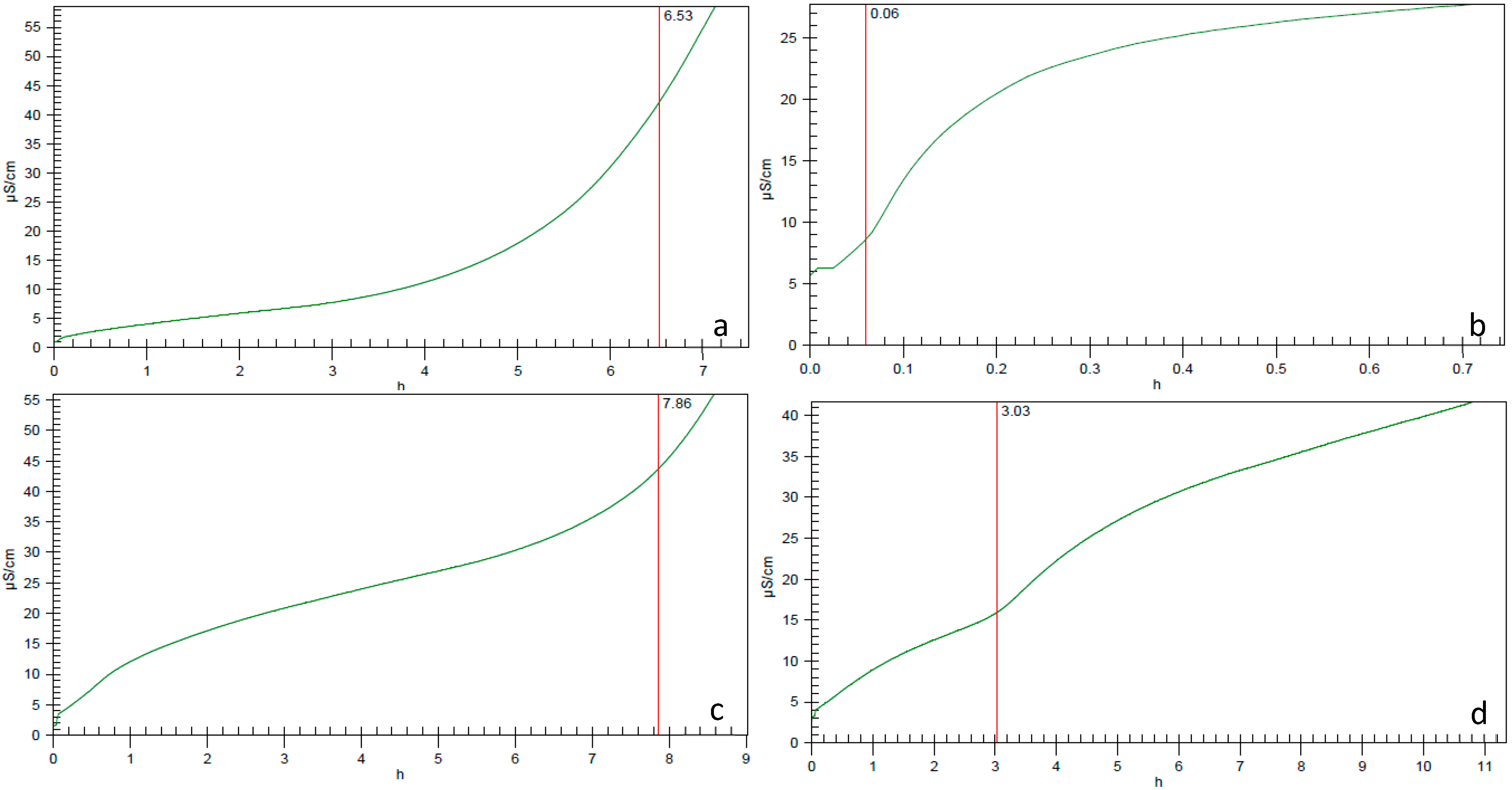

3.1.3. Oxidative Stability Determined via the Enhanced Electrical Conductivity Method

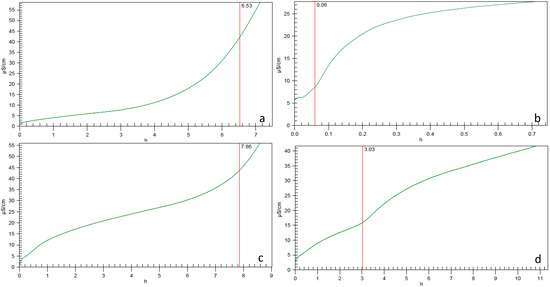

Oxidative degradation was also assessed using the oils obtained via the different solvents (hexane and ethanol) through pressurized liquid extraction in an intermittent process and compared with commercial oil. Figure 4 shows the oxidation curve and the induction period (IP) for the oils extracted with hexane (a) and ethanol (b) via PLE and Soxhlet extraction (c), and the commercial oil (d) for comparison purposes.

Figure 4.

Oxidation curve and induction period (IP) of oils extracted with hexane (a), ethanol (b), the Soxhlet method (c), and commercial oil (d).

The induction point (IP) is the point at which the concentration of free radicals present in the oil, due to oxidation, is sufficient to promote electrical conductivity in the distilled water.

Oxidative stability measures the resistance of an oil to the oxidation process [42]. This physicochemical parameter is important in monitoring the quality of edible oils, as it is directly related to the antioxidant compounds that the oil naturally possesses or that are added during its processing [42,43,44]. This property is essential for indicating the storage time and consumption of the product without any changes in its sensory (flavor, texture, smell, and color) and nutritional characteristics [45,46].

Table 5 shows the values of the induction period (IP) and the conductivity of the analyzed samples. It can be noted that the oil extracted with hexane presented a higher IP compared with the other oils (8.38 h), followed by the commercial oil (5.66 h) and the oil extracted with ethanol (0.21 h). Other authors found similar values. [47]. The ethanol-extracted oil exhibited faster oxidation than the other oils, although it had similar acidity levels to the oil extracted with hexane (2.11% ± 0.02 for ethanol and 2.12% ± 0.01 for hexane) [48]. This may be because ethanol and its polarity extracts compounds that hexane does not. These compounds can accelerate lipid oxidation, releasing radicals that sharply increase conductivity, causing the oil’s oxidation time to be shorter than that of the oils extracted with hexane and commercial oil.

Table 5.

Induction period and conductivity, measured with a Rancimat, and the antioxidant activity of soybean oil extracted with pressurized hexane and ethanol compared with conventional Soxhlet extraction and commercial soybean oil.

Among the compounds that can accelerate oxidation, we highlight transition metals, which exhibit thermal conductivity and numerous oxidation states [49], and phospholipids, which may contain unsaturated fatty acids in their composition [47,50]. Additionally, Kehili et al. [45], Musakhanian et al. [51], and Shahidi et al. [33] described how soybean oil has low oxidative stability, which can be affected by inappropriate handling and storage conditions, light exposure, and high humidity, as well as the oil’s intrinsic characteristics such as its fatty acid composition and the presence of free fatty acids, phospholipids, natural antioxidants (tocopherol), and pigments. Oils with a high degree of unsaturation are more susceptible to oxidation [43,52]. According to Ramos et al. [7], the percentage of unsaturated fatty acids in oils obtained with ethanol was 73.20% of the total, and the percentage of linolenic acid was higher in the oil extracted with ethanol (8.25%) than in the oil extracted with hexane (6.16%), on average.

Some authors have reported that adding natural or synthetic antioxidant compounds increases the oxidative stability and oxidation time of vegetable oils. For example, the study by Abdo et al. [24] used lyophilized extracts of pomegranate, orange, and beetroot (at a concentration of 1:1:1) as a natural antioxidant in the assessment of thermal oxidation of soybean oil during frying. The authors noted a reduction in the total oil oxidation by up to 65%, compared with crude oil, when using 800 μg/mL of the extracts.

3.1.4. Antioxidant Activity Determined via the ABTS Method

The oil extracted with hexane presented an antioxidant activity of 617.8 ± 3.9 μmol of Trolox equivalent antioxidant capacity (TEAC)/mg of oil. The oil extracted with ethanol showed similar antioxidant activity, with 618.9 ± 10.2 μmol TEAC/g of oil. For the commercial oil, the observed antioxidant activity was lower (548.89 ± 5.09 μmol TEAC/g of oil), while the oil extracted by the Soxhlet method had an antioxidant activity of 507.78 ± 1.92 μmol TEAC/g of oil (Table 5).

It can be noted that the solvents used in the extractions (hexane or ethanol) did not have a significant influence on antioxidant activity, as the values of such activity for the oil extracted with hexane were very close to those of the oil extracted with ethanol. Regarding the extraction process, it can be stated that oils obtained through pressurized liquid extraction showed a higher antioxidant effect than oils obtained through the conventional process (commercial) and the Soxhlet method.

Freitas et al. [53] analyzed the antioxidant activity of pure soybean oil and obtained a value of 255.3 ± 2.9 μmol TEAC/g of oil on the incorporation of grape seed extract into soybean oil. This suggests that the high-pressure process may influence the solubilization of compounds with antioxidant activity.

3.2. Scale-Up and Economic Viability of Implementation

3.2.1. Pressurized Liquid Extraction in Pilot-Scale Equipment Using Ethanol as the Solvent

The pilot-scale extraction was conducted in triplicate and yielded a mean extraction efficiency of 19.28 ± 0.03%, with a mean oil recovery of 86.27 ± 0.12%. Soybean oil recovery under identical processing conditions in PLE (at the optimal point) on a laboratory scale was the same (86.16%), with an extraction yield of 19.26%.

In the scale-up process, the ratio between the mass of the solvent (ethanol) and the mass of laminated soybeans (S/F) was kept constant; therefore, it was expected that the yield would be the same, as this is commonly observed in scaled up processes [17,18]. In the studies by Prado et al. [19] and Colivet et al. [18], the authors demonstrated that the S/F ratio proved to be a suitable criterion for process scaling. Prado et al. [19] investigated the scale-up of the supercritical fluid extraction process from grape seeds (Vitis vinifera L.) from a 290 mL extractor to a 5.15 L pilot-scale extractor, and noted that the extraction kinetic curves for both the laboratory-scale and the pilot-scale processes were similar. Colivet et al. [18] showed that if the S/F ratio is maintained, the extractor size has no influence on the yield of watermelon seed oil obtained with pressurized ethanol in an intermittent process.

Conventional soybean oil extraction, used industrially, achieves yields of around 99%. PLE with pressurized ethanol utilizes a different, non-toxic solvent derived from renewable sources, and it is generally recognized as safe (GRAS) for health. This solvent is non-polar and, along with the oil, extracts other compounds. The separation of the oil requires a centrifugation process, which also leads to losses in the extracted oil content.

Although the processing conditions applied in this experiment originated from the optimization of soybean oil extraction via PLE on a laboratory scale, it is important to emphasize that there were still some controls that need improvement in the design of the pilot-scale PLE in an intermittent process, such as, for example, the heating of the solvent at the extractor’s inlet. If this step is not conducted, the processing temperature is not immediately reached during each cycle until it stabilizes, resulting in a longer contact time between the solvent and the matrix. Additionally, the temperature was not kept constant throughout the entire extraction, as it should be.

3.2.2. Economic Analysis and Industrial-Scale Implementation/Production Costs

Through use of SuperPro Design® 8.5 software, 16 scenarios were simulated using 2 extractors, with volumes ranging from 2 to 5000 L. In addition to the extractor’s volume, the number of operators (two and four) and the number of shifts per day (one to three 8 h shifts) also varied. In some scenarios, solvent recovery and recycling were considered in the process. Table 3 shows the variations used in each scenario and the simulations that allowed the scenario to yield better results, such as decreasing the raw material’s acquisition cost or increasing the product sales price.

The optimized intermittent process adopted in the processing approach (Gantt diagram) (Figure 3) consisted of three cycles in the extraction process. Initially, there was the manual loading of soybeans (soybean charging), followed by ethanol loading, heating, and system pressurization (Pressurizing 1), marking the start of the first cycle (Static time 1). After the end of the first cycle, the ethanol/oil mixture was removed (Oil purging 1) concurrently with the injection of a new amount of solvent (400 mL) and pressurization (Ethanol loading 2 + Pressurizing 2), marking the end of Cycle 1 and the start of Cycle 2. At the end of the third cycle, while the ethanol was purged along with the soybean oil, nitrogen was injected for complete solvent removal.

The unloading of soybeans after extraction was also performed manually (residue discharging), and the separation/recovery of the used ethanol (evaporation) and obtaining the desired product was carried out in separate equipment, but still with the processing time added to the presented Gantt diagram. It can be noted that heating was the process stage with the longest continuous duration, as it was necessary to maintain a constant temperature throughout the process to achieve the expected yield.

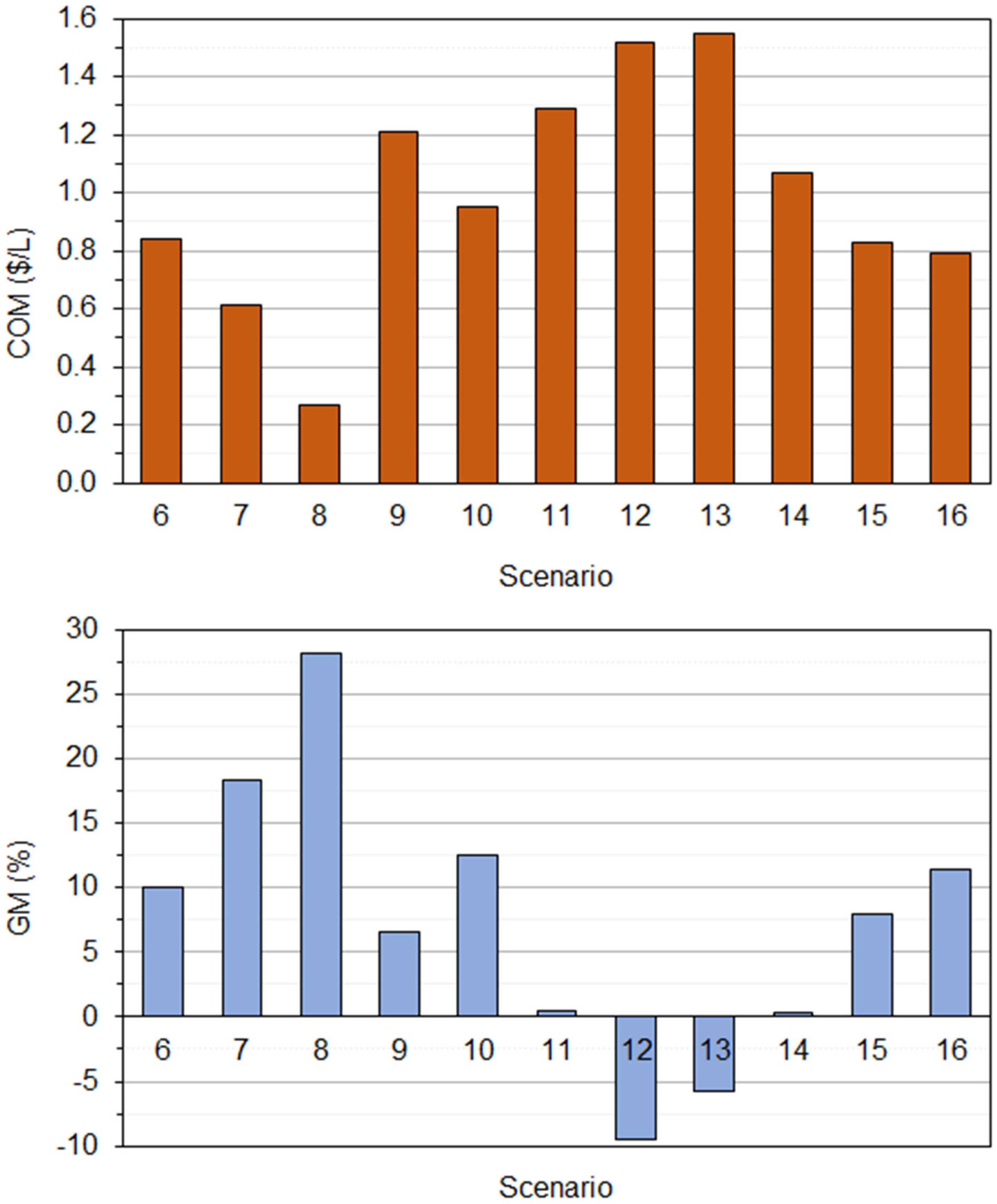

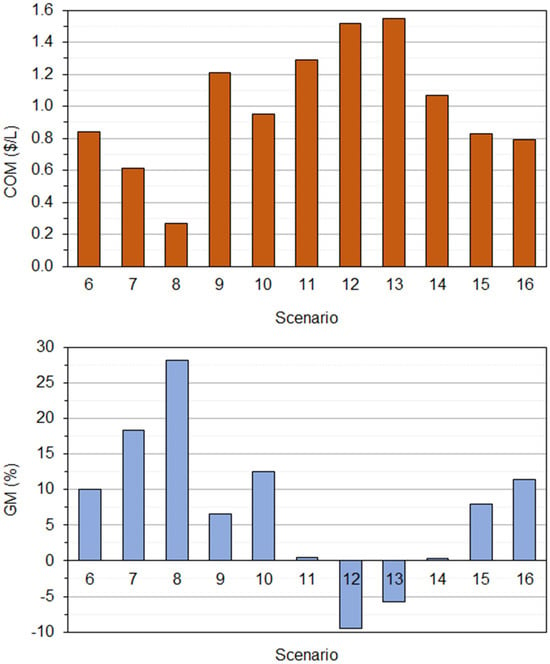

Through the simulations, it was possible to determine the total capital investment (TCI), the operation cost (OC), the total revenue (TR), the productivity of the oil (PO), the cost of manufacturing (COM), the gross margin (GM), the return on investment (ROI), the payback time (PT), the net present value (NPV), the cost of the raw material (CRM), the cost of operational labor (COL), the fixed capital investment (FCI), the cost of utilities (CUT), the gross profit (GP), and the productivity of the bran (PB) for all scenarios, identifying the best one among them for industrial implementation (Table 6). Figure 5 shows the cost of manufacturing (COM) and the gross margin (GM) for Scenarios 6 to 16.

Table 6.

Results obtained in simulated scenarios for implementation of the extraction process with pressurized ethanol on an industrial scale.

Figure 5.

COM of oil (USD/L) and gross margin (GM) for Scenarios 6–16 (2 × 5000 L plant) with preheating.

Among the 16 simulated scenarios, 8 proved to be ineffective for implementation (Scenarios 1, 2, 3, 4, 11, 12, 13, and 14). It can be noted that in the referenced scenarios, the return on investment (ROI) was either negative or very low (close to zero) (Table 6, Figure 5), indicating that these scenarios would not be sustainable over time, regardless of variations in the sales price or the acquisition cost of raw materials and solvents.

Among the scenarios that did not show a positive return on investment, two of them did not promote ethanol recycling (Scenarios 1 and 2). These were smaller systems using sets of extractors with volumes of 2.0 and 10 L. Six scenarios, on the other hand, using sets of extractors with volumes of 50, 500, 1000, and 5000 L, involved ethanol recycling (Scenarios 3, 4, 11, 12, 13, and 14).

Through an analysis of Scenarios 4 and 5, it can be observed that the variation in the production volume using a set of extractors ranging from 500 L (Scenario 4) to 1000 L (Scenario 5), while maintaining all the other variables constant, had a positive effect on the ROI, making the latter scenario favorable for implementation. Thus, in the proposed installation with two systems, where one extractor is prepared while the other is in operation (Figure 1 and Figure 2), the extractors should have volumes greater than 1000 L to achieve positive financial returns and feasibility in their implementation. However, not all production lines with larger extractors proved favorable due to other factors, such as the purchase price of soybeans and ethanol or the sales price of the oil and bran (Table 3).

When comparing Scenarios 10 and 11 (Table 3), for instance, a small variation in the sales price of soybean oil and bran, while maintaining the other variables constant, rendered Scenario 11 unfavorable for implementation, whereas Scenario 10 became favorable. This can also be seen in Figure 5, where Scenario 10 has a lower COM and a much higher GM than Scenario 11, indicating lower production costs and a higher profit percentage. Regarding the raw material acquisition price, Scenarios 14 and 15 showed that a decrease in the soybean acquisition price (Scenario 15) can make the scenario favorable for implementation.

In contrast with the negative scenarios, Scenarios 5, 6, 7, 8, 9, 10, 15, and 16 (Table 6 and Figure 5) evidenced a positive return on investment and proved suitable for implementation. These production lines, containing two 5000 L extractors, were designed to be operated by four people in 8-h shifts, with ethanol recycling, which is crucial for the process’s economy, and with the plant’s operational time ranging from 12 to 24 h of service. The differentiation between these scenarios is related to variations in the cost of product acquisition and the sales price of the product and residues (oil and soybean). This can be noted in Figure 5, where a significant contrast can be observed between favorable scenarios with a positive GM and unfavorable scenarios with a negative GM.

The return-on-investment percentages in the first year ranged from 9.0 (Scenario 5) to 133.5% (Scenario 8), with payback times varying from 0.7 (Scenario 8) to 11.1 years (Scenario 5). The best implementation design (Scenario 8, Table 6) was undoubtedly the one with the highest return on investment (133.5%) in the shortest time (0.7 years). Figure 5 graphically illustrates this, showing that Scenario 8 had the lowest cost of manufacturing (COM) at USD 0.27/L and the highest gross margin (GM) of 28.2%. In this process line, two 5000 L extractors with ethanol recycling were considered, reaching a significant annual soybean oil production of 3,325,300 L, resulting in a cost of manufacturing oil of around USD 1.25/L.

Considering that the sales price of soybean oil is USD 1.34/L (August 2023 on the Chicago Stock Exchange), soybean oil extracted via industrial-scale PLE is 6.71% cheaper than soybean oil extracted by conventional methods (not taking into account the oil refining step). In addition to financial viability, oil extracted via pressurized ethanol has the advantage of using a renewable solvent, with lower environmental impact and greater safety for consumers.

An economic assessment that allows the establishment of a large-scale company with a payback time of up to 5 years [29] can be considered favorable. Scenarios 14 and 20 (Table 6) showed a payback time exceeding 5 years.

With the aid of the data simulated using SuperPro Design® 8.5 (Table 5) based on the scaled up data, it can be noted that the cost of raw material (soybeans) and the production volume are factors that impact economic parameters, and the process of pressurized ethanol extraction is viable. Thus, the importance of seeking for processes that use smaller amounts of solvent and optimize the use of raw materials is evident, increasing productivity and obtaining a product that is safe for health without toxic solvent residues.

4. Conclusions

It can be concluded that the different extraction methods used, as well as the different solvents, did not significantly affect the physicochemical properties of the analyzed oils. The variations in the viscosity and mean induction period (IP) found in the soybean oil extracted with pressurized ethanol may be related to non-lipid compounds extracted along with the oil due to the polarity of the solvent.

The antioxidant activity showed very similar values regardless of the solvent used in the PLE extraction process. In the commercial oil, which was extracted by the conventional extraction method (atmospheric pressure), the antioxidant activity showed a lower value, demonstrating that the extraction pressure slightly favored the maintenance of antioxidant compounds in the oil.

The DSC analysis also showed that the solvents used did not influence the oil’s melting temperature or enthalpy variation, as expected, since the extraction process should not affect the oil’s thermal profile. The melting temperature of the soybean oil extracted with ethanol was practically identical to that of the conventionally extracted soybean oil (commercial).

The pilot-scale extraction yield reached values that were very close to the laboratory-scale yields when ethanol was used as a solvent, indicating that the pilot-scale PLE equipment has the potential for improved yields as its performance is refined.

The economic and implementation cost analyses on an industrial scale showed that there is viability for implementing pressurized fluid extraction equipment on an industrial scale and that the sales price of the oil extracted with pressurized ethanol was lower than that of commercial oil. In addition to being cheaper, ethanol-extracted oil is more sustainable and less toxic.

Author Contributions

Methodology, L.d.C.R. and P.R.R.; Software, P.R.R., L.d.C.R. and G.L.Z.; Formal analysis, P.R.R.; Investigation, P.R.R.; Resources, A.L.d.O.; Data curation, P.R.R.; Writing—original draft, P.R.R. and G.L.Z.; Writing—review & editing, A.L.d.O.; Supervision, A.L.d.O.; Project administration, A.L.d.O.; Funding acquisition, A.L.d.O. All authors have read and agreed to the published version of the manuscript.

Funding

We would like to thank the São Paulo State Research Support Foundation (FAPESP; Process No. 2018/18024-7) and the National Council for Scientific and Technological Development (CNPq; Processes No. 304573/2019-1 and No. 306317/2016-8) for their financial support.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

R.P.R. would like to express his gratitude to the Brazilian agency Coordination for the Improvement of Higher Education Personnel (CAPES) for the scholarship (Process No. 001) and to Bunge Agronegócios, Alimentos e Bioenergia.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

C, cycle; COL, cost of operational labor; COM, cost of manufacturing; Cp, heat capacity; CRM, cost of raw materials; CUT, cost of utilities; DSC, differential scanning calorimetry; Ea, activation energy; FCI, fixed capital investment; GM, gross margin; GP, gross profit; GRAS, generally recognized as safe; IP, induction period; NPV, net present value; OC, operating cost; PLE, pressurized liquid extraction; PO, productivity of the oil; PB, productivity of the bran; PT, payback time; ROI, return on investment; S/F ratio, solvent mass (S)/matrix mass ratio (F); St, static time; SV, solvent volume; TAGs, triacylglycerols; Tb, boiling temperature; TCI, total capital investment; TEAC, Trolox equivalent antioxidant capacity; Tg, glass transition temperature; Tm, melting temperature; TR, total revenues; ΔHfus, fusion enthalpy.

References

- Carabias-Martínez, R.; Rodríguez-Gonzalo, E.; Revilla-Ruiz, P.; Hernández-Méndez, J. Pressurized Liquid Extraction in the Analysis of Food and Biological Samples. J. Chromatogr. A 2005, 1089, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Richter, B.E.; Jones, B.A.; Ezzell, J.L.; Porter, N.L.; Avdalovic, N.; Pohl, C. Accelerated Solvent Extraction: A Technique for Sample Preparation. Anal. Chem. 1996, 68, 1033–1039. [Google Scholar] [CrossRef]

- Pallaroni, L.; Von Holst, C. Development of an Extraction Method for the Determination of Zearalenone in Corn Using Less Organic Solvents. J. Chromatogr. A 2004, 1055, 247–249. [Google Scholar] [CrossRef]

- Khan, Z.; Kamble, N.; Bhongale, A.; Girme, M.; Bahadur Chauhan, V.; Banerjee, K. Analysis of Pesticide Residues in Tuber Crops Using Pressurised Liquid Extraction and Gas Chromatography-Tandem Mass Spectrometry. Food Chem. 2018, 241, 250–257. [Google Scholar] [CrossRef]

- Putra, N.R.; Yustisia, Y.; Heryanto, R.B.; Asmaliyah, A.; Miswarti, M.; Rizkiyah, D.N.; Yunus, M.A.C.; Irianto, I.; Qomariyah, L.; Rohman, G.A.N. Advancements and Challenges in Green Extraction Techniques for Indonesian Natural Products: A Review, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2023; Volume 46. [Google Scholar]

- Putnik, P.; Barba, F.J.; Španić, I.; Zorić, Z.; Dragović-Uzelac, V.; Bursać Kovačević, D. Green Extraction Approach for the Recovery of Polyphenols from Croatian Olive Leaves (Olea europea). Food Bioprod. Process. 2017, 106, 19–28. [Google Scholar] [CrossRef]

- Ramos, P.R.; Vicentini-Polette, C.M.; Mazalli, M.R.; de Lima Caneppele, F.; de Oliveira, A.L. Pressurized Liquid Extraction of Soybean Oil Using Intermittent Process with Ethanol and Hexane as Solvent: Extraction Yield and Physicochemical Parameters Comparison. J. Food Process Eng. 2024, 47, e14562. [Google Scholar] [CrossRef]

- Bittencourt, G.M.; Firmiano, D.M.; Fachini, R.P.; Lacaz-Ruiz, R.; Fernandes, A.M.; Oliveira, A.L. Application of Green Technology for the Acquisition of Extracts of Araçá (Psidium grandifolium Mart. Ex DC.) Using Supercritical CO2 and Pressurized Ethanol: Characterization and Analysis of Activity. J. Food Sci. 2019, 84, 1297–1307. [Google Scholar] [CrossRef]

- Bittencourt, G.M.; dos Reis Simprônio, M.; Mothé, I.R.; Ferreira, G.R.; de Oliveira, A.L. Globe Artichoke Leaf Extracts and Production of Phytotherapeutic Solid Lipid Particles Using High Pressure Technologies. J. Supercrit. Fluids 2023, 201, 106028. [Google Scholar] [CrossRef]

- Okiyama, D.C.G.; Soares, I.D.; Cuevas, M.S.; Crevelin, E.J.; Moraes, L.A.B.; Melo, M.P.; Oliveira, A.L.; Rodrigues, C.E.C. Pressurized Liquid Extraction of Flavanols and Alkaloids from Cocoa Bean Shell Using Ethanol as Solvent. Food Res. Int. 2018, 114, 20–29. [Google Scholar] [CrossRef]

- Viganó, J.; Brumer, I.Z.; de Campos Braga, P.A.; da Silva, J.K.; Maróstica Júnior, M.R.; Reyes Reyes, F.G.; Martínez, J. Pressurized Liquids Extraction as an Alternative Process to Readily Obtain Bioactive Compounds from Passion Fruit Rinds. Food Bioprod. Process. 2016, 100, 382–390. [Google Scholar] [CrossRef]

- de Jesus, S.S.; Filho, R.M. Recent Advances in Lipid Extraction Using Green Solvents. Renew. Sustain. Energy Rev. 2020, 133, 110289. [Google Scholar] [CrossRef]

- Cornelio-Santiago, H.P.; Mazalli, M.R.; Rodrigues, C.E.C.; de Oliveira, A.L. Extraction of Brazil Nut Kernel Oil Using Green Solvents: Effects of the Process Variables in the Oil Yield and Composition. J. Food Process Eng. 2019, 42, e13271. [Google Scholar] [CrossRef]

- de Oliveira, N.A.; Cornelio-Santiago, H.P.; Fukumasu, H.; de Oliveira, A.L. Green Coffee Extracts Rich in Diterpenes—Process Optimization of Pressurized Liquid Extraction Using Ethanol as Solvent. J. Food Eng. 2018, 224, 148–155. [Google Scholar] [CrossRef]

- Santos, K.A.; de Aguiar, C.M.; da Silva, E.A.; da Silva, C. Evaluation of Favela Seed Oil Extraction with Alternative Solvents and Pressurized-Liquid Ethanol. J. Supercrit. Fluids 2021, 169, 105125. [Google Scholar] [CrossRef]

- Ferro, D.M.; Mayer, D.A.; Oliveira Müller, C.M.; Ferreira, S.R.S. Scale-up Simulation of PLE Process Applied to Recover Bio-Based Materials from Sida Rhombifolia Leaves. J. Supercrit. Fluids 2020, 166, 105033. [Google Scholar] [CrossRef]

- Ferreira, W.S.; Viganó, J.; Veggi, P.C. Economic Assessment of Emerging Extraction Techniques: Hybridization of High-Pressure Extraction and Low-Frequency Ultrasound to Produce Piceatannol-Rich Extract from Passion Fruit Bagasse. Chem. Eng. Process.—Process Intensif. 2022, 174, 108850. [Google Scholar] [CrossRef]

- Colivet, J.; Oliveira, A.L.; Carvalho, R.A. Influence of the Bed Height on the Kinetics of Watermelon Seed Oil Extraction with Pressurized Ethanol. Sep. Purif. Technol. 2016, 169, 187–195. [Google Scholar] [CrossRef]

- Prado, J.M.; Dalmolin, I.; Carareto, N.D.D.; Basso, R.C.; Meirelles, A.J.A.; Oliveira, J.V.; Batista, E.A.C.; Meireles, M.A.A. Supercritical Fluid Extraction of Grape Seed: Process Scale-up, Extract Chemical Composition and Economic Evaluation. J. Food Eng. 2012, 109, 249–257. [Google Scholar] [CrossRef]

- Rosa, P.T.V.; Meireles, M.A.A. Rapid Estimation of the Manufacturing Cost of Extracts Obtained by Supercritical Fluid Extraction. J. Food Eng. 2005, 67, 235–240. [Google Scholar] [CrossRef]

- Varona, E.; Tres, A.; Rafecas, M.; Vichi, S.; Barroeta, A.C.; Guardiola, F. Methods to Determine the Quality of Acid Oils and Fatty Acid Distillates Used in Animal Feeding. MethodsX 2021, 8, 101334. [Google Scholar] [CrossRef]

- Maldonade, I.R.; Lozada, M.I.O.; de Oliveira, L.d.L.; Amaro, G.B. Estabilidade Oxidativa de Óleos de Sementes de Cucurbitáceas; Boletim de Pesquisa e Desenvolvimento, 185; EMBRAPA: Brasília, Brasil, 2019. [Google Scholar]

- Magalhães, L.M.; Segundo, M.A.; Reis, S.; Lima, J.L.F.C. Methodological Aspects about in Vitro Evaluation of Antioxidant Properties. Anal. Chim. Acta 2008, 613, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Abdo, E.M.; Shaltout, O.E.; Mansour, H.M.M. Natural Antioxidants from Agro-Wastes Enhanced the Oxidative Stability of Soybean Oil during Deep-Frying. LWT 2023, 173, 114321. [Google Scholar] [CrossRef]

- Flieger, J.; Flieger, W.; Baj, J. Antioxidants: Classification, Natural Sources, Activity/Capacity. Materials 2021, 14, 4135. [Google Scholar] [CrossRef] [PubMed]

- do Socorro Moura Rufino, M.; Alves, R.E.; de Brito, E.S.; de Morais, S.M.; de Goes Sampaio, C.; Pérez-Jiménez, J.; Saura-Calixto, F. Metodologia Científica: Determinação da Atividade Antioxidante Total em Frutas pela Captura do Radical Livre DPPH; EMBRAPA: Brasília, Brazil, 2007. [Google Scholar]

- Confortin, T.C.; Todero, I.; Luft, L.; Ugalde, G.A.; Mazutti, M.A.; Oliveira, Z.B.; Bottega, E.L.; Knies, A.E.; Zabot, G.L.; Tres, M.V. Oil Yields, Protein Contents, and Cost of Manufacturing of Oil Obtained from Different Hybrids and Sowing Dates of Canola. J. Environ. Chem. Eng. 2019, 7, 102972. [Google Scholar] [CrossRef]

- Turton, R.; Bailie, R.; Whiting, W.B.; Shaeiwitz, J.A.; Bhattacharyya, D. Analysis, Synthesis, and Design of Chemical Processes, 4th ed.; Prentice Hall: Hoboken, NJ, USA, 2013; Volume 1, ISBN 9788578110796. [Google Scholar]

- Buarque, C. Avaliação Econômica de Projetos; Elsevier: Amsterdam, The Netherlands, 1994. [Google Scholar]

- Osorio-Tobón, J.F.; Carvalho, P.I.N.; Rostagno, M.A.; Meireles, M.A.A. Process Integration for Turmeric Products Extraction Using Supercritical Fluids and Pressurized Liquids: Economic Evaluation. Food Bioprod. Process. 2016, 98, 227–235. [Google Scholar] [CrossRef]

- Carvalho, P.I.N.; Osorio-Tobón, J.F.; Zabot, G.L.; Meireles, M.A.A. Spatial and Temporal Temperature Distributions in Fixed Beds Undergoing Supercritical Fluid Extraction. Innov. Food Sci. Emerg. Technol. 2018, 47, 504–516. [Google Scholar] [CrossRef]

- Peters, M.S.; Timmerhaus, K.D. Plant Design and Economics for Chemical Engineers, 4th ed.; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Shahidi, F. (Ed.) Bailey’s Industrial Oil and Fat Products, 6th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Ibrahim, S.; Gad, M.; Abed, K.; Mustafa, H. Design, Manufacturing and Testing of Hydraulic Press to Produce the Oil from Egyptian Jatropha Seeds. J. Int. Soc. Sci. Eng. 2019, 2, 8–15. [Google Scholar] [CrossRef]

- Brock, J.; Nogueira, M.R.; Zakrzevski, C.; De Castilhos Corazza, F.; Corazza, M.L.; De Oliveira, J.V. Determinação Experimental Da Viscosidade e Condutividade Térmica de Óleos Vegetais. Cienc. Tecnol. Aliment. 2008, 28, 564–570. [Google Scholar] [CrossRef]

- Wang, S.; Gao, Z.; Qi, X.; Li, C.; He, L.; Bi, J.; Liu, Z. Superhydrophobic Carbon Black-Loaded Polyurethane Sponge for Efficient Oil-Water Separation and Solar-Driven Cleanup of High-Viscosity Crude Oil. J. Water Process Eng. 2023, 53, 103812. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Shylaja, M.H.; Manjunath, M.S.; Sankar, U. Rheology of Lecithin Dispersions. J. Am. Oil Chem. Soc. 1998, 75, 871–874. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, Y.; Li, C.; Yang, M.; Gao, T.; Said, Z.; Sharma, S. Lubrication-Enhanced Mechanisms of Titanium Alloy Grinding Using Lecithin Biolubricant. Tribol. Int. 2022, 169, 107461. [Google Scholar] [CrossRef]

- Subroto, E. Characteristics, Purification, and the Recent Applications of Soybean Oil in Fat-Based Food Products: A Review. Int. J. Emerg. Trends Eng. Res. 2020, 8, 3003–3011. [Google Scholar] [CrossRef]

- Nassu, R.T.; Gonçalves, L.A.G. Determination of Melting Point of Vegetable Oils and Fats by Differential Scanning Calorimetry (DSC) Technique. Grasas Aceites 1999, 50, 16–22. [Google Scholar] [CrossRef]

- Litwinienko, G.; Kasprzycka-Guttman, T. Study on the Autoxidation Kinetics of Fat Components by Differential Scanning Calorimetry. 2. Unsaturated Fatty Acids and Their Esters. Ind. Eng. Chem. Res. 2000, 39, 13–17. [Google Scholar] [CrossRef]

- Aktas, A.B.; Dastan, T.; Katin, K.P.; Kaya, S. Determination of Oxidative Stability of Different Vegetable Oils by Means of Middle Infrared Spectroscopy and DFT Calculations. Microchem. J. 2023, 194, 109232. [Google Scholar] [CrossRef]

- Maszewska, M.; Florowska, A.; Dłuzewska, E.; Wroniak, M.; Marciniak-Lukasiak, K.; Zbikowska, A. Oxidative Stability of Selected Edible Oils. Molecules 2018, 23, 1746. [Google Scholar] [CrossRef]

- Velasco, J.; Dobarganes, C. Oxidative Stability of Virgin Olive Oil. Eur. J. Lipid Sci. Technol. 2002, 104, 661–676. [Google Scholar] [CrossRef]

- Kehili, M.; Choura, S.; Zammel, A.; Allouche, N.; Sayadi, S. Oxidative Stability of Refined Olive and Sunflower Oils Supplemented with Lycopene-Rich Oleoresin from Tomato Peels Industrial by-Product, during Accelerated Shelf-Life Storage. Food Chem. 2018, 246, 295–304. [Google Scholar] [CrossRef]

- Farhoosh, R. Shelf-Life Prediction of Edible Fats and Oils Using Rancimat. Lipid Technol. 2007, 19, 232–234. [Google Scholar] [CrossRef]

- Dunn, R.O. Oxidative Stability of Soybean Oil Fatty Acid Methyl Esters by Oil Stability Index (OSI). J. Am. Oil Chem. Soc. 2005, 82, 381–387. [Google Scholar] [CrossRef]

- Medeiros Vicentini-Polette, C.; Rodolfo Ramos, P.; Bernardo Gonçalves, C.; De Oliveira, A.L. Determination of Free Fatty Acids in Crude Vegetable Oil Samples Obtained by High-Pressure Processes. Food Chem. X 2021, 12, 100166. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, M.J.; Lee, J. Effects of Deuterium Oxide on the Oxidative Stability and Change of Headspace Volatiles of Corn Oil. J. Am. Oil Chem. Soc. 2014, 91, 623–628. [Google Scholar] [CrossRef]

- Silva, F.A.M.; Borges, M.F.M.; Ferreira, M.A. Métodos para Avaliação do Grau de Oxidação Lipídica e Da Capacidade Antioxidante. Quim. Nova 1999, 22, 94–103. [Google Scholar] [CrossRef]

- Musakhanian, J.; Rodier, J.D.; Dave, M. Oxidative Stability in Lipid Formulations: A Review of the Mechanisms, Drivers, and Inhibitors of Oxidation. AAPS PharmSciTech 2022, 23, 151. [Google Scholar] [CrossRef]

- Pardauil, J.J.R.; Souza, L.K.C.; Molfetta, F.A.; Zamian, J.R.; Rocha Filho, G.N.; Da Costa, C.E.F. Determination of the Oxidative Stability by DSC of Vegetable Oils from the Amazonian Area. Bioresour. Technol. 2011, 102, 5873–5877. [Google Scholar] [CrossRef]

- Freitas, I.R.; Cattelan, M.G.; Rodrigues, M.L.; Luzia, D.M.M.; Jorge, N. Effect of Grape Seed Extract (Vitis labrusca L.) on Soybean Oil under Thermal Oxidation. Nutr. Food Sci. 2017, 47, 610–622. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).