Completion Performance Evaluation in Multilateral Wells Incorporating Single and Multiple Types of Flow Control Devices Using Grey Wolf Optimizer

Abstract

:1. Introduction

2. Problem Formulation

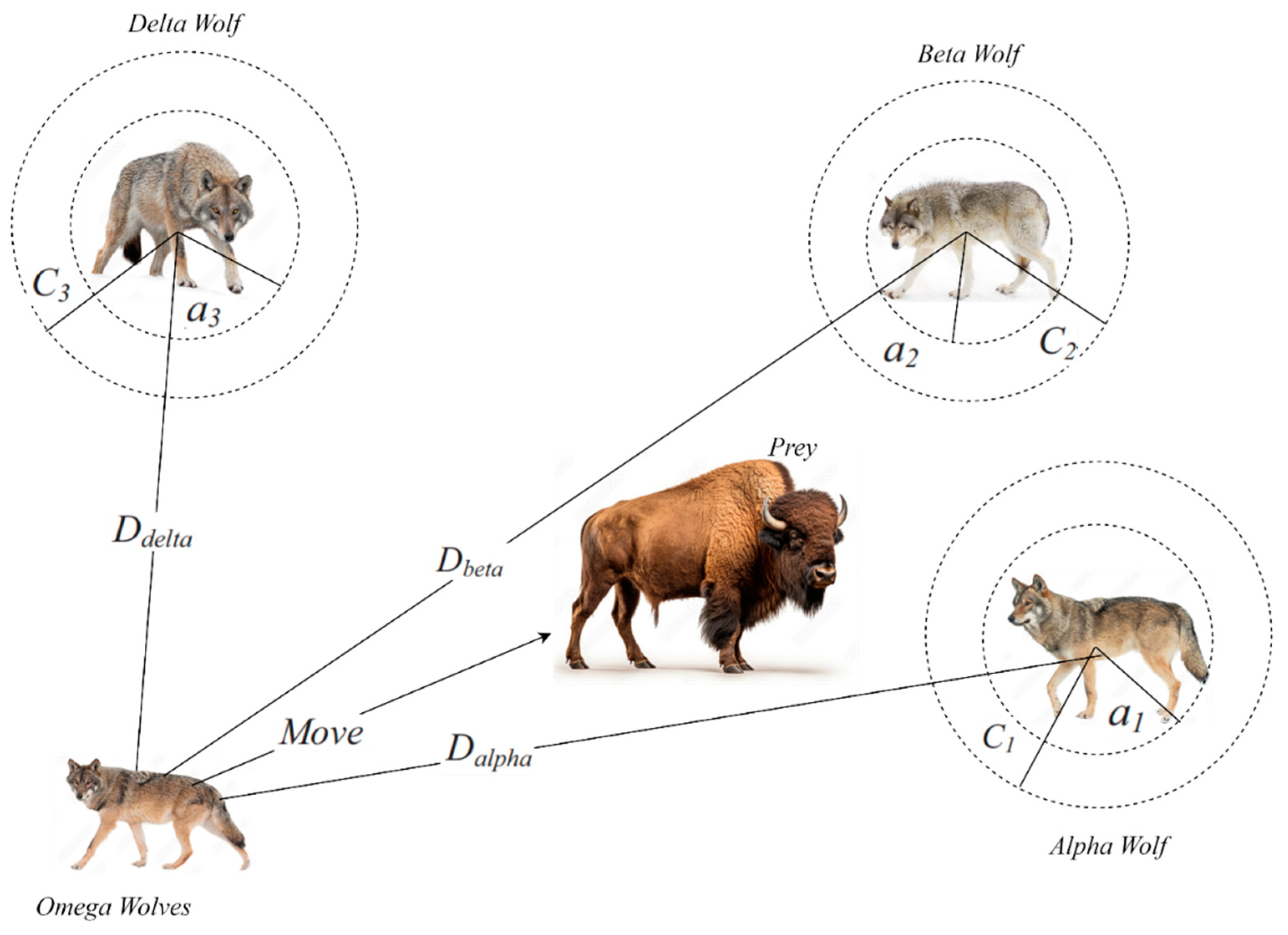

2.1. Grey Wolf Optimizer

2.1.1. Social Hierarchy

- The Alpha wolf (α) represents the optimum solution.

- The Beta wolf (β), representing the second-best solution.

- The Delta wolf (δ) is the third-best solution.

- All remaining candidate solutions are designated as Omega wolves (ω).

2.1.2. Encircling Prey

2.1.3. Hunting

2.1.4. Attacking Prey (Exploitation)

2.1.5. Search for Prey (Exploration)

3. Modelling of Advanced Wells

3.1. ICV Modelling and Control

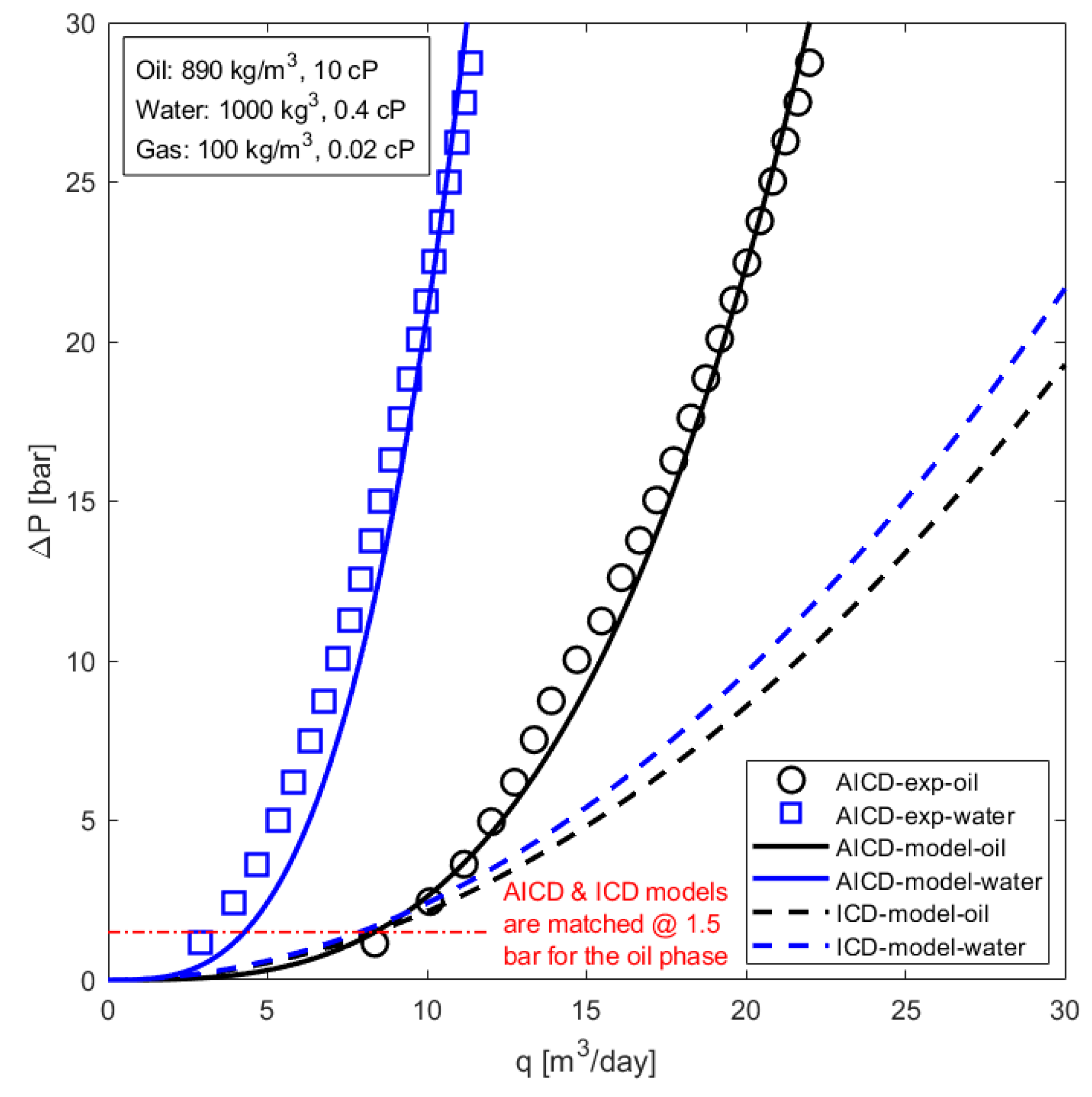

3.2. ICD/AICD Modelling

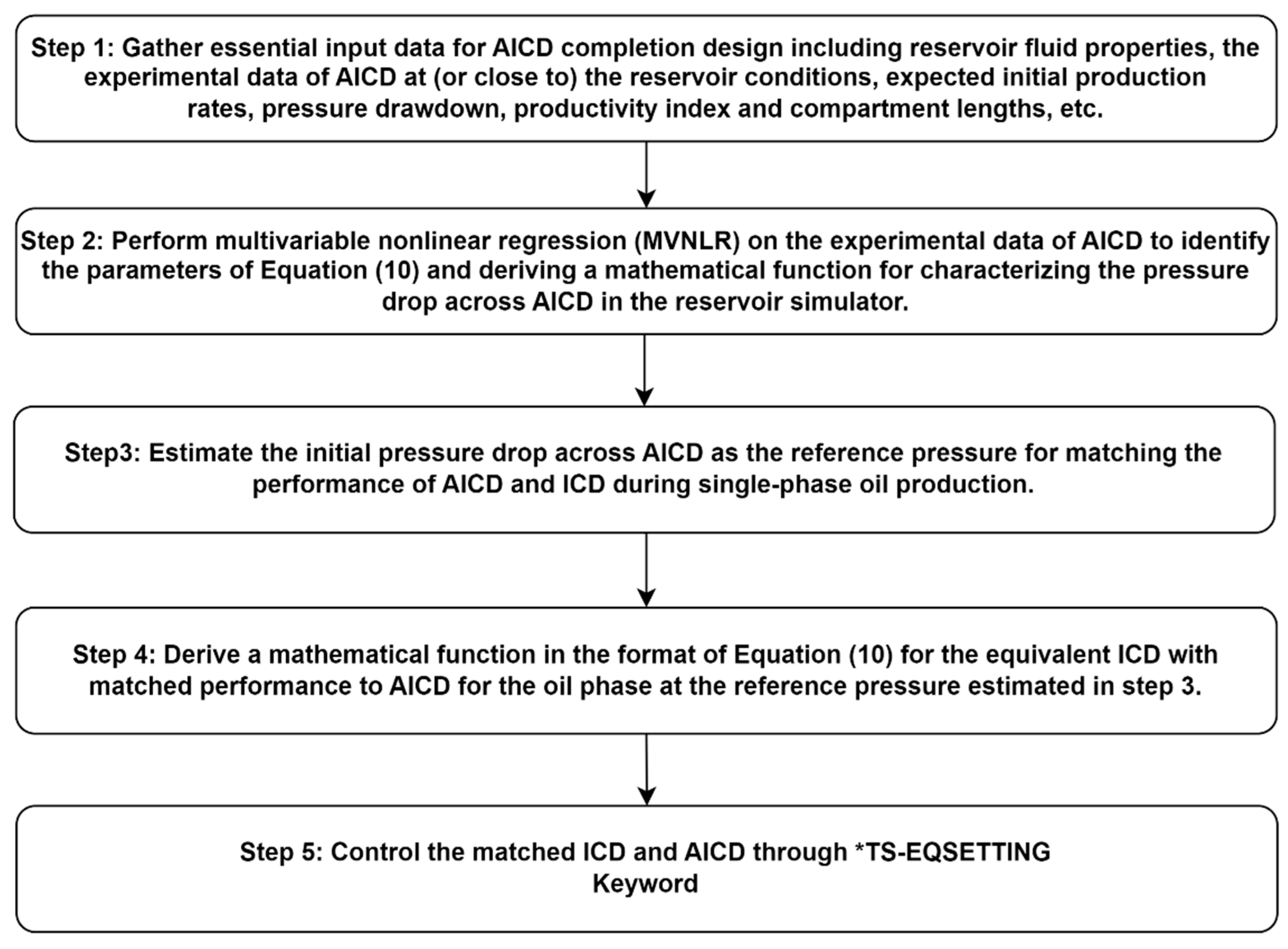

3.3. Matching ICD and AICD Performance before Breakthrough

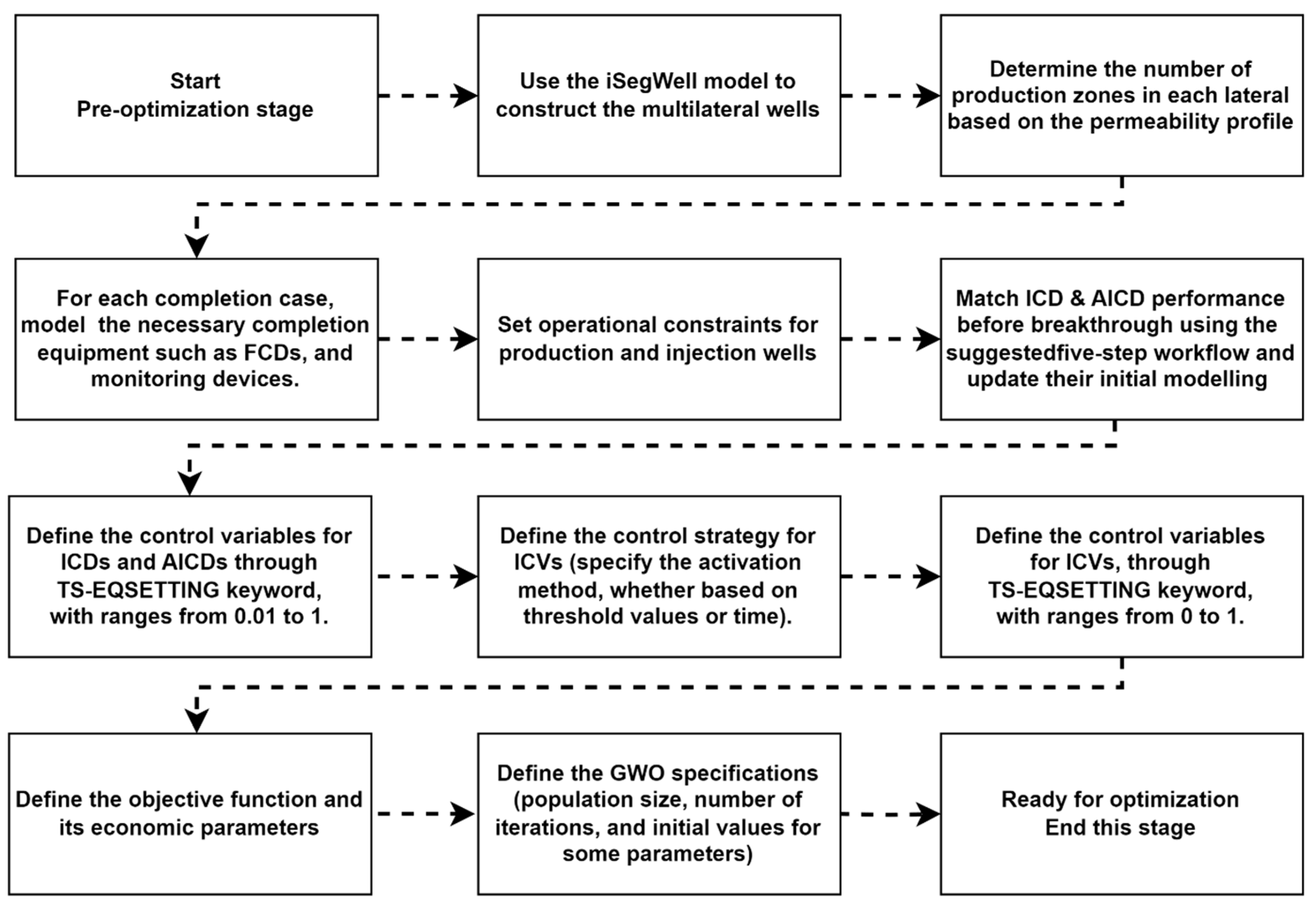

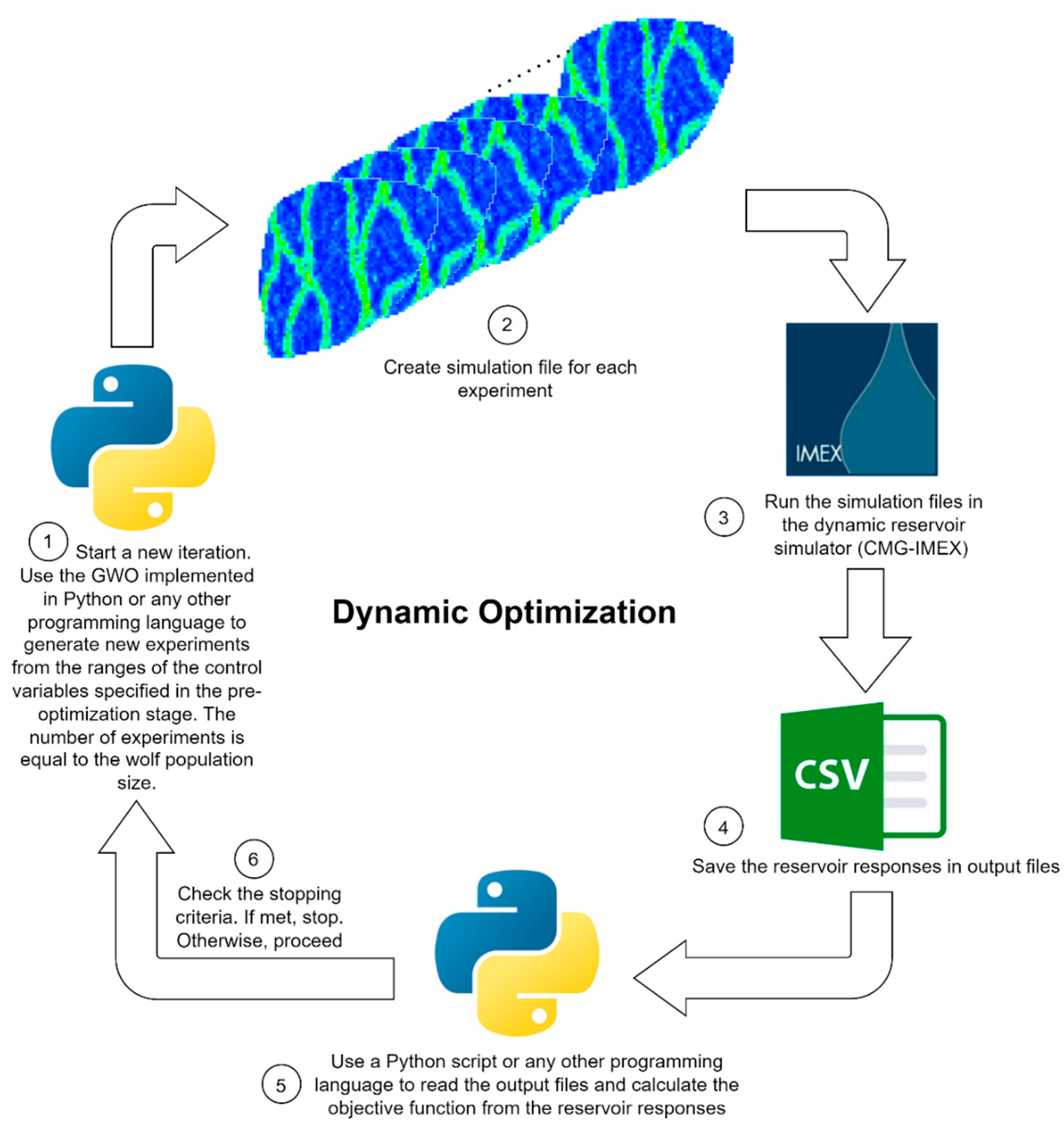

4. Methodology

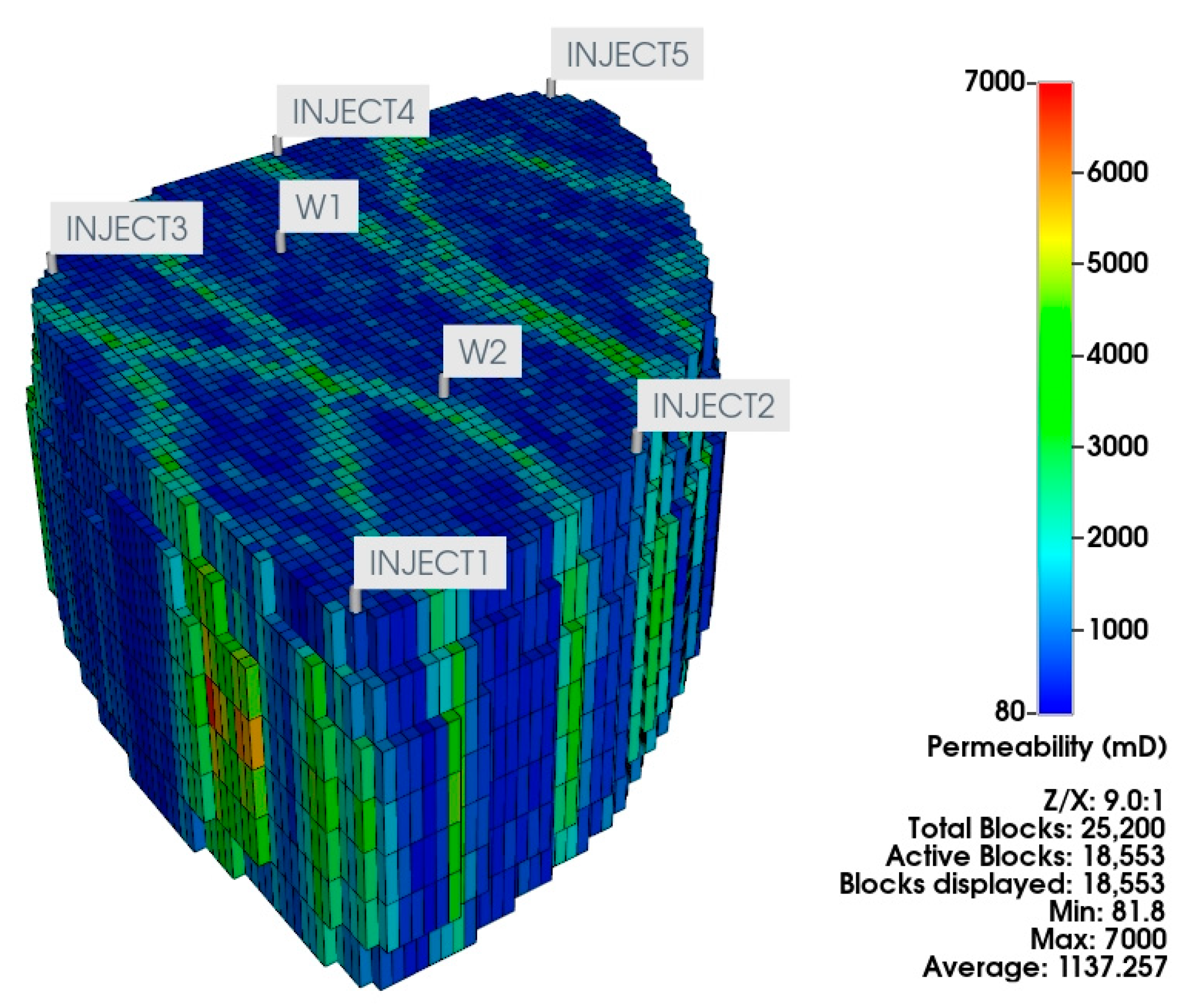

5. Case Study–Egg Field Model

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| FCD | Flow Control Device |

| MLW | Multilateral Well |

| ICV | Inflow (Interval) Control Valve |

| ICD | Inflow Control Device |

| AICD | Autonomous Inflow Control Device |

| USD | United States Dollar |

| NPV | Net Present Value |

| FD | Fluidic Diode |

| RCP | Rate-Controlled Production |

| AICV | Autonomous Inflow Control Valve |

| PDGs | Permanent Downhole Gauges |

| TEC | Tubing Encased Conductor |

| SCADA | Supervisory Control and Data Acquisition |

| CAPEX | Capital Expenditure |

| OPEX | Operational Expenditure |

| WAG | Water Alternating Gas |

| CO2 | Carbon Dioxide |

| MSW | Multi-Segmented Well |

Appendix A. Pseudocode of the GWO Algorithm

| Step1: Initialize the population of grey wolves randomly (= 1, 2, …, n) Step2: Initialize the value of , and Step3: Calculate the objective function of all wolves in the population = the best solution = the second-best solution = the third-best solution Step4: while < total number of iterations: For each search agent Update the location of the wolves use Equation (8) End for Update , and Calculate objective function of all wolves Update , and End while Step5: return |

Appendix B. All Completion Scenarios (Cases) Implemented in This Study

| Case No. | Completion Case Name | Explanation | No. Control Variables | Completion Type Based on FCDs | Control Strategy |

| 0 | OH (Base case) | Open-hole lateral branches without any control | 0 | Open hole | No control |

| 1 | OH_PICVs_12 m | Open-hole lateral branches with proactive ICVs at lateral junctions, where ICVs are controlled at 12-month intervals | 40 | Single | Proactive |

| 2 | OH_PICVs_6 m | Open-hole lateral branches with proactive ICVs at lateral junctions, where ICVs are controlled at 6-month intervals | 80 | Single | Proactive |

| 3 | OH_RICVs_50% WC | Open-hole lateral branches with fast-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥50% of the branch production) | 4 | Single | Reactive |

| 4 | OH_RICVs_70% WC | Open-hole lateral branches with intermediate-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥70% of the branch production) | 4 | Single | Reactive |

| 5 | OH_RICVs_90% WC | Open-hole lateral branches with slow-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥90% of the branch production) | 4 | Single | Reactive |

| 6 | ICDs | ICDs installed within lateral branches | 15 | Single | No control |

| 7 | ICDs_PICVs_12 m | ICDs installed within lateral branches with proactive ICVs at lateral junctions, where ICVs are controlled at 12-month intervals | 55 | Multiple | Proactive |

| 8 | ICDs_PICVs_6 m | ICDs within lateral branches with proactive ICVs at lateral junctions, where ICVs are controlled at 6-month intervals | 95 | Multiple | Proactive |

| 9 | ICDs_RICVs_50% WC | ICDs installed within lateral branches with fast-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥ 50% of the branch production) | 19 | Multiple | Reactive |

| 10 | ICDs_RICVs_70% WC | ICDs installed within lateral branches with intermediate-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥ 70% of the branch production) | 19 | Multiple | Reactive |

| 11 | ICDs_RICVs_90% WC | ICDs installed within lateral branches with slow-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥90% of the branch production) | 19 | Multiple | Reactive |

| 12 | AICDs | AICDs installed within lateral branches | 15 | Single | No control |

| 13 | AICDs_PICVs_12 m | AICDs installed within lateral branches with proactive ICVs at lateral junctions, where ICVs are controlled at 12-month intervals | 55 | Multiple | Proactive |

| 14 | AICDs_PICVs_6 m | AICDs installed within lateral branches with proactive ICVs at lateral junctions, where ICVs are controlled at 6-month intervals | 95 | Multiple | Proactive |

| 15 | AICDs_RICVs_50% WC | AICDs installed within lateral branches with fast-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥50% of the branch production) | 19 | Multiple | Reactive |

| 16 | AICDs_RICVs_70% WC | AICDs installed within lateral branches with intermediate-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥70% of the branch production) | 19 | Multiple | Reactive |

| 17 | AICDs_RICVs_90% WC | AICDs installed within lateral branches with slow-reactive ICVs at lateral junctions (each ICV is activated when the local water cut is ≥90% of the branch production) | 19 | Multiple | Reactive |

| 18 | PICVs_12 m | Proactive ICVs installed within lateral branches, where ICVs are controlled at 12-month intervals | 150 | Single | Proactive |

| 19 | PICVs_6 m | Proactive ICVs installed within lateral branches, where ICVs are controlled at 12-month intervals | 300 | Single | Proactive |

| 20 | RICVs_50% WC | Fast reactive ICVs installed within lateral branches (each ICV is activated when the local water cut is ≥50% of the layer production) | 15 | Single | Reactive |

| 21 | RICVs_70% WC | Intermediate reactive ICVs installed within lateral branches (each ICV is activated when the local water cut is ≥70% of the layer production) | 15 | Single | Reactive |

| 22 | RICVs_90% WC | Slow reactive ICVs installed within lateral branches (each ICV is activated when the local water cut is ≥90% of the layer production) | 15 | Single | Reactive |

References

- Rosi, G.A.; Zhu, D.; Gates, I.D.; Wang, J. Passive Flow Control Devices—Well Design and Physics of Their Different Flow Regimes: A Review. J. Pet. Sci. Eng. 2022, 218, 110999. [Google Scholar] [CrossRef]

- Muradov, K.; Haghighat Sefat, M.; Moradi Dowlatabad, M. Fast Optimization of Packer Locations in Wells with Flow Control Completions. J. Pet. Sci. Eng. 2021, 205, 108933. [Google Scholar] [CrossRef]

- Zhang, N.; Li, H.; Liu, Y.; Shan, J.; Tan, Y.; Li, Y. A New Autonomous Inflow Control Device Designed for a Loose Sand Oil Reservoir with Bottom Water. J. Pet. Sci. Eng. 2019, 178, 344–355. [Google Scholar] [CrossRef]

- Tendeka. FloSure Autonomous ICD. Available online: https://tq.com/solutions/completions/subsurface-flow-control/production/flosure-autonomous-icd/ (accessed on 9 January 2024).

- Inflow Control. Autonomous Inflow Control Valve (AICV). Available online: https://www.inflowcontrol.no/ (accessed on 12 February 2024).

- Halliburton. EquiFlow® Autonomous Inflow Control Devices (AICD). Available online: https://www.halliburton.com/en/completions/well-completions/sand-control/halliburton-equiflow-inflow-control-devices (accessed on 9 January 2024).

- Baker Oil Tools. Inflow Control Device. Available online: https://www.bakerhughes.com/completions/subsurface-flow-control/inflow-control-devices (accessed on 21 March 2024).

- SLB. Inflow Control Valve (ICV). Available online: https://glossary.slb.com/terms/i/inflow_control_valve (accessed on 19 January 2024).

- Eltaher, E.; Muradov, K.; Davies, D.; Grassick, P. Autonomous Flow Control Device Modelling and Completion Optimisation. J. Pet. Sci. Eng. 2019, 177, 995–1009. [Google Scholar] [CrossRef]

- Moradi, A.; Samani, N.A.; Kumara, A.S.; Moldestad, B.M.E. Evaluating the Performance of Advanced Wells in Heavy Oil Reservoirs under Uncertainty in Permeability Parameters. Energy Rep. 2022, 8, 8605–8617. [Google Scholar] [CrossRef]

- Mathiesen, V.; Brent, B. Autonomous Valve Controls Excess Water, Gas Production to Increase Oil Recovery. J. Pet. Technol. 2020, 72, 44–46. [Google Scholar] [CrossRef]

- Aljubran, M.J.; Horne, R. Surrogate-Based Prediction and Optimization of Multilateral Inflow Control Valve Flow Performance with Production Data. SPE Prod. Oper. 2021, 36, 224–233. [Google Scholar] [CrossRef]

- Botechia, V.E.; Schiozer, D.J. Model-Based Life Cycle Control of ICVs in Injectors in a Benchmark Analogous to a Pre-Salt Field. J. Pet. Sci. Eng. 2022, 215, 110707. [Google Scholar] [CrossRef]

- Shahreyar, N.; Butler, B.; Shakeel, M. Improved Reservoir Management with Multi Positioning Interval Control Valves in Multilateral Wells. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 19–21 February 2023; Society of Petroleum Engineers (SPE): Houston, TX, USA, 2023. [Google Scholar] [CrossRef]

- Broni–bediako, E.; Fuseini, N.I.; Akoto, R.N.A.; Brantson, E.T. Application of Intelligent Well Completion in Optimising Oil Production from Oil Rim Reservoirs. Adv. Geo-Energy Res. 2019, 3, 343–354. [Google Scholar] [CrossRef]

- Grebenkin, I.M.; Davies, D.R. A Novel Optimisation Algorithm for Inflow Control Valve Management. In Proceedings of the SPE Europec/EAGE Annual Conference, Copenhagen, Denmark, 4–7 June 2012. [Google Scholar] [CrossRef]

- Elfeel, M.A.; Tonkin, T.; Watanabe, S.; Abbas, H.; Bratvedt, F.; Goh, G.; Gottumukkala, V.; Giddins, M.A. Employing Smart Flow. Control Valves for Fast Closed-Loop Reservoir Management. Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 12–15 November 2018; SLB: Austin, TX, USA, 2018. [Google Scholar] [CrossRef]

- Dilib, F.A.; Jackson, M.D. Closed-Loop Feedback Control for Production Optimization of Intelligent Wells Under Uncertainty. SPE Prod. Oper. 2013, 28, 345–357. [Google Scholar] [CrossRef]

- Augusto, M.; Pinto, S. Short-Term and Long-Term Optimizations for Reservoir Management with Intelligent Wells. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015. [Google Scholar] [CrossRef]

- Vasper, A.; Endre, J.; Mjos, S.; Thi, T.; Duong, T. Efficient Optimization Strategies for Developing Intelligent Well Business Cases. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Aberdeen, UK, 6–8 September 2016. [Google Scholar] [CrossRef]

- Barreto, C.E.A.G.; Schiozer, D.J. Optimal Placement Design of Inflow Control Valve Using a Dynamic Optimization Process Based on Technical and Economic Indicators. J. Pet. Sci. Eng. 2015, 125, 117–127. [Google Scholar] [CrossRef]

- Addiego-Guevara, E.A.; Jackson, M.D.; Giddins, M.A. Insurance Value of Intelligent Well Technology against Reservoir Uncertainty. In Proceedings of the Improved Oil Recovery Symposium, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar] [CrossRef]

- Ebadi, F.; Davies, D. Should “Proactive” or “Reactive” Control Be Chosen for Intelligent Well Management? In Proceedings of the Intelligent Energy Conference and Exhibition, Amsterdam, The Netherlands, 11–13 April 2006. [CrossRef]

- Sampaio, M.A.; Barreto, C.E.A.G.; Schiozer, D.J. Optimization of Proactive Control Valves of Producer and Injector Intelligent Wells under Economic Uncertainty. In Proceedings of the SPE Europec/EAGE Annual Conference, Copenhagen, Denmark, 4–7 June 2012; SPE: Tulsa, OK, USA, 2012. [Google Scholar] [CrossRef]

- Chen, B.; Reynolds, A.C. Optimal Control of ICV’s and Well Operating Conditions for the Water-Alternating-Gas Injection Process. J. Pet. Sci. Eng. 2017, 149, 623–640. [Google Scholar] [CrossRef]

- Brouwer, D.; Jansen, J.; Intl, S.E. Dynamic Optimization of Waterflooding with Smart Wells Using Optimal Control Theory. SPE J. 2004, 9, 391–402. [Google Scholar] [CrossRef]

- Ilamah, O.; Waterhouse, R. Field-Scale Production Optimization with Intelligent Wells; SLB: Austin, TX, USA, 2018. [Google Scholar]

- Sefat, M.H.; Muradov, K.M.; Davies, D.R. Optimal Field Development and Control Yields Accelerated, More Reliable, Production: A North Sea Case Study. In Proceedings of the SPE Intelligent Energy International Conference and Exhibition, Aberdeen, UK, 6–8 September 2016. [Google Scholar] [CrossRef]

- Sefat, M.H.; Muradov, K.; Davies, D. Field Management by Proactive Optimisation of Intelligent Wells-A Practical Approach. In Proceedings of the SPE Middle East Intelligent Energy Conference and Exhibition, Manama, Bahrain, 28–30 October 2013. [Google Scholar] [CrossRef]

- Alghareeb, Z.M.; Horne, R.N.; Yuen, B.B.; Shenawi, S.H. Proactive Optimization of Oil Recovery in Multilateral Wells Using Real Time Production Data. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar] [CrossRef]

- Asthana, P.; Jacob, S.; Bouldin, B.; Zeghlache, M.L.; Almulhim, M. Downhole Flow Control Technologies: From Simple Starts to Wireless Smarts. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 10–12 October 2023. [Google Scholar] [CrossRef]

- Schlumberger. Manara. Available online: https://www.slb.com/products-and-services/innovating-in-oil-and-gas/completions/well-completions/intelligent-completions/intelligent-completion-systems/manara-production-and-reservoir-management (accessed on 9 January 2024).

- Baker Hughes. MultiNode. Available online: https://www.bing.com/search?q=MultiNodeTM+completion&cvid=e0fdd1779df34c478581defc5e5e2c8a&gs_lcrp=EgZjaHJvbWUqBggAEEUYOzIGCAAQRRg7MgYIARAAGEAyBggCEAAYQDIGCAMQABhAMgYIBBAAGEAyBggFEAAYQDIGCAYQABhAMgYIBxAAGEAyBggIEEUYPDIHCAkQRRj8VdIBCDg1NDhqMGo5qAIAsAIA&FORM=ANAB01&PC=EDGEESS (accessed on 9 January 2024).

- Tendeka. PulseEight. Available online: https://tq.com/solutions/completions/wireless-intelligent-completions/intelligent-control-valve/ (accessed on 9 January 2024).

- Shahreyar, N.; Butler, B.; Corona, G. Maximizing Asset Value & Field Recovery with Advanced Completion Solutions-A Digital Twin Field Case Study with Multilateral, Intelligent Completion, and AICD Completion Technologies; SPE: Tulsa, OK, USA, 2021. [Google Scholar]

- Langaas, K.; Jeurissen, E.J.W.G.; Abay, H.K. Combining Passive and Autonomous Inflow-Control Devices in a Trilateral Horizontal Well in the Alvheim Field. In SPE Production and Operations; Society of Petroleum Engineers (SPE): Tulsa, OK, USA, 2019; Volume 34, pp. 446–460. [Google Scholar] [CrossRef]

- Carvajal, G.; Saldierna, N.; Querales, M.; Thornton, K.; Loiza, J. Coupling Reservoir and Well Completion Simulators for Intelligent Multi-Lateral Wells: Part 1; SPE: Tulsa, OK, USA, 2018. [Google Scholar]

- Prakash Das, O.; Al-Enezi, K.; Aslam, M.; El-Gezeeri, T.; Ziyab, K.; Fipke, S.R.; Ewens, S. Novel Design and Implementation of Kuwait’s First Smart Multilateral Well with Inflow Control Device and Inflow Control Valve for Life-Cycle Reservoir Management in High Mobility Reservoir, West Kuwait; SPE: Tulsa, OK, USA, 2012. [Google Scholar]

- Mark, G.; Clifford, A.; Bona, P. Simulations Demonstrate the Benefits of Continuous Improvement in Multilateral Wells in the Norwegian Sea. In Proceedings of the SPE Annual Technical Conference & Exhibition, Virtual, 27–29 October 2020; SPE: Tulsa, OK, USA, 2020. [Google Scholar]

- Carpenter, C. Intelligent Completion in Water-Injector Well Improves Field Development. J. Pet. Technol. 2019, 71, 62–64. [Google Scholar] [CrossRef]

- Halliburton. NETool. 2023. Available online: https://www.halliburton.com/en/software/decisionspace-365-enterprise/decisionspace-365-reservoir-and-production (accessed on 9 January 2024).

- Ahdeema, J.; Sefat, M.H.; Muradov, K. Hybrid Framework for Enhanced Dynamic Optimization of Intelligent Completion Design in Multilateral Wells with Multiple Types of Flow Control Devices. Energies 2023, 16, 7189. [Google Scholar] [CrossRef]

- Ahdeema, J.; Sefat, M.H.; Muradov, K. Hybrid Optimization Technique Allows Dynamic Completion Design and Control in Advanced Multilateral Wells with Multiple Types of Flow Control Devices. In Proceedings of the SPE Offshore Europe Conference and Exhibition, Aberdeen, UK, 5–8 September 2023. [Google Scholar] [CrossRef]

- CMG. IMEX; Computer Modelling Group Ltd.: Calgary, AB, Canada, 2023. [Google Scholar]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Ng, C.S.W.; Jahanbani Ghahfarokhi, A.; Nait Amar, M. Production Optimization under Waterflooding with Long Short-Term Memory and Metaheuristic Algorithm. Petroleum 2023, 9, 53–60. [Google Scholar] [CrossRef]

- Ocran, D.; Ikiensikimama, S.S.; Broni-Bediako, E. Grey Wolf Optimizer for Solving Well Placement Optimization Problem Constrained to Minimum Well Distance. Pet. Sci. Technol. 2023, 41, 1391–1413. [Google Scholar] [CrossRef]

- Rezvani, H.; Rafiei, Y. A Novel Analytical Technique for Determining Inflow Control Devices Flow Area in CO2-EOR and CCUS Projects. J. Pet. Explor. Prod. Technol. 2023, 13, 1951–1962. [Google Scholar] [CrossRef]

- Nait Amar, M.; Jahanbani Ghahfarokhi, A.; Ng, C.S.W.; Zeraibi, N. Optimization of WAG in Real Geological Field Using Rigorous Soft Computing Techniques and Nature-Inspired Algorithms. J. Pet. Sci. Eng. 2021, 206, 109038. [Google Scholar] [CrossRef]

- Delavar, M.R. Hybrid Machine Learning Approaches for Classification and Detection of Fractures in Carbonate Reservoir. J. Pet. Sci. Eng. 2022, 208, 109327. [Google Scholar] [CrossRef]

- Holmes, J.; Barkve, T.; Hydro ASA, N. Application of a Multisegment Well Model to Simulate Flow in Advanced Wells. In Proceedings of the SPE European Petroleum Conference, Hague, The Netherlands, 20–22 October 1998. [Google Scholar] [CrossRef]

- Jansen, J.D.; Fonseca, R.M.; Kahrobaei, S.; Siraj, M.M.; Van Essen, G.M.; Van den Hof, P.M.J. The Egg Model—A Geological Ensemble for Reservoir Simulation. Geosci. Data J. 2014, 1, 192–195. [Google Scholar] [CrossRef]

| Parameters | Field Units | SI Units |

|---|---|---|

| Crude Oil price | 60 USD/STB | 377.4 USD/m3 |

| Water management cost | 6 USD/STB | 37.7 USD/m3 |

| Water injection cost | 6 USD/STB | 37.7 USD/m3 |

| Annual discount rate | 10% | 10% |

| Property | Value | Unit (SI) |

|---|---|---|

| ) | 0.2 | - |

| ) | 1.0 × 10−10 | Pa−1 |

| ) | 1.0 × 10−10 | Pa−1 |

| ) | 0.0 | Pa−1 |

| ) | 0.2 | Pa s |

| ) | 5.0 × 10−3 | Pa s |

| ) | 40 × 106 | Pa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahdeema, J.; Sefat, M.H.; Muradov, K.; Moradi, A.; Moldestad, B.M.E. Completion Performance Evaluation in Multilateral Wells Incorporating Single and Multiple Types of Flow Control Devices Using Grey Wolf Optimizer. Processes 2024, 12, 785. https://doi.org/10.3390/pr12040785

Ahdeema J, Sefat MH, Muradov K, Moradi A, Moldestad BME. Completion Performance Evaluation in Multilateral Wells Incorporating Single and Multiple Types of Flow Control Devices Using Grey Wolf Optimizer. Processes. 2024; 12(4):785. https://doi.org/10.3390/pr12040785

Chicago/Turabian StyleAhdeema, Jamal, Morteza Haghighat Sefat, Khafiz Muradov, Ali Moradi, and Britt M. E. Moldestad. 2024. "Completion Performance Evaluation in Multilateral Wells Incorporating Single and Multiple Types of Flow Control Devices Using Grey Wolf Optimizer" Processes 12, no. 4: 785. https://doi.org/10.3390/pr12040785

APA StyleAhdeema, J., Sefat, M. H., Muradov, K., Moradi, A., & Moldestad, B. M. E. (2024). Completion Performance Evaluation in Multilateral Wells Incorporating Single and Multiple Types of Flow Control Devices Using Grey Wolf Optimizer. Processes, 12(4), 785. https://doi.org/10.3390/pr12040785