Implementations of Digital Transformation and Digital Twins: Exploring the Factory of the Future

Abstract

1. Introduction

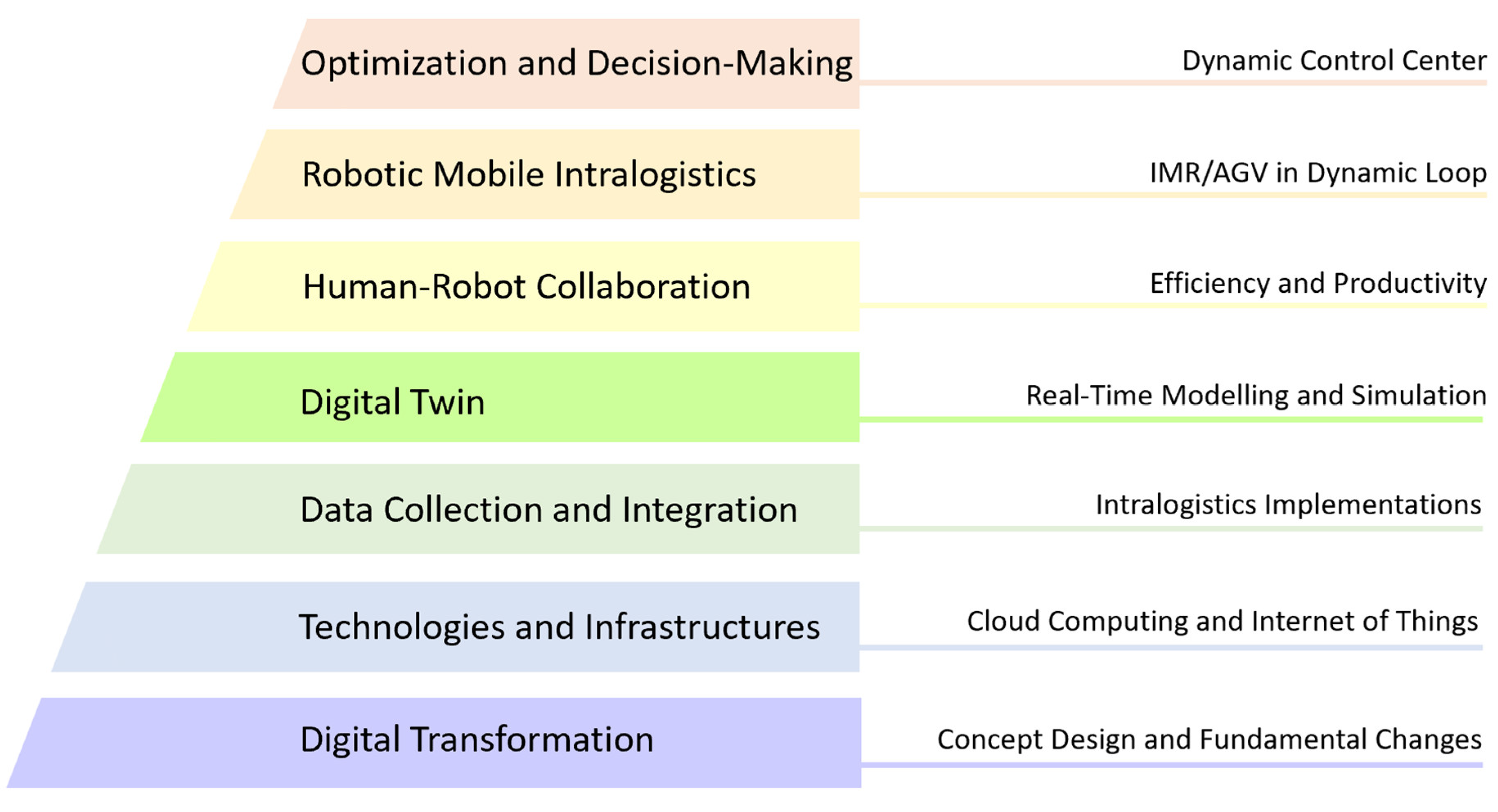

2. Configuration of Digital Transformation

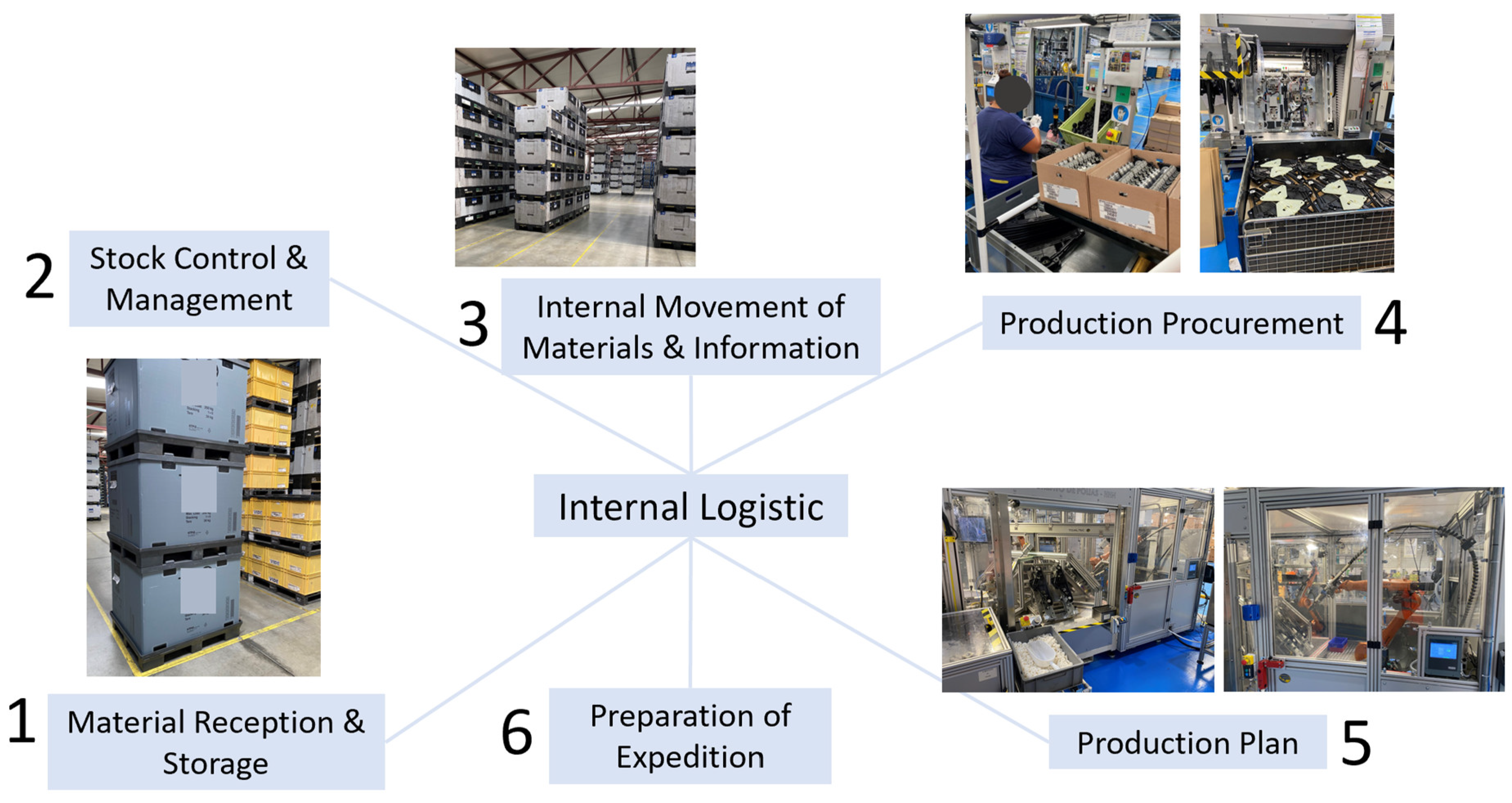

2.1. Logistic Challenges

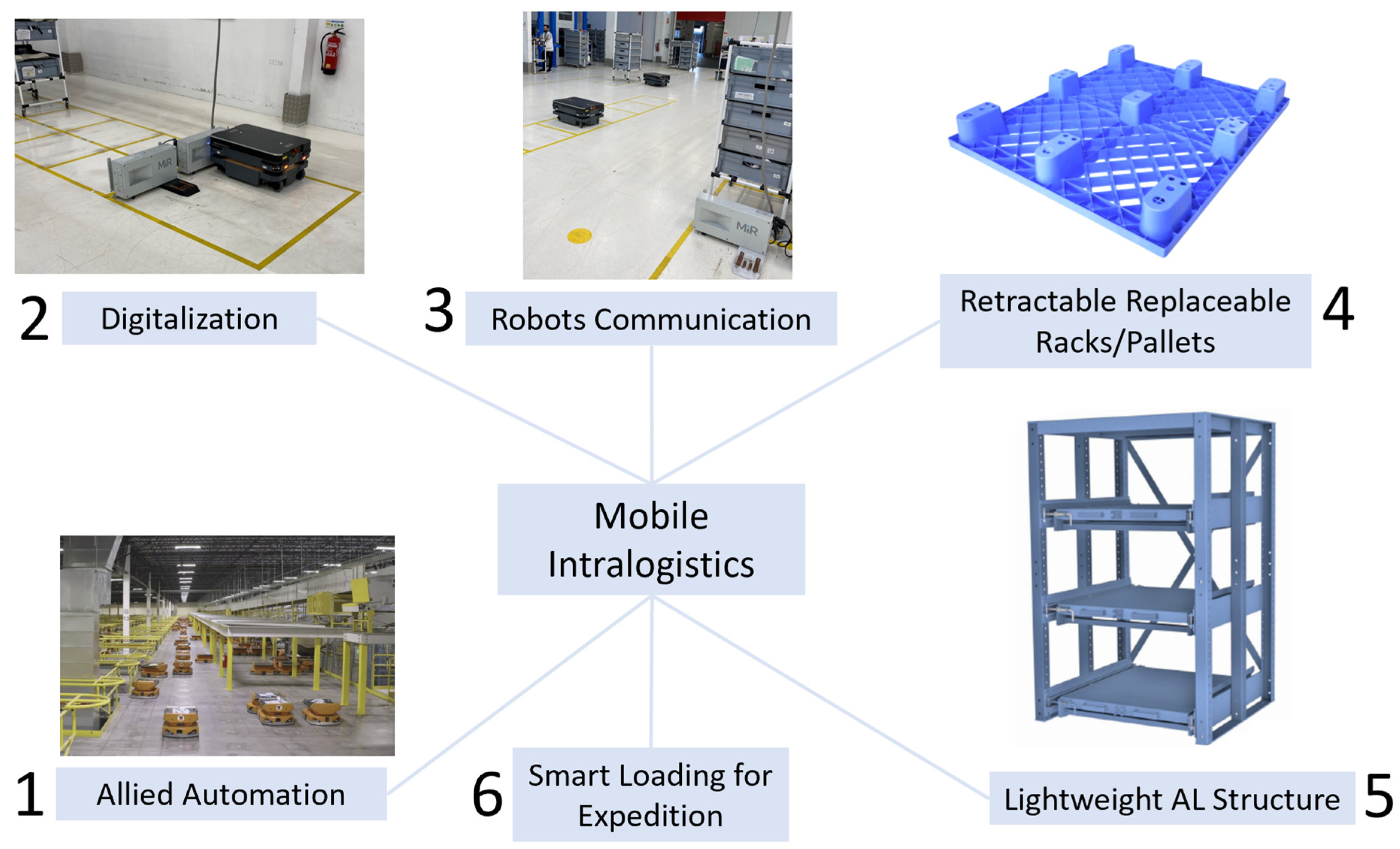

2.2. Intralogistics Approach

- -

- Using compact, collapsible, and easily transportable shelving units integrated with an AMR or AGV for efficient mobile intralogistics operations, facilitating the transportation of stocks and productions.

- -

- Utilizing MAM to create lightweight jigs and fixtures offers advantages in rapid prototyping, on-site fabrication, cost and time savings, and adaptability to evolving design requirements and changes.

- -

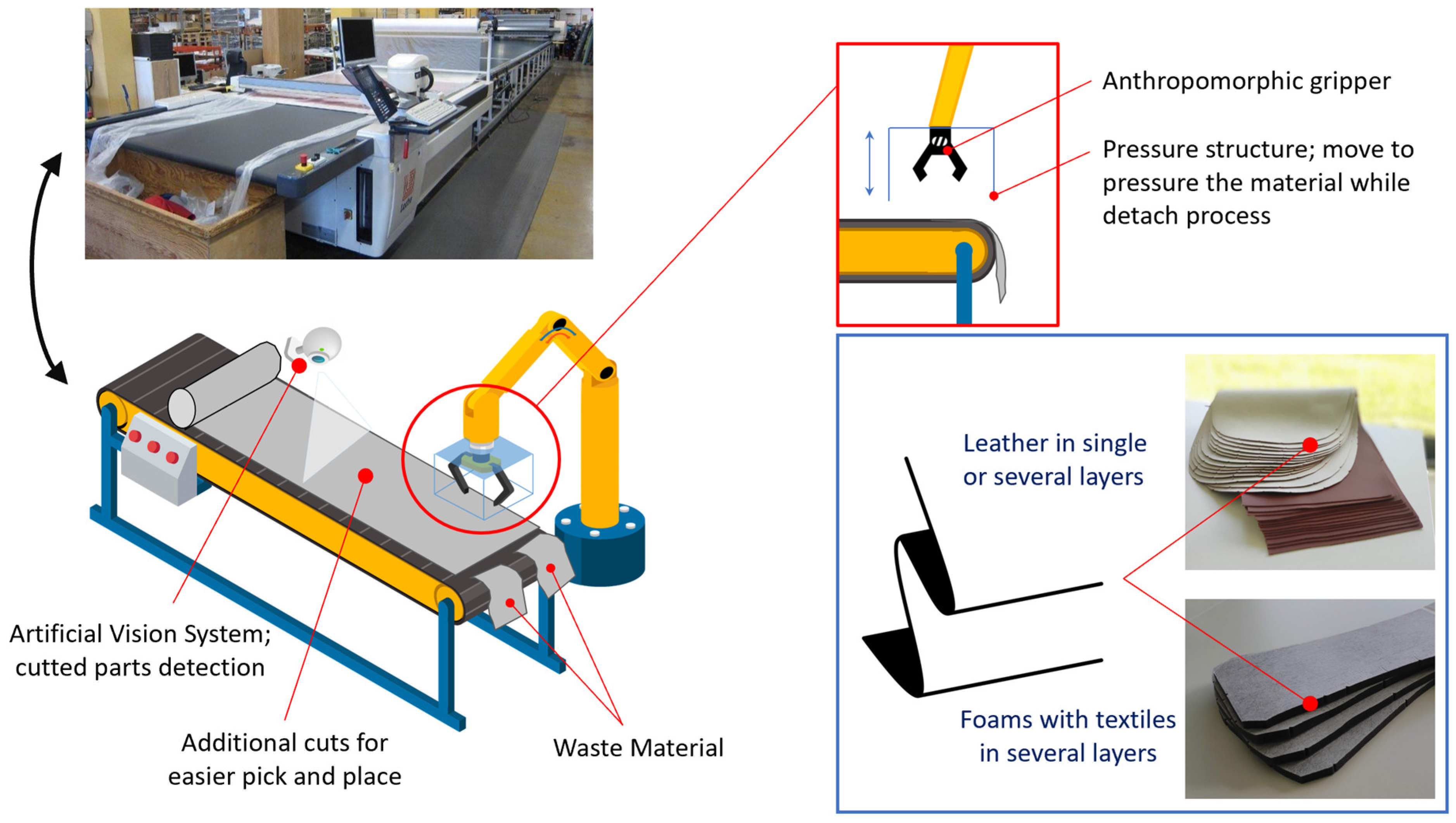

- Design of specialized robot arms or grippers tailored for the gentle handling of both hard and soft materials, enabling damage-free pick-and-place operations with the use of compact articulated joints suitable for confined spaces.

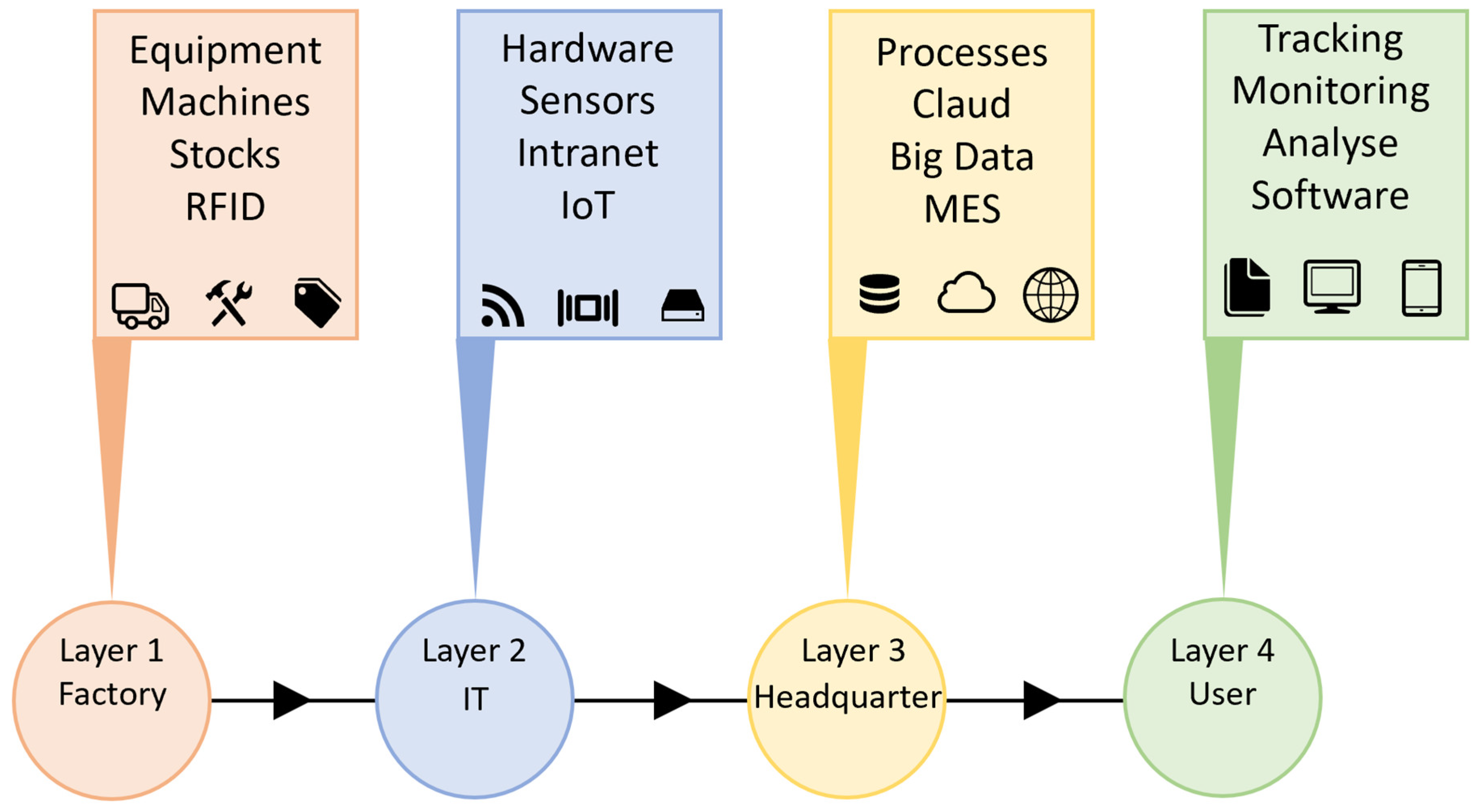

2.3. Mobile and Cloud Computing

3. Configuration of Digital Twins

3.1. Physical and Virtual Systems

3.2. RFID-Based Smart Factory

4. Technology-Driven in Light Vehicles Industries

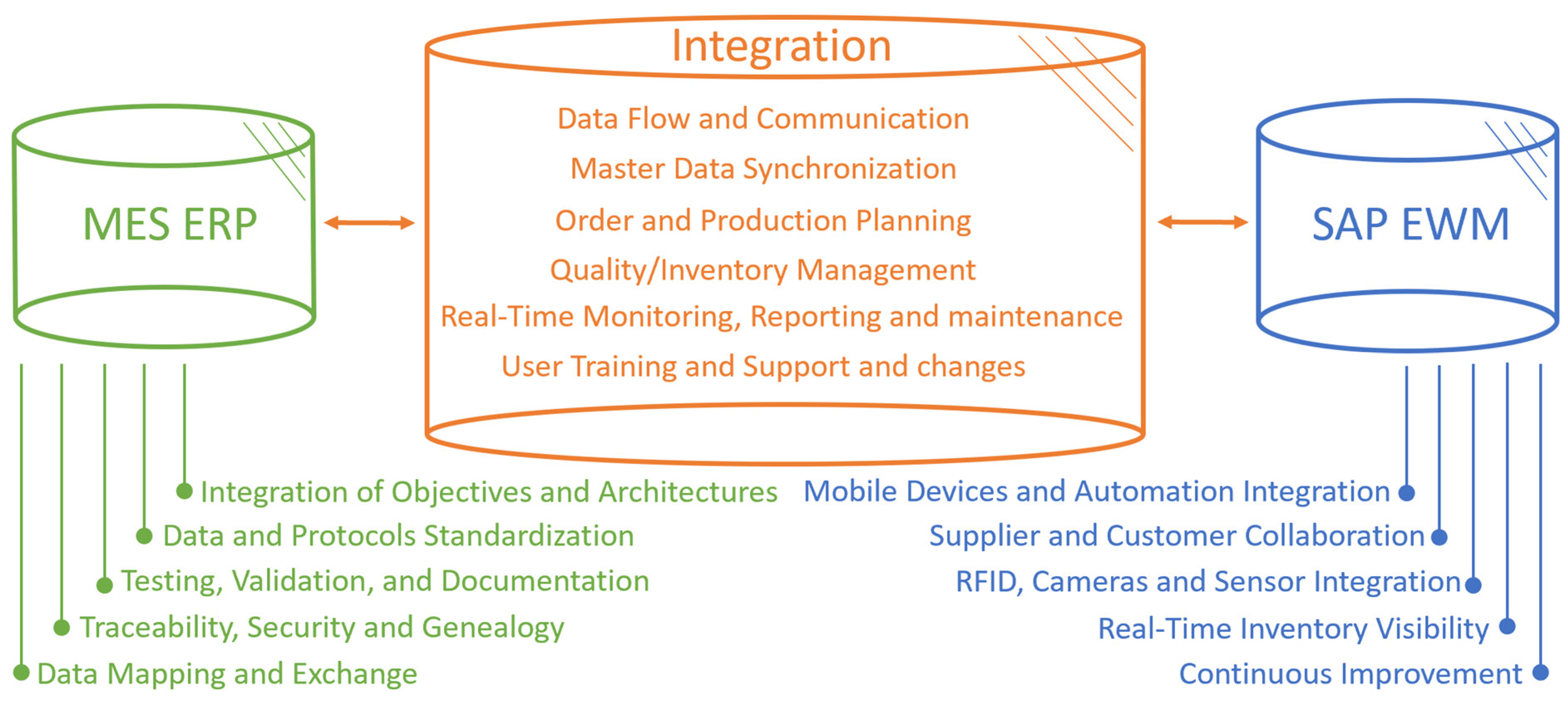

4.1. Manufacturing Execution Methodology

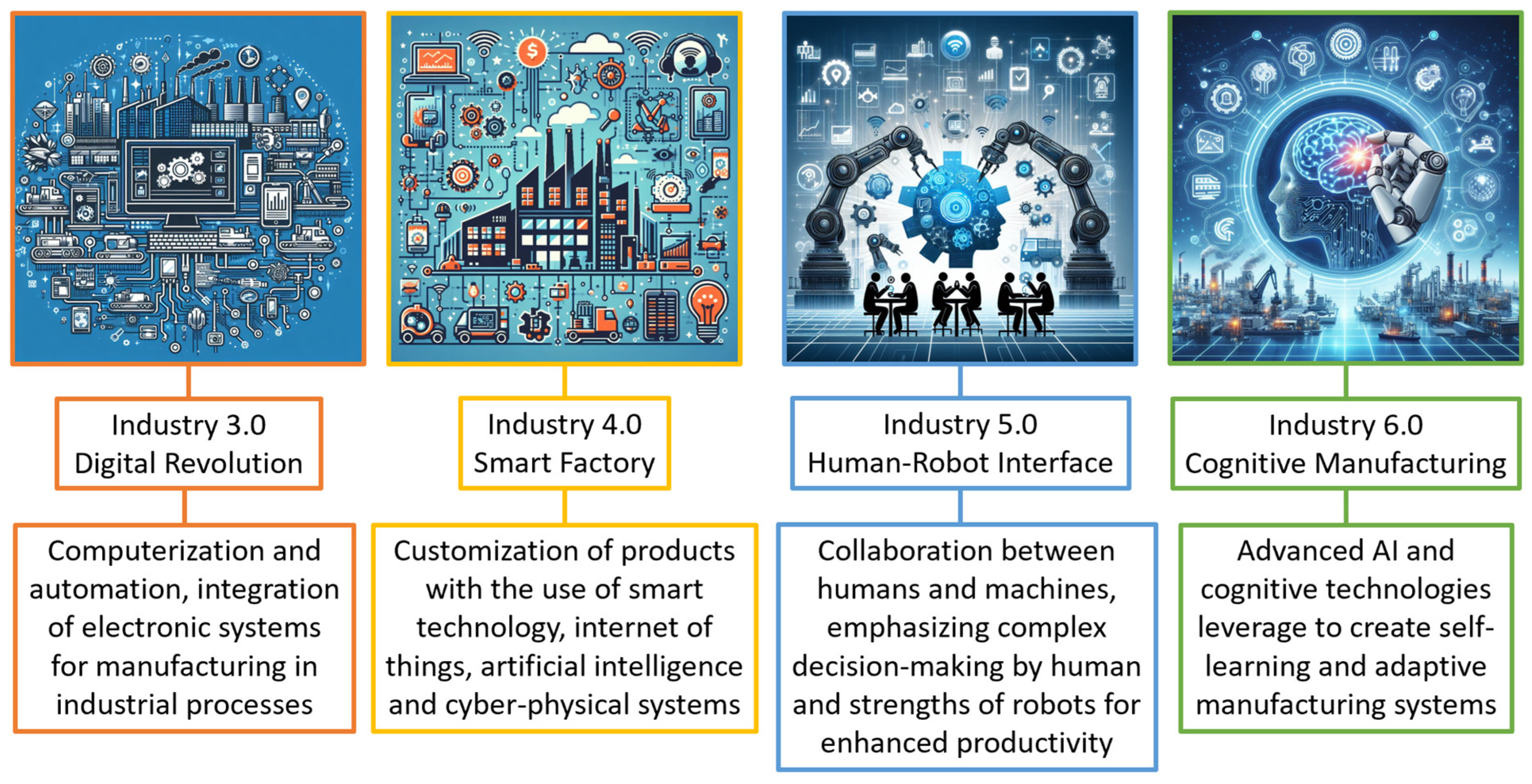

4.2. Technology Roadmap and Industry Impact

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Fraga-Lamas, P.; Lopes, S.I.; Fernández-Caramés, T.M. Green IoT and Edge AI as Key Technological Enablers for a Sustainable Digital Transition towards a Smart Circular Economy: An Industry 5.0 Use Case. Sensors 2021, 21, 5745. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, R.; Karimi, J.; Resende, P.R.; Abrantes, J.C.C.; Lopes, S.I. Overview of Selective Laser Melting for Industry 5.0: Toward Customizable, Sustainable, and Human-Centric Technologies. Machines 2023, 11, 522. [Google Scholar] [CrossRef]

- Jesus, C.; Lima, R.M. Literature Search of Key Factors for the Development of Generic and Specific Maturity Models for Industry 4.0. Appl. Sci. 2020, 10, 5825. [Google Scholar] [CrossRef]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Jones, M.D.; Hutcheson, S.; Camba, J.D. Past, present, and future barriers to digital transformation in manufacturing: A review. J. Manuf. Syst. 2021, 60, 936–948. [Google Scholar] [CrossRef]

- Jafari, N.; Azarian, M.; Yu, H. Moving from Industry 4.0 to Industry 5.0: What Are the Implications for Smart Logistics? Logistics 2022, 6, 26. [Google Scholar] [CrossRef]

- Kutnjak, A.; Pihiri, I.; Furjan, M.T. Digital Transformation Case Studies Across Industries—Literature Review. In Proceedings of the 2019 42nd International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 20–24 May 2019. [Google Scholar] [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Appl. Sci. 2022, 12, 5727. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Honghong, S.; Gang, Y.; Haijiang, L.; Tian, Z.; Annan, J. Digital twin enhanced BIM to shape full life cycle digital transformation for bridge engineering. Autom. Constr. 2023, 147, 104736. [Google Scholar] [CrossRef]

- Bilberg, A.; Malik, A.A. Digital twin driven human–robot collaborative assembly. CIRP Ann. 2019, 68, 499–502. [Google Scholar] [CrossRef]

- Maurice, P.; Padois, V.; Measson, Y.; Bidaud, P. Human-oriented design of collaborative robots. Int. J. Ind. Ergon. 2017, 57, 88–102. [Google Scholar] [CrossRef]

- Liu, L.; Guo, F.; Zou, Z.; Duffy, V.G. Application, Development and Future Opportunities of Collaborative Robots (Cobots) in Manufacturing: A Literature Review. Int. J. Hum.-Comput. Interact. 2022, 40, 915–932. [Google Scholar] [CrossRef]

- Sherwani, F.; Asad, M.M.; Ibrahim, B.S.K.K. Collaborative Robots and Industrial Revolution 4.0 (IR 4.0). In Proceedings of the International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 26–27 March 2020. [Google Scholar] [CrossRef]

- Rossi, J.; Bianchini, A.; Guarnieri, P. Circular Economy Model Enhanced by Intelligent Assets from Industry 4.0: The Proposition of an Innovative Tool to Analyze Case Studies. Sustainability 2020, 12, 7147. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Atzori, L.; Iera, A.; Morabito, G. The Internet of Things: A survey. Comput. Netw. 2010, 54, 2787–2805. [Google Scholar] [CrossRef]

- Santos, C.; Mehrsai, A.; Barros, A.C.; Araújo, M.; Ares, E. Towards Industry 4.0: An overview of European strategic roadmaps. Procedia Manuf. 2017, 13, 972–979. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.-S.; Yang, J.-H.; Wang, K.-S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Erol, T.; Mendi, A.F.; Doğan, D. Digital Transformation Revolution with Digital Twin Technology. In Proceedings of the 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020. [Google Scholar] [CrossRef]

- Qian, C.; Liu, X.; Ripley, C.; Qian, M.; Liang, F.; Yu, W. Digital Twin—Cyber Replica of Physical Things: Architecture, Applications and Future Research Directions. Future Internet 2022, 14, 64. [Google Scholar] [CrossRef]

- Fusic, S.J.; Sugumari, T. A Review of Perception-Based Navigation System for Autonomous Mobile Robots. Recent Pat. Eng. 2023, 17, 13–22. [Google Scholar] [CrossRef]

- Sierra-García, J.E.; Santos, M. Mechatronic Modelling of Industrial AGVs: A Complex System Architecture. Complexity 2020, 2020, 6687816. [Google Scholar] [CrossRef]

- Gunasekaran, J.; Sevvel, P.; John Solomon, I. Metallic materials fabrication by selective laser melting: A review. Mater. Today Proc. 2021, 37, 252–256. [Google Scholar] [CrossRef]

- Suresh, A.; Udendhran, R.; Yamini, G. Internet of Things and Additive Manufacturing: Toward Intelligent Production Systems in Industry 4.0. In Internet Things Industry 4.0; Springer: Cham, Switzerland, 2019; pp. 73–89. [Google Scholar] [CrossRef]

- Rahmani, R.; Lopes, S.I.; Prashanth, K.G. Selective Laser Melting and Spark Plasma Sintering: A Perspective on Functional Biomaterials. J. Funct. Biomater. 2023, 14, 521. [Google Scholar] [CrossRef] [PubMed]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22, 5396. [Google Scholar] [CrossRef]

- Bonci, A.; Cheng, P.D.C.; Indri, M.; Nabissi, G.; Sibona, F. Human-Robot Perception in Industrial Environments: A Survey. Sensors 2021, 21, 1571. [Google Scholar] [CrossRef] [PubMed]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Santhi, A.R.; Muthuswamy, P. Industry 5.0 or industry 4.0S? Introduction to industry 4.0 and a peek into the prospective industry 5.0 technologies. Int. J. Interact. Des. Manuf. 2023, 17, 947–979. [Google Scholar] [CrossRef]

- Wang, C.; Chen, X.; Soliman, A.H.A.; Zhu, Z. RFID Based Manufacturing Process of Cloud MES. Future Internet 2018, 10, 104. [Google Scholar] [CrossRef]

- Kumar, R.; Kariminejad, A.; Antonov, M.; Goljandin, D.; Klimczyk, P.; Hussainova, I. Progress in Sustainable Recycling and Circular Economy of Tungsten Carbide Hard Metal Scraps for Industry 5.0 and Onwards. Sustainability 2023, 15, 12249. [Google Scholar] [CrossRef]

- Aslam, M.; Khan, T.M.; Naqvi, S.S.; Holmes, G.; Naffa, R. On the Application of Automated Machine Vision for Leather Defect Inspection and Grading: A Survey. IEEE Access 2019, 7, 176065–176086. [Google Scholar] [CrossRef]

- Gebbe, C.; Hilmer, S.; Götz, G.; Lutter-Günther, M.; Chen, Q.; Unterberger, E.; Glasschröder, J.; Schmidt, V.; Riss, F.; Kamps, T.; et al. Concept of the Green Factory Bavaria in Augsburg. Procedia CIRP 2015, 32, 53–57. [Google Scholar] [CrossRef]

- Rahmani, R.; Karimi, J.; Kamboj, N.; Kumar, R.; Brojan, M.; Tchórz, A.; Skrabalak, G.; Lopes, S.I. Fabrication of localized dia-mond-filled copper structures via selective laser melting and spark plasma sintering. Diam. Relat. Mater. 2023, 136, 109916. [Google Scholar] [CrossRef]

- Hassoun, A.; Prieto, M.A.; Carpena, M.; Bouzembrak, Y.; Marvin, H.J.P.; Pallarés, N.; Barba, F.J.; Bangar, S.P.; Chaudhary, V.; Ibra-him, S.; et al. Exploring the role of green and Industry 4.0 technologies in achieving sustainable development goals in food sectors. Food Res. Int. Part B 2022, 162, 112068. [Google Scholar] [CrossRef] [PubMed]

- Govindaraju, R.; Putra, K. A methodology for Manufacturing Execution Systems (MES) implementation. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012094. [Google Scholar] [CrossRef]

- Choi, B.K.; Kim, B.H. MES (manufacturing execution system) architecture for FMS compatible to ERP (enterprise planning system). Int. J. Comput. Integr. Manuf. 2002, 15, 274–284. [Google Scholar] [CrossRef]

- Reinkemeyer, L. Process Mining in Action; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar] [CrossRef]

- Craiut, L.; Bungau, C.; Bungau, T.; Grava, C.; Otrisal, P.; Radu, A.-F. Technology Transfer, Sustainability, and Development, World-wide and in Romania. Sustainability 2022, 14, 15728. [Google Scholar] [CrossRef]

- Yun, J.J.; Liu, Z. Micro- and Macro-Dynamics of Open Innovation with a Quadruple-Helix Model. Sustainability 2019, 11, 3301. [Google Scholar] [CrossRef]

- Tantawi, K.H.; Sokolov, A.; Tantawi, O. Advances in Industrial Robotics: From Industry 3.0 Automation to Industry 4.0 Collaboration. In Proceedings of the 2019 4th Technology Innovation Management and Engineering Science International Conference (TIMES-iCON), Bangkok, Thailand, 11–13 December 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Leng, J.; Sha, W.; Wang, B.; Zheng, P.; Zhuang, C.; Liu, Q.; Wuest, T.; Mourtzis, D.; Wang, L. Industry 5.0: Prospect and retrospect. J. Manuf. Syst. 2022, 65, 279–295. [Google Scholar] [CrossRef]

- Chourasia, S.; Tyagi, A.; Pandey, S.M.; Walia, R.S.; Murtaza, Q. Sustainability of Industry 6.0 in Global Perspective: Benefits and Challenges. MAPAN 2022, 37, 443–452. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmani, R.; Jesus, C.; Lopes, S.I. Implementations of Digital Transformation and Digital Twins: Exploring the Factory of the Future. Processes 2024, 12, 787. https://doi.org/10.3390/pr12040787

Rahmani R, Jesus C, Lopes SI. Implementations of Digital Transformation and Digital Twins: Exploring the Factory of the Future. Processes. 2024; 12(4):787. https://doi.org/10.3390/pr12040787

Chicago/Turabian StyleRahmani, Ramin, Cristiano Jesus, and Sérgio I. Lopes. 2024. "Implementations of Digital Transformation and Digital Twins: Exploring the Factory of the Future" Processes 12, no. 4: 787. https://doi.org/10.3390/pr12040787

APA StyleRahmani, R., Jesus, C., & Lopes, S. I. (2024). Implementations of Digital Transformation and Digital Twins: Exploring the Factory of the Future. Processes, 12(4), 787. https://doi.org/10.3390/pr12040787