Re-Calibrating the Mercury-Intrusion-Porosimetry-Measured Pore Size Distribution of Coals: A Novel Method for Calculating the Matrix Compression Coefficient

Abstract

1. Introduction

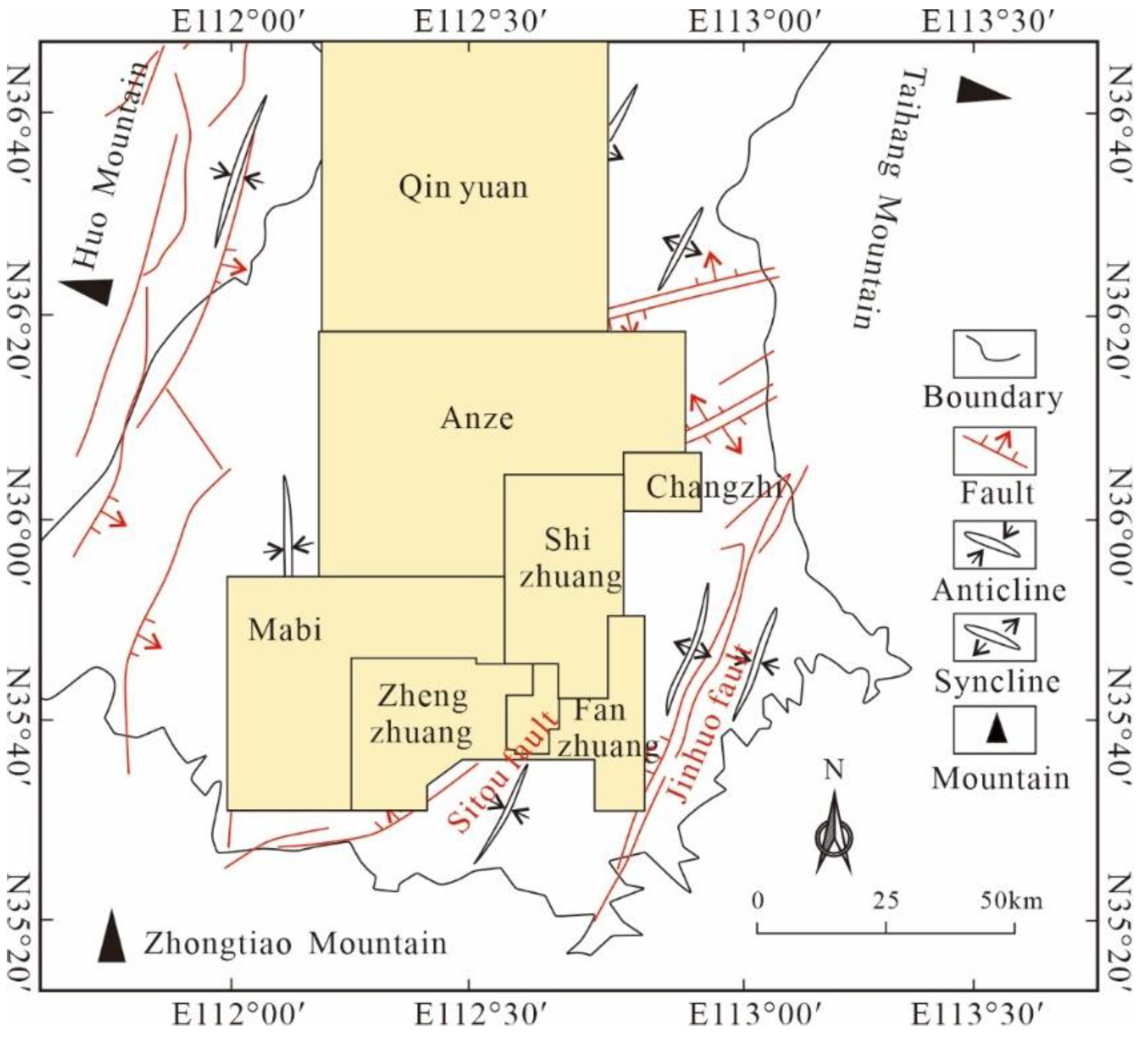

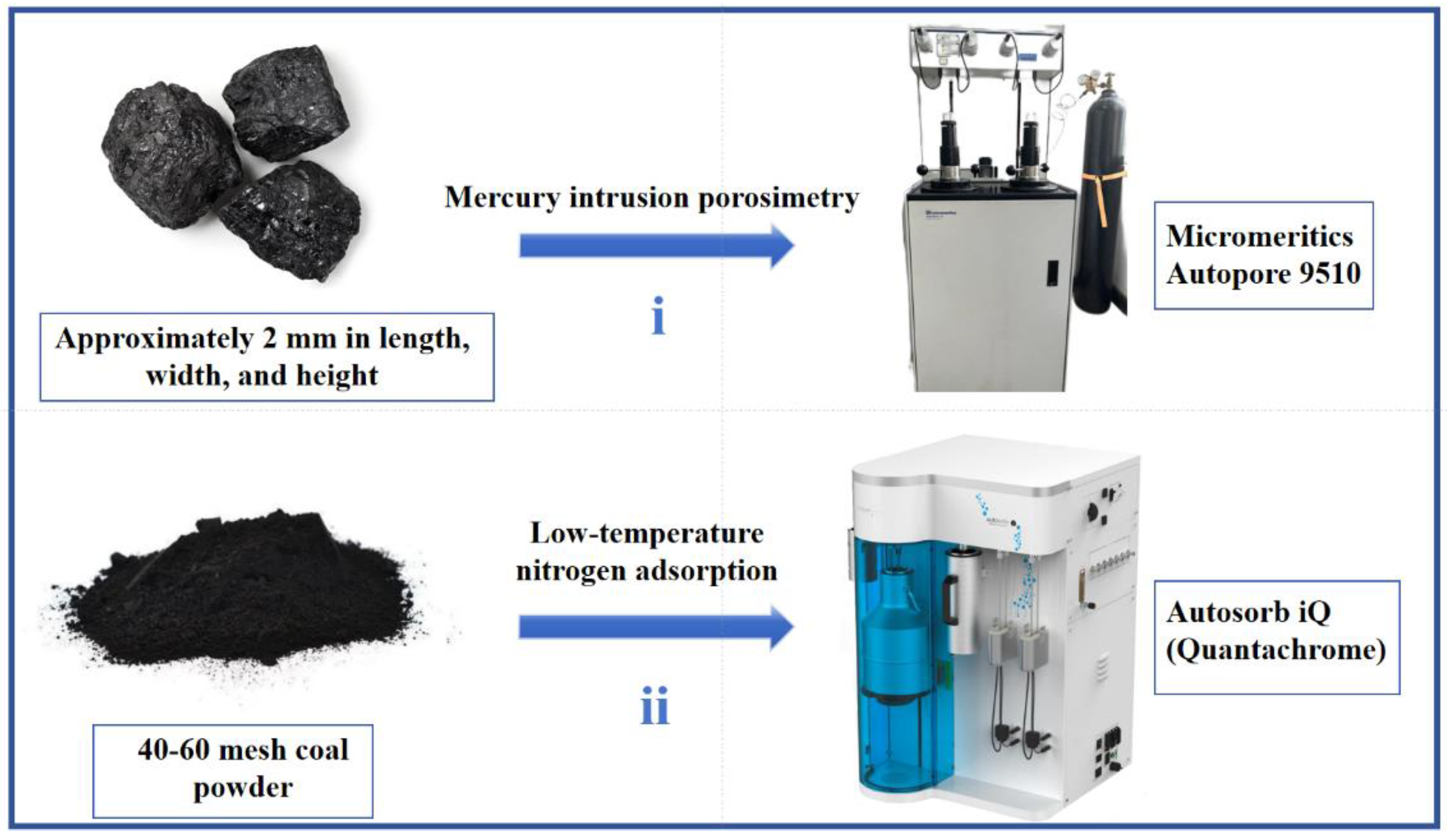

2. Samples and Experiments

3. Results and Discussion

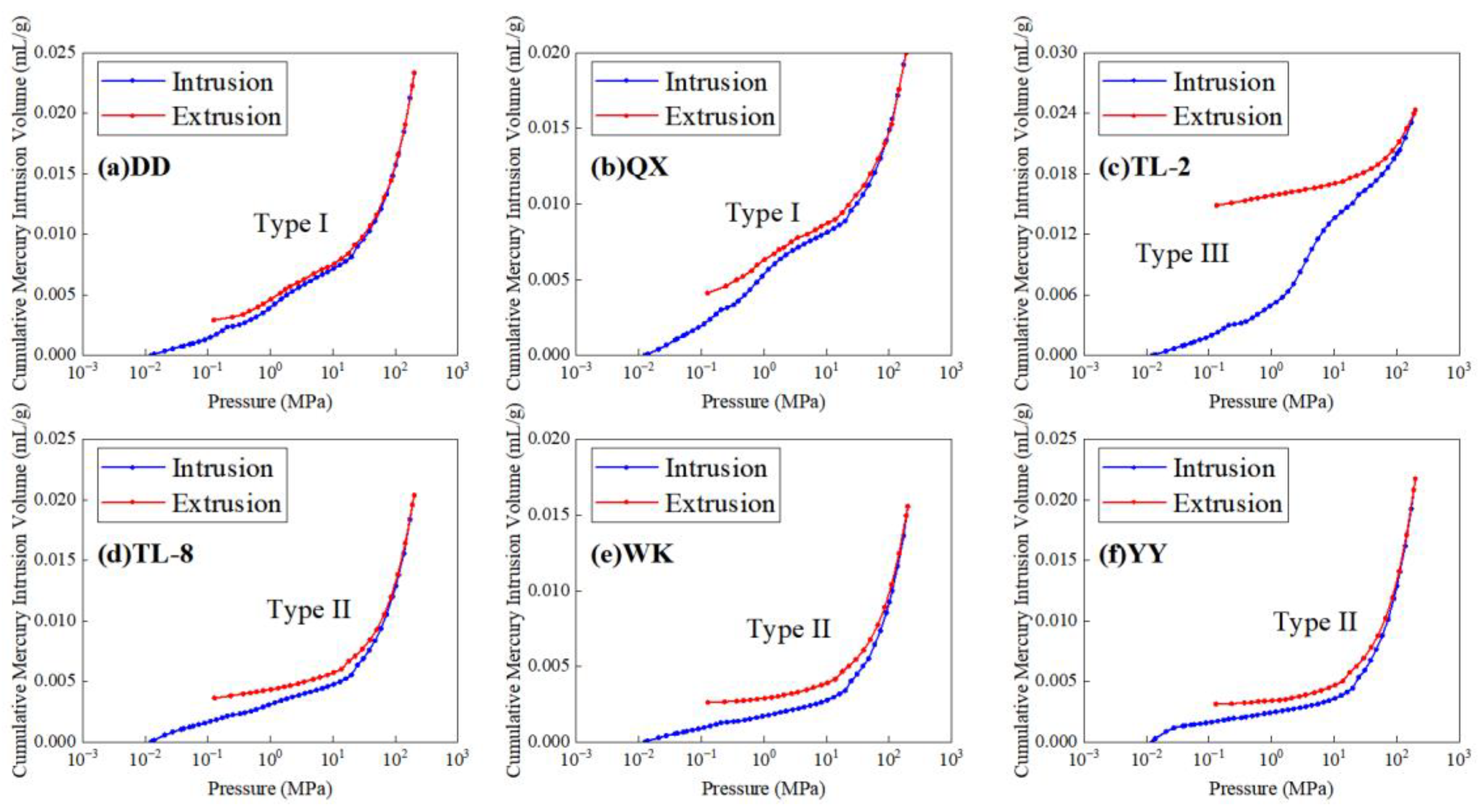

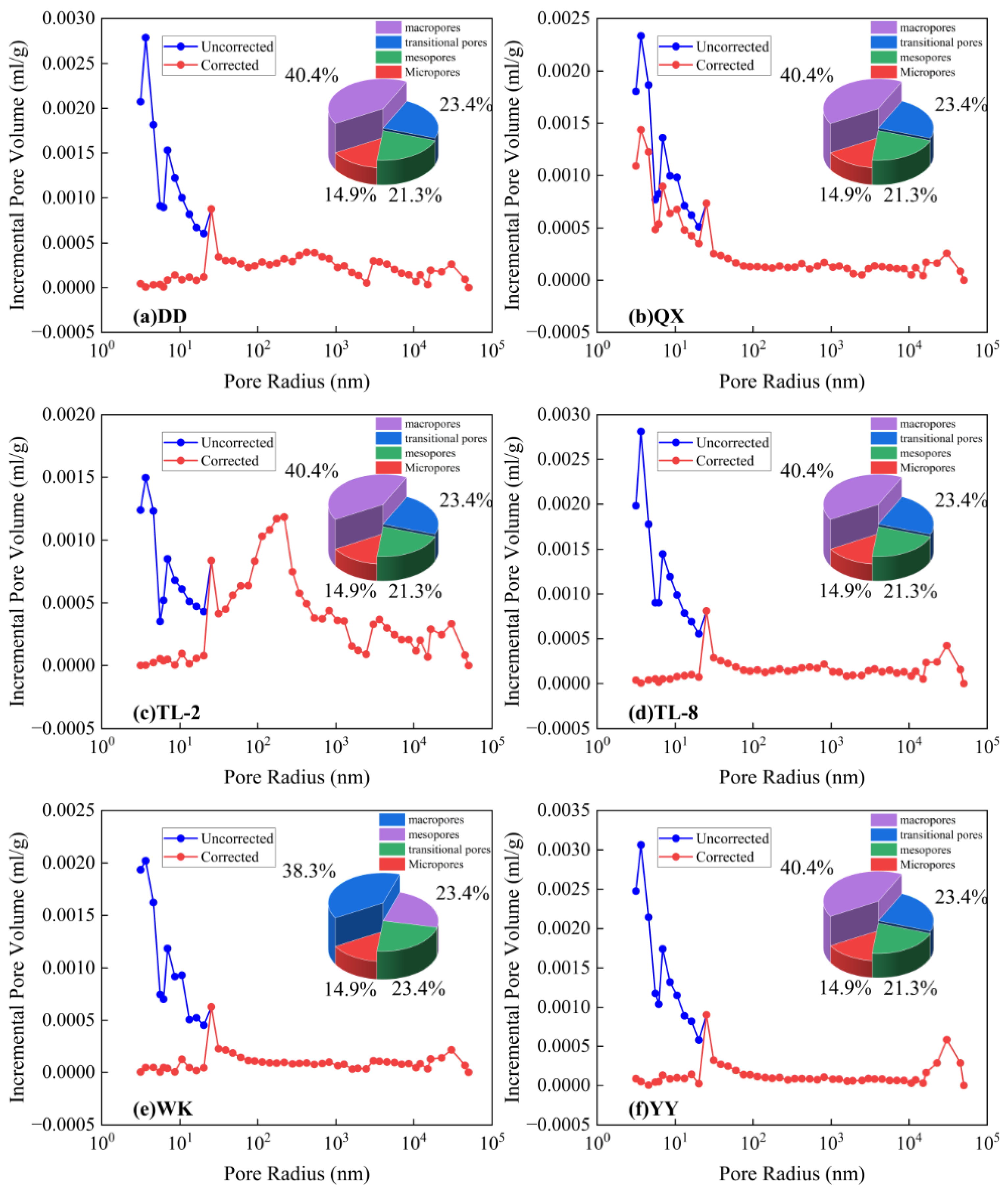

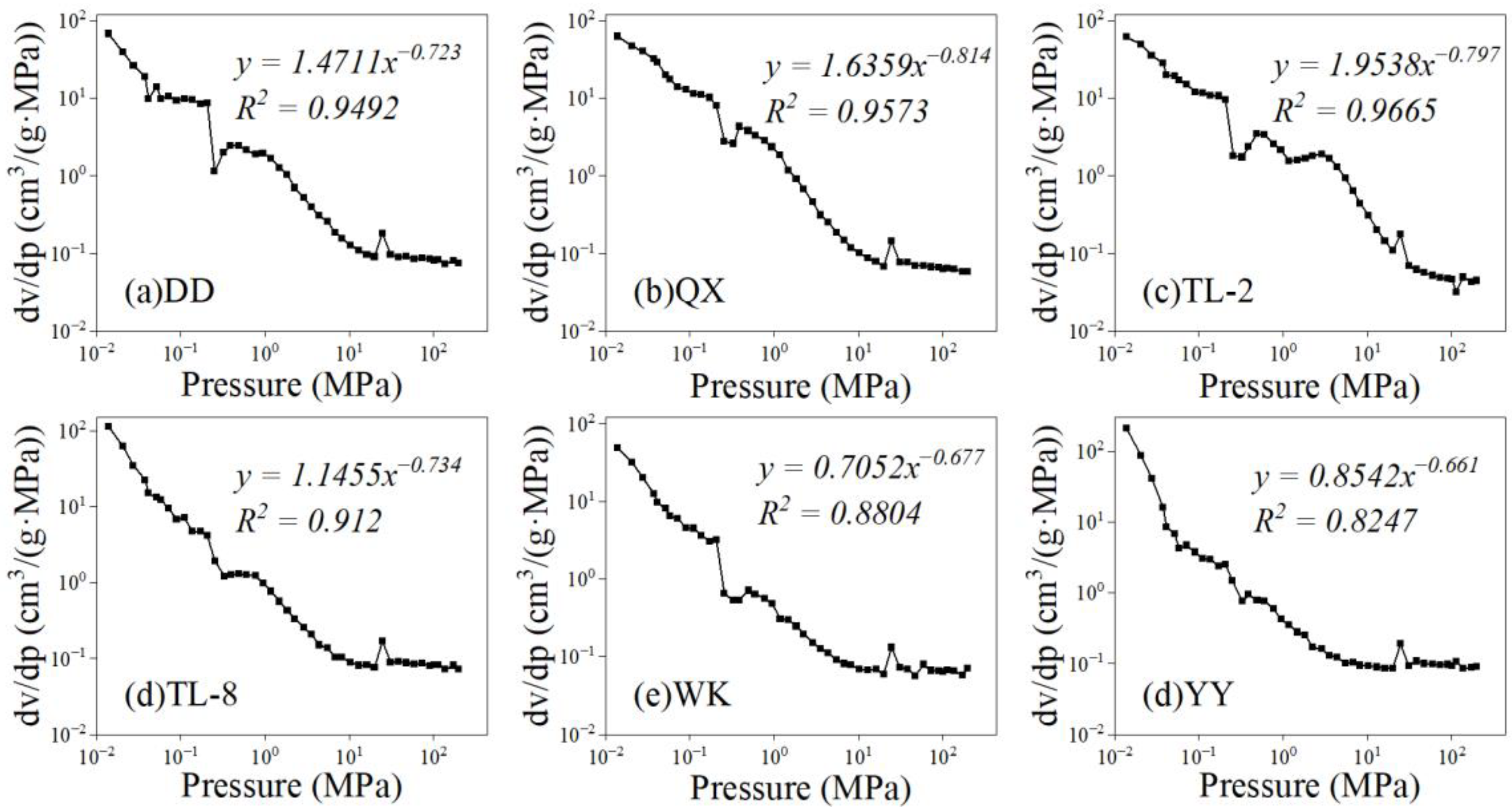

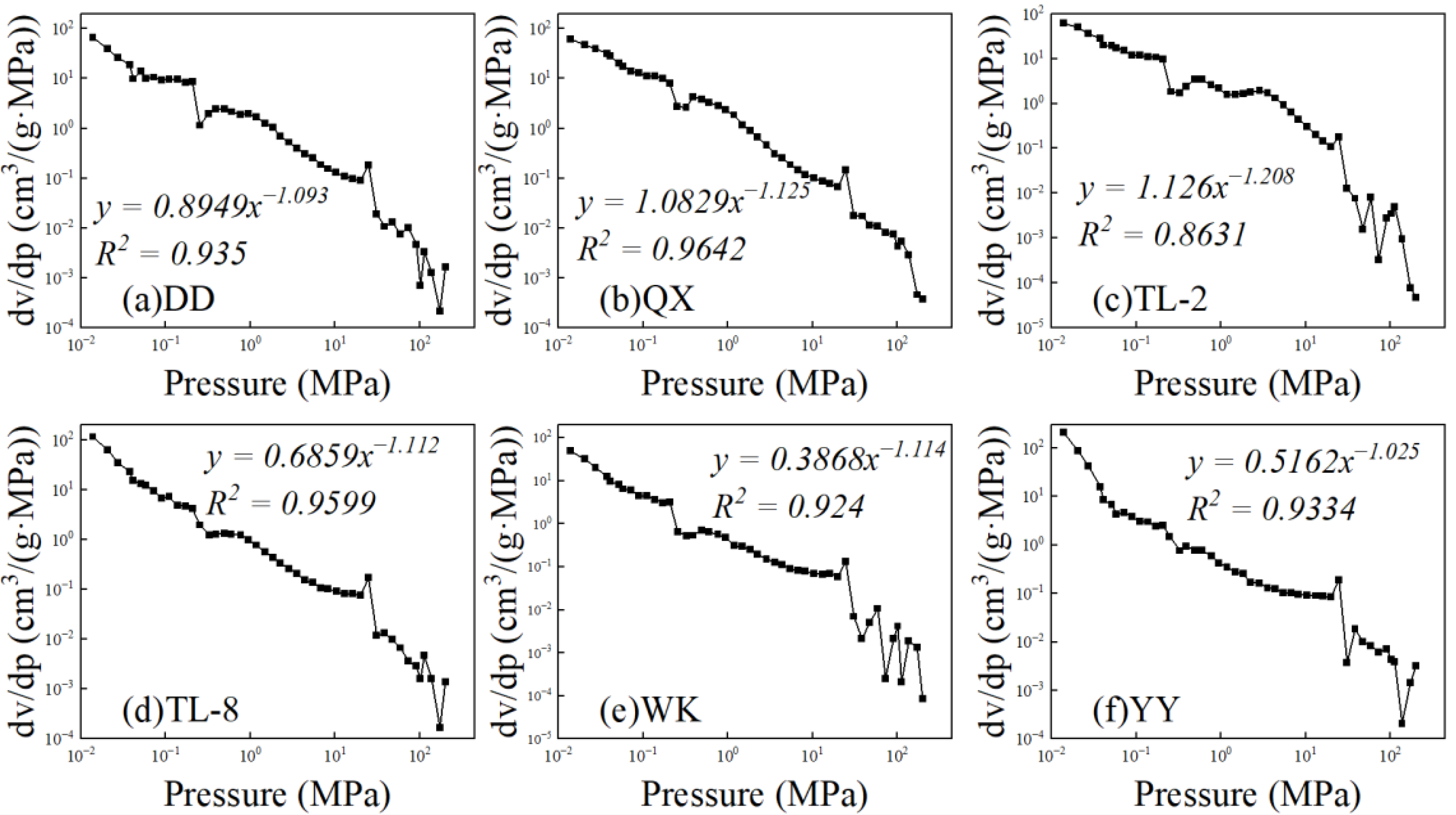

3.1. MIP Experimental Results

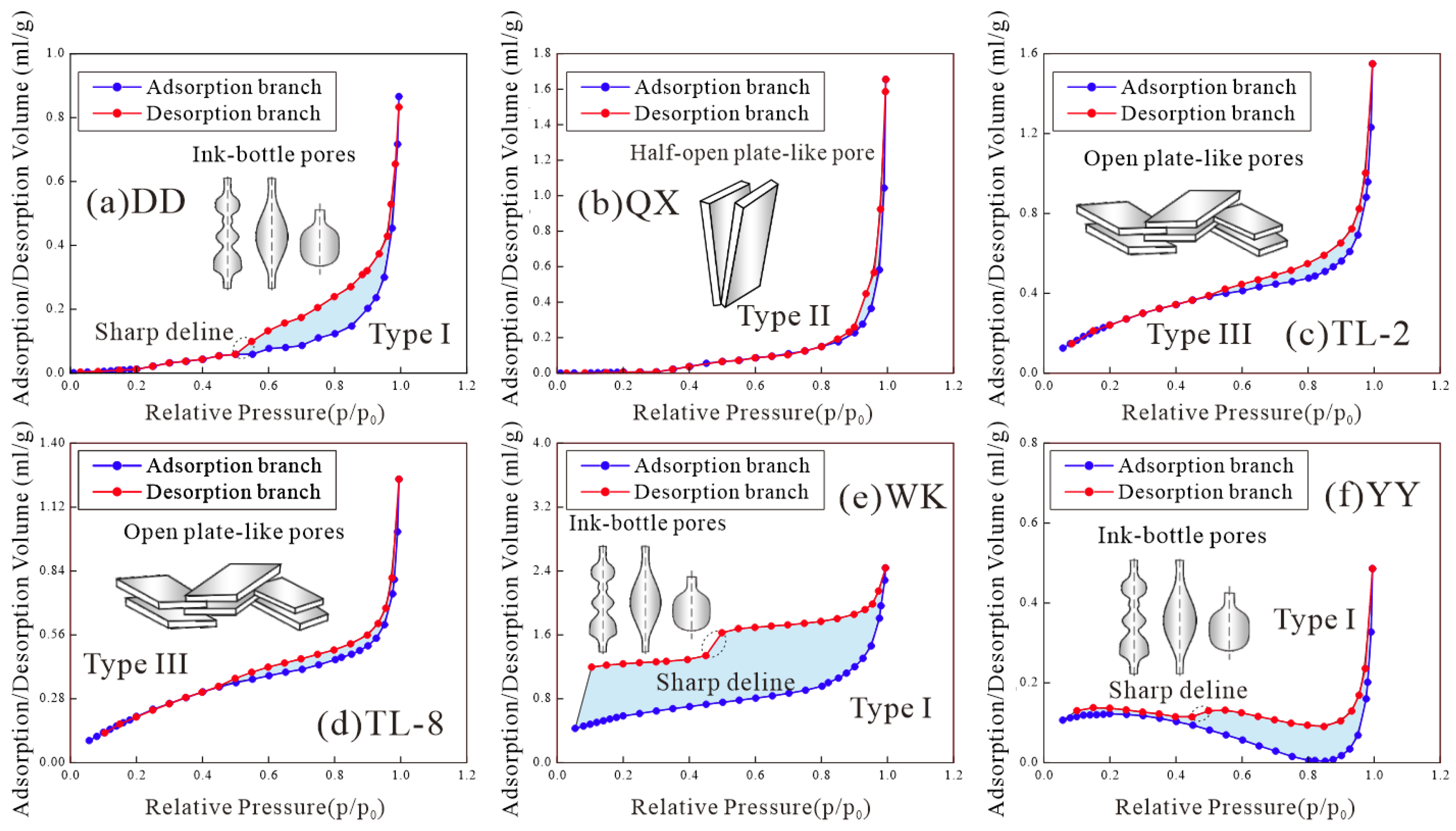

3.2. LTNA Experimental Results

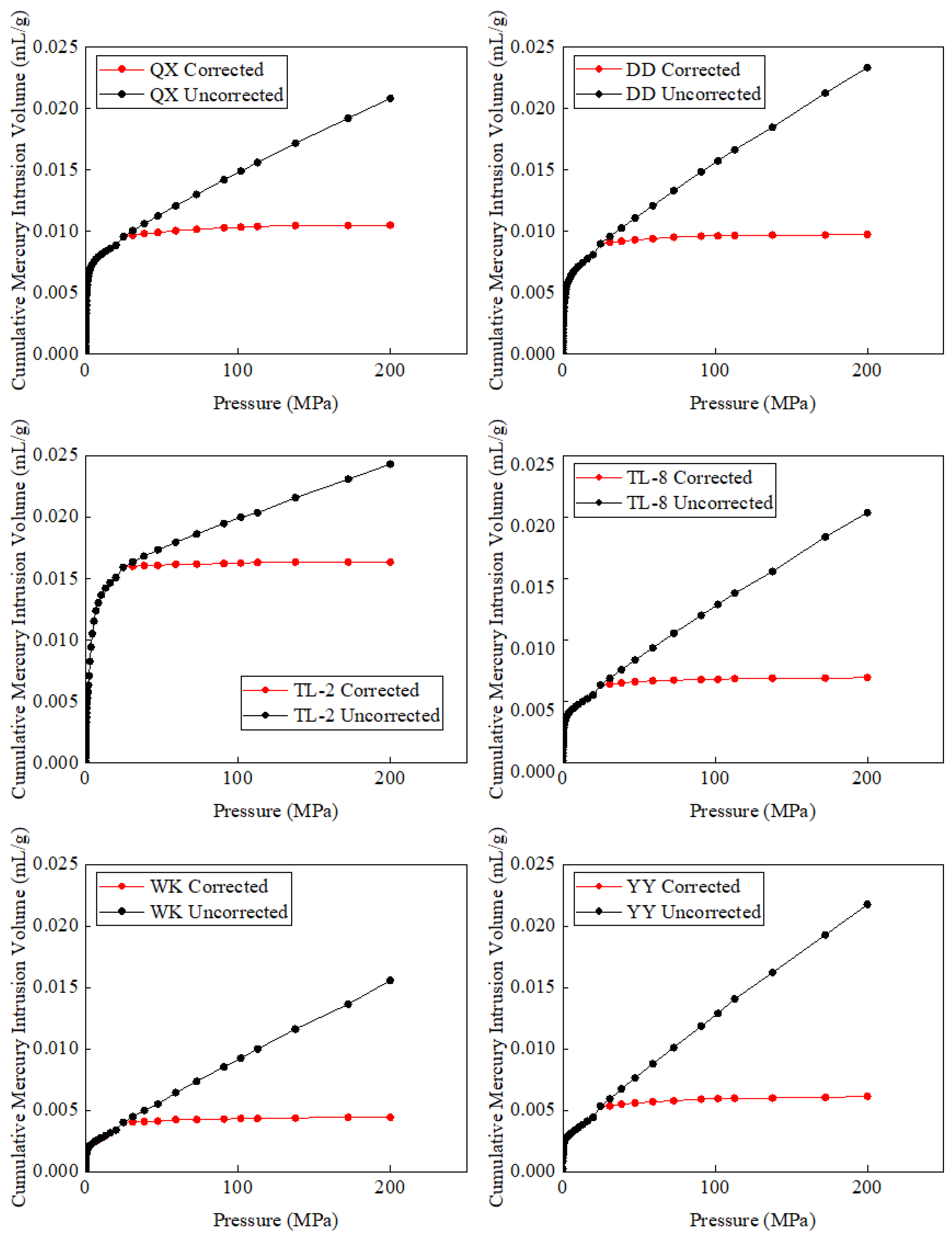

3.3. Considering MIP Data Correction for Matrix Compression

3.3.1. Traditional Correction Method

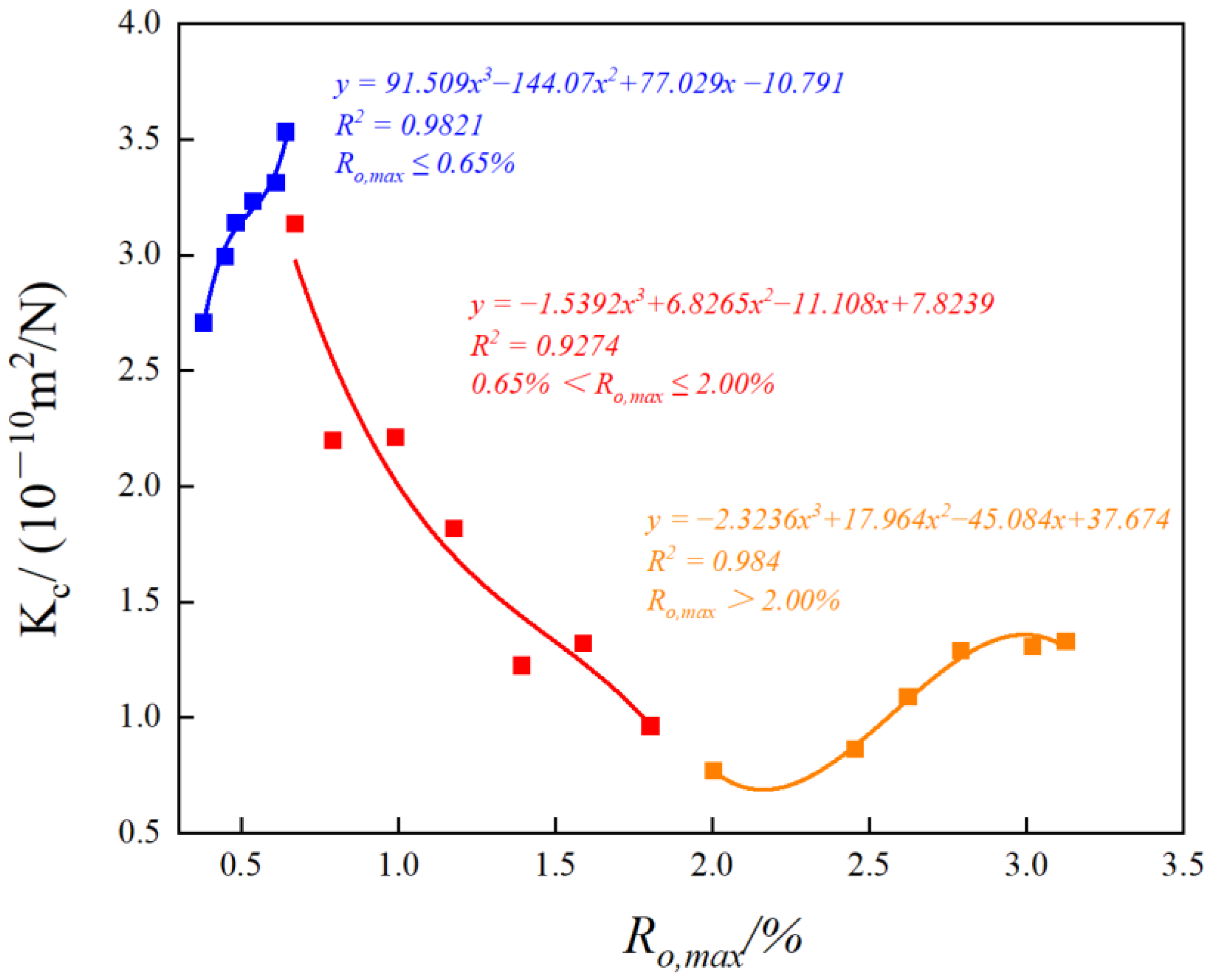

3.3.2. Statistical Correction Method

3.4. Analysis of Calibration Results

4. Fractal Dimension Characteristics before and after Calibration

5. Research and Prospects

6. Conclusions

- (1)

- The analysis of MIP data reveals significant differences in the pore structure and the connectivity of coal samples from different mining areas. Type I coal samples predominantly exhibit semi-open pores with poor connectivity. Type II coal samples show poor connectivity in the transitional pores segment but good connectivity in the large pore segment. In contrast, Type III coal samples mainly feature open pores with good connectivity. Furthermore, data from LTNA experiments indicate notable pore morphology variations among coal samples. Ink-bottle, semi-open, and open plate-shaped pores primarily characterize these morphologies.

- (2)

- Considering the matrix compression effect of coal, a novel statistical correction method was devised based on statistical analysis. Compared to KC values calculated using the traditional correction method, the statistical correction methods have high practical applicability. This statistical correction method was applied to correct MIP data under pressures ranging from 24 to 200 MPa, resulting in a decrease in the corrected mercury intrusion volume by 91.75% to 96.40%. The correction effect was significant, enabling a more precise characterization of the PSD.

- (3)

- The D2 of MIP-measured initial uncorrected data values ranged from 3.186 to 3.339, with fractal dimensions between 3 and 4, indicating the suboptimal fractal characteristics of the overall pore structure. After PSD correction, D2 values ranged from 2.792 to 2.975 within the 2 to 3 range, reflecting improved fractal characteristics. Correcting the MIP data significantly enhances the fractal representation of the coal’s pore structure, aligning the fractal dimensions more closely with their true values and thus offering a more accurate depiction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, M.; Xie, W.D.; Huang, K. Fine characterization of lithofacies and pore network structure of continental shale: Case study of the Shuinan Formation in the north Jiaolai Basin, China. J. Pet. Sci. Eng. 2019, 175, 948–960. [Google Scholar] [CrossRef]

- Cai, Y.D.; Liu, D.M.; Pan, Z.J.; Yao, Y.B.; Li, J.Q.; Qiu, Y.K. Pore structure and its impact on CH4 adsorption capacity and flow capability of bituminous and subbituminous coals from Northeast China. Fuel 2013, 103, 258–268. [Google Scholar] [CrossRef]

- Liu, S.; Harpalani, S. Compressibility of sorptive porous media: Part 1. Background and theory. AAPG Bull. 2014, 98, 1761–1772. [Google Scholar] [CrossRef]

- Zheng, S.J.; Yao, Y.B.; Liu, D.M.; Cai, Y.D.; Liu, Y. Characterizations of full-scale pore size distribution, porosity and permeability of coals: A novel methodology by nuclear magnetic resonance and fractal analysis. Int. J. Coal Geol. 2018, 196, 148–158. [Google Scholar] [CrossRef]

- Moore, T.A. Coalbed methane: A review. Int. J. Coal Geol. 2012, 101, 36–81. [Google Scholar] [CrossRef]

- Liu, X.F.; Nie, B.S. Fractal characteristics of coal samples utilizing image analysis and gas adsorption. Fuel 2016, 182, 314–322. [Google Scholar] [CrossRef]

- Liu, S.Q.; Sang, S.X.; Wang, G.; Ma, J.S.; Wang, X.; Wang, W.F.; Du, Y.; Wang, T. FIB-SEM and X-ray CT characterization of interconnected pores in high-rank coal formed from regional metamorphism. J. Pet. Sci. Eng. 2017, 148, 21–31. [Google Scholar] [CrossRef]

- Wang, G.C.; Ju, Y.W.; Yan, Z.F.; Li, Q.G. Pore structure characteristics of coal-bearing shale using fluid invasion methods: A case study in the Huainan—Huaibei Coalfield in China. Mar. Pet. Geol. 2015, 62, 1–13. [Google Scholar] [CrossRef]

- Song, Y.; Jiang, B.; Shao, P.; Wu, J.H. Matrix compression and multifractal characterization for tectonically deformed coals by Hg porosimetry. Fuel 2018, 211, 661–675. [Google Scholar]

- Golab, A.; Ward, C.R.; Permana, A.; Lennox, P.; Botha, P. High-resolution three-dimensional imaging of coal using microfocus X-ray computed tomography, with special reference to modes of mineral occurrence. Int. J. Coal Geol. 2013, 113, 97–108. [Google Scholar] [CrossRef]

- Pan, J.N.; Zhu, H.T.; Hou, Q.L.; Wang, H.C.; Wang, S. Macromolecular and pore structures of Chinese tectonically deformed coals studied by atomic force microscopy. Fuel 2015, 139, 94–101. [Google Scholar] [CrossRef]

- Guan, C.; Liu, S.; Li, C.; Wang, Y.; Zhao, Y. The temperature effect on the methane and CO2 adsorption capacities of Illinois coal. Fuel 2018, 211, 241–250. [Google Scholar] [CrossRef]

- Meng, Z.; Liu, S.; Li, G. Adsorption capacity, adsorption potential and surface free energy of different structure high rank coals. J Pet. Sci. Eng. 2016, 146, 856–865. [Google Scholar] [CrossRef]

- Jian, K.; Fu, X.; Ding, Y.; Wang, H.; Li, T. Characteristics of pores and methane adsorption of low-rank coal in China. J. Nat. Gas Sci. Eng. 2015, 27, 207–218. [Google Scholar] [CrossRef]

- Yi, L.C.; Yong, Q.; Tang, H. Particle size effect of pore structure of anthracite by mercury porosimetry. Nat. GasGe-Oscience 2015, 26, 1629–1639. [Google Scholar]

- Zhang, P.; Lu, S.; Li, J. Characterization of pore size distributions of shale oil reservoirs: A case study from Dongying sag, Bohai Bay basin China. Mar. Pet. Geol. 2019, 100, 297–308. [Google Scholar] [CrossRef]

- Cai, Y.; Li, Q.; Liu, D.; Zhou, Y.; Lv, D. Insights into matrix compressibility of coals by mercury intrusion porosimetry and N2 adsorption. Int. J. Coal Geol. 2018, 200, 199–212. [Google Scholar] [CrossRef]

- Gan, H.; Nandi, S.; Walker, P., Jr. Nature of the porosity in American coals. Fuel 1972, 51, 272–277. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Friesen, W.; Ogunsola, O. Mercury porosimetry of upgraded western Canadian coals. Fuel 1995, 74, 604–609. [Google Scholar] [CrossRef]

- Day, S.; Fry, R.; Sakurovs, R. Swelling of Australian coals in supercritical CO2. Int. J. Coal Geol. 2008, 74, 41–52. [Google Scholar] [CrossRef]

- Friesen, W.I.; Mikula, R.J. Mercury porosimetry of coals: Pore volume distribution and compressibility. Fuel 1988, 67, 1516–1520. [Google Scholar] [CrossRef]

- Friesen, W.I.; Mikula, R.J. Fractal dimensions of coal particles. J. Colloid Interface Sci. 1987, 120, 263–271. [Google Scholar] [CrossRef]

- Harpalani, S.; Schraufnagel, R.A. Shrinkage of coal matrix with release of gas and its impact on permeability of coal. Fuel 1990, 69, 551–556. [Google Scholar] [CrossRef]

- Spitzer, Z. Mercury porosimetry and its application to the analysis of coal pore structure. Powder Technol. 1981, 29, 177–186. [Google Scholar] [CrossRef]

- Ritter, H.L.; Dake, L.C. Pressure porosimeter and determination of complete Macropore-Size distributions. Ind. Eng. Chem. Anal. Ed. 1945, 17, 782–786. [Google Scholar] [CrossRef]

- Toda, Y.; Toyoda, S. Application of mercury porosimetry to coal. Fuel 1972, 51, 199–201. [Google Scholar] [CrossRef]

- Dickinson, J.M.; Shore, J.W. Observations concerning the determination of porosities in graphites. Carbon 1968, 6, 937–941. [Google Scholar] [CrossRef]

- Debelak, K.A.; Schrodt, J.T. Comparison of pore structure in Kentucky coals by mercury penetration and carbon dioxide adsorption. Fuel 1979, 58, 732–736. [Google Scholar] [CrossRef]

- Jin, Y.; Zhao, M.; Liu, S.; Liu, X. Study on the effect of coal matrix compression on fractal characteristics of pore structure by mercury intrusion method. China Coal 2018, 43, 103–109. [Google Scholar]

- Liu, J.; Ren, B.; Wang, C. Study on coal full pore aperture distribution chaeacteristics considering coal matrix compression effect. Ind. Mine Autom. 2022, 48, 125–130. [Google Scholar]

- Han, B.B.; Qin, Y.; Zhang, Z.; Wang, G.; Yu, P. Study on coal compressibility and correction of compression amount based on compressibility of mercury injection test. Coal Sci. Technol. 2015, 43, 68–72. [Google Scholar]

- Zheng, S.; Yao, Y.; Zhang, S.; Liu, Y.; Yang, J. Insights into Multifractal Characterization of Coals by Mercury Intrusion Porosimetry. Energies 2019, 12, 4743. [Google Scholar] [CrossRef]

- Guo, X.Q.; Yao, Y.B.; Liu, D.M. Characteristics of coal matrix compressibility: An investigation by mercury intrusion porosimetry. Energy Fuels 2014, 28, 3673–3678. [Google Scholar] [CrossRef]

- Ettinger, I.L.; Zhupakhina, E.S. Method of determining porosity of mineral coals. Fuel 1960, 39, 387–392. [Google Scholar]

- Lu, J.L. Characterization of Pore Structure and Full Aperture Splicing of Coal with Different Coal Ranks. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2021. [Google Scholar]

- Cheng, L.; Li, W. Tectonic coal matrix compression characteristics based on mercury intrusion method and its impact on pore structure. Saf. Coal Mines 2016, 47, 175–179. [Google Scholar]

- Shao, P.; Wang, X.; Song, Y.; Li, Y. Study on the characteristics of matrix compressibility and its influence factors for different rank coals. J. Nat. Gas Sci. Eng. 2018, 56, 93–106. [Google Scholar] [CrossRef]

- Yang, Q.L.; Xue, J.H.; Li, W.; Du, X.; Ma, Q.; Zhan, K.; Chen, Z. Comprehensive evaluation and interpretation of mercury intrusion porosimetry data of coals based on fractal theory, Tait equation and matrix compressibility. Fuel 2021, 298, 120823. [Google Scholar] [CrossRef]

- Yang, Q.L.; Li, W.; Jin, K. Supercritical CO2 interaction induced pore morphology alterations of various ranked coals: A comparative analysis using corrected mercury intrusion porosimetry and low-pressure N2 gas adsorption. ACS Omega 2020, 5, 9276–9290. [Google Scholar] [CrossRef]

- Zhang, J.J.; Wei, C.T.; Zhao, J.L.; Ju, W.; Chen, Y.; Tamehe, L.S. Comparative evaluation of the compressibility of middle and high rank coals by different experimental methods. Fuel 2019, 245, 39–51. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, J.; He, F.; Jiang, Y. Compressibility and fractal dimension analysis in the bituminous coal specimens. AIP Adv. 2018, 8, 075118. [Google Scholar] [CrossRef]

- Li, W.; Liu, H.F.; Song, X.X. Multifractal analysis of Hg pore size distributions of tectonically deformed coals. Int. J. Coal Geol. 2015, 144, 138–152. [Google Scholar] [CrossRef]

- Yang, Y.; Li, M.; Zhang, H.; Mi, Z.; Peng, C.; Wang, N.; Chan, Y. Evaluation of control factors and favourable zones for coalbed methane enrichment and high production in the mid-deep southern Qinshui Basin. Nat. Gas Geosci. 2024, 8, 1–12. [Google Scholar]

- Ren, J.; Zhang, Z.; Xing, L.; Wang, P.; Yu, W.; Long, P. The Influence of Coal Body Structure on Coal Fines’ Output Characteristics in the Southern Qinshui Basin. Processes 2024, 12, 656. [Google Scholar] [CrossRef]

- Jiang, L.; Song, Y.; Zhao, W.; Bo, D.; Liu, S.; Hao, J. Main controlling factor of coalbed methane enrichment area in southern Qinshui Basin, China. J. Pet. Explor. Prod. Technol. 2024, 14, 165–173. [Google Scholar] [CrossRef]

- Liu, J.; Chang, S.; Zhang, S.; Li, Y.; Hao, Y.; He, G.; He, Y.; Liu, B. Prediction of coalbed methane content based on seismic identification of key geological parameters: A case in a study area, Southern Qinshui Basin. Acta Geophys. 2023, 71, 2645–2662. [Google Scholar] [CrossRef]

- Yang, C.; Qiu, F.; Xiao, F.; Chen, S.; Fang, Y. CBM Gas Content Prediction Model Based on the Ensemble Tree Algorithm with Bayesian Hyper-Parameter Optimization Method: A Case Study of Zhengzhuang Block, Southern Qinshui Basin, North China. Processes 2023, 11, 527. [Google Scholar] [CrossRef]

- Wang, H.; Yao, Y.; Li, Z.; Yang, Y.; Yi, J.; Qiu, Y.; Zhou, S. Multi-stage gas diffusion and its implications for the productivity of coalbed methane in the southern Qinshui Basin, north China. Front. Earth Sci. 2023, 17, 109–120. [Google Scholar] [CrossRef]

- Han, W.; Li, Y.; Wang, Y.; Ni, X.; Wang, L.; Zhou, Y. Characterization of Coal Fines and their Production Controlling Factors: A Case Study from Southern Qinshui Basin, China. Nat. Resour. Res. 2023, 32, 1777–1794. [Google Scholar] [CrossRef]

- SY/T 5346-2005; Rock Capillary Pressure Measurement. Petroleum Industry Press: Beijing, China, 2005.

- Gao, Y.; Cao, J.; Zhang, S.; Li, Z. Analysis of the Pore Structure and Fractal Characteristics of Coal and Gas Outburst Coal Seams Based on Matrix Compression Correction. Sustainability 2023, 15, 12670. [Google Scholar] [CrossRef]

- Liu, D.; Jia, Q.; Cai, Y.; Gao, C.; Qiu, F.; Zhao, Z.; Chen, S. A new insight into coalbed methane occurrence and accumulation in the Qinshui Basin, China. Gondwana Res. 2022, 111, 280–297. [Google Scholar] [CrossRef]

- Pape, H.; Tillich, J.E.; Holz, M. Pore geometry of sandstone derived from pulsed field gradient NMR. J. Appl. Geophys. 2006, 58, 232–252. [Google Scholar] [CrossRef]

- Jin, Y.; Zhu, Y.B.; Li, X.; Zheng, J.L.; Dong, J.B. Scaling Invariant Effects on the Permeability of Fractal Porous Media. Transp. Porous Media 2015, 109, 433–453. [Google Scholar] [CrossRef]

- Li, Y.; Song, D.; Liu, S.; Ji, X.; Hao, H. Evaluation of pore properties in coal through compressibility correction based on mercury intrusion porosimetry: A practical approach. Fuel 2021, 291, 0016–2361. [Google Scholar] [CrossRef]

- Zhang, B.; Liu, W.; Liu, X. Scale-dependent nature of the surface fractal dimension for bi- and multi-disperse porous solids by mercury porosimetry. Appl. Surf. Sci. 2006, 253, 1349–1355. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Tang, D.Z.; Tang, S.H.; Huang, W.H.; Liu, Z.H.; Che, Y. Fractal characterization of seepage-pores of coals from China: An investigation on permeability of coals. Comput. Geosci. 2009, 35, 1159–1166. [Google Scholar] [CrossRef]

- Menger, K. Dimensionstheorie; Vieweg+ Teubner Verlag Publishers: Wiesbaden, Germany, 1928; 324p. [Google Scholar]

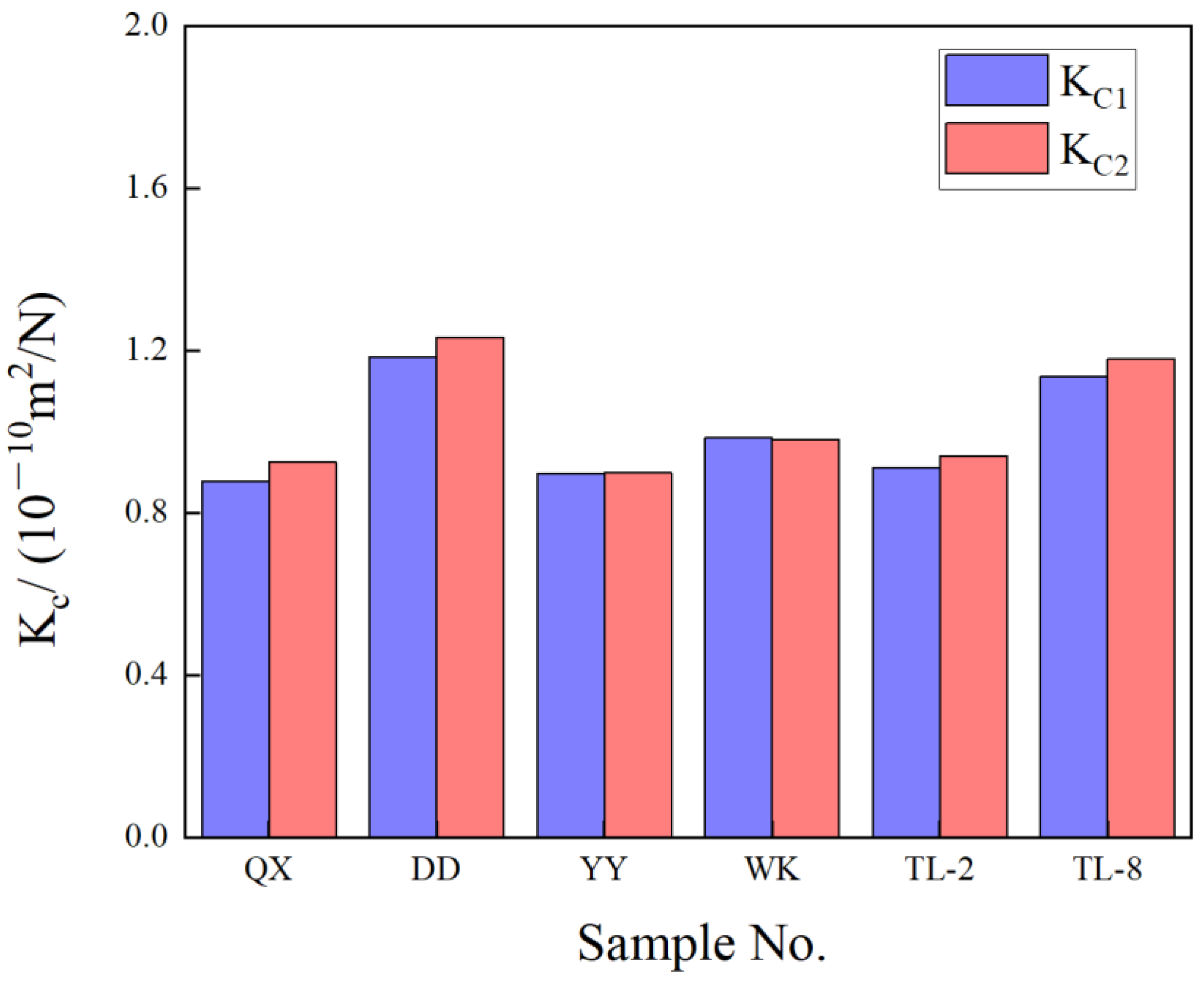

| Sample No. | Ro,max/% | Kc/(10−10 m2/N) | Error Rate | |

|---|---|---|---|---|

| Kc1 | Kc2 | |||

| QX | 1.83 | 0.876 | 0.925 | 5.25% |

| DD | 1.59 | 1.184 | 1.233 | 3.97% |

| YY | 2.47 | 0.897 | 0.898 | 0.11% |

| WK | 2.54 | 0.984 | 0.980 | 0.35% |

| TL-2 | 1.82 | 0.911 | 0.940 | 3.12% |

| TL-8 | 1.64 | 1.137 | 1.178 | 3.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, B.; Zheng, S.; Ping, L.; Wang, M.; Dai, X.; Liu, Y.; Xu, S.; Wu, X. Re-Calibrating the Mercury-Intrusion-Porosimetry-Measured Pore Size Distribution of Coals: A Novel Method for Calculating the Matrix Compression Coefficient. Processes 2024, 12, 1928. https://doi.org/10.3390/pr12091928

Ren B, Zheng S, Ping L, Wang M, Dai X, Liu Y, Xu S, Wu X. Re-Calibrating the Mercury-Intrusion-Porosimetry-Measured Pore Size Distribution of Coals: A Novel Method for Calculating the Matrix Compression Coefficient. Processes. 2024; 12(9):1928. https://doi.org/10.3390/pr12091928

Chicago/Turabian StyleRen, Bin, Sijian Zheng, Lihua Ping, Meng Wang, Xuguang Dai, Yanzhi Liu, Shen Xu, and Xiuping Wu. 2024. "Re-Calibrating the Mercury-Intrusion-Porosimetry-Measured Pore Size Distribution of Coals: A Novel Method for Calculating the Matrix Compression Coefficient" Processes 12, no. 9: 1928. https://doi.org/10.3390/pr12091928

APA StyleRen, B., Zheng, S., Ping, L., Wang, M., Dai, X., Liu, Y., Xu, S., & Wu, X. (2024). Re-Calibrating the Mercury-Intrusion-Porosimetry-Measured Pore Size Distribution of Coals: A Novel Method for Calculating the Matrix Compression Coefficient. Processes, 12(9), 1928. https://doi.org/10.3390/pr12091928