Sustainable Energy from Pickled Chili Waste in Microbial Fuel Cells

Abstract

1. Introduction

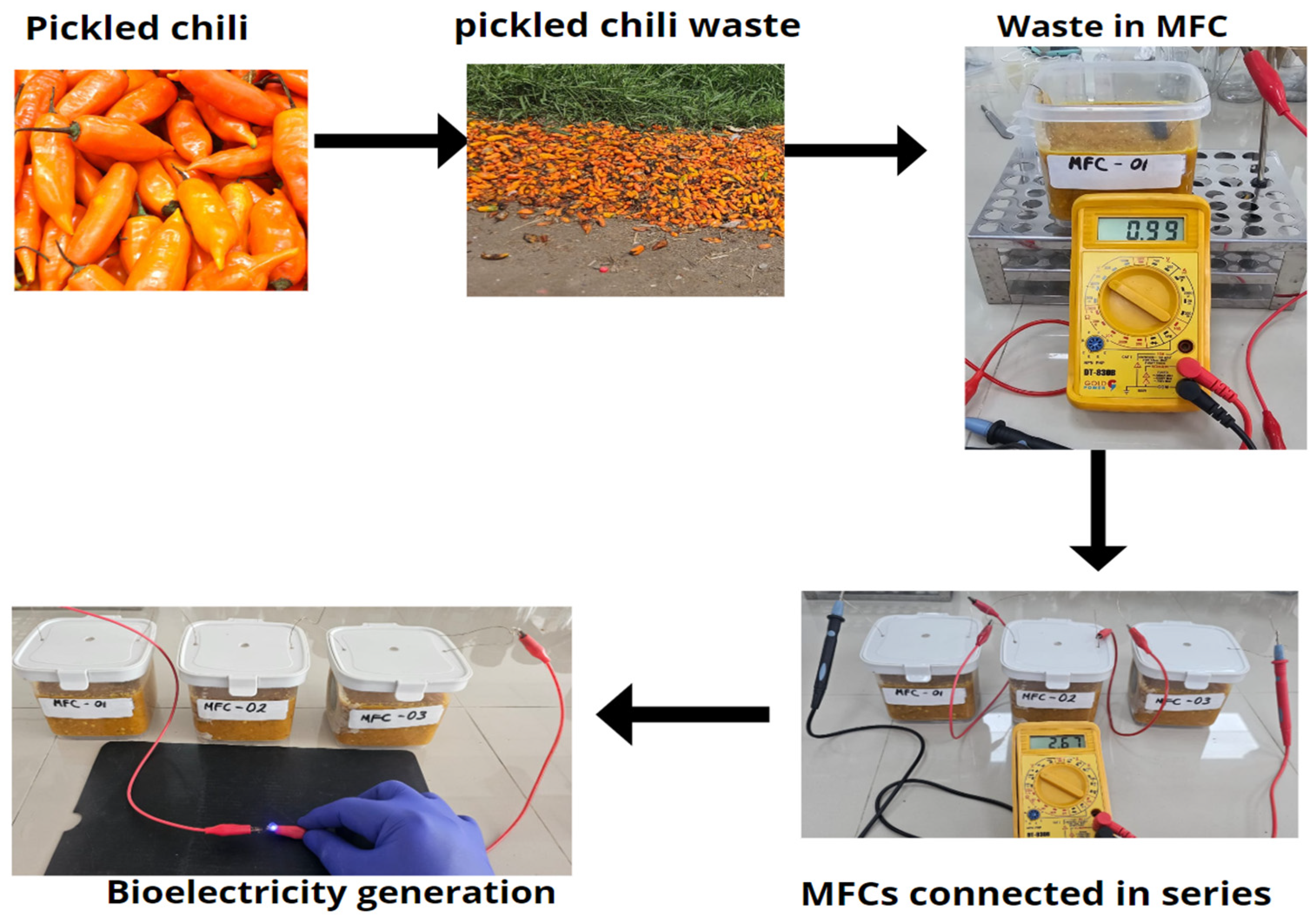

2. Materials and Methods

- Manufacturing of the anode electrode

- b.

- Preparation of the single-chamber fuel cells

- c.

- Obtaining samples used as substrates

- d.

- Obtaining the parameters of the SC-MFCs

- e.

- Molecular process

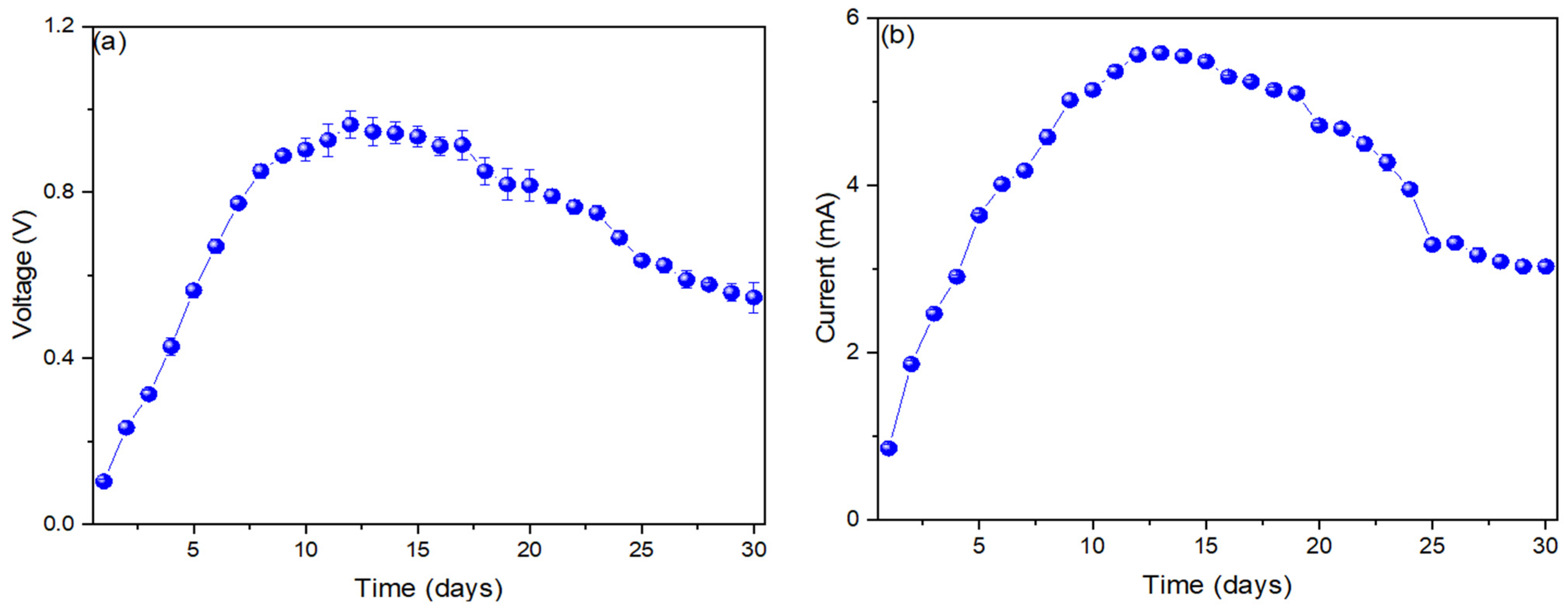

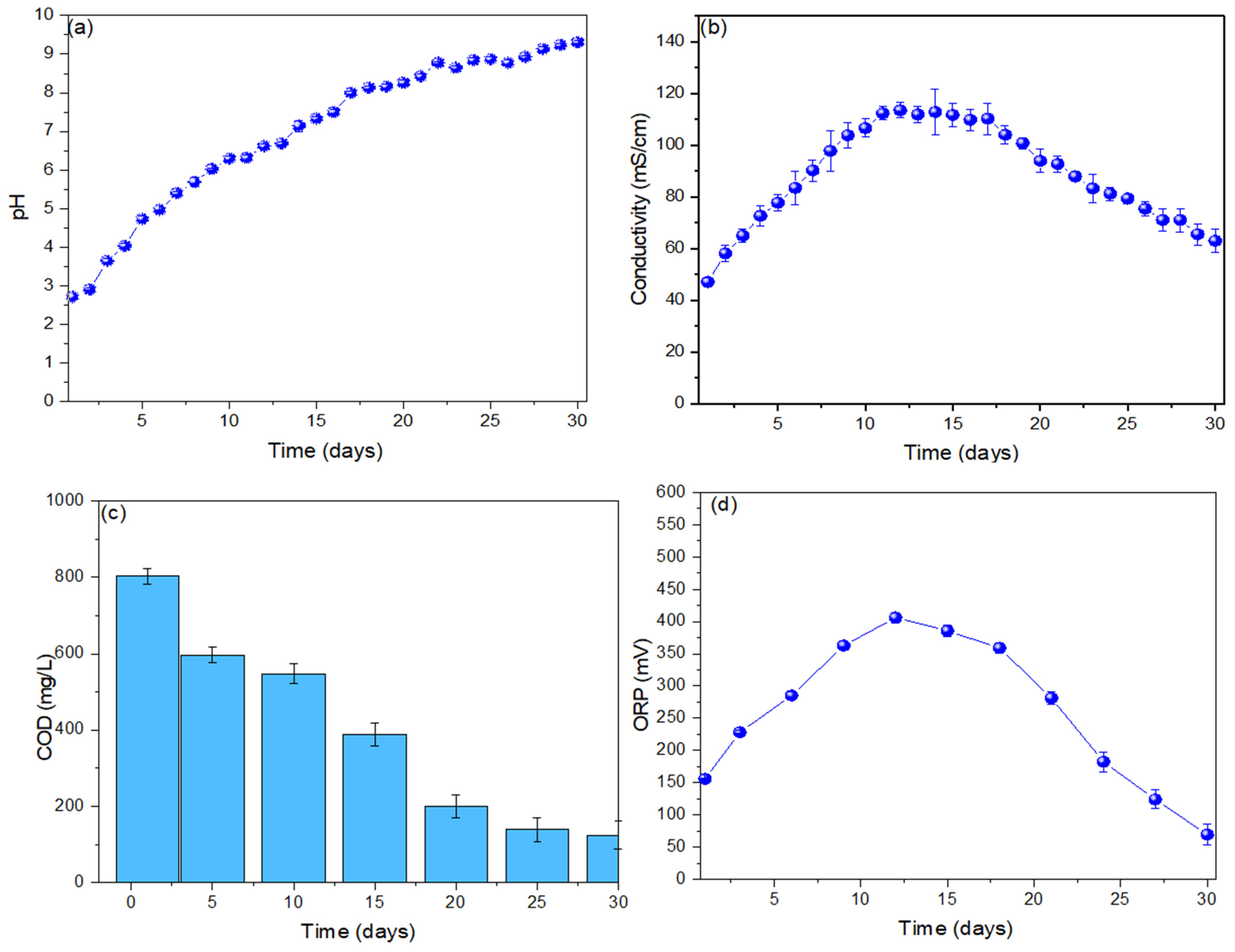

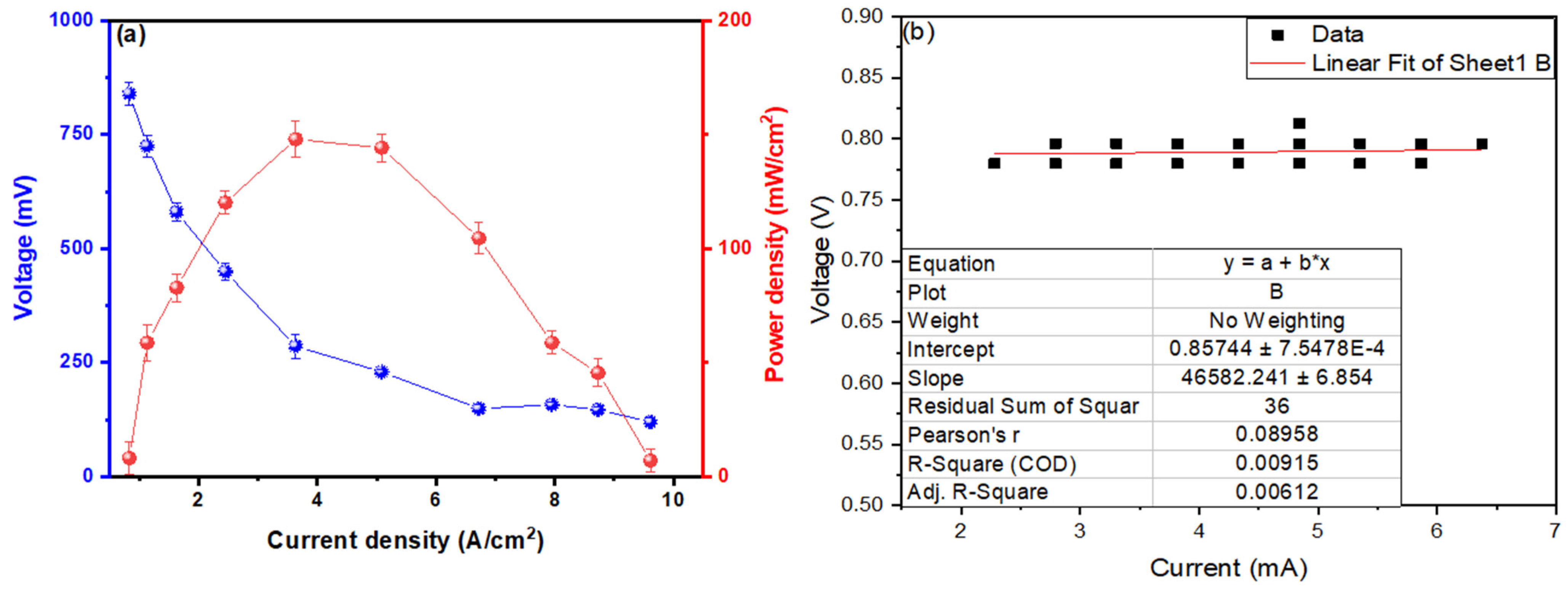

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Periyasamy, S.; Adego, A.A.; Kumar, P.S.; Desta, G.G.; Zelalem, T.; Karthik, V.; Isabel, J.B.; Jayakumar, M.; Sundramurthy, V.P.; Rangasamy, G. Influencing factors and environmental feasibility analysis of agricultural waste preprocessing routes towards biofuel production—A review. Biomass Bioenergy 2024, 180, 107001. [Google Scholar] [CrossRef]

- Ramalingam, G.; Priya, A.K.; Gnanasekaran, L.; Rajendran, S.; Hoang, T.K. Biomass and waste derived silica, activated carbon and ammonia-based materials for energy-related applications—A review. Fuel 2024, 355, 129490. [Google Scholar] [CrossRef]

- Shankar, A.; Saini, S.; Sharma, K.K. Fungal-integrated second-generation lignocellulosic biorefinery: Utilization of agricultural biomass for co-production of lignocellulolytic enzymes, mushroom, fungal polysaccharides, and bioethanol. Biomass Convers. Biorefinery 2024, 14, 1117–1131. [Google Scholar] [CrossRef]

- Wei, Z.; Cheng, Z.; Shen, Y. Recent development in production of pellet fuels from biomass and polyethylene (PE) wastes. Fuel 2024, 358, 130222. [Google Scholar] [CrossRef]

- Tleubergenova, A.; Han, B.C.; Meng, X.Z. Assessment of biomass-based green hydrogen production potential in Kazakhstan. Int. J. Hydrog. Energy 2024, 49, 349–355. [Google Scholar] [CrossRef]

- Sharmila, V.G.; Shanmugavel, S.P.; Banu, J.R. A review on emerging technologies and machine learning approaches for sustainable production of biofuel from biomass waste. Biomass Bioenergy 2024, 180, 106997. [Google Scholar] [CrossRef]

- Riseh, R.S.; Vazvani, M.G.; Hassanisaadi, M.; Thakur, V.K. Agricultural wastes: A practical and potential source for the isolation and preparation of cellulose and application in agriculture and different industries. Ind. Crop. Prod. 2024, 208, 117904. [Google Scholar] [CrossRef]

- Hosen, M.E.; Siddik, M.N.A.; Miah, M.F.; Kabiraj, S. Biomass energy for sustainable development: Evidence from Asian countries. Environ. Dev. Sustain. 2024, 26, 3617–3637. [Google Scholar] [CrossRef]

- Erdem, K.; Han, D.G.; Midilli, A. A parametric study on hydrogen production by fluidized bed co-gasification of biomass and waste plastics. Int. J. Hydrog. Energy 2024, 52, 1434–1444. [Google Scholar] [CrossRef]

- Ida, T.K.; Mandal, B. Microbial fuel cell design, application and performance: A review. Mater. Today Proc. 2023, 76, 88–94. [Google Scholar]

- Bazina, N.; Ahmed, T.G.; Almdaaf, M.; Jibia, S.; Sarker, M. Power generation from wastewater using microbial fuel cells: A review. J. Biotechnol. 2023, 374, 17–30. [Google Scholar] [CrossRef]

- Malik, S.; Kishore, S.; Dhasmana, A.; Kumari, P.; Mitra, T.; Chaudhary, V.; Kumari, R.; Bora, J.; Ranjan, A.; Minkina, T.; et al. A Perspective Review on Microbial Fuel Cells in Treatment and Product Recovery from Wastewater. Water 2023, 15, 316. [Google Scholar] [CrossRef]

- Esfandyari, M.; Jafari, D.; Azami, H. Microbial fuel cells for energy production in wastewater treatment plants-a review. Biofuels 2024, 15, 743–753. [Google Scholar] [CrossRef]

- Ahirwar, A.; Das, S.; Das, S.; Yang, Y.H.; Bhatia, S.K.; Vinayak, V.; Ghangrekar, M.M. Photosynthetic microbial fuel cell for bioenergy and valuable production: A review of circular bio-economy approach. Algal Res. 2023, 70, 102973. [Google Scholar] [CrossRef]

- Gupta, S.; Patro, A.; Mittal, Y.; Dwivedi, S.; Saket, P.; Panja, R.; Saeed, T.; Martínez, F.; Yadav, A.K. The race between classical microbial fuel cells, sediment-microbial fuel cells, plant-microbial fuel cells, and constructed wetlands-microbial fuel cells: Applications and technology readiness level. Sci. Total Environ. 2023, 879, 162757. [Google Scholar] [CrossRef]

- Garbini, G.L.; Barra Caracciolo, A.; Grenni, P. Electroactive Bacteria in Natural Ecosystems and Their Applications in Microbial Fuel Cells for Bioremediation: A Review. Microorganisms 2023, 11, 1255. [Google Scholar] [CrossRef] [PubMed]

- Segundo, R.F.; Benites, S.M.; De La Cruz-Noriega, M.; Vives-Garnique, J.; Otiniano, N.M.; Rojas-Villacorta, W.; Gallozzo-Cardenas, M.; Delfín-Narciso, D.; Díaz, F. Impact of Dragon Fruit Waste in Microbial Fuel Cells to Generate Friendly Electric Energy. Sustainability 2023, 15, 7316. [Google Scholar] [CrossRef]

- Ho, Q.N.; Mitsuoka, K.; Yoshida, N. Microbial fuel cell in long-term operation and providing electricity for intermittent aeration to remove contaminants from sewage. Environ. Res. 2024, 259, 119503. [Google Scholar] [CrossRef] [PubMed]

- Aleid, G.M.; Alshammari, A.S.; Alomari, A.D.; Sa’ad Abdullahi, S.; Mohammad, R.E.A.; Abdulrahman, R.M.I. Degradation of Metal Ions with Electricity Generation by Using Fruit Waste as an Organic Substrate in the Microbial Fuel Cell. Int. J. Chem. Eng. 2023, 2023, 1334279. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; Cabanillas-Chirinos, L.; Nazario-Naveda, R.; Gallozzo-Cardenas, M.; Diaz, F.; Delfin-Narciso, D.; Rojas-Villacorta, W. Use of Tangerine Waste as Fuel for the Generation of Electric Current. Sustainability 2023, 15, 3559. [Google Scholar] [CrossRef]

- Păucean, A.; Kádár, C.B.; Simon, E.; Vodnar, D.C.; Ranga, F.; Rusu, I.E.; Vișan, V.G.; Socaci, S.A.; Man, S.; Chiș, M.S.; et al. Freeze-Dried Powder of Fermented Chili Paste—New Approach to Cured Salami Production. Foods 2022, 11, 3716. [Google Scholar] [CrossRef] [PubMed]

- Ye, Z.; Shang, Z.; Zhang, S.; Li, M.; Zhang, X.; Ren, H.; Hu, X.; Yi, J. Dynamic analysis of flavor properties and microbial communities in Chinese pickled chili pepper (Capsicum frutescens L.): A typical industrial-scale natural fermentation process. Food Res. Int. 2022, 153, 110952. [Google Scholar] [CrossRef]

- Zhang, S.; Xiao, Y.; Jiang, Y.; Wang, T.; Cai, S.; Hu, X.; Yi, J. Effects of brines and containers on flavor production of Chinese pickled chili pepper (Capsicum frutescens L.) during natural fermentation. Foods 2022, 12, 101. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Bao, X.; Zhang, X.; Ren, H.; Cai, S.; Hu, X.; Yi, J. Exploring the phytochemicals and inhibitory effects against α-glucosidase and dipeptidyl peptidase-IV in Chinese pickled chili pepper: Insights into mechanisms by molecular docking analysis. LWT 2022, 162, 113467. [Google Scholar] [CrossRef]

- Galleani, C.; Valdelvira, R.; Diéguez, M.C.; Crespo, J.F.; Cabanillas, B. Anaphylaxis to pickled chili pepper (Capsicum frutescens): Role of pickling processing in the allergic reactivity. Ann. Allergy Asthma Immunol. 2023, 130, 369–370. [Google Scholar] [CrossRef]

- Ye, Z.; Shang, Z.; Li, M.; Qu, Y.; Long, H.; Yi, J. Evaluation of the physiochemical and aromatic qualities of pickled Chinese pepper (Paojiao) and their influence on consumer acceptability by using targeted and untargeted multivariate approaches. Food Res. Int. 2020, 137, 109535. [Google Scholar] [CrossRef]

- Devi, Y.P.; Bembem, K.; Bhupenchandra, I.; Devi, Y.J. Formulation and shelf life evaluation of king chilli pickle. Environ. Ecol. 2021, 39, 706–713. [Google Scholar]

- Simeon, M.I.; Asoiro, F.U.; Aliyu, M.; Raji, O.A.; Freitag, R. Polarization and power density trends of a soil-based microbial fuel cell treated with human urine. Int. J. Energy Res. 2020, 44, 5968–5976. [Google Scholar] [CrossRef]

- Dziegielowski, J.; Mascia, M.; Metcalfe, B.; Di Lorenzo, M. Voltage evolution and electrochemical behaviour of Soil microbial fuel cells operated in different quality soils. Sustain. Energy Technol. Assess. 2023, 56, 103071. [Google Scholar] [CrossRef]

- Abazarian, E.; Gheshlaghi, R.; Mahdavi, M.A. Interactions between sediment microbial fuel cells and voltage loss in series connection in open channels. Fuel 2023, 332, 126028. [Google Scholar] [CrossRef]

- Saran, C.; Purchase, D.; Saratale, G.D.; Saratale, R.G.; Ferreira, L.F.R.; Bilal, M.; Iqbal, H.M.; Hussain, C.M.; Mulla, S.I.; Bharagava, R.N. Microbial fuel cell: A green eco-friendly agent for tannery wastewater treatment and simultaneous bioelectricity/power generation. Chemosphere 2023, 312, 137072. [Google Scholar] [CrossRef]

- Hamdan, H.Z.; Salam, D.A. Sediment microbial fuel cells for bioremediation of pollutants and power generation: A review. Environ. Chem. Lett. 2023, 21, 2761–2787. [Google Scholar] [CrossRef]

- Verma, M.; Mishra, V. Bioelectricity generation by microbial degradation of banana peel waste biomass in a dual-chamber S. cerevisiae-based microbial fuel cell. Biomass Bioenergy 2023, 168, 106677. [Google Scholar] [CrossRef]

- Verma, M.; Mishra, V. Bioelectricity generation using sweet lemon peels as anolyte and cow urine as catholyte in a yeast-based microbial fuel cell. Waste Biomass Valorization 2023, 14, 2643–2657. [Google Scholar] [CrossRef]

- Yaakop, A.S.; Ahmad, A.; Hussain, F.; Oh, S.E.; Alshammari, M.B.; Chauhan, R. Domestic Organic Waste: A Potential Source to Produce the Energy via a Single-Chamber Microbial Fuel Cell. Int. J. Chem. Eng. 2023, 2023, 2425735. [Google Scholar] [CrossRef]

- Maddalwar, S.; Nayak, K.K.; Singh, L. Evaluation of power generation in plant microbial fuel cell using vegetable plants. Bioresour. Technol. Rep. 2023, 22, 101447. [Google Scholar] [CrossRef]

- Zafar, H.; Peleato, N.; Roberts, D. A comparison of reactor configuration using a fruit waste fed two-stage anaerobic up-flow leachate reactor microbial fuel cell and a single-stage microbial fuel cell. Bioresour. Technol. 2023, 374, 128778. [Google Scholar] [CrossRef]

- Latuihamallo, Y.; Mahulette, F.; Watuguly, T.W. Potential of vegetable waste as alternative production bioelectricity. BIOEDUPAT Pattimura J. Biol. Learn. 2023, 3, 90–94. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Nazario-Naveda, R.; Gallozzo-Cardenas, M.; Diaz, F.; Murga-Torres, E. Potential Use of Coriander Waste as Fuel for the Generation of Electric Power. Sustainability 2023, 15, 896. [Google Scholar] [CrossRef]

- Banerjee, A.; Calay, R.K.; Das, S. Effect of pH, COD, and HRT on the performance of microbial fuel cell using synthetic dairy wastewater. Water 2023, 15, 3472. [Google Scholar] [CrossRef]

- Gul, H.; Raza, W.; Lee, J.; Azam, M.; Ashraf, M.; Kim, K.H. Progress in microbial fuel cell technology for wastewater treatment and energy harvesting. Chemosphere 2021, 281, 130828. [Google Scholar] [CrossRef]

- Kebaili, H.; Kameche, M.; Innocent, C.; Ziane, F.Z.; Sabeur, S.A.; Sahraoui, T.; Ouis, M.; Zerrouki, A.; Charef, M.A. Treatment of fruit waste leachate using microbial fuel cell: Preservation of agricultural environment. Acta Ecol. Sin. 2021, 41, 97–105. [Google Scholar] [CrossRef]

- Flores, S.R.; Nazario-Naveda, R.; Delfín-Narciso, D.; Cardenas, M.G.; Diaz, N.D.; Ravelo, K.V. Generation of bioelectricity from organic fruit waste. Environ. Res. Eng. Manag. 2021, 77, 6–14. [Google Scholar] [CrossRef]

- Guo, F.; Luo, H.; Shi, Z.; Wu, Y.; Liu, H. Substrate salinity: A critical factor regulating the performance of microbial fuel cells, a review. Sci. Total Environ. 2021, 763, 143021. [Google Scholar] [CrossRef]

- Ullah, Z.; Zeshan, S. Effect of substrate type and concentration on the performance of a double chamber microbial fuel cell. Water Sci. Technol. 2020, 81, 1336–1344. [Google Scholar] [CrossRef] [PubMed]

- Obileke, K.; Onyeaka, H.; Meyer, E.L.; Nwokolo, N. Microbial fuel cells, a renewable energy technology for bio-electricity generation: A mini-review. Electrochem. Commun. 2021, 125, 107003. [Google Scholar] [CrossRef]

- Dwivedi, K.A.; Huang, S.J.; Wang, C.T.; Kumar, S. Fundamental understanding of microbial fuel cell technology: Recent development and challenges. Chemosphere 2022, 288, 132446. [Google Scholar] [CrossRef]

- Barakat, N.A.; Gamal, S.; Ghouri, Z.K.; Fadali, O.A.; Abdelraheem, O.H.; Hashem, M.; Moustafa, H.M. Graphitized mango seed as an effective 3D anode in batch and continuous mode microbial fuel cells for sustainable wastewater treatment and power generation. RSC Adv. 2024, 14, 3163–3177. [Google Scholar] [CrossRef]

- Zonfa, T.; Kamperidis, T.; Falzarano, M.; Lyberatos, G.; Polettini, A.; Pomi, R.; Rossi, A.; Tremouli, A. Two-Stage Process for Energy Valorization of Cheese Whey through Bio-Electrochemical Hydrogen Production Coupled with Microbial Fuel Cell. Fermentation 2023, 9, 306. [Google Scholar] [CrossRef]

- Adegunloye, D.V.; Olusegun-Awosika, D.B.; Odjegba, P.I. Production potential of cow dung for the generation of electric current using microbial fuel cell. World J. Adv. Res. Rev. 2023, 17, 533–548. [Google Scholar] [CrossRef]

- Lu, R.; Chen, Y.; Wu, J.; Chen, D.; Wu, Z.; Xiao, E. In situ COD monitoring with use of a hybrid of constructed wetland-microbial fuel cell. Water Res. 2022, 210, 117957. [Google Scholar] [CrossRef]

- Tan, S.M.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Thung, W.E.; Teoh, T.P. The reaction of wastewater treatment and power generation of single chamber microbial fuel cell against substrate concentration and anode distributions. J. Environ. Health Sci. Eng. 2020, 18, 793–807. [Google Scholar] [CrossRef]

- Agüero-Quiñones, R.; Ávila-Sánchez, Z.; Rojas-Flores, S.; Cabanillas-Chirinos, L.; De La Cruz-Noriega, M.; Nazario-Naveda, R.; Rojas-Villacorta, W. Activated Carbon Electrodes for Bioenergy Production in Microbial Fuel Cells Using Synthetic Wastewater as Substrate. Sustainability 2023, 15, 13767. [Google Scholar] [CrossRef]

- Sayed, E.T.; Rezk, H.; Abdelkareem, M.A.; Olabi, A.G. Artificial neural network based modelling and optimization of microalgae microbial fuel cell. Int. J. Hydrog. Energy 2024, 52, 1015–1025. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Al-Zaqri, N.; Yaakop, A.S.; Umar, K. Potato waste as an effective source of electron generation and bioremediation of pollutant through benthic microbial fuel cell. Sustain. Energy Technol. Assess. 2022, 53, 102560. [Google Scholar] [CrossRef]

- Kumar, K.; Harindran, S.V.; Gajalakshmi, S. Biosorptionally treated dye wastewater employed in “Olla-pot coupled microbial fuel cell” for tomato (Solanum lycopersicum L.) irrigation and bio-electricity production. Bioresour. Technol. Rep. 2021, 13, 100626. [Google Scholar]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Nazario-Naveda, R.; Benites, S.M.; Delfín-Narciso, D.; Rojas-Villacorta, W.; Romero, C.V. Bioelectricity through microbial fuel cells using avocado waste. Energy Rep. 2022, 8, 376–382. [Google Scholar] [CrossRef]

- Lawson, K.; Rossi, R.; Regan, J.M.; Logan, B.E. Impact of cathodic electron acceptor on microbial fuel cell internal resistance. Bioresour. Technol. 2020, 316, 123919. [Google Scholar] [CrossRef]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Benites, S.M.; Delfín-Narciso, D.; Luis, A.S.; Díaz, F.; Luis, C.C.; Moises, G.C. Electric Current Generation by Increasing Sucrose in Papaya Waste in Microbial Fuel Cells. Molecules 2022, 27, 5198. [Google Scholar] [CrossRef]

- Rincón-Catalán, N.I.; Cruz-Salomón, A.; Sebastian, P.J.; Pérez-Fabiel, S.; Hernández-Cruz, M.D.C.; Sánchez-Albores, R.M.; Hernández-Méndez, J.M.E.; Domínguez-Espinosa, M.E.; Esquinca-Avilés, H.A.; Ríos-Valdovinos, E.I.; et al. Banana Waste-to-Energy Valorization by Microbial Fuel Cell Coupled with Anaerobic Digestion. Processes 2022, 10, 1552. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Bakar, M.A.B.A.; Kim, H.C.; Ahmad, A.; Alshammari, M.B.; Yaakop, A.S. Oxidation of food waste as an organic substrate in a single chamber microbial fuel cell to remove the pollutant with energy generation. Sustain. Energy Technol. Assess. 2022, 52, 102282. [Google Scholar] [CrossRef]

- Santiago, B.; Rojas-Flores, S.; De La Cruz Noriega, M.; Cabanillas-Chirinos, L.; Otiniano, N.M.; Silva-Palacios, F.; Luis, A.S. Bioelectricity from Saccharomyces cerevisiae yeast through low-cost microbial fuel cells. In Proceedings of the 18th LACCEI International Multi-Conference for Engineering, Education, and Technology: Engineering, Integration, and Alliances for a Sustainable Development, Virtual, 27–31 July 2020; Volume 27. [Google Scholar]

- Rozene, J.; Morkvenaite-Vilkonciene, I.; Bruzaite, I.; Dzedzickis, A.; Ramanavicius, A. Yeast-based microbial biofuel cell mediated by 9,10-phenantrenequinone. Electrochim. Acta 2021, 373, 137918. [Google Scholar] [CrossRef]

- Rojas-Villacorta, W.; Rojas-Flores, S.; Benites, S.M.; Delfín-Narciso, D.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Rodríguez-Serin, H.; Rebaza-Araujo, S. Potential use of pepper waste and microalgae Spirulina sp. for bioelectricity generation. Energy Rep. 2023, 9, 253–261. [Google Scholar] [CrossRef]

- Angelaalincy, M.J.; Navanietha Krishnaraj, R.; Shakambari, G.; Ashokkumar, B.; Kathiresan, S.; Varalakshmi, P. Biofilm engineering approaches for improving the performance of microbial fuel cells and bioelectrochemical systems. Front. Energy Res. 2018, 6, 63. [Google Scholar] [CrossRef]

| Identified Species | pb | BLAST | |

|---|---|---|---|

| Identity (%) | Accession Number | ||

| Pseudomonas taiwanensis | 1443 | 100.00% | NR_116172.1 |

| Candida parapsilosis | 523 | 100.00% | NR_130673.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segundo, R.-F.; Magaly, D.L.C.-N.; Otiniano, N.M.; Soto-Deza, N.; Terrones-Rodriguez, N.; Mayra, D.L.C.-C.; Luis, C.-C.; Angelats-Silva, L.M. Sustainable Energy from Pickled Chili Waste in Microbial Fuel Cells. Processes 2024, 12, 2028. https://doi.org/10.3390/pr12092028

Segundo R-F, Magaly DLC-N, Otiniano NM, Soto-Deza N, Terrones-Rodriguez N, Mayra DLC-C, Luis C-C, Angelats-Silva LM. Sustainable Energy from Pickled Chili Waste in Microbial Fuel Cells. Processes. 2024; 12(9):2028. https://doi.org/10.3390/pr12092028

Chicago/Turabian StyleSegundo, Rojas-Flores, De La Cruz-Noriega Magaly, Nélida Milly Otiniano, Nancy Soto-Deza, Nicole Terrones-Rodriguez, De La Cruz-Cerquin Mayra, Cabanillas-Chirinos Luis, and Luis M. Angelats-Silva. 2024. "Sustainable Energy from Pickled Chili Waste in Microbial Fuel Cells" Processes 12, no. 9: 2028. https://doi.org/10.3390/pr12092028

APA StyleSegundo, R.-F., Magaly, D. L. C.-N., Otiniano, N. M., Soto-Deza, N., Terrones-Rodriguez, N., Mayra, D. L. C.-C., Luis, C.-C., & Angelats-Silva, L. M. (2024). Sustainable Energy from Pickled Chili Waste in Microbial Fuel Cells. Processes, 12(9), 2028. https://doi.org/10.3390/pr12092028