Solid-State Compounding for Recycling of Sawdust Waste into Green Packaging Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. PCL/SD Compounding and Sample Preparation

2.3. Sample Characterization

3. Results and Discussion

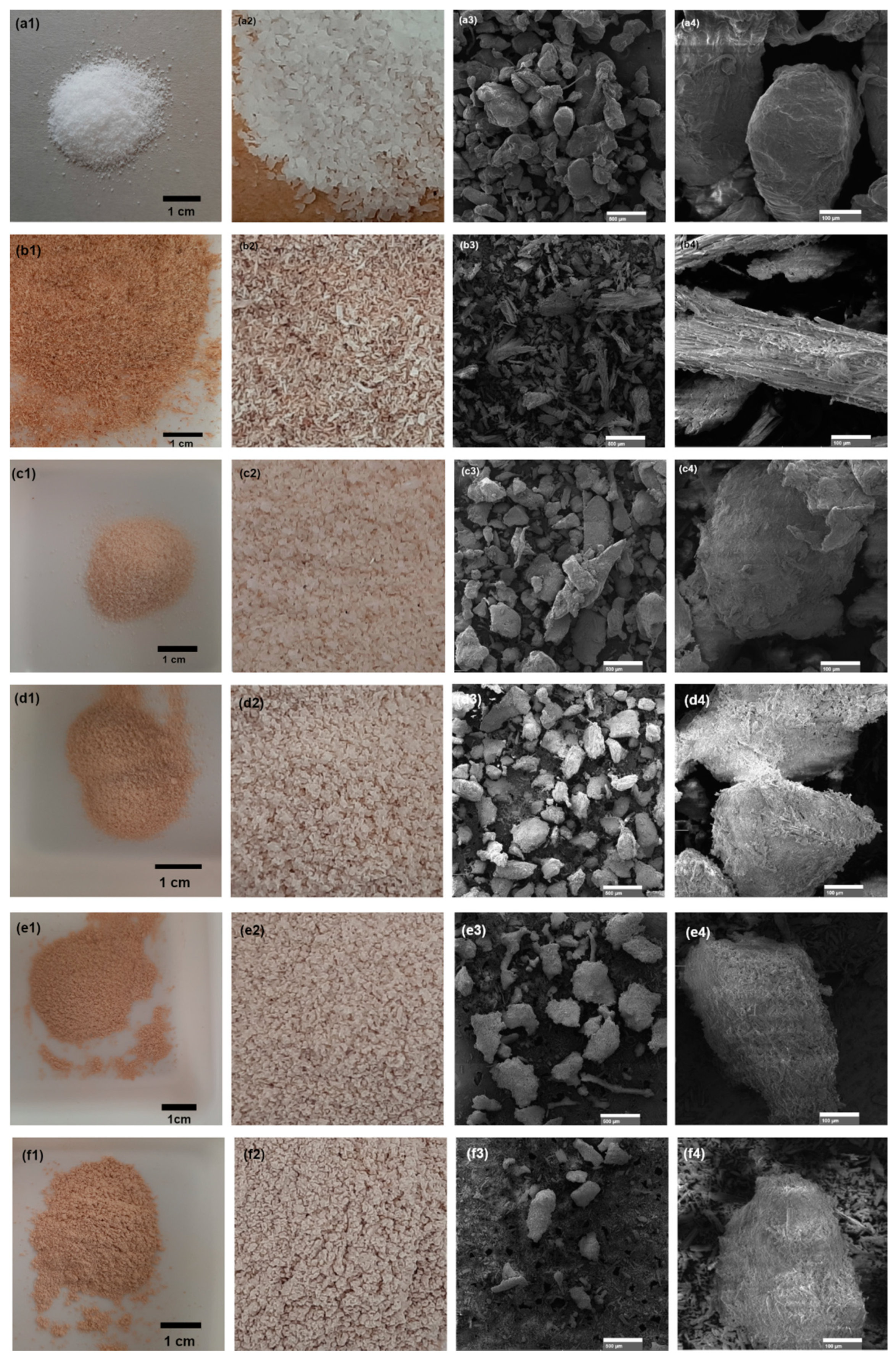

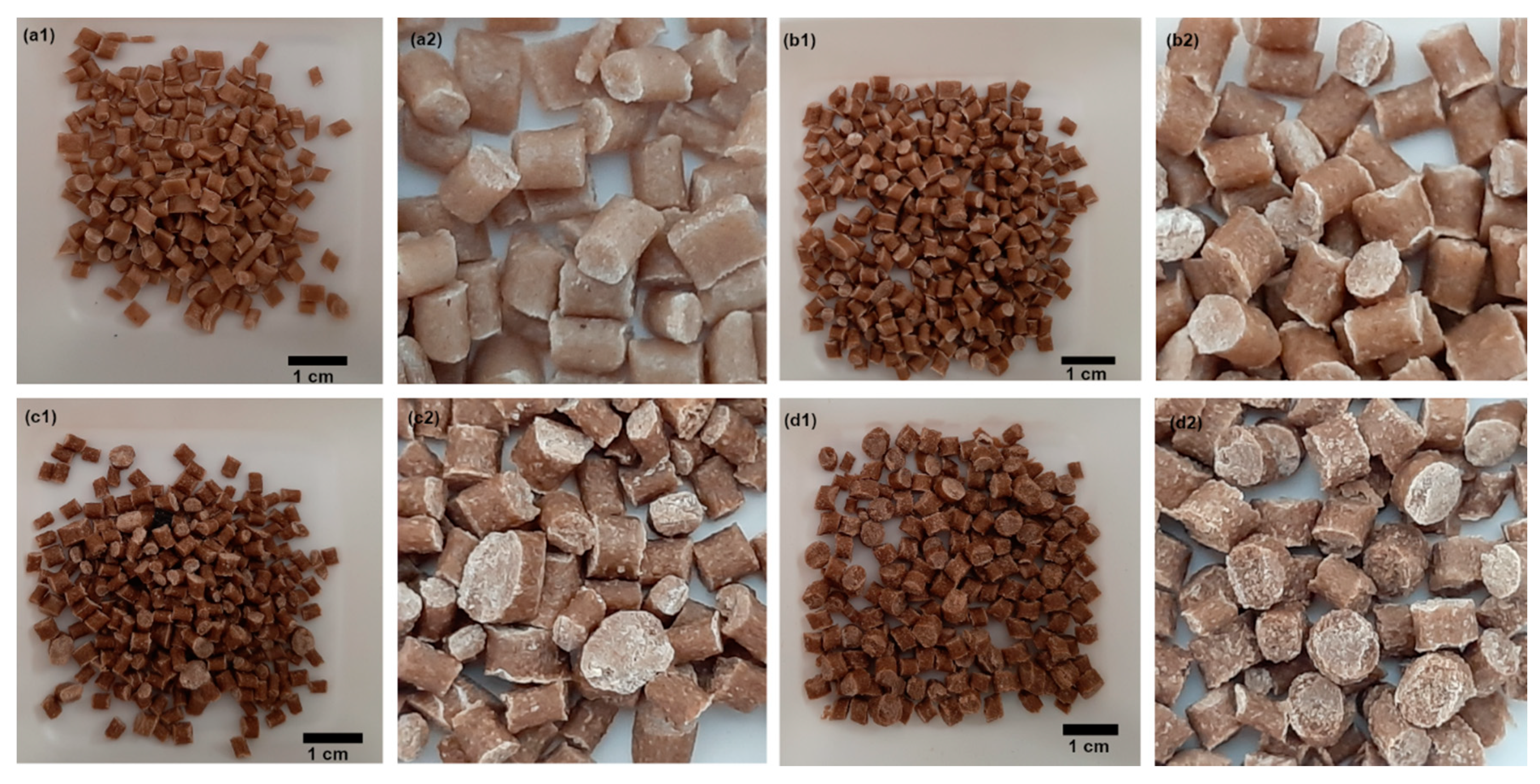

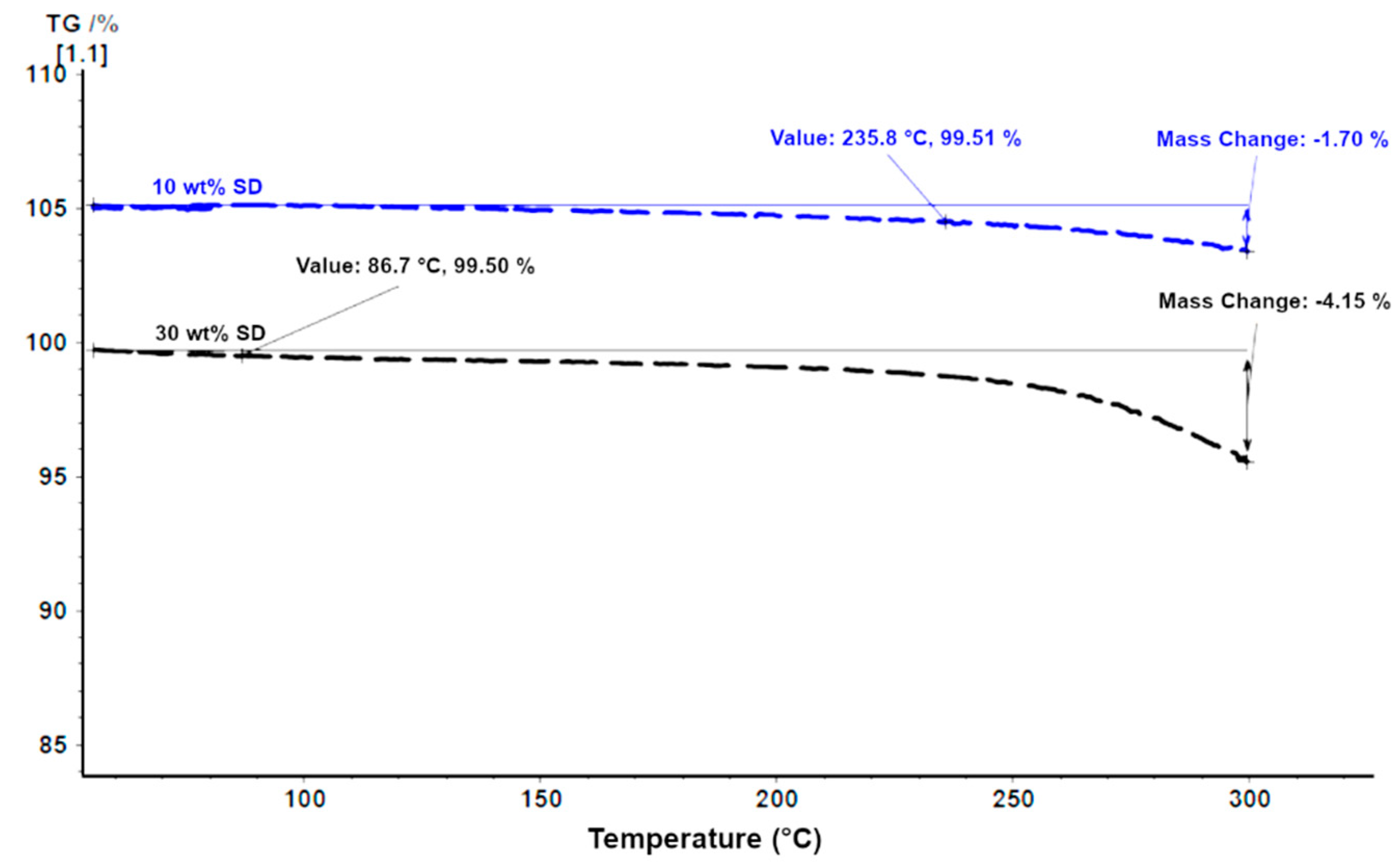

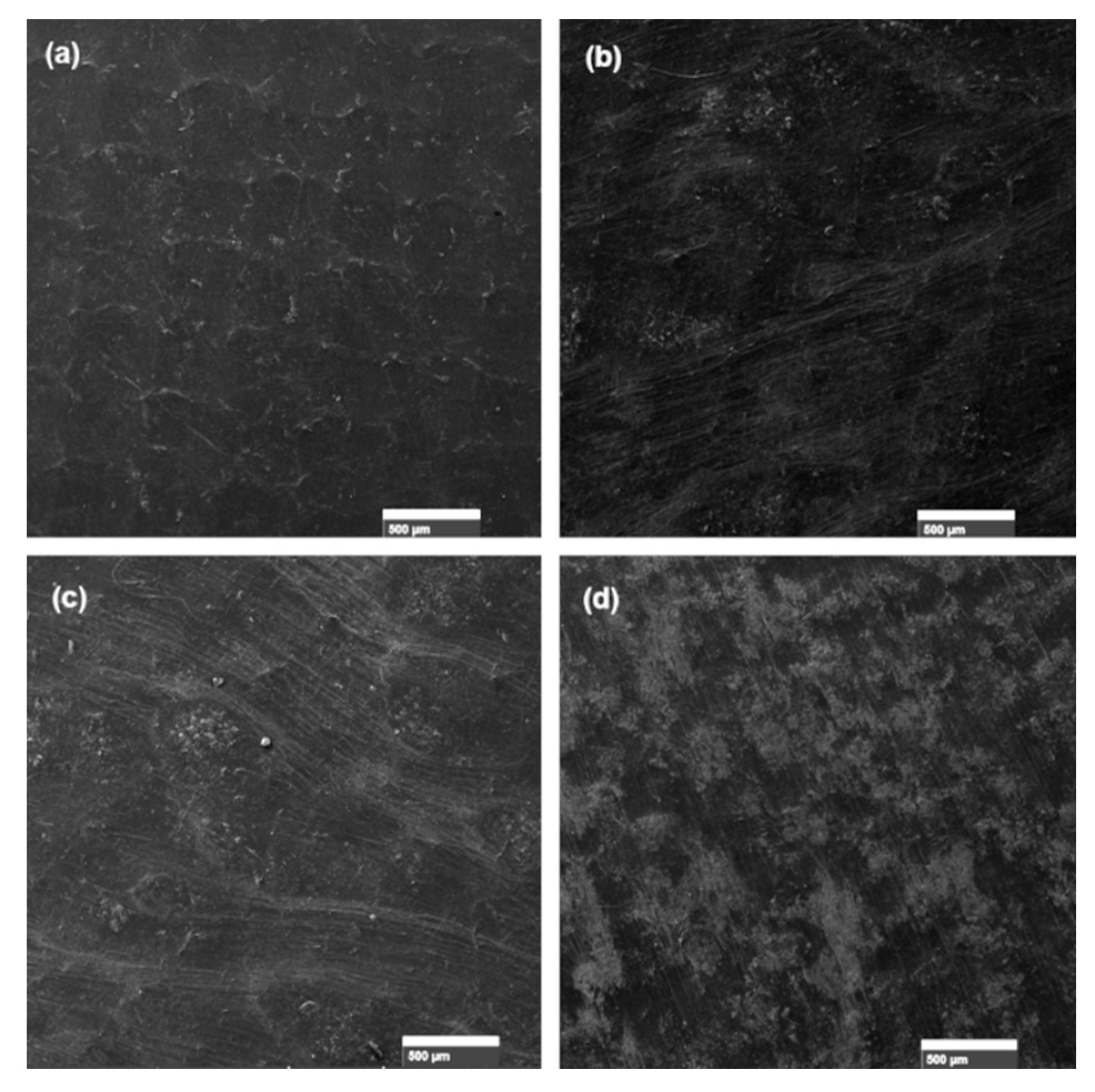

3.1. Properties of Compounded PCL/SD

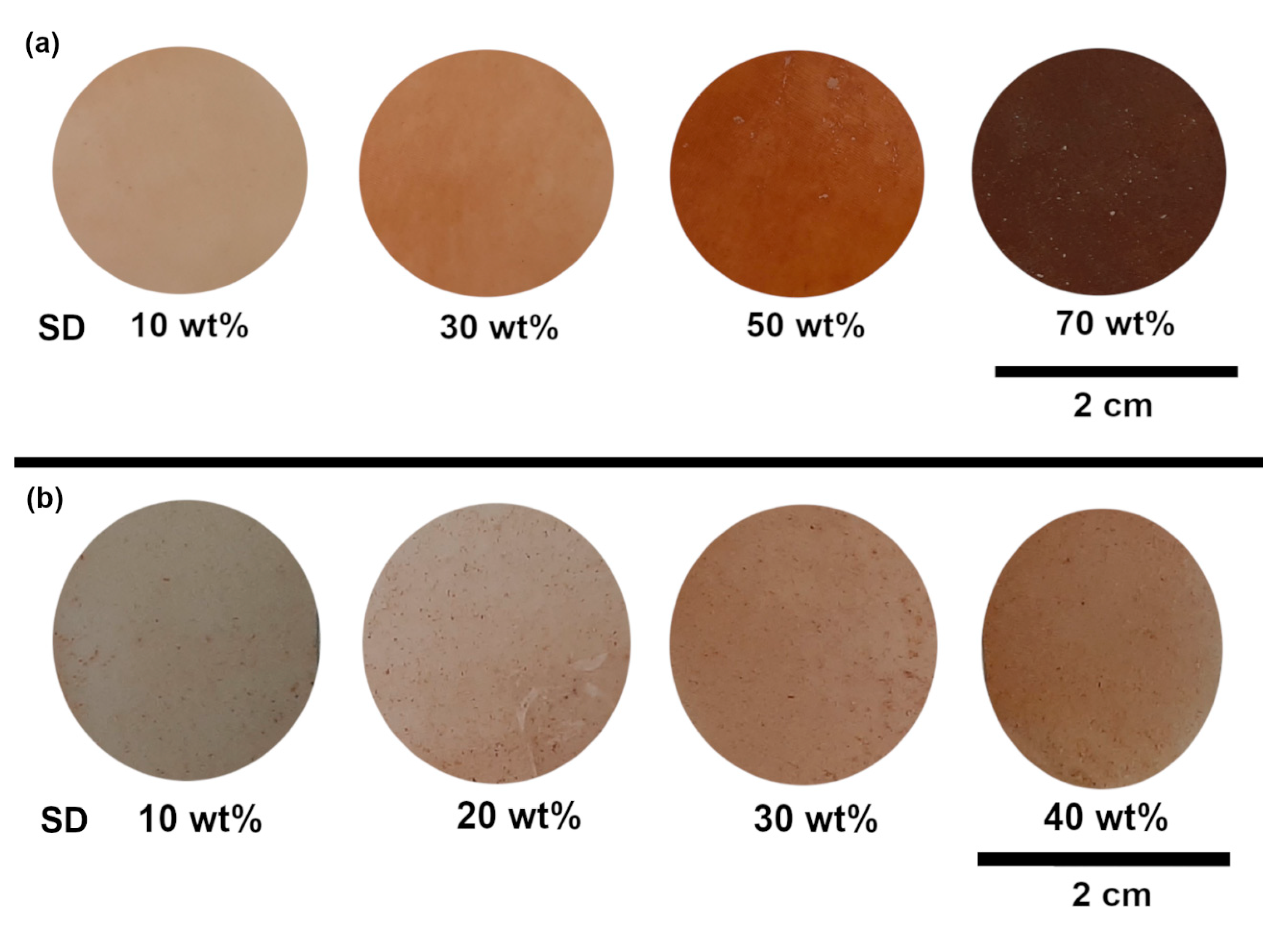

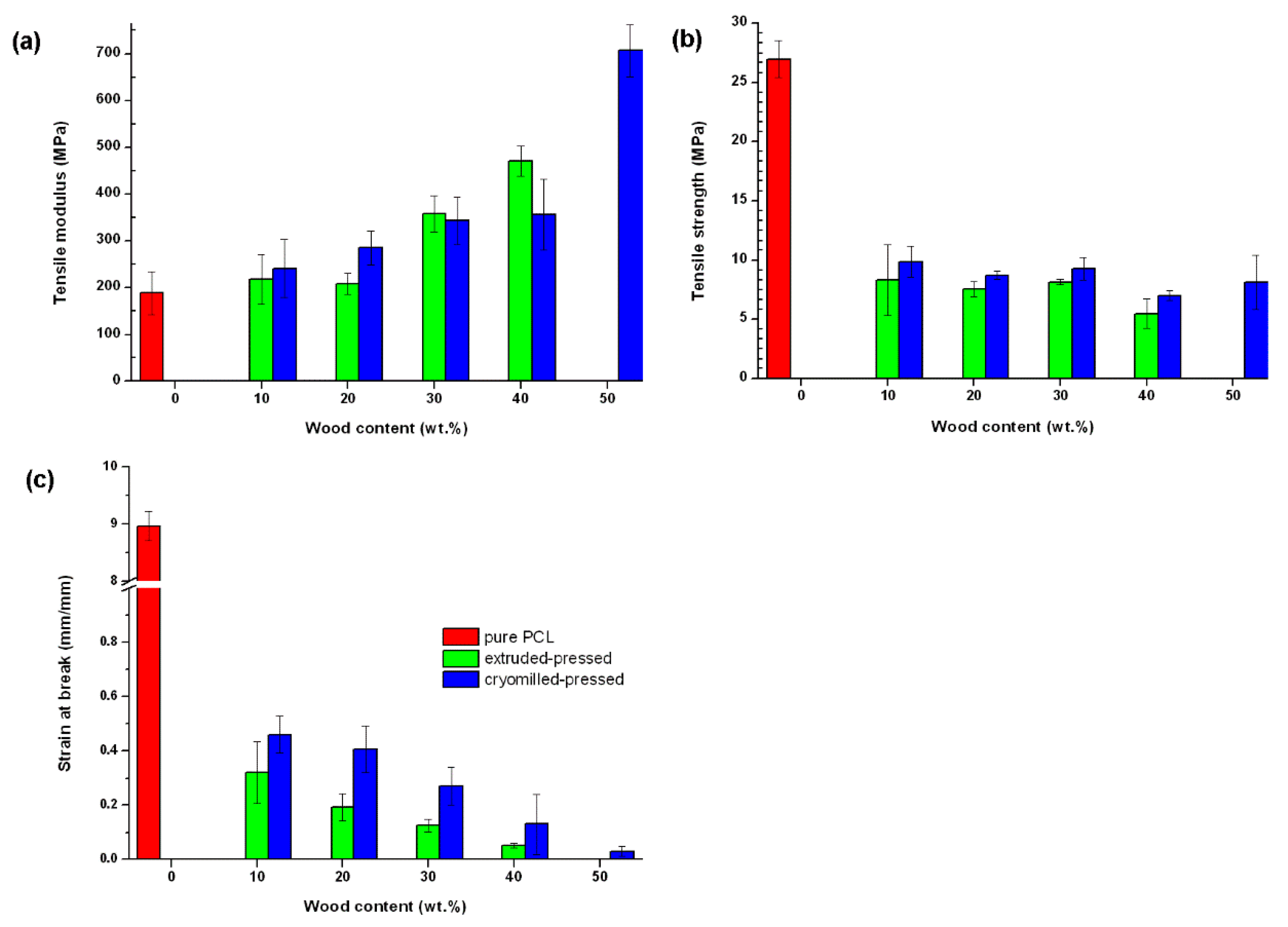

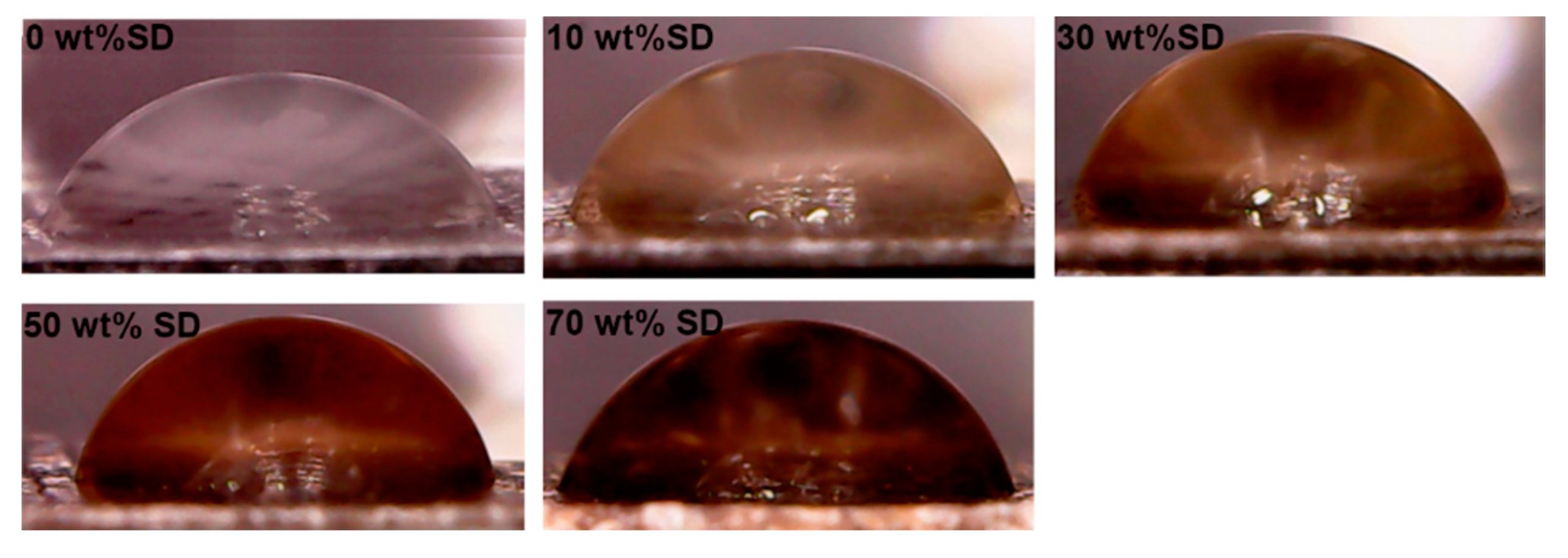

3.2. Properties of PCL/SD Composite Sheets

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morreale, M.; Liga, A.; Mistretta, M.C.; Ascione, L.; La Mantia, F.P. Mechanical; thermomechanical and reprocessing behavior of green composites from biodegradable polymer and wood flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef]

- Bravo, A.; Toubal, L.; Koffi, D.; Erchiqui, F. Development of novel green and biocomposite materials: Tensile and flexural properties and damage analysis using acoustic emission. Mater. Des. 2015, 66, 16–28. [Google Scholar] [CrossRef]

- Abdulkhani, A.; Hosseinzadeh, J.; Ashori, A.; Dadashi, S.; Takzare, Z. Preparation and characterization of modified cellulose nanofibers reinforced polylactic acid nanocomposite. Polym. Test. 2014, 35, 73–79. [Google Scholar] [CrossRef]

- Cavdar, A.D.; Mengeloglu, F.; Karakus, K. Effect of boric acid and borax on mechanical; fire and thermal properties of wood flour filled high density polyethylene composites. Meas. J. Int. Meas. Confed. 2015, 60, 6–12. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing; properties; and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Berthet, M.A.; Angellier-Coussy, H.; Chea, V.; Guillard, V.; Gastaldi, E.; Gontard, N. Sustainable food packaging: Valorising wheat straw fibres for tuning PHBV-based composites properties. Compos. Part A Appl. Sci. Manuf. 2015, 72, 139–147. [Google Scholar] [CrossRef]

- Fazita, M.R.N.; Jayaraman, K.; Bhattacharyya, D.; Hossain, M.S.; Haafiz, M.K.M.; Abdul Khalil, H.P.S. Disposal options of bamboo fabric-reinforced poly(lactic) acid composites for sustainable packaging: Biodegradability and recyclability. Polymers 2015, 7, 1476–1496. [Google Scholar] [CrossRef]

- Johansson, C.; Bras, J.; Mondragon, I.; Nechita, P.; Plackett, D.; Simon, P.; Svetec, D.G.; Virtanen, S.; Baschetti, M.G.; Breen, C.; et al. Renewable fibers and bio-based materials for packaging applications—A review of recent developments. BioResources 2012, 7, 2506–2552. [Google Scholar] [CrossRef]

- Van den Broek, L.A.M.; Knoop, R.J.I.; Kappen, F.H.J.; Boeriu, C.G. Chitosan films and blends for packaging material. Carbohydr. Polym. 2015, 116, 237–242. [Google Scholar] [CrossRef] [PubMed]

- Jamshidian, M.; Tehrany, E.A.; Imran, M.; Jacquot, M.; Desobry, S. Poly-lactic acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef]

- Armentano, I.; Bitinis, N.; Fortunati, E.; Mattioli, S.; Rescignano, N.; Verdejo, R.; Lopez-Manchado, M.A.; Kenny, J.M. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog. Polym. Sci. 2013, 38, 1720–1747. [Google Scholar] [CrossRef]

- Ahmed, J.; Varshney, S.K. Polylactides-chemistry, properties and green packaging technology: A review. Int. J. Food Prop. 2011, 14, 37–58. [Google Scholar] [CrossRef]

- Eng, C.C.; Ibrahim, N.A.; Zainuddin, N.; Ariffin, H.; Yunus, W.M.Z.W.; Then, Y.Y.; Teh, C.C. Enhancement of mechanical and thermal properties of polylactic acid/polycaprolactone blends by hydrophilic nanoclay. Indian J. Mater. Sci. 2013, 2013, 1–11. [Google Scholar] [CrossRef]

- Bhatia, A.; Gupta, R.K.; Bhattacharya, S.N.; Choi, H.J. Compatibility of biodegradable poly (lactic acid) (PLA) and poly (butylene succinate) (PBS) blends for packaging application. Korea Aust. Rheol. J. 2007, 19, 125–131. [Google Scholar]

- Khan, R.A.; Beck, S.; Dussault, D.; Salmieri, S.; Bouchard, J.; Lacroix, M. Mechanical and barrier properties of nanocrystalline cellulose reinforced poly(caprolactone) composites: Effect of gamma radiation. J. Appl. Polym. Sci. 2013, 129, 3038–3046. [Google Scholar] [CrossRef]

- Ludueña, L.; Vázquez, A.; Alvarez, V. Effect of lignocellulosic filler type and content on the behavior of polycaprolactone based eco-composites for packaging applications. Carbohydr. Polym. 2012, 87, 411–421. [Google Scholar] [CrossRef]

- García, A.V.; Santonja, M.R.; Sanahuja, A.B.; Selva, M.D.C.G. Characterization and degradation characteristics of poly(ε-caprolactone)-based composites reinforced with almond skin residues. Polym. Degrad. Stab. 2014, 108, 269–279. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kumar, S.; Pandey, R.; Mahajan, A.; Nandana, D.; Katti, D.S.; Mehrotra, D. Polycaprolactone as biomaterial for bone scaffolds: Review of literature. J. Oral Biol. Craniofacial Res. 2020, 10, 381–388. [Google Scholar] [CrossRef]

- Mohamed, R.M.; Yusoh, K. A review on the recent research of polycaprolactone (PCL). Adv. Mater. Res. 2015, 1134, 249–255. [Google Scholar] [CrossRef]

- Guarás, M.P.; Alvarez, V.A.; Ludueña, L.N. Processing and characterization of thermoplastic starch/polycaprolactone/compatibilizer ternary blends for packaging applications. J. Polym. Res. 2015, 22, 1–12. [Google Scholar] [CrossRef]

- Ahmed, J.; Mulla, M.; Jacob, H.; Luciano, G.; Bini, T.B.; Almusallam, A. Polylactide/poly(ε-caprolactone)/zinc oxide/clove essential oil composite antimicrobial films for scrambled egg packaging. Food Packag. Shelf Life 2019, 21, 1–9. [Google Scholar] [CrossRef]

- Joseph, C.S.; Prashanth, K.V.H.; Rastogi, N.K.; Indiramma, A.R.; Reddy, S.Y.; Raghavarao, K.S.M.S. Optimum blend of chitosan and poly-(ε-caprolactone) for fabrication of films for food packaging applications. Food Bioprocess Technol. 2011, 4, 1179–1185. [Google Scholar] [CrossRef]

- Wu, C.-S. Analysis of mechanical; thermal; and morphological behavior of polycaprolactone/wood flour blends. J. Appl. Polym. Sci. 2004, 94, 1000–1006. [Google Scholar] [CrossRef]

- Karakus, K.; Mengeloglu, F. Polycaprolactone (PCL) based polymer composites filled wheat straw flour. Kast. Univ. J. For. Fac. 2016, 16, 264–268. [Google Scholar] [CrossRef][Green Version]

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.-E.; Beaugrand, J. Development of sustainable biodegradable lignocellulosic hemp fiber/polycaprolactone biocomposites for light weight applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Follain, N.; Belbekhouche, S.; Bras, J.; Siqueira, G.; Chappey, C.; Marais, S.; Dufresne, A. Tunable gas barrier properties of filled-PCL film by forming percolating cellulose network. Colloids Surf. A Physicochem. Eng. Asp. 2018, 545, 26–30. [Google Scholar] [CrossRef]

- Martínez-Abad, A.; Sánchez, G.; Fuster, V.; Lagaron, J.M.; Ocio, M.J. Antibacterial performance of solvent cast polycaprolactone (PCL) films containing essential oils. Food Control 2013, 34, 214–220. [Google Scholar] [CrossRef]

- Dhakal, H.; Bourmaud, A.; Berzin, F.; Almansour, F.; Zhang, Z.; Shah, D.U.; Beaugrand, J. Mechanical properties of leaf sheath date palm fibre waste biomass reinforced polycaprolactone (PCL) biocomposites. Ind. Crop. Prod. 2018, 126, 394–402. [Google Scholar] [CrossRef]

- Najafi, S.K.; Hamidinia, E.; Tajvidi, M. Mechanical properties of composites from sawdust and recycled plastics. J. Appl. Polym. Sci. 2006, 100, 3641–3645. [Google Scholar] [CrossRef]

- Rahman, K.-S.; Islam, M.; Rahman, M.; Hannan, M.; Dungani, R.; Khalil, H. Flat-pressed wood plastic composites from sawdust and recycled polyethylene terephthalate (PET): Physical and mechanical properties. SpringerPlus 2013, 2, 629–636. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.P.; Spontak, R.J.; Ade, H.; Smith, S.D.; Koch, C.C. High-energy cryogenic blending and compatibilizing of immiscible polymers. Adv. Mater. 1999, 11, 1277–1281. [Google Scholar] [CrossRef]

- Smith, A.P.; Spontak, R.J.; Ade, H. On the similarity of macromolecular responses to high-energy processes: Mechanical milling vs. irradiation. Polym. Degrad. Stab. 2001, 72, 519–524. [Google Scholar] [CrossRef]

- Vertuccio, L.; Gorrasi, G.; Sorrentino, A.; Vittoria, V. Nano clay reinforced PCL/starch blends obtained by high energy ball milling. Carbohydr. Polym. 2009, 75, 172–179. [Google Scholar] [CrossRef]

- Jia, S.; Yu, D.; Zhu, Y.; Wang, Z.; Chen, L.; Fu, L. Morphology, crystallization and thermal behaviors of PLA-based composites: Wonderful effects of hybrid GO/PEG via dynamic impregnating. Polymers 2017, 9, 528. [Google Scholar] [CrossRef] [PubMed]

- Lebourg, M.; Serra, R.S.; Estellés, J.M.; Sánchez, F.H.; Ribelles, J.G.; Antón, J.S. Biodegradable polycaprolactone scaffold with controlled porosity obtained by modified particle-leaching technique. J. Mater. Sci. Mater. Med. 2008, 19, 2047–2053. [Google Scholar] [CrossRef] [PubMed]

- Panthapulakkal, S.; Sain, M. Preparation and characterization of cellulose nanofibril films from wood fibre and their thermoplastic polycarbonate composites. Int. J. Polym. Sci. 2012, 2012, 1–6. [Google Scholar] [CrossRef]

- Banat, R.; Fares, M.M. Thermo-gravimetric stability of high density polyethylene composite filled with olive shell flour. Am. J. Polym. Sci. 2015, 5, 65–74. [Google Scholar]

- Liminana, P.; Quiles-Carrillo, L.; Boronat, T.; Balart, R.; Montanes, N. The effect of varying almond shell flour (ASF) loading in composites with poly(butylene succinate (PBS) matrix compatibilized with maleinized linseed oil (MLO). Materials 2018, 11, 2179. [Google Scholar] [CrossRef]

- Khan, A.; Khan, R.A.; Salmieri, S.; Le Tien, C.; Riedl, B.; Bouchard, J.; Chauve, G.; Tan, V.; Kamal, M.R.; Lacroix, M. Mechanical and barrier properties of nanocrystalline cellulose reinforced chitosan based nanocomposite films. Carbohydr. Polym. 2012, 90, 1601–1608. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Valea, A.; Mondragon, I. Mechanical properties of short flax fibre bundle/poly(ε-caprolactone) composites: Influence of matrix modification and fibre content. Carbohydr. Polym. 2006, 64, 224–232. [Google Scholar] [CrossRef]

- Jiménez, A.; Ruseckaite, R.A. Binary mixtures based on polycaprolactone and cellulose derivatives: Thermal degradation and pyrolysis. J. Therm. Anal. Calorim. 2007, 88, 851–856. [Google Scholar] [CrossRef]

- Annandarajah, C.; Li, P.; Michel, M.; Chen, Y.; Jamshidi, R.; Kiziltas, A.; Hoch, R.; Grewell, D.; Montazami, R. Study of agave fiber-reinforced biocomposite films. Materials 2018, 12, 99. [Google Scholar] [CrossRef] [PubMed]

- Niaounakis, M. Polymers used in flexible packaging. In Recycling of Flexible Plastic Packaging, 1st ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2020; pp. 57–96. [Google Scholar]

- Majeed, K.; Jawaid, M.; Hassan, A.; Abu Bakar, A.; Abdul Khalil, H.P.S.; Salema, A.A.; Inuwa, I. Potential materials for food packaging from nanoclay/natural fibres filled hybrid composites. Mater. Des. 2013, 46, 391–410. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Banerjee, A.; Saurabh, C.K.; Tye, Y.Y.; Suriani, A.B.; Mohamed, A.; Karim, A.A.; Rizal, S.; Paridah, M.T. Biodegradable films for fruits and vegetables packaging application: Preparation and properties. Food Eng. Rev. 2018, 10, 139–153. [Google Scholar] [CrossRef]

| SD Content | Melt Peak Temperature, Tm (◦C) | Melt Enthalpy, ∆Hm (J/g) | Degree of Crystallinity, Xc (%) |

|---|---|---|---|

| 1st heating scan | |||

| 10 wt.% | 65.3 | 59.0 | 40 |

| 30 wt.% | 57.0 | 28.5 | 25 |

| 2nd heating scan | |||

| 10 wt.% | 56.5 | 31.3 | 25 |

| 30 wt.% | 56.5 | 25.6 | 26 |

| SD Content | 0.5% Weight Loss Temperature (T0.5%) (°C) | Mass Loss at 300 °C (%) |

|---|---|---|

| 10 wt.% | 236 | 1.7 |

| 30 wt.% | 87 | 4.2 |

| SD Content | Tensile Modulus (MPa) | Tensile Strength (MPa) | Strain at Break (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10 wt.% | 30 wt.% | 50 wt.% | 10 wt.% | 30 wt.% | 50 wt.% | 10 wt.% | 30 wt.% | 50 wt.% | ||

| Molding Temperature | 100 °C | 318 (80) | 493 (79) | 707 (55) | 14.6 (2.9) | 10.3 (1.5) | 8.1 (2.3) | 60.2 (48.3) | 6.4 (2.4) | 2.6 (1.8) |

| 150 °C | 269 (17) | 337 (168) | 707 (133) | 11.1 (1.3) | 8.2 (1.7) | 6.8 (0.5) | 22.7 (11.6) | 8.3 (4.1) | 1.5 (0.8) | |

| Ref | Fiber Type and Content | Matrix | Fabrication Method 1 | Modulus of Elasticity (MPa) | Tensile Strength (MPa) | Strain at Break (%) |

|---|---|---|---|---|---|---|

| [17] 3 | PCL (0.3–0.5 mm) 2 | Mixer-Press | 330 ± 12 | 19.0 ± 0.5 | 897 ± 48 | |

| [17] 3 | CO 6 (15 wt.%) | PCL | Mixer-Press | 488 ± 22 | 14.2 ± 0.3 | 188 ± 80 |

| [17] 3 | CE 6 (15 wt.%) | PCL | Mixer-Press | 497 ± 40 | 19.4 ± 0.9 | 410 ± 65 |

| [17] 3 | HCE 6 (15 wt.%) | PCL | Mixer-Press | 407 ± 23 | 12.1 ± 0.7 | 385 ± 72 |

| [18] 3 | PCL (210 µm) 2 | Mixer-Press | 335 ± 8 | 68 ± 7 | ||

| [18] 3 | AS 6 (10 wt.%) | PCL | Mixer-Press | 392 ± 8 | 38 ± 1 | |

| [18] 3 | AS (30 wt.%) | PCL | Mixer-Press | 280 ± 4 | 18 ± 1 | |

| [39] | PBS 6 | Extrusion-Injection | 417 ± 21 | 31.5 ± 0.9 | 215.6 ± 16.5 | |

| [39] | ASF 6 (30 wt.%) 4 | PBS | Extrusion-Injection | 790 ± 56 | 14.8 ± 0.5 | 6.3 ± 0.9 |

| [39] | ASF (10 wt.%) + MLO 6 (1.5 wt.%) | PBS | Extrusion-Injection | 561 ± 29 | 24.6 ± 0.2 | 17.0 ± 0.6 |

| [39] | ASF (30 wt.%) + MLO (4.5 wt.%) | PBS | Extrusion-Injection | 535 ± 51 | 13.8 ± 0.3 | 25.8 ± 1.0 |

| [39] | ASF (50 wt.%) + MLO (7.5 wt.%) | PBS | Extrusion-Injection | 364 ± 47 | 7.1 ± 0.2 | 16.4 ± 1.0 |

| [45] 3,4 | PP 6 | 1300 | 35 | |||

| [45] 3,4 | Ramie fiber (10 wt.%) + PP-g-MA (3 wt.%) | PP | 1400 | 42 | ||

| [45] 3,4 | Ramie fiber (30 wt.%) + PP-g-MA 6 (3 wt.%) | PP | 2250 | 66 | ||

| [45] 3,4 | HDPE 6 | 475 | 17.5 | |||

| [45] 3,4 | Date palm trunk fiber (30 wt.%) + PP-g-MA (2 wt.%) | HDPE | 975 | 18 | ||

| [45] 3,4 | LDPE 6 | 130 | 7.6 | |||

| [45] 3,4 | Bleached date palm leafs (28 wt.%) | LDPE | 390 | 6.8 | ||

| [45] 3,4 | PP | 800 | 27.5 | |||

| [45] 3,4 | Bleached date palm leafs (28 wt.%) | PP | 675 | 17 | ||

| [45] 3,4 | PC 6 | 1100 | 67.5 | |||

| [45] 3,4 | Alkali treated pineapple leaf fiber (20 wt.%) | PC | 2000 | 71.0 | ||

| [2] | LLDPE | 2-Roll mill-Press | 1160(200) | 21.11(2.56) | - | |

| [2] | Birch fibers (30 wt.%) | LLDPE | 2-Roll mill-Press | 2460(230) | 33.04(1.85) | 5.90(0.92) |

| [2] | Birch fibers (30 wt.%) + MAPE 6 (3 wt.%) | LLDPE | 2-Roll mill-Press | 3300(200) | 40.09(1.59) | 4.35(0.53) |

| [2] | HDPE | 2-Roll mill-Press | 1270(70) | 22.00(0.86) | - | |

| [2] | Birch fibers (30 wt.%) | HDPE | 2-Roll mill-Press | 2940(130) | 34.04(1.13) | 3.50(0.39) |

| [2] | Birch fibers (30 wt.%) + MAPE (3 wt.%) | HDPE | 2-Roll mill-Press | 2890(60) | 36.88(1.10) | 4.60(0.10) |

| [2] | NHDPE 6 | 2-Roll mill-Press | 1170(170) | 21.39(0.34) | 7.80(0.51) | |

| [2] | Birch fibers (10 wt.%) | NHDPE | 2-Roll mill-Press | 1930(160) | 26.89(1.03) | 4.00(0.94) |

| [2] | Birch fibers (10 wt.%) + MAPE (3 wt.%) | NHDPE | 2-Roll mill-Press | 1990(180) | 27.21(0.55) | 3.19(0.31) |

| [2] | Birch fibers (30 wt.%) | NHDPE | 2-Roll mill-Press | 3040(290) | 33.47(3.13) | 2.18(0.35) |

| [2] | Birch fibers (30 wt.%) + MAPE (3 wt.%) | NHDPE | 2-Roll mill-Press | 3500(130) | 40.60(1.37) | 2.50(0.03) |

| [1] | BioFlex (0.5–0.7 mm) 2 | Extrusion-Press | 142 | 10.7 | 123 | |

| BioFlex 6 | Re-processed | 143 | 10.1 | 99 | ||

| [1] | Beech wood flour (15 wt.%) | BioFlex | Extrusion-Press | 313 | 9.2 | 12.9 |

| Beech wood flour (15 wt.%) | BioFlex | Re-processed | 300 | 8.9 | 11.5 | |

| [1] | Beech wood flour (30 wt.%) | BioFlex | Extrusion-Press | 539 | 11.2 | 6.6 |

| Beech wood flour (30 wt.%) | BioFlex | Re-processed | 477 | 10.8 | 7.3 | |

| [44] 4,5 | Nylon-MXD6 6 (15 µm) 2 | Biaxial stretch | 3800(385) | 220(22) | 75 | |

| [44] 4,5 | Nylon 6 (15 µm) 2 | Biaxial stretch | 1700(170) | 200(20) | 90 | |

| [44] 4,5 | PET 6 (15 µm) 2 | Biaxial stretch | 3400(350) | 160(16) | 140 | |

| [46] 3,4 | PVC 6 (12 µm) 2,5 | 120 ± 20 | 42 ± 7 | 35 ± 5 | ||

| [46] 3,4 | Montmorillonite | Cassava starch (71 µm) 2 | 1100 -1200 | 21–25 | 1082–2000 | |

| [46] 3,4 | Chitosan+ PLA 6 (67 µm) 2 | 17–11 | 30–25 | 165 ± 7 |

| Wood Content (wt.%) | 0 | 10 | 30 | 50 | 70 |

| Water Contact Angle (°) | 57 (1) | 78 (5) | 88 (11) | 81 (2) | 71 (7) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Allaf, R.M.; Futian, M. Solid-State Compounding for Recycling of Sawdust Waste into Green Packaging Composites. Processes 2020, 8, 1386. https://doi.org/10.3390/pr8111386

Allaf RM, Futian M. Solid-State Compounding for Recycling of Sawdust Waste into Green Packaging Composites. Processes. 2020; 8(11):1386. https://doi.org/10.3390/pr8111386

Chicago/Turabian StyleAllaf, Rula M., and Mohammad Futian. 2020. "Solid-State Compounding for Recycling of Sawdust Waste into Green Packaging Composites" Processes 8, no. 11: 1386. https://doi.org/10.3390/pr8111386

APA StyleAllaf, R. M., & Futian, M. (2020). Solid-State Compounding for Recycling of Sawdust Waste into Green Packaging Composites. Processes, 8(11), 1386. https://doi.org/10.3390/pr8111386