Numerical Analysis on Enhancing Spray Performance of SCR Mixer Device and Heat Transfer Performance Based on Field Synergy Principle

Abstract

1. Introduction

2. Methods and Model Validation

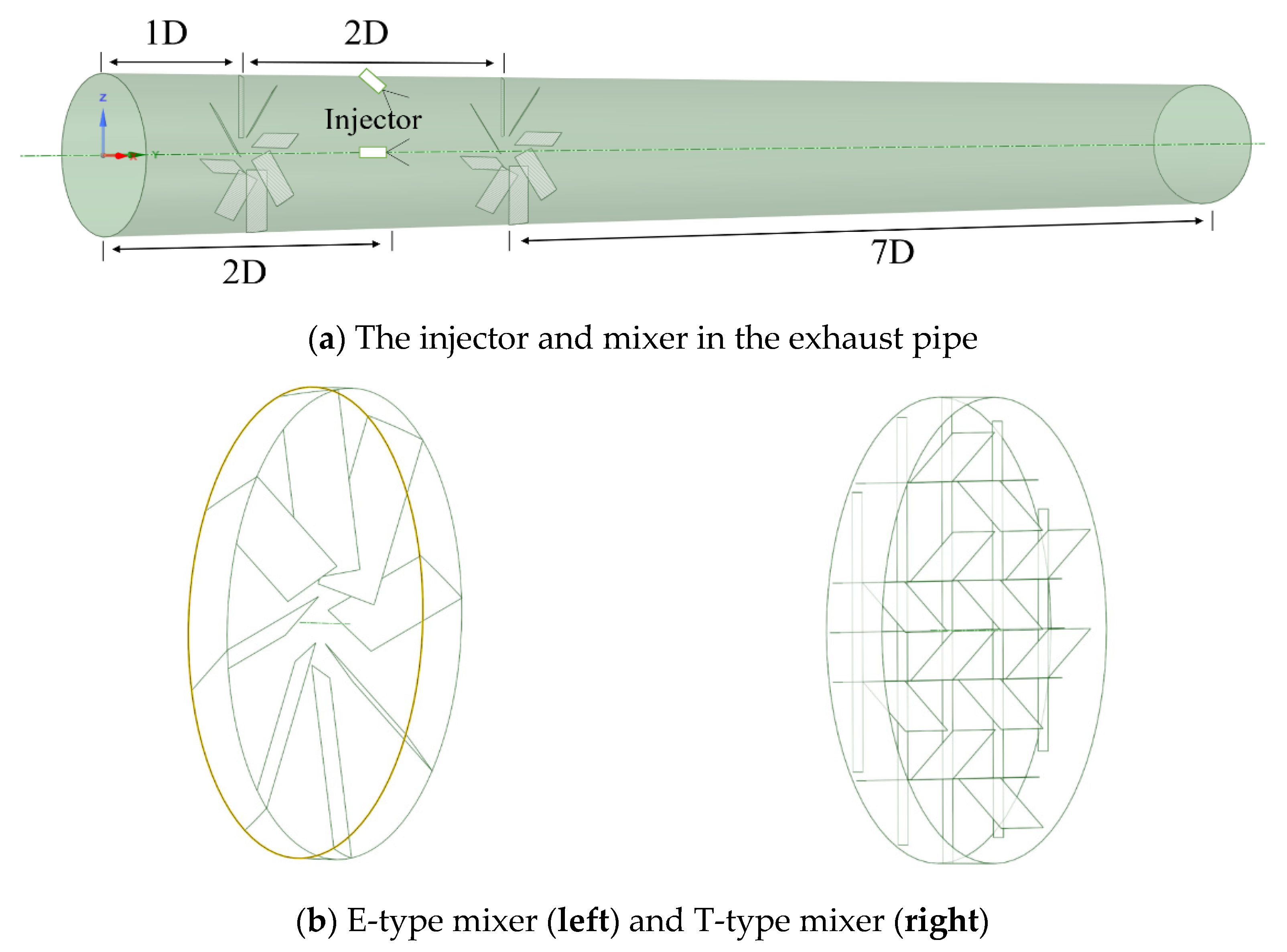

2.1. Physical Model

- The mixer’s influence on the flow field is constant, and the influence of UWS on the wall film formed on the mixer is ignored [24].

- The initial turbulence intensity of exhaust gas from the diesel engine is 5%, and the impact of chemical reactions on the flow state is ignored [25].

- The exhaust pipe is filled with hot exhaust gas and treats the thermal waste as an incompressible fluid.

2.2. Mathematical Models

- (1)

- Balance equation of the exhaust gas

- (2)

- Turbulence model of the exhaust gas

- (3)

- The spray model of UWS spray particles

- (4)

- Evaporation model of UWS spray particles

- (5)

- Field synergy model

- (6)

- Evaluation method of spray quality

- (7)

- Evaluation method eddy

2.3. Design of Simulation Cases

2.4. Gird Independence

2.5. Model Verification

3. Results and Discussion

3.1. The Flow Characteristics for Static Mixer

3.2. Urea Conversion

3.3. NH3 Distribution Uniformity

3.4. Field Synergy Analysis

4. Conclusions

- (1)

- From the flow field, the flow characteristics of mixers in different arrangement methods were evaluated. The mixer increases the vortex or turbulence strength of the entire flow field, while also increasing the inlet pressure. The average inlet pressure of the single mixer is 16.5 Pa, and in the dual-mixer, the average inlet pressure increases by 8.7 Pa.

- (2)

- In terms of concentration field, urea conversion rate and NH3 distribution were evaluated. The result shows that the effect of mixer is significant, and the dual-mixer can improve urea conversion rate and NH3 uniformity index by 169.5% and 136.4%, respectively.

- (3)

- Based on the field synergy principle, the synergy degree between the temperature field and velocity field was evaluated. The result shows that when the stay time of the UWS in the exhaust pipe is consistent (the same number of mixers), higher field synergy is more conducive to the generation of NH3. In single mixer cases, Case A-T2 had a maximum field synergy of 3.86%t and the corresponding NH3 volume concentration of 1528 ppm.

Author Contributions

Funding

Conflicts of Interest

| Nomenclature | |

| The area of the surface () | |

| Droplet surface area () | |

| Spalding mass number | |

| Closing coefficient | |

| Specific Heat at Constant Pressure () | |

| The distance between the pre-mixer and the nozzle () | |

| The distance between the common-mixer and the nozzle () | |

| Turbulent diffusivity () | |

| Spray droplet diameter () | |

| Vector volume force () | |

| Heat flow vector () | |

| Turbulent kinetic energy () | |

| Characteristic length () | |

| Droplet mass () | |

| Stress tensor () | |

| Normalized Q criterion number | |

| Radiant heat distribution function | |

| Hot exhaust gas temperature () | |

| Represents time () | |

| Internal energy () | |

| x directional velocity vector | |

| y directional velocity vector | |

| Velocity vector () | |

| Characteristic velocity () | |

| Turbulent viscosity () | |

| z directional velocity vector | |

| Three-dimensional direction x | |

| Vapor mass fraction in the bulk gas | |

| Vapor mass fraction at the surface | |

| Three-dimensional direction y | |

| Three-dimensional direction z | |

| The temperature gradient () | |

| Greek Letters | |

| Uniformity index | |

| Turbulent dissipation number | |

| Dynamic viscosity () | |

| Field variable a | |

| The average value of the field variable over the surface | |

| Heat transfer coefficient () | |

| Fluid density () | |

| Density of bulk gas () | |

| Fluid surface tension coefficient | |

| Dimensionless Numbers | |

| Synergy degree | |

| Nusselt number | |

| Prandtl number | |

| Reynolds number | |

| Schmidt number | |

| Sherwood number corrected | |

| Sherwood number | |

| Abbreviations | |

| CFD | Computational fluid dynamics |

| FSP | Field synergy principle |

| NOx | Nitrogen oxides |

| OED | Orthogonal experimental design |

| PM | Particulate matter |

| RNG | Renormalization-group |

| SCR | Selective catalytic reduction |

| UWS | Urea–water solution |

References

- Jiaqiang, E.; Zuo, W.; Gao, J.; Peng, Q.; Zhang, Z.; Hieu, P.M. Effect analysis on pressure drop of the continuous regeneration-diesel particulate filter based on NO2 assisted regeneration. Appl. Therm. Eng. 2016, 100, 356–366. [Google Scholar]

- Jiaqiang, E.; Liu, G.; Zhang, Z.; Han, D.; Chen, J.; Wei, K.; Gong, J.; Yin, Z. Effect analysis on cold starting performance enhancement of a diesel engine fueled with biodiesel fuel based on an improved thermodynamic model. Appl. Energy 2019, 243, 321–335. [Google Scholar]

- Cai, T.; Zhao, D.; Li, X.; Shi, B.; Li, J. Mitigating NO emissions from an ammonia-fueled micro-power system with a perforated plate implemented. J. Hazard. Mater. 2021, 401, 123848. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Wu, D.; Li, Y.; Meng, L. Effect of Acetone-n-Butanol-Ethanol (ABE) as an Oxygenate on Combustion, Performance, and Emission Characteristics of a Spark Ignition Engine. J. Chem. 2020, 2020, 1–11. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, J.; Tan, D.; Feng, Z.; Luo, J.; Tan, Y.; Huang, Y. The effects of Fe2O3 based DOC and SCR catalyst on the combustion and emission characteristics of a diesel engine fueled with biodiesel. Fuel 2021, 290, 120039. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Effects of fuel composition and wall thermal conductivity on thermal and NOx emission performances of an ammonia/hydrogen-oxygen micro-power system. Fuel Process. Technol. 2020, 209, 106527. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D.; Wang, B.; Li, J.; Guan, Y. NOx emission and thermal performances studies on premixed ammonia-oxygen combustion in a CO2-free micro-planar combustor. Fuel 2020, 280, 118554. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Zhang, Z.; Chen, J.; Pham, M.; Zhao, X.; Peng, Q.; Zhang, B.; Yin, Z. Performance and emission evaluation of a marine diesel engine fueled by water biodiesel-diesel emulsion blends with a fuel additive of a cerium oxide nanoparticle. Energy Convers. Manag. 2018, 169, 194–205. [Google Scholar]

- Zhang, Z.; Jiaqiang, E.; Deng, Y.; Pham, M.; Zuo, W.; Peng, Q.; Yin, Z. Effects of fatty acid methyl esters proportion on combustion and emission characteristics of a biodiesel fueled marine diesel engine. Energy Convers. Manag. 2018, 159, 244–253. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiaqiang, E.; Chen, J.; Zhao, X.; Zhang, B.; Deng, Y.; Peng, Q.; Yin, Z. Effects of boiling heat transfer on the performance enhancement of a medium speed diesel engine fueled with diesel and rapeseed methyl ester. Appl. Therm. Eng. 2020, 169, 114984. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Zhang, Z.; Tu, Z.; Zuo, W.; Hu, W.; Han, D.; Jin, Y. Effect analysis on flow and boiling heat transfer performance of cooling water-jacket of bearing in the gasoline engine turbocharger. Appl. Therm. Eng. 2018, 130, 754–766. [Google Scholar]

- Zhang, B.; Zuo, H.; Huang, Z.; Tan, J.; Zuo, Q. Endpoint forecast of different diesel-biodiesel soot filtration process in diesel particulate filters considering ash deposition. Fuel 2020, 272, 117678. [Google Scholar] [CrossRef]

- Han, D.; Jiaqiang, E.; Deng, Y.; Chen, J.; Leng, E.; Liao, G.; Zhao, X.; Feng, C.; Zhang, F. A review of studies using hydrocarbon adsorption material for reducing hydrocarbon emissions from cold start of gasoline engine. Renew. Sustain. Energy Rev. 2021, 135, 110079. [Google Scholar] [CrossRef]

- Cho, Y.S.; Lee, S.W.; Choi, W.C.; Yoon, Y.B. Urea-SCR system optimization with various combinations of mixer types and decomposition pipe lengths. Int. J. Automot. Technol. 2014, 15, 723–731. [Google Scholar] [CrossRef]

- Um, H.S.; Kim, D.; Kim, K.H. Numerical study on the design of urea decomposition chamber in LP SCR system. Int. J. Nav. Arch. Ocean Eng. 2019, 11, 307–313. [Google Scholar] [CrossRef]

- Chen, Q.; Meng, J.-A. Field synergy analysis and optimization of the convective mass transfer in photocatalytic oxidation reactors. Int. J. Heat Mass Transf. 2008, 51, 2863–2870. [Google Scholar] [CrossRef]

- Guo, J.; Huai, X. Numerical investigation of helically coiled tube from the viewpoint of field synergy principle. Appl. Therm. Eng. 2016, 98, 137–143. [Google Scholar] [CrossRef]

- Li, F.; Zhu, W.; He, H. Numerical optimization on microchannel flow and heat transfer performance based on field synergy principle. Int. J. Heat Mass Transf. 2019, 130, 375–385. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Zhao, X.; Xie, L.; Zhang, B.; Chen, J.; Zuo, Q.; Han, D.; Hu, W.; Zhang, Z. Performance enhancement of microwave assisted regeneration in a wall-flow diesel particulate filter based on field synergy theory. Energy 2019, 169, 719–729. [Google Scholar] [CrossRef]

- Van Gils, R.W.; Speetjens, M.F.M.; Zwart, H.J.; Nijmeijer, H. Output-based modal control of three-dimensional pool-boiling systems. Int. J. Therm. Sci. 2014, 82, 34–46. [Google Scholar] [CrossRef]

- Kang, M.G. Effects of the location of side inflow holes on pool boiling heat transfer in a vertical annulus. Int. J. Heat Mass Transf. 2008, 51, 1707–1712. [Google Scholar] [CrossRef]

- Das, S.; Saha, B.; Bhaumik, S. Experimental study of nucleate pool boiling heat transfer of water by surface functionalization with crystalline TiO2 nanostructure. Appl. Therm. Eng. 2017, 113, 1345–1357. [Google Scholar] [CrossRef]

- Marelli, S.; Marmorato, G.; Capobianco, M. Evaluation of heat transfer effects in small turbochargers by theoretical model and its experimental validation. Energy 2016, 112, 264–272. [Google Scholar] [CrossRef]

- Mohammadi, A.; Hashemi, H.; Jazayeri, A.; Ahmadi, M. Two Phase Flow Simulation for Film Boiling Heat Transfer Calculation in Water-jacket of Diesel Engine. In Proceedings of the Seventh International Conference on Internal Combustion Engines, Tehran, Iran, 24–29 July 2011; pp. 1721–1729. [Google Scholar]

- Kang, M.G. Effects of pool subcooling on boiling heat transfer in a vertical annulus with closed bottom. Int. J. Heat Mass Transf. 2005, 48, 255–263. [Google Scholar] [CrossRef]

- Payri, F.; Olmeda, P.; Arnau, F.J.; Dombrovsky, A.; Smith, L. External heat losses in small turbochargers: Model and experiments. Energy 2014, 71, 534–546. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiaqiang, E.; Chen, J.; Zhu, H.; Zhao, X.; Han, D.; Zuo, W.; Peng, Q.; Gong, J.; Yin, Z. Effects of low-level water addition on spray, combustion and emission characteristics of a medium speed diesel engine fueled with biodiesel fuel. Fuel 2019, 239, 245–262. [Google Scholar] [CrossRef]

- Ong, H.C.; Masjuki, H.; Mahlia, T.; Silitonga, A.; Chong, W.; Leong, K. Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energy Convers. Manag. 2014, 81, 30–40. [Google Scholar] [CrossRef]

- Tan, D.; Chen, Z.; Li, J.; Luo, J.; Yang, D.; Cui, S.; Zhang, Z. Effects of Swirl and Boiling Heat Transfer on the Performance Enhancement and Emission Reduction for a Medium Diesel Engine Fueled with Biodiesel. Processes 2021, 9, 568. [Google Scholar] [CrossRef]

- Zuo, Q.; Xie, Y.; Jiaqiang, E.; Zhu, X.; Zhang, B.; Tang, Y.; Zhu, G.; Wang, Z.; Zhang, J. Effect of different exhaust parameters on NO conversion efficiency enhancement of a dual-carrier catalytic converter in the gasoline engine. Energy 2020, 191, 116521. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D. Combustion noise radiation during dynamic diesel engine operation including effects of various biofuel blends: A review. Renew. Sustain. Energy Rev. 2016, 54, 1099–1113. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M.; Turkcan, A.; Sayin, C. Performance and combustion characteristics of a DI diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009, 88, 629–636. [Google Scholar] [CrossRef]

- Catania, A.E.; Finesso, R.; Spessa, E. Predictive zero-dimensional combustion model for DI diesel engine feed-forward control. Energy Convers. Manag. 2011, 52, 3159–3175. [Google Scholar] [CrossRef]

- Yang, Y.; Dec, J.E.; Dronniou, N.; Sjöberg, M. Tailoring HCCI heat-release rates with partial fuel stratification: Comparison of two-stage and single-stage-ignition fuels. Proc. Combust. Inst. 2011, 33, 3047–3055. [Google Scholar] [CrossRef]

- Watson, N.; Janota, M.S. Turbocharging the Internal Combustion Engine; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 1982. [Google Scholar]

- Baldi, F.; Theotokatos, G.; Andersson, K. Development of a combined mean value–zero dimensional model and application for a large marine four-stroke Diesel engine simulation. Appl. Energy 2015, 154, 402–415. [Google Scholar] [CrossRef]

- Yu, W.; Zhang, Z.; Liu, B. Effect Analysis on the Performance Enhancement and Emission Reduction of Diesel Engine Fueled with Biodiesel Fuel Based on an Improved Model. Int. J. Aerosp. Eng. 2020, 2020, 1–14. [Google Scholar] [CrossRef]

- Heywood, J.N. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Yu, W.; Zhang, Z.; Liu, B. Investigation on the Performance Enhancement and Emission Reduction of a Biodiesel Fueled Diesel Engine Based on an Improved Entire Diesel Engine Simulation Model. Processes 2021, 9, 104. [Google Scholar] [CrossRef]

- Zhang, B.; Jiaqiang, E.; Gong, J.; Yuan, W.; Zuo, W.; Li, Y.; Fu, J. Multidisciplinary design optimization of the diesel particulate filter in the composite regeneration process. Appl. Energy 2016, 181, 14–28. [Google Scholar] [CrossRef]

- Feng, C.; Jiaqiang, E.; Han, W.; Deng, Y.; Zhang, B.; Zhao, X.; Han, D. Key technology and application analysis of zeolite adsorption for energy storage and heat-mass transfer process: A review. Renew. Sustain. Energy Rev. 2021, 144, 110954. [Google Scholar] [CrossRef]

- Wang, S.; Fan, A. Combustion regimes of syngas flame in a micro flow reactor with controlled temperature profile: A numerical study. Combust. Flame. 2021, 230, 111457. [Google Scholar] [CrossRef]

- Zuo, H.; Tan, J.; Wei, K.; Huang, Z.; Zhong, D.; Xie, F. Effects of different poses and wind speeds on wind-induced vibration characteristics of a dish solar concentrator system. Renew. Energy 2021, 168, 1308–1326. [Google Scholar] [CrossRef]

- Peng, Q.; Yang, W.; Jiaqiang, E.; Li, Z.; Xu, H.; Fu, G.; Li, S. Investigation on H2/air combustion with C3H8 addition in the combustor with part/full porous medium. Energy Convers. Manag. 2021, 228, 113652. [Google Scholar] [CrossRef]

- Peng, Q.; Yang, W.; Jiaqiang, E.; Li, S.; Li, Z.; Xu, H.; Fu, G. Effects of propane addition and burner scale on the combustion characteristics and working performance. Appl. Energy 2021, 285, 116484. [Google Scholar] [CrossRef]

- Wei, K.; Yang, Y.; Zuo, H.; Zhong, D. A review on ice detection technology and ice elimination technology for wind turbine. Wind Energy 2020, 23, 433–457. [Google Scholar] [CrossRef]

| Case | Injector Position | Mixer Number | Mixer Type |

|---|---|---|---|

| A0 | Pipe wall | 0 | - ; - |

| A-E1 | 1 | E ; - | |

| A-E2 | - ; E | ||

| A-T1 | T ; - | ||

| A-T2 | - ; T | ||

| A-E3 | 2 | E ; E | |

| A-T3 | T ; T | ||

| B0 | Pipe center | 0 | - ; - |

| B-E1 | 1 | E ; - | |

| B-E2 | - ; E | ||

| B-T1 | T ; - | ||

| B-T2 | - ; T | ||

| B-E3 | 2 | E ; E | |

| B-T3 | T ; T |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.; Lv, J.; Tan, D.; Ai, Z.; Feng, Z. Numerical Analysis on Enhancing Spray Performance of SCR Mixer Device and Heat Transfer Performance Based on Field Synergy Principle. Processes 2021, 9, 786. https://doi.org/10.3390/pr9050786

Ye J, Lv J, Tan D, Ai Z, Feng Z. Numerical Analysis on Enhancing Spray Performance of SCR Mixer Device and Heat Transfer Performance Based on Field Synergy Principle. Processes. 2021; 9(5):786. https://doi.org/10.3390/pr9050786

Chicago/Turabian StyleYe, Jiedong, Junshuai Lv, Dongli Tan, Zhiqiang Ai, and Zhiqiang Feng. 2021. "Numerical Analysis on Enhancing Spray Performance of SCR Mixer Device and Heat Transfer Performance Based on Field Synergy Principle" Processes 9, no. 5: 786. https://doi.org/10.3390/pr9050786

APA StyleYe, J., Lv, J., Tan, D., Ai, Z., & Feng, Z. (2021). Numerical Analysis on Enhancing Spray Performance of SCR Mixer Device and Heat Transfer Performance Based on Field Synergy Principle. Processes, 9(5), 786. https://doi.org/10.3390/pr9050786