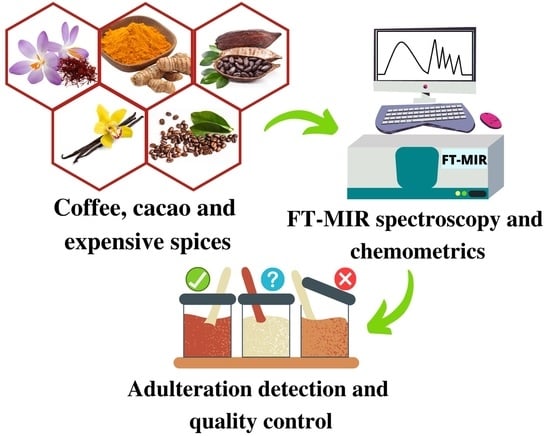

Uses of FT-MIR Spectroscopy and Multivariate Analysis in Quality Control of Coffee, Cocoa, and Commercially Important Spices

Abstract

:1. Introduction

- Evaluation of sensory and physical characteristics, i.e., solubility, density, presence or absence of external materials;

- Analysis of physicochemical parameters such as moisture content, ash, protein, and fat;

- Presence and concentration of bioactive compounds;

- Microbiological analysis and absence of natural contaminants such as mycotoxins and heavy metals;

2. Mid-Infrared (MIR) Spectroscopy

3. Multivariate Analysis

- -

- Normalization: Reduces spectral variation generated by sample manipulation. Multivariate analysis programs offer different normalization methods, with multiple scatter correction (MSC) and standard normal variable transformation (SNV) being the most used. MSC separates the light scattering signals from the chemical absorption signals of the sample, making the chemometric analysis insensitive to changes in the baseline spectrum. At the same time, SNV removes multiplicative scattering and particle size interferences. Both normalizations lead to similar results, so it is unnecessary to test both when optimizing a model [60,61];

- -

- Baseline correction: Removes baseline slopes from spectra commonly generated by IR beam scattering. Baseline correction attempts to correct spectra without distorting band intensities or introducing discontinuities [62];

- -

- Smoothing: Removes or reduces noise from MIR spectra using algorithms but also degrades the resolution of the spectrum by broadening its characteristics. The amount of noise in the spectrum is related to the number of scans performed, the higher the number, the lower the analytical signal’s noise. The most commonly used algorithm is the Savitzky–Golay algorithm, which aims to minimize the distortion of the spectrum; the degree of smoothing to be applied will depend on the bandwidth, care must be taken since a very high smoothing excessively broadens the bands generating a loss of resolution, so its use is not recommended in very sharp bands [53,60];

- -

- Derivative: It can be first or second order and is used to correct for changes in the baseline and reduce the effect of overlapping bands. Derived spectra present sharper features compared to the original spectra. The first and second-order derivatives eliminate any deviation in the baseline. However, the second-order derivative is also helpful in identifying band positions in complex regions [53,63].

3.1. Principal Component Analysis (PCA)

3.2. Partial Least Squares Regression (PLS)

4. FT-MIR Spectroscopy Applications in Coffee, Cocoa, and High-Priced Spices

4.1. Coffee

| Spectral Range (cm−1) | Sampling Technique | Algorithm | Purpose of the Analysis | Reference |

|---|---|---|---|---|

| Arabica coffee variety Kona typica | ||||

| 1900–800 | ZnSe ATR | PCR PLS | Detection and quantification of adulteration of coffee grown in Kona, Hawaii, with coffee from another region. | [90] |

| Brazilian coffee | ||||

| 3600–2820 1800–784 1900–800 | DRIFT | PCA PLS-DA | Discrimination of decaffeinated coffee and classification according to roasting degree. | [91] |

| KBr pellets | RBF (ANN) | Coffee classification by geographic and genotypic origin. | [102] | |

| Green Arabica coffee | ||||

| 4000–700 | ZnSe ATR DRIFT | PCA, LDA HCA | Discrimination of immature coffee (defective) and mature coffee (non-defective). | [92] |

| 4000–700 | KBr pellets ZnSe ATR, DRIFT | PCA HCA | Discrimination of defective and non-defective coffee using three different sampling techniques. | [93] |

| 3600–600 | DRIFT | PCA, LDA | Discrimination of defective and non-defective roasted coffee. | [94] |

| 1800–800 | KBr pellets | SVM | Geographical classification of different coffee genotypes. | [103] |

| 4000-600 2920–2850 1745 | ZnSe ATR | PCA | Discrimination of coffee beans according to their origin (Brazil, Colombia, Ethiopia, Kenya, and Yemen). | [106] |

| 3000–900 | ZnSe ATR | PLS | Prediction of quality scores given by cuppers for coffee beverage samples. | [108] |

| Roasted Arabica coffee | ||||

| 3200–700 | DRIFT | PCA LDA | Discrimination between roasted coffee, corn, coffee husk, coffee-corn, and coffee-husk blends. | [96] |

| 3200–700 | DRIFT | PCA LDA | Discrimination between roasted coffee, coffee husks, coffee grounds, corn, barley, and coffee-adulterant blends. | [97] |

| 3200–700 | DRIFT | PLS | Prediction of adulteration levels of roasted coffee with different adulterants (pure and blended). | [98] |

| 4000–700 | ZnSe ATR | PLS | Simultaneous quantification of four adulterants (coffee husk, coffee grounds, barley, and corn) in roasted coffee. | [99] |

| 4000–525 | Diamond ATR | PCA PLS | Detection and quantification of adulteration of roasted coffee with corn. | [101] |

| 3200–700 4000–600 | DRIFT ZnSe ATR | PLS-DA HM DF | Discrimination between roasted coffee and adulterated coffee using two sampling techniques and merging data. | [100] |

| ZnSe ATR | PCA PLS-DA | Classification of cup quality of coffee with different roasting degrees. | [95] | |

| 3500–2800 1800–800 | Diamond ATR | SIMCA PCR PLS1, PLS2 | Identification and quantification of adulterated coffee with coffee husks, corn, barley, soybeans, oats, and rice. | [109] |

| Arabica and Robusta coffee | ||||

| 4000–600 2000–1500 3000–2750 | ZnSe ATR | PLS | Quantification of Robusta coffee content in blends with Arabica coffee. | [104] |

| 1800–800 | ATR | PCA PLS-DA | Comparison of three spectroscopic techniques (1H-NMR, NIR, and MIR) for the discrimination of coffee by species and origin. | [105] |

| Commercial coffee capsules | ||||

| 3000–600 | ZnSe ATR | PCA PLS-DA | Discrimination of espresso coffee according to sensory characteristics. | [107] |

4.2. Cocoa

4.3. Saffron

| Spectral Range (cm−1) | Sampling Technique | Algorithm | Purpose of the Analysis | Reference |

|---|---|---|---|---|

| Ground saffron stigmas | ||||

| 1028 1175–1157 | KBr pellets | PCA MLR | Evaluation of the effects of storage conditions and spoilage detection. | [131] |

| 4000–400 | Diamond ATR | PCA | Discrimination between pure and adulterated samples (safflower, calendula, and turmeric). | [132] |

| 4000–600 2000–600 | DRIFT | PLS-DA PLS | Detection, identification, and quantification of adulteration with saffron stamens, calendula, safflower, turmeric, buddleja, and gardenia. | [133] |

| 1800–1400 1300–700 | KBr pellets | PCA PLS-DA | Classification of pure and adulterated samples with carminic acid. | [134] |

| 4000–400 | KBr pellets | PCA PLS-DA PLS | Classification by origin, detection, and quantification of adulteration with C. sativus style, calendula, safflower, and Rubia genus. | [135] |

| 4000–400 | Diamond ATR | EPO-PCA EPO-SVM | Classification by origin, detection, and quantification of adulteration with C. sativus style, calendula, safflower, and Rubia genus. | [136] |

| Ground stigmas and volatile extracts from Saffron | ||||

| 2000–700 | DRIFT ZnSe window | PCA DA | Classification by geographical origin (Greece, Iran, Italy, and Spain). | [130] |

| Ground stigmas and aqueous extracts from Saffron | ||||

| 4000–400 | Diamond ATR | SO-PLS-LDA SO-CovSel-LDA | Classification by geographical origin (four zones of Italy). | [137] |

4.4. Vanilla

4.5. Turmeric

4.6. Other Spices

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Clemenson, S. Herbs and Spices. In Swainson’s Handbook of Technical and Quality Management for the Food Manufacturing Sector; Woodhead Publishing: Sawston, UK, 2019; pp. 433–455. [Google Scholar] [CrossRef]

- Sormaz, Ü. Spices Used in Mevlevi Cuisine and Their Functional Features. Int. J. Gastron. Food Sci. 2020, 22, 100261. [Google Scholar] [CrossRef]

- U.S. Food & Drug Administration. Compliance Policy Guide (CPG) Sec 525.750. Available online: https://www.fda.gov/regulatory-information/search-fda-guidance-documents/cpg-sec-525750-spices-definitions (accessed on 30 October 2021).

- Darriet, A. Herbs, Spices, and Essential Oils. In Handbook of Food Products Manufacturing; Hui, Y.H., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 205–220. [Google Scholar] [CrossRef]

- Embuscado, M.E. Spices and Herbs: Natural Sources of Antioxidants–A Mini Review. J. Funct. Foods 2015, 18, 811–819. [Google Scholar] [CrossRef]

- Kunnumakkara, A.B.; Koca, C.; Dey, S.; Gehlot, P.; Yodkeeree, S.; Danda, D.; Sung, B.; Aggarwal, B.B. Traditional Uses of Spices: An Overview. In Molecular Targets and Therapeutic Uses of Spices; World Scientific: Singapore, 2009; pp. 1–24. [Google Scholar] [CrossRef]

- Jessica Elizabeth, D.L.T.; Gassara, F.; Kouassi, A.P.; Brar, S.K.; Belkacemi, K. Spice Use in Food: Properties and Benefits. Crit. Rev. Food Sci. Nutr. 2017, 57, 1078–1088. [Google Scholar] [CrossRef] [PubMed]

- El-Sayed, S.M.; Youssef, A.M. Potential Application of Herbs and Spices and Their Effects in Functional Dairy Products. Heliyon 2019, 5, e01989. [Google Scholar] [CrossRef] [Green Version]

- Martínez-Graciá, C.; González-Bermúdez, C.A.; Cabellero-Valcárcel, A.M.; Santaella-Pascual, M.; Frontela-Saseta, C. Use of Herbs and Spices for Food Preservation: Advantages and Limitations. Curr. Opin. Food Sci. 2015, 6, 38–43. [Google Scholar] [CrossRef]

- Nair, K.P.P. Ginger as a Spice and Flavorant. In The Agronomy and Economy of Turmeric and Ginger; Elsevier: Amsterdam, The Netherlands, 2013; pp. 497–510. [Google Scholar] [CrossRef]

- Sanlier, N.; Gencer, F. Role of Spices in the Treatment of Diabetes Mellitus: A Minireview. Trends Food Sci. Technol. 2020, 99, 441–449. [Google Scholar] [CrossRef]

- Sasikumar, B.; Swetha, V.P.; Parvathy, V.A.; Sheeja, T.E. Advances in Adulteration and Authenticity Testing of Herbs and Spices. In Advances in Food Authenticity Testing; Woodhead Publishing: Sawston, UK, 2016; pp. 585–624. [Google Scholar] [CrossRef]

- Singhal, R.S.; Kulkarni, P.R. Herbs and Spices. In Food Authenticity and Traceability; Woodhead Publishing: Sawston, UK, 2003; pp. 386–414. [Google Scholar] [CrossRef]

- Peter, K.V.; Babu, K.N. Introduction to Herbs and Spices: Medicinal Uses and Sustainable Production. In Handbook of Herbs and Spices; Woodhead Publishing: Sawston, UK, 2012; pp. 1–16. [Google Scholar] [CrossRef]

- Clemenson, S.; Muggeridge, M.; Clay, M. Quality Specifications for Herbs and Spices. In Handbook of Herbs and Spices; Woodhead Publishing: Sawston, UK, 2012; pp. 25–41. [Google Scholar] [CrossRef]

- Galvin-King, P.; Haughey, S.A.; Elliott, C.T. Herb and Spice Fraud; the Drivers, Challenges and Detection. Food Control 2018, 88, 85–97. [Google Scholar] [CrossRef] [Green Version]

- Reinholds, I.; Bartkevics, V.; Silvis, I.C.J.; van Ruth, S.M.; Esslinger, S. Analytical Techniques Combined with Chemometrics for Authentication and Determination of Contaminants in Condiments: A Review. J. Food Compos. Anal. 2015, 44, 56–72. [Google Scholar] [CrossRef]

- Institute for Global Food Security, Queen’s University Belfast; Galvin-King, P.; Haughey, S.A.; Elliott, C.T. Spices. In FoodIntegrity Handbook; Morin, J.-F., Lees, M., Eds.; Eurofins Analytics France: Nantes, France, 2018; pp. 167–186. [Google Scholar] [CrossRef]

- Lohumi, S.; Lee, S.; Lee, H.; Cho, B.-K. A Review of Vibrational Spectroscopic Techniques for the Detection of Food Authenticity and Adulteration. Trends Food Sci. Technol. 2015, 46, 85–98. [Google Scholar] [CrossRef]

- Modupalli, N.; Naik, M.; Sunil, C.K.; Natarajan, V. Emerging Non-Destructive Methods for Quality and Safety Monitoring of Spices. Trends Food Sci. Technol. 2021, 108, 133–147. [Google Scholar] [CrossRef]

- Zachariah, T.J.; Leela, N.K.; Shamina, A. Methods of Analysis of Herbs and Spices. In Handbook of Herbs and Spices; Woodhead Publishing: Sawston, UK, 2012; pp. 89–117. [Google Scholar] [CrossRef]

- Wadood, S.A.; Boli, G.; Xiaowen, Z.; Hussain, I.; Yimin, W. Recent Development in the Application of Analytical Techniques for the Traceability and Authenticity of Food of Plant Origin. Microchem. J. 2020, 152, 104295. [Google Scholar] [CrossRef]

- Ayvaz, H.; Plans, M.; Towers, B.N.; Auer, A.; Rodriguez-Saona, L.E. The Use of Infrared Spectrometers to Predict Quality Parameters of Cornmeal (Corn Grits) and Differentiate between Organic and Conventional Practices. J. Cereal Sci. 2015, 62, 22–30. [Google Scholar] [CrossRef]

- Shiroma, C.; Rodriguez-Saona, L. Application of NIR and MIR Spectroscopy in Quality Control of Potato Chips. J. Food Compos. Anal. 2009, 22, 596–605. [Google Scholar] [CrossRef]

- Lin, X.; Sun, D.-W. Recent Developments in Vibrational Spectroscopic Techniques for Tea Quality and Safety Analyses. Trends Food Sci. Technol. 2020, 104, 163–176. [Google Scholar] [CrossRef]

- Bureau, S. Contributions of Fourier-Transform Mid Infrared (FT-MIR) Spectroscopy to the Study of Fruit and Vegetables_ A Review. Postharvest Biol. Technol. 2019, 148, 1–14. [Google Scholar] [CrossRef]

- Karoui, R. Spectroscopic Technique: Mid-Infrared (MIR) and Fourier Transform Mid-Infrared (FT-MIR) Spectroscopies. In Modern Techniques for Food Authentication; Academic Press: Cambridge, MA, USA, 2018; pp. 23–50. [Google Scholar] [CrossRef]

- Rodriguez-Saona, L.E.; Giusti, M.M.; Shotts, M. Advances in Infrared Spectroscopy for Food Authenticity Testing. In Advances in Food Authenticity Testing; Woodhead Publishing: Sawston, UK, 2016; pp. 71–116. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Lin, T.; Ying, Y. Food and Agro-Product Quality Evaluation Based on Spectroscopy and Deep Learning: A Review. Trends Food Sci. Technol. 2021, 112, 431–441. [Google Scholar] [CrossRef]

- Galvin-King, P.; Haughey, S.A.; Elliott, C.T. Garlic Adulteration Detection Using NIR and FTIR Spectroscopy and Chemometrics. J. Food Compos. Anal. 2021, 96, 103757. [Google Scholar] [CrossRef]

- Giraudo, A.; Grassi, S.; Savorani, F.; Gavoci, G.; Casiraghi, E.; Geobaldo, F. Determination of the Geographical Origin of Green Coffee Beans Using NIR Spectroscopy and Multivariate Data Analysis. Food Control 2019, 99, 137–145. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Shao, Q.; Lu, Z.; Duan, C.; Yi, H.; Su, L. Rapid Determination of Crocins in Saffron by Near-Infrared Spectroscopy Combined with Chemometric Techniques. Spectrochim. Acta. A Mol. Biomol. Spectrosc. 2018, 190, 283–289. [Google Scholar] [CrossRef]

- Lohumi, S.; Lee, S.; Lee, W.-H.; Kim, M.S.; Mo, C.; Bae, H.; Cho, B.-K. Detection of Starch Adulteration in Onion Powder by FT-NIR and FT-IR Spectroscopy. J. Agric. Food Chem. 2014, 62, 9246–9251. [Google Scholar] [CrossRef]

- Moros, J.; Llorca, I.; Cervera, M.L.; Pastor, A.; Garrigues, S.; de la Guardia, M. Chemometric Determination of Arsenic and Lead in Untreated Powdered Red Paprika by Diffuse Reflectance Near-Infrared Spectroscopy. Anal. Chim. Acta 2008, 613, 196–206. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.M.; Cruz-Tirado, J.P.; Roque, J.V.; Teófilo, R.F.; Barbin, D.F. Portable Near-Infrared Spectroscopy for Rapid Authentication of Adulterated Paprika Powder. J. Food Compos. Anal. 2020, 87, 103403. [Google Scholar] [CrossRef]

- Shawky, E.; Abu El-Khair, R.M.; Selim, D.A. NIR Spectroscopy-Multivariate Analysis for Rapid Authentication, Detection and Quantification of Common Plant Adulterants in Saffron (Crocus sativus L.) Stigmas. LWT 2020, 122, 109032. [Google Scholar] [CrossRef]

- Teye, E.; Anyidoho, E.; Agbemafle, R.; Sam-Amoah, L.K.; Elliott, C. Cocoa Bean and Cocoa Bean Products Quality Evaluation by NIR Spectroscopy and Chemometrics: A Review. Infrared Phys. Technol. 2020, 104, 103127. [Google Scholar] [CrossRef]

- Thangavel, K.; Dhivya, K. Determination of Curcumin, Starch and Moisture Content in Turmeric by Fourier Transform near Infrared Spectroscopy (FT-NIR). Eng. Agric. Environ. Food 2019, 12, 264–269. [Google Scholar] [CrossRef]

- Huang, J.; Bekiaris, G.; Fitamo, T.; Scheutz, C.; Bruun, S. Prediction of Biochemical Methane Potential of Urban Organic Waste Using Fourier Transform Mid-Infrared Photoacoustic Spectroscopy and Multivariate Analysis. Sci. Total Environ. 2021, 790, 147959. [Google Scholar] [CrossRef]

- Rodriguez-Saona, L.E.; Allendorf, M.E. Use of FTIR for Rapid Authentication and Detection of Adulteration of Food. Annu. Rev. Food Sci. Technol. 2011, 2, 467–483. [Google Scholar] [CrossRef]

- Skoog, D.A. Fundamentals of Analytical Chemistry, 9th ed.; Cengage–Brooks/Cole: Belmont, CA, USA, 2012. [Google Scholar]

- Subramanian, A.; Rodriguez-Saona, L. Fourier Transform Infrared (FTIR) Spectroscopy. In Infrared Spectroscopy for Food Quality Analysis and Control; Academic Press: Cambridge, MA, USA, 2009; pp. 145–178. [Google Scholar] [CrossRef]

- Stuart, B. Infrared Spectroscopy. In Kirk-Othmer Encyclopedia of Chemical Technology; John Wiley & Sons: Hoboken, NJ, USA, 2005; pp. 1–20. [Google Scholar] [CrossRef]

- Barth, A. Infrared Spectroscopy of Proteins. Biochim. Biophys. Acta Bioenerg. 2007, 1767, 1073–1101. [Google Scholar] [CrossRef] [Green Version]

- Garrigues, S.; de la Guardia, M. Vibrational Spetroscopy. In Comprehensive Analytical Chemistry, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2013; Volume 60, p. 122. [Google Scholar] [CrossRef]

- Abbas, O.; Pissard, A.; Baeten, V. Near-Infrared, Mid-Infrared, and Raman Spectroscopy. In Chemical Analysis of Food, 2nd ed.; Academic Press: Cambridge, MA, USA, 2020; p. 134. [Google Scholar] [CrossRef]

- Craig, A.P.; Franca, A.S.; Irudayaraj, J. Vibrational Spectroscopy for Food Quality and Safety Screening. In High Throughput Screening for Food Safety Assessment: Biosensor Technologies, Hyperspectral Imaging and Practical Applications; Woodhead Publishing: Sawston, UK, 2015; p. 194. [Google Scholar] [CrossRef]

- Dutta, A. Fourier Transform Infrared Spectroscopy. In Spectroscopic Methods for Nanomaterials Characterization; Elsevier: Amsterdam, The Netherlands, 2017; Volume 2, p. 93. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra, A Practical Approach. Encycl. Anal. Chem. 2006, 1–23. [Google Scholar] [CrossRef]

- Blum, M.M.; John, H. Historical Perspective and Modern Applications of Attenuated Total Reflectance–Fourier Transform Infrared Spectroscopy (ATR-FTIR). Drug Test. Anal. 2012, 4, 298–302. [Google Scholar] [CrossRef]

- Cozzolino, D. Authentication of Cereals and Cereal Products. In Advances in Food Authenticity Testing; Woodhead Publishing: Sawston, UK, 2016; pp. 441–457. [Google Scholar] [CrossRef]

- Cozzolino, D.; Cynkar, W.U.; Shah, N.; Smith, P. Multivariate Data Analysis Applied to Spectroscopy: Potential Application to Juice and Fruit Quality. Food Res. Int. 2011, 44, 1888–1896. [Google Scholar] [CrossRef]

- Nicolaï, B.M.; Beullens, K.; Bobelyn, E.; Peirs, A.; Saeys, W.; Theron, K.I.; Lammertyn, J. Nondestructive Measurement of Fruit and Vegetable Quality by Means of NIR Spectroscopy: A Review. Postharvest Biol. Technol. 2007, 46, 99–118. [Google Scholar] [CrossRef]

- Canizo, B.V.; Escudero, L.B.; Pellerano, R.G.; Wuilloud, R.G. Quality Monitoring and Authenticity Assessment of Wines: Analytical and Chemometric Methods. In Quality Control in the Beverage Industry; Academic Press: Cambridge, MA, USA, 2019; Volume 17, p. 384. [Google Scholar] [CrossRef]

- Leardi, R. Chemometric Methods in Food Authentication. In Modern Techniques for Food Authentication, 2nd ed.; Academic Press: Cambridge, MA, USA, 2018; p. 729. [Google Scholar] [CrossRef]

- Biancolillo, A.; Marini, F. Chemometrics Applied to Plant Spectral Analysis. In Comprehensive Analytical Chemistry, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 80, p. 104. [Google Scholar] [CrossRef]

- Oliveri, P.; Malegori, C.; Casale, M. Chemometrics: Multivariate Analysis of Chemical Data. In Chemical Analysis of Food, 2nd ed.; Academic Press: Cambridge, MA, USA, 2020; p. 76. [Google Scholar] [CrossRef]

- Bona, E.; Março, P.H.; Valderrama, P. Chemometrics Applied to Food Control. In Food Control and Biosecurity; Academic Press: Cambridge, MA, USA, 2018; Volume 16, p. 133. [Google Scholar] [CrossRef]

- Luna, A.S.; de Gois, J.S. Application of Chemometric Methods Coupled with Vibrational Spectroscopy for the Discrimination of Plant Cultivars and to Predict Physicochemical Properties Using R. In Comprehensive Analytical Chemistry, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2018; Volume 80, p. 194. [Google Scholar] [CrossRef]

- PerkinElmer. AssureID User’s Guide; PerkinElmer Inc.: Waltham, MA, USA, 2014. [Google Scholar]

- Wang, X. Near-Infrared Spectroscopy for Food Quality Evaluation. In Evaluation Technologies for Food Quality; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 105–118. [Google Scholar] [CrossRef]

- PerkinElmer. Spectrum User’s Guide; PerkinElmer Inc.: Waltham, MA, USA, 2016. [Google Scholar]

- PerkinElmer. Spectrum Quant User’s Guide; PerkinElmer Inc.: Waltham, MA, USA, 2015. [Google Scholar]

- Yu, X.; Gao, Y.; Zhao, Z.; Gao, J.M. Rapid Determination of Amino Acids in Chinese Wolfberry (Lycium bararum L.) Fruit by Using Fourier Transform Infrared Spectroscopy and Partial Least Square Regression. Food Anal. Methods 2017, 10, 2436–2443. [Google Scholar] [CrossRef]

- Djuris, J.; Ibric, S.; Djuric, Z. Chemometric Methods Application in Pharmaceutical Products and Processes Analysis and Control. In Computer-Aided Applications in Pharmaceutical Technology; Woodhead Publishing: Sawston, UK, 2013; p. 90. [Google Scholar] [CrossRef]

- Gonzálvez, A.; de la Guardia, M. Basic Chemometric Tools. Compr. Anal. Chem. 2013, 60, 299–315. [Google Scholar] [CrossRef]

- Karoui, R. Food Authenticity and Fraud. In Chemical Analysis of Food, 2nd ed.; Academic Press: Cambridge, MA, USA, 2020; p. 608. [Google Scholar] [CrossRef]

- Callao, M.P.; Ruisánchez, I. An Overview of Multivariate Qualitative Methods for Food Fraud Detection. Food Control 2018, 86, 283–293. [Google Scholar] [CrossRef]

- Karoui, R.; Downey, G.; Blecker, C. Mid-Infrared Spectroscopy Coupled with Chemometrics: A Tool for the Analysis of Intact Food Systems and the Exploration of Their Molecular Structure-Quality Relationships—A Review. Chem. Rev. 2010, 110, 6144–6168. [Google Scholar] [CrossRef]

- Borràs, E.; Ferré, J.; Boqué, R.; Mestres, M.; Aceña, L.; Busto, O. Data Fusion Methodologies for Food and Beverage Authentication and Quality Assessment—A Review. Anal. Chim. Acta 2015, 891, 1–14. [Google Scholar] [CrossRef]

- Blanco Romía, M.; Alcalà Bernàrdez, M. Multivariate Calibration for Quantitative Analysis. In Infrared Spectroscopy for Food Quality Analysis and Control; Academic Press: Cambridge, MA, USA, 2009; pp. 51–82. [Google Scholar] [CrossRef]

- Diby, L.; Kahia, J.; Kouamé, C.; Aynekulu, E. Tea, Coffee, and Cocoa. In Encyclopedia of Applied Plant Sciences; Elsevier: Amsterdam, The Netherlands, 2017; pp. 420–425. [Google Scholar] [CrossRef]

- Barbin, D.F.; Felicio, A.L.; Sun, D.W.; Nixdorf, S.L.; Hirooka, E.Y. Application of Infrared Spectral Techniques on Quality and Compositional Attributes of Coffee: An Overview. Food Res. Int. 2014, 61, 23–32. [Google Scholar] [CrossRef] [Green Version]

- Sezer, B.; Apaydin, H.; Bilge, G.; Boyaci, I.H. Coffee Arabica Adulteration: Detection of Wheat, Corn and Chickpea. Food Chem. 2018, 264, 142–148. [Google Scholar] [CrossRef]

- Hoseini, M.; Cocco, S.; Casucci, C.; Cardelli, V.; Corti, G. Coffee By-Products Derived Resources. A Review. Biomass Bioenergy 2021, 148, 106009. [Google Scholar] [CrossRef]

- Franca, A.S.; Oliveira, L.S. Coffee. In Integrated Processing Technologies for Food and Agricultural by-Products; Academic Press: Cambridge, MA, USA, 2019; pp. 413–438. [Google Scholar] [CrossRef]

- Gibson, M.; Newsham, P. Tea and Coffee. In Food Science and the Culinary Arts; Academic Press: Cambridge, MA, USA, 2018; pp. 353–372. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; de Carvalho Neto, D.P.; Magalhães Júnior, A.I.; do Prado, F.G.; Pagnoncelli, M.G.B.; Karp, S.G.; Soccol, C.R. Chemical Composition and Health Properties of Coffee and Coffee By-Products. In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2020; Volume 91, pp. 65–96. [Google Scholar] [CrossRef]

- Munyendo, L.M.; Njoroge, D.M.; Owaga, E.E.; Mugendi, B. Coffee Phytochemicals and Post-Harvest Handling—A Complex and Delicate Balance. J. Food Compos. Anal. 2021, 102, 103995. [Google Scholar] [CrossRef]

- Wang, X.; Lim, L.-T. Physicochemical Characteristics of Roasted Coffee. In Coffee in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2015; pp. 247–254. [Google Scholar] [CrossRef]

- Komes, D.; Bušić, A. Antioxidants in Coffee. In Processing and Impact on Antioxidants in Beverages; Academic Press: Cambridge, MA, USA, 2014; pp. 25–32. [Google Scholar] [CrossRef]

- Carneiro, S.M.; Oliveira, M.B.P.P.; Alves, R.C. Neuroprotective Properties of Coffee: An Update. Trends Food Sci. Technol. 2021, 113, 167–179. [Google Scholar] [CrossRef]

- dos Santos, É.M.; de Macedo, L.M.; Tundisi, L.L.; Ataide, J.A.; Camargo, G.A.; Alves, R.C.; Oliveira, M.B.P.P.; Mazzola, P.G. Coffee by-products in topical formulations: A review. Trends Food Sci. Technol. 2021, 111, 280–291. [Google Scholar] [CrossRef]

- Yisak, H.; Redi-Abshiro, M.; Chandravanshi, B.S. Selective Determination of Caffeine and Trigonelline in Aqueous Extract of Green Coffee Beans by FT-MIR-ATR Spectroscopy. Vib. Spectrosc. 2018, 97, 33–38. [Google Scholar] [CrossRef]

- Winkler, A. Coffee, Cocoa and Derived Products (e.g., Chocolate). In Food Safety Management; Academic Press: Cambridge, MA, USA, 2014; pp. 251–282. [Google Scholar] [CrossRef]

- Combes, M.-C.; Joët, T.; Lashermes, P. Development of a Rapid and Efficient DNA-Based Method to Detect and Quantify Adulterations in Coffee (Arabica versus Robusta). Food Control 2018, 88, 198–206. [Google Scholar] [CrossRef]

- Diaz-de-Cerio, E.; Guerra-Hernandez, E.; Garcia-Estepa, R.; Garcia-Villanova, B.; Verardo, V. Analytical Approaches in Coffee Quality Control. In Caffeinated and Cocoa Based Beverages; Woodhead Publishing: Sawston, UK, 2019; pp. 285–336. [Google Scholar] [CrossRef]

- Fioresi, D.B.; Pereira, L.L.; Catarina da Silva Oliveira, E.; Moreira, T.R.; Ramos, A.C. Mid Infrared Spectroscopy for Comparative Analysis of Fermented Arabica and Robusta Coffee. Food Control 2021, 121, 107625. [Google Scholar] [CrossRef]

- de Morais, T.C.B.; Rodrigues, D.R.; de Carvalho Polari Souto, U.T.; Lemos, S.G. A Simple Voltammetric Electronic Tongue for the Analysis of Coffee Adulterations. Food Chem. 2019, 273, 31–38. [Google Scholar] [CrossRef]

- Wang, J.; Jun, S.; Bittenbender, H.C.; Gautz, L.; Li, Q.X. Fourier Transform Infrared Spectroscopy for Kona Coffee Authentication. J. Food Sci. 2009, 74, 385–391. [Google Scholar] [CrossRef]

- Ribeiro, J.S.; Salva, T.J.; Ferreira, M.M.C. Chemometric Studies for Quality Control of Processed Brazilian Coffees Using Drifts. J. Food Qual. 2010, 33, 212–227. [Google Scholar] [CrossRef]

- Craig, A.P.; Franca, A.S.; Oliveira, L.S. Discrimination between Immature and Mature Green Coffees by Attenuated Total Reflectance and Diffuse Reflectance Fourier Transform Infrared Spectroscopy. J. Food Sci. 2011, 76, C1162–C1168. [Google Scholar] [CrossRef]

- Craig, A.P.; Franca, A.S.; Oliveira, L.S. Discrimination between Defective and Non-Defective Roasted Coffees by Diffuse Reflectance Infrared Fourier Transform Spectroscopy. LWT Food Sci. Technol. 2012, 47, 505–511. [Google Scholar] [CrossRef] [Green Version]

- Craig, A.P.; Franca, A.S.; Oliveira, L.S. Evaluation of the Potential of FTIR and Chemometrics for Separation between Defective and Non-Defective Coffees. Food Chem. 2012, 132, 1368–1374. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Craig, A.P.; Botelho, B.G.; Oliveira, L.S.; Franca, A.S. Mid Infrared Spectroscopy and Chemometrics as Tools for the Classification of Roasted Coffees by Cup Quality. Food Chem. 2018, 245, 1052–1061. [Google Scholar] [CrossRef] [PubMed]

- Reis, N.; Franca, A.S.; Oliveira, L.S. Discrimination between Roasted Coffee, Roasted Corn and Coffee Husks by Diffuse Reflectance Infrared Fourier Transform Spectroscopy. LWT Food Sci. Technol. 2013, 50, 715–722. [Google Scholar] [CrossRef] [Green Version]

- Reis, N.; Franca, A.S.; Oliveira, L.S. Performance of Diffuse Reflectance Infrared Fourier Transform Spectroscopy and Chemometrics for Detection of Multiple Adulterants in Roasted and Ground Coffee. LWT Food Sci. Technol. 2013, 53, 395–401. [Google Scholar] [CrossRef] [Green Version]

- Reis, N.; Franca, A.S.; Oliveira, L.S. Quantitative Evaluation of Multiple Adulterants in Roasted Coffee by Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFTS) and Chemometrics. Talanta 2013, 115, 563–568. [Google Scholar] [CrossRef] [Green Version]

- Reis, N.; Franca, A.S.; Oliveira, L.S. Concomitant Use of Fourier Transform Infrared Attenuated Total Reflectance Spectroscopy and Chemometrics for Quantification of Multiple Adulterants in Roasted and Ground Coffee. J. Spectrosc. 2016, 2016, 4974173. [Google Scholar] [CrossRef]

- Reis, N.; Botelho, B.G.; Franca, A.S.; Oliveira, L.S. Simultaneous Detection of Multiple Adulterants in Ground Roasted Coffee by ATR-FTIR Spectroscopy and Data Fusion. Food Anal. Methods 2017, 10, 2700–2709. [Google Scholar] [CrossRef]

- Brondi, A.M.; Torres, C.; Garcia, J.S.; Trevisan, M.G. Differential Scanning Calorimetry and Infrared Spectroscopy Combined with Chemometric Analysis to the Determination of Coffee Adulteration by Corn. J. Braz. Chem. Soc. 2017, 28, 1308–1314. [Google Scholar] [CrossRef]

- Link, J.V.; Lemes, A.L.G.; Marquetti, I.; dos Santos Scholz, M.B.; Bona, E. Geographical and Genotypic Classification of Arabica Coffee Using Fourier Transform Infrared Spectroscopy and Radial-Basis Function Networks. Chemom. Intell. Lab. Syst. 2014, 135, 150–156. [Google Scholar] [CrossRef]

- Bona, E.; Marquetti, I.; Link, J.V.; Makimori, G.Y.F.; da Costa Arca, V.; Guimarães Lemes, A.L.; Ferreira, J.M.G.; dos Santos Scholz, M.B.; Valderrama, P.; Poppi, R.J. Supp.ort Vector Machines in Tandem with Infrared Spectroscopy for Geographical Classification of Green Arabica Coffee. LWT Food Sci. Technol. 2017, 76, 330–336. [Google Scholar] [CrossRef]

- Correia, R.M.; Loureiro, L.B.; Rodrigues, R.R.T.; Costa, H.B.; Oliveira, B.G.; Filgueiras, P.R.; Thompson, C.J.; Lacerda, V.; Romão, W. Chemical Profiles of Robusta and Arabica Coffee by ESI(-)FT-ICR MS and ATR-FTIR: A Quantitative Approach. Anal. Methods 2016, 8, 7678–7688. [Google Scholar] [CrossRef]

- Medina, J.; Caro Rodríguez, D.; Arana, V.A.; Bernal, A.; Esseiva, P.; Wist, J. Comparison of Attenuated Total Reflectance Mid-Infrared, Near Infrared, and 1H-Nuclear Magnetic Resonance Spectroscopies for the Determination of Coffee’s Geographical Origin. Int. J. Anal. Chem. 2017, 2017, 7210463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Obeidat, S.M.; Hammoudeh, A.Y.; Alomary, A.A. Application of FTIR Spectroscopy for Assessment of Green Coffee Beans According to Their Origin. J. Appl. Spectrosc. 2018, 84, 1051–1055. [Google Scholar] [CrossRef]

- Belchior, V.; Botelho, B.G.; Oliveira, L.S.; Franca, A.S. Attenuated Total Reflectance Fourier Transform Spectroscopy (ATR-FTIR) and Chemometrics for Discrimination of Espresso Coffees with Different Sensory Characteristics. Food Chem. 2019, 273, 178–185. [Google Scholar] [CrossRef]

- Belchior, V.; Botelho, B.G.; Casal, S.; Oliveira, L.S.; Franca, A.S. FTIR and Chemometrics as Effective Tools in Predicting the Quality of Specialty Coffees. Food Anal. Methods 2020, 13, 275–283. [Google Scholar] [CrossRef]

- Flores-Valdez, M.; Meza-Márquez, O.G.; Osorio-Revilla, G.; Gallardo-Velázquez, T. Identification and Quantification of Adulterants in Coffee (Coffea arabica L.) Using FT-MIR Spectroscopy Coupled with Chemometrics. Foods 2020, 9, 851. [Google Scholar] [CrossRef]

- Ruf, F.; Schroth, G.; Doffangui, K. Climate Change, Cocoa Migrations and Deforestation in West Africa: What Does the Past Tell Us about the Future? Sustain. Sci. 2015, 10, 101–111. [Google Scholar] [CrossRef]

- Franzen, M.; Borgerhoff Mulder, M. Ecological, Economic and Social Perspectives on Cocoa Production Worldwide. Biodivers. Conserv. 2007, 16, 3835–3849. [Google Scholar] [CrossRef]

- Nair, K.P. Cocoa (Theobroma cacao L.). In Tree Crops; Springer International Publishing: Cham, Switzerland, 2021; pp. 153–213. [Google Scholar] [CrossRef]

- Santos, I.A.; Conceição, D.G.; Viana, M.B.; de Jesus Silva, G.; Santos, L.S.; Ferrão, S.P. NIR and MIR Spectroscopy for Quick Detection of the Adulteration of Cocoa Content in Chocolates. Food Chem. 2021, 349, 129095. [Google Scholar] [CrossRef]

- Hu, Y.; Pan, Z.J.; Liao, W.; Li, J.; Gruget, P.; Kitts, D.D.; Lu, X. Determination of Antioxidant Capacity and Phenolic Content of Chocolate by Attenuated Total Reflectance-Fourier Transformed-Infrared Spectroscopy. Food Chem. 2016, 202, 254–261. [Google Scholar] [CrossRef] [PubMed]

- Batista, N.N.; de Andrade, D.P.; Ramos, C.L.; Dias, D.R.; Schwan, R.F. Antioxidant Capacity of Cocoa Beans and Chocolate Assessed by FTIR. Food Res. Int. 2016, 90, 313–319. [Google Scholar] [CrossRef] [PubMed]

- Mandrile, L.; Barbosa-Pereira, L.; Sorensen, K.M.; Giovannozzi, A.M.; Zeppa, G.; Engelsen, S.B.; Rossi, A.M. Authentication of Cocoa Bean Shells by Near- and Mid-Infrared Spectroscopy and Inductively Coupled Plasma-Optical Emission Spectroscopy. Food Chem. 2019, 292, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Guclu, G.; Kelebek, H.; Selli, S. Saffron (Crocus sativus L.): Its Aroma and Key Odorants. In Saffron; Academic Press: Cambridge, MA, USA, 2020; pp. 69–82. [Google Scholar] [CrossRef]

- Alonso, G.L.; Zalacain, A.; Carmona, M. Saffron. In Handbook of Herbs and Spices; Woodhead Publishing: Sawston, UK, 2012; pp. 469–498. [Google Scholar] [CrossRef]

- Saeidirad, M.-H. Mechanization of Saffron Production. In Saffron; Academic Press: Cambridge, MA, USA, 2020; pp. 187–204. [Google Scholar] [CrossRef]

- Koocheki, A.; Milani, E. Saffron Adulteration. In Saffron; Academic Press: Cambridge, MA, USA, 2020; pp. 321–334. [Google Scholar] [CrossRef]

- Bhooma, V.; Nagasathiya, K.; Vairamani, M.; Parani, M. Identification of Synthetic Dyes Magenta III (New Fuchsin) and Rhodamine B as Common Adulterants in Commercial Saffron. Food Chem. 2020, 309, 125793. [Google Scholar] [CrossRef]

- Cardone, L.; Castronuovo, D.; Perniola, M.; Cicco, N.; Candido, V. Saffron (Crocus sativus L.), the King of Spices: An Overview. Sci. Hortic. 2020, 272, 109560. [Google Scholar] [CrossRef]

- Farag, M.A.; Hegazi, N.; Dokhalahy, E.; Khattab, A.R. Chemometrics Based GC-MS Aroma Profiling for Revealing Freshness, Origin and Roasting Indices in Saffron Spice and Its Adulteration. Food Chem. 2020, 331, 127358. [Google Scholar] [CrossRef]

- Kumari, L.; Jaiswal, P.; Tripathy, S.S. Various Techniques Useful for Determination of Adulterants in Valuable Saffron: A Review. Trends Food Sci. Technol. 2021, 111, 301–321. [Google Scholar] [CrossRef]

- Mehri, S.; Razavi, B.-M.; Hosseinzadeh, H. Safety and Toxicity of Saffron. In Saffron; Academic Press: Cambridge, MA, USA, 2020; pp. 517–530. [Google Scholar] [CrossRef]

- Melnyk, J.P.; Wang, S.; Marcone, M.F. Chemical and Biological Properties of the World’s Most Expensive Spice: Saffron. Food Res. Int. 2010, 43, 1981–1989. [Google Scholar] [CrossRef]

- Gautam, N.; Bhattacharya, A. Molecular Marker Based Assessment of Genetic Homogeneity within the in Vitro Regenerated Plants of Crocus sativus L.–A Globally Important High Value Spice Crop. S. Afr. J. Bot. 2021, 140, 461–467. [Google Scholar] [CrossRef]

- Khan, M.; Hanif, M.A.; Ayub, M.A.; Jilani, M.I.; Shahid Chatha, S.A. Saffron. In Medicinal Plants of South Asia; Elsevier: Amsterdam, The Netherlands, 2020; pp. 587–600. [Google Scholar] [CrossRef]

- Kucharska-Ambrożej, K.; Karpinska, J. The Application of Spectroscopic Techniques in Combination with Chemometrics for Detection Adulteration of Some Herbs and Spices. Microchem. J. 2020, 153, 104278. [Google Scholar] [CrossRef]

- Anastasaki, E.; Kanakis, C.; Pappas, C.; Maggi, L.; del Campo, C.P.; Carmona, M.; Alonso, G.L.; Polissiou, M.G. Differentiation of Saffron from Four Countries by Mid-Infrared Spectroscopy and Multivariate Analysis. Eur. Food Res. Technol. 2010, 230, 571–577. [Google Scholar] [CrossRef]

- Ordoudi, S.A.; de los Mozos Pascual, M.; Tsimidou, M.Z. On the Quality Control of Traded Saffron by Means of Transmission Fourier-Transform Mid-Infrared (FT-MIR) Spectroscopy and Chemometrics. Food Chem. 2014, 150, 414–421. [Google Scholar] [CrossRef] [PubMed]

- Varliklioz Er, S.; Eksi-Kocak, H.; Yetim, H.; Boyaci, I.H. Novel Spectroscopic Method for Determination and Quantification of Saffron Adulteration. Food Anal. Methods 2017, 10, 1547–1555. [Google Scholar] [CrossRef]

- Petrakis, E.A.; Polissiou, M.G. Assessing Saffron (Crocus sativus L.) Adulteration with Plant-Derived Adulterants by Diffuse Reflectance Infrared Fourier Transform Spectroscopy Coupled with Chemometrics. Talanta 2017, 162, 558–566. [Google Scholar] [CrossRef] [PubMed]

- Ordoudi, S.A.; Staikidou, C.; Kyriakoudi, A.; Tsimidou, M.Z. A Stepwise Approach for the Detection of Carminic Acid in Saffron with Regard to Religious Food Certification. Food Chem. 2018, 267, 410–419. [Google Scholar] [CrossRef]

- Amirvaresi, A.; Nikounezhad, N.; Amirahmadi, M.; Daraei, B.; Parastar, H. Comparison of Near-Infrared (NIR) and Mid-Infrared (MIR) Spectroscopy Based on Chemometrics for Saffron Authentication and Adulteration Detection. Food Chem. 2021, 344, 128647. [Google Scholar] [CrossRef]

- Amirvaresi, A.; Parastar, H. External Parameter Orthogonalization-Supp.ort Vector Machine for Processing of Attenuated Total Reflectance-Mid-Infrared Spectra: A Solution for Saffron Authenticity Problem. Anal. Chim. Acta 2021, 1154, 338308. [Google Scholar] [CrossRef]

- Biancolillo, A.; Foschi, M.; D’Archivio, A.A. Geographical Classification of Italian Saffron (Crocus sativus L.) by Multi-Block Treatments of UV-Vis and IR Spectroscopic Data. Molecules 2020, 25, 2332. [Google Scholar] [CrossRef]

- Korthou, H.; Verpoorte, R. Vanilla. In Flavours and Fragrances; Berger, R.G., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 203–217. [Google Scholar] [CrossRef]

- Moreno-Ley, C.M.; Hernández-Martínez, D.M.; Osorio-Revilla, G.; Tapia-Ochoategui, A.P.; Dávila-Ortiz, G.; Gallardo-Velázquez, T. Prediction of Coumarin and Ethyl Vanillin in Pure Vanilla Extracts Using MID-FTIR Spectroscopy and Chemometrics. Talanta 2019, 197, 264–269. [Google Scholar] [CrossRef]

- Jiménez-Carvelo, A.M.; Tonolini, M.; McAleer, O.; Cuadros-Rodríguez, L.; Granato, D.; Koidis, A. Multivariate Approach for the Authentication of Vanilla Using Infrared and Raman Spectroscopy. Food Res. Int. 2021, 141, 110196. [Google Scholar] [CrossRef]

- Sharp, M.D.; Kocaoglu-Vurma, N.A.; Langford, V.; Rodriguez-Saona, L.E.; Harper, W.J. Rapid Discrimination and Characterization of Vanilla Bean Extracts by Attenuated Total Reflection Infrared Spectroscopy and Selected Ion Flow Tube Mass Spectrometry. J. Food Sci. 2012, 77, 284–292. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.L.; Li, X.Z.; Kuang, C.T. Antioxidant Pathways and Chemical Mechanism of Curcumin. Adv. Mater. Res. 2011, 236–238, 2311–2314. [Google Scholar] [CrossRef]

- Harjanti, D.W.; Ciptaningtyas, R.; Wahyono, F. Phytochemical Properties and Antibacterial Activity of Ageratum Conyzoides, Piper Betle, Muntinga Calabura and Curcuma Domestica against Mastitis Bacteria Isolates. IOP Conf. Ser. Earth Environ. Sci. 2019, 247, 012049. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Shi, X.; Zhang, J.; Zhang, X.; Martin, R.C.G. Hepatic Protection and Anticancer Activity of Curcuma: A Potential Chemopreventive Strategy against Hepatocellular Carcinoma. Int. J. Oncol. 2014, 44, 505–513. [Google Scholar] [CrossRef] [Green Version]

- Mujumdar, A.M.; Naik, D.G.; Dandge, C.N.; Puntambekar, H.M. Antiinflammatory Activity of Curcuma Amada Roxb. In Albino Rats. Indian J. Pharmacol. 2000, 32, 375–377. [Google Scholar]

- Dhakal, S.; Schmidt, W.F.; Kim, M.; Tang, X.; Peng, Y.; Chao, K. Detection of Additives and Chemical Contaminants in Turmeric Powder Using FT-IR Spectroscopy. Foods 2019, 8, 143. [Google Scholar] [CrossRef] [Green Version]

- Wulandari, R.; Sudjadi; Martono, S.; Rohman, A. Liquid Chromatography and Fourier Transform Infrared Spectroscopy for Quantitative Analysis of Individual and Total Curcuminoid in Curcuma longa Extract. J. Appl. Pharm. Sci. 2018, 8, 107–113. [Google Scholar] [CrossRef] [Green Version]

- Gad, H.A.; Bouzabata, A. Application of Chemometrics in Quality Control of Turmeric (Curcuma longa) Based on Ultra-Violet, Fourier Transform-Infrared and 1H NMR Spectroscopy. Food Chem. 2017, 237, 857–864. [Google Scholar] [CrossRef]

- Siregar, C.; Martono, S.; Rohman, A. Application of Fourier Transform Infrared (FTIR) Spectroscopy Coupled with Multivariate Calibration for Quantitative Analysis of Curcuminoid in Tablet Dosage Form. J. Appl. Pharm. Sci. 2018, 8, 151–156. [Google Scholar] [CrossRef] [Green Version]

- Rohaeti, E.; Rafi, M.; Syafitri, U.D.; Heryanto, R. Fourier Transform Infrared Spectroscopy Combined with Chemometrics for Discrimination of Curcuma longa, Curcuma xanthorrhiza and Zingiber cassumunar. Spectrochim. Acta Part Mol. Biomol. Spectrosc. 2015, 137, 1244–1249. [Google Scholar] [CrossRef]

- Yeung, A.W.K.; Horbańczuk, M.; Tzvetkov, N.T.; Mocan, A.; Carradori, S.; Maggi, F.; Marchewka, J.; Sut, S.; Dall’Acqua, S.; Gan, R.Y.; et al. Curcumin: Total-Scale Analysis of the Scientific Literature. Molecules 2019, 24, 1393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lohumi, S.; Joshi, R.; Kandpal, L.M.; Lee, H.; Kim, M.S.; Cho, H.; Mo, C.; Seo, Y.-W.; Rahman, A.; Cho, B.-K. Quantitative Analysis of Sudan Dye Adulteration in Paprika Powder Using FTIR Spectroscopy. Food Addit. Contam. Part A 2017, 34, 678–686. [Google Scholar] [CrossRef] [PubMed]

- McGoverin, C.M.; September, D.J.F.; Geladi, P.; Manley, M. Near Infrared and Mid-Infrared Spectroscopy for the Quantification of Adulterants in Ground Black Pepper. J. Infrared Spectrosc. 2012, 20, 521–528. [Google Scholar] [CrossRef]

- Wang, Y.; Mei, M.; Ni, Y.; Kokot, S. Combined NIR/MIR Analysis: A Novel Method for the Classification of Complex Substances Such as Illicium Verum Hook. F. and Its Adulterants. Spectrochim. Acta. A Mol. Biomol. Spectrosc. 2014, 130, 539–545. [Google Scholar] [CrossRef]

- Wilde, A.S.; Haughey, S.A.; Galvin-King, P.; Elliott, C.T. The Feasibility of Applying NIR and FT-IR Fingerprinting to Detect Adulteration in Black Pepper. Food Control 2019, 100, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Hu, L.; Yin, C.; Ma, S.; Liu, Z. Assessing the Authenticity of Black Pepp.er Using Diffuse Reflectance Mid-Infrared Fourier Transform Spectroscopy Coupled with Chemometrics. Comput. Electron. Agric. 2018, 154, 491–500. [Google Scholar] [CrossRef]

- Lafeuille, J.L.; Frégière-Salomon, A.; Michelet, A.; Henry, K.L. A Rapid Non-Targeted Method for Detecting the Adulteration of Black Pepp.er with a Broad Range of Endogenous and Exogenous Material at Economically Motivating Levels Using Micro-ATR-FT-MIR Imaging. J. Agric. Food Chem. 2020, 68, 390–401. [Google Scholar] [CrossRef]

- Horn, B.; Esslinger, S.; Pfister, M.; Fauhl-Hassek, C.; Riedl, J. Non-Targeted Detection of Paprika Adulteration Using Mid-Infrared Spectroscopy and One-Class Classification–Is It Data Preprocessing That Makes the Performance? Food Chem. 2018, 257, 112–119. [Google Scholar] [CrossRef]

- Biancolillo, A.; Di Donato, F.; Merola, F.; Marini, F.; D’Archivio, A.A. Sequential Data Fusion Techniques for the Authentication of the P.G.I. Senise (“Crusco”) Bell Pepper. Appl. Sci. 2021, 11, 1709. [Google Scholar] [CrossRef]

- Black, C.; Haughey, S.A.; Chevallier, O.P.; Galvin-King, P.; Elliott, C.T. A Comprehensive Strategy to Detect the Fraudulent Adulteration of Herbs: The Oregano Approach. Food Chem. 2016, 210, 551–557. [Google Scholar] [CrossRef] [Green Version]

- Wielogorska, E.; Chevallier, O.; Black, C.; Galvin-King, P.; Delêtre, M.; Kelleher, C.T.; Haughey, S.A.; Elliott, C.T. Development of a Comprehensive Analytical Platform for the Detection and Quantitation of Food Fraud Using a Biomarker Approach. The Oregano Adulteration Case Study. Food Chem. 2018, 239, 32–39. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lohumi, S.; Lee, S.; Cho, B.K. Optimal Variable Selection for Fourier Transform Infrared Spectroscopic Analysis of Starch-Adulterated Garlic Powder. Sens. Actuators B Chem. 2015, 216, 622–628. [Google Scholar] [CrossRef]

| Spectral Range (cm−1) | Sampling Technique | Algorithm | Purpose of the Analysis | Reference |

|---|---|---|---|---|

| Chocolate | ||||

| 3600–2800 1800–500 | ATR cell | PCA PLS | Determination of cocoa solids content in chocolates. | [113] |

| 1800–700 | Diamond ATR | PLS | Quantification and prediction of antioxidant capacity and catechin concentration in chocolate. | [114] |

| Chocolate and fermented cocoa beans | ||||

| 4400–600 | ZnSe ATR | PLS | Prediction of antioxidant capacity and total phenolic content. | [115] |

| Cocoa bean shells | ||||

| 4000–500 | Ge ATR | PCA PLS-DA | Identification of systematic patterns related to the geographical origin of the samples. | [116] |

| Spectral Range (cm−1) | Sampling Technique | Algorithm | Purpose of the Analysis | Reference |

|---|---|---|---|---|

| Ethanolic vanilla extracts | ||||

| 4000–700 | ZnSe ATR | SIMCA | Determination of origin according to the main compounds of the vanilla pods. | [141] |

| 3000–1100 1700–1110 1800–850 | ZnSe ATR | PLS1 PLS2 PCR | Quantification of adulteration with ethyl vanillin and coumarin. | [139] |

| 4000–700 1549–778 | ZnSe ATR | PCA; SIMCA PLS-DA SVM-C | Discrimination between pure and adulterated samples as well as by origin (from Madagascar or other than Madagascar). | [140] |

| Spectral Range (cm−1) | Sampling Technique | Algorithm | Purpose of the Analysis | Reference |

|---|---|---|---|---|

| Yellow turmeric powder | ||||

| 1700–700 | Ge ATR | PLS | Adulteration with Sudan red G dye. | [146] |

| 1820–1172 | Ge ATR | PLS | Prediction of total and individual curcuminoid composition. | [147] |

| 4000–400 | KBr pellets | PCA HCA | Discrimination between turmeric from Egypt and Algeria. | [148] |

| White turmeric powder | ||||

| 1700–900 | Ge ATR | PLS | Adulteration with Sudan red G dye. | [146] |

| Curcuminoid tablets | ||||

| 2975–660 1784–1587 | Diamond ATR | PLS PCR | Quantification of curcuminoids (curcumin and desmethoxycurcumin). | [149] |

| Ethanolic extract of Curcuma longa and Curcuma xanthorrhiza | ||||

| 4000–400 2000–400 | KBr pellets | PCA CVA | Discrimination and identification between Curcuma longa and Curcuma xanthorrhiza. | [150] |

| Spectral Range (cm−1) | Sampling Technique | Algorithm | Purpose of the Analysis | Reference |

|---|---|---|---|---|

| Black pepper | ||||

| 3050–2800 1770–550 | Diamond ATR | PLS | Comparison of NIR and MIR techniques to quantify the level of adulteration with buckwheat and millet in black pepper. | [153] |

| 4000–400 | DRIFT | PCA GA-SVM PLS-DA | Classification of pure pepper and pepper adulterated with sorghum or Sichuan pepper (5–50%). | [156] |

| 3800–2800 1800–400 | Diamond ATR | PCA OPLS-DA | Comparison between NIR and MIR to detect adulteration of black pepper with peels, pinheads, spent material, papaya, and chili seeds. | [155] |

| 4000–720 | Ge ATR | PCA | Application of microscopy and FT-MIR spectroscopy to detect organic and mineral adulterants in black pepper. | [157] |

| Paprika | ||||

| 1800–650 | Diamond ATR | HLA | Detection of paprika adulteration with Sudan I dye. | [152] |

| 3300–2700 1800–400 | Diamond ATR | PCA SIMCA | Detection of paprika adulteration with adulterants (Sudan I and IV, lead chromate, lead oxide, among others). | [158] |

| 4000–400 | Diamond ATR | SO-PLS-LDA SO-CovSel-LDA | Authentication of Senise bell pepper and detection of adulteration with ordinary paprika. | [159] |

| Oregano | ||||

| 3999–2800 1800–550 | Diamond ATR | PCA OPLS-DA | Detection of oregano adulteration with olive, hazelnut, myrtle, cistus g, and sumac leaves. | [160] |

| 4000–600 | Diamond ATR | PCA PLS | FT-MIR detection of adulteration in oregano and quantification by LC-MS/MS. | [161] |

| Garlic powder | ||||

| 4000–650 1500–650 1666–1508 | Diamond ATR | PLS PLS-SR PLS-VIP | Prediction of adulteration of garlic powder with cornstarch (1–35% w/w). | [162] |

| 4000–550 | Diamond ATR | PCA OPLS-DA | Comparison of NIR and MIR for the detection of different adulterants in garlic. | [30] |

| Onion powder | ||||

| 4000–650 | Diamond ATR | PCA PLS | Quantification of onion adulteration with cornstarch (1–35% w/w) using NIR and MIR spectroscopy. | [33] |

| Star anise powder | ||||

| 4000–400 | KBr pellets | PCA LDA | Comparison of NIR and MIR spectroscopy and the combination of both techniques to detect adulteration of star anise with lower-quality species. | [154] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillejos-Mijangos, L.A.; Acosta-Caudillo, A.; Gallardo-Velázquez, T.; Osorio-Revilla, G.; Jiménez-Martínez, C. Uses of FT-MIR Spectroscopy and Multivariate Analysis in Quality Control of Coffee, Cocoa, and Commercially Important Spices. Foods 2022, 11, 579. https://doi.org/10.3390/foods11040579

Castillejos-Mijangos LA, Acosta-Caudillo A, Gallardo-Velázquez T, Osorio-Revilla G, Jiménez-Martínez C. Uses of FT-MIR Spectroscopy and Multivariate Analysis in Quality Control of Coffee, Cocoa, and Commercially Important Spices. Foods. 2022; 11(4):579. https://doi.org/10.3390/foods11040579

Chicago/Turabian StyleCastillejos-Mijangos, Lucero Azusena, Aracely Acosta-Caudillo, Tzayhrí Gallardo-Velázquez, Guillermo Osorio-Revilla, and Cristian Jiménez-Martínez. 2022. "Uses of FT-MIR Spectroscopy and Multivariate Analysis in Quality Control of Coffee, Cocoa, and Commercially Important Spices" Foods 11, no. 4: 579. https://doi.org/10.3390/foods11040579