Modeling the Influence of Okara Flour Supplementation from Time-Temperature Drying Treatment on the Quality of Gluten-Free Roll Produced from Rice Flour

Abstract

:1. Introduction

2. Material and Methods

2.1. Okara Flour Preparation

2.2. Chemical Properties of Okara Flour

2.3. Preparation of Gluten-Free Roll

2.4. Chemical Properties of Gluten-Free Roll

2.5. Small Deformation of Gluten-Free Roll Batter

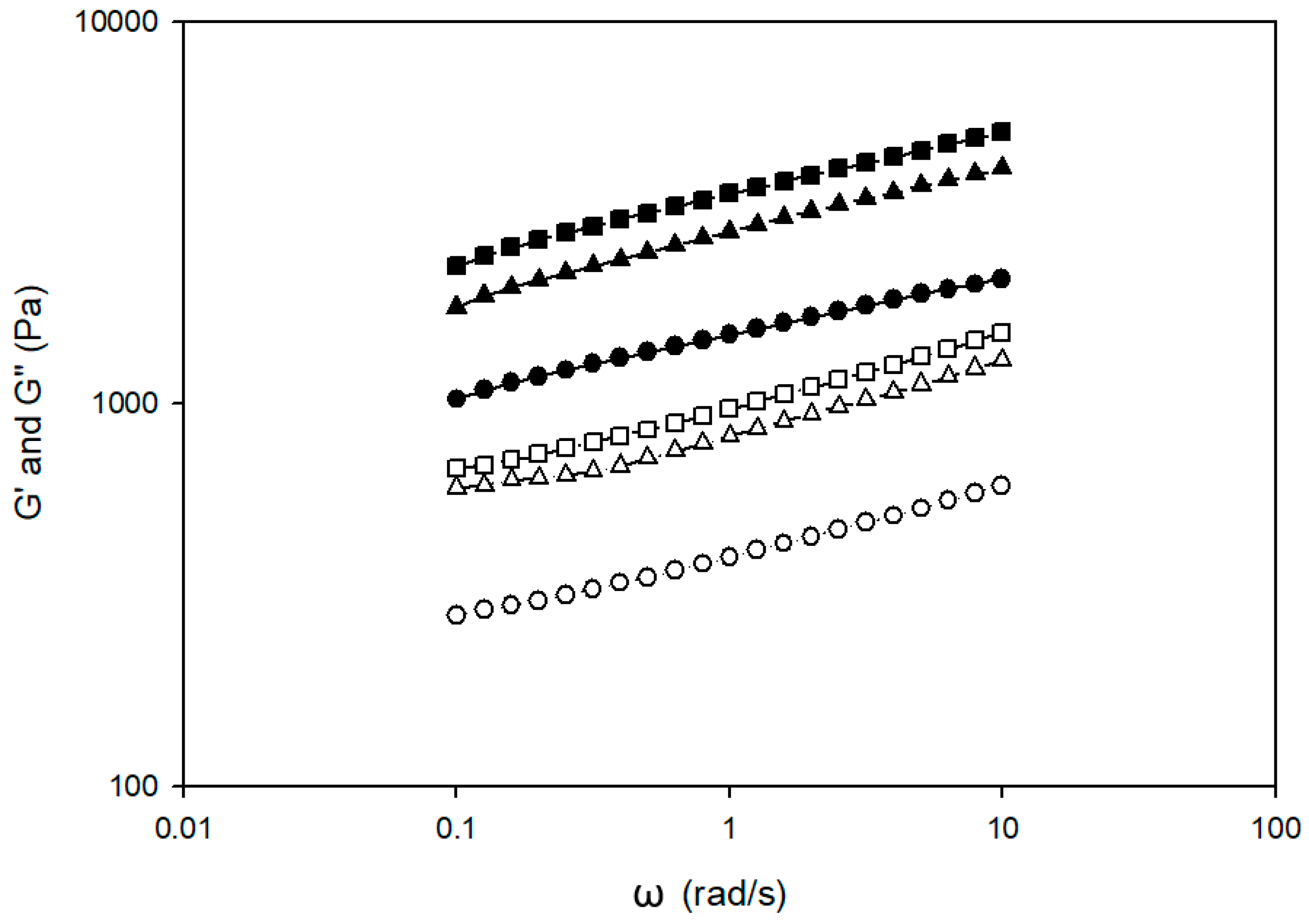

2.5.1. Frequency Sweep Test

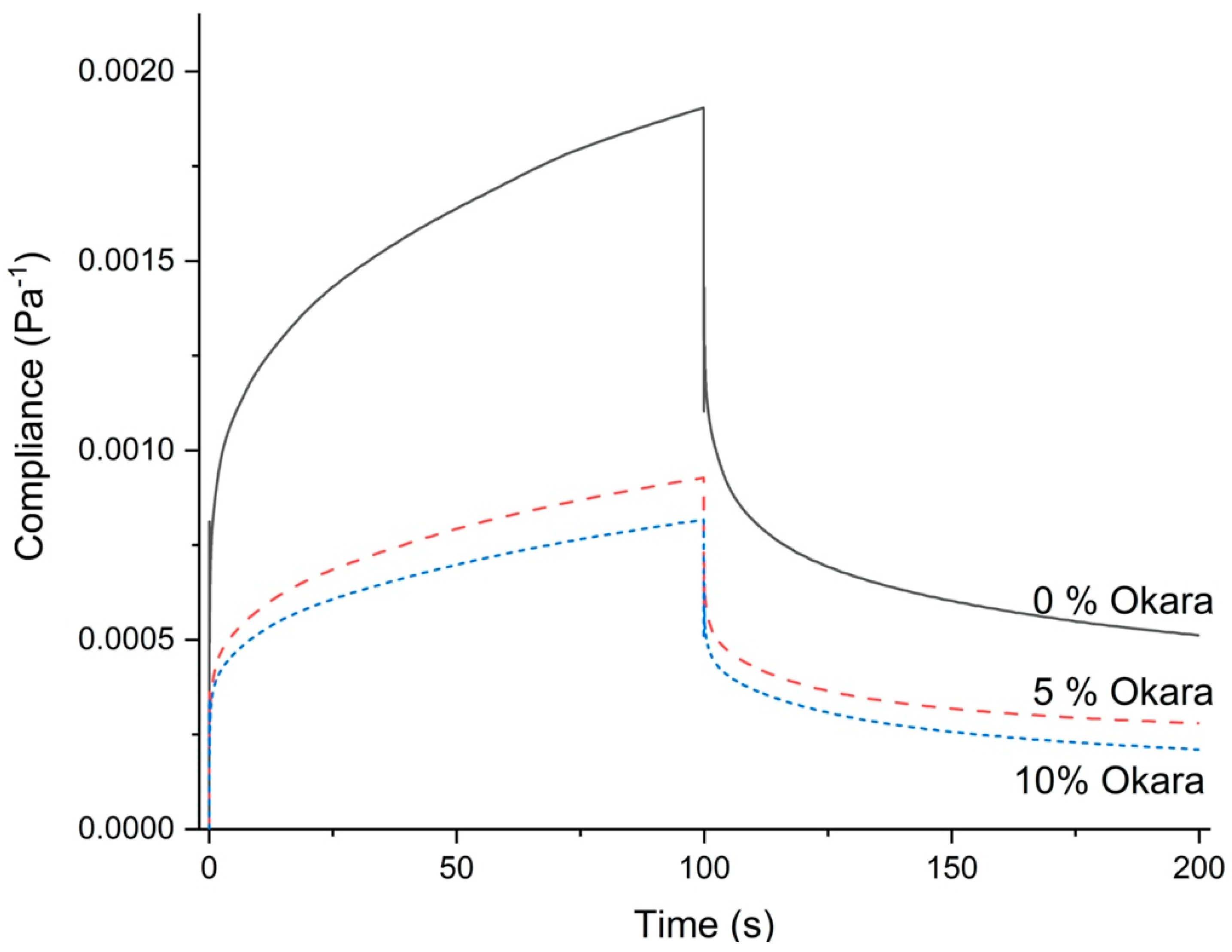

2.5.2. Creep-Recovery Test

2.6. Physical and Textural Properties of Gluten-Free Rolls

2.6.1. Volume and Color of Gluten-Free Rolls and Batter

2.6.2. Texture of Gluten-Free Rolls

2.7. Sensory Properties of Gluten-Free Rolls

2.8. Statistical Analysis

3. Results and Discussion

3.1. Okara Flour Characteristics

3.2. Chemical Properties of Gluten-Free Roll

3.3. Gluten-Free Roll Batter Rheological Properties

3.4. Gluten-Free Roll Properties

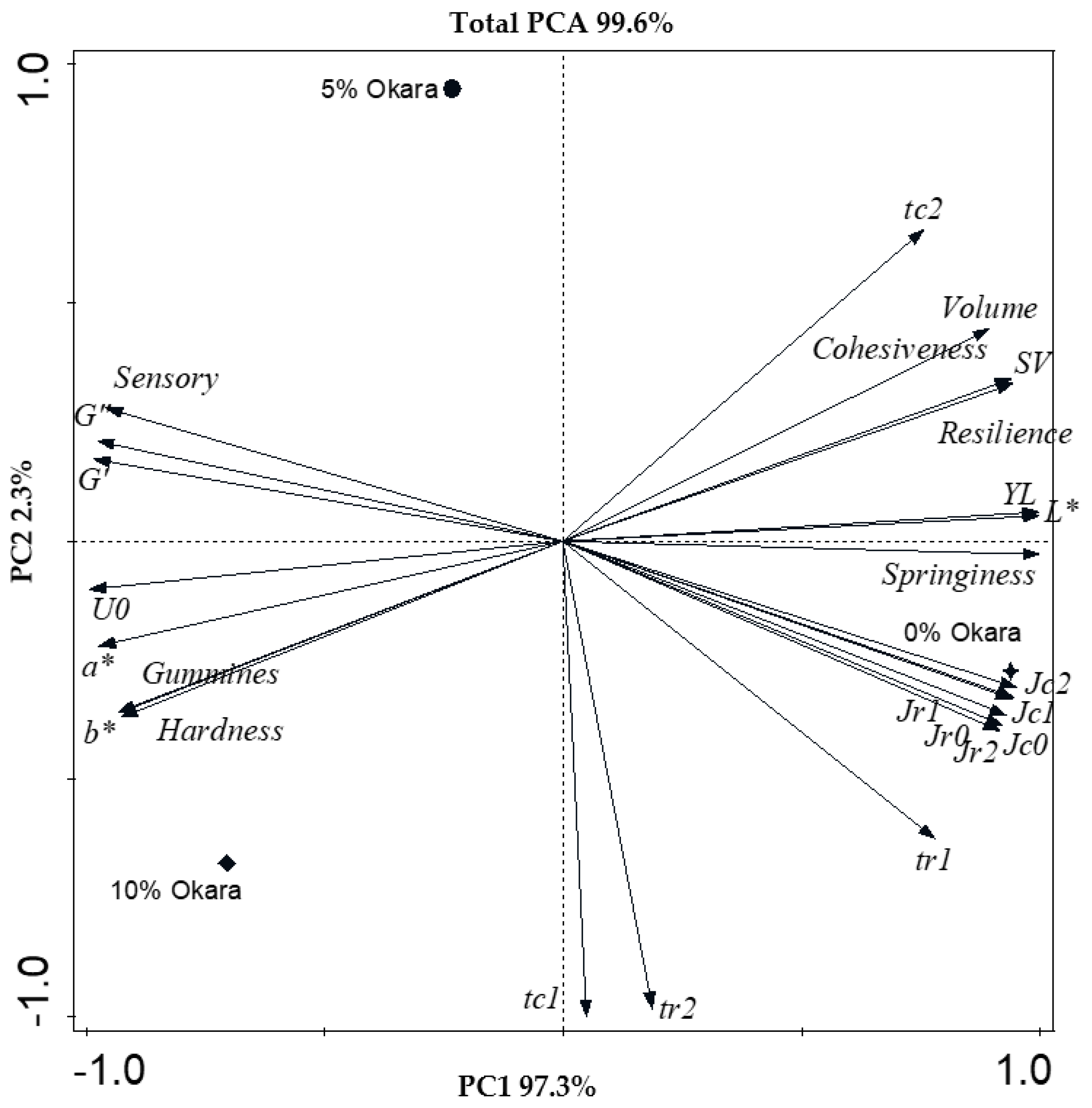

3.5. Principal Component Analysis (PCA)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, B.; Qiao, M.; Lu, F. Composition, nutrition, and utilization of okara (soybean residue). Food Rev. Int. 2012, 28, 231–252. [Google Scholar] [CrossRef]

- Park, J.; Choi, I.; Kim, Y. Cookies formulated from fresh okara using starch, soy flour and hydroxypropyl methylcellulose have high quality and nutritional value. Lwt—Food Sci Technol. 2015, 63, 660–666. [Google Scholar] [CrossRef]

- Rinaldi, V.; Ng, P.; Bennink, M. Effects of extrusion on dietary fiber and isoflavone contents of wheat extrudates enriched with wet okara. Cereal Chem. 2000, 77, 237–240. [Google Scholar] [CrossRef]

- Wickramarathna, G.; Arampath, P. Utilization of okara in bread making. J. Biosci. 2003, 31, 29–33. [Google Scholar]

- Varzakas, T.; Zakynthinos, G.; Verpoort, F. Plant food residues as a source of nutraceuticals and functional foods. Foods 2016, 5, 88. [Google Scholar] [CrossRef] [PubMed]

- Voss, G.; Rodríguez-Alcalá, L.; Valente, L.; Pintado, M. Impact of different thermal treatments and storage conditions on the stability of soybean byproduct (okara). J. Food Meas. Charact. 2018, 12, 1981–1996. [Google Scholar] [CrossRef]

- Mateos-Aparicio, I.; Mateos-Peinado, C.; Jiménez-Escrig, A.; Rupérez, P. Multifunctional antioxidant activity of polysaccharide fractions from the soybean byproduct okara. Carbohydr. Polym. 2010, 82, 245–250. [Google Scholar] [CrossRef]

- O'Shea, N.; Arendt, E.K.; Gallagher, E. Dietary fibre and phytochemical characteristics of fruit and vegetable by-products and their recent applications as novel ingredients in food products. Innov. Food Sci. Emerg. Technol. 2012, 16, 1–10. [Google Scholar] [CrossRef]

- Sharma, S.K.; Bansal, S.; Mangal, M.; Dixit, A.K.; Gupta, R.K.; Mangal, A. Utilization of food processing by-products as dietary, functional, and novel fiber: A review. Crit. Rev. Food Sci. Nutr. 2016, 56, 1647–1661. [Google Scholar] [CrossRef]

- Ayadi, M.; Abdelmaksoud, W.; Ennouri, M.; Attia, H. Cladodes from Opuntia ficus indica as a source of dietary fiber: Effect on dough characteristics and cake making. Ind. Crops. Prod. 2009, 30, 40–47. [Google Scholar] [CrossRef]

- Lian, H.; Luo, K.; Gong, Y.; Zhang, S.; Serventi, L. Okara flours from chickpea and soy are thickeners: Increased dough viscosity and moisture content in gluten-free bread. Int. J. Food Sci. Technol. 2020, 55, 805–812. [Google Scholar] [CrossRef]

- Kamble, D.B.; Singh, R.; Rani, S.; Pratap, D. Physicochemical properties, in vitro digestibility and structural attributes of okara-enriched functional pasta. J. Food Process. Preserv. 2019, 43, e14232. [Google Scholar] [CrossRef]

- AACC International. Approved Methods of Analysis, 11th ed.; Method 44-15.02. Moisture-Air-Oven Methods. Approved November 3 1999; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- AACC International. Approved Methods of Analysis, 11th ed.; Method 08-01.01. Ash-Basic Method. Approved November 3 1999; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- AACC International. Approved Methods of Analysis, 11th ed.; Method 30-10.01. Crude Fat in Flour, Bread, and Baked Cereal Products Not Containing Fruit. Approved November 3 1999; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- AACC International. Approved Methods of Analysis, 11th ed.; Method 46-10.01. Crude Protein-Improved Kjeldahl Method. Approved November 3 1999; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- AACC International. Approved Methods of Analysis, 11th ed.; Method 32-05.01. Crude Fiber in Flours, Feeds, and Feedstuffs. Approved November 3 1999; AACC International: St. Paul, MN, USA, 1999. [Google Scholar]

- Chompoorat, P.; Kantanet, N.; Estrada, Z.J.H.; Rayas-Duarte, P. Physical and dynamic oscillatory shear properties of gluten-free red kidney bean batter and cupcakes affected by rice flour addition. Foods 2020, 9, 616. [Google Scholar] [CrossRef]

- Chompoorat, P.; Rayas-Duarte, P.; Hernández-Estrada, Z.J.; Phetcharat, C.; Khamsee, Y. Effect of heat treatment on rheological properties of red kidney bean gluten free cake batter and its relationship with cupcake quality. J. Food Sci. Technol. 2018, 55, 4937–4944. [Google Scholar] [CrossRef] [PubMed]

- Jekle, M.; Fuchs, A.; Becker, T. A normalized texture profile analysis approach to evaluate firming kinetics of bread crumbs independent from its initial texture. J. Cereal Sci. 2018, 81, 147–152. [Google Scholar] [CrossRef]

- Braak, C.J.F.; Šmilauer, P. CANOCO Reference Manual and CanoDraw for Windows User’s Guide: Software for Canonical Community Ordination (Version 4.5); Biometris: Wageningen, The Natherlands, 2002; p. 500. [Google Scholar]

- Guimaraes, R.M.; Ida, E.I.; Falcao, H.G.; de Rezende, T.A.M.; de Santana Silva, J.; Alves, C.C.F.; da Silva, M.A.P.; Egea, M.B. Evaluating technological quality of okara flours obtained by different drying processes. Lwt—Food Sci Technol. 2020, 123, 109062. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Carrillo-Navas, H.; Pérez-Alonso, C.; Vernon-Carter, E.; Alvarez-Ramirez, J. Thermal and rheological properties of sponge cake batters and texture and microstructural characteristics of sponge cake made with native corn starch in partial or total replacement of wheat flour. Lwt—Food Sci Technol. 2016, 70, 46–54. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Creep-recovery parameters of gluten-free batter and crumb properties of bread prepared from pregelatinised cassava starch, sorghum and selected proteins. Int. J. Food Sci. 2009, 44, 2493–2499. [Google Scholar] [CrossRef]

- Ronda, F.; Pérez-Quirce, S.; Angioloni, A.; Collar, C. Impact of viscous dietary fibres on the viscoelastic behaviour of gluten-free formulated rice doughs: A fundamental and empirical rheological approach. Food Hydrocoll. 2013, 32, 252–262. [Google Scholar] [CrossRef]

- Ronda, F.; Villanueva, M.; Collar, C. Influence of acidification on dough viscoelasticity of gluten-free rice starch-based dough matrices enriched with exogenous protein. Lwt—Food Sci Technol. 2014, 59, 12–20. [Google Scholar] [CrossRef]

- Steffe, J.F. Rheological methods in food process engineering; Freeman press: East Lansing, MI, USA, 1996; p. 418. [Google Scholar]

- Van Bockstaele, F.; De Leyn, I.; Eeckhout, M.; Dewettinck, K. Rheological properties of wheat flour dough and the relationship with bread volume. I. Creep-recovery measurements. Cereal Chem. 2008, 85, 753–761. [Google Scholar] [CrossRef]

- Chompoorat, P.; Ambardekar, A.; Mulvaney, S.; Rayas-Duarte, P. Rheological characteristics of gluten after modified by DATEM, ascorbic acid, urea and DTT using creep-recovery test. J. Mod. Phys. 2013, 4, 1–8. [Google Scholar] [CrossRef]

- Chompoorat, P.; Hernández-Estrada, Z.J.; Mulvaney, S.J.; Payton, M.E.; Lavine, B.K.; Fasasi, A.; Rayas-Duarte, P. Comparison of rheological properties of wet gluten: Creep-recovery and biaxial compression. Lwt—Food Sci Technol. 2018, 98, 197–203. [Google Scholar] [CrossRef]

- Hernández-Estrada, Z.; Figueroa, J.; Rayas-Duarte, P.; Peña, R. Viscoelastic characterization of glutenins in wheat kernels measured by creep tests. J. Food Eng. 2012, 113, 19–26. [Google Scholar] [CrossRef]

- Hernández-Estrada, Z.J.; Rayas-Duarte, P.; Cárdenas, J.d.D.F. Creep recovery of wet gluten and high-molecular-weight glutenin subunit composition: Relationship with viscoelasticity of dough and breadmaking quality of hard red winter wheat. Cereal Chem. 2017, 94, 223–229. [Google Scholar] [CrossRef]

- Guermani, L.; Villaume, C.; Bau, H.W.; Chandrasiri, V.; Nicolas, J.P.; Mejean, L. Composition and nutritional value of okara fermented by rhizopus oligosporus. Sci. Aliments. 1992, 12, 441–451. [Google Scholar]

- Chami Khazraji, A.; Robert, S. Interaction effects between cellulose and water in nanocrystalline and amorphous regions: A novel approach using molecular modeling. J. Nanomater. 2013, 2013, 1–10. [Google Scholar] [CrossRef]

- Pan, W.-C.; Liu, Y.-M.; Shiau, S.-Y. Effect of okara and vital gluten on physico-chemical properties of noodle. Czech J. Food Sci. 2018, 36, 301–306. [Google Scholar] [CrossRef]

- Ostermann-Porcel, M.V.; Quiroga-Panelo, N.; Rinaldoni, A.N.; Campderrós, M.E. Incorporation of okara into gluten-free cookies with high quality and nutritional value. J. Food Qual. 2017, 2017, 4071585. [Google Scholar] [CrossRef]

- Grizotto, R.K.; Rufi, C.R.G.; Yamada, E.A.; Vicente, E. Evaluation of the quality of a molded sweet biscuit enriched with okara flour. Food Sci. Technol. 2010, 30, 270–275. [Google Scholar] [CrossRef]

- Ostermann-Porcel, M.V.; Rinaldoni, A.N.; Campderrós, M.E.; Gómez, M. Evaluation of gluten-free layer cake quality made with okara flour. J. Food Meas. Charact. 2020, 14, 1614–1622. [Google Scholar] [CrossRef]

| Analyses | Time-Temperature Drying Treatment | |||||

|---|---|---|---|---|---|---|

| 4 h-70 °C | 3 h-80 °C | 2 h-100 °C | ||||

| As Is | d.b. | As Is | d.b. | As Is | d.b. | |

| Moisture (g/100 g) | 6.29 a | - | 5.68 b | - | 5.28 b | - |

| Protein (g/100 g) | 41.9 a | 44.7 a | 41.9 a | 44.5 a | 38.0 a | 40.1 a |

| Lipid (g/100 g) | 16.2 a | 17.3 a | 15.3 a | 16.2 a | 15.4 a | 16.2 a |

| Ash (g/100 g) | 2.80 a | 3.00 a | 3.09 a | 3.40 a | 3.07 a | 3.31 a |

| Total dietary fiber (g/100 g) | 26.1 a | 27.7 a | 25.4 a | 26.4 a | 25.0 a | 25.3 a |

| Carbohydrate (g/100 g) | 32.8 a | 35.0 a | 33.6 a | 35.6 a | 36.3 a | 38.3 a |

| TPC (mg Trolox/100 g) | 26.2 c | 27.9 c | 28.2 b | 29.9 b | 35.9 a | 37.8 a |

| Total bacteria count (CFU/g of sample) | 1.2 × 10 5a | - | 5.4 × 10 5a | - | 6.2 × 10 4b | - |

| Analyses | Okara Flour Addition | |||||

|---|---|---|---|---|---|---|

| 0% Flour | 5% Flour | 10% Flour | ||||

| As Is | d.b. | As Is | d.b. | As Is | d.b. | |

| Moisture (g/100 g) | 38.4 a | - | 39.0 a | - | 38.4 a | - |

| Protein (g/100 g) | 5.1 b | 8.3 b | 5.1 b | 8.3 b | 5.3 a | 8.5 a |

| Lipid (g/100 g) | 8.1 a | 13.0 a | 7.3 a | 12.0 b | 7.6 a | 12.4 b |

| Ash (g/100 g) | 1.09 a | 1.77 a | 1.05 a | 1.72 a | 1.06 a | 1.72 a |

| Total dietary fiber (g/100 g) | 1.99 b | 3.23 b | 2.36 b | 3.8 b | 4.63 a | 7.5 a |

| Carbohydrate (g/100 g) | 47.4 a | 76.9 a | 47.5 a | 77.9 a | 47.6 a | 77.3 a |

| TPC (mg Trolox/100 g) | 5.01 a | 8.1 a | 5.02 a | 8.2 a | 5.00 a | 8.1 a |

| Measurements | Parameters | Okara Flour Addition | ||

|---|---|---|---|---|

| 0% | 5% | 10% | ||

| Creep-recovery test of batter | (Pa−1 × 10−3) | 2.0 a | 1.3 b | 1.0 b |

| (Pa−1 × 10−3) | 1.6 a | 0.6 b | 0.7 b | |

| RCY (%) | 67.1 c | 71.1 b | 76.2 a | |

| (Pa−1 × 10−5) | 6.2 a | 2.1 b | 2.6 b | |

| (Pa−1 × 10−5) | 4.5 a | 1.8 b | 1.9 b | |

| (s) | 0.9 a | 0.9 a | 1.0 a | |

| (Pa−1 × 10−5) | 5.0 a | 2.1 b | 2.2 b | |

| (s) | 16.5 a | 16.4 a | 14.8 b | |

| (× 106) | 2.1 b | 2.9 b | 3.5 a | |

| (Pa−1 × 10−5) | 7.1 a | 2.4 b | 2.9 b | |

| (Pa−1 × 10−5) | 4.1 a | 1.6 b | 1.8 b | |

| (s) | 2.1 a | 1.5 b | 1.7 b | |

| (Pa−1 × 10−5) | 4.5 a | 1.8 b | 2.2 b | |

| (s) | 34.0 a | 31.8 b | 31.1 b | |

| Frequency sweep test of batter | (Pa × 103) | 2.2 c | 4.3 b | 4.6 a |

| G″ (Pa × 103) | 0.6 b | 1.2 a | 1.2 a | |

| Texture profile analysis of roll | Hardness (N) | 312.3 c | 445.2 b | 796.1 a |

| Springiness (m) | 2.4 a | 1.4 b | 1.1 c | |

| Cohesiveness | 0.7 a | 0.7 a | 0.6 b | |

| Gumminess (N) | 220.7 c | 305.1 b | 506.0 a | |

| Resilience | 0.4 a | 0.4 a | 0.4 a | |

| Baking performance | Volume (cm3) | 330.0 a | 315.0 b | 283.3 c |

| SV (cm3/g) | 3.0 a | 2.7 b | 2.4 c | |

| YL (%) | 14.1 a | 11.8 b | 10.7 c | |

| Color of batter | L* | 81.4 a | 72.7 b | 75.9 b |

| a* | 3.0 b | 5.6 a | 5.5 a | |

| b* | 23.2 b | 33.9 a | 31.7 a | |

| Color of roll | L* | 77.8 a | 72.2 b | 69.4 b |

| a* | 1.8 b | 5.7 a | 6.6 a | |

| b* | 29.8 b | 36.6 a | 37.6 a | |

| Sensory evaluation | Appearance | 6.4 a | 6.5 a | 6.4 a |

| Taste | 7.1 a | 7.2 a | 7.2 a | |

| Texture | 7.5 a | 7.3 b | 7.2 b | |

| Overall quality | 6.9 a | 7.0 a | 7.0 a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tridtitanakiat, P.C.; Hernández-Estrada, Z.J.; Rayas-Duarte, P. Modeling the Influence of Okara Flour Supplementation from Time-Temperature Drying Treatment on the Quality of Gluten-Free Roll Produced from Rice Flour. Foods 2023, 12, 3421. https://doi.org/10.3390/foods12183421

Tridtitanakiat PC, Hernández-Estrada ZJ, Rayas-Duarte P. Modeling the Influence of Okara Flour Supplementation from Time-Temperature Drying Treatment on the Quality of Gluten-Free Roll Produced from Rice Flour. Foods. 2023; 12(18):3421. https://doi.org/10.3390/foods12183421

Chicago/Turabian StyleTridtitanakiat, Pavalee Chompoorat, Zorba J. Hernández-Estrada, and Patricia Rayas-Duarte. 2023. "Modeling the Influence of Okara Flour Supplementation from Time-Temperature Drying Treatment on the Quality of Gluten-Free Roll Produced from Rice Flour" Foods 12, no. 18: 3421. https://doi.org/10.3390/foods12183421

APA StyleTridtitanakiat, P. C., Hernández-Estrada, Z. J., & Rayas-Duarte, P. (2023). Modeling the Influence of Okara Flour Supplementation from Time-Temperature Drying Treatment on the Quality of Gluten-Free Roll Produced from Rice Flour. Foods, 12(18), 3421. https://doi.org/10.3390/foods12183421