Utilization of Spent Coffee Grounds as a Food By-Product to Produce Edible Films Based on κ-Carrageenan with Biodegradable and Active Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Extraction of the Oil from Spent Coffee Grounds

2.2. Emulsion Preparation

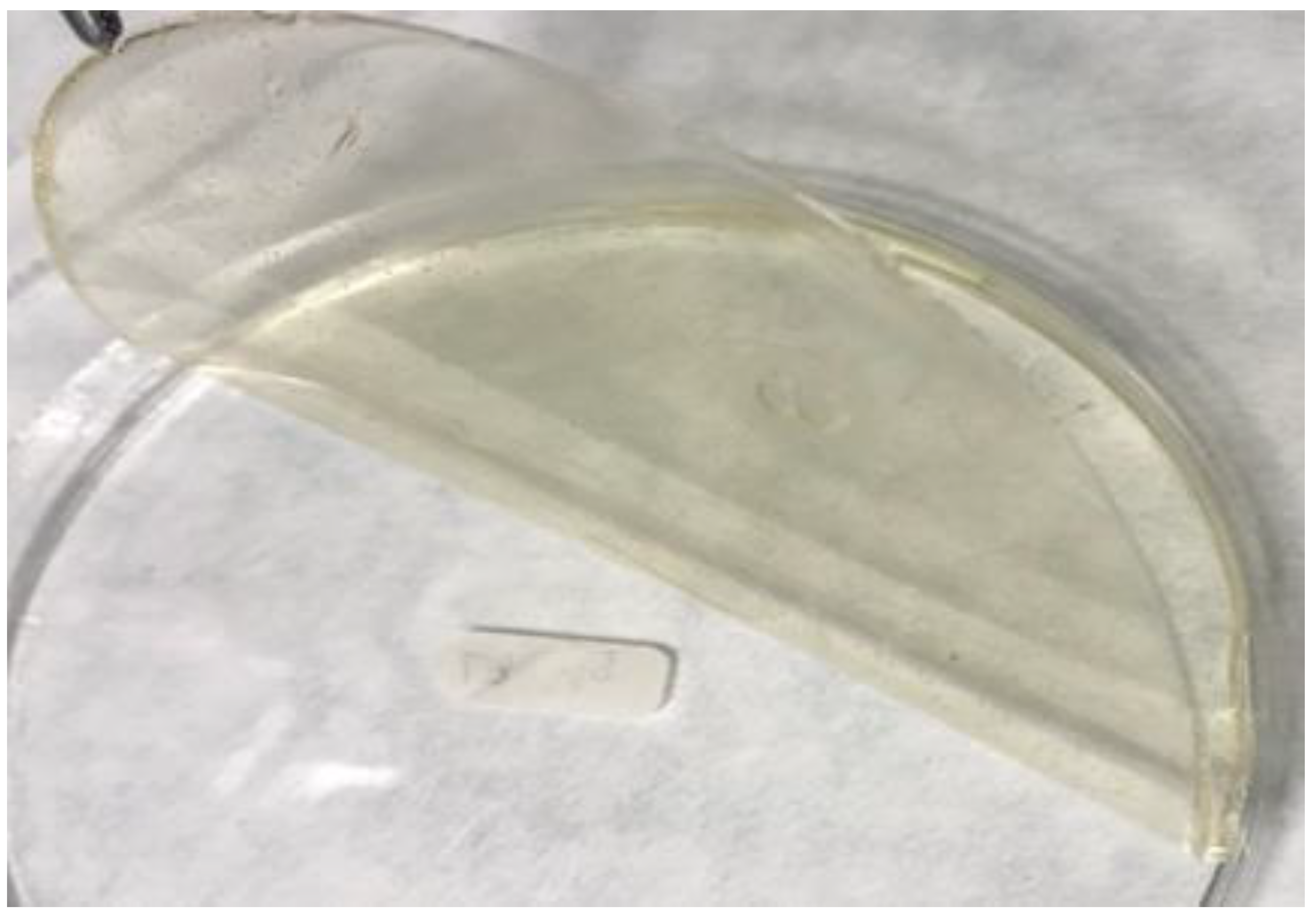

2.3. Edible/Biodegradable Package Preparation

2.4. Determination of Fat Content in Spent Coffee Grounds

2.5. Determination of Acid Value (AV) in Oil Extracted from Spent Coffee Grounds

2.6. Determination of Peroxide Value (PV) in Oil Extracted from Spent Coffee Grounds

2.7. Determination of Total Polyphenols

2.8. Determination of Antioxidant Capacity; FRAP (Ferric Reducing Antioxidant Power)

2.9. Determination of Antioxidant Capacity; ABTS (2,2′-Azinobis (3-ethylbenzothiazoline-6-sulfonic Acid))

2.10. Determination of Antioxidant Capacity; CUPRAC (Cupric Ion Reducing Antioxidant Capacity)

2.11. Determination of Malondialdehyde Content (MDA)

2.12. Textural Properties

2.13. Water Content, Solubility, and Swelling Degree

2.14. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Statista.Com. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 3 August 2023).

- World Economic Forum, Ellen MacArthur Foundation, and McKinsey and Company (2016). The New Plastics Economy-Rethinking the Future of Plastics. Available online: https://www.weforum.org/press/2016/01/more-plastic-than-fish-in-the-ocean-by-2050-report-offers-blueprint-for-change/ (accessed on 3 August 2023).

- OECD.Org. Available online: https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm (accessed on 3 August 2023).

- Santos, É.M.D.; Macedo, L.M.D.; Tundisi, L.L.; Ataide, J.A.; Camargo, G.A.; Alves, R.C.; Oliveira, M.B.P.P.; Mazzola, P.G. Coffee By-Products in Topical Formulations: A Review. Trends Food Sci. Technol. 2021, 111, 280–291. [Google Scholar] [CrossRef]

- Skorupa, A.; Worwąg, M.; Kowalczyk, M. Coffee Industry and Ways of Using By-Products as Bioadsorbents for Removal of Pollutants. Water 2022, 15, 112. [Google Scholar] [CrossRef]

- Oliveira, G.; Passos, C.P.; Ferreira, P.; Coimbra, M.A.; Gonçalves, I. Coffee By-Products and Their Suitability for Developing Active Food Packaging Materials. Foods 2021, 10, 683. [Google Scholar] [CrossRef] [PubMed]

- Klingel, T.; Kremer, J.I.; Gottstein, V.; Rajcic De Rezende, T.; Schwarz, S.; Lachenmeier, D.W. A Review of Coffee By-Products Including Leaf, Flower, Cherry, Husk, Silver Skin, and Spent Grounds as Novel Foods within the European Union. Foods 2020, 9, 665. [Google Scholar] [CrossRef] [PubMed]

- Statista.Com. Available online: https://www.statista.com/statistics/292595/global-coffee-consumption/ (accessed on 4 August 2023).

- Lee, K.-T.; Shih, Y.-T.; Rajendran, S.; Park, Y.-K.; Chen, W.-H. Spent Coffee Ground Torrefaction for Waste Remediation and Valorization. Environ. Pollut. 2023, 324, 121330. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Sun, X. Using Cow Dung and Spent Coffee Grounds to Enhance the Two-stage Co-Composting of Green Waste. Bioresour. Technol. 2017, 245, 152–161. [Google Scholar] [CrossRef] [PubMed]

- Forcina, A.; Petrillo, A.; Travaglioni, M.; Di Chiara, S.; De Felice, F. A Comparative Life Cycle Assessment of Different Spent Coffee Ground Reuse Strategies and a Sensitivity Analysis for Verifying the Environmental Convenience Based on the Location of Sites. J. Clean. Prod. 2023, 385, 135727. [Google Scholar] [CrossRef]

- Passos, C.P.; Rudnitskaya, A.; Neves, J.M.M.G.C.; Lopes, G.R.; Evtuguin, D.V.; Coimbra, M.A. Structural Features of Spent Coffee Grounds Water-Soluble Polysaccharides: Towards Tailor-Made Microwave Assisted Extractions. Carbohydr. Polym. 2019, 214, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Bomfim, A.S.C.D.; De Oliveira, D.M.; Walling, E.; Babin, A.; Hersant, G.; Vaneeckhaute, C.; Dumont, M.-J.; Rodrigue, D. Spent Coffee Grounds Characterization and Reuse in Composting and Soil Amendment. Waste 2022, 1, 2–20. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Hu, G.; Al-Romaima, A.; Liu, X.; Bai, X.; Li, J.; Li, Z.; Qiu, M. Effect of Green Coffee Oil as a Natural Active Emulsifying Agent on the Properties of Corn Starch-Based Films. LWT 2022, 170, 114087. [Google Scholar] [CrossRef]

- Davis, A.P.; Rakotonasolo, F. Six New Species of Coffee (Coffea) from Northern Madagascar. Kew Bull. 2021, 76, 497–511. [Google Scholar] [CrossRef]

- Bosmali, I.; Lagiotis, G.; Stavridou, E.; Haider, N.; Osathanunkul, M.; Pasentsis, K.; Madesis, P. Novel Authentication Approach for Coffee Beans and the Brewed Beverage Using a Nuclear-Based Species-Specific Marker Coupled with High Resolution Melting Analysis. LWT 2021, 137, 110336. [Google Scholar] [CrossRef]

- Wagemaker, T.A.L.; Carvalho, C.R.L.; Maia, N.B.; Baggio, S.R.; Guerreiro Filho, O. Sun Protection Factor, Content and Composition of Lipid Fraction of Green Coffee Beans. Ind. Crops Prod. 2011, 33, 469–473. [Google Scholar] [CrossRef]

- Piotr Konieczka, P.; Aliaño-González, M.J.; Ferreiro-González, M.; Barbero, G.F.; Palma, M. Characterization of Arabica and Robusta Coffees by Ion Mobility Sum Spectrum. Sensors 2020, 20, 3123. [Google Scholar] [CrossRef]

- D’Amelio, N.; De Angelis, E.; Navarini, L.; Schievano, E.; Mammi, S. Green Coffee Oil Analysis by High-Resolution Nuclear Magnetic Resonance Spectroscopy. Talanta 2013, 110, 118–127. [Google Scholar] [CrossRef]

- Lin, Y.-T.; We, Y.-L.; Kao, Y.-M.; Tseng, S.-H.; Wang, D.-Y.; Chen, S.-Y. Authentication of Coffee Blends by 16-O-Methylcafestol Quantification Using NMR Spectroscopy. Processes 2023, 11, 871. [Google Scholar] [CrossRef]

- FDA.Gov. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=172.620/ (accessed on 14 August 2023).

- Tomadoni, B.; Cassani, L.; Ponce, A.; Moreira, M.R.; Agüero, M.V. Optimization of Ultrasound, Vanillin and Pomegranate Extract Treatment for Shelf-Stable Unpasteurized Strawberry Juice. LWT—Food Sci. Technol. 2016, 72, 475–484. [Google Scholar] [CrossRef]

- Behbahani, B.A.; Shahidi, F.; Yazdi, F.T.; Mortazavi, S.A.; Mohebbi, M. Use of Plantago Major Seed Mucilage as a Novel Edible Coating Incorporated with Anethum Graveolens Essential Oil on Shelf Life Extension of Beef in Refrigerated Storage. Int. J. Biol. Macromol. 2017, 94, 515–526. [Google Scholar] [CrossRef]

- Thaipong, K.; Boonprakob, U.; Crosby, K.; Cisneros-Zevallos, L.; Hawkins Byrne, D. Comparison of ABTS, DPPH, FRAP, and ORAC Assays for Estimating Antioxidant Activity from Guava Fruit Extracts. J. Food Compos. Anal. 2006, 19, 669–675. [Google Scholar] [CrossRef]

- Apak, R.; Güçlü, K.; Demirata, B.; Özyürek, M.; Çelik, S.; Bektaşoğlu, B.; Berker, K.; Özyurt, D. Comparative Evaluation of Various Total Antioxidant Capacity Assays Applied to Phenolic Compounds with the CUPRAC Assay. Molecules 2007, 12, 1496–1547. [Google Scholar] [CrossRef] [PubMed]

- Khalifa, I.; Barakat, H.; El-Mansy, H.A.; Soliman, S.A. Improving the Shelf-Life Stability of Apple and Strawberry Fruits Applying Chitosan-Incorporated Olive Oil Processing Residues Coating. Food Packag. Shelf Life 2016, 9, 10–19. [Google Scholar] [CrossRef]

- Symoniuk, E.; Ratusz, K.; Krygier, K. Evaluation of the Oxidative Stability of Cold-Pressed Rapeseed Oil by Rancimat and Pressure Differential Scanning Calorimetry Measurements. Eur. J. Lipid Sci. Technol. 2019, 121, 1800017. [Google Scholar] [CrossRef]

- Merillon, J.M. Bioactive Molecules in Food; Springer Berlin Heidelberg: New York, NY, USA, 2019; ISBN 978-3-319-78029-0. [Google Scholar]

- Issaoui, M.; Delgado, A.M. Grading, Labeling and Standardization of Edible Oils. In Fruit Oils: Chemistry and Functionality; Ramadan, M.F., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 9–52. ISBN 978-3-030-12472-4. [Google Scholar]

- Panpraneecharoen, S. Optimization of the Oil Extraction, Study the Chemical and Physical Properties of Arabica Spent Coffee Grounds. Sci. Technol. Asia 2020, 25, 1219. [Google Scholar] [CrossRef]

- Bijla, L.; Aissa, R.; Bouzid, H.A.; Sakar, E.H.; Ibourki, M.; Gharby, S. Spent Coffee Ground Oil as a Potential Alternative for Vegetable Oil Production: Evidence from Oil Content, Lipid Profiling, and Physicochemical Characterization. Biointerface Res. Appl. Chem. 2021, 12, 6308–6320. [Google Scholar] [CrossRef]

- Kusnandar, F. Prediction of Acid, Peroxide and TBA values of Heat-Treated Palm Oil Using a Partial Least Squares–Ordinary Least Squares Model Based on Fouriertransform Infrared Spectroscopy. J. Oil Palm Res. 2020, 33, 514–523. [Google Scholar] [CrossRef]

- Prakoso, F.A.H.; Indiarto, R.; Utama, G.L. Edible Film Casting Techniques and Materials and Their Utilization for Meat-Based Product Packaging. Polymers 2023, 15, 2800. [Google Scholar] [CrossRef]

- Douny, C.; Tihon, A.; Bayonnet, P.; Brose, F.; Degand, G.; Rozet, E.; Milet, J.; Ribonnet, L.; Lambin, L.; Larondelle, Y.; et al. Validation of the Analytical Procedure for the Determination of Malondialdehyde and Three Other Aldehydes in Vegetable Oil Using Liquid Chromatography Coupled to Tandem Mass Spectrometry (LC-MS/MS) and Application to Linseed Oil. Food Anal. Methods 2015, 8, 1425–1435. [Google Scholar] [CrossRef]

- Ma, L.; Liu, G. Simultaneous Analysis of Malondialdehyde, 4-Hydroxy-2-Hexenal, and 4-Hydroxy-2-Nonenal in Vegetable Oil by Reversed-Phase High-Performance Liquid Chromatography. J. Agric. Food Chem. 2017, 65, 11320–11328. [Google Scholar] [CrossRef]

- Custodio-Mendoza, J.A.; Valente, I.M.; Ramos, R.M.; Lorenzo, R.A.; Carro, A.M.; Rodrigues, J.A. Analysis of Free Malondialdehyde in Edible Oils Using Gas-Diffusion Microextraction. J. Food Compos. Anal. 2019, 82, 103254. [Google Scholar] [CrossRef]

- Papastergiadis, A.; Fatouh, A.; Jacxsens, L.; Lachat, C.; Shrestha, K.; Daelman, J.; Kolsteren, P.; Van Langenhove, H.; De Meulenaer, B. Exposure Assessment of Malondialdehyde, 4-Hydroxy-2-(E)-Nonenal and 4-Hydroxy-2-(E)-Hexenal through Specific Foods Available in Belgium. Food Chem. Toxicol. 2014, 73, 51–58. [Google Scholar] [CrossRef] [PubMed]

- Cong, S.; Dong, W.; Zhao, J.; Hu, R.; Long, Y.; Chi, X. Characterization of the Lipid Oxidation Process of Robusta Green Coffee Beans and Shelf Life Prediction during Accelerated Storage. Molecules 2020, 25, 1157. [Google Scholar] [CrossRef] [PubMed]

- Viau, M.; Genot, C.; Ribourg, L.; Meynier, A. Amounts of the reactive aldehydes, malonaldehyde, 4-hydroxy-2-hexenal, and 4-hydroxy-2-nonenal in fresh and oxidized edible oils do not necessary reflect their peroxide and anisidine values. Eur. J. Lipid Sci. Tech. 2016, 118, 435–444. [Google Scholar] [CrossRef]

- Bouyanfif, A.; Liyanage, S.; Hequet, E.; Moustaid-Moussa, N.; Abidi, N. FTIR Microspectroscopy Reveals Fatty Acid-Induced Biochemical Changes in C. Elegans. Vib. Spectrosc. 2019, 102, 8–15. [Google Scholar] [CrossRef]

- Ma, L.; He, Q.; Qiu, Y.; Liu, H.; Wu, J.; Liu, G.; Brennan, C.; Brennan, M.A.; Zhu, L. Food Matrixes Play a Key Role in the Distribution of Contaminants of Lipid Origin: A Case Study of Malondialdehyde Formation in Vegetable Oils during Deep-Frying. Food Chem. 2021, 347, 129080. [Google Scholar] [CrossRef] [PubMed]

- Muangrat, R.; Pongsirikul, I. Recovery of Spent Coffee Grounds Oil Using Supercritical CO2: Extraction Optimisation and Physicochemical Properties of Oil. CyTA—J. Food 2019, 17, 334–346. [Google Scholar] [CrossRef]

- Obruca, S.; Petrik, S.; Benesova, P.; Svoboda, Z.; Eremka, L.; Marova, I. Utilization of Oil Extracted from Spent Coffee Grounds for Sustainable Production of Polyhydroxyalkanoates. Appl. Microbiol. Biotechnol. 2014, 98, 5883–5890. [Google Scholar] [CrossRef] [PubMed]

- Al-Hamamre, Z.; Foerster, S.; Hartmann, F.; Kröger, M.; Kaltschmitt, M. Oil Extracted from Spent Coffee Grounds as a Renewable Source for Fatty Acid Methyl Ester Manufacturing. Fuel 2012, 96, 70–76. [Google Scholar] [CrossRef]

- Lauberts, M.; Mierina, I.; Pals, M.; Latheef, M.A.A.; Shishkin, A. Spent Coffee Grounds Valorization in Biorefinery Context to Obtain Valuable Products Using Different Extraction Approaches and Solvents. Plants 2022, 12, 30. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Kitts, D.D. Confirmation That the Maillard Reaction Is the Principle Contributor to the Antioxidant Capacity of Coffee Brews. Food Res. Int. 2011, 44, 2418–2424. [Google Scholar] [CrossRef]

- Nicoli, M.C.; Anese, M.; Manzocco, L.; Lerici, C.R. Antioxidant Properties of Coffee Brews in Relation to the Roasting Degree. LWT—Food Sci. Technol. 1997, 30, 292–297. [Google Scholar] [CrossRef]

- Liao, Y.-C.; Kim, T.; Silva, J.L.; Hu, W.-Y.; Chen, B.-Y. Effects of Roasting Degrees on Phenolic Compounds and Antioxidant Activity in Coffee Beans from Different Geographic Origins. LWT 2022, 168, 113965. [Google Scholar] [CrossRef]

- Opitz, S.E.W.; Goodman, B.A.; Keller, M.; Smrke, S.; Wellinger, M.; Schenker, S.; Yeretzian, C. Understanding the Effects of Roasting on Antioxidant Components of Coffee Brews by Coupling On-Line ABTS Assay to High Performance Size Exclusion Chromatography: Analysis of Coffee Antioxidants Using ABTS-HPSEC On-Line Assay. Phytochem. Anal. 2017, 28, 106–114. [Google Scholar] [CrossRef]

- Andrade, C.; Perestrelo, R.; Câmara, J.S. Bioactive Compounds and Antioxidant Activity from Spent Coffee Grounds as a Powerful Approach for Its Valorization. Molecules 2022, 27, 7504. [Google Scholar] [CrossRef]

- Choi, B.; Koh, E. Spent Coffee as a Rich Source of Antioxidative Compounds. Food Sci. Biotechnol. 2017, 26, 921–927. [Google Scholar] [CrossRef]

- Sharma, A.; Ray, A.; Singhal, R.S. A Biorefinery Approach towards Valorization of Spent Coffee Ground: Extraction of the Oil by Supercritical Carbon Dioxide and Utilizing the Defatted Spent in Formulating Functional Cookies. Future Foods 2021, 4, 100090. [Google Scholar] [CrossRef]

- Dordevic, D.; Kushkevych, I.; Jancikova, S.; Zeljkovic, S.C.; Zdarsky, M.; Hodulova, L. Modeling the Effect of Heat Treatment on Fatty Acid Composition in Home-Made Olive Oil Preparations. Open Life Sci. 2020, 15, 606–618. [Google Scholar] [CrossRef]

- Dordevic, D.; Dordevic, S.; Ćavar-Zeljković, S.; Kulawik, P.; Kushkevych, I.; Tremlová, B.; Kalová, V. Monitoring the Quality of Fortified Cold-Pressed Rapeseed Oil in Different Storage Conditions. Eur. Food Res. Technol. 2022, 248, 2695–2705. [Google Scholar] [CrossRef]

- Song, J.L.; Asare, T.S.; Kang, M.Y.; Lee, S.C. Changes in Bioactive Compounds and Antioxidant Capacity of Coffee under Different Roasting Conditions. Korean J. Plant Resour. 2018, 31, 704–713. [Google Scholar] [CrossRef]

- Alonso-Salces, R.M.; Serra, F.; Reniero, F.; HÉberger, K. Botanical and Geographical Characterization of Green Coffee (Coffea Arabica and Coffea Canephora): Chemometric Evaluation of Phenolic and Methylxanthine Contents. J. Agric. Food Chem. 2009, 57, 4224–4235. [Google Scholar] [CrossRef]

- Mannino, G.; Kunz, R.; Maffei, M.E. Discrimination of Green Coffee (Coffea Arabica and Coffea Canephora) of Different Geographical Origin Based on Antioxidant Activity, High-Throughput Metabolomics, and DNA RFLP Fingerprinting. Antioxidants 2023, 12, 1135. [Google Scholar] [CrossRef]

- Dias, R.; Benassi, M. Discrimination between Arabica and Robusta Coffees Using Hydrosoluble Compounds: Is the Efficiency of the Parameters Dependent on the Roast Degree? Beverages 2015, 1, 127–139. [Google Scholar] [CrossRef]

- Rocha De Souza, M.C.; Marques, C.T.; Guerra Dore, C.M.; Ferreira Da Silva, F.R.; Oliveira Rocha, H.A.; Leite, E.L. Antioxidant Activities of Sulfated Polysaccharides from Brown and Red Seaweeds. J. Appl. Phycol. 2007, 19, 153–160. [Google Scholar] [CrossRef]

- Lombo Vidal, O.; Tsukui, A.; Garrett, R.; Miguez Rocha-Leão, M.H.; Piler Carvalho, C.W.; Pereira Freitas, S.; Moraes De Rezende, C.; Simões Larraz Ferreira, M. Production of Bioactive Films of Carboxymethyl Cellulose Enriched with Green Coffee Oil and Its Residues. Int. J. Biol. Macromol. 2020, 146, 730–738. [Google Scholar] [CrossRef]

- Dordevic, D.; Dordevic, S.; Abdullah, F.A.A.; Mader, T.; Medimorec, N.; Tremlova, B.; Kushkevych, I. Edible/Biodegradable Packaging with the Addition of Spent Coffee Grounds Oil. Foods 2023, 12, 2626. [Google Scholar] [CrossRef]

- Balasubramanian, R.; Kim, S.S.; Lee, J. Novel Synergistic Transparent K-Carrageenan/Xanthan Gum/Gellan Gum Hydrogel Film: Mechanical, Thermal and Water Barrier Properties. Int. J. Biol. Macromol. 2018, 118, 561–568. [Google Scholar] [CrossRef]

- Balaban, P.; Puška, A. Influence of Packaging Process on Mechanical Characteristics of the Flexible Packaging Materials. Adeletters 2022, 1, 65–70. [Google Scholar] [CrossRef]

- Kong, I.; Degraeve, P.; Pui, L.P. Polysaccharide-Based Edible Films Incorporated with Essential Oil Nanoemulsions: Physico-Chemical, Mechanical Properties and Its Application in Food Preservation—A Review. Foods 2022, 11, 555. [Google Scholar] [CrossRef]

- Shah, Y.A.; Bhatia, S.; Al-Harrasi, A.; Afzaal, M.; Saeed, F.; Anwer, M.K.; Khan, M.R.; Jawad, M.; Akram, N.; Faisal, Z. Mechanical Properties of Protein-Based Food Packaging Materials. Polymers 2023, 15, 1724. [Google Scholar] [CrossRef]

- Holm, V.K.; Ndoni, S.; Risbo, J. The Stability of Poly(Lactic Acid) Packaging Films as Influenced by Humidity and Temperature. J. Food Sci. 2006, 71, E40–E44. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Sharma, L.; Kaur, M.; Kaur, R. Physical, Structural and Thermal Properties of Composite Edible Films Prepared from Pearl Millet Starch and Carrageenan Gum: Process Optimization Using Response Surface Methodology. Int. J. Biol. Macromol. 2020, 143, 704–713. [Google Scholar] [CrossRef]

- Bomfim, A.; Oliveira, D.; Voorwald, H.; Benini, K.; Dumont, M.-J.; Rodrigue, D. Valorization of Spent Coffee Grounds as Precursors for Biopolymers and Composite Production. Polymers 2022, 14, 437. [Google Scholar] [CrossRef]

- Yan, J.; Yu, H.; Yang, Z.; Li, L.; Qin, Y.; Chen, H. Development of Smart Films of a Chitosan Base and Robusta Coffee Peel Extract for Monitoring the Fermentation Process of Pickles. Foods 2023, 12, 2337. [Google Scholar] [CrossRef]

- Tarique, J.; Sapuan, S.M.; Khalina, A. Effect of Glycerol Plasticizer Loading on the Physical, Mechanical, Thermal, and Barrier Properties of Arrowroot (Maranta Arundinacea) Starch Biopolymers. Sci. Rep. 2021, 11, 13900. [Google Scholar] [CrossRef]

- Farhan, A.; Hani, N.M. Characterization of Edible Packaging Films Based on Semi-Refined Kappa-Carrageenan Plasticized with Glycerol and Sorbitol. Food Hydrocoll. 2017, 64, 48–58. [Google Scholar] [CrossRef]

- Martiny, T.R.; Pacheco, B.S.; Pereira, C.M.P.; Mansilla, A.; Astorga–España, M.S.; Dotto, G.L.; Moraes, C.C.; Rosa, G.S. A Novel Biodegradable Film Based on Κ-carrageenan Activated with Olive Leaves Extract. Food Sci. Nutr. 2020, 8, 3147–3156. [Google Scholar] [CrossRef]

- Apriliyani, M.W.; Purwadi, P.; Manab, A.; Apriliyanti, M.W.; Ikhwan, A.D. Characteristics of Moisture Content, Swelling, Opacity and Transparency with Addition Chitosan as Edible Films/Coating Base on Casein. Adv. J. Food Sci. Technol. 2020, 18, 9–14. [Google Scholar] [CrossRef]

- Abdillah, A.A.; Charles, A.L. Characterization of a Natural Biodegradable Edible Film Obtained from Arrowroot Starch and Iota-Carrageenan and Application in Food Packaging. Int. J. Biol. Macromol. 2021, 191, 618–626. [Google Scholar] [CrossRef]

- Travalini, A.P.; Lamsal, B.; Magalhães, W.L.E.; Demiate, I.M. Cassava Starch Films Reinforced with Lignocellulose Nanofibers from Cassava Bagasse. Int. J. Biol. Macromol. 2019, 139, 1151–1161. [Google Scholar] [CrossRef]

- Nguyen, B.T.; Nicolai, T.; Benyahia, L.; Chassenieux, C. Synergistic Effects of Mixed Salt on the Gelation of κ-Carrageenan. Carbohydr. Polym. 2014, 112, 10–15. [Google Scholar] [CrossRef] [PubMed]

- Thakur, R.; Pristijono, P.; Golding, J.B.; Stathopoulos, C.E.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Amylose-Lipid Complex as a Measure of Variations in Physical, Mechanical and Barrier Attributes of Rice Starch- ι -Carrageenan Biodegradable Edible Film. Food Packag. Shelf Life 2017, 14, 108–115. [Google Scholar] [CrossRef]

- Silva, M.A.D.; Bierhalz, A.C.K.; Kieckbusch, T.G. Alginate and Pectin Composite Films Crosslinked with Ca2+ Ions: Effect of the Plasticizer Concentration. Carbohydr. Polym. 2009, 77, 736–742. [Google Scholar] [CrossRef]

- Wahyuni, S.; Holilah; Asranudin; Rianse, M.I.K.; Sadimantara, M.S. Effect of κ-Carrageenan Concentration on Physical and Mechanical Properties of Vegetable Leather Based on Kelor Leaves (Moringa Oleifera L.). IOP Conf. Ser. Earth Environ. Sci. 2019, 260, 012180. [Google Scholar] [CrossRef]

| Sample ID | Coffee Emulsion Addition (g) | Ingredients |

|---|---|---|

| CC | 0 | Carrageenan + glycerol +Tween 80 + dH2O |

| CC01 | 0.1 | Carrageenan + coffee emulsion + glycerol + Tween 80 + dH2O |

| CC045 | 0.45 | Carrageenan + coffee emulsion + glycerol + Tween 80 + dH2O |

| CC08 | 0.8 | Carrageenan + coffee emulsion + glycerol + Tween 80 + dH2O |

| CC1 | 1 | Carrageenan + coffee emulsion + glycerol + Tween 80 + dH2O |

| Analysis | 100% ACO | 50/50 ACO/RCO |

|---|---|---|

| Peroxide value (meqO2/kg) | 5.01 ± 0.78 | 4.11 ± 0.48 |

| Malondialdehyde (µg/g) | 0.73 ± 0.1 b | 0.50 ± 0.02 a |

| Acid value (mg KOH/g) | 7.31 ± 1.00 | 9.09 ± 0.39 |

| FRAP (Trolox µmol/g) | 118.27 ± 7.39 b | 128.71 ± 5.70 a |

| ABTS (%) | 7.45 ± 0.34 b | 10.84 ± 0.49 a |

| CUPRAC (Trolox µmol/g) | 117.22 ± 5.07 | N/A |

| Total polyphenols (mg gallic acid/g) | 14.87 ± 0.06 | 13.96 ± 2.03 |

| Sample ID | FRAP (Trolox µmol/g) | ABTS (%) | CUPRAC (Trolox µmol/g) | Total Polyphenols (mg gallic acid/g) | Malondialdehyde (µg/g) |

|---|---|---|---|---|---|

| CC | 3.09 ± 0.39 | 4.52 ± 1.00 | 4.71 ± 0.72 a | 0.11 ± 0.02 a | 0.58 ± 0.14 a |

| CC01 | 2.79 ± 0.09 a | 3.94 ± 0.19 | 11.77 ± 4.38 | 3.25 ± 0.09 b | 6.81 ± 0.21 c |

| CC045 | 3.37 ± 0.23 b | 4.37 ± 0.77 | 15.38 ± 0.83 b | 3.11 ± 0.03 b | 7.04 ± 0.79d c |

| CC08 | 3.33 ± 0.21 b | 4.33 ± 0 | 22.04 ± 0.77 c | 3.85 ± 0.13 c | 23.85 ± 2.72 b |

| CC1 | 3.21 ± 0.15 b | 4.37 ± 0.01 | 23.90 ± 1.23 dc | 3.41 ± 0.17 b | 19.53 ± 0.30 b |

| Sample ID | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|

| CC | 0.121 ± 0.023 | 77.03 ± 13.264 |

| CC01 | 0.074 ± 0.013 | 84.314 ± 4.155 |

| CC045 | 0.063 ± 0.01 | 90.336 ± 2.235 |

| CC08 | 0.071 ± 0.007 | 90.336 ± 2.235 |

| CC1 | 0.074 ± 0.026 | 84.880 ± 1.321 |

| Sample ID | Solubility in dH2O (%) | Solubility in Seawater (%) | Swelling Degree in Seawater (100%) | Water Content– dH2O |

|---|---|---|---|---|

| CC | 100 | 45.95 ± 27.67 | 383.88 ± 32.77 | 29.79 ± 1.34 a |

| CC01 | 100 | 100 | - | 11.04 ± 3.57 bc |

| CC045 | 100 | 100 | - | 7.98 ± 0.19 c |

| CC08 | 100 | 100 | - | 6.01 ± 1.69 bc |

| CC1 | 100 | 100 | - | 6.72 ± 0.32 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dordevic, D.; Gablo, N.; Zelenkova, L.; Dordevic, S.; Tremlova, B. Utilization of Spent Coffee Grounds as a Food By-Product to Produce Edible Films Based on κ-Carrageenan with Biodegradable and Active Properties. Foods 2024, 13, 1833. https://doi.org/10.3390/foods13121833

Dordevic D, Gablo N, Zelenkova L, Dordevic S, Tremlova B. Utilization of Spent Coffee Grounds as a Food By-Product to Produce Edible Films Based on κ-Carrageenan with Biodegradable and Active Properties. Foods. 2024; 13(12):1833. https://doi.org/10.3390/foods13121833

Chicago/Turabian StyleDordevic, Dani, Natalia Gablo, Lenka Zelenkova, Simona Dordevic, and Bohuslava Tremlova. 2024. "Utilization of Spent Coffee Grounds as a Food By-Product to Produce Edible Films Based on κ-Carrageenan with Biodegradable and Active Properties" Foods 13, no. 12: 1833. https://doi.org/10.3390/foods13121833