Effectiveness of Chemical Sanitizers against Salmonella Typhimurium in Nutrient Film Technique (NFT) Hydroponic Systems: Implications for Food Safety, Crop Quality, and Nutrient Content in Leafy Greens

Abstract

1. Introduction

2. Materials and Methods

2.1. Effectiveness of Chemical Sanitizers against Salmonella Typhimurium on NFT Surfaces

2.1.1. Experimental Design and Hydroponic Surfaces

2.1.2. Bacterial Strain and Inoculation of Surfaces

2.1.3. Sanitizer Application, Sample Processing, and Bacterial Enumeration

2.2. Impact of Chemical Sanitizers on Yield and Nutritional Attributes of Lettuce and Basil Grown in NFT Hydroponic System

2.2.1. Experimental Design and Crop Production

2.2.2. Treatment of Nutrient Solution with Sanitizers and Measurement of Fresh Edible Weight (Marketable Yield) and Leaf and Root Color

2.2.3. Impact of Chemical Sanitizers on Nutritional Content (Chlorophyll and Carotenoid) of Lettuce and Basil

2.3. Statistical Analysis

3. Results

3.1. Effectiveness of Chemical Sanitizers on Eliminating Salmonella Typhimurium from Inanimate NFT Surfaces

3.2. Effect of Chemical Sanitizers on Yield, Quality, and Nutritional Value of Lettuce and Basil Grown in NFT Hydroponic Systems

3.2.1. Sanitizer Residues

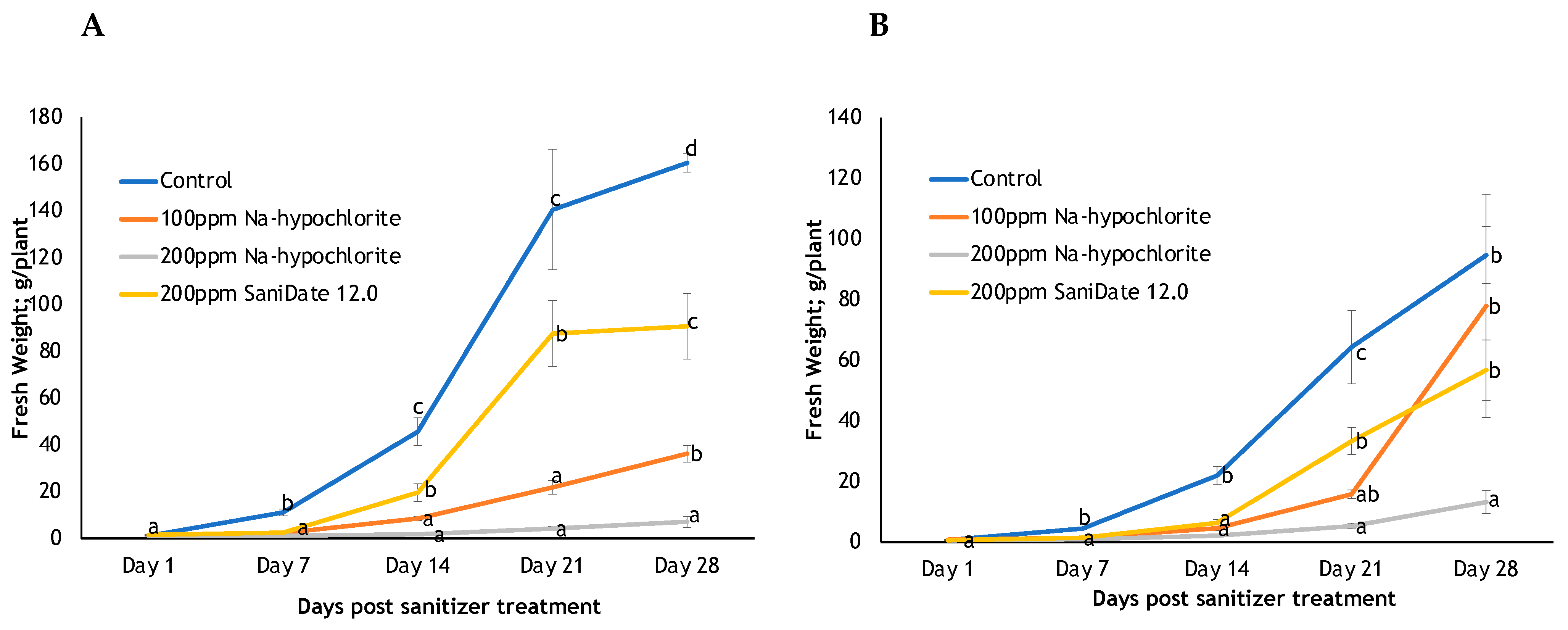

3.2.2. Quality and Yield

3.2.3. Nutritional Value

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Five Keys to Growing Safer Fruits and Vegetables: Promoting Health by Decreasing Microbial Contamination; WHO: Geneva, Switzerland, 2012; Available online: https://www.who.int/publications/i/item/9789241504003 (accessed on 2 September 2023).

- World Health Organization. Prevention and Control of Microbiological Hazards in Fresh Fruits and Vegetables—Part 4: Specific Commodities; FAO: Rome, Italy; WHO: Geneva, Switzerland, 2023. [Google Scholar] [CrossRef]

- Painter, J.A.; Hoekstra, R.M.; Ayers, T.; Tauxe, R.V.; Braden, C.R.; Angulo, F.J.; Griffin, P.M. Attribution of Foodborne Illnesses, Hospitalizations, and Deaths to Food Commodities by Using Outbreak Data, United States, 1998–2008. J. Emerg. Infect. Dis. 2013, 19, 407. [Google Scholar] [CrossRef]

- CDC. Multistate Outbreak of Salmonella Reading and Salmonella Abony Infections Linked to Alfalfa Sprouts|August 2016|Salmonella|CDC. Available online: https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://archive.cdc.gov/www_cdc_gov/salmonella/reading-08-16/index.html&ved=2ahUKEwiUmOfi4eWGAxUFrYkEHU3bDJcQFnoECBkQAQ&usg=AOvVaw2-H1wGBWsMpcbicOKVlBRZ (accessed on 15 March 2022).

- US Food and Drug Administration. Factors Potentially Contributing to the Contamination of Packaged Leafy Greens Implicated in the Outbreak of Salmonella Typhimurium During the Summer of 2021; US Food and Drug Administration: Silver Spring, MD, USA, 2022; 8p. [Google Scholar]

- Breuer, T.; Benkel, D.H.; Shapiro, R.L.; Hall, W.N.; Winnett, M.M.; Linn, M.J.; Neimann, J.; Barrett, T.J.; Dietrich, S.; Downes, F.P.; et al. A Multistate Outbreak of Escherichia coli O157:H7 Infections Linked to Alfalfa Sprouts Grown from Contaminated Seeds. J. Emerg. Infect. Dis. 2001, 7, 977–982. [Google Scholar] [CrossRef]

- Ilic, S.; LeJeune, J.; Lewis Ivey, M.L.; Miller, S. Delphi Expert Elicitation to Prioritize Food Safety Management Practices in Greenhouse Production of Tomatoes in the United States. Food Control 2017, 78, 108–115. [Google Scholar] [CrossRef]

- Aryal, M.; Muriana, P.M. Efficacy of Commercial Sanitizers Used in Food Processing Facilities for Inactivation of Listeria monocytogenes, E. coli O157:H7, and Salmonella Biofilms. Foods 2019, 8, 639. [Google Scholar] [CrossRef]

- Allende, A.; Selma, M.V.; López-Gálvez, F.; Villaescusa, R.; Gil, M.I. Role of Commercial Sanitizers and Washing Systems on Epiphytic Microorganisms and Sensory Quality of Fresh-Cut Escarole and Lettuce. Postharvest Biol. Technol. 2008, 49, 155–163. [Google Scholar] [CrossRef]

- Korany, A.M.; Hua, Z.; Green, T.; Hanrahan, I.; El-Shinawy, S.H.; El-kholy, A.; Hassan, G.; Zhu, M.-J. Efficacy of Ozonated Water, Chlorine, Chlorine Dioxide, Quaternary Ammonium Compounds and Peroxyacetic Acid against Listeria monocytogenes Biofilm on Polystyrene Surfaces. Front. Microbiol. 2018, 9, 2296. [Google Scholar] [CrossRef]

- Pahariya, P.; Fisher, D.J.; Choudhary, R. Comparative Analyses of Sanitizing Solutions on Microbial Reduction and Quality of Leafy Greens. LWT 2022, 154, 112696. [Google Scholar] [CrossRef]

- Shang, H.; Tan, B.Z.; Dakwa, V.; D’Agnese, E.; Stanley, R.A.; Sassi, H.; Lai, Y.-W.; Deaker, R.; Bowman, J.P. Effect of Pre-Harvest Sanitizer Treatments on Listeria Survival, Sensory Quality and Bacterial Community Dynamics on Leafy Green Vegetables Grown under Commercial Conditions. Food Res. Int. 2023, 173, 113341. [Google Scholar] [CrossRef]

- Dankwa, A.S.; Machado, R.M.; Perry, J.J. Sanitizer Efficacy in Reducing Microbial Load on Commercially Grown Hydroponic Lettuce. J. Sci. Food Agric. 2021, 101, 1403–1410. [Google Scholar] [CrossRef]

- Aramrueang, N.; Asavasanti, S.; Khanunthong, A.; Pan, Z.; Zhang, R.; Zicari, S. (Eds.) Chapter 10—Leafy Vegetables. In Integrated Processing Technologies for Food and Agricultural by-Products; Academic Press: Cambridge, MA, USA, 2019; pp. 245–272. [Google Scholar] [CrossRef]

- Mampholo, B.M.; Maboko, M.M.; Soundy, P.; Sivakumar, D. Phytochemicals and Overall Quality of Leafy Lettuce (Lactuca sativa L.) Varieties Grown in Closed Hydroponic System. J. Food Qual. 2016, 39, 805–815. [Google Scholar] [CrossRef]

- El-Nakhel, C.; Pannico, A.; Graziani, G.; Kyriacou, M.C.; Giordano, M.; Ritieni, A.; De Pascale, S.; Rouphael, Y. Variation in Macronutrient Content, Phytochemical Constitution and In Vitro Antioxidant Capacity of Green and Red Butterhead Lettuce Dictated by Different Developmental Stages of Harvest Maturity. Antioxidants 2020, 9, 300. [Google Scholar] [CrossRef]

- Martins, T.; Barros, A.N.; Rosa, E.; Antunes, L. Enhancing Health Benefits through Chlorophylls and Chlorophyll-Rich Agro-Food: A Comprehensive Review. Molecules 2023, 28, 5344. [Google Scholar] [CrossRef]

- Kim, M.J.; Moon, Y.; Tou, J.C.; Mou, B.; Waterland, N.L. Nutritional Value, Bioactive Compounds and Health Benefits of Lettuce (Lactuca sativa L.). J. Food Compos. Anal. 2016, 49, 19–34. [Google Scholar] [CrossRef]

- Voutilainen, S.; Nurmi, T.; Mursu, J.; Rissanen, T.H. Carotenoids and Cardiovascular Health. Am. J. Clin. Nutr. 2006, 83, 1265–1271. [Google Scholar] [CrossRef]

- Grune, T.; Lietz, G.; Palou, A.; Ross, A.C.; Stahl, W.; Tang, G.; Thurnham, D.; Yin, S.; Biesalski, H.K. β-Carotene Is an Important Vitamin A Source for Humans123. J. Nutr. 2010, 140, 2268S–2285S. [Google Scholar] [CrossRef]

- Copolovici, L.; Lupitu, A.; Moisa, C.; Taschina, M.; Copolovici, D.M. The Effect of Antagonist Abiotic Stress on Bioactive Compounds from Basil (Ocimum basilicum). Appl. Sci. 2021, 11, 9282. [Google Scholar] [CrossRef]

- Deblais, L.; Miller, S.A.; Rajashekara, G. Impact of Plant Pathogen Infection on Salmonella enterica Subsp. enterica Serotype Typhimurium Persistence in Tomato Plants. J. Food Prot. 2021, 84, 563–571. [Google Scholar] [CrossRef]

- Moodispaw, M.R. Establishing Science-Based Strategies for Prevention and Mitigation of Human Pathogens in Leafy Greens Grown in Nutrient Film Technique (NFT) Hydroponic Systems. 2022. Available online: http://rave.ohiolink.edu/etdc/view?acc_num=osu1650622577802721 (accessed on 16 September 2023).

- Gillespie, D.P.; Kubota, C.; Miller, S.A. Effects of Low pH of Hydroponic Nutrient Solution on Plant Growth, Nutrient Uptake, and Root Rot Disease Incidence of Basil (Ocimum basilicum L.). HortScience 2020, 55, 1251–1258. [Google Scholar] [CrossRef]

- Lichtenthaler, H.K. [34] Chlorophylls and Carotenoids: Pigments of Photosynthetic Biomembranes. In Methods in Enzymology; Plant Cell Membranes; Academic Press: Cambridge, MA, USA, 1987; Volume 148, pp. 350–382. [Google Scholar] [CrossRef]

- Nordstokke, D.W.; Zumbo, B.D. A New Nonparametric Levene Test for Equal Variances. Psicologica 2010, 32, 401–430. [Google Scholar]

- Dharmarha, V.; Boyer, R.R.; Strawn, L.K.; Drape, T.A.; Eifert, J.; Vallotton, A.D.; Pruden, A.; Ponder, M.A. An Assessment of Produce Growers’ Sanitizer Knowledge and Practices on the Correct Use of Sanitizers. Food Prot. Trend 2020, 40, 140–146. [Google Scholar]

- Tham, C.A.T.; Zwe, Y.H.; Ten, M.M.Z.; Ng, G.S.Y.; Toh, J.Y.L.; Poh, B.L.; Zhou, W.; Li, D. Microbial Analysis and Sanitization of Hydroponic Farming Facilities in Singapore. bioRxiv 2024. [Google Scholar] [CrossRef]

- Howard, R.; Harding, M.; Savidov, N.; Lisowski, S.; Burke, D.; Pugh, S. Identifying Effective Chemical Disinfectants for Use in Sanitizing Greenhouses. In Alberta Professional Horticultural Growers Congress and Foundation Society; Alberta Horticultural Association: Grande Prairie, AB, Canada, 2007. [Google Scholar]

- Juarez-Lopez, O.-C.; Lopez-Martinez, A.-T.; Mendoza-Tafolla, R.; Ronald, E.; Ontiveros-Capurata, R.E.; Juarez-Lopez, P.; Alia Tejacal, I.; Lopez-Martinez, V.; Ruiz Alvarez, O. Nitrogen and Chlorophyll Status in Romaine Lettuce Using Spectral Indices from RGB Digital Images. Zemdirb.-Agric. 2021, 108, 79–86. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Zhu, J.-K. Thriving under Stress: How Plants Balance Growth and the Stress Response. Dev. Cell 2020, 55, 529–543. [Google Scholar] [CrossRef]

- Du, L.; Yang, H.; Song, X.; Wei, N.; Yu, C.; Wang, W.; Zhao, Y. Estimating Leaf Area Index of Maize Using UAV-Based Digital Imagery and Machine Learning Methods. Sci. Rep. 2022, 12, 15937. [Google Scholar] [CrossRef]

- Qi, X.; Zhao, Y.; Huang, Y.; Wang, Y.; Qin, W.; Fu, W.; Guo, Y.; Ye, Y. A Novel Approach for Nitrogen Diagnosis of Wheat Canopies Digital Images by Mobile Phones Based on Histogram. Sci. Rep. 2021, 11, 13012. [Google Scholar] [CrossRef]

- Schifferstein, H.N.J.; Wehrle, T.; Carbon, C.-C. Consumer Expectations for Vegetables with Typical and Atypical Colors: The Case of Carrots. Food Qual. Prefer. 2019, 72, 98–108. [Google Scholar] [CrossRef]

- US EPA Office of Inspector General. EPA Needs to Assure Effectiveness of Antimicrobial Pesticide Products Report Number 11-P-0029. 2010. Available online: http://www.epaoig.gov/sites/default/files/2015-10/documents/20101215-11-p-0029.pdf (accessed on 7 March 2024).

| Sanitizer Type | Sanitizer Brand | Active Ingredient (%) | Treatment Concentrations | Contact Time (min) |

|---|---|---|---|---|

| Chlorine-based | Bleach | Sodium hypochlorite (6) | 100 ppm | 10 |

| Bleach | Sodium hypochlorite (6) | 200 ppm | 10 | |

| NatriChlor™ CD | Aqueous chlorine dioxide (0.3) | 10 ppm, | 10 | |

| NatriChlor™ CD | Aqueous chlorine dioxide (0.3) | 50 ppm | 10 | |

| PPA 1 | Zerotol™ | Hydrogen peroxide (27.1) and Peroxyacetic acid (2.0) | 5% | 10 |

| SaniDate™12.0 | Hydrogen peroxide (18.5) and Peroxyacetic acid (12.0) | 100 ppm | 5 | |

| SaniDate™ 12.0 | Hydrogen peroxide (18.5) and Peroxyacetic acid (12.0) | 200 ppm | 5 | |

| Quaternary Ammonia Compounds (QAC) 3 | KleenGrow™ | Didecyl dimethyl ammonium chloride (7.5) | 2% | 10 |

| Green Shield™ | Alkyl dimethyl benzyl ammonium chloride (10.0) and Alkyl dimethyl ethyl benzyl ammonium chloride (10) | 5% | 10 | |

| PPM 2,3 | Virkon™ | Potassium peroxymonosulfate (21.42) and Sodium chloride (1.50) | 1% | 10 |

| Nutrients | Concentration Extract (μg/mL) | Concentration Plant Tissue (μg/g Fresh Weight) |

|---|---|---|

| Chlorophyll a | 12.25 A663.2–2.79 A646.8 | Chl a extract × volume/g tissue |

| Chlorophyll b | 21.50 A646.8–5.1 A663.2 | Chl b extract × volume/g tissue |

| Chlorophyll a + b | 7.5 A663.2 + 18.71 A646.8 | Chl a + b extract × volume/g tissue |

| Carotenoid | 1000 A470–1.8 Chl a–85.02 Chl b/198 | Carotenoid extract × volume/g tissue |

| Sanitizer Group | Treatment | NFT Surfaces for Hydroponic Production of Leafy Greens | |||

|---|---|---|---|---|---|

| Reservoir | Top Cover | Growing Channel | Main Drain Line | ||

| Log Reduction (CFU/cm2 ± SE) (% Reduction) | Log Reduction (CFU/cm2 ± SE) (% Reduction) | Log Reduction (CFU/cm2 ± SE) (% Reduction) | Log Reduction (CFU/cm2 ± SE) (% Reduction) | ||

| Control | Water Treatment | 0.45 ± 0.19 b | 0.62 ± 0.10 b | 1.53 ± 0.27 b | 2.36 ± 0.60 b |

| (64.000) | (72.624) | (94.735) | (99.559) | ||

| Chlorine-based | Bleach 100 ppm | 0.68 ± 0.04 b | 1.83 ± 0.43 b | 0.68 ± 0.08 b | 0.86 ± 0.43 b |

| (78.562) | (95.187) | (78.749) | (69.342) | ||

| Bleach 200 ppm | 1.78 ± 0.32 ab | 3.21 ± 0.4 b | 3.42 ± 0.19 ab | 0.89 ± 0.07 b | |

| (93.810) | (99.823) | (99.931) | (86.041) | ||

| NatriChlor™ CD 10 ppm | 0.57 ± 0.07 b | 1.35 ± 0.23 b | 1.37 ± 0.51 b | 1.21 ± 0.21 b | |

| (70.781) | (91.739%) | (90.616%) | (90.979%) | ||

| NatriChlor™ CD 50 ppm | 0.67 ± 0.10 b | 4.14 ± 0.40 ab | 2.39 ± 0.29 b | 2.46 ± 0.06 b | |

| (73.500) | (99.907) | (98.763) | (99.643) | ||

| PPA | Zerotol™ 5% | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.21 ± 0.00 a |

| SaniDate™ 12.0 100 ppm | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | 4.49 ± 0.35 a | 4.24 ± 0.51 a | |

| (99.971) | (99.926) | ||||

| SaniDate™ 12.0 200 ppm | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.21 ± 0.00 a | |

| PPM | Virkon™ 1% | * 5.60 ± 0.00 a | 5.18 ± 0.00 a | 5.15 ± 0.00 a | * 5.21 ± 0.00 a |

| Quaternary ammonia | KleenGrow™ 2% | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.21 ± 0.00 a |

| Green Shield™ 5% | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.21 ± 0.00 a | |

| p-value | <0.001 | <0.001 | <0.001 | <0.001 | |

| Sanitizer Group | Treatment | NFT Surfaces for Hydroponic Production of Leafy Greens | |||

|---|---|---|---|---|---|

| Reservoir | Top Cover | Growing Channel | Main Drain Line | ||

| Log Reduction (CFU/cm2 ± SE) (% Reduction) | Log Reduction (CFU/cm2 ± SE) (% Reduction) | Log Reduction (CFU/cm2 ± SE) (% Reduction) | Log Reduction (CFU/cm2 ± SE) (% Reduction) | ||

| Control | Water Treatment | 4.49 ± 0.07 b | 4.28 ± 0.34 b | 3.68 ± 0.35 b | 4.90 ± 0.16 b |

| (99.997) | (99.990) | (99.951) | (99.997) | ||

| Chlorine-based | Bleach 100 ppm | 3.90 ± 1.18 b | 3.65 ± 0.61 b | 4.22 ± 0.54 bc | 4.98 ± 0.14 ab |

| (99.904) | (99.870) | (99.970) | (99.998) | ||

| Bleach 200 ppm | 4.61 ± 0.33 b | 4.67 ± 0.30 ab | ☩ 5.07 ± 0.08 ac | ☩ 5.20 ab | |

| (99.996) | (99.996) | (99.999) | (100.000) | ||

| NatriChlor™ CD 10 ppm | ☩ 5.08 ab | 3.90 ± 0.32 b | 4.17 ± 0.28 b | 4.87 ± 0.23 ab | |

| (99.999) | (99.977) | (99.986) | (99.998) | ||

| NatriChlor™ CD 50 ppm | ☩ 5.34 ± 0.26 ab | 4.13 ± 0.03 b | 4.83 ± 0.23 bc | * 5.11 ± 0.09 ab | |

| (99.999) | (99.991) | (99.997) | (99.999) | ||

| PPA | Zerotol™ 5% | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.20 ab |

| SaniDate™ 12.0 100 ppm | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | 5.03 ± 0.10 ab | |

| SaniDate™ 12.0 200 ppm | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.20 ± 0.00 a | |

| PPM | Virkon™ 1% | * 5.60 ± 0.00 a | 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.20 ± 0.00 a |

| Quaternary ammonia | KleenGrow™ 2% | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.20 ± 0.00 a |

| Green Shield™ 5% | * 5.60 ± 0.00 a | * 5.18 ± 0.00 a | * 5.15 ± 0.00 a | * 5.20 ± 0.00 a | |

| p-value | 0.039 | <0.001 | <0.001 | 0.097 | |

| Bleach | Day | Free Chlorine 1 (mg/L) | Total Chlorine 1 (mg/L) | ORP (mV) | Relative ORP (∆ORP) (mV) | Temperature of Nutrient Solution (°C) |

|---|---|---|---|---|---|---|

| 100 ppm | 1 | 7.49 ± 3.55 | 25.73 ± 11.87 | 872.33 ± 33.45 | 203.00 ± 33.5 | 22.64 ± 1.32 |

| 2 | 3.67 ± 0.68 | 9.90 ± 1.87 | 775.75 ± 55.78 | 113.50 ± 34.65 | 11.23 ± 2.24 | |

| 7 | 0.15 ± 0.29 | <1.0 | 417.93 ± 152.16 | 38.63 ± 39.68 | 22.53 ± 1.68 | |

| 14 | <0.10 | <1.0 | 448.20 ± 65.99 | 2 17 ± 6.63 | 23.86 ± 2.30 | |

| 200 ppm | ||||||

| 1 | >25 | 110.69 ± 31.09 | 857.67 ± 25.45 | 194.50 ± 30.97 | 23.35 ± 1.70 | |

| 2 | 18.63 ± 4.32 | 69.90 ± 9.84 | 830.25 ± 28.34 | 144.00 ± 36.77 | 19.78 ± 2.59 | |

| 7 | 6.71 ± 6.25 | 16.46 ± 13.40 | 788.79 ± 1.58 | 365.38 ± 134.59 | 23.89 ± 2.71 | |

| 14 | 0.81 ± 1.69 | 1.25 ± 1.81 | 534.10 ± 200.14 | 33.80 ± 71.69 | 23.78 ± 2.04 |

| R | G | B | HEX Code | ||

|---|---|---|---|---|---|

| Lettuce | Non-treated (control) | 139.33 ± 24.25 | 195.33 ± 12.19 | 52.33 ± 10.61 | #8BC334 |

| Bleach 100 ppm | 136.67 ± 11.17 | 190.17 ± 8.32 | 45.67 ± 3.95 | #BDE254 | |

| Bleach 200 ppm | 138.50 ± 16.46 | 189.83 ± 11.93 | 28.50 ± 12.88 | #8BBE1D | |

| SaniDate 12.0 200 ppm | 127.38 ± 6.76 | 192.88 ± 7.76 | 39.50 ± 8.73 | #7FC128 | |

| Basil | Non-treated (control) | 114.17 ± 13.10 | 177.50 ± 15.73 | 75.83 ± 12.24 | #72B24C |

| Bleach 100 ppm | 189.00 ± 17.69 | 226.33 ± 6.58 | 84.00 ± 6.82 | #BDE254 | |

| Bleach 200 pm | 173.67 ± 9.33 | 220.17 ± 8.93 | 69.33 ± 5.50 | #AEDC45 | |

| SaniDate 12.0 200 ppm | 135.88 ± 5.40 | 199.88 ± 5.35 | 86.38 ± 6.64 | #88C856 |

| Nutritional Value | |||||||

|---|---|---|---|---|---|---|---|

|

Chlorophyll (μg/g. FW) |

Carotenoid (μg/g. FW) | Total Chlorophyll: Carotenoid | |||||

| Total | “a” | “b” | “a:b” | ||||

| Lettuce | Non-treated | 2004.30 ± 104.27 A | 1206.05 ± 54.53 A | 453.64 ± 19.78 A | 2.66 ± 0.02 A | 321.29 ± 21.78 A | 6.27 ± 0.12 A |

| Bleach 100 ppm | 1100.79 ± 99.03 B | 673.96 ± 64.17 B | 250.45 ± 24.50 B | 2.70 ± 0.05 A | 232.11 ± 14.19 B | 4.72 ± 0.20 B | |

| Bleach 200 ppm | 730.75 ± 73.64 C | 430.72 ± 48.80 C | 147.07 ± 21.33 C | 3.01 ± 0.13 A | 116.82 ± 13.29 C | 4.36 ± 0.19 C | |

| SaniDate 12.0 200 ppm | 1650.95 ± 109.30 D | 1051.67 ± 61.33 A | 352.25 ± 24.12 D | 3.04 ± 0.21 A | 280.53 ± 14.35 A | 5.85 ± 0.12 C | |

| p-value | <0.001 | <0.001 | <0.001 | 0.076 | <0.001 | <0.001 | |

| Basil | Non-treated | 1105.11 ± 77.16 A | 661.35 ± 43.29 A | 235.40 ± 17.07 A | 2.82 ± 0.05 A | 235.73 ± 18.09 A | 4.71 ± 0.07 A |

| Bleach 100 ppm | 727.31 ± 29.47 B | 430.16 ± 18.34 B | 146.51 ± 8.14 A | 2.95 ± 0.06 A | 186.91 ± 6.51 A | 3.90 ± 0.12 A | |

| Bleach 200 ppm | 490.74 ± 22.11 B | 282.74 ± 18.08 B | 78.24 ± 7.06 A | 3.66 ± 0.11 B | 149.85 ± 3.09 A | 3.27 ± 0.12 A | |

| SaniDate 12.0 200 ppm | 1047.37 ± 162.36 A | 738.94 ± 159.95 A | 357.67 ± 191.02 A | 3.23 ± 0.35 AB | 110.89 ± 89.54 A | 3.44 ± 1.08 A | |

| p-value | 0.002 | 0.018 | 0.276 | 0.03 | 0.426 | 0.39 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mensah, A.A.; Lewis Ivey, M.L.; Moodispaw, M.R.; Ilic, S. Effectiveness of Chemical Sanitizers against Salmonella Typhimurium in Nutrient Film Technique (NFT) Hydroponic Systems: Implications for Food Safety, Crop Quality, and Nutrient Content in Leafy Greens. Foods 2024, 13, 1929. https://doi.org/10.3390/foods13121929

Mensah AA, Lewis Ivey ML, Moodispaw MR, Ilic S. Effectiveness of Chemical Sanitizers against Salmonella Typhimurium in Nutrient Film Technique (NFT) Hydroponic Systems: Implications for Food Safety, Crop Quality, and Nutrient Content in Leafy Greens. Foods. 2024; 13(12):1929. https://doi.org/10.3390/foods13121929

Chicago/Turabian StyleMensah, Abigail A., Melanie L. Lewis Ivey, Margaret R. Moodispaw, and Sanja Ilic. 2024. "Effectiveness of Chemical Sanitizers against Salmonella Typhimurium in Nutrient Film Technique (NFT) Hydroponic Systems: Implications for Food Safety, Crop Quality, and Nutrient Content in Leafy Greens" Foods 13, no. 12: 1929. https://doi.org/10.3390/foods13121929

APA StyleMensah, A. A., Lewis Ivey, M. L., Moodispaw, M. R., & Ilic, S. (2024). Effectiveness of Chemical Sanitizers against Salmonella Typhimurium in Nutrient Film Technique (NFT) Hydroponic Systems: Implications for Food Safety, Crop Quality, and Nutrient Content in Leafy Greens. Foods, 13(12), 1929. https://doi.org/10.3390/foods13121929