Yogurt Enriched with Chia Seeds: Physicochemical, Microbiological, and Sensory Changes during Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Methods

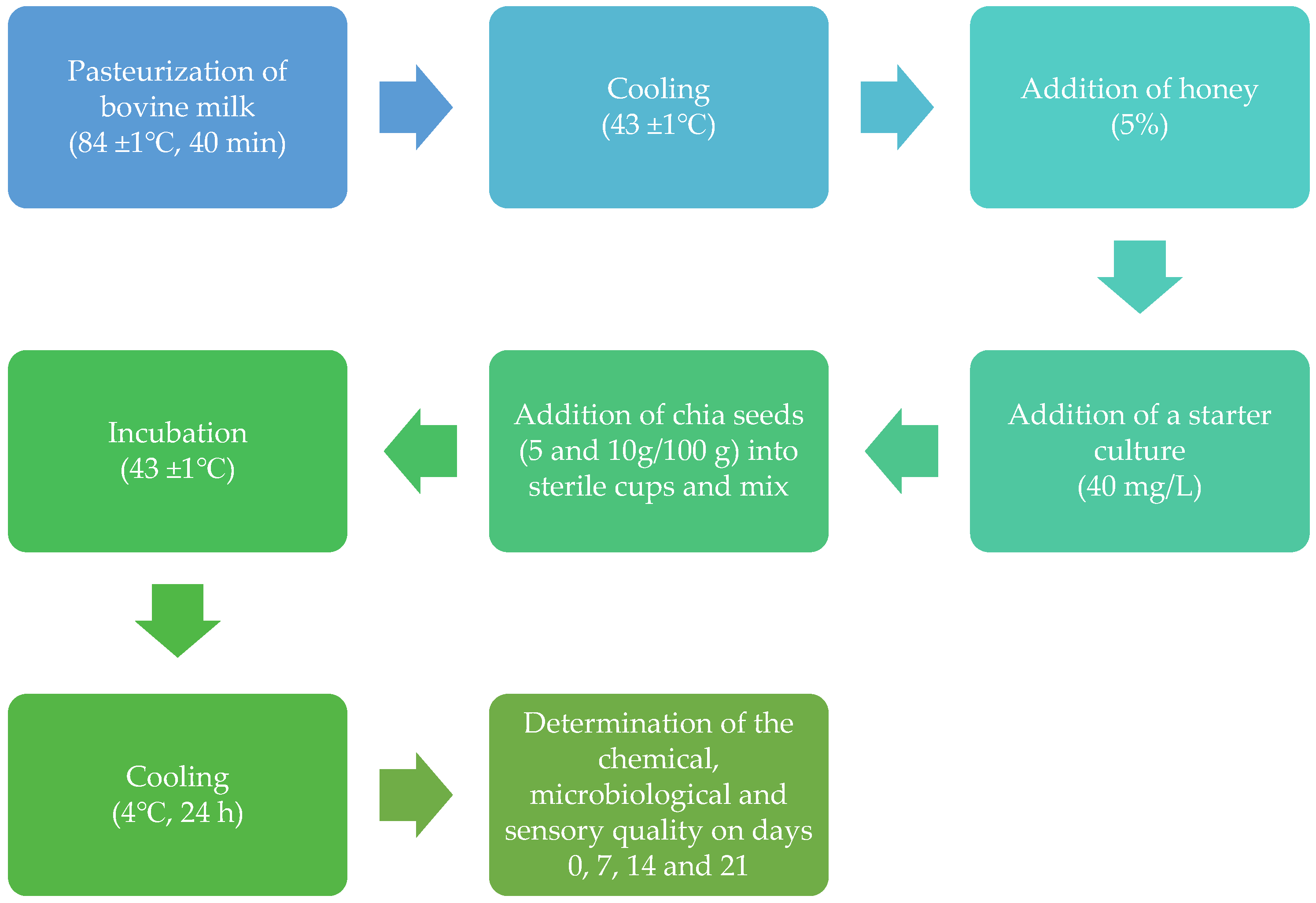

2.2.1. Production of Yogurt with Different Amounts of Chia Seeds

2.2.2. Microbiological Analysis

2.2.3. Changes in Chemical Properties during Storage

2.2.4. Sensory Analysis

2.2.5. Statistical Analysis

3. Results and Discussion

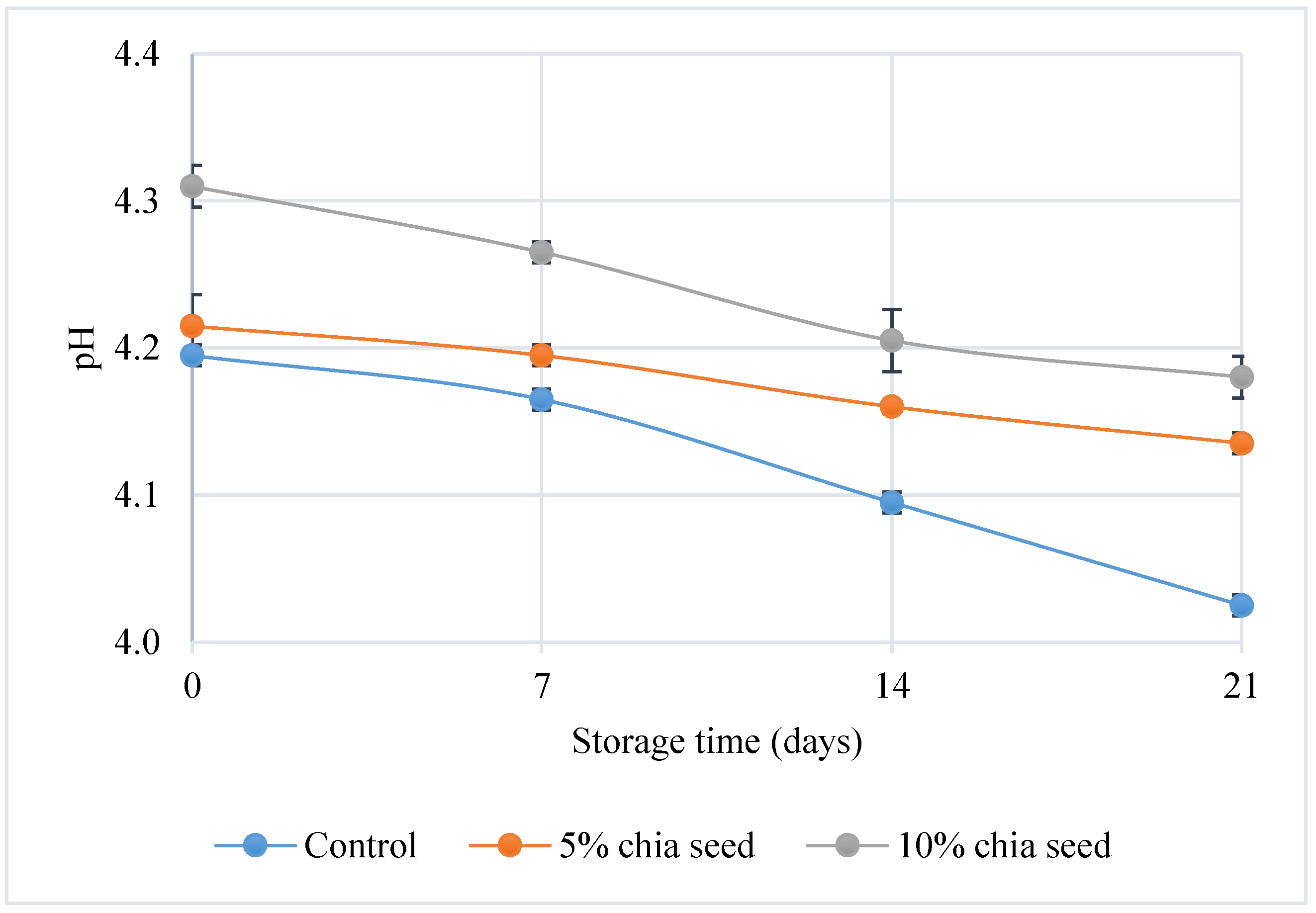

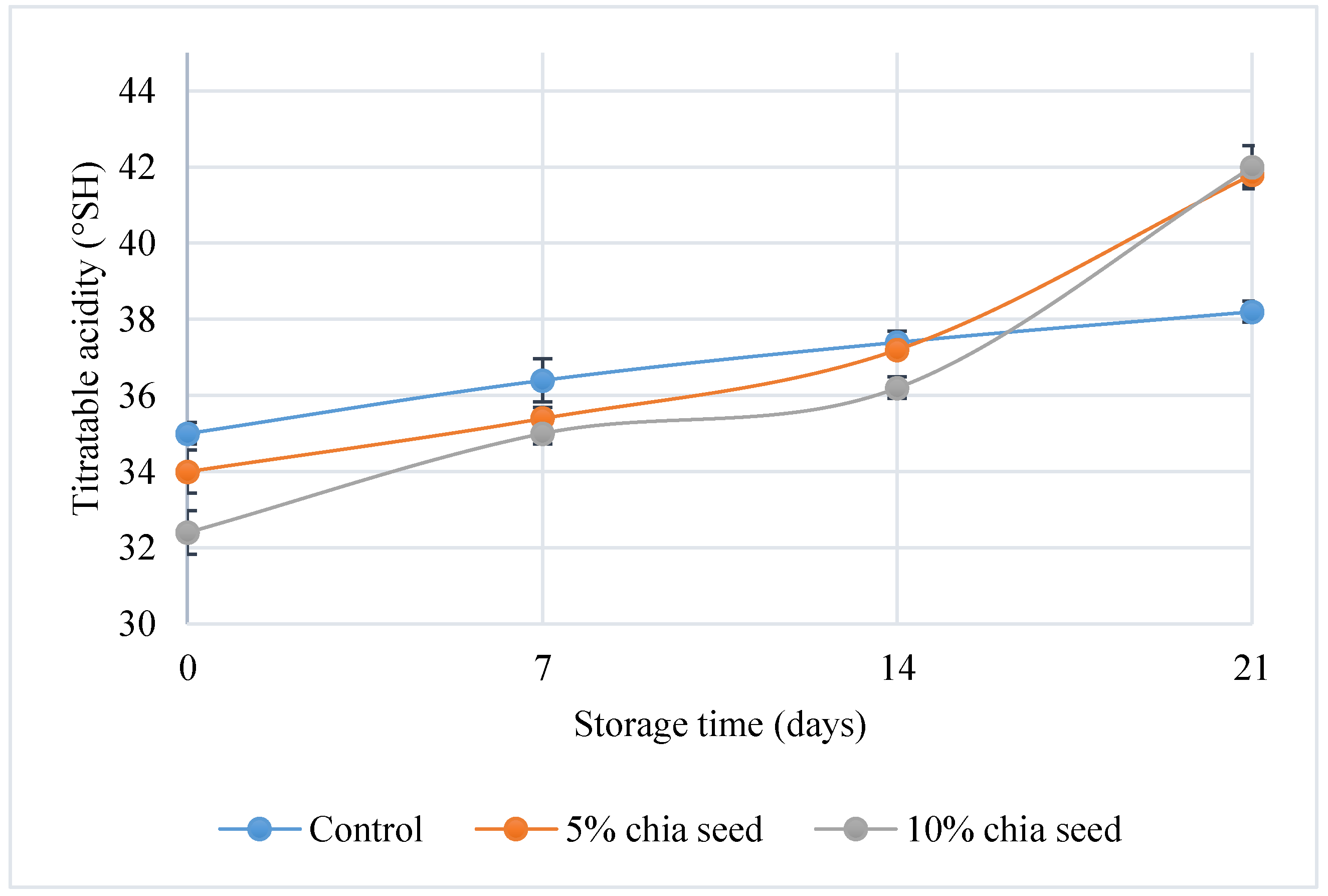

3.1. Change in pH Value and Titratable Acidity during Storage of Yogurt

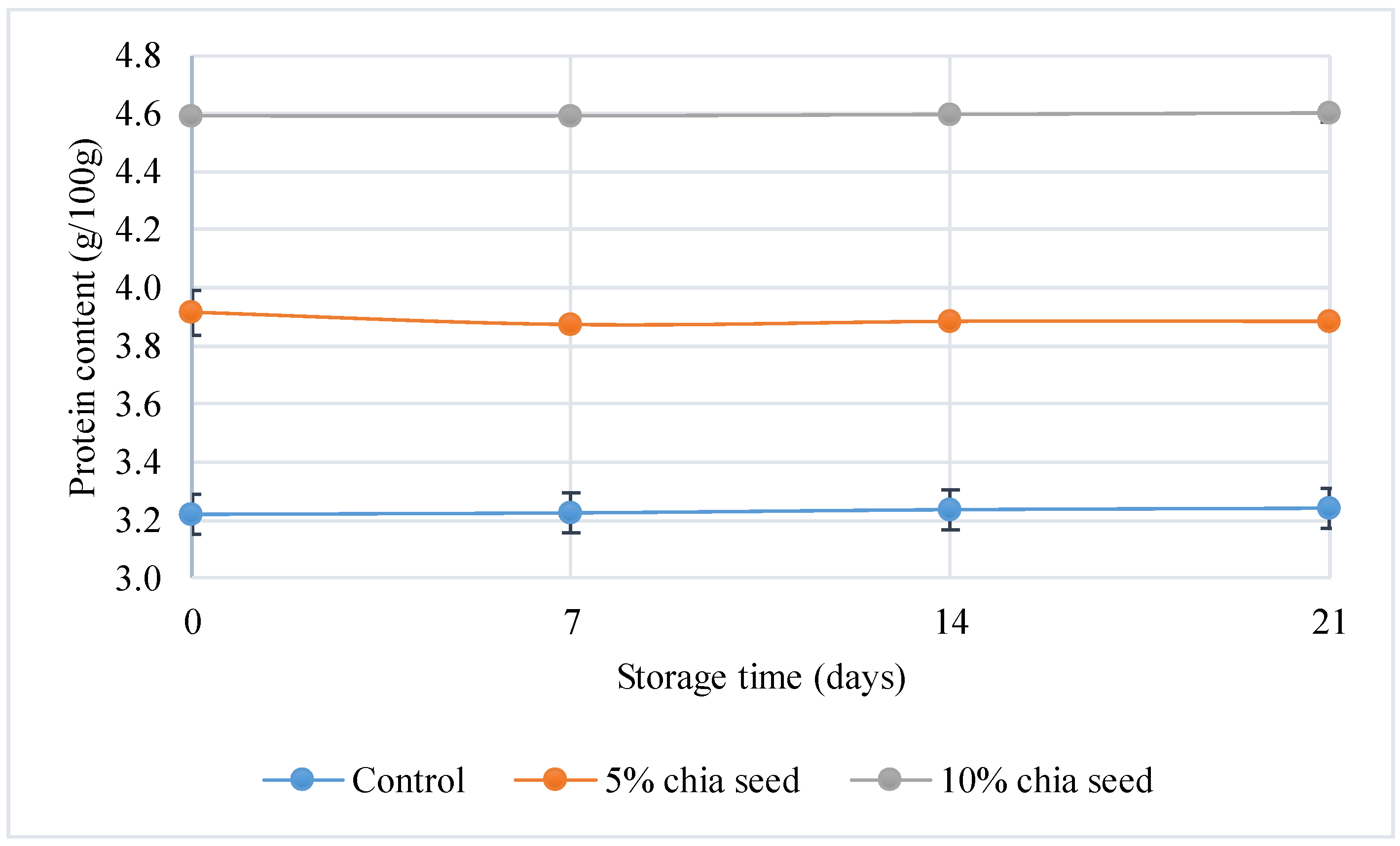

3.2. Change in Chemical Composition during Storage of Yogurt

3.3. Changes in the Microbial Composition of Yogurt during Storage

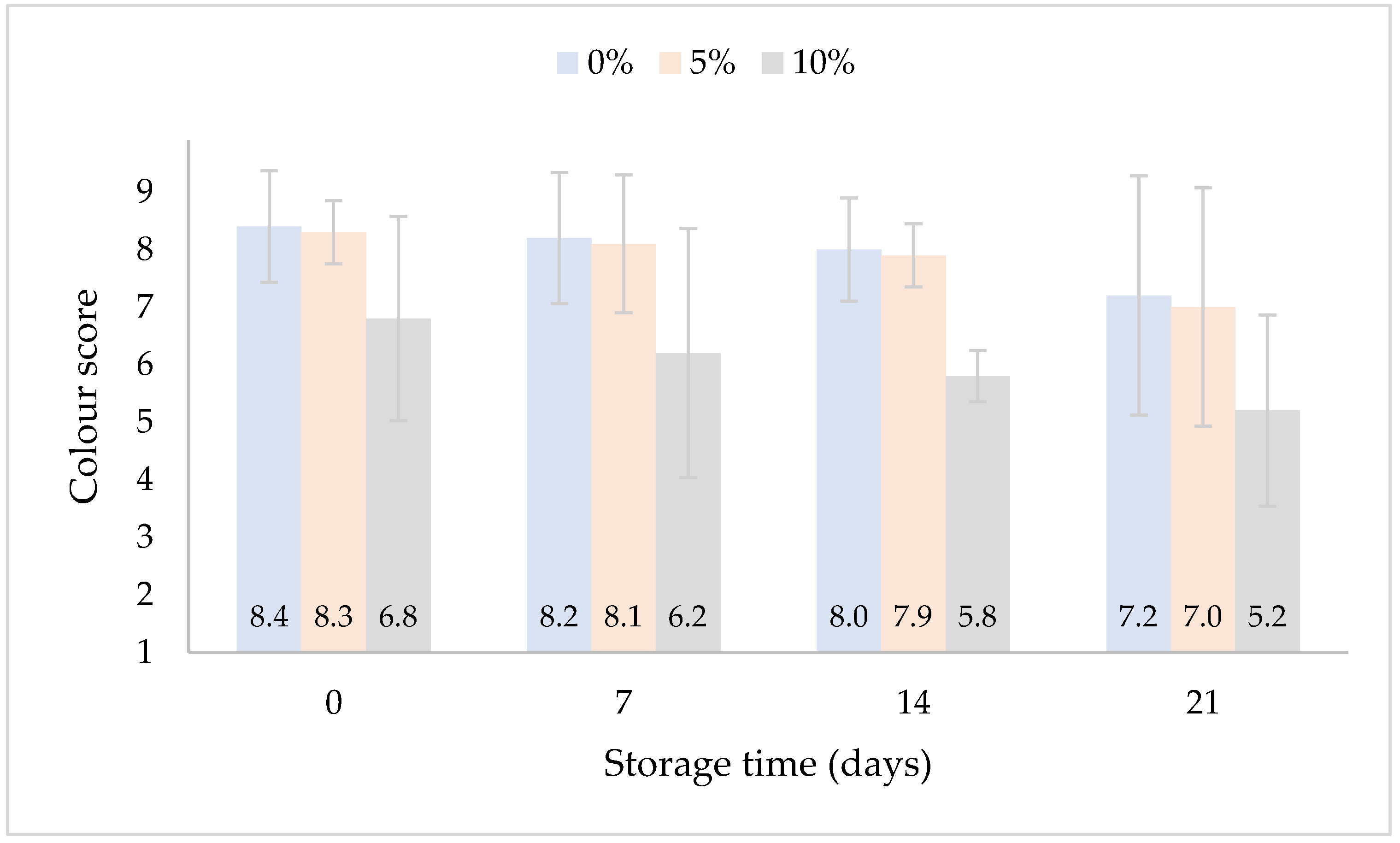

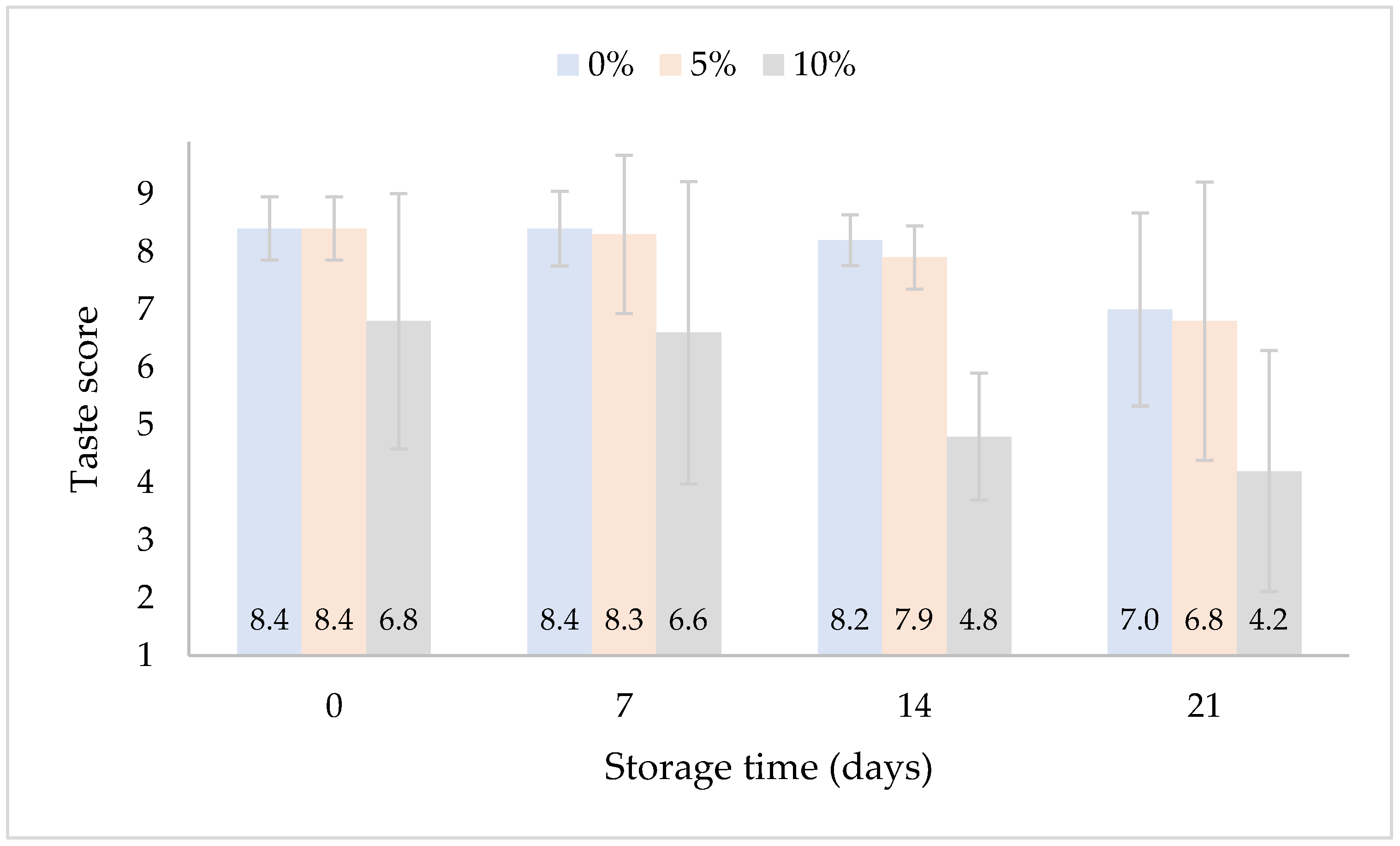

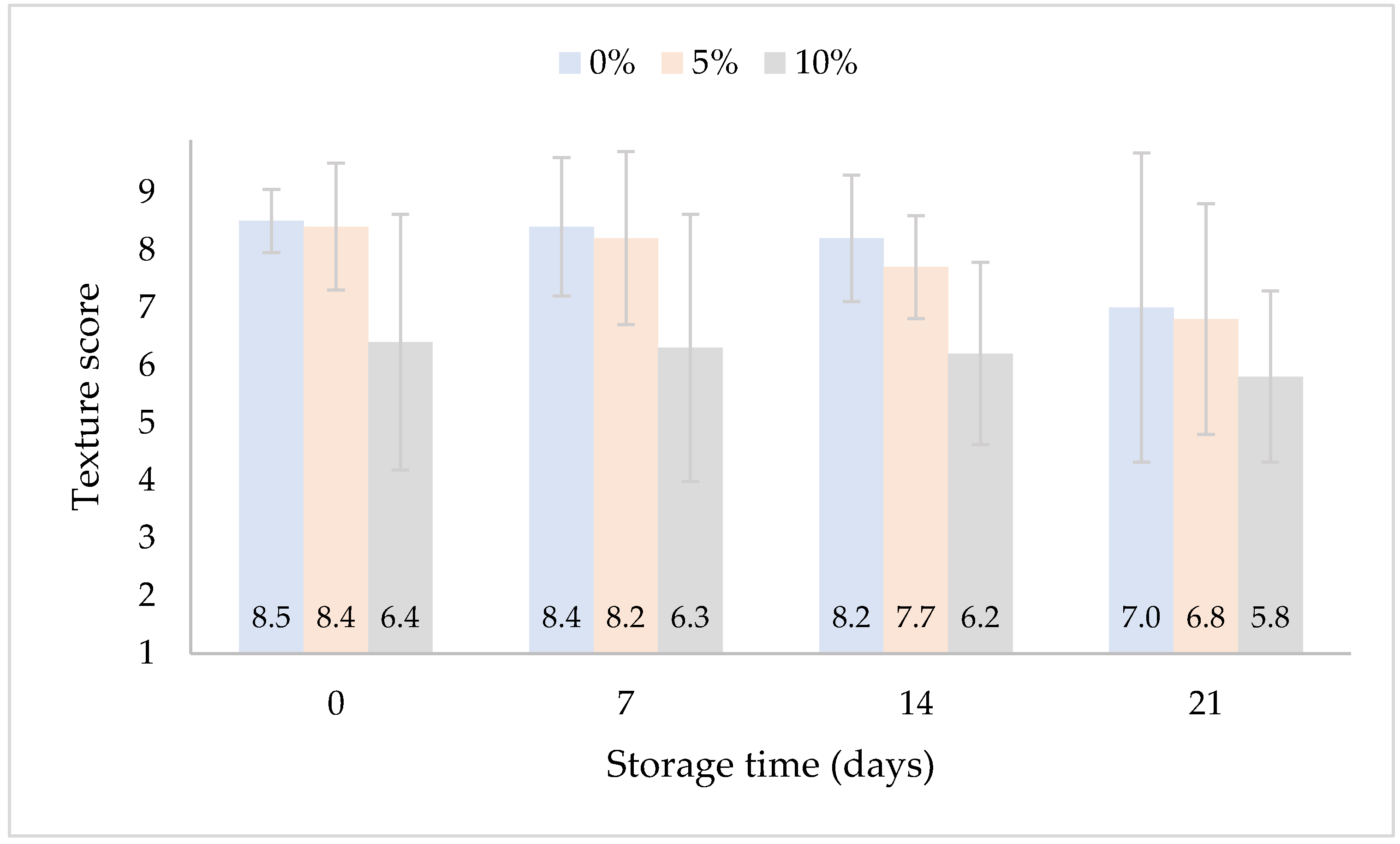

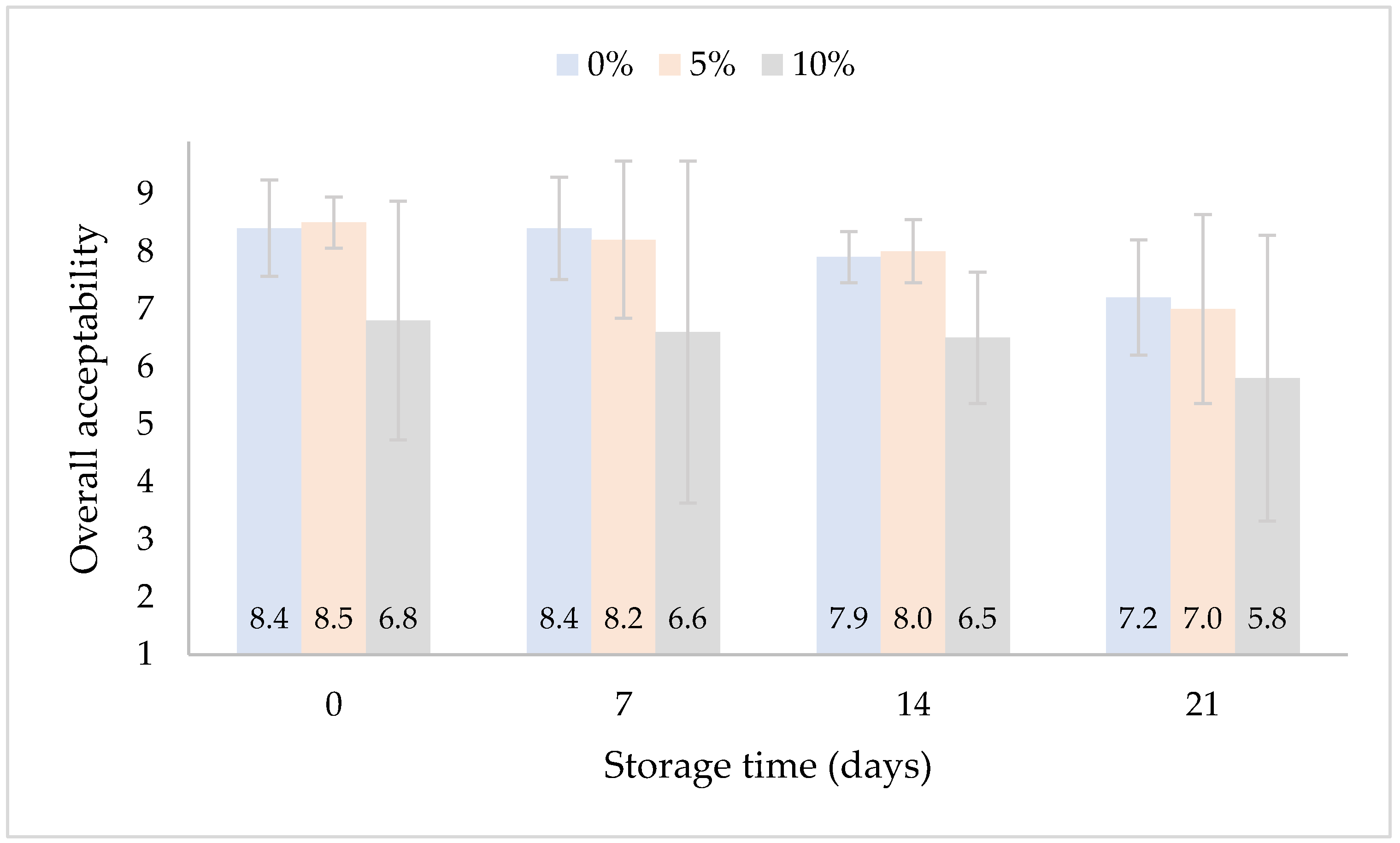

3.4. Change in Sensory Analysis during Storage of the Yogurts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Din, Z.; Alam, M.; Ullah, H.; Shi, D.; Xu, B.; Li, H.; Xiao, C. Nutritional, phytochemical and therapeutic potential of chia seed (Salvia hispanica L.). A mini-review. Food Hydrocolloids Health 2021, 1, 100010. [Google Scholar] [CrossRef]

- Orona-Tamayo, D.; Paredes-López, O. Chia—The New Golden Seed for the 21st Century: Nutraceutical Properties and Technological Uses. In Sustainable Protein Sources; Elsevier: Amsterdam, The Netherlands, 2024; pp. 443–470. [Google Scholar] [CrossRef]

- Silveira Coelho, M.; de Araujo Aquino, S.; Machado Latorres, J.; de las Mercedes Salas-Mellado, M. In vitro and in vivo antioxidant capacity of chia protein hydrolysates and peptides. Food Hydrocolloids 2019, 91, 19–25. [Google Scholar] [CrossRef]

- Cotabarren, J.; Rosso, A.M.; Tellechea, M.; García-Pardo, J.; Rivera, J.L.; Obregón, W.D.; Parisi, M.G. Adding value to the chia (Salvia hispanica L.) expeller: Production of bioactive peptides with antioxidant properties by enzymatic hydrolysis with Papain. Food Chem. 2019, 274, 848–856. [Google Scholar] [CrossRef] [PubMed]

- Cruz, A.G.; Cavalcanti, R.N.; Guerreiro, L.M.R.; Sant’Ana, A.S.; Nogueira, L.C.; Oliveira, C.A.F.; Deliza, R.; Cunha, R.L.; Faria, J.A.F.; Bolini, H.M.A. Developing a prebiotic yogurt: Rheological, physico-chemical and microbiological aspects and adequacy of survival analysis methodology. J. Food Eng. 2013, 114, 323–330. [Google Scholar] [CrossRef]

- Hadjimbei, E.; Botsaris, G.; Goulas, V.; Alexandri, E.; Gekas, V.; Gerothanassis, I.P. Functional stability of goats’ milk yoghurt supplemented with Pistacia atlantica resin extracts and Saccharomyces boulardii. Int. J. Dairy Technol. 2019, 73, 134–143. [Google Scholar] [CrossRef]

- Alizadeh Khaledabad, M.; Ghasempour, Z.; Moghaddas Kia, E.; Rezazad Bari, M.; Zarrin, R. Probiotic yoghurt functionalised with microalgae and Zedo gum: Chemical, microbiological, rheological and sensory characteristics. Int. J. Dairy Technol. 2019, 73, 67–75. [Google Scholar] [CrossRef]

- Dimov, M.D.; Dimitrova, I.T.; Zlatev, Z.D. Application of dill essential oil as additive to Bulgarian yoghurt. J. Chem. Technol. Metall. 2024, 59, 53–60. [Google Scholar] [CrossRef]

- Shori, A.B. Proteolytic activity, antioxidant, and α-Amylase inhibitory activity of yogurt enriched with coriander and cumin seeds. LWT 2020, 133, 109912. [Google Scholar] [CrossRef]

- Fernandez, M.A.; Marette, A. Potential health benefits of combining yogurt and fruits based on their probiotic and prebiotic properties. Adv. Nutr. 2017, 8, 155S–164S. [Google Scholar] [CrossRef]

- Ahmad, I.; Hao, M.; Li, Y.; Zhang, J.; Ding, Y.; Lyu, F. Fortification of yogurt with bioactive functional foods and ingredients and associated challenges—A review. Trends Food Sci. Technol. 2022, 129, 558–580. [Google Scholar] [CrossRef]

- Casado-Hidalgo, G.; Morante-Zarcero, S.; Pérez-Quintanilla, D.; Sierra, I. Influence of fermentation and storage on the content of opium alkaloids in poppy seed yoghurt. J. Food Compos. Anal. 2023, 121, 105412. [Google Scholar] [CrossRef]

- Nazari, A.; Zarringhalami, S.; Asghari, B. Influence of germinated black cumin (Nigella sativa L.) seeds extract on the physicochemical, antioxidant, antidiabetic, and sensory properties of yogurt. Food Biosci. 2023, 53, 102437. [Google Scholar] [CrossRef]

- Eker, M.E.; Karakaya, S. Influence of the addition of chia seeds and germinated seeds and sprouts on the nutritional and beneficial properties of yogurt. Int. J. Gastron. Food Sci. 2020, 22, 100276. [Google Scholar] [CrossRef]

- Nakov, G.; Trajkovska Biljana, Z.; Zlatev, Z.; Jukić, M.; Lukinac, J. Quality characteristics of probiotic yoghurt enriched with honey and by-products left after the production of hemp oil by cold pressing the seeds of Cannabis sativa L. Mljekarstvo 2023, 73, 3–11. [Google Scholar] [CrossRef]

- ISO 21528-2:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Enterobacteriaceae—Part 2: Colony-Count Technique. International Standard Organization: Geneva, Switzerland, 2017.

- ISO 6611:2006; Milk and Milk Products—Enumeration of Colony-Forming Units of Yeasts and/or Moulds—Colony-Count Technique at 25 Degrees C. International Standard Organization: Geneva, Switzerland, 2006.

- ISO 6888-1:2021; Microbiology of the Food Chain—Horizontal Method for the Enumeration of Coagulase-Positive Staphylococci (Staphylococcus aureus and Other Species)—Part 1: Method Using Baird-Parker Agar Medium. International Standard Organization: Geneva, Switzerland, 2021.

- ISO 6579-1:2017/Amd 1:2020; Microbiology of the Food Chain—Microbiology of the Food Chain—Horizontal Method for the Detection, Enumeration and Serotyping of Salmonella—Part 1: Detection of Salmonella spp.—Amendment 1 Broader Range of Incubation Temperatures, Amendment to the Status of Annex D, and Correction of the Composition of MSRV and SC. International Standard Organization: Geneva, Switzerland, 2020.

- ISO 11290-1:2017; Microbiology of the Food Chain—Horizontal Method for the Detection and Enumeration of Listeria monocytogenes and of Listeria spp.—Part 1: Detection Method. International Standard Organization: Geneva, Switzerland, 2017.

- ISO 7889:2005; Yogurt—Enumeration of Characteristic Microorganisms—Colony-Count Technique at 37 Degrees C. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2005.

- ISO 7889:2003; Yogurt Enumeration of Characteristic Microorganisms. Colony-Count Technique at 37 Degrees C. International Standard Organization: Geneva, Switzerland, 2003.

- ISO 8968-1:2014; Milk and Milk Products—Determination of Nitrogen Content Part 1: Kjeldahl Principle and Crude Protein Calculation. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2014.

- 1111:1980; Milk and Milk Products—Determination of Acidity. Bulgarian Institute for Standardization: Sofia, Bulgaria, 1980.

- Alfonsi, A.; Coles, D.; Hasle, C.; Koppel, J.; Ladikas, M.; Schmucker von Koch, J.; Schroeder, D.; Sprumont, D.; Verbeke, W.; Zaruk, D. Guidance Note: Ethics and Food-Related Research; European Commission Ethics Review Sector: Brussels, Belgium, 2012; Available online: http://hdl.handle.net/1854/LU-3160248 (accessed on 28 May 2024).

- Kowaleski, J.; Quast, L.B.; Steffens, J.; Lovato, F.; Rodrigues dos Santos, L.; Zambiazi da Silva, S.; Maschio de Souza, D.; Felicetti, M.A. Functional yogurt with strawberries and chia seeds. Food Biosci. 2020, 37, 100726. [Google Scholar] [CrossRef]

- Ribes, S.; Peña, N.; Fuentes, A.; Talens, P.; Barat, J.M. Chia (Salvia hispanica L.) seed mucilage as a fat replacer in yogurts: Effect on their nutritional, technological, and sensory properties. J. Dairy Sci. 2021, 104, 2822–2833. [Google Scholar] [CrossRef]

- Drużyńska, B.; Wołosiak, R.; Grzebalska, M.; Majewska, E.; Ciecierska, M.; Worobiej, E. Comparison of the content of selected bioactive components and antiradical properties in yoghurts enriched with chia seeds (Salvia hispanica L.) and chia seeds soaked in apple juice. Antioxidants 2021, 10, 1989. [Google Scholar] [CrossRef]

- Valdivia-López, M.Á.; Tecante, A. Chia (Salvia hispanica): A Review of Native Mexican Seed and Its Nutritional and Functional Properties. Adv. Food Nutr. Res. 2015, 75, 53–75. [Google Scholar] [CrossRef]

- Grancieri, M.; Martino, H.S.D.; Gonzalez de Mejia, E. Chia Seed (Salvia hispanica L.) as a Source of Proteins and Bioactive Peptides with Health Benefits: A Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 480–499. [Google Scholar] [CrossRef]

- Coorey, R.; Tjoe, A.; Jayasena, V. Gelling Properties of Chia Seed and Flour. J. Food Sci. 2014, 79, E859–E866. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wu, J.; Lv, M.; Shao, Z.; Hungwe, M.; Wang, J.; Bai, X.; Xie, J.; Wang, Y.; Geng, W. Metabolism Characteristics of Lactic Acid Bacteria and the Expanding Applications in Food Industry. Front. Bioeng. Biotechnol. 2021, 9, 612285. [Google Scholar] [CrossRef] [PubMed]

- Tammie, A.Y.; Deeth, H.C. Yogurt: Technology and Biochemistry. J. Food Protect. 1980, 43, 939–977. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Hyeonbin, O.; Lee, P.; Kim, Y.-S. The quality characteristics, antioxidant activity, and sensory evaluation of reduced-fat yogurt and nonfat yogurt supplemented with basil seed gum as a fat substitute. J. Dairy Sci. 2019, 103, 1324–1336. [Google Scholar] [CrossRef]

- Darwish, A.; El-Sohaimy, S.A. Functional Properties of Chia Seed Mucilage Supplemented In Low Fat Yoghurt. Alex. Med. J. 2018, 39, 450–459. [Google Scholar] [CrossRef]

- Nieman, D.C.; Cayea, E.J.; Austin, M.D.; Henson, D.A.; McAnulty, S.R.; Jin, F. Chia seed does not promote weight loss or alter disease risk factors in overweight adults. Nutr. Res. 2009, 29, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Ayerza, R.; Coates, W. Chia: Rediscovering a Forgotten Crop of the Aztecs; University of Arizona Press: Tucson, AZ, USA; p. 2005. [CrossRef]

- Valdivia-López, M.Á.; Tecante, A. Chia (Salvia hispanica). In Advances in Food and Nutrition Research; Elsevier: Amsterdam, The Netherlands, 2015; pp. 53–75. [Google Scholar] [CrossRef]

- Codex Alimentarius Commission. Available online: https://www.fao.org/fao-who-codexalimentarius/en/ (accessed on 15 May 2023).

- Khalil, O.S.F.; Ismail, H.A.; Elkot, W.F. Physicochemical, functional and sensory properties of probiotic yoghurt flavored with white sapote fruit (Casimiroa edulis). J. Food Sci. Technol. 2022, 59, 3700–3710. [Google Scholar] [CrossRef] [PubMed]

- Rabail, R.; Sultan, M.T.; Khalid, A.R.; Sahar, A.T.; Zia, S.; Kowalczewski, P.Ł.; Jeżowski, P.; Shabbir, M.A.; Aadil, R.M. Clinical, Nutritional, and Functional Evaluation of Chia Seed-Fortified Muffins. Molecules 2022, 27, 5907. [Google Scholar] [CrossRef] [PubMed]

- de Souza, A.Á.; Lima, A.M.; Dede Oliveira BezerraSousa, D.; Nogueira, F.C.; do Sacramento Neto, J.C.; Dias, L.P.; Araújo, N.M.S.; Nagano, C.S.; Júnior, H.V.N.; da Silva, C.R.; et al. Chia (Salvia hispanica L.) Seeds Contain a Highly Stable Trypsin Inhibitor with Potential for Bacterial Management Alone or in Drug Combination Therapy with Oxacillin. Probiotics Antimicrob. Prot. 2023, 15, 1221–1233. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food: Principles and Practices; Springer: Berlin, Germany, 2010. [Google Scholar] [CrossRef]

| Total LAB (log CFU/g) | Day 0 | Day 7 | Day 14 | Day 21 |

|---|---|---|---|---|

| Control | 9.005 ± 0.007 | 8.980 ± 0.014 | 8.845 ± 0.007 | 8.775 ± 0.007 |

| 5% chia seeds | 8.795 ± 0.007 | 8.740 ± 0.000 | 8.620 ± 0.028 | 8.500 ± 0.141 |

| 10% chia seeds | 8.495 ± 0.007 | 8.370 ± 0.014 | 8.315 ± 0.021 | 8.150 ± 0.212 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakov, G.; Ninova-Nikolova, N.; Ivanova, N.; Raykova, V.; Trajkovska, B.; Čolić, M.L.; Lukinac, J.; Jukić, M. Yogurt Enriched with Chia Seeds: Physicochemical, Microbiological, and Sensory Changes during Storage. Fermentation 2024, 10, 431. https://doi.org/10.3390/fermentation10080431

Nakov G, Ninova-Nikolova N, Ivanova N, Raykova V, Trajkovska B, Čolić ML, Lukinac J, Jukić M. Yogurt Enriched with Chia Seeds: Physicochemical, Microbiological, and Sensory Changes during Storage. Fermentation. 2024; 10(8):431. https://doi.org/10.3390/fermentation10080431

Chicago/Turabian StyleNakov, Gjore, Nadya Ninova-Nikolova, Nastia Ivanova, Violeta Raykova, Biljana Trajkovska, Mirela Lučan Čolić, Jasmina Lukinac, and Marko Jukić. 2024. "Yogurt Enriched with Chia Seeds: Physicochemical, Microbiological, and Sensory Changes during Storage" Fermentation 10, no. 8: 431. https://doi.org/10.3390/fermentation10080431

APA StyleNakov, G., Ninova-Nikolova, N., Ivanova, N., Raykova, V., Trajkovska, B., Čolić, M. L., Lukinac, J., & Jukić, M. (2024). Yogurt Enriched with Chia Seeds: Physicochemical, Microbiological, and Sensory Changes during Storage. Fermentation, 10(8), 431. https://doi.org/10.3390/fermentation10080431