Abstract

As global urbanisation, industrialisation, and population growth escalate, the production of wastewater also increases, leading to significant water pollution on a global scale. This pollution poses severe threats to environmental health, wildlife, and human communities. In rural areas where centralised sewage systems are often absent, septic tanks play a crucial role in managing wastewater. They separate solids from liquids and facilitate the biological decomposition of organic matter. This paper utilises a Patent Landscape Review (PLR) to analyse the scope and direction of innovations in septic tank technology. Conducted on 23 September 2022, the patent search targeted filings from January 2001 through June 2022 to identify prevailing trends and advancements within this field. Through a detailed examination of 889 patents, categorised by keywords, processes, materials, and designs, this study offers a comprehensive overview of the patent landscape for septic tanks. Key findings indicate that fibreglass cylindrical tanks dominate the market due to their durability and efficiency. This review also highlights a growing trend towards modular septic systems, which offer scalable solutions adaptable to specific environmental conditions. Furthermore, some patents propose the repurposing of various objects as septic tanks, demonstrating a move towards sustainability by reducing waste and enhancing environmental conservation. This paper emphasises the importance of continued innovation in septic tank technology to address the challenges of effective wastewater management in underserved rural communities.

1. Introduction

Over the past century, global water consumption has increased by 600%, primarily due to industrialisation in many countries and a burgeoning global population [1]. This increase in urbanisation, industrialisation, and agricultural production has had a significant impact on both the quantity and quality of water resources. As a result, inadequate management of the water cycle poses considerable risks to global ecosystems, social well-being, and economic progress [2]. With the expansion of urban areas and the growth of industries, water consumption and wastewater production have surged, emphasising the urgent requirement for effective wastewater management solutions.

Wastewater, which refers to liquids and waterborne solids discharged into sewerage systems, stems from a range of sources, including domestic, industrial, commercial, and agricultural activities [3]. Domestic wastewater generally comprises effluents originating from bathrooms, kitchens, and laundry facilities. Conversely, industrial wastewater is a byproduct of manufacturing processes and operations, which can differ substantially depending on the specific industries involved. Additionally, commercial wastewater generated by establishments like hotels, supermarkets, and offices, as well as agricultural wastewater produced from farming activities, further contribute to the array of wastewater types.

The composition of wastewater is complex, encompassing natural inorganic and organic materials, synthetic substances, chemical cleaning agents, detergents, and a variety of pathogens such as viruses, bacteria, and fungi [3,4]. The discharge of untreated wastewater into the environment poses significant health risks due to the toxic effects of its constituents. For instance, biodegradable organic materials can lead to oxygen depletion in water bodies through bacterial aerobic digestion [5], while excessive nutrients may cause algae blooms, leading to eutrophication that severely depletes the oxygen needed for aquatic life [6,7]. Additionally, the thermal effects of wastewater can alter aquatic ecosystems and negatively affect the health of water bodies, as temperature plays a crucial role in maintaining the balance of aquatic life [8].

Wastewater quality and quantity from domestic and commercial sources are generally predictable, whereas industrial wastewater varies with specific manufacturing processes and requires industry-specific treatment solutions [9]. Commonly, wastewater undergoes primary and secondary treatment processes before being released into the environment. Primary treatment typically involves sedimentation to remove settleable solids, while secondary treatment utilises aerobic organisms to biochemically degrade organic materials into stable inorganic substances.

For areas lacking centralised sewerage systems, particularly in rural settings, onsite or decentralised wastewater treatment systems are crucial. These systems, which include septic tanks [10,11,12,13], anaerobic baffled reactors [14,15,16], anaerobic filters [17,18,19], and biogas reactors [20,21], provide vital services by treating wastewater at or near its source.

The utilisation of decentralised wastewater treatment systems, especially septic tanks, exhibits significant variation globally, with a lower percentage being utilised in developed countries compared to developing countries. In total, 13% of the population in Australia employs septic tanks for wastewater management [22], and approximately one-third of the population in Ireland [23] and 23% of the 115 million homes in the United States utilise such systems [24]. In Canada, 10% of the population [25], and in Hungary, 12.1%, have access to sewerage systems [26]. In the context of developing countries, Brunei Darussalam has a 34% adoption rate of decentralised systems [27], while Myanmar exhibits a dual approach, with 14% of the population using septic tanks and 60% utilising pit latrines [28]. Thailand has a high coverage rate, with 92.7% of its population using decentralised wastewater treatment [28]. The coverage stands at 51.2% in Vietnam [28], while Indonesia reports a 62% utilisation rate [29]. Additionally, the Philippines leads with a 93% adoption rate of decentralised systems [29], and 44% of the Indian population depends on septic tanks for their sanitation [30]. The remaining percentages in these countries primarily utilise centralised sewerage systems, indicating a diverse range of approaches to wastewater management worldwide.

The existence of a specific type of impermeable septic tank, constructed from concrete and featuring perforated walls, allows for the direct leakage of wastewater. Such a practice poses an even greater threat to the environment [26]. Groundwater pollution caused by septic tanks is a major concern, with contaminants such as nitrogen, phosphorus, and pathogens frequently detected in affected areas. This is often a result of inadequate soil filtration and microbial activity [31,32]. Moreover, the eutrophication of surface water is a critical problem, as the release of nutrients from septic tanks raises nutrient concentrations downstream, leading to the growth of harmful algae and damage to ecosystems [33].

Given the critical role of these systems, this paper focuses on the technological advancements and trends in onsite wastewater treatment, particularly septic tanks. By conducting a comprehensive Patent Landscape Review (PLR), this study aims to uncover and analyse key innovations and developments within septic tank technology, shedding light on potential improvements and the future direction of this essential infrastructure. Specifically, this study examines (i) the classification of patents into distinct categories: structure-based, process-based, and those that encompass both elements; (ii) the distribution of patent filing activity by applicant profile, including companies, universities, and inventors; (iii) the spatio-temporal and geographical distribution of patent filings; and (iv) the technological trends and advancements within the septic tank industry.

2. The Evolution of Septic Tanks

From ancient times, civilisations have recognised the importance of clean drinking water and effective waste management for urban populations. However, a full understanding and proper implementation of comprehensive sanitation systems were often lacking in modern cities until much later, leading to significant environmental and public health challenges. Initially, the most common method for disposing of human waste involved simply covering ground holes after use [3]. During the Mesopotamian empire (3500–2500 BC) [34], some advancements were seen, such as the stormwater drainage systems used to manage waste in urban areas. In Babylon, structured sanitation efforts were more evident, with cesspools connected to latrines using vertical shafts lined with porous clay pipes 450 mm in diameter. Unfortunately, most urban residents still dispose of waste and trash on unpaved streets, leading to significant environmental health issues over time.

The first sophisticated urban sanitation systems emerged in Harappa and Mohenjo-Daro, Pakistan, around 2500 BCE [3]. During this time, houses were connected to well-engineered drainage systems that channelled wastewater through tapered terracotta pipes to communal sumps, which then discharged into the main street sewer. By 2100 BCE, the wealthier homes in Herakopolis included baths and limestone toilet seats, showcasing early luxury in sanitary facilities [3]. These homes had floors of slightly slanted stone slabs and walls lined with stone to prevent moisture damage, with wastewater managed through carefully designed drainage systems that directed flow into the desert sands beyond the city walls. Less affluent residents used more rudimentary toilet stools with ceramic bowls, and waste was collected in jars filled with sand and then disposed of into community trenches or nearby water bodies.

By the Middle Ages, the collection of untreated water from rivers and wells was a common practice. However, the absence of proper sanitation infrastructure often resulted in disease outbreaks. During this period, there was a low emphasis on cleanliness in society, and personal hygiene was only sporadically practised, usually being limited to special occasions or religious rituals. There were also prevailing misconceptions, such as the belief that using the restroom could open skin pores, making individuals more susceptible to diseases [34]. The majority of households lacked proper sanitation facilities, leading to the prevalent practice of dumping chamber pots directly into the streets [3]. Recognising the severe public health implications, King Francois I of France mandated the construction of cesspools in all new houses in 1539 in order to manage waste more effectively. This practice continued into the late 1700s [34].

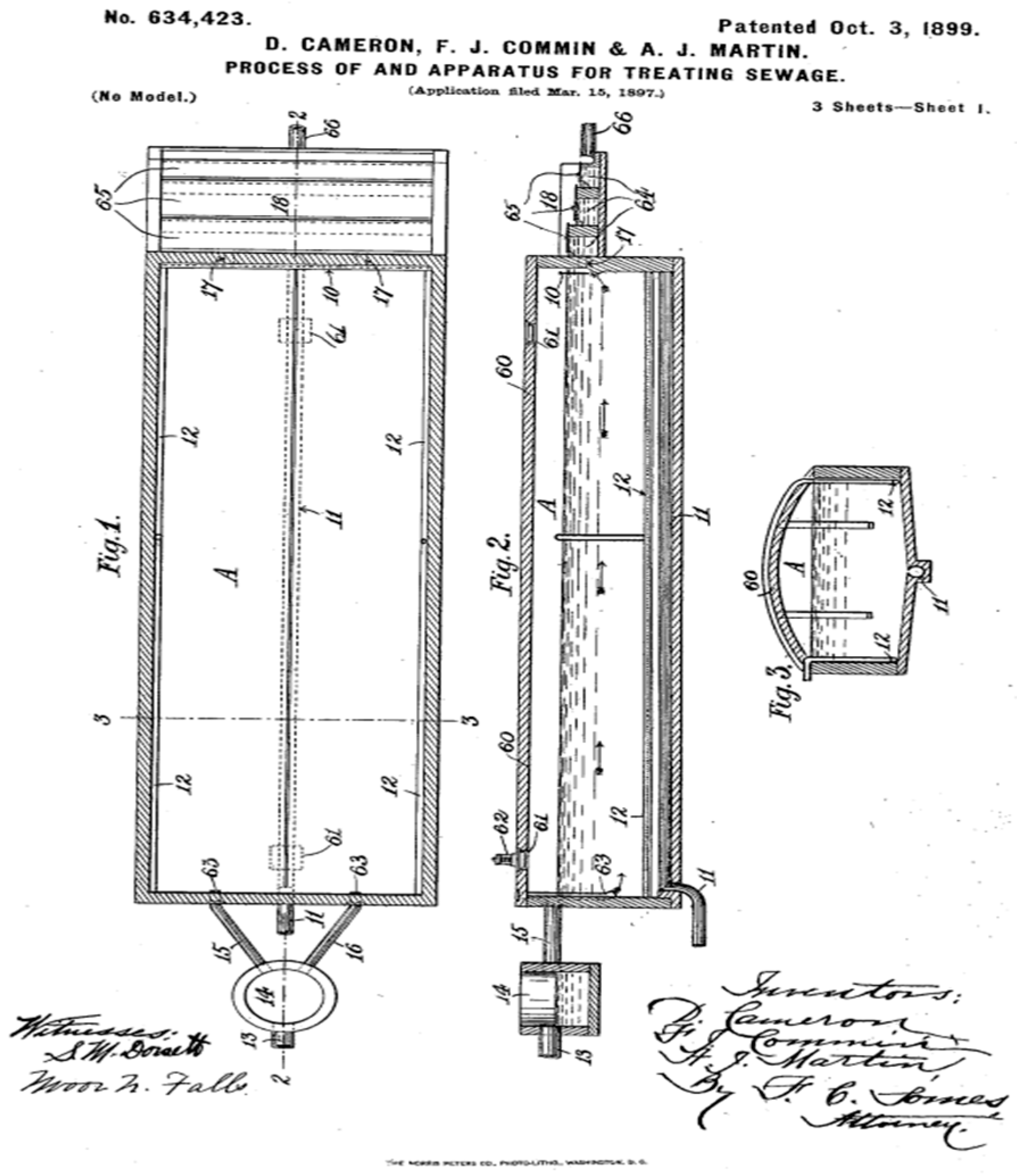

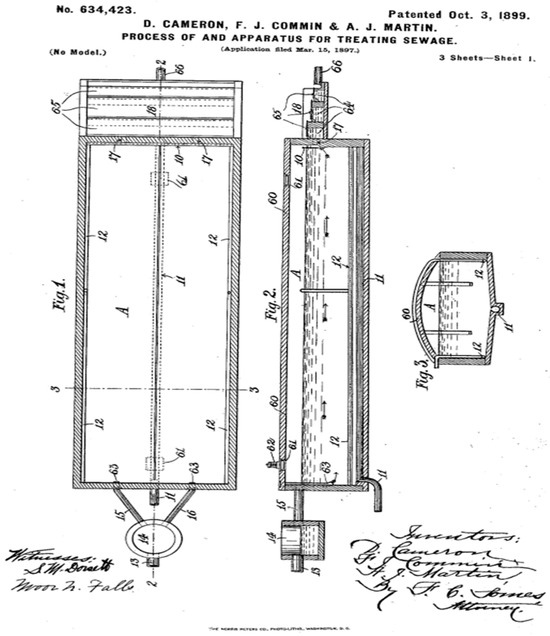

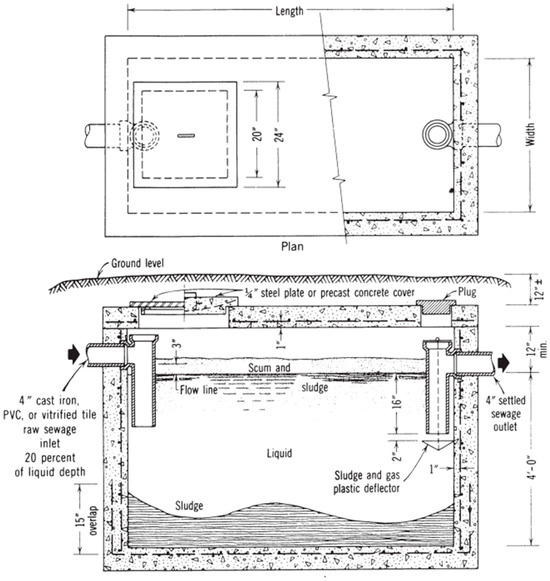

A significant breakthrough came in the 1860s with L.H. Mouras’s invention of the ‘fosses Mouras’, a cesspit system with inlet and outlet pipes that extended below the water surface to create a seal, preventing odours from escaping. Building upon these advancements, Donald Cameron introduced the modern septic tank system (Figure 1) in 1895 [3], which was designed for efficient, sludge-free sewage liquefaction and purification using an anaerobic process [35]. His design used airtight, cement–concrete tanks that facilitated anaerobic digestion, breaking down waste without the presence of air or light so that all solid organic matter it contained was liquefied. Subsequently, only liquid effluent was discharged into the environment.

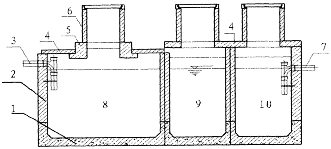

Figure 1.

Donald Cameron’s original patent drawing from 1895 showcases the anaerobic septic tank design [35].

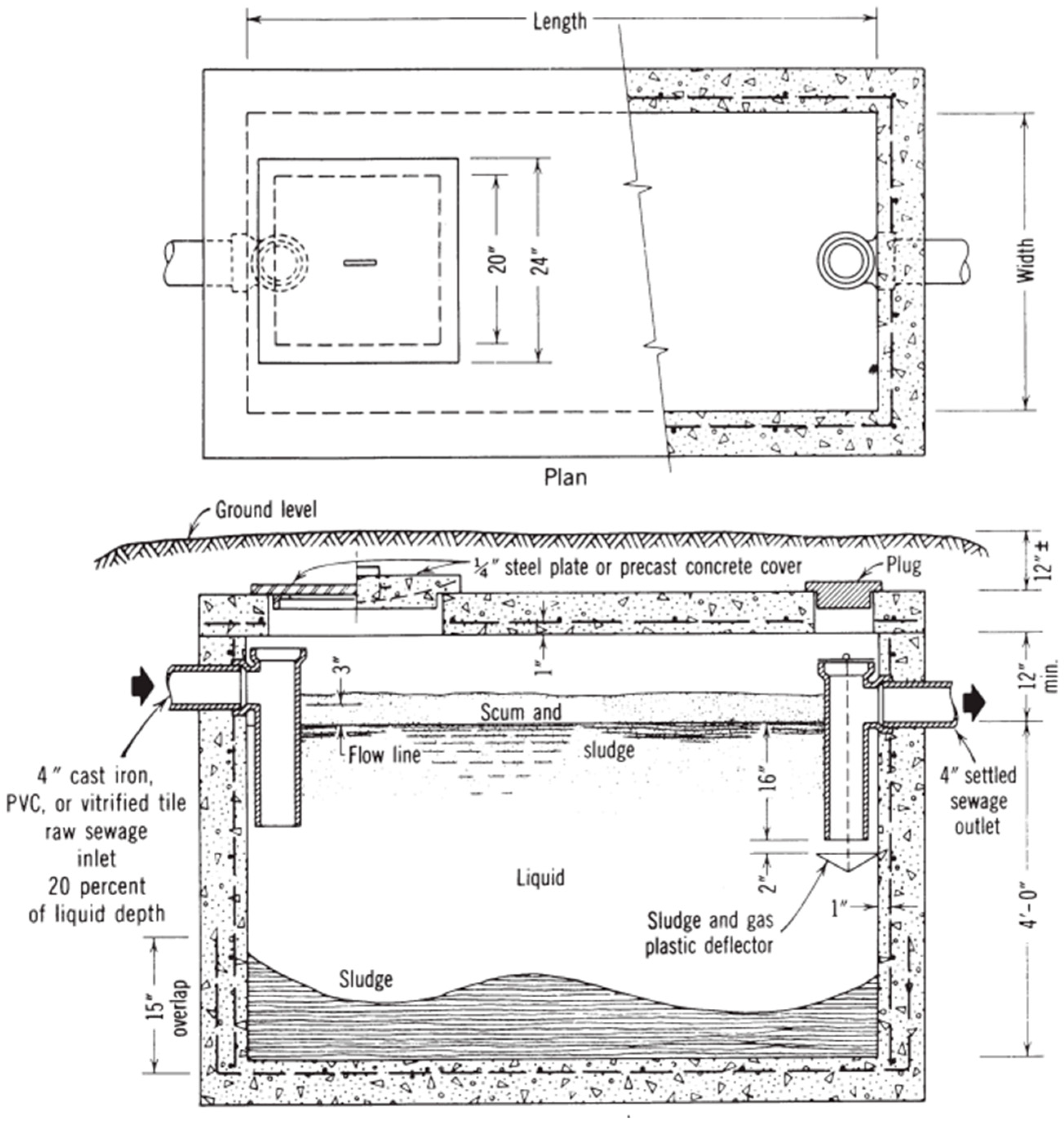

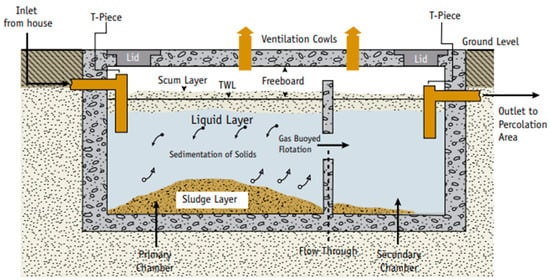

Donald Cameron’s basic septic tank design has evolved significantly, with improvements driven by environmental research and new material technologies. Current septic systems may utilise durable materials [36,37] such as fibreglass, polyethene, and precast reinforced concrete to overcome the limitations of earlier designs, such as corrosion in metal tanks. Modern septic tanks are engineered for optimal performance, including specific requirements for detention times, surface area-to-depth ratios, and multi-chamber configurations to enhance the treatment process (Figure 2 and Figure 3) [38,39]. These tanks primarily operate through anaerobic digestion, where microorganisms break down waste into sludge and scum. Some designs may sometimes incorporate aerobic processes to hasten digestion when external oxygen is introduced, although this is less common due to the higher costs associated with oxygenation systems. Figure 2 and Figure 3 depict septic tank designs built using good-quality reinforced concrete, as recommended in reference [36], and a simple diagram of a two-chamber septic tank, respectively.

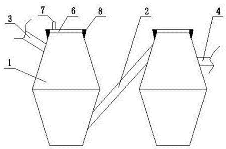

Figure 2.

Illustration of a recommended modern reinforced concrete septic tank [36].

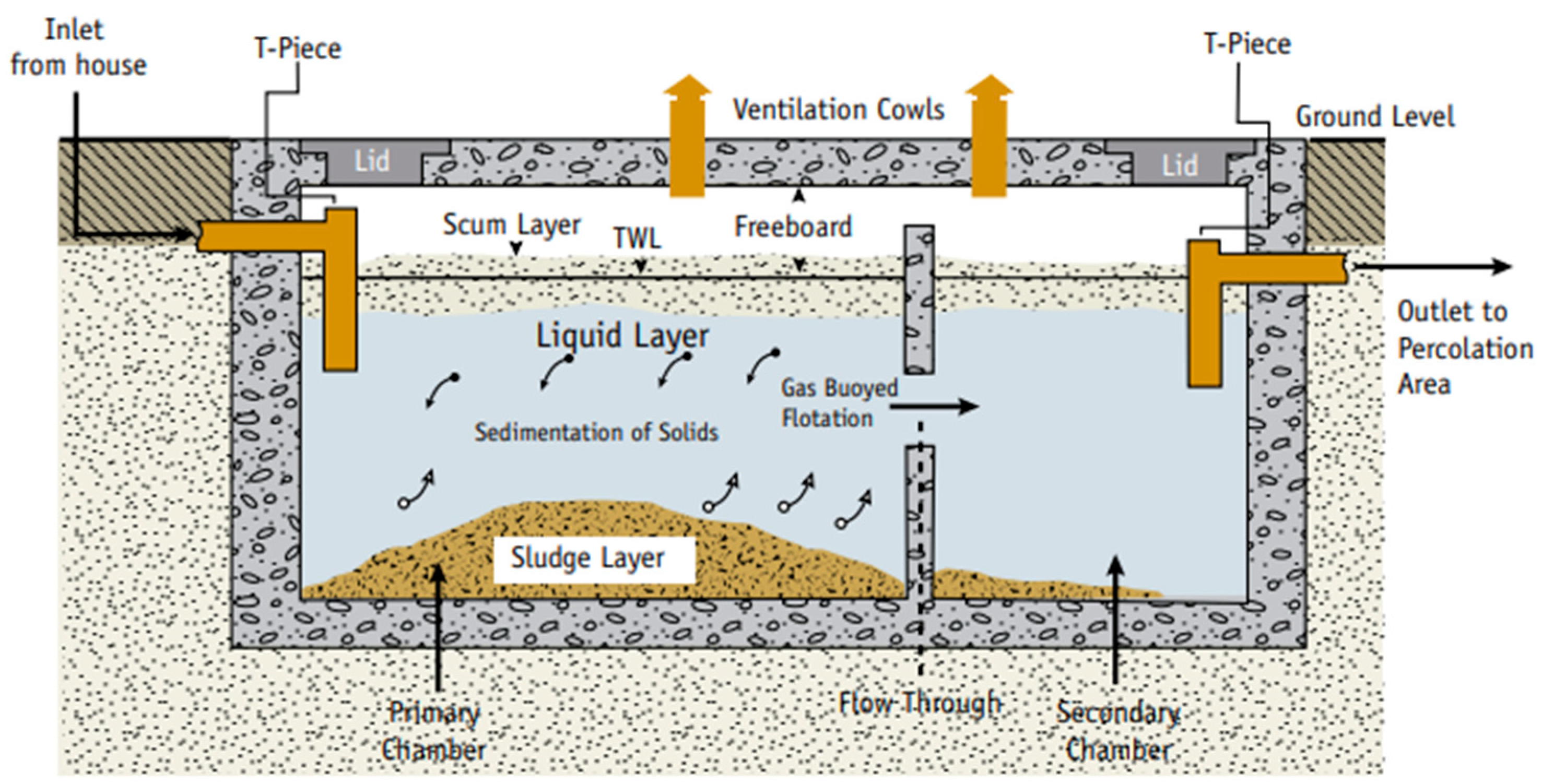

Figure 3.

Schematic of a typical two-chamber septic tank showing how waste is processed and effluent is treated before discharge [23].

In a typical two-chamber septic tank, wastewater enters through an inlet into the first chamber. Here, the force of gravity causes heavier, suspended solids to settle at the bottom, forming a layer of sludge, while less dense substances such as oils and fats rise to the top, creating a scum layer [20]. This stratification is crucial for the separation of solid waste and effluent. Microorganisms naturally present in the wastewater then initiate the anaerobic digestion process in this first chamber [40]. These microbes break down the organic matter in the sludge and scum without the presence of oxygen, converting them into simpler compounds. As more wastewater flows into the first chamber, the partially digested effluent—referred to as the supernatant—is gently pushed into the second chamber. This transition allows further separation and digestion to occur, refining the purification process before the effluent is ultimately discharged through the outlet into the environment, typically into a drainage field or leach field or, in more advanced countries, pumped to a wastewater treatment plant through a network of underground pipes.

The effectiveness of septic tanks largely relies on the principle of particle settling aided by gravity, where solids are naturally separated from liquids [20]. Most septic systems operate under anaerobic conditions due to the lack of oxygen within the sealed tank, making this process energy-efficient and cost-effective. However, some modern systems incorporate an aerobic stage, where oxygen is introduced into the system to accelerate the breakdown of organic materials. Aerobic digestion is faster than anaerobic but requires external oxygen sources, such as mechanical pumps or diffusers, which can increase operational costs. Despite the higher speed of aerobic processes, the simplicity and lower cost of anaerobic systems make them a popular choice in residential and rural applications [41].

3. Methodology

3.1. Patent Review Process

The objective of patent landscaping is to asses technological progress within a specific domain by systematically examining a range of innovations and scientific documentation. A patent is a form of intellectual property that grants inventors temporary exclusivity over their creations. This exclusivity allows them to develop and commercialise their inventions without competition. Patents prioritise detailed technical descriptions and practical applications to ensure that the novelty, inventiveness, and utility of the technology are clearly articulated and protected [42,43]. In contrast, academic papers aim to share research discoveries with the scientific community, expanding the body of knowledge in various fields. These papers undergo peer review to validate their scientific merit, emphasising theoretical and empirical contributions rather than practical applications. Thus, while academic papers advance knowledge, patents protect innovative applications of this knowledge, providing legal protection against unauthorised use [42,43]. Patent landscaping involves methodical strategies such as keyword searches and the use of international patent classification codes to uncover technological trends and innovation gaps. For instance, in the septic tank technology field, patent analyses can reveal shifts towards more sustainable materials and systems, contrasting academic research that might focus more on the ecological impacts and optimisation of these systems [44,45,46]. This approach not only identifies the current state of technology but also predicts future developments by highlighting emerging leaders in the field [46].

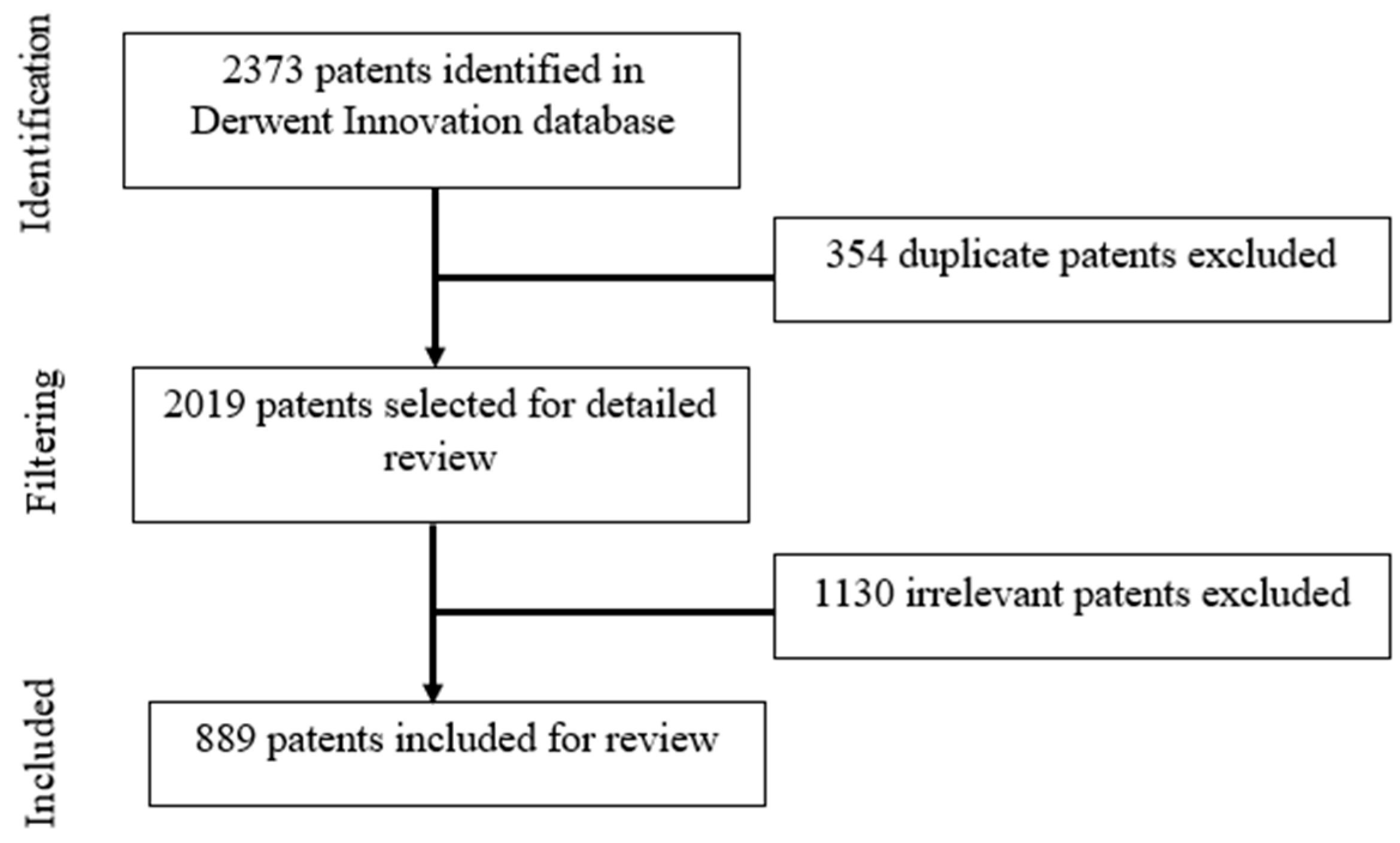

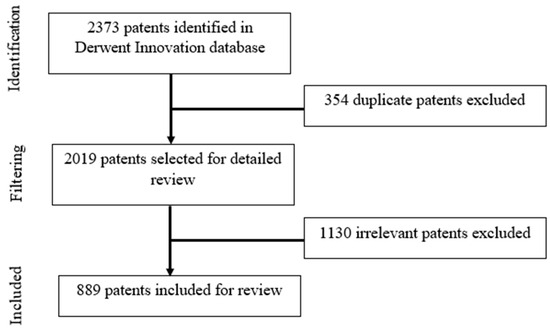

To ensure a comprehensive analysis, our methodology adhered to the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines [47]. The systematic process involved several key steps, illustrated in Figure 4, beginning with the identification of relevant patents. This was achieved through a targeted search using a set of carefully selected keywords relevant to septic tank technology alongside appropriate International Patent Classification (IPC) codes. The initial search aimed to capture a wide range of innovations by including patents that described both the processes and structures integral to septic tank technologies. After identifying the patents, duplicates and irrelevant ones were filtered out before categorisation. Subsequently, a thorough review was conducted on the remaining patents related to septic tanks.

Figure 4.

Process review of the patent search query according to PRISMA [48].

For this analysis, the Derwent Innovation database was utilised. This database is essential for conducting international patent searches and contains over 36 million patent families derived from more than 100 million patents worldwide. These patents are sourced from over 50 regional and national patent offices [48].

The patent search was carried out on 23 September 2022, with the focus narrowed down to patents filed between January 2001 and June 2022. A combination of keyword searches and IPC codes was used to refine our search queries. The selected keywords were chosen to encompass both the structural components and functional processes of septic tanks, as outlined in Table 1. The search was performed on the titles, abstracts, and claims of the patent documents. Patent examiners typically categorise patent documents based on their technological field using the IPC system, which was also employed in this study. Carefully chosen IPC codes relevant to the technological domain of wastewater treatment were used to ensure comprehensive coverage of the field, as demonstrated in Table 2.

Table 1.

Keywords of patents used in the search.

Table 2.

Selected IPC code and its description used in the search query [49].

From the initial query in the Derwent Innovation database, 2373 patents were identified. The screening process involved removing duplicates and filtering out irrelevant entries, typically those that did not directly pertain to septic tank technologies or those that related to general wastewater treatment systems without specific innovations in septic tank design. Priority documents within the same patent family were retained, resulting in a refined set of 2019 patents.

A manual review followed, scrutinising each patent to confirm its relevance based on predefined criteria, focusing solely on patents that dealt with septic tanks or specific distribution devices for treated wastewater. This rigorous review process led to the selection of 889 patents, representing 37.5% of the initially identified patents, for further detailed analysis.

It is important to note that the scope of our patent review was confined to patents catalogued in the Derwent Innovation database. Consequently, patents not listed in this database were not considered in our analysis. Moreover, the inclusion criteria for patents in this study were stringent; only those identified through a systematic search using both specific keywords and relevant International Patent Classification (IPC) codes were included in the review process. This method ensured a focused and relevant dataset tailored to the specific technological domain of septic tank innovations.

3.2. Patent Analysis

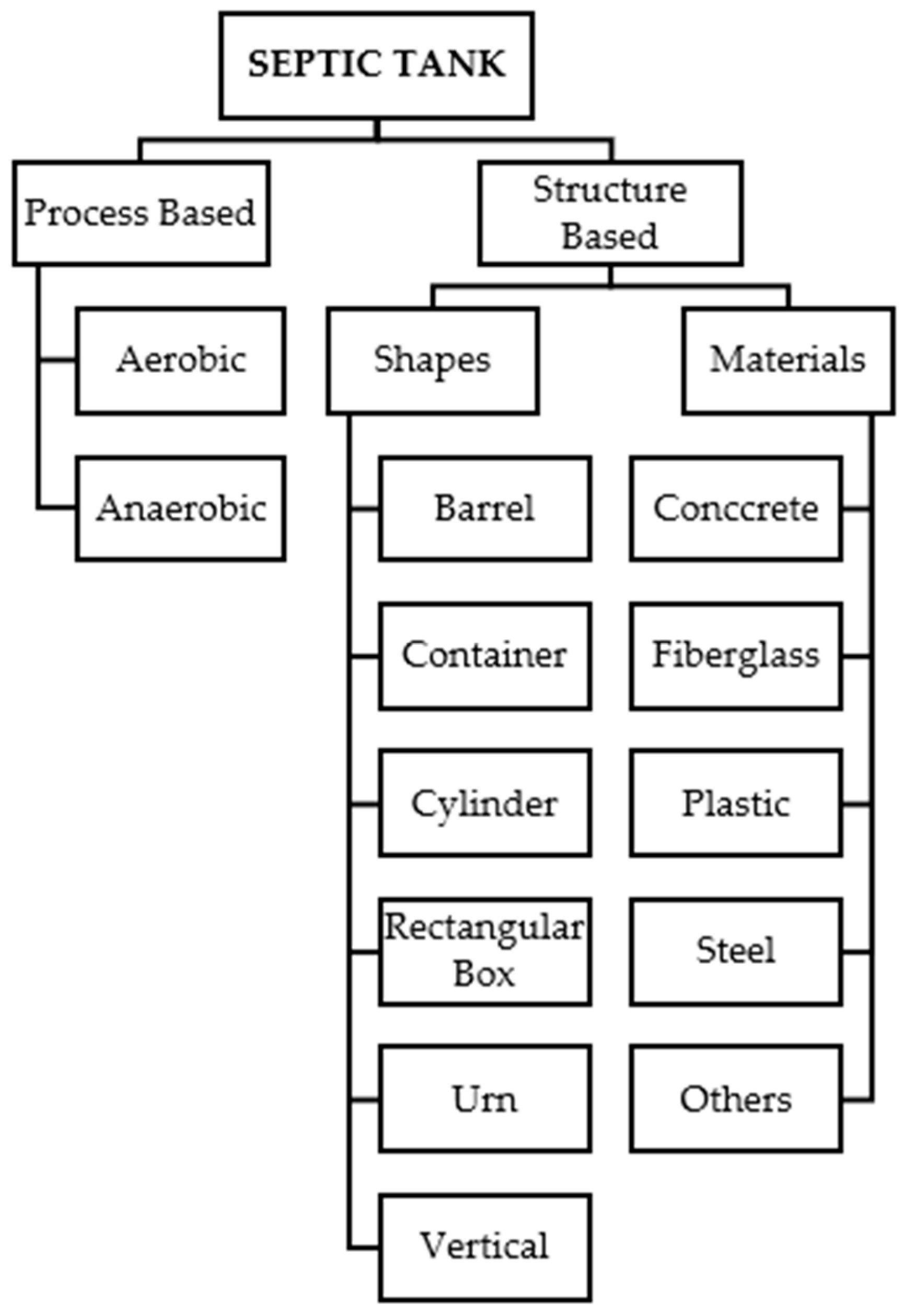

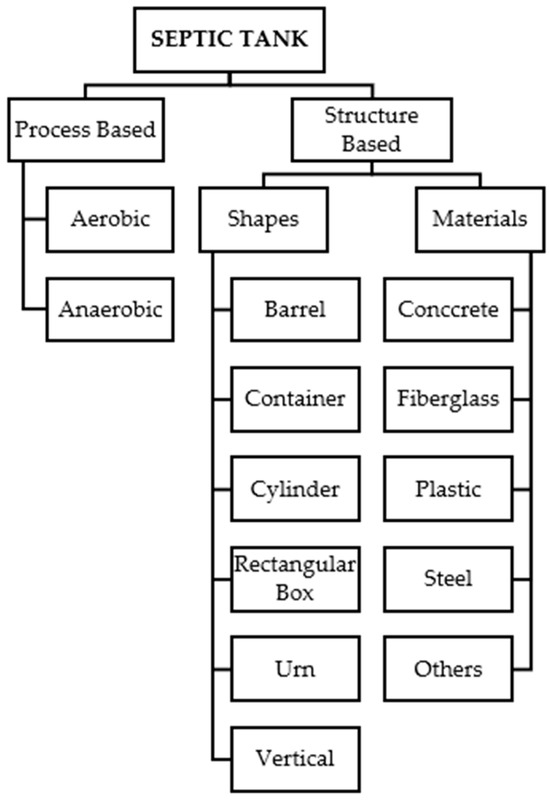

In the subsequent phase of patent landscaping, the retained patents were categorised into two primary groups: process-based and structure-based innovations, as depicted in Figure 5. This categorisation was pivotal in mapping the landscape of septic tank technology, allowing us to distinguish between innovations focused on treatment processes (aerobic vs. anaerobic) and those related to the physical structure (shapes and materials) of tanks. Structure-based patents were further subdivided according to the specific shapes and materials identified during the comprehensive analysis. This approach not only facilitated a detailed examination of each structural variant but also highlighted evolutionary trends in septic tank design. For illustrative purposes and to provide concrete examples, representative patents from each structural category were selected and are detailed in Table 3.

Figure 5.

Categorisation of patents in the septic tank Patent Landscape Review (PLR).

Table 3.

The main shapes of septic tanks investigated in the PLR.

Through meticulous categorisation and analysis, a deeper understanding of both the historical evolution and current advancements in septic tank technologies was achieved. Each category was explored thoroughly to ascertain the direction of technological progress and innovation within the field.

3.3. Technological Updates

The final step involved a detailed examination of selected patents, leveraging tools such as the Derwent World Patent Index (DWPI) for curated data and the Derwent Patent Citation Index (DPCI) for assessing the influence and reach of specific patents. This review focused on technological updates, patent family size, and citation impact to draw insights into the technological advancements and their potential applications.

4. Results and Discussion

This section is structured into two primary subsections to provide a detailed examination of the current patent landscape and the latest technological advancements in septic tank systems. Section 4.1, ‘Patent Landscape Overview’, presents an aggregated view of the patent activities, highlighting key trends, geographical distributions, and filing dynamics over the studied period. This overview aims to provide macroscopic insight into the proliferation of septic tank technologies and the focus areas within this field. On the other hand, Section 4.2, ‘Technological Updates’, delves deeper into the specific technological innovations emerging from the patents, categorised into process-based, structure-based, and combined-based patents. This section explores the implications of these innovations and assesses their potential impact on the industry and environmental practices, providing a nuanced understanding of both discrete and integrated advancements in septic tank technology. Together, these sections aim to provide a comprehensive analysis of the advancements in septic tank technologies, mapping out the landscape of innovation and forecasting future directions in this vital field.

4.1. Patent Landscape Overview

From the comprehensive patent landscape search that initially yielded 2373 published patents using combined keywords and IPC codes, a total of 889 patents remained after resolving duplicates and irrelevant entries. This study focused on patent applications filed between January 2001 and June 2022, reflecting significant technological trends and innovations in septic tank technology during this period.

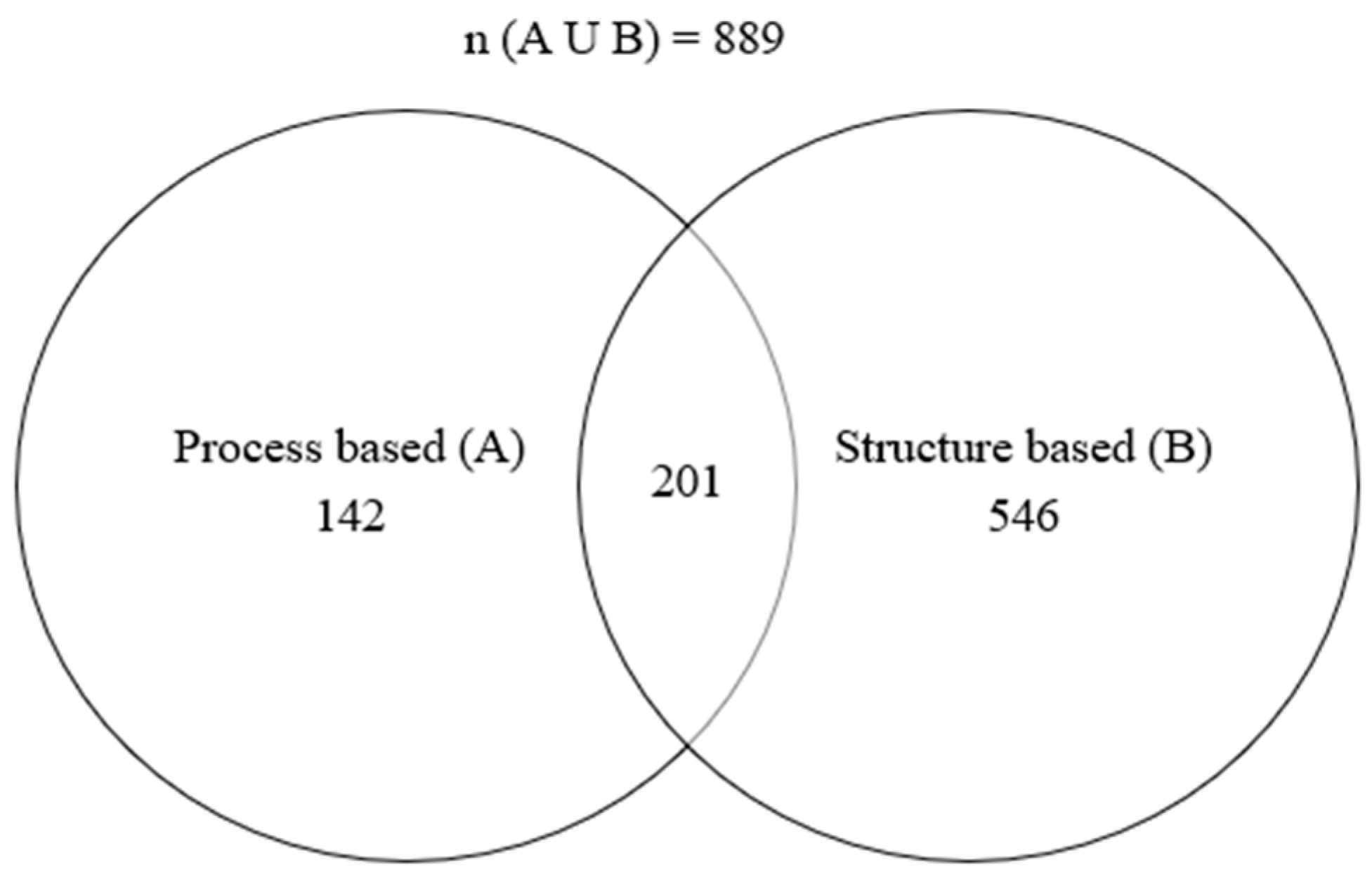

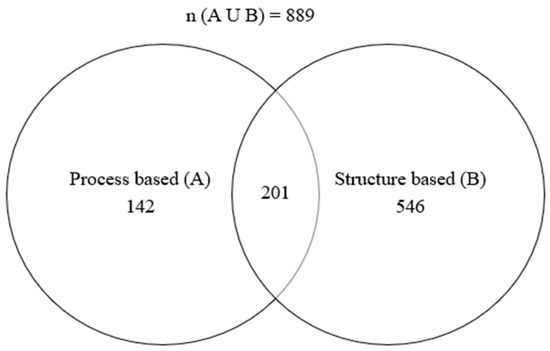

Figure 6 illustrates the classification of patents into distinct categories: structure-based, process-based, and those that encompass both elements. It visualises how patents are segmented based on the primary keywords and IPC codes used in the search, providing a clear representation of the overlap and distinct areas within the patent landscape for septic tank technologies. Out of the 889 patents, 201 were identified in both the structure- and process-based searches, illustrating the intersection of functional and structural innovations in septic tank technology. A majority of 546 patents were predominantly structure-based, while 142 patents focused on process innovations. This categorisation aided in understanding how advancements in materials and design have evolved alongside improvements in septic system processes.

Figure 6.

Venn diagram of structure-based and process-based categories for relevant patents from January 2001 to June 2022.

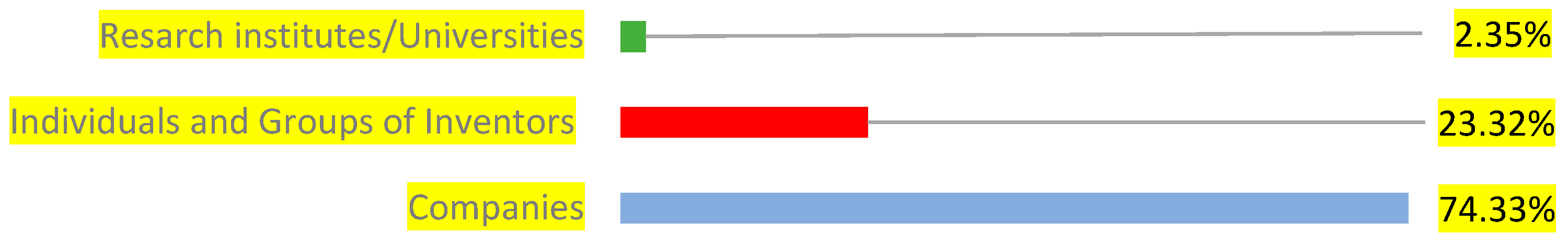

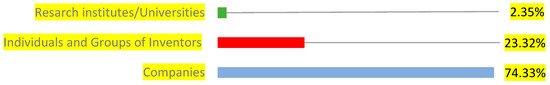

The categorisation of patent filers referred to as applicant profiles is pivotal for understanding the driving forces behind patent activities. To simplify the analysis, applicant profiles were segmented into three primary categories: companies, individuals and groups of inventors, and research institutes and universities. The classification of each patent was based on the ‘optimised assignee’ field in the patent documentation, which indicated the primary entity responsible for the patent and reflected the underlying corporate or organisational structure. In instances where a patent listed more than one optimised assignee, it was categorised under all applicable profiles to accurately reflect shared interests or collaborative efforts.

Figure 7 illustrates the distribution of patent filings among these groups, providing a visual representation of the varied motivations and contributions to the field of septic tank technology. The analysis revealed that companies were the predominant filers, accounting for almost three-quarters of all patents at 74.33%. This dominance underscored the significant commercial interest in septic tank technologies, likely driven by the potential for substantial financial returns. Individuals and groups of inventors also played a substantial role, contributing over a fifth of the filings at 23.32%. This group often represented grassroots innovation and entrepreneurial ventures within the field. In contrast, research institutes and universities accounted for only 2.35% of filings. These entities typically prioritised foundational research and technological developments aimed at societal benefits, often with less emphasis on direct financial gain.

Figure 7.

Patent filing activity by applicant profile from January 2001 to June 2022.

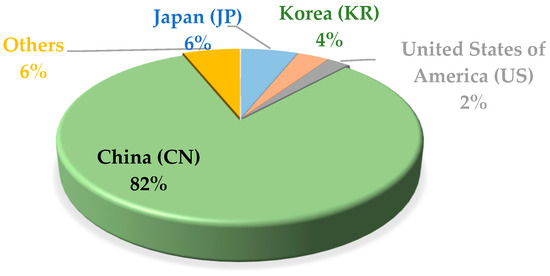

The geographical distribution of patent filings revealed dominant players and regional focuses in septic tank development from January 2001 to June 2022. The analysis categorised the data into developed and developing countries, highlighting significant differences in the adoption and technological advancement of septic systems.

In developed countries such as Australia, Canada, Germany, Spain, France, Greece, Japan, the Netherlands, New Zealand, Poland, Romania, the Russian Federation, Ukraine, and the United States, there was a higher incidence of patents related to aerobic septic tanks. This trend reflects a preference for more technologically advanced and resource-intensive septic systems that offer faster waste breakdown and better effluent quality, supported by the availability of advanced materials and technologies. Conversely, developing countries, including Brazil, China, Colombia, Indonesia, India, Korea, Mexico, Malaysia, the Philippines, Thailand, Taiwan, and Vietnam, exhibited a greater reliance on anaerobic septic tanks. These systems are favoured for their lower cost, simpler installation, and reduced energy requirements, making them more suitable for regions with limited economic resources or less developed waste management infrastructure.

A detailed table is included to provide a comprehensive overview of these variations (Table 4). This table categorises the types of septic tanks used across different regions and indicates the preferred technologies in developed versus developing countries.

Table 4.

Comparative overview of septic tank technologies used in developed and developing countries.

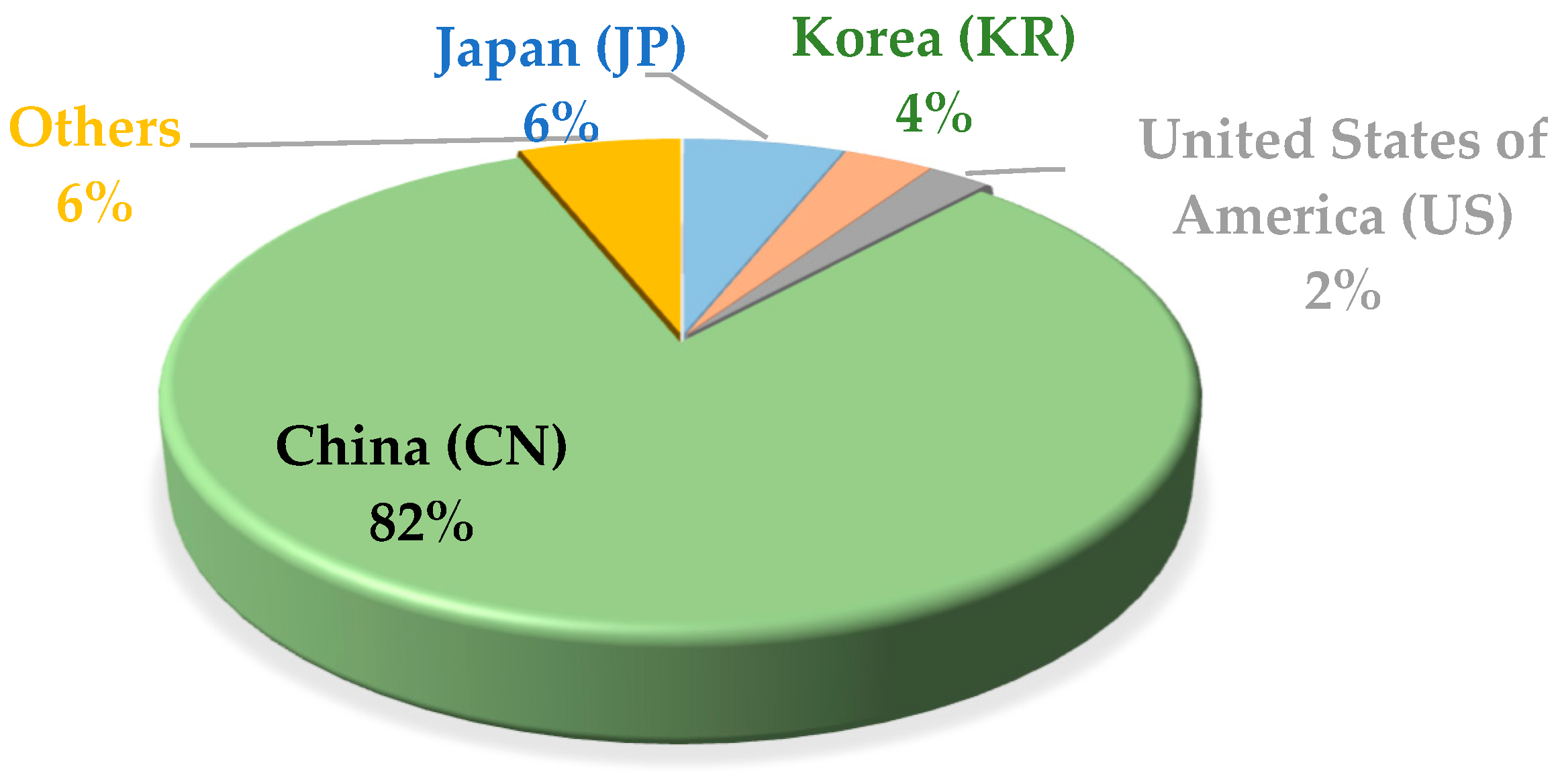

As shown in Figure 8, China led with an overwhelming majority, accounting for more than four-fifths of the total patents at 730, indicating a significant focus on advancing septic tank technologies within the country. Japan, South Korea, and the U.S. followed with 54, 30, and 21 patents, respectively, highlighting their contributions to the field. Other countries collectively filed 54 patents, with Brazil, Russia, Thailand, and Taiwan each filing more than five patents over the analysed period, reflecting a broader, yet less concentrated, global interest in septic tank technology improvements.

Figure 8.

Patent filing countries from January 2001 to June 2022.

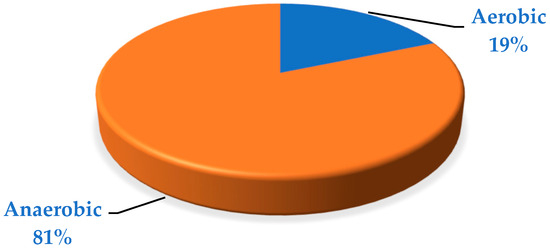

In the categorisation of patents based on the treatment processes used in septic tanks, if the specific process was not mentioned in a patent, it was typically assumed to be anaerobic digestion. Anaerobic digestion is the predominant method for sludge breakdown in septic tanks due to its operational simplicity and effectiveness without the need for additional oxygen.

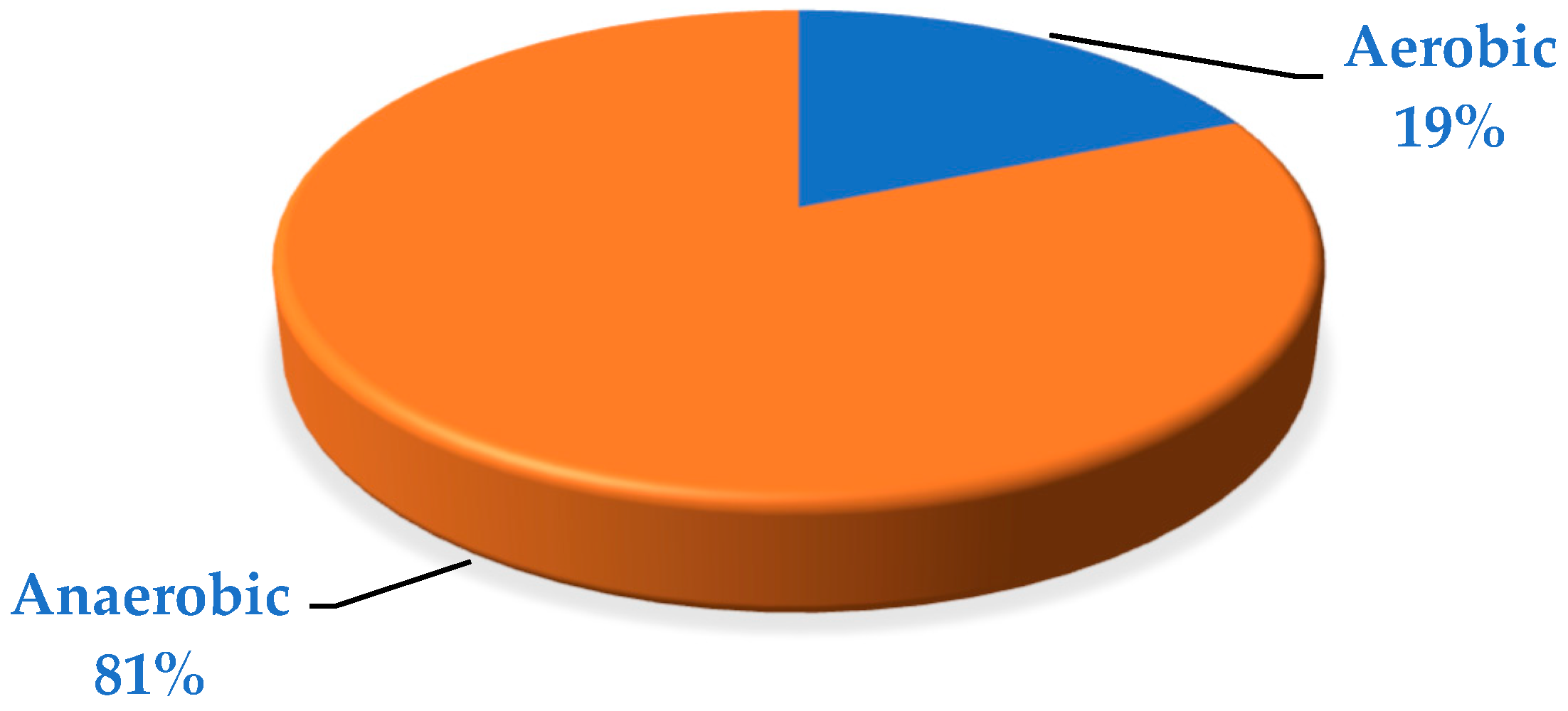

Figure 9 illustrates the distribution between anaerobic and aerobic septic systems. It reveals that anaerobic digestion-based septic tanks significantly outnumbered those based on aerobic digestion, with over four-fifths of the patents falling into the anaerobic category. Only less than 20% of septic tanks utilised aerobic processes. The prevalence of anaerobic systems can largely be attributed to their simpler design and lower complexity. Aerobic systems, while effective, require additional components such as air pumps or blowers to facilitate the oxygenation necessary for aerobic digestion, adding to the complexity and cost of the system. This inherent simplicity of anaerobic systems makes them more accessible and easier to implement, which is reflected in their dominant presence in patent filings.

Figure 9.

Process-based search categories from relevant patents from January 2001 to June 2022.

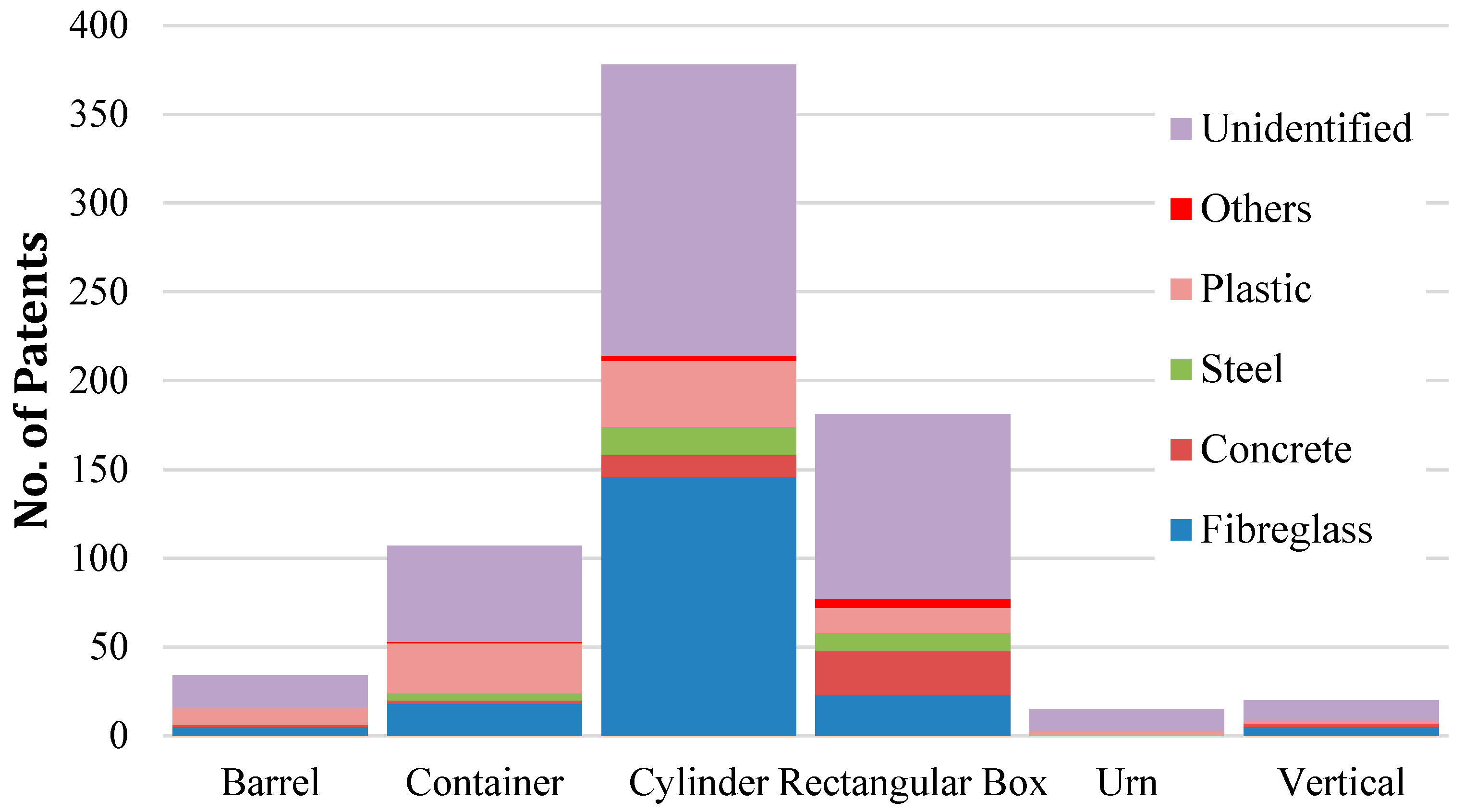

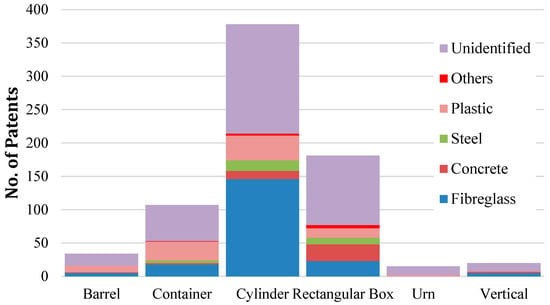

In the structure-based search categories of this study, a variety of septic tank shapes and materials were identified and recorded as the review of patents progressed. The analysis revealed six main shapes commonly used in septic tank design: cylinders, rectangular boxes, containers, barrels, vertical shapes, and urns. Figure 10 illustrates the proportion of patents categorised by different septic tank shapes and further details the materials used in their construction. It provides a visual breakdown of the most commonly used shapes—cylinders, rectangular boxes, containers, barrels, vertical shapes, and urns—and correlates these with materials such as fibreglass, plastic, concrete, and others. This visualisation helps in understanding the trends in material preferences and design choices within the septic tank industry, showcasing how different materials are favoured for specific tank configurations.

Figure 10.

Structure-based search categories from relevant patents from January 2001 to June 2022.

The cylindrical shape emerged as the most prevalent due to its effective volume utilisation and ease of manufacture, followed by the versatile rectangular boxes and containers that accommodate a range of installation environments.

In terms of material, fibreglass, or glass fibre-reinforced plastic, was the predominant material, favoured for its strength, lightweight nature, and corrosion resistance. These properties make fibreglass ideal for septic tanks, enhancing their durability and reducing maintenance requirements. Plastics, including polyethene and polypropylene, ranked as the second most used materials, offering a cheaper alternative to fibreglass, with considerable flexibility in terms of tank shapes and sizes. Concrete was frequently employed due to its robustness, making it suitable for larger installations that demand long-term durability. Although less common, materials such as steel and cement were also noted in the literature. However, they are generally less preferred due to factors such as higher costs and susceptibility to corrosion. Moreover, patents that did not clearly indicate their material composition were classified as ‘unidentified’, which could be attributed to either proprietary concerns or incomplete documentation in the patent records.

The discovery and categorisation of these materials and shapes during the patent review process highlighted ongoing innovations and adaptations in septic tank technology. These advancements were driven by demands for cost-efficiency, installation flexibility, and environmental considerations.

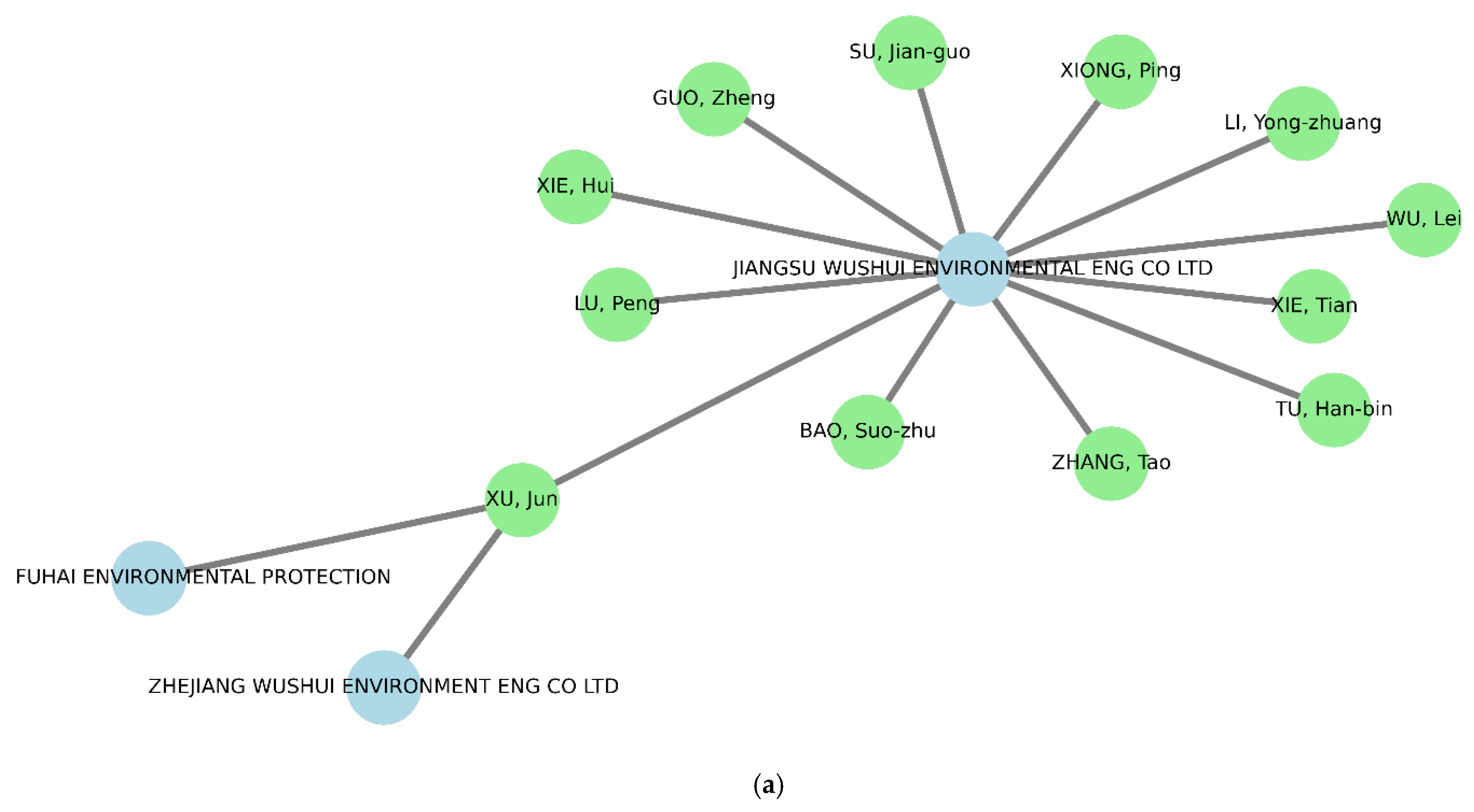

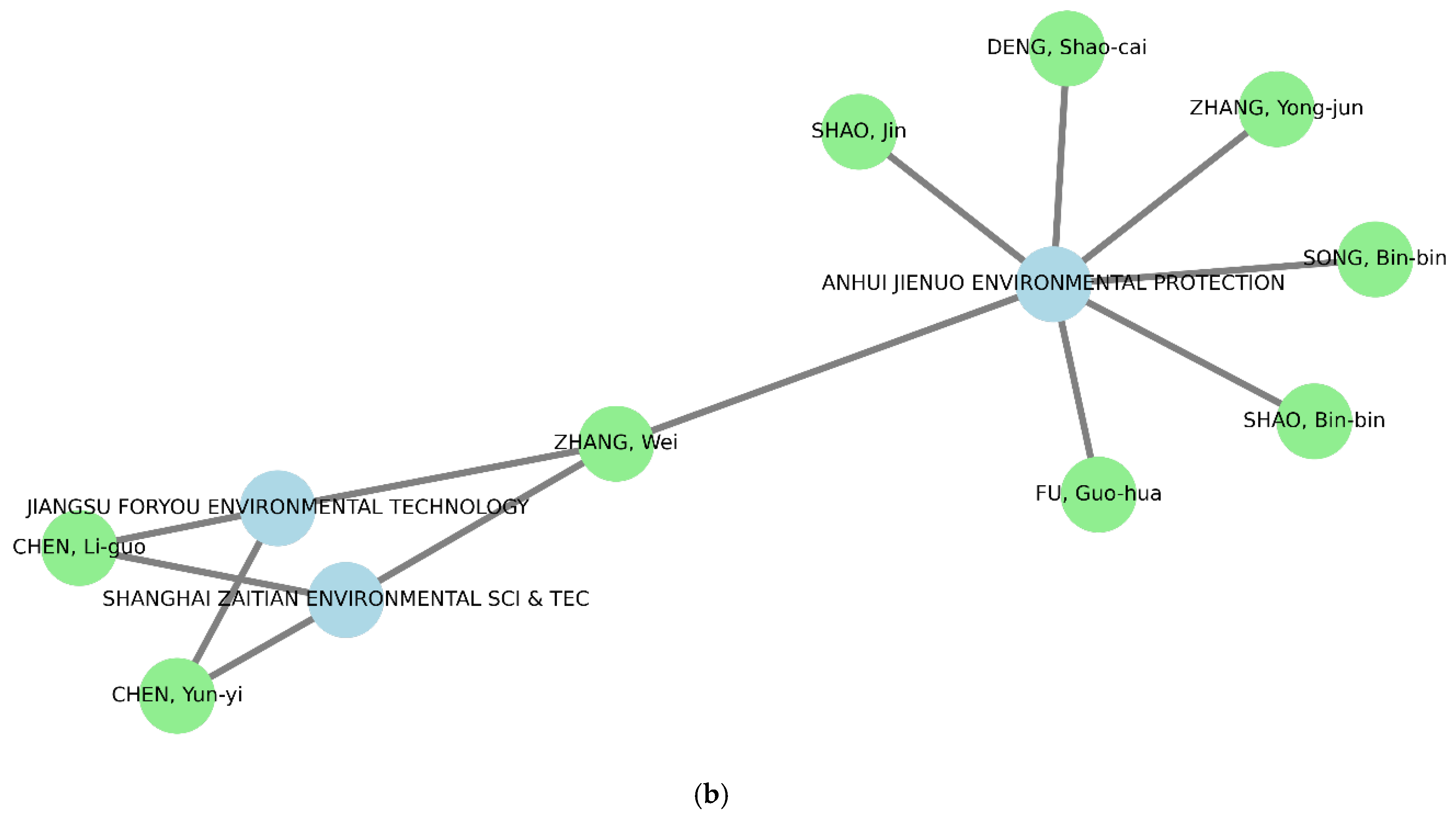

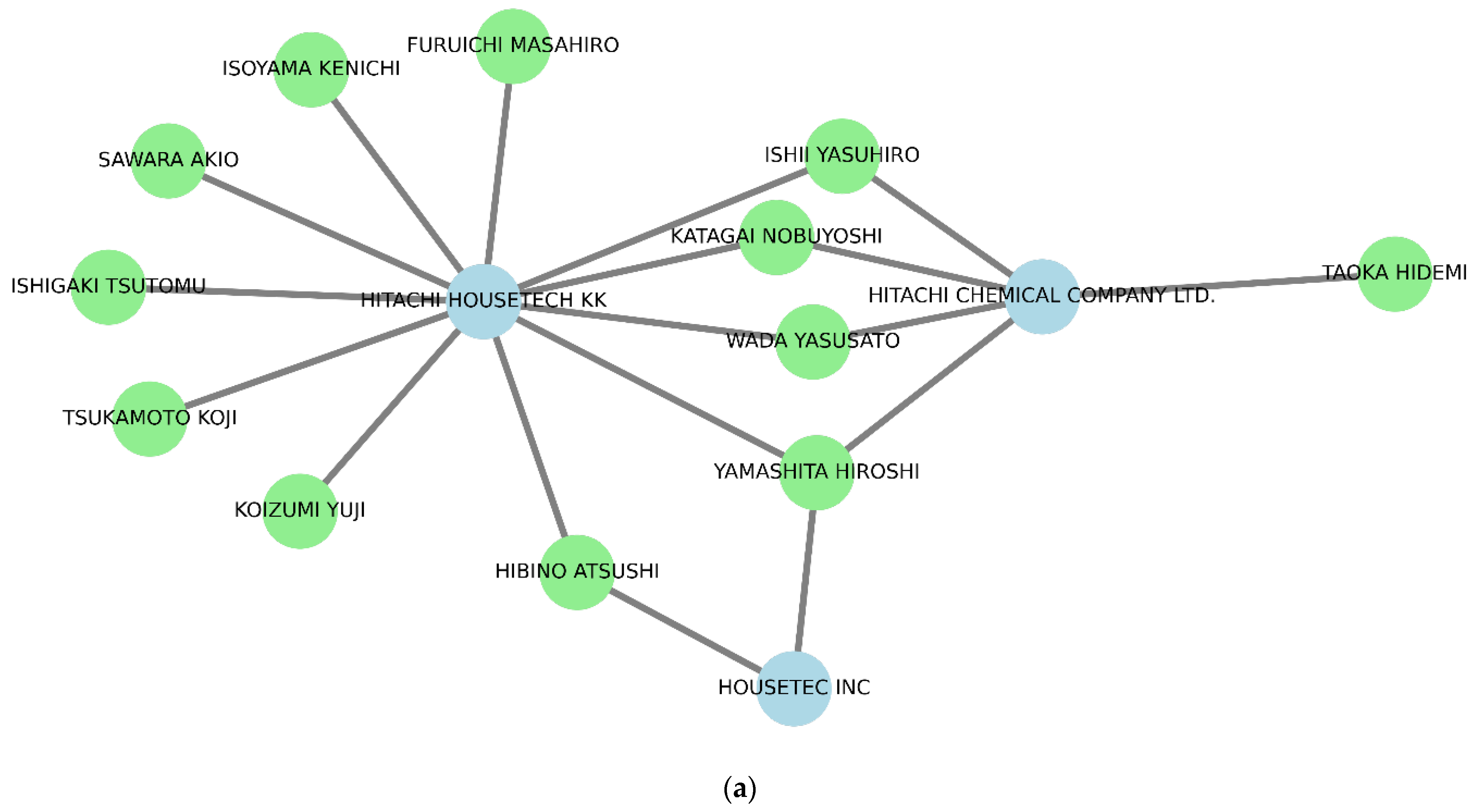

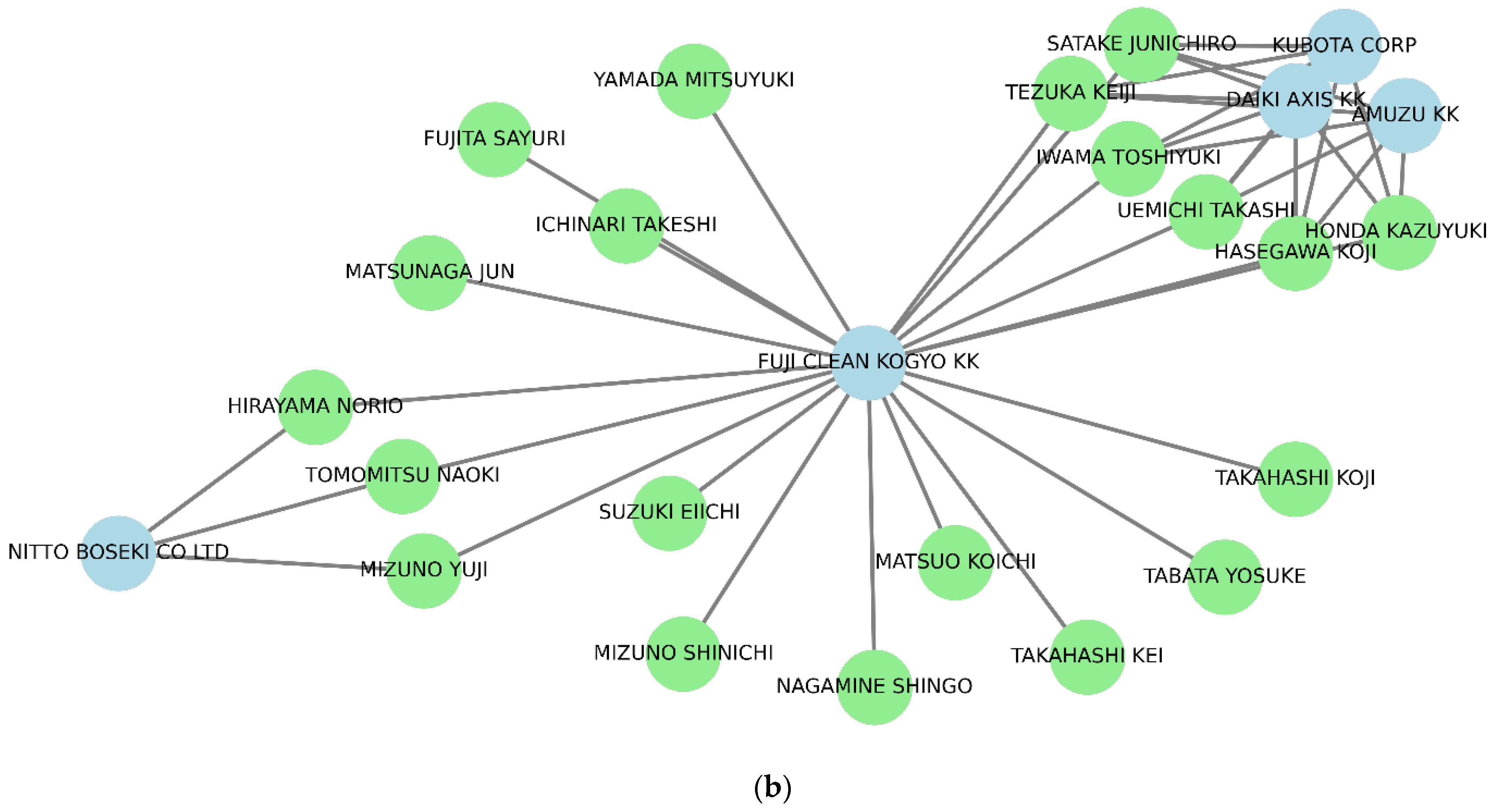

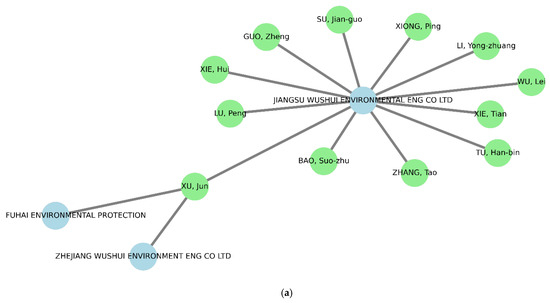

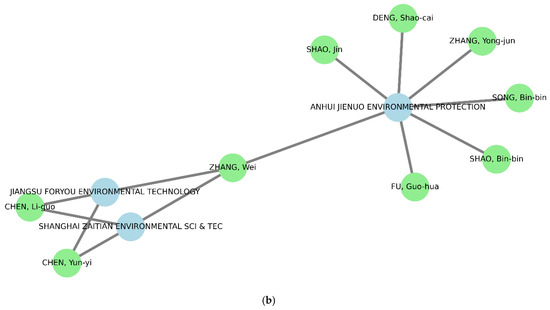

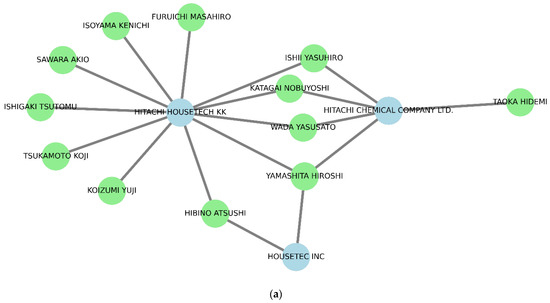

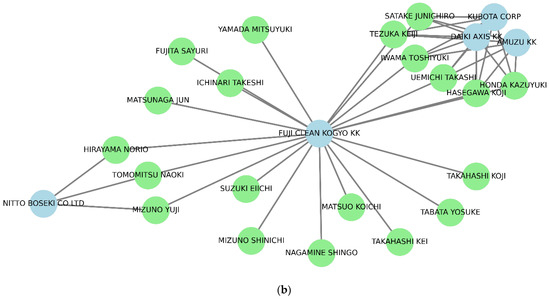

Figure 11 and Figure 12 showcase network diagrams that illustrate this and which are crucial for visualising the collaborative dynamics and synergies that drive innovation in the industry. They also help identify key players and their relationships, which can prevent redundant work and foster resource conservation by highlighting potential areas for collaboration.

Figure 11.

Collaboration networks in Chinese septic tank patent filings. (a) Collaborations involving inventor Xu Jun with Fuhai Environmental Protection, Jiangsu Wushui Environmental Engineering Co., Ltd. and Zhejiang Wushui Environment Eng Co., Ltd. from 2017 to 2020. (b) Collaborations of inventor Zhang Wei with entities like Anhui Jienuo Environment Protection and Jiangsu Foryou Environmental Technology. Light blue nodes indicate the entities holding patents and light green nodes represent the inventors of the patents.

Figure 12.

Collaborative networks in Japanese septic tank patents. (a) Collaborations involving Hitachi Chemical Company Ltd. and other entities from 2001 to 2019. (b) Fuji Clean Kogyo’s patent activities and partnerships in 2002. Light blue nodes indicate the entities holding patents and light green nodes represent the inventors of the patents.

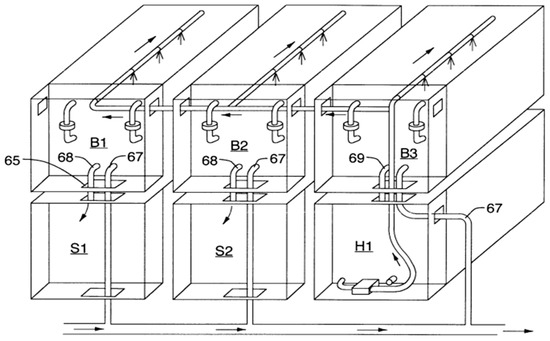

In 2017, inventor Xu Jun filed a patent under Fuhai Environmental Protection [56], marking the beginning of a series of innovations in high-efficiency, high-resistance, glass fiber-reinforced plastic septic tanks. Subsequent collaborations saw Xu Jun partnering with Jiangsu Wushui Environmental Engineering Co., Ltd. [57] and Zhejiang Wushui Environment Eng Co., Ltd. [58] in 2018 and 2020, respectively, leading to further advancements in this technology. Similarly, Jiangsu Wushui Environmental Eng Co., Ltd. expanded its patent portfolio, with four additional patents on similar technologies, developed by a team including Xie Tian, Xie Hui, and others, illustrating a concentrated effort in this area [59,60,61]. This network of collaborations is shown in Figure 11a.

Figure 11b illustrates inventor Zhang Wei’s extensive collaborative efforts, in which he filed two patents under Anhui Jienuo Environment Protection and Jiangsu Foryou Environmental Technology, as well as with Shanghai Zaitian Environmental Sci & Tec. These collaborations involved multiple co-inventors and were aimed at enhancing septic tank technologies, showcasing a vibrant network of innovation within the region [62,63].

The early 2000s marked a prolific period for Hitachi Chemical Company Ltd., which published two significant patents related to septic tanks in 2001 alone. The first patent was the result of collaborations involving Katagai Nobuyoshi and Yamashita Hiroshi, while the other was invented by Ishi Yasuhiro, Wada Yasusato, Yamashita Hiroshi, and Taoka Hidemi [64,65]. From 2001 to 2005, Hitachi Housetech continued this trend, registering eight patents that contributed to advancements in septic tank design and function [64,65,66,67]. These patents were invented by the same inventors from Hitachi Chemical Company: Katagai Nobuyoshi, Ishi Yasuhiro, Wada Yasusato, and Yamashita Hiroshi, as well as additional inventors: Furuichi Masahiro, Isoyama Kenichi, Tsukamoto Koji, Sawara Akio, Ishigaki Tsutomu, Koizumi Yuji, and Hibino Atsushi. Hibino Atsushi published a patent under Housetec Inc. in 2016 and, in 2019, he collaborated with Yamashita Hiroshi and published another patent on a septic tank under the same optimised assignee [66,67]. This information can be seen in Figure 12a.

Fuji Clean Kogyo was active in the patent landscape (Figure 12b), filing nine patents in 2002 concerning septic tank technologies and methods for treating sewage [68,69,70,71,72,73,74,75,76]. Collaborations with Nitto Boseki Co., Ltd. enriched this endeavour, culminating in additional filings in the same year with inventors Mizuno Yuji, Hirayama Norio, and Tomomitsu Naoki [77]. Fuji Clean Kogyo also co-filed another patent with Kubota Corp., Daiki Axis, and Amuzu in 2005, invented by a group of inventors from different companies: Honda Kazuyuki, Uemichi Takashi, Satake Junichiro, Tezuka Keiji, Hasegawa Koji, and Iwama Toshiyuki [78].

These network diagrams provide a snapshot of the collaborative landscape within the septic tank industry, illustrating how companies and inventors across different regions are interconnected through their collective efforts to drive technological progress.

4.2. Technology Updates on Septic Tank Technology

This section provides a detailed analysis of septic tank patents that stand out based on several key indicators: the highest Derwent World Patents Index (DWPI) count of family members and the Derwent Patents Citation Index (DPCI) count of citing patents. Additionally, it includes an examination of both the most recent and the earliest patents in the areas of process and structure. This approach aims to highlight significant technological trends and advancements within the septic tank industry, offering insights into how these technologies have evolved over time and their potential future trajectory. By categorising the patents into process-based, structure-based, and combined, this analysis provides a comprehensive overview of the innovative landscape and its impact on the field. All numerical identifiers in the following figures, corresponding to component names of the selected patents, are detailed in Appendix A.

4.2.1. Technology Updates on Process-Based Septic Tanks

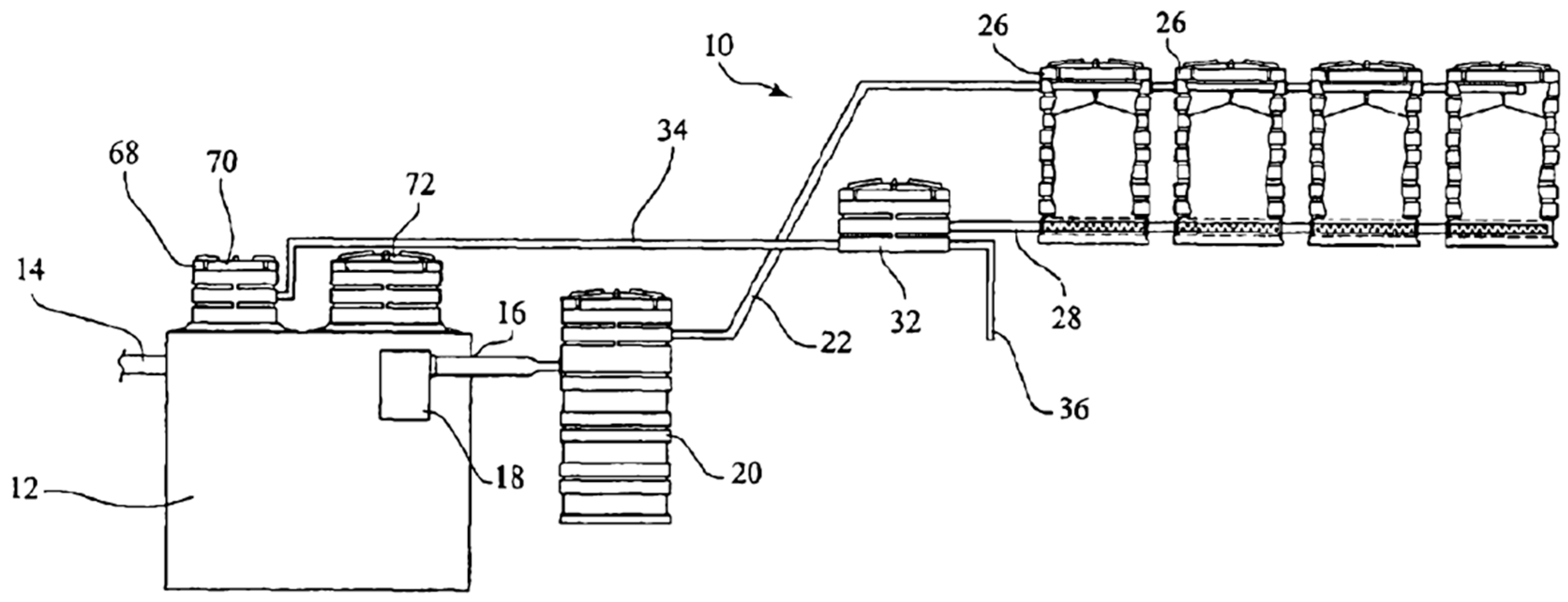

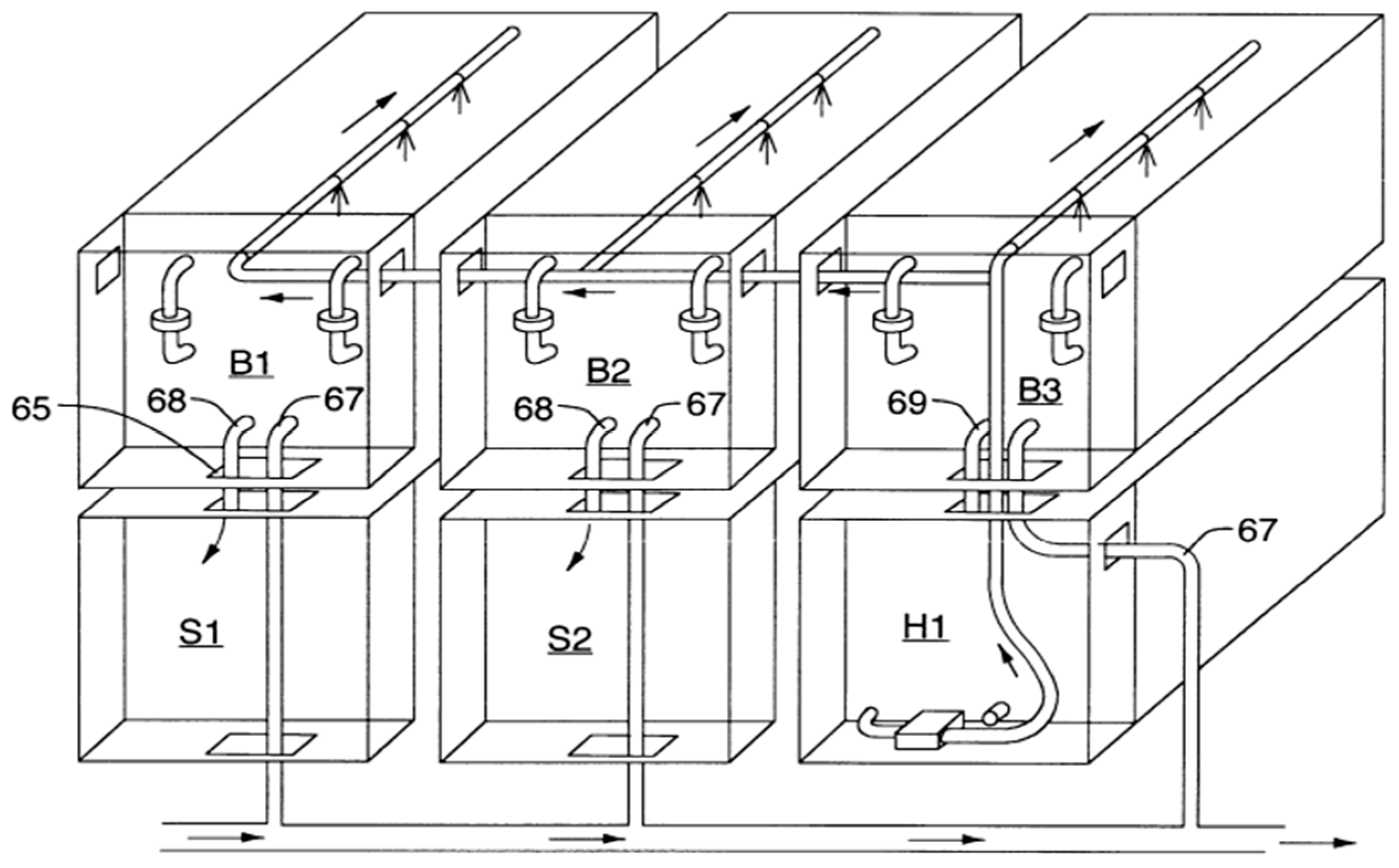

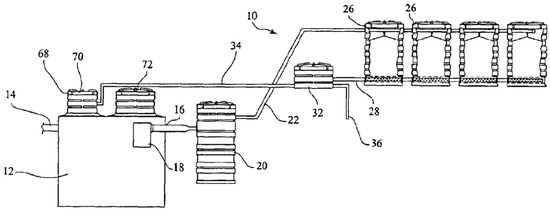

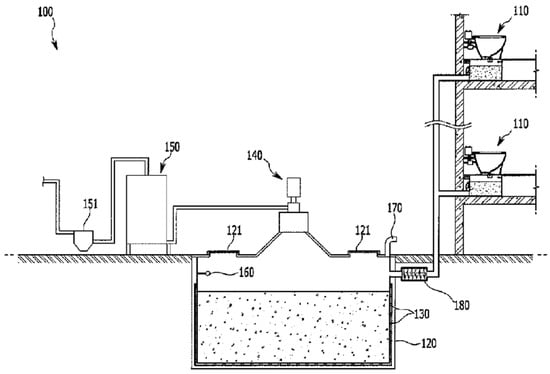

Patent AU2004218003B2 [79] introduced an advanced wastewater treatment system that incorporates a septic tank coupled with one or more biofilter containers. This innovation was selected for analysis due to its notable presence in the Derwent World Patents Index (DWPI), as it has the highest family count and the third-highest Derwent Patents Citation Index (DPCI) count of citing for process-based patents. The system, depicted in Figure 13, operates by directing wastewater from the septic tank (no. 12 in Figure 13) through a filter (no. 18), which then moves into an additional tank (no. 20). From there, it travels through a conduit before being processed in one or more biofilter containers (no. 26). This configuration enhances the wastewater treatment capabilities beyond those of traditional septic systems by incorporating biofiltration stages that improve effluent quality and reduce environmental impact.

Figure 13.

Septic tank from patent AU2004218003B2 [79].

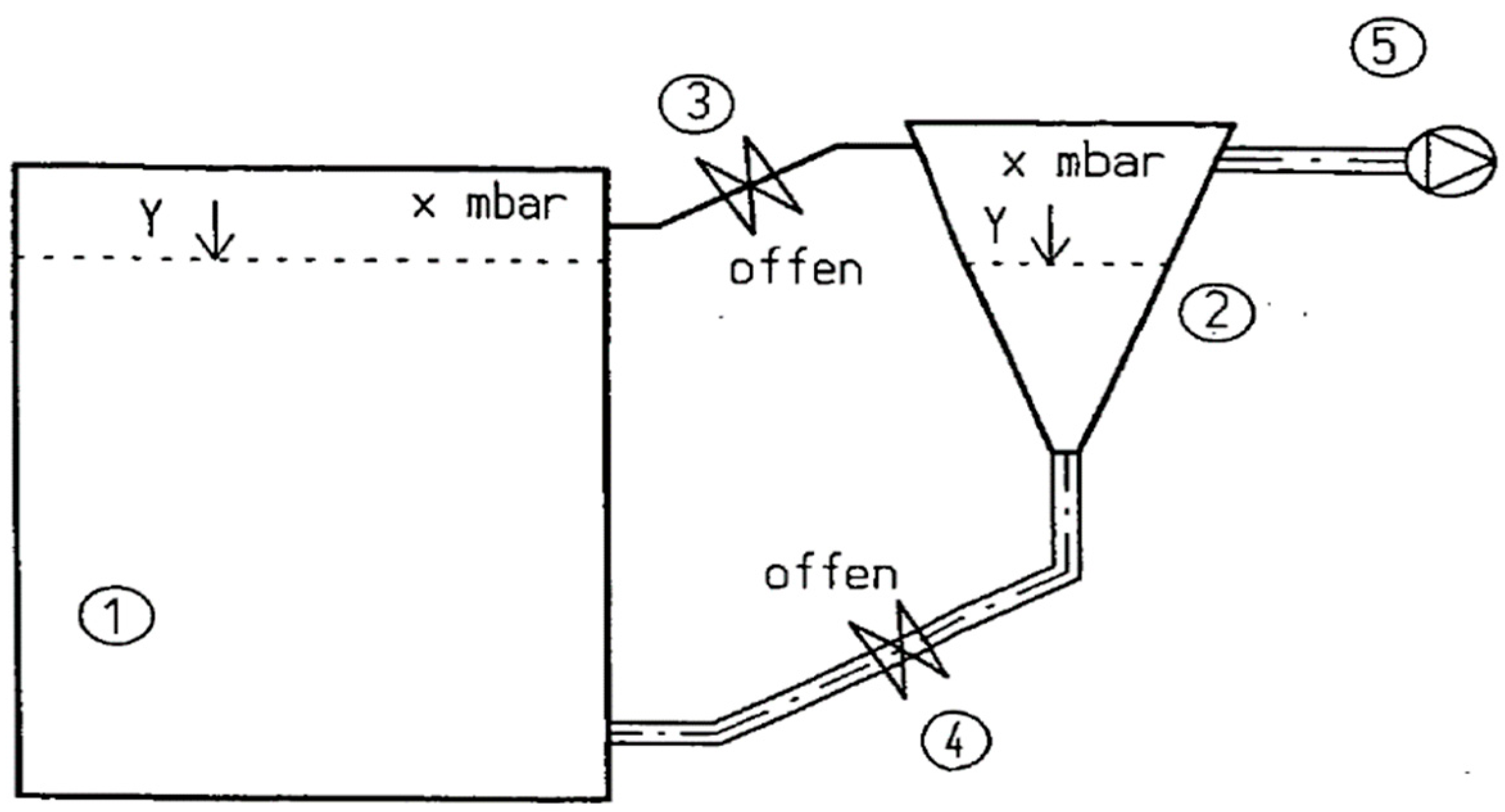

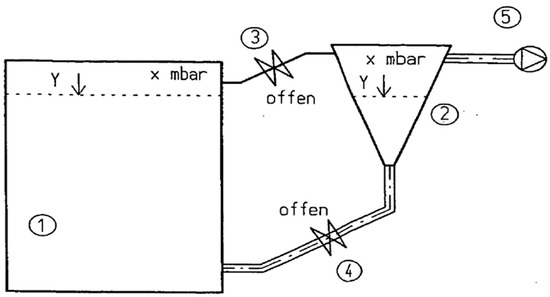

Building upon advancements in septic tank technology, the German patent DE502007002448D1 [80], titled ‘Verfahren Zur Behandlung von Schlämmen’ or ‘Process for treating sludges’, introduced another innovative septic tank system designed specifically for enhanced sludge treatment. Similar to the Australian patent AU2004218003B2, which integrates biofilters for improved wastewater treatment, this German patent also emphasises efficiency in processing but focuses on sludge management within septic systems. Selected for its high DWPI family count among process-based patents, this system features a novel configuration consisting of two separate tanks and a gas pump. The operational mechanism involves transferring digested sludge from the primary septic tank (1) in batches to a secondary digested sludge enrichment reactor (2). The enriched sludge is then recirculated back to the septic tank, optimising the treatment process. This circulation is facilitated by a gas pump, ensuring the efficient movement and treatment of sludge, as depicted in Figure 14. This method enhances the breakdown and stabilisation of sludge, thereby improving the overall efficiency and effectiveness of the septic system.

Figure 14.

Septic tank with a digested sludge enrichment reactor, patent DE502007002448D [80].

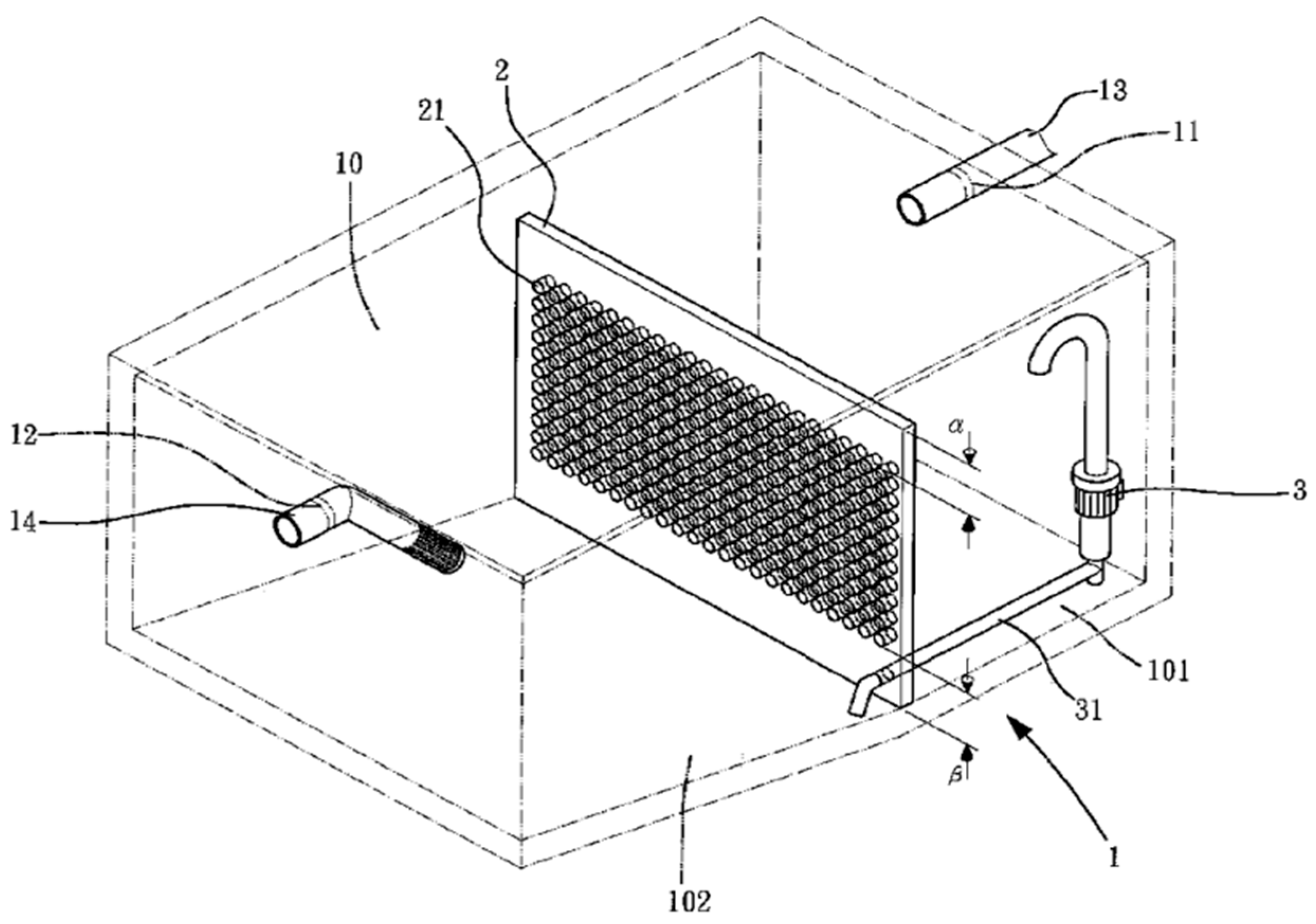

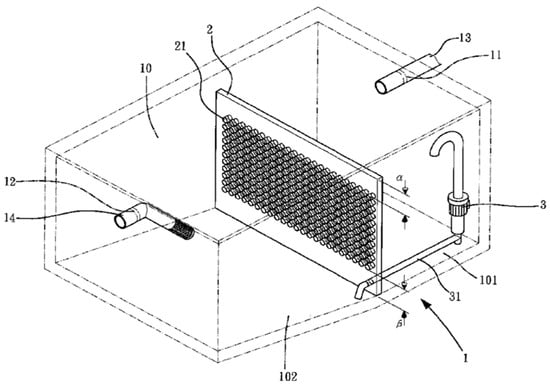

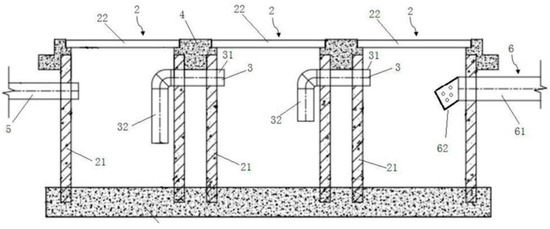

Continuing the examination of innovative septic tank designs, U.S. patent US7282143B2 [81] introduced a septic tank with two sub-chambers separated by a partitioning member. This design offers a significant enhancement over the single-chamber systems discussed in patents AU2004218003B2 and DE502007002448D1, which utilise either additional external biofilter containers or a basic sludge treatment approach. Selected for its high impact, evidenced by the second-highest DPCI count of citing for process-based patents, this dual-chamber design addresses several challenges inherent in traditional septic systems. The partitioning member is designed with small holes that allow water transfer while blocking the passage of suspended solids into the second chamber. This feature enhances sediment control, significantly improving the separation process and preventing the carryover of solids, which often leads to system clogs and inefficiency.

Moreover, the dual-chamber structure allows for more refined management of the biological degradation process. The first chamber acts as the primary treatment zone, where solids settle and begin decomposing anaerobically. The separated second chamber then serves as the secondary treatment stage, providing further degradation and clarification of the wastewater. This staged treatment process results in a higher effluent quality and reduces the frequency of septic tank pumping, ultimately extending the lifespan of the septic system. The dual chambers also facilitate a more controlled discharge rate, which is critical in preventing overload of the drain field and enhancing overall environmental safety. Figure 15 illustrates this septic tank, highlighting the two sub-chambers and the partitioning member (2), which plays a crucial role in optimising the treatment efficacy and operational reliability of the system.

Figure 15.

Septic tank, patent US7282143B2, and its partitioning member [81].

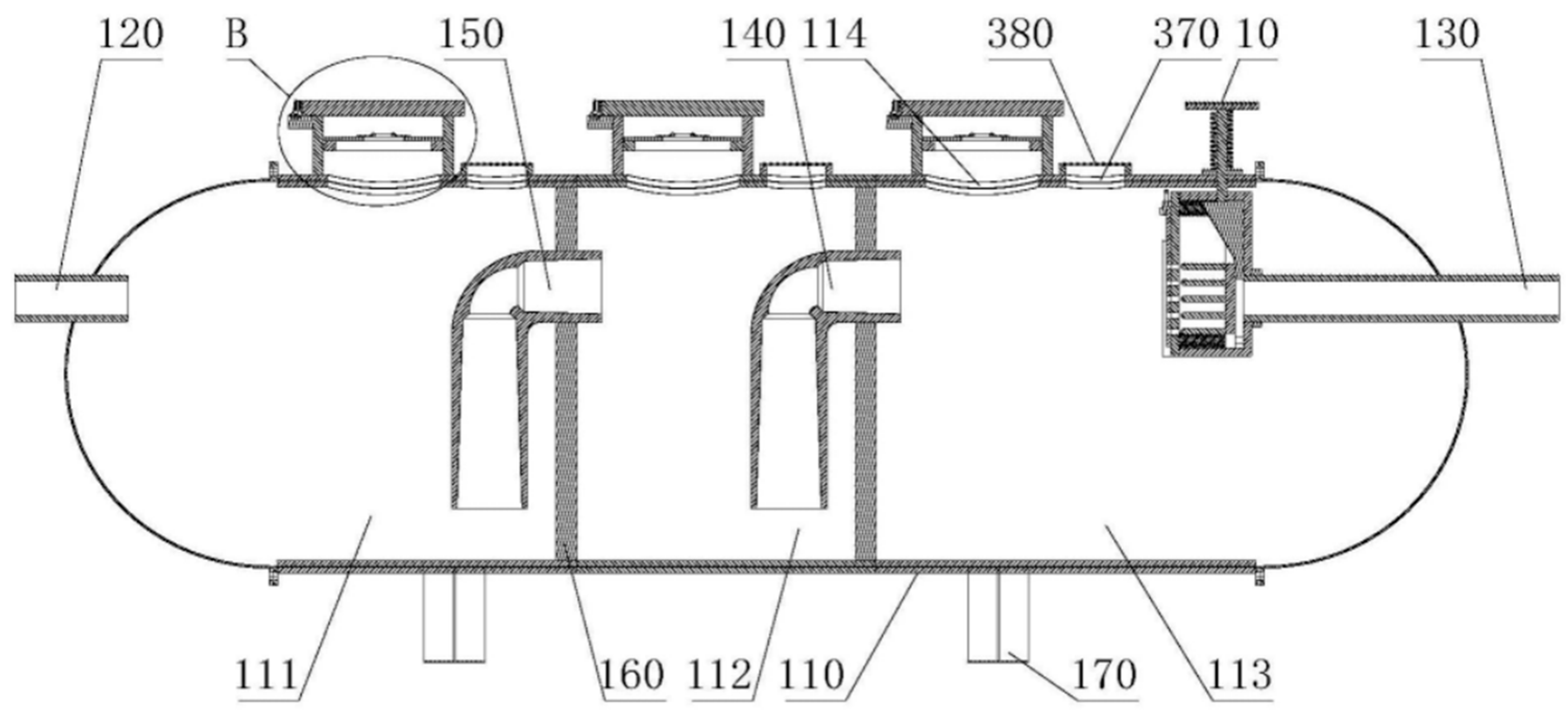

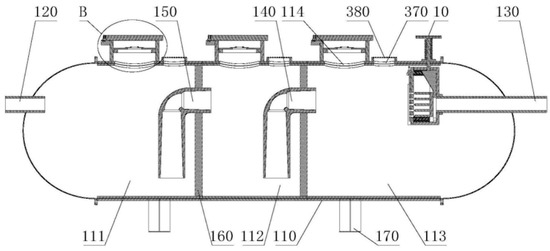

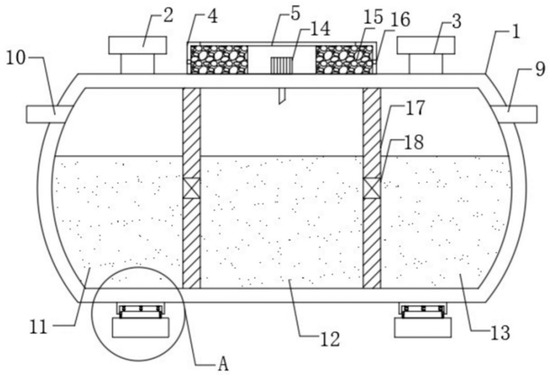

Building upon the progression from single to dual-chamber septic tanks, as seen in U.S. patent US7282143B2, Chinese patent CN114988659A [82] introduced a further evolution, with its three-chamber system aimed at enhancing environmental efficiency for farm use. This patent, which holds the most recent priority date among process-based patents, exemplifies the latest advancements in septic tank technology. The system, detailed in Figure 16, includes a novel filtering and blockage prevention mechanism (no. 10 in Figure 16) situated before the tank’s outlet, optimising waste processing and enabling adaptability for both agricultural and domestic applications.

Figure 16.

Side profile of the environmentally friendly septic tank, patent CN114988659A [82].

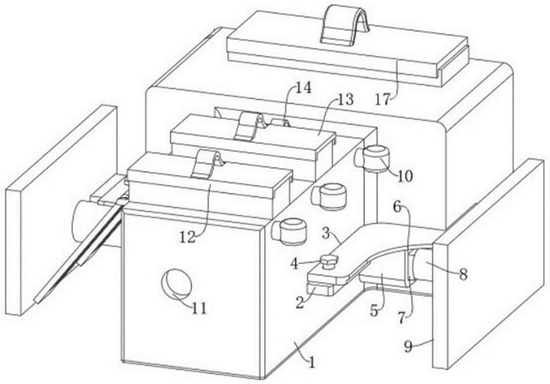

Expanding on the multi-chamber approach, another Chinese patent, patent CN217351132U [83], also features a three-chamber system comprising a primary septic tank, a deep septic tank, and a clarifying tank. Selected as the second most recent patent based on priority date among process-based patents, this design not only enhances the separation and treatment processes but also offers better structural support. It simplifies the installation, reducing construction time and labour significantly compared to traditional systems. This integrated steel septic tank design is depicted in Figure 17.

Figure 17.

Integral turnover steel septic tank, patent CN217351132U [83].

These advancements in multi-chamber septic tanks represent a significant shift towards more sophisticated, efficient, and versatile waste management solutions. Each additional chamber allows for more staged and thorough processing of waste, thereby improving the system’s overall efficiency and environmental impact. This is achieved by facilitating more effective sedimentation and digestion before discharge.

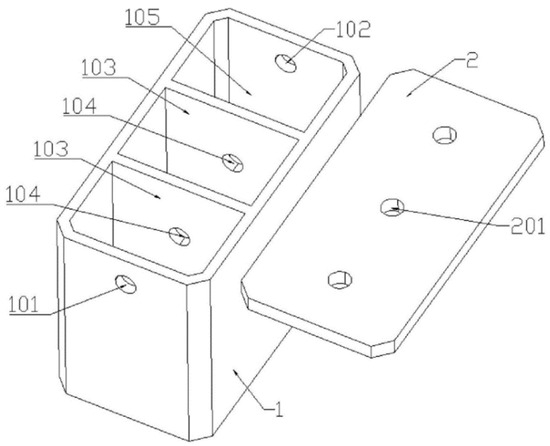

Further advancing the concept of multi-chamber septic systems, as exemplified by patents CN114988659A and CN217351132U, the Chinese patent CN217265358U [84] introduced an integrated multi-stage septic tank. This represents one of the latest innovations in the process-based patents category. This design utilises clapboards with strategically placed holes to create distinct stages within the tank, allowing for the sequential treatment and settling of solids. Notably, the water inlet and outlet of the septic tank are aligned at the same height, while the holes in the clapboards are positioned lower. This arrangement enhances the settling process and significantly improves the effluent quality by ensuring that wastewater remains in each chamber for a longer period of time, thus enabling effective treatment.

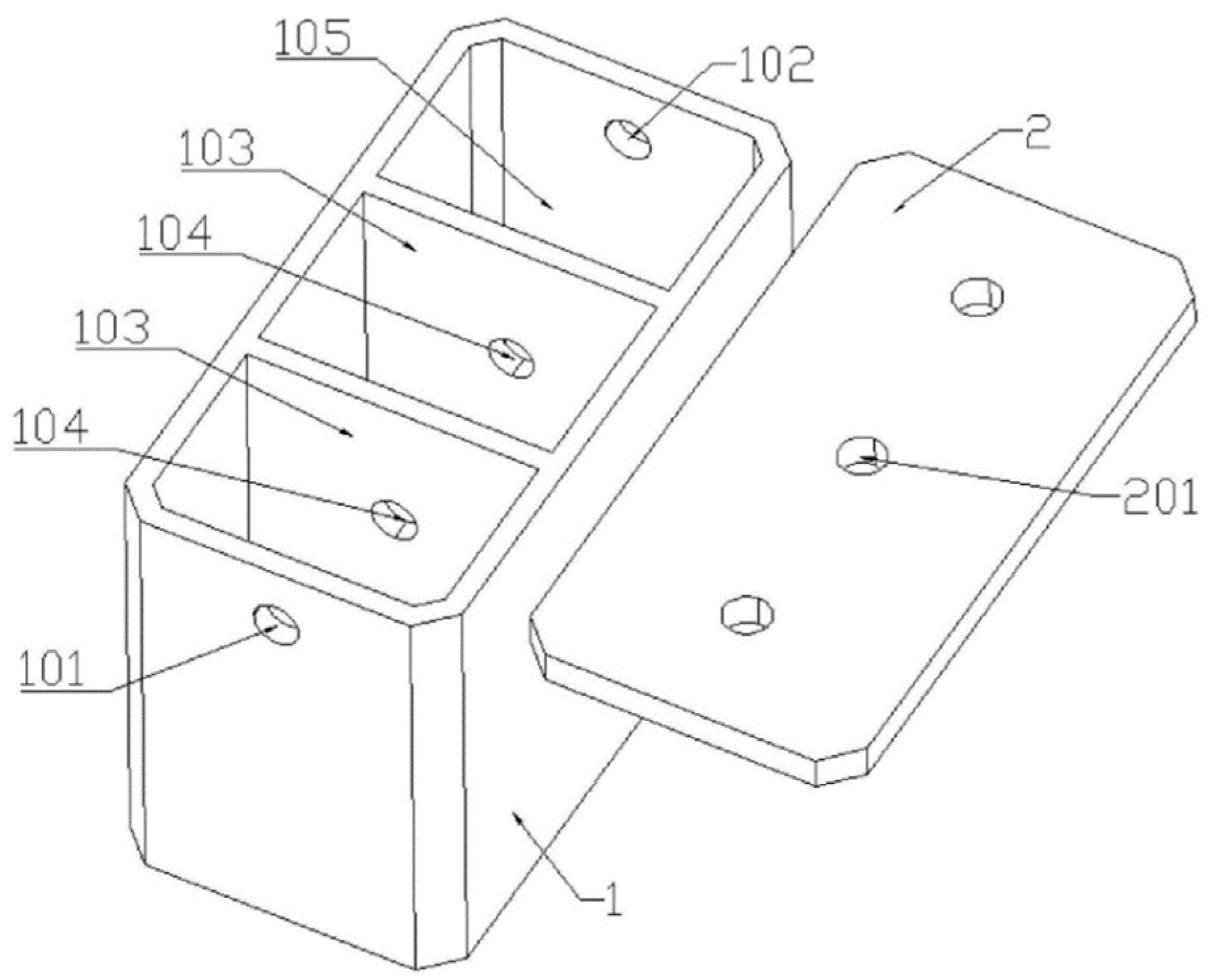

This patent, which is the third most recent in its category, showcases practical advancements in septic tank design. The straightforward design of the clapboards facilitates easier manufacturing and installation, making it a practical solution for efficient wastewater management. Figure 18 illustrates this innovative use of clapboards (103) within the septic tank main body (1), highlighting how each chamber contributes to the overall effectiveness of the system.

Figure 18.

Integrated multi-stage septic tank, patent CN217265358U [84].

This study explores the technological advancements in process-based patents related to septic tank technologies. The findings highlight a clear trend towards more efficient and environmentally friendly solutions for wastewater management. The evolution from single-chamber designs to multi-chamber configurations represents a significant step forward in optimising the treatment process, improving the quality of effluent, and minimising the environmental impact. The recent shift from dual to triple-chamber systems, as evidenced by the latest patents, demonstrates a dedication to enhancing separation and sedimentation processes. This development ensures that septic systems are not only more effective but also adaptable to the diverse needs of both residential and commercial settings.

Moreover, the integration of features such as biofilters, enhanced sludge treatment mechanisms, and innovative clapboard designs within these systems emphasises a commitment to technology that promotes sustainable practices. These improvements, which are rooted in process-based approaches, play a crucial role in ensuring the long-term viability and efficiency of septic systems, particularly in areas without access to centralised sewer systems.

As the discussion transitions from process-based enhancements to structure-based patents, it becomes clear that the drive for innovation in septic tank design is integral to addressing both current and future challenges in wastewater management. The forthcoming section delves into structural innovations that complement these process-based advancements, thus continuing our exploration of how modern engineering meets environmental stewardship.

4.2.2. Technology Updates on Structure-Based Septic Tanks

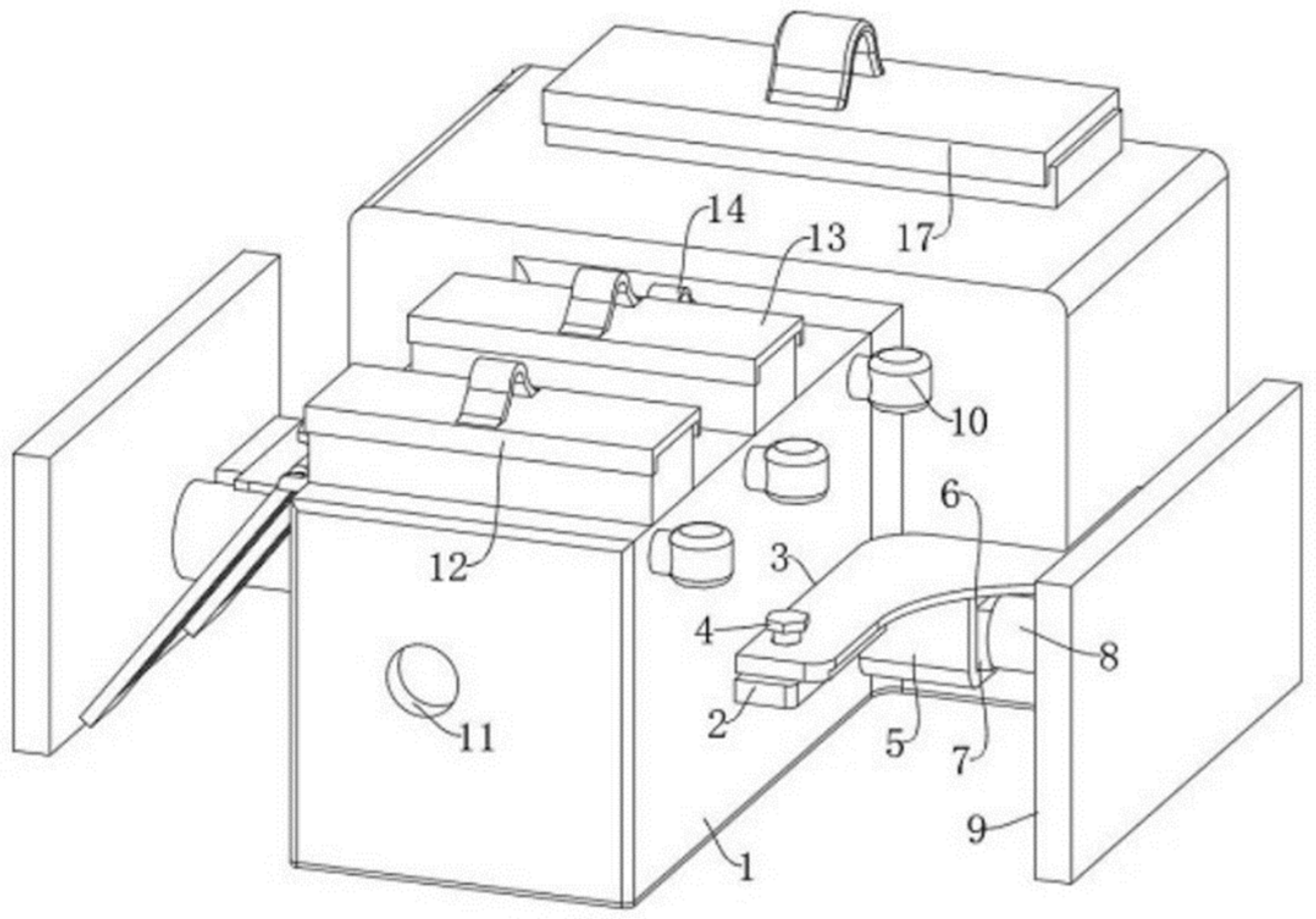

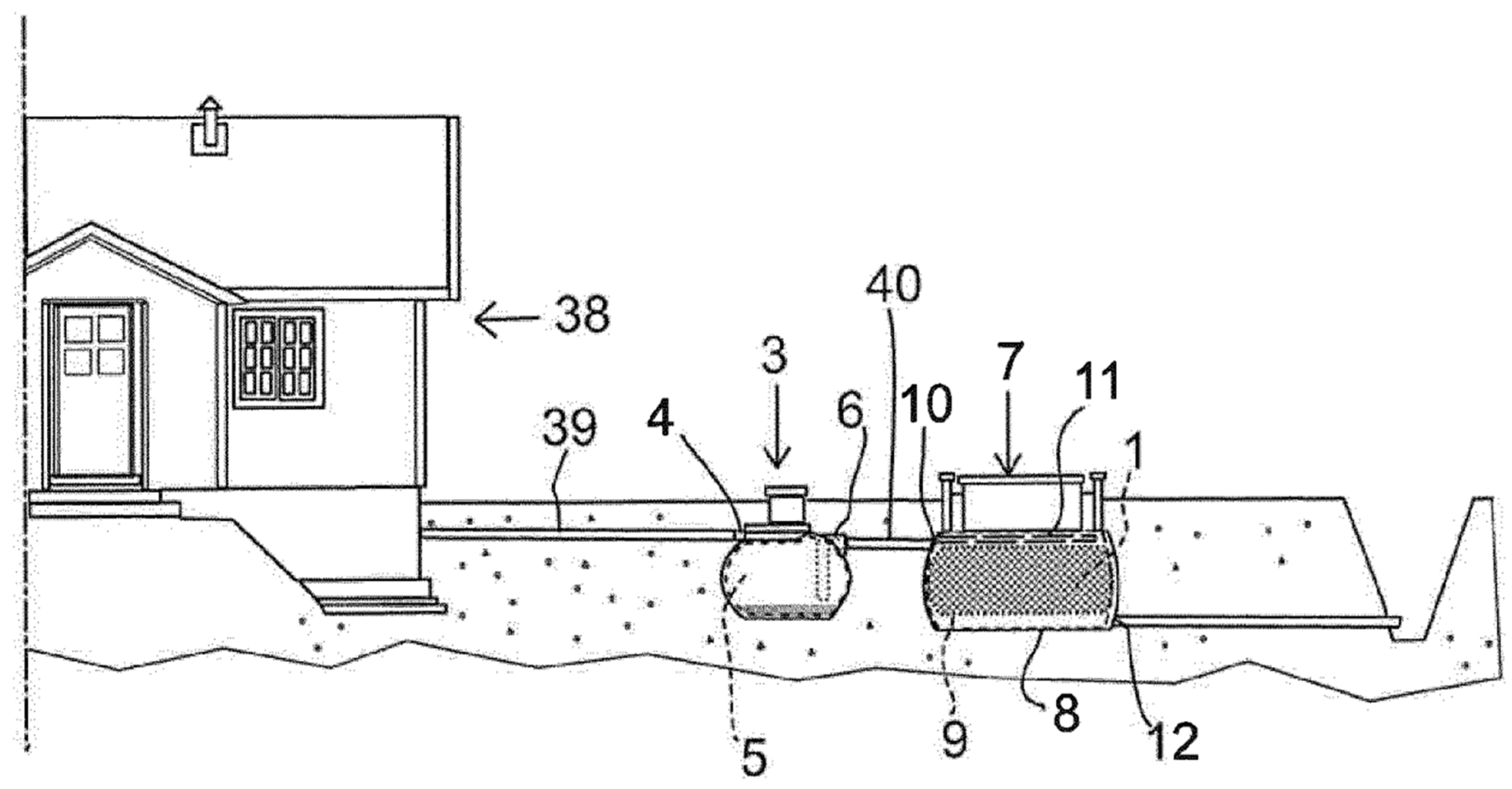

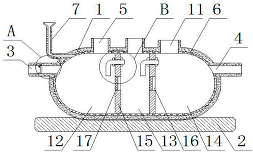

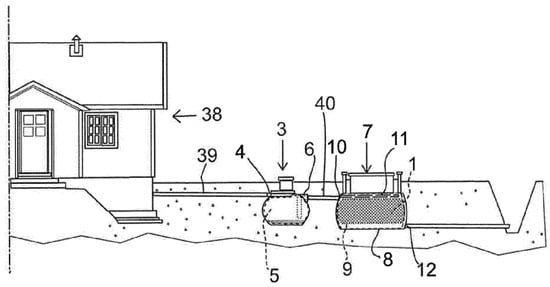

The Russian patent RU2659992C2 [85] introduced an innovative septic system that uniquely comprises two main components: a septic tank and a distribution device. This system ranks third-highest in the Derwent World Patents Index (DWPI) count of families among structure-based patents, highlighting its significance in the field. Specifically designed to process household greywater, which includes all domestic wastewater except for sewage containing toxic chemicals and human excrement, this system offers a crucial environmental advantage. Greywater typically contains lower levels of sludge compared to blackwater, allowing for a more efficient and less resource-intensive treatment process. As a result, the effluent from this system is considerably more environmentally friendly, reducing the ecological impact associated with the disposal of treated wastewater. Figure 19 illustrates the configuration of the septic tank (no. 3 in Figure 19) and the distribution device (no. 11), showcasing how this system effectively manages and repurposes greywater for safer environmental discharge.

Figure 19.

Septic tank from Russian patent RU2659992C2 [85].

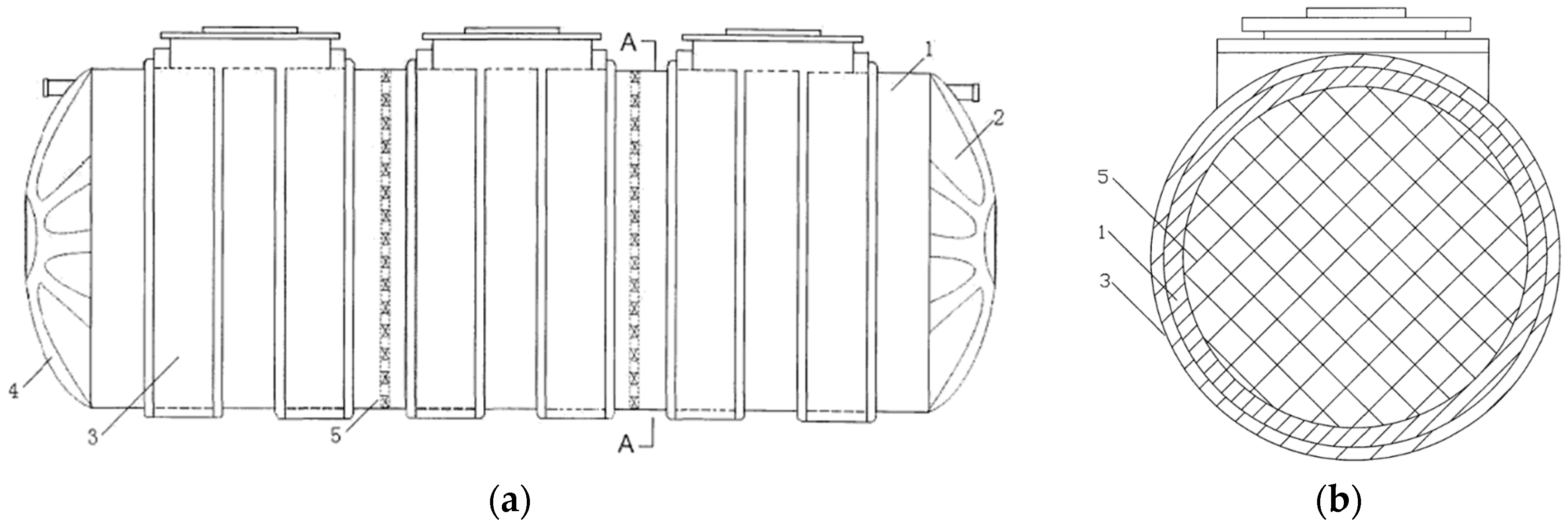

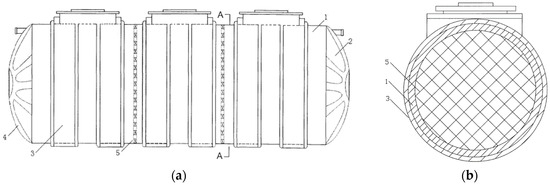

Advancing the structural complexity observed in the Russian patent RU2659992C2, which comprised a septic tank and a distribution device for greywater, the Chinese patent CN201132808Y [86] introduced a double-wall corrugated integration manure pit. This design further innovated by enhancing the structural integrity and modular capabilities of the septic tank. The tank’s main body features corrugation that not only enhances durability but also supports the radial ribs at the end closures (no. 4 in Figure 20), which are essential for maintaining shape and stability under soil pressure.

Figure 20.

(a) The main body and (b) cross-section of the double-wall corrugated-type integration manure pit, patent CN201132808Y [86].

Figure 20a,b showcase the septic tank’s sophisticated design. Figure 20a illustrates the main body of the tank (no. 1) and the partitioning members (no. 5), which are crucial for the multi-chamber configuration. Unlike typical flat partitions, these members have a net-like shape, allowing for the passage of larger solids into subsequent chambers, thereby optimising the separation and incremental treatment of waste. Figure 20b displays the cross-section of the tank, highlighting the innovative use of fastening rings (no. 3) that facilitate the modular assembly of the tank, allowing for flexibility in size and capacity based on the number of partitioning members used.

This patent represents a significant advancement in septic tank design as it combines sturdy structural features with flexible, modular configurations that can be customised to meet specific requirements. These innovations not only enhance the effectiveness of waste management systems but also enhance their adaptability and longevity in various installation environments.

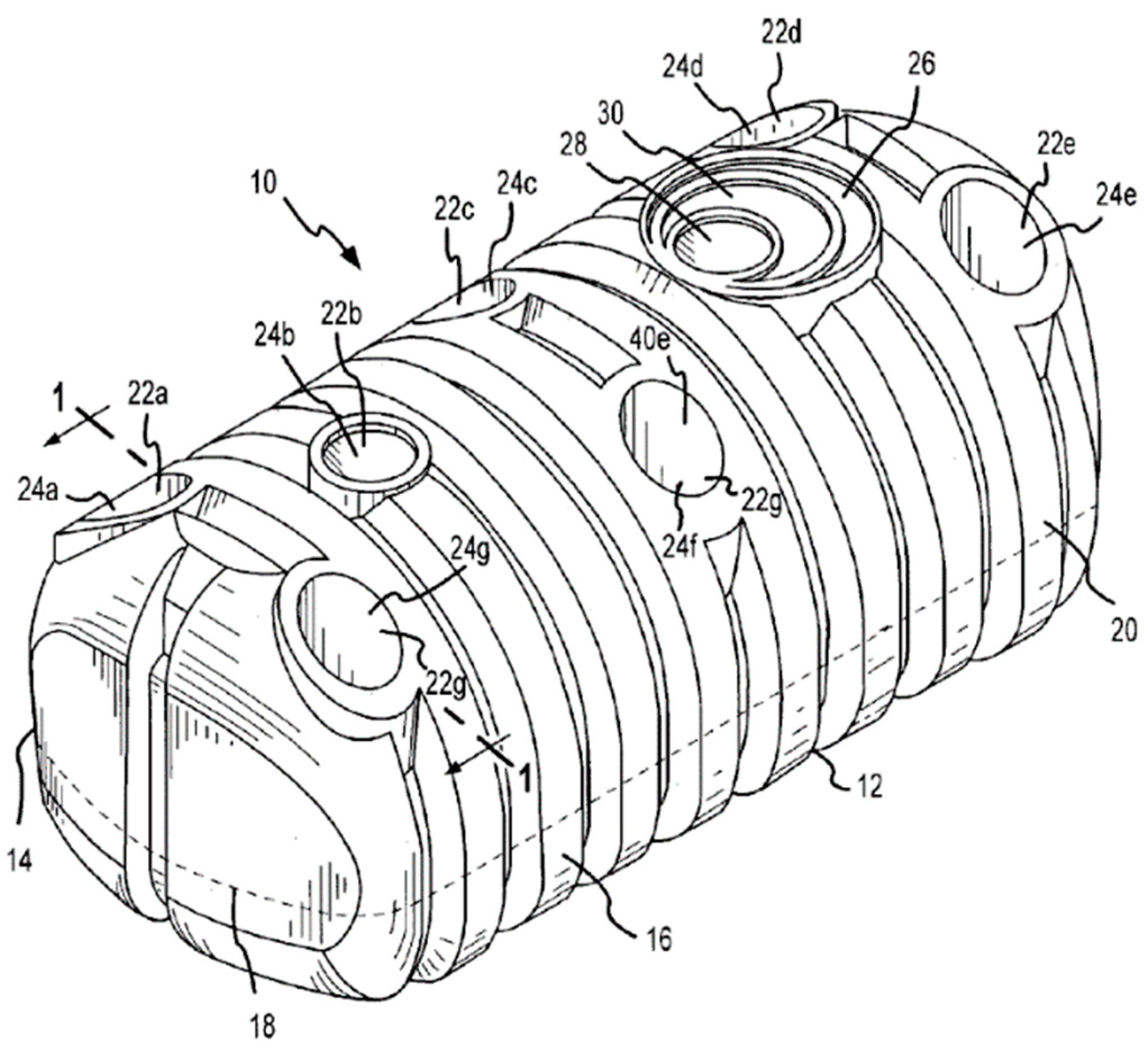

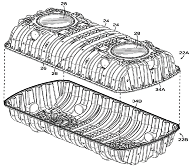

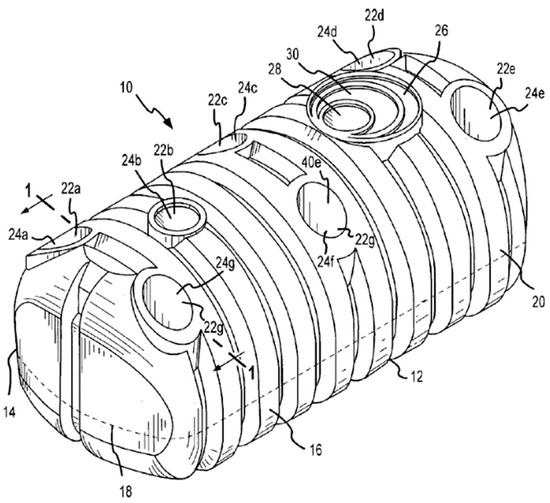

Following the innovative structural designs of the previous patents, which focused on enhancing the integrity and modular capabilities of septic tanks, the U.S. patent US20040011786A1 [87] introduced a cutting-edge approach to septic tank construction using thermoplastic materials. Ranked third-highest in the Derwent Patents Citation Index (DPCI) count of citing among structure-based patents, this design showcases a thermoplastic moulded septic tank, depicted in Figure 21. The utilisation of thermoplastic material allows for a robust yet flexible tank structure capable of resisting a variety of environmental stresses.

Figure 21.

Thermoplastic moulded tank, patent US20040011786A1 [87].

This tank was specifically engineered to withstand the compressive forces exerted by the soil above, buoyant forces from groundwater below, and any eccentric forces that the tank may encounter in situ. It is important to note that its design incorporates a lower profile compared to traditional concrete or fibreglass tanks, making it easier to install in shallower excavations. Despite its reduced size, the tank maintains, and, in some cases, even exceeds, the structural rigidity of more conventional septic tank designs. The innovative use of thermoplastics not only enhances the tank’s durability and longevity but also results in significant weight reductions. This, in turn, facilitates easier transport and installation while minimising environmental disruption during setup.

The introduction of this thermoplastic moulded septic tank represents a progressive step in the evolution of septic tank materials, following the structural advancements seen in the double-wall corrugated and modular designs of Chinese patents CN201132808Y and CN217265358U. This U.S. patent highlights the ongoing push towards materials that offer superior performance, adaptability, and environmental sustainability in septic tank construction.

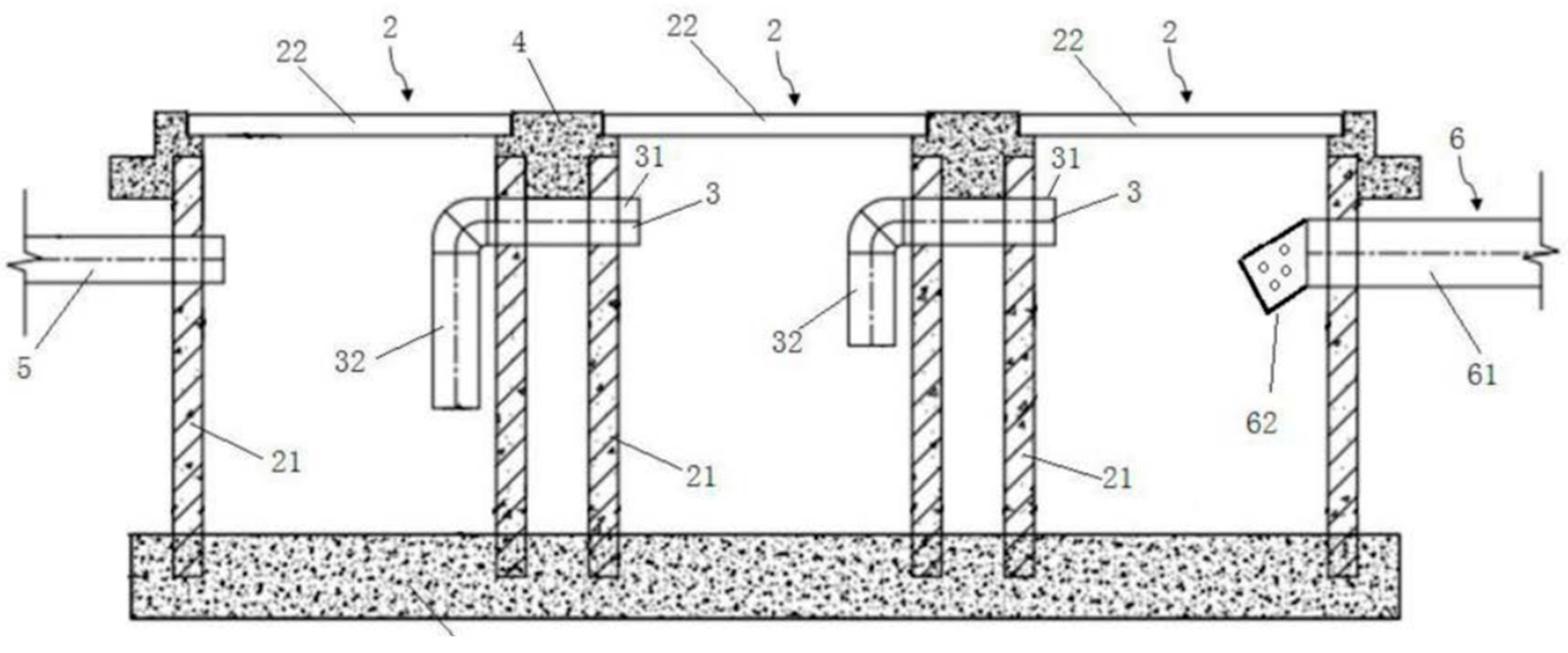

Building upon the modular and structural advancements exemplified by previous patents such as patent CN201132808Y, the Chinese patent CN217351134U [88] introduced another innovative septic tank design that utilises concrete pipes to create a multi-chamber or multi-grid system. Each chamber, referred to as a ‘septic unit’ (no. 2 in Figure 22), is crafted from a robust pipe body and sealed with a cover plate (no. 21) on each end to enhance structural integrity and prevent leaks. The individual units are interconnected using connecting pipes, allowing for fluid communication between the chambers and facilitating efficient waste processing. This is visually detailed in Figure 22, which depicts the interconnected concrete pipe system.

Figure 22.

Concrete pipe multi-grid septic tank, patent CN217351134U [88].

Similar to the double-wall corrugated integrated septic tank discussed in CN201132808Y, this design also incorporates the modular concept, which enables the septic system to be customised according to specific site requirements by adjusting the number of septic units. This adaptability is essential for accommodating different household sizes or commercial needs. Furthermore, the utilisation of concrete improves the longevity and durability of the septic tank, ensuring it can withstand challenging underground environments and substantial soil loads without compromising its structural integrity.

The introduction of patent CN217351134U underlines a persistent trend towards modular septic systems that integrate conventional materials such as concrete with inventive configurations to improve functionality and adaptability. This approach exemplifies a substantial advancement in septic tank design, transitioning from the previous use of thermoplastic and corrugated tanks to more scalable and sturdy multi-chamber systems that can accommodate various installation and operational requirements.

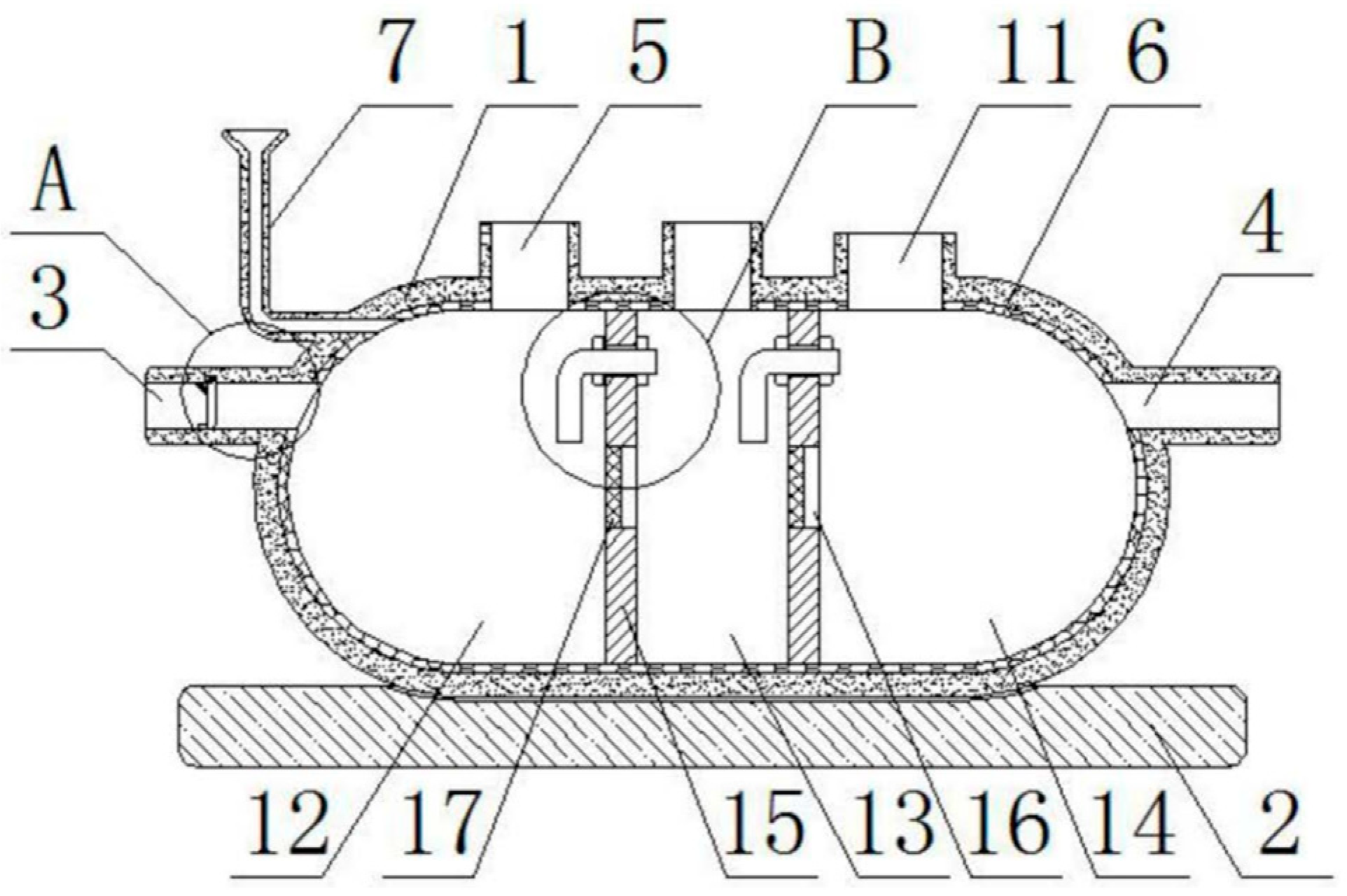

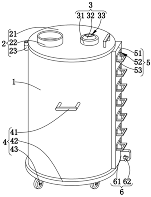

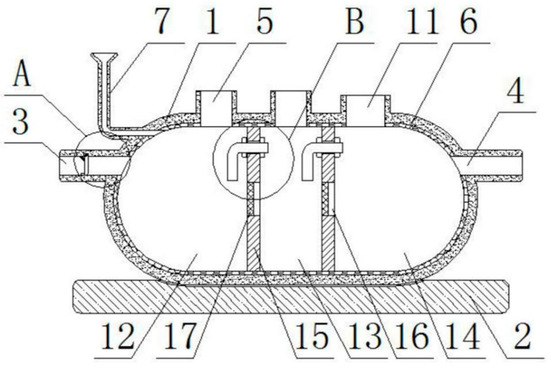

Continuing the trend of utilising advanced materials and modular designs in septic tank construction, Chinese patents CN217297637U [52] and CN217418478U [89] both feature cylindrical septic tanks made of fibreglass, a material known for its durability and resistance to corrosion. These tanks represent the second and third most recent innovations in their category, demonstrating ongoing enhancements in septic system technology.

Figure 23 illustrates patent CN217297637U, which introduced a multi-stage septic tank reinforced with an interior layer of steel (no. 6 in Figure 23) to enhance its structural integrity. This design incorporates fibreglass clapboards (no. 15) to separate the chambers, each equipped with a reflux pipe (B) that allows floating waste to circulate back to previous chambers for further processing. This feature optimises the waste treatment cycle and improves the overall efficiency of the septic system by preventing the advancement of unprocessed waste.

Figure 23.

Integrated fibreglass multi-stage septic tank, patent CN217297637U, reinforced by steel [52].

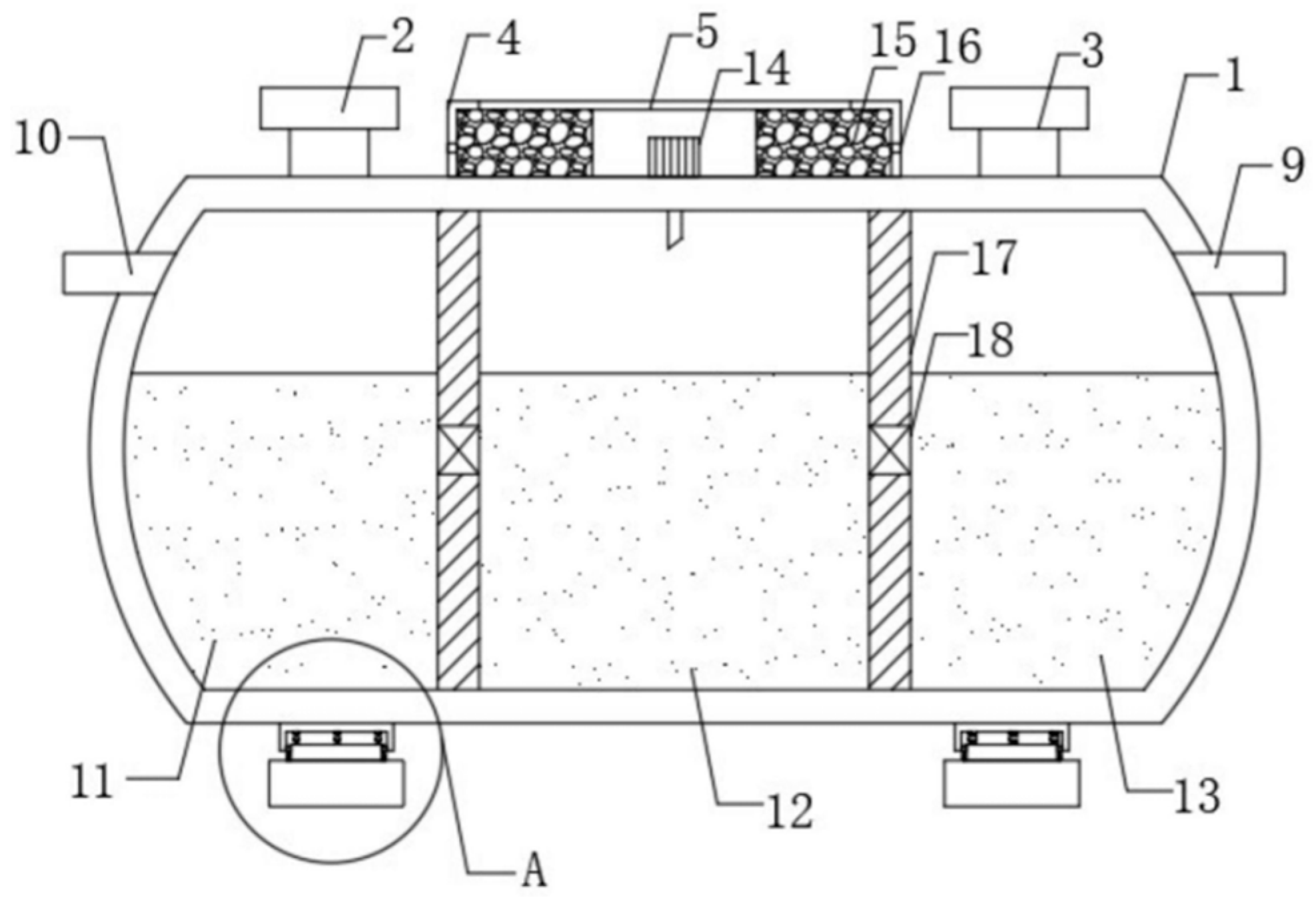

In a similar advancement, Figure 24 displays patent CN217418478U, which details a three-chamber fibreglass septic tank incorporating innovative treatment stages. This tank is structured to include an aerobic treatment chamber (no. 11 in Figure 24), an anaerobic treatment chamber (no. 12), and a clarifying chamber (no. 13), each designed to handle different stages of waste treatment. The aerobic chamber is equipped with a fixed air inlet hole (no. 2) that introduces oxygen, enhancing the breakdown of organic matter. Effluent from this chamber then passes into the anaerobic chamber, where an air pump (no. 14) and activated carbon particles (no. 15) work together to remove air and reduce odours before the wastewater progresses to the clarifying chamber. This sequential treatment process, facilitated by partition plates (no. 17) with strategically placed holes, ensures the thorough and efficient purification of wastewater.

Figure 24.

Fibreglass septic tank, patent CN217418478U, with activated carbon particles [89].

Patents CN217297637U and CN217418478U highlight significant improvements in septic tank technology by integrating multiple chambers with specialised functions and using materials that enhance the system’s durability and functionality. Such innovations are pivotal in the evolution of septic systems, providing more reliable, effective, and environmentally friendly wastewater treatment solutions. They build on the earlier developments of modular and robust tank designs, such as those discussed in patents CN217351134U and US20040011786A1, by further optimising the structural and process-based aspects of septic tank construction.

This section on structure-based septic tank patents highlighted a range of noteworthy innovations that have progressively advanced the field of wastewater management systems. The utilisation of durable materials like concrete and fibreglass, along with the introduction of sophisticated design elements such as multi-chamber configurations and reinforced structural components, has collectively contributed to the improvement of septic tank functionality and longevity.

The patents discussed, including the cylindrical fibreglass tanks with interior steel reinforcements and multi-stage treatment capabilities, highlight an industry trend towards the integration of materials that offer superior strength, longevity, and resistance to environmental factors. The modular designs, as seen in the various patents, not only facilitate customised installations tailored to specific needs but also promote more efficient waste processing and easier maintenance.

These structural innovations are crucial as they provide the foundational elements that support advanced process-based treatments, ensuring not only robust septic systems but also higher environmental compliance and operational efficiency. As we transition from purely structural innovations to explore patents that combine both process-based and structure-based advancements, it becomes evident that the future of septic tank technology lies in the seamless integration of form and function. This next section will delve into combined patents that exemplify this integration, highlighting how these holistic approaches are setting new standards for septic system design and functionality.

4.2.3. Technological Updates on Process- and Structure-Based Septic Tanks

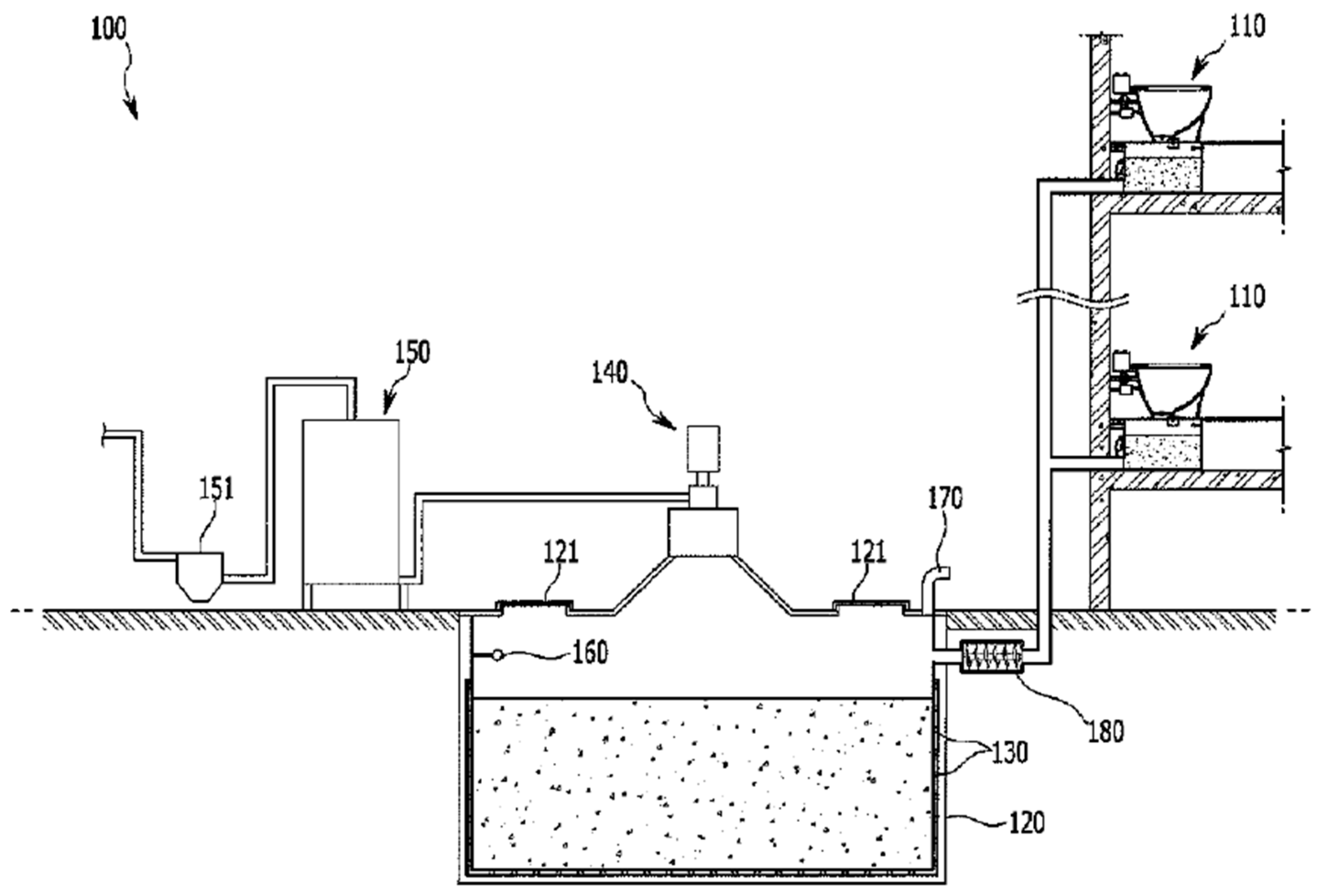

US patent US9969636B2 [90] introduces a groundbreaking septic tank design that not only treats wastewater but also harnesses its potential to generate methane gas, as depicted in Figure 25. This patent stands out due to its significant recognition in both process and structural innovations, evidenced by its high DWPI Count of Family Members in both categories. The design cleverly integrates the septic system with a toilet stool within a bathroom setup, featuring a wastewater storage tank specifically engineered for biogas production.

Figure 25.

Septic tank for Generating Methane Gas, US9969636B2 [90].

Innovatively, this system incorporates heaters to expedite the fermentation process of the stored wastewater, significantly enhancing the rate of methane gas production. This strategic use of controlled heating elevates the efficiency of microbial activity, optimising the tank’s functionality not just for waste treatment but also for renewable energy generation. The methane produced is then captured and can be repurposed for various household needs, including cooking and heating, thereby adding a sustainable component to the conventional septic system.

This patent exemplifies the advanced capabilities of combined process and structure-based patents, showcasing how integrating engineering innovations can lead to multifunctional septic systems that contribute to energy sustainability while effectively managing waste. Such technologies not only provide practical solutions to waste management but also add value by transforming waste into usable energy, marking a significant step forward in the eco-friendly optimisation of domestic infrastructure.

Building on the innovative use of septic systems for additional functionalities as seen in U.S. patent US9969636B2, which integrated methane gas production, the Canadian patent CA2418876C [91] introduced another versatile approach by repurposing shipping containers as septic tanks. This adaptation aligns with the recurring theme in this Patent Landscape Review (PLR) of utilising unconventional structures for environmental technologies. By retrofitting watertight shells or liners within these containers, the patent ensures that they are leak-proof and suitable for processing wastewater. Additionally, a specialised compartment is constructed inside each container to accommodate essential utilities such as pipework and pumps, optimising the space for efficient wastewater treatment.

Figure 26 showcases the modified shipping containers, highlighting their transformation into functional septic tanks. This inventive reuse not only addresses waste management challenges but also promotes recycling and resource efficiency by giving new life to otherwise obsolete shipping containers. Similar to the approach described in patent US9969636B2, which creatively uses heaters to enhance methane production, patent CA2418876C leverages existing industrial materials to create a sustainable and economically viable solution. Together, these patents exemplify the trend towards integrating environmental sustainability with innovative repurposing in septic tank design, paving the way for more adaptive and resource-efficient wastewater management systems.

Figure 26.

The septic tank made from shipping containers, patent CA2418876C [91].

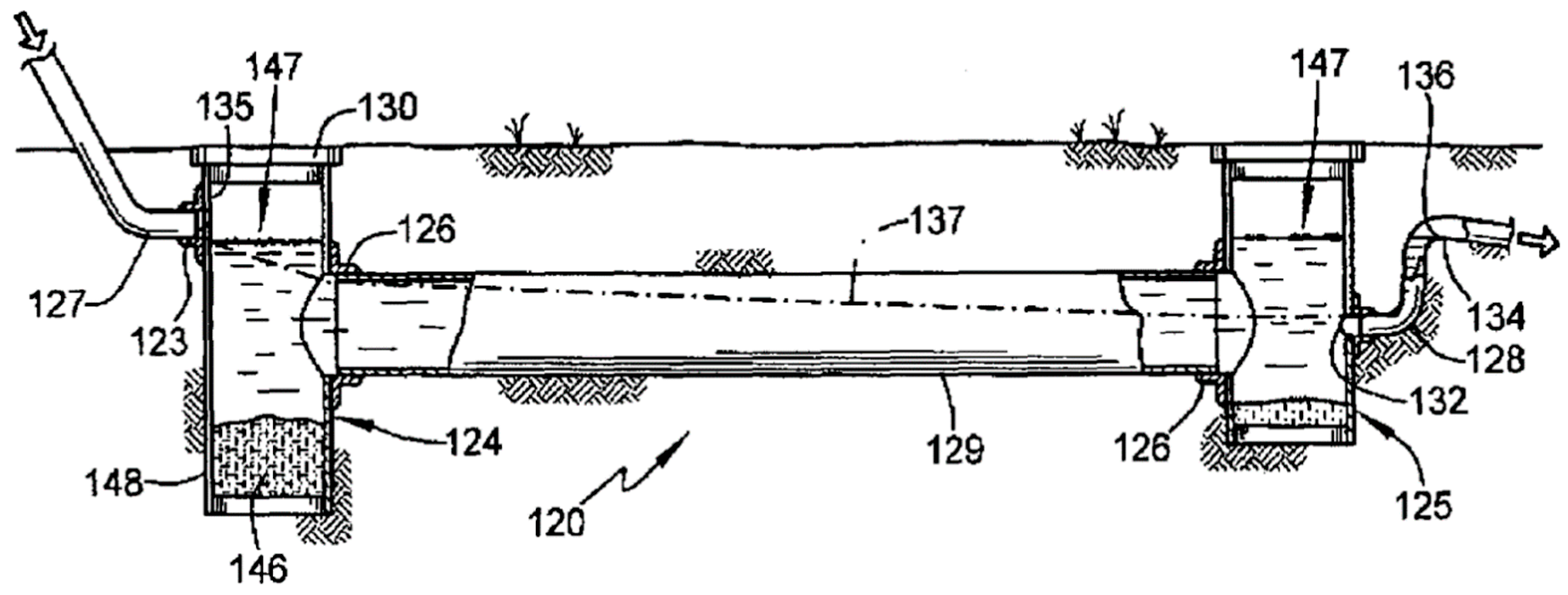

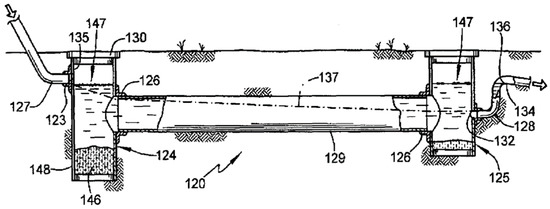

Continuing with the theme of multifunctionality and innovative repurposing in septic system design, as seen in patents US9969636B2 and CA2418876C, U.S. patent US7022222B2 [92] introduced a septic tank with a unique in-pipe wastewater treatment system that incorporated three distinct sections: an initial chamber, a long and narrow pipe, and an end chamber. As depicted in Figure 27, this design is noted for being the oldest among those reviewed in both the process-based and structure-based categories of the Patent Landscape Review (PLR), highlighting its foundational role in the evolution of modern septic systems.

Figure 27.

Septic tank, patent US7022222B2, with a long and narrow pipe between the chambers [92].

The design strategically utilises the geometry of the system to enhance the efficiency of wastewater processing. The chambers within the pipe are intentionally made shallower than the pipe itself, a feature that cleverly prevents the complete settling of solids and potential blockages. This configuration guarantees that the majority of solid waste settles in the initial chamber, where it can be easily accessed and removed. Meanwhile, the narrower pipe promotes faster flow of the liquid effluent to the end chamber. The end chamber serves as a sump for collecting any remaining sludge, thus ensuring a clean discharge of effluent.

This in-pipe design demonstrates an early application of segmented treatment within a septic system, providing a streamlined and effective solution for waste separation and treatment. By comparing this with subsequent innovations in patents, such as the methane-producing system of patent US9969636B2 and the repurposed shipping container system of patent CA2418876C, it is evident that the principles of functional compartmentalisation and resource efficiency have long guided advancements in septic tank technology. Together, these patents showcase a progressive enhancement of septic system designs, each contributing to more sustainable and effective wastewater management solutions.

This comprehensive review of combined process-based and structure-based septic tank patents concludes with U.S. patent US7022222B2, which was the earliest among the patents discussed. By examining the sequence from this foundational patent to more recent innovations, the evolutionary trajectory of septic tank designs that incorporate both structural ingenuity and process efficiency is clearly delineated. From early implementations of in-pipe wastewater treatment systems to advanced multifunctional designs that integrate methane gas production and repurpose existing materials such as shipping containers [92], the progression in septic tank technology reflects a continuous push towards optimising functionality and environmental sustainability.

The chronological exploration of these patents highlights how initial concepts have been expanded and refined over time, leading to today’s sophisticated systems that offer enhanced treatment capabilities, greater durability, and increased environmental benefits. Examining these developments in a historical context provides a deeper appreciation for the innovative spirit that drives the septic tank industry. Moving forward, the insights gained from these foundational technologies will undoubtedly continue to inspire future advancements, ensuring that septic systems not only meet the basic needs of waste management but also contribute positively to environmental conservation and resource efficiency.

4.3. Discussion

The patent landscape overview and detailed patent analysis conducted in this review have collectively shed light on a trajectory of significant advancements in septic tank technologies, highlighting innovations in both process-based and structure-based solutions. Over time, septic tank designs have progressed from simple, single-chamber tanks to more intricate configurations, such as multi-chamber and modular designs [25]. These innovations demonstrate ongoing efforts to improve wastewater treatment efficiency and adapt to various environmental and usage demands.

Materials have played a crucial role in this evolution. The utilisation of durable materials, such as fibreglass [58] and concrete [57], which offer longevity and resilience, has been a focal point. Innovations, including double-wall constructions and corrugated designs [55], have enhanced the structural integrity of septic tanks. These materials enable the tanks to better withstand environmental stresses, making them suitable for diverse installation needs and environmental conditions [93].

From a process standpoint, there is a noticeable trend towards systems that incorporate biofiltration and methane production capabilities [60]. These features not only enhance the quality of effluent but also harness waste to generate energy, thus demonstrating a shift towards resource recovery and sustainability in wastewater treatment. The combination of advanced treatment processes with robust and adaptable designs has resulted in the development of septic systems that are better suited to meet modern environmental standards and user demands.

Geographically, patent filings reveal that China leads in septic tank technology development, followed by Japan, South Korea, and the United States. This distribution underscores the global significance of efficient septic systems, particularly in rapidly urbanising regions. The analysis also highlights considerable interest from commercial entities in septic tank technology, with companies dominating patent filings. This commercial interest is likely driven by the potential for market growth in regions lacking centralised sewage systems and the ongoing push for more environmentally friendly wastewater treatment solutions.

The integration of smart technologies, such as sensors and automated controls, has begun to optimise septic system operations and maintenance [39]. These technologies not only enhance efficiency but also improve monitoring capabilities to ensure the maintenance of safe environmental parameters. However, despite these technological advancements, challenges such as cost, complexity, and the need for sophisticated maintenance protocols remain, potentially impeding widespread adoption.

Looking ahead, the industry appears poised for further innovations that will likely focus on increasing automation, improving the recyclability of system components, and enhancing the integration of septic systems with other home and municipal waste treatment solutions. As technologies advance, there will be an increasing need for updated regulatory frameworks and standards that can accommodate new innovations while ensuring public health and environmental protection. Effective collaboration between industry stakeholders and regulatory bodies will be essential to foster innovation while maintaining safety and sustainability.

Collaboration between companies advancing technological solutions and research institutes conducting foundational studies is vital for providing policymakers with the data and insights needed to develop informed and effective regulations. This partnership ensures that policy decisions are grounded in up-to-date scientific knowledge and industry trends, enabling the creation of supportive frameworks that foster innovation while ensuring public safety and environmental sustainability. While research institutes often focus on more fundamental research, industries typically work on developing innovations closer to commercialisation. It is essential that these entities collaborate to transition innovative products from basic research to market-ready solutions, thereby creating more impactful technologies. This synergy fosters innovation, offering insights into emerging trends and proactive solutions to societal challenges. Additionally, it ensures transparency and accountability, building public trust [94,95]. Policymakers play a critical role in promoting investment and crafting a conducive regulatory environment that balances the interests of researchers, industry players, and consumers. By supporting this ecosystem, policymakers can ensure that innovations not only reach the market efficiently but also adhere to standards that protect the environment and public health. Such initiatives are crucial for driving the industry forward, addressing the challenges posed by outdated systems, and capitalising on emerging opportunities in septic tank technologies.

Moreover, the complexity and importance of modern septic systems suggest a growing need for educational programs to train technicians and inform users about the benefits and maintenance requirements of advanced septic systems. Increasing public awareness and understanding is crucial to achieving the widespread acceptance and optimal use of these technologies. The global market for septic tank innovations shows diverse needs and opportunities, driving localised adaptations of the technologies discussed. Continued investment in research and development is critical for the ongoing improvement and adaptation of septic tank technologies.

In conclusion, the findings from this review offer valuable insights into the current state and future prospects of septic tank technology. By continuing to focus on both technological innovation and practical applications, the industry can ensure that septic systems remain a vital and effective solution for wastewater management globally.

5. Conclusions

As urbanisation and industrialisation accelerate globally, the effective management of wastewater becomes increasingly crucial. This is particularly true in rural areas where septic systems are often the primary means of sewage treatment. These systems not only facilitate the local treatment of wastewater but also significantly alleviate the load on municipal treatment facilities by effectively removing solids.

This paper conducted a comprehensive Patent Landscape Review (PLR) to analyse advancements in septic tank technologies through patent filings. This review highlighted a robust engagement from companies, individuals, and groups of inventors, indicating a dynamic field of innovation driven by both commercial and environmental imperatives. Developed countries file fewer patents on septic tanks compared to developing countries. However, they produce more patents on aerobic septic tanks compared to anaerobic tanks. Notably, China has emerged as a leader in septic tank technology, demonstrating the highest volume of patent activity from 2001 to June 2022, followed by Japan, South Korea, and the United States. These patents frequently advocate for anaerobic decomposition as the primary process for sludge breakdown, reflecting its efficiency and simplicity.

The material preferences identified in the patents indicate a strong inclination towards fibreglass. This material is chosen for its excellent mechanical properties, durability, and chemical resistance. Additionally, the cylindrical shape dominates the patent landscape due to its ability to uniformly distribute forces, enhancing the structural integrity of the tanks. Several patents explore the potential of repurposing materials and existing containers, such as shipping containers and oil barrels, for septic system use. This suggests a trend towards cost-effectiveness and aligns with global sustainability goals by promoting recycling and efficient resource use.

Looking ahead, the future of septic tanks appears to be moving towards the adoption of modular designs using anaerobic fibreglass cylindrical tanks and creatively repurposed objects. This trajectory supports a shift towards more sustainable, efficient, and environmentally friendly wastewater solutions. As these technologies evolve, they will likely incorporate smarter, more automated systems to enhance operational efficiency and adaptability. This will ensure that septic systems can meet the challenges of modern environmental standards and contribute positively to global sustainability efforts.

In essence, the advancements in septic tank technologies, as revealed through patent analyses, promise a future where environmental compatibility, innovation, and efficiency converge to redefine rural and suburban wastewater management.

Author Contributions

Conceptualisation, N.M.Z. and P.E.A.; methodology, N.M.Z. and P.E.A.; software, R.R. and A.H.; validation, R.R. and A.H.; formal analysis, R.R., A.H., N.M.Z. and P.E.A.; investigation, R.R., A.H., N.M.Z. and P.E.A.; resources, N.M.Z. and P.E.A.; data curation, R.R. and A.H.; writing—original draft preparation, A.H. and R.R.; writing—review and editing, P.E.A. and S.G.; visualisation, A.H. and R.R.; supervision, N.M.Z., S.G. and P.E.A.; project administration, P.E.A.; funding acquisition, P.E.A. and S.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universiti Brunei Darussalam, grant number UBD/RSCH/1.3/FICBF(b)/2024/023.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

The tables below describe the numbering in the figures of the selected patents that are included in this paper.

Table A1.

Septic tank from patent AU2004218003B2 [48].

Table A1.

Septic tank from patent AU2004218003B2 [48].

| Number in Figure | Description |

|---|---|

| 12 | Septic tank |

| 14 | Inlet |

| 16 | Outlet |

| 18 | Filter |

| 20 | Transfer or holding tank |

| 22 | Conduit |

| 26 | Biotreatment containers |

| 28 | Discharge conduit |

| 32 | Recirculating tank |

| 34 | Recirculating line |

| 36 | Discharge conduit |

| 68 | Riser |

| 70 | Cover |

| 72 | Manhole opening |

Table A2.

Septic tank with a digested sludge enrichment reactor from patent DE502007002448D1 [49].

Table A2.

Septic tank with a digested sludge enrichment reactor from patent DE502007002448D1 [49].

| Number in Figure | Description |

|---|---|

| 1 | Digester reactor |

| 2 | Enrichment reactor |

| 3 | Gas valve |

| 4 | Sludge valve |

| 5 | Gas pump |

Table A3.

The septic tank and its partitioning member from patent US7282143B2 [50].

Table A3.

The septic tank and its partitioning member from patent US7282143B2 [50].

| Number in Figure | Description |

|---|---|

| 2 | Partitioning member |

| 3 | Submersible pump |

| 10 | Chamber |

| 11 | Wastewater inlet |

| 12 | Waste water outlet |

| 13 | Inlet pipe |

| 14 | Outlet pipe |

| 21 | Through-holes |

| 31 | Recycling tube |

| 101 | Subchamber |

Table A4.

Side profile of the environmentally friendly septic tank from patent CN114988659A [51].

Table A4.

Side profile of the environmentally friendly septic tank from patent CN114988659A [51].

| Number in Figure | Description |

|---|---|

| 10 | Manure pit main part |

| 110 | Storage tank |

| 111 | Primary septic chamber |

| 112 | Deep digestion chamber |

| 113 | Clarification chamber |

| 114 | Excrement drawing port |

| 120 | Water inlet pipe |

| 130 | Water outlet pipe |

| 140 | First manure passing pipe |

| 150 | Second manure passing pipe |

| 160 | Partition plate |

| 170 | Support frame |

| 370 | Observation port |

| 380 | Transparent plate |

Table A5.

Integral turnover steel septic tank, patent CN217351132U [52].

Table A5.

Integral turnover steel septic tank, patent CN217351132U [52].

| Number in Figure | Description |

|---|---|

| 1 | Device housing |

| 2 | Fixing plate |

| 3 | First connecting plate |

| 4 | Bolt |

| 5 | Connecting sleeve |

| 6 | Card slot |

| 7 | Limiting groove |

| 8 | Electric telescopic rod |

| 9 | Second connecting plate |

| 10 | Thermometer |

| 11 | Flow-through hole |

| 12 | Second manure lifting cover plate |

| 13 | Third manure lifting cover plate |

| 14 | Checking of exhaust hole |

| 17 | Water discharge outlet |

Table A6.

Integrated multi-stage septic tank from patent CN217265358U [53].

Table A6.

Integrated multi-stage septic tank from patent CN217265358U [53].

| Number in Figure | Description |

|---|---|

| 1 | Septic tank body |

| 2 | Top cover |

| 101 | Water inlet |

| 102 | Water outlet |

| 103 | Clapboard |

| 104 | Water through-hole |

| 105 | Separate cavity |

| 201 | Wellhead |

Table A7.

Septic tank from Russian patent RU2659992C2 [54].

Table A7.

Septic tank from Russian patent RU2659992C2 [54].

| Number in Figure | Description |

|---|---|

| 1 | Layer |

| 3 | Septic tank |

| 4 | First inlet |

| 5 | Interior space |

| 6 | First outlet |

| 7 | Filtering device |

| 8 | Container |

| 9 | Second interior space |

| 10 | Second inlet |

| 11 | Distribution device |

| 12 | Second outlet |

| 39 | First pipe |

| 40 | Second pipe |

Table A8.

Double-wall corrugated-type integration manure pit from patent CN201132808Y [55].

Table A8.