Review and Insights Toward Cognitive Digital Twins in Pavement Assets for Construction 5.0

Abstract

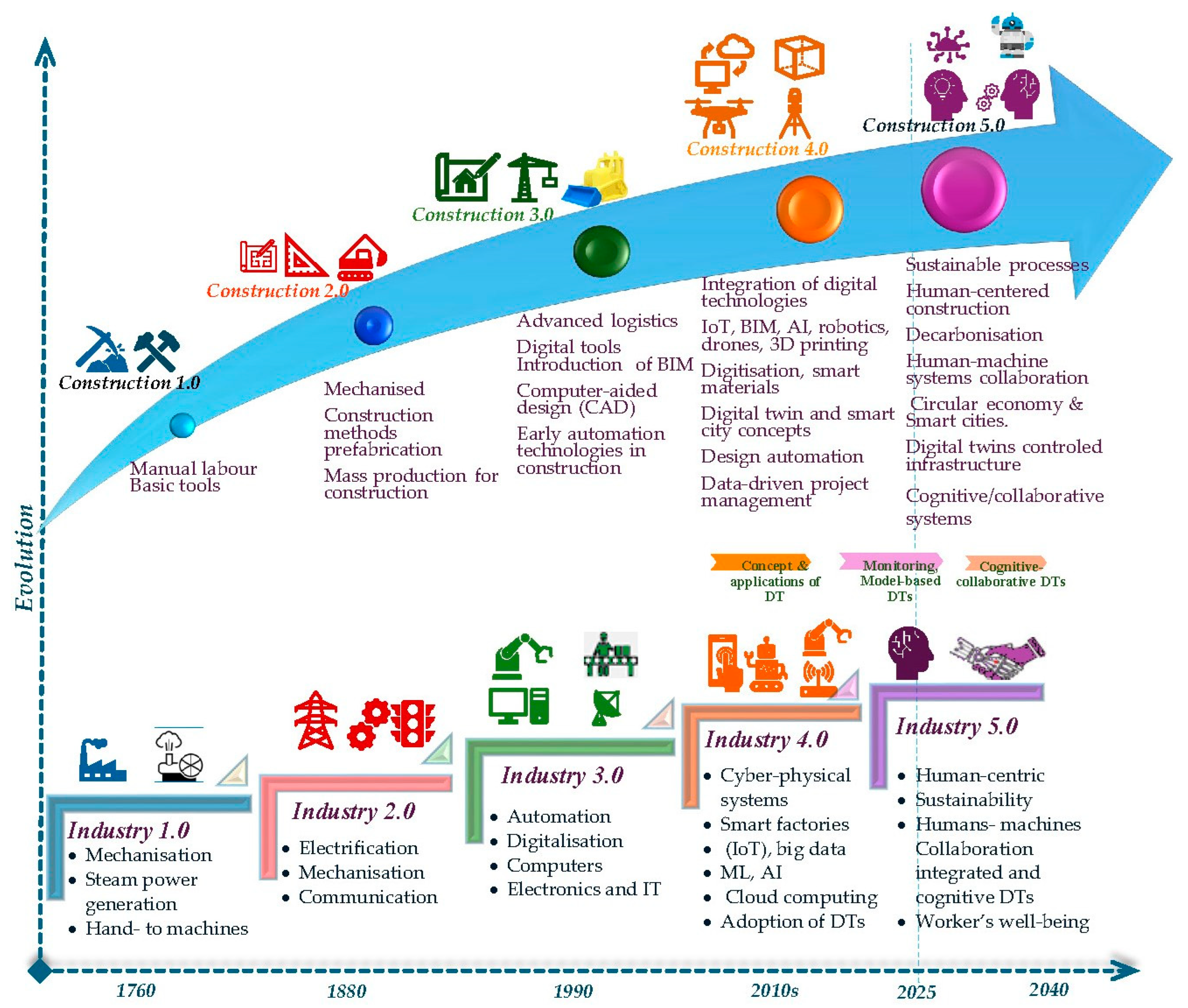

1. Introduction

1.1. Flexible Pavement Assets

1.2. Pavement Management Systems

1.2.1. Data Collection

1.2.2. Pavement Performance Modelling

1.3. Digital Twin for Pavement Management

Recent Reviews of DTs in Transportation

- What are the components and critical considerations of digital twins (DTs) in the pavement assets; their current maturity, and the gaps for cognitive DT capabilities?

- What are the required framework elements, processes, and methods for developing predictive cognitive DT for pavement that enable enhanced decision-making and support the Construction 5.0 paradigm?

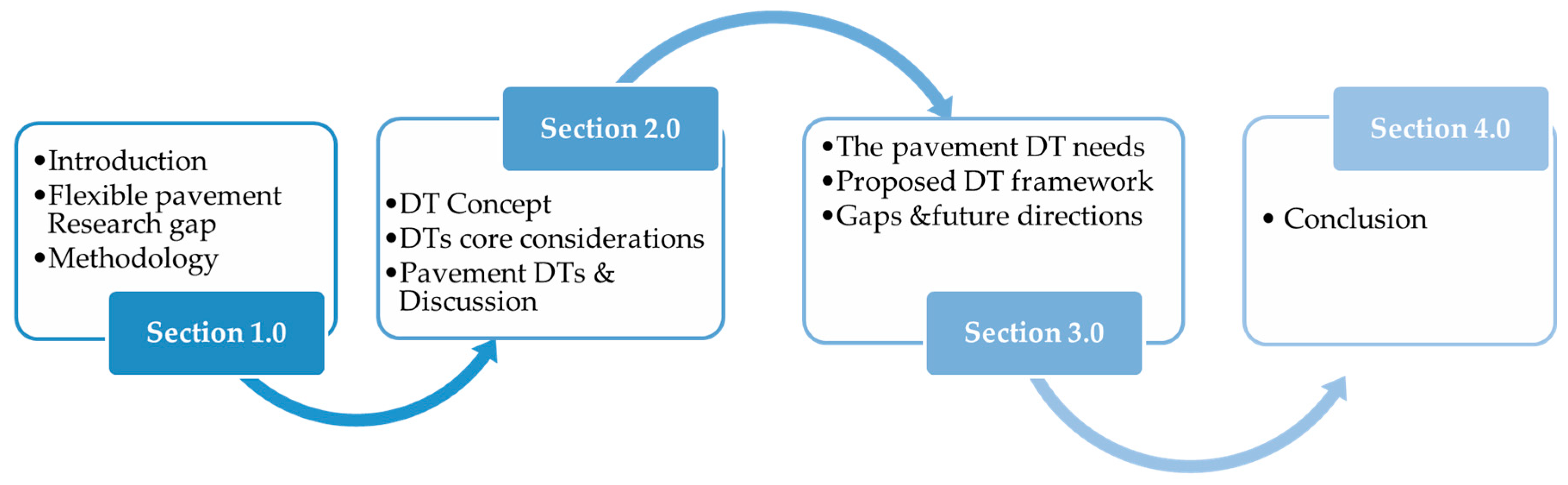

1.4. Research Structure

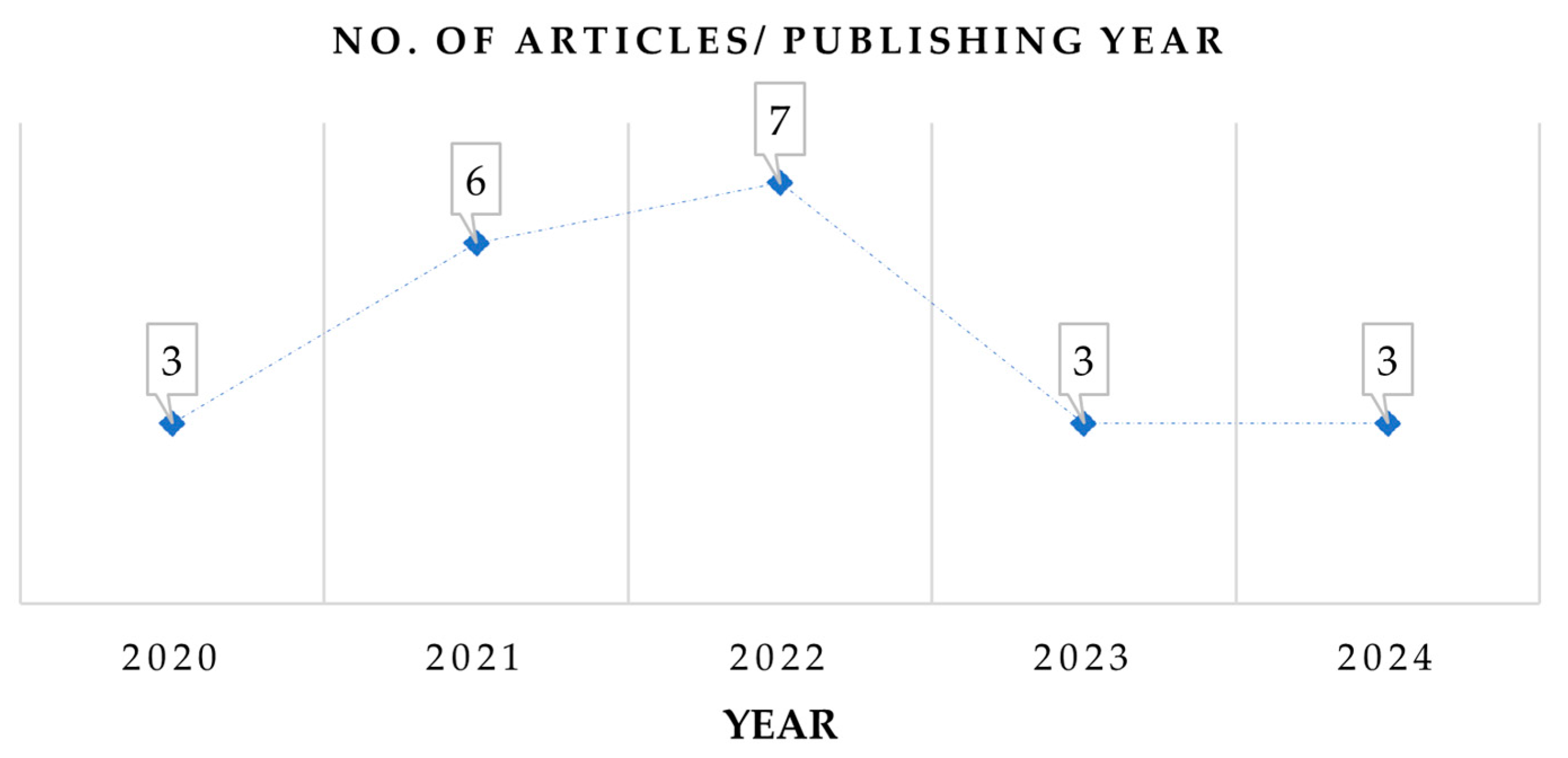

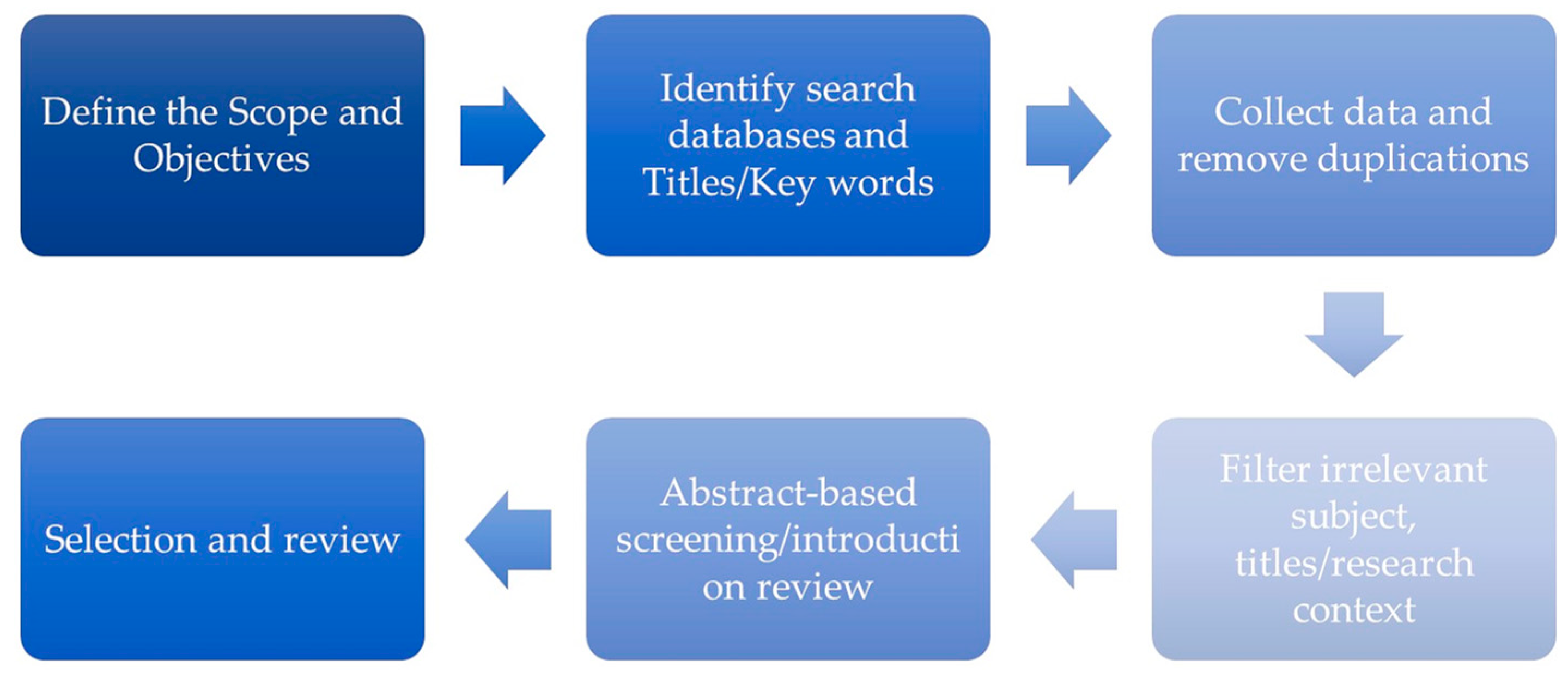

1.5. Methodology

2. Digital Twins and Pavement Management Digital Twins

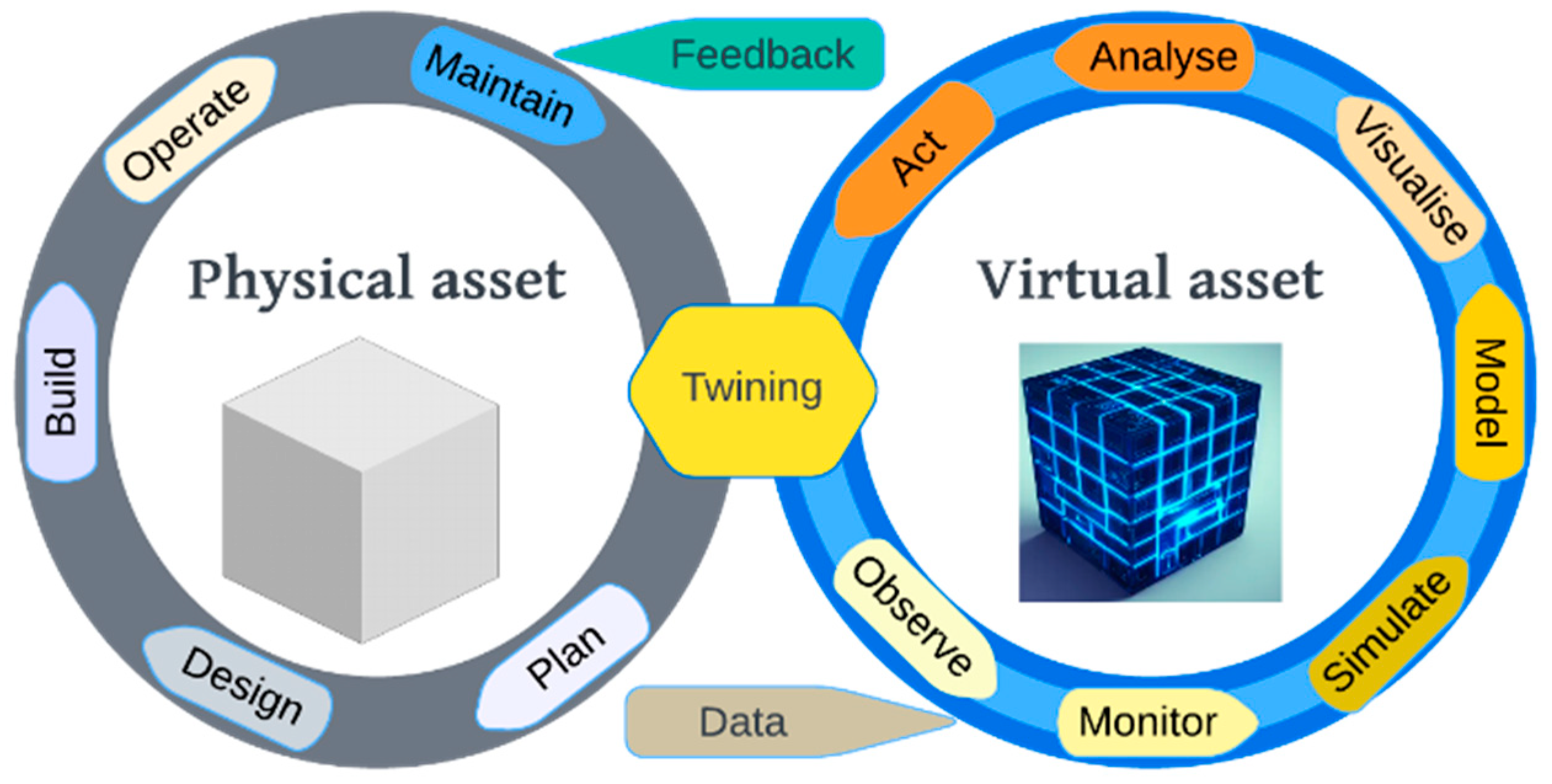

2.1. Digital Twins Concept

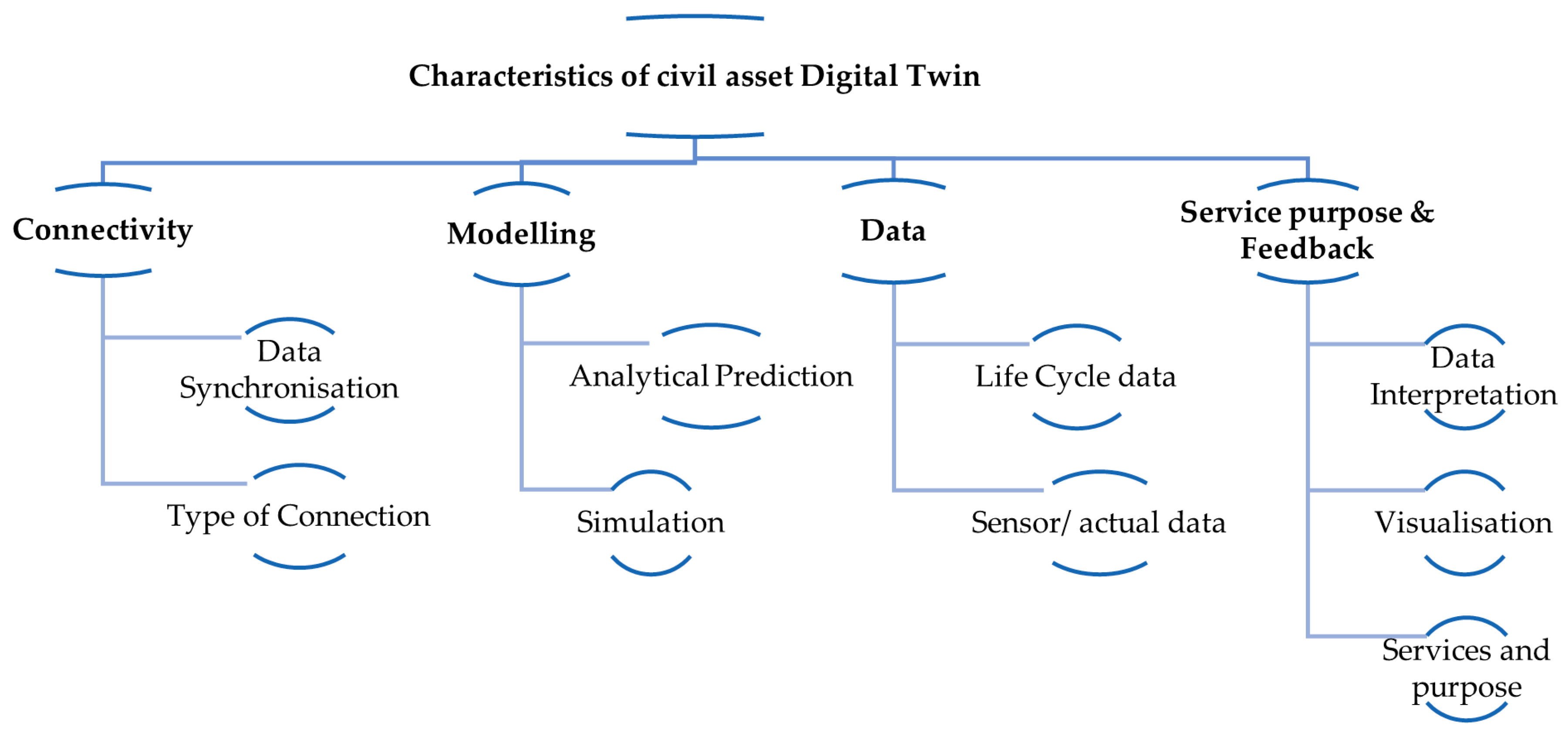

2.2. Civil Assets DT Core Considerations

2.2.1. Connectivity

2.2.2. Modelling

2.2.3. Data

2.2.4. Interpretation, Services, and Feedback

2.3. Road Pavement DTs Discussion

2.3.1. Pavement Surface Prediction DTs

2.3.2. Sensing and Monitoring DTs

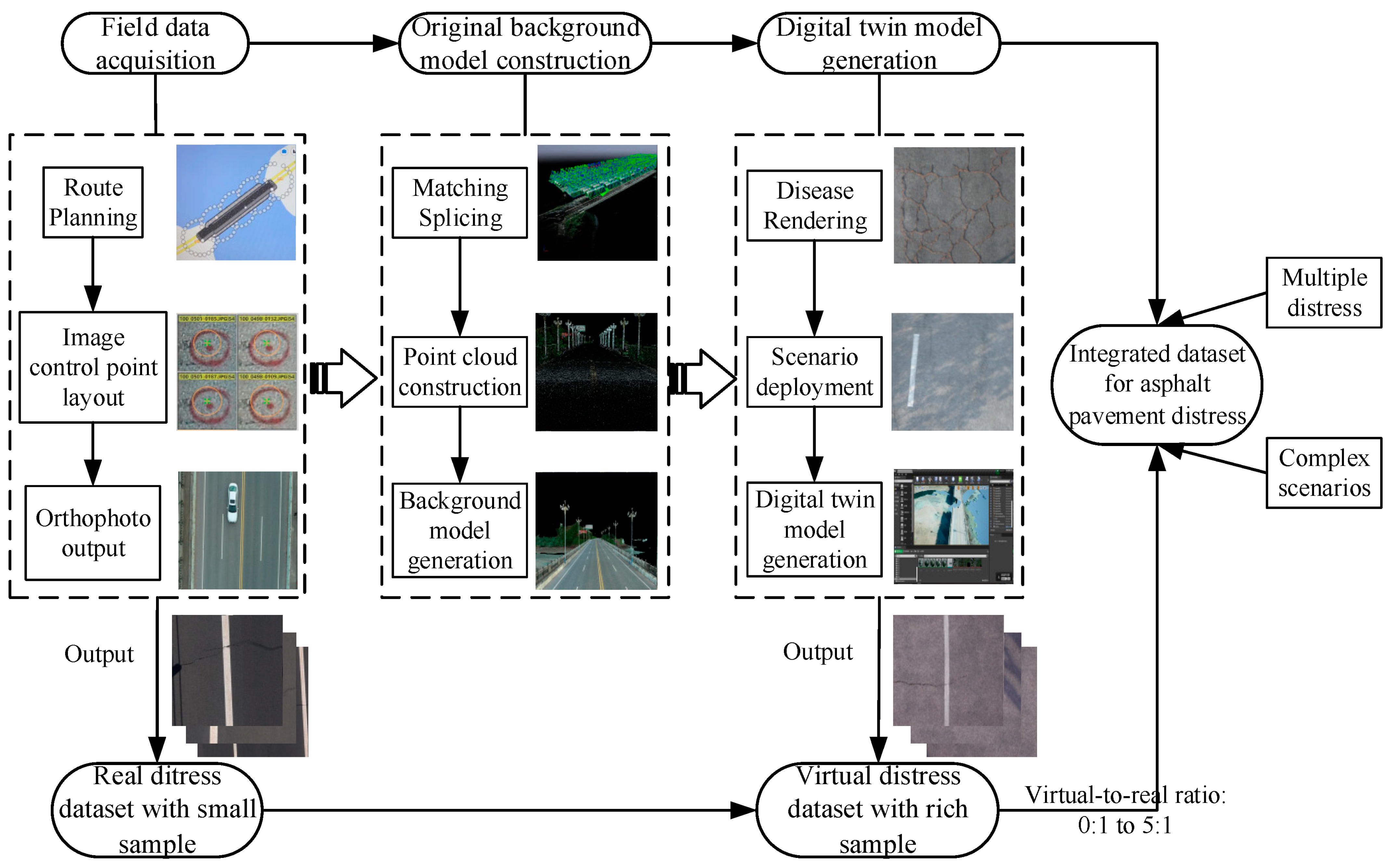

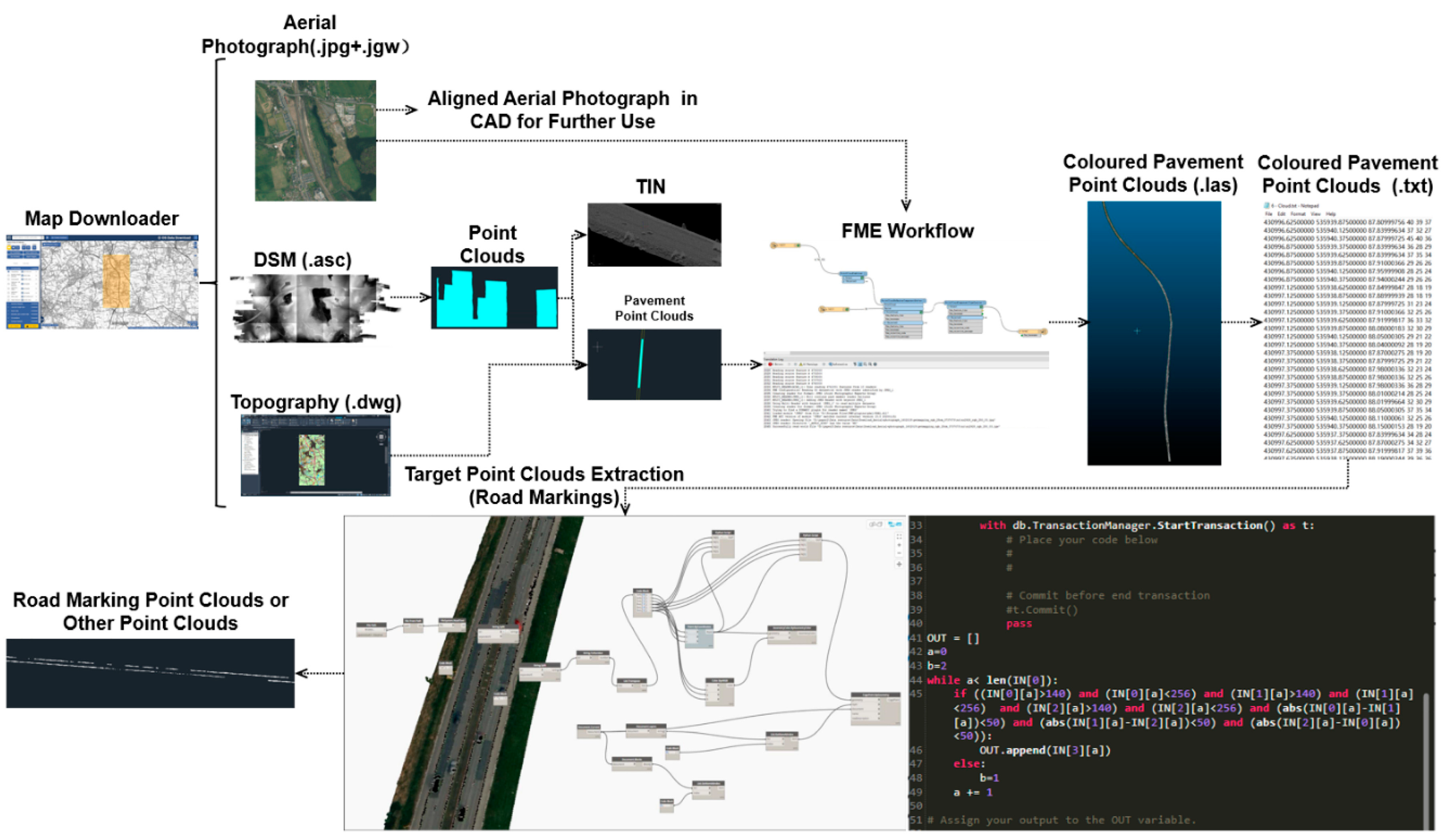

2.3.3. Surface Defect Detection, Visualisation, and As-Built Digitisation

2.3.4. Developed Pavement DTs Summary

3. Advancing Toward Cognitive Pavement DT

3.1. Operational Data, Asset Databases and Performance Modelling

3.2. Intelligent Decision-Making Support Systems

3.3. Visualisation & Data Integration

3.4. DT Platforms

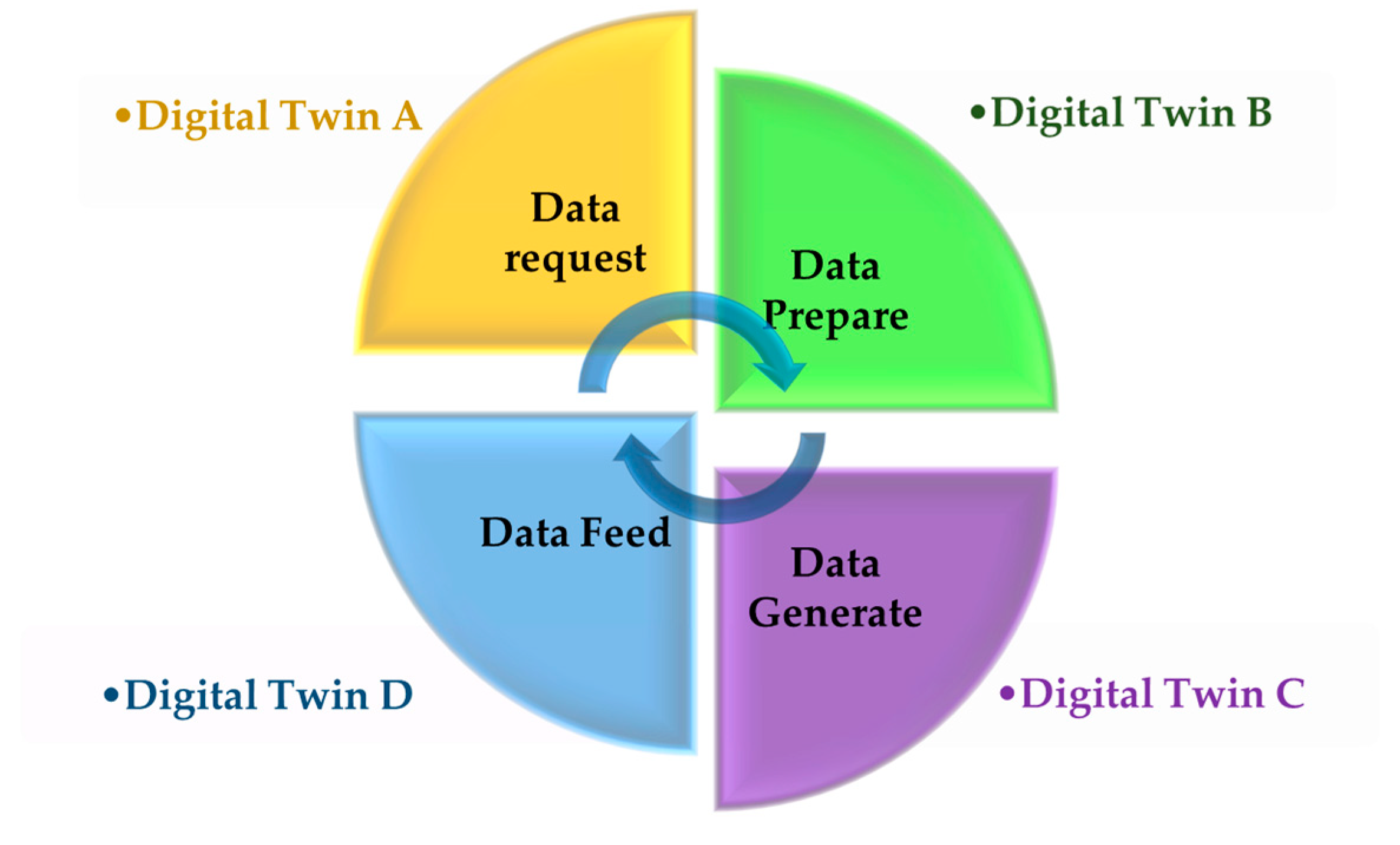

3.5. Integrated & Collaborative DTs

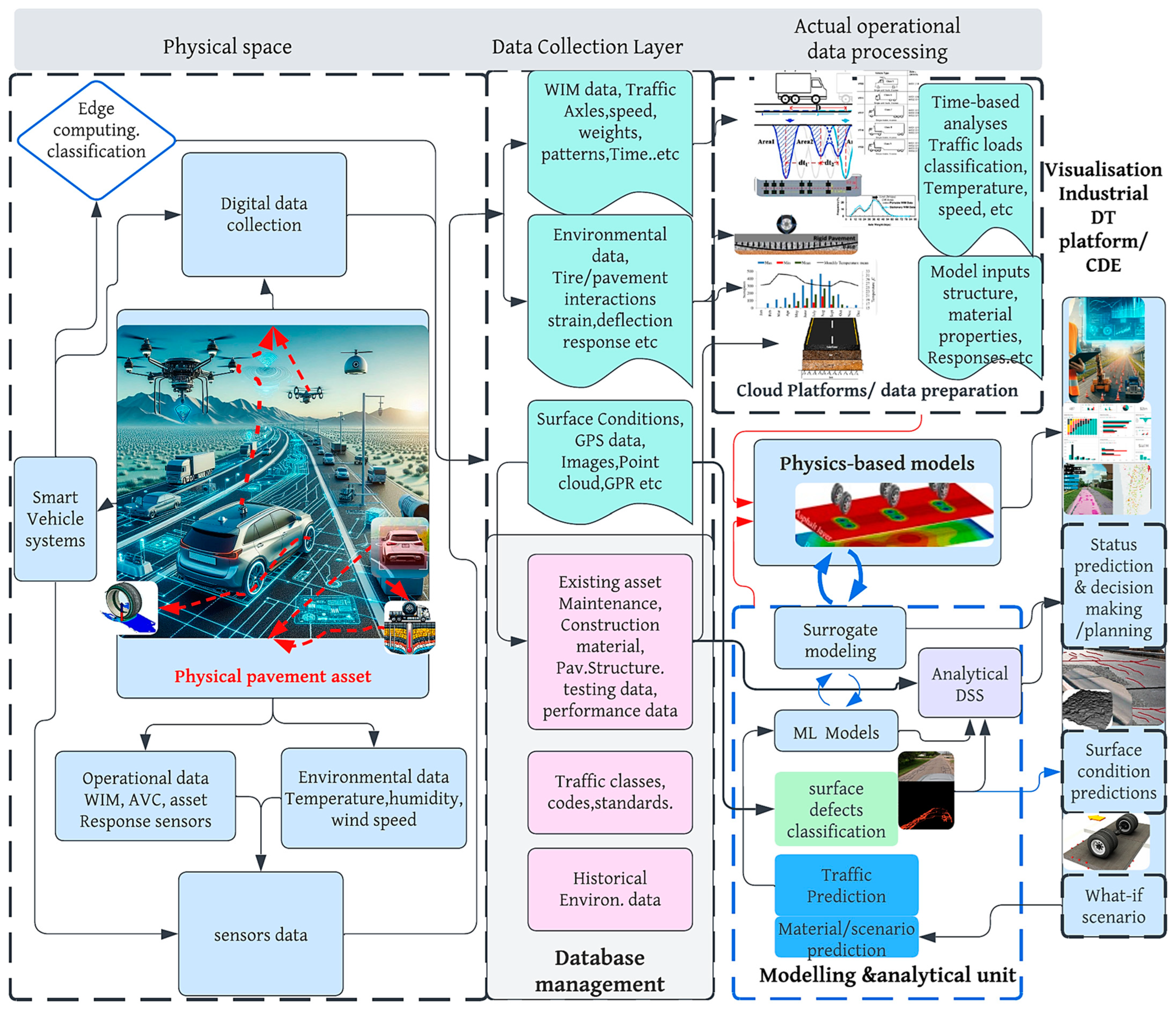

3.6. Proposed Cognitive Pavement DT Framework

3.7. Research Gaps and Future Recommendations

- To advance the current underdevelopment practice of DTs, implementation should align with the proposed DT concept. The structural aspect of the asset and actual operational conditions need to be incorporated. Furthermore, the predictions and decision processes of pavement DTs need improvements. Simulation is a core feature of the DT fundamentals. However, it is not mentioned in most developed works. Methods for integrating modelling and simulation for advanced analytical modelling and what-if scenario functionalities require further research. Physics-based simulations, such as the finite element method, and other model updating and optimisation techniques outlined in the proposed framework require further investigations. In addition, real case implementation as proof of concept is required for physics-based methods and ML hybrid integration. This considers real asset operational and lifecycle data to overcome current limitations and achieve improved prediction in growing DT. This work recommends further exploring and assessing these hybrid simulation methods incorporating real-life data.

- Visualisation tools are critical in predicting complex systems for user-friendly use, interpreting findings and making informed decisions through intelligent systems. It is a conjunction of all data types, from simulation, modelling, and decisions to asset state visualisation as proposed in the proposed framework. A few works have developed virtual models that replicate assets and visualise current defects and surface conditions, which are proposed in the literature. However, there is a need for methods to reflect further predicted data and conditions for the future state of the asset, in addition to developing visualisation components for users within DT platforms to align with full DT capabilities.

- DT depends on leveraging remote actual data from the physical asset. Recent NDT methods, i.e., [80], used 3D-digital image correlation to the in situ testing based on vehicle tyre load deflections, or a Laser dynamic deflectometer (LDD) to capture the deflection as the vehicle moves [81]. A work presented tyre–pavement interaction to provide data potentially helping road damage analysis [115]. However, these approaches imply collecting actual data and asset responses based on on-road vehicles, as highlighted in the asset response sensor data in the proposed framework. This significant research direction on the future of non-destructive sensing enables the enhanced asset status prediction of future DT implementation.

- Cognitive DT implementation involves a complex and wide range of data parameters and information. This can also challenge the traditional decision-making processes due to their complexity and numerous dependencies. Therefore, optimising these decisions would require advanced self-learning DSS for managing, interpreting, and optimising detailed and complex datasets. Consequently, more sophisticated DSSs are required to facilitate the effective implementation of DTs and adapt for Construction 5.0.

- The reliance of DTs on existing asset data highlights the critical importance of structured databases, such as LTPP. However, this presents other challenges due to the lack of digitised data records in integrating data within DTs. The solution for data operability, security, and existing database use requires developing innovative methods to facilitate their implementation. Therefore, interoperability and data security solutions must be addressed, and cloud service solutions in integrated diverse data for modelling, storing, and visualising need to be explored. This will help move toward a sustainable digital built-in shared environment across multiple sectors.

- In the current literature, there is an absence of works investigating the cost and environmental considerations of DT implementation for asset management. This includes human–machine relations, trust, connection, and sustainability factors within infrastructure asset DTs for Construction 5.0 readiness. In addition, it is essential to understand the factors that influence the adaptation and adoption of DT systems. These required contributions will impact the successful deployment of DTs.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dunhoft, M.-C. “This Is a Paradigm Shift for the Entire Industry”: Employee Resistance to Technological Innovation in the German AEC Industry; University of Twente: Enschede, The Netherlands, 2022. [Google Scholar]

- Singh, M.; Fuenmayor, E.; Hinchy, E.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Index, D. Digital America: A Tale of the Haves and Have-Mores; McKinsey: Chicago, IL, USA, 2015. [Google Scholar]

- Moshood, T.D.; Rotimi, J.O.B.; Shahzad, W.; Bamgbade, J.A. Infrastructure digital twin technology: A new paradigm for future construction industry. Technol. Soc. 2024, 77, 102519. [Google Scholar] [CrossRef]

- Sawhney, A.; Riley, M.; Irizarry, J.; Riley, M. (Eds.) Construction 4.0.; Routledge: London, UK, 2020. [Google Scholar]

- Musarat, M.A.; Irfan, M.; Alaloul, W.S.; Maqsoom, A.; Ghufran, M. A Review on the Way Forward in Construction through Industrial Revolution 5.0. Sustainability 2023, 15, 13862. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Sindhwani, R.; Afridi, S.; Kumar, A.; Banaitis, A.; Luthra, S.; Singh, P.L. Can industry 5.0 revolutionize the wave of resilience and social value creation? A multi-criteria framework to analyze enablers. Technol. Soc. 2022, 68, 101887. [Google Scholar] [CrossRef]

- Tyagi, A.K.; Lakshmi Priya, R.; Mishra, A.K.; Balamurugan, G. Industry 5.0. In Privacy Preservation of Genomic and Medical Data; Wiley: Hoboken, NJ, USA, 2023; pp. 409–432. [Google Scholar]

- Forcael, E.; Ferrari, I.; Opazo-Vega, A.; Pulido-Arcas, J.A. Construction 4.0: A literature review. Sustainability 2020, 12, 9755. [Google Scholar] [CrossRef]

- Vu, T.L.A.; Le, T.Q. Development orientation for higher education training programme of mechanical engineering in industrial revolution 4.0: A perspective in Vietnam. J. Mech. Eng. Res. Dev. 2019, 42, 68–70. [Google Scholar]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- Lee, H.; Kim, T. Smart factory use case model based on digital twin. ICIC Express Lett. Part B Appl. 2018, 9, 931–936. [Google Scholar]

- Page, G.; Yorke-Biggs, B.; De-Guido, S. IDE Digital Twin White Paper: Harnessing the Digital Twin for Real Competitive Advantage; Loughborough University: Loughborough, UK, 2023. [Google Scholar]

- Seaton, H.; Savian, C.; Sepasgozar, S.; Sawhney, A. Digital Twins from Design to Handover of Constructed Assets; Royal Institute of Chartered Surveyors: London, UK, 2022. [Google Scholar]

- Research and Markets. Digital Twins Market by Technology, Twinning Type, Cyber-to-Physical Solutions, Use Cases and Applications in Industry Verticals 2024–2029. Available online: https://www.researchandmarkets.com/reports/5308850/digital-twins-market-by-technology-twinning?utm_source=dynamic&utm_medium=CI&utm_code=6q68tb&utm_campaign=1366076+-The+Future+of+the+Digital+Twins+Industry+to+2025+in+Manufacturing,+Smart+Cities,+Auto (accessed on 3 February 2024).

- Pregnolato, M.; Gunner, S.; Voyagaki, E.; De Risi, R.; Carhart, N.; Gavriel, G.; Tully, P.; Tryfonas, T.; Macdonald, J.; Taylor, C. Towards Civil Engineering 4.0: Concept, workflow and application of Digital Twins for existing infrastructure. Autom. Constr. 2022, 141, 104421. [Google Scholar] [CrossRef]

- Saback, V.; Popescu, C.; Blanksvärd, T.; Täljsten, B. Analysis of Digital Twins in the Construction Industry: Practical Applications, Purpose, and Parallel with other Industries. Buildings 2024, 14, 1361. [Google Scholar] [CrossRef]

- Wang, W.; Zaheer, Q.; Qiu, S.; Wang, W.; Ai, C.; Wang, J.; Wang, S.; Hu, W. Digital Twin Technologies in Transportation Infrastructure Management; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of predictive maintenance based on digital twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef] [PubMed]

- Broo, D.G.; Schooling, J. Digital twins in infrastructure: Definitions, current practices, challenges and strategies. Int. J. Constr. Manag. 2021, 23, 1254–1263. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Yan, B.; Yang, F.; Qiu, S.; Wang, J.; Cai, B.; Wang, S.; Zaheer, Q.; Wang, W.; Chen, Y.; Hu, W. Digital twin in transportation infrastructure management: A systematic review. Intell. Transp. Infrastruct. 2023, 2, liad024. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Li, H.; Wang, C.; Feng, P. Applications and challenges of digital twin intelligent sensing technologies for asphalt pavements. Autom. Constr. 2024, 164, 105480. [Google Scholar] [CrossRef]

- Vieira, J.; Poças Martins, J.; Marques de Almeida, N.; Patrício, H.; Gomes Morgado, J. Towards Resilient and Sustainable Rail and Road Networks: A Systematic Literature Review on Digital Twins. Sustainability 2022, 14, 7060. [Google Scholar] [CrossRef]

- Autodesk. What is a Digital Twin? Available online: https://www.autodesk.com/design-make/articles/what-is-a-digital-twin (accessed on 1 February 2025).

- Chen, Z.-S.; Chen, K.-D.; Xu, Y.-Q.; Pedrycz, W.; Skibniewski, M.J. Multiobjective optimization-based decision support for building digital twin maturity measurement. Adv. Eng. Inform. 2024, 59, 102245. [Google Scholar] [CrossRef]

- Mantalovas, K.; Di Mino, G.; Jimenez Del Barco Carrion, A.; Keijzer, E.; Kalman, B.; Parry, T.; Lo Presti, D. European National Road Authorities and Circular Economy: An Insight into Their Approaches. Sustainability 2020, 12, 7160. [Google Scholar] [CrossRef]

- Liu, Z.; Balieu, R.; Kringos, N. Integrating sustainability into pavement maintenance effectiveness evaluation: A systematic review. Transp. Res. Part D Transp. Environ. 2022, 104, 103187. [Google Scholar] [CrossRef]

- Lu, R.; Brilakis, I. Generating Bridge Geometric Digital Twins from Point Clouds; European Council on Computing in Construction: St-Niklaas, Belgium, 2019; pp. 367–376. [Google Scholar]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive maintenance using digital twins: A systematic literature review. Inf. Softw. Technol. 2022, 151, 107008. [Google Scholar] [CrossRef]

- Nikolaev, S.; Belov, S.; Gusev, M.; Uzhinsky, I. Hybrid Data-Driven and Physics-Based Modelling for Prescriptive Maintenance of Gas-Turbine Power Plant. In Proceedings of the Product Lifecycle Management in the Digital Twin Era, Moscow, Russia, 8–12 July 2019; Springer: Cham, Switzerland, 2019; pp. 379–388. [Google Scholar]

- Camposano, J.C.; Smolander, K.; Ruippo, T. Seven metaphors to understand digital twins of built assets. IEEE Access 2021, 9, 27167–27181. [Google Scholar] [CrossRef]

- Adigopula, V.K. A Simplified Empirical Approach for Prediction of Pavement Layer Moduli Values Using Lightweight Deflectometer Data. Int. J. Pavement Res. Technol. 2022, 15, 751–763. [Google Scholar] [CrossRef]

- Canestrari, F.; Ingrassia, L.P.; Virgili, A. A semi-empirical model for top-down cracking depth evolution in thick asphalt pavements with open-graded friction courses. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 244–260. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, F.; Birgisson, B.; Lytton, R.L. Viscoelasticplastic–fracture modeling of asphalt mixtures under monotonic and repeated loads. Transp. Res. Rec. 2017, 2631, 20–29. [Google Scholar] [CrossRef]

- Wang, H.; Al-Qadi, I.L. Combined effect of moving wheel loading and three-dimensional contact stresses on perpetual pavement responses. Transp. Res. Rec. 2009, 2095, 53–61. [Google Scholar] [CrossRef]

- Brewer, K.A. AASHTO Maintenance Manual for Roadways and Bridges; Aashto: Washington, DC, USA, 2007. [Google Scholar]

- Irrgang, F.C.; Maze, T. Status of Pavement Management Systems and Data Analysis Models at State Highway Agencies. Transportation Research Record No. 1397; National Academy Press: Washington, DC, USA, 1993; pp. 1–6. [Google Scholar]

- Gharaibeh, N.G.; Darter, M.I.; Uzarski, D.R. Development of prototype highway asset management system. J. Infrastruct. Syst. 1999, 5, 61–68. [Google Scholar] [CrossRef]

- Amândio, M.; Parente, M.; Neves, J.; Fonseca, P. Integration of Smart Pavement Data with Decision Support Systems: A Systematic Review. Buildings 2021, 11, 579. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, M. Multi-objective optimization for pavement maintenance and rehabilitation decision-making: A critical review and future directions. Autom. Constr. 2021, 130, 103840. [Google Scholar] [CrossRef]

- Haas, R.; Hudson, W.R. Pavement Asset Management; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Brown, D.; Liu, W.; Henning, T. Identifying Pavement Deterioration by Enhancing the Definition of Road Roughness; NZ Transport Agency: Auckland, New Zealand, 2010.

- Coenen, T.B.; Golroo, A. A review on automated pavement distress detection methods. Cogent Eng. 2017, 4, 1374822. [Google Scholar] [CrossRef]

- Zhang, S.; Lippitt, C.D.; Bogus, S.M.; Neville, P.R. Characterizing pavement surface distress conditions with hyper-spatial resolution natural color aerial photography. Remote Sens. 2016, 8, 392. [Google Scholar] [CrossRef]

- Aleadelat, W.; Ksaibati, K. Estimation of pavement serviceability index through android-based smartphone application for local roads. Transp. Res. Rec. 2017, 2639, 129–135. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, X.; Sun, M.; Zhao, Q. Object-based and supervised detection of potholes and cracks from the pavement images acquired by UAV. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, 42, 209–217. [Google Scholar] [CrossRef]

- Maeda, H.; Sekimoto, Y.; Seto, T.; Kashiyama, T.; Omata, H. Road damage detection using deep neural networks with images captured through a smartphone. arXiv 2018, arXiv:1801.09454. [Google Scholar]

- Peraka, N.S.P.; Biligiri, K.P. Pavement asset management systems and technologies: A review. Autom. Constr. 2020, 119, 103336. [Google Scholar] [CrossRef]

- Gopalakrishnan, K. Deep learning in data-driven pavement image analysis and automated distress detection: A review. Data 2018, 3, 28. [Google Scholar] [CrossRef]

- Zhu, J.; Zhong, J.; Ma, T.; Huang, X.; Zhang, W.; Zhou, Y. Pavement distress detection using convolutional neural networks with images captured via UAV. Autom. Constr. 2022, 133, 103991. [Google Scholar] [CrossRef]

- Du, Y.; Pan, N.; Xu, Z.; Deng, F.; Shen, Y.; Kang, H. Pavement distress detection and classification based on YOLO network. Int. J. Pavement Eng. 2021, 22, 1659–1672. [Google Scholar] [CrossRef]

- Zakeri, H.; Nejad, F.M.; Fahimifar, A. Image based techniques for crack detection, classification and quantification in asphalt pavement: A review. Arch. Comput. Methods Eng. 2017, 24, 935–977. [Google Scholar] [CrossRef]

- Li, Z. Transportation Asset Management: Methodology and Applications; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Al-Mansoori, T.; Abdalkadhum, A.; Al-Husainy, A.S. A GIS-enhanced pavement management system: A case study in Iraq. J. Eng. Sci. Technol. 2020, 15, 2639–2648. [Google Scholar]

- Justo-Silva, R.; Ferreira, A.; Flintsch, G. Review on Machine Learning Techniques for Developing Pavement Performance Prediction Models. Sustainability 2021, 13, 5248. [Google Scholar] [CrossRef]

- Wang, W.; Qin, Y.; Li, X.; Wang, D.; Chen, H. Comparisons of Faulting-Based Pavement Performance Prediction Models. Adv. Mater. Sci. Eng. 2017, 2017, 6845215. [Google Scholar] [CrossRef]

- Marcelino, P.; de Lurdes Antunes, M.; Fortunato, E.; Gomes, M.C. Machine learning approach for pavement performance prediction. Int. J. Pavement Eng. 2021, 22, 341–354. [Google Scholar] [CrossRef]

- Abdualaziz Ali, A.; Heneash, U.; Hussein, A.; Khan, S. Application of Artificial neural network technique for prediction of pavement roughness as a performance indicator. J. King Saud Univ. Eng. Sci. 2023, 36, 128–139. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, J.; Li, Q.; Fang, N.; Wang, P.; Ding, L.; Li, S. A Hybrid Model for Prediction in Asphalt Pavement Performance Based on Support Vector Machine and Grey Relation Analysis. J. Adv. Transp. 2020, 2020, 7534970. [Google Scholar] [CrossRef]

- Barros, R.; Yasarer, H.; Uddin, W.; Sultana, S. Roughness Modeling for Composite Pavements using Machine Learning. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203, 032035. [Google Scholar] [CrossRef]

- Sandamal, K.; Shashiprabha, S.; Muttil, N.; Rathnayake, U. Pavement Roughness Prediction Using Explainable and Supervised Machine Learning Technique for Long-Term Performance. Sustainability 2023, 15, 9617. [Google Scholar] [CrossRef]

- Martin, T.; Sen, R. Austroads Road Deterioration Model Update: Rutting; Austroads: Sydney, Australia, 2023; ISBN 978-1-922700-70-4.

- Martin, T.; Sen, R. Austroads Road Deterioration Model Update: Roughness; Austroads: Sydney, Australia, 2023; ISBN 978-1-922700-69-8.

- Basnet, K.S.; Shrestha, J.K.; Shrestha, R.N. Pavement performance model for road maintenance and repair planning: A review of predictive techniques. Digit. Transp. Saf. 2023, 2, 253–267. [Google Scholar] [CrossRef]

- Gunner, S.; Voyagaki, E.; Gavriel, G.; Carhart, N.; MacDonald, J.; Tryfonas, T.; Taylor, C.; Pregnolato, M. Digital Twins for civil engineering: The Clifton Suspension Bridge (UK). In Proceedings of the 10th International Conference on Structural Health Monitoring of Intelligent Infrastructure, SHMII, Porto, Portugal, 30 June–2 July 2021; pp. 1–6. [Google Scholar]

- American Association of State Highway and Transportation Officials. Mechanistic-Empirical Pavement Design Guide: A Manual of Practice; AASHTO: Washington, DC, USA, 2008. [Google Scholar]

- Wang, H.; Al-Qadi, I.L.; Stanciulescu, I. Simulation of tyre–pavement interaction for predicting contact stresses at static and various rolling conditions. Int. J. Pavement Eng. 2012, 13, 310–321. [Google Scholar] [CrossRef]

- Selezneva, O.I.; Hallenbeck, M.E. Facilitating Analysts’ Use of Traffic Data from the Long-Term Pavement Performance (LTPP) Program; United States Federal Highway Administration, Office of Infrastructure: Washington, DC, USA, 2022.

- Dong, J.; Meng, W.; Liu, Y.; Ti, J. A framework of pavement management system based on IoT and big data. Adv. Eng. Inform. 2021, 47, 101226. [Google Scholar] [CrossRef]

- Piryonesi, S.M. The Application of Data Analytics to Asset Management: Deterioration and Climate Change Adaptation in Ontario Roads; University of Toronto (Canada): Toronto, ON, Canada, 2019. [Google Scholar]

- Oditallah, M.; Alam, M.M.; Ekambaram, P. Digital Twins in AEC Infrastructures and Buildings Management Systems. In Proceedings of the 2nd International Conference on Civil Infrastructure and Construction (CIC 2023), Doha, Qatar, 5–8 February 2023. [Google Scholar]

- Kun, C.; Mehran, E.T.; Mingjie, C.; Long, Z.; Alvaro, G.-H. Identifying the most suitable machine learning approach for a road digital twin. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2021, 174, 88–101. [Google Scholar]

- Arup. Digital Twin: Towards a Meaningful Framework; Technical Report; Arup: London, UK, 2019. [Google Scholar]

- MEED. Digital Evolution—The Critical Impact of Digital Twins on Middle East Construction; MEED: Dubai, United Arab Emirates, 2021. [Google Scholar]

- Love, P.E.; Matthews, J.; Zhou, J. Is it just too good to be true? Unearthing the benefits of disruptive technology. Int. J. Inf. Manag. 2020, 52, 102096. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M.; Famakinwa, T.; Bamdad, K. Drivers for Digital Twin Adoption in the Construction Industry: A Systematic Literature Review. Buildings 2022, 12, 113. [Google Scholar] [CrossRef]

- Núñez-Temes, C.; Bastos, G.; Arza-García, M.; Castro, A.; Lorenzana Fernández, J.A.; Ortiz-Sanz, J.; Portela, M.; Gil-Docampo, M.; Prego, F.J. Assessment of pavement deflection under vehicle loads using a 3D-DIC system in the field. Sci. Rep. 2022, 12, 9491. [Google Scholar] [CrossRef]

- Liao, J.; Lin, H.; Li, Q.; Zhang, D. A correction model for the continuous deflection measurement of pavements under dynamic loads. IEEE Access 2019, 7, 154770–154785. [Google Scholar] [CrossRef]

- Wang, X.; Wang, H.; Wang, C.; Feng, P.; Irfan, M.; Gao, J.; Leng, Z.; Zhang, C. Real-time monitoring of asphalt pavement structure fatigue response based on tri-axis accelerometer. Int. J. Pavement Eng. 2024, 25, 2308158. [Google Scholar] [CrossRef]

- Braunfelds, J.; Senkans, U.; Skels, P.; Porins, J.; Haritonovs, V.; Spolitis, S.; Bobrovs, V. Development of the strain measurement calibration technique for road pavement structural health monitoring applications using optical FBG sensors. In Proceedings of the 2023 Photonics & Electromagnetics Research Symposium (PIERS), Prague, Czech Republic, 3–6 July 2023; pp. 1060–1065. [Google Scholar]

- Wang, D.; Lv, H.; Tang, F.; Ye, C.; Liu, P. Intelligent detection technology of contact state between asphalt pavement layers based on 3D ground penetrating radar technology. J. Beijing Univ. Technol 2022, 48, 573. [Google Scholar]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmström, J. Digital twin: Vision, benefits, boundaries, and creation for buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Grieves, M. Digital twin: Manufacturing excellence through virtual factory replication. White Pap. 2014, 1, 1–7. [Google Scholar]

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.-L.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Xu, H.; Huang, Z. Five-dimension digital twin model and its ten applications. Comput. Integr. Manuf. Syst 2019, 25, 1–18. [Google Scholar]

- Yu, H.; Yao, D.; Qian, G.; Zhu, X.; Shi, Z.; Zhang, C.; Li, P. Review on Digital Twin Model of Asphalt Mixture Performance Based on Mesostructure Characteristics. China J. Highw. Transp 2023, 36, 20–44. [Google Scholar]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Comput. Ind. 2020, 123, 103316. [Google Scholar] [CrossRef]

- Wang, M.; Yin, X. Construction and maintenance of urban underground infrastructure with digital technologies. Autom. Constr. 2022, 141, 104464. [Google Scholar] [CrossRef]

- Gao, C.; Wang, J.; Dong, S.; Liu, Z.; Cui, Z.; Ma, N.; Zhao, X. Application of Digital Twins and Building Information Modeling in the Digitization of Transportation: A Bibliometric Review. Appl. Sci. 2022, 12, 11203. [Google Scholar] [CrossRef]

- Ge, C.; Qin, S. Digital twin intelligent transportation system (DT-ITS)—A systematic review. IET Intell. Transp. Syst. 2024, 18, 2325–2358. [Google Scholar] [CrossRef]

- Irfan, M.S.; Dasgupta, S.; Rahman, M. Toward Transportation Digital Twin Systems for Traffic Safety and Mobility: A Review. IEEE Internet Things J. 2024, 11, 24581–24603. [Google Scholar] [CrossRef]

- Werbińska-Wojciechowska, S.; Giel, R.; Winiarska, K. Digital Twin Approach for Operation and Maintenance of Transportation System—Systematic Review. Sensors 2024, 24, 6069. [Google Scholar] [CrossRef]

- Sanfilippo, F.; Thorstensen, R.T.; Jha, A.; Jiang, Z.; Robbersmyr, K.G. A Perspective Review on Digital Twins for Roads, Bridges, and Civil Infrastructures. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Male, Maldives, 16–18 November 2022; pp. 1–6. [Google Scholar]

- Talaghat, M.A.; Golroo, A.; Kharbouch, A.; Rasti, M.; Heikkilä, R.; Jurva, R. Digital twin technology for road pavement. Autom. Constr. 2024, 168, 105826. [Google Scholar] [CrossRef]

- Cepa, J.J.; Pavón, R.M.; Alberti, M.G.; Ciccone, A.; Asprone, D. A Review on the Implementation of the BIM Methodology in the Operation Maintenance and Transport Infrastructure. Appl. Sci. 2023, 13, 3176. [Google Scholar] [CrossRef]

- Ersöz, O.Ö.; İnal, A.F.; Aktepe, A.; Türker, A.K.; Ersöz, S. A Systematic Literature Review of the Predictive Maintenance from Transportation Systems Aspect. Sustainability 2022, 14, 14536. [Google Scholar] [CrossRef]

- Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Modeling, Simulation, Information Technology and Processing Roadmap; NASA: Washington, DC, USA, 2010.

- Bado, M.F.; Tonelli, D.; Poli, F.; Zonta, D.; Casas, J.R. Digital Twin for Civil Engineering Systems: An Exploratory Review for Distributed Sensing Updating. Sensors 2022, 22, 3168. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A digital twin-based approach for designing and multi-objective optimization of hollow glass production line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Stark, R.; Damerau, T. Digital Twin. In CIRP Encyclopedia of Production Engineering; Chatti, S., Tolio, T., Eds.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 1–8. [Google Scholar]

- Zhang, L.; Zhou, L.; Ren, L.; Laili, Y. Modeling and simulation in intelligent manufacturing. Comput. Ind. 2019, 112, 103123. [Google Scholar] [CrossRef]

- Defraeye, T.; Shrivastava, C.; Berry, T.; Verboven, P.; Onwude, D.; Schudel, S.; Bühlmann, A.; Cronje, P.; Rossi, R.M. Digital twins are coming: Will we need them in supply chains of fresh horticultural produce? Trends Food Sci. Technol. 2021, 109, 245–258. [Google Scholar] [CrossRef]

- Li, J.; Yin, G.; Wang, X.; Yan, W. Automated decision making in highway pavement preventive maintenance based on deep learning. Autom. Constr. 2022, 135, 104111. [Google Scholar] [CrossRef]

- Gao, L.; Yu, Y.; Ren, Y.H.; Lu, P. Detection of Pavement Maintenance Treatments using Deep-Learning Network. Transp. Res. Rec. 2021, 2675, 1434–1443. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, S.; Hu, M.; Wang, Y.K. Prediction of Highway Tunnel Pavement Performance Based on Digital Twin and Multiple Time Series Stacking. Adv. Civ. Eng. 2020, 2020, 8824135. [Google Scholar] [CrossRef]

- Consilvio, A.; Hernández, J.S.; Chen, W.; Brilakis, I.; Bartoccini, L.; Gennaro, F.D.; Welie, M.V. Towards a digital twin-based intelligent decision support for road maintenance. Transp. Res. Procedia 2023, 69, 791–798. [Google Scholar] [CrossRef]

- Zeiada, W.; Dabous, S.A.; Hamad, K.; Al-Ruzouq, R.; Khalil, M.A. Machine Learning for Pavement Performance Modelling in Warm Climate Regions. Arab. J. Sci. Eng. 2020, 45, 4091–4109. [Google Scholar] [CrossRef]

- Kaliske, M.; Behnke, R.; Wollny, I. Vision on a Digital Twin of the Road-Tire-Vehicle System for Future Mobility. Tire Sci. Technol. 2021, 49, 2–18. [Google Scholar] [CrossRef]

- Ficara, A.; Fazio, M.; Pellegrino, O.; Ruggeri, A.; Ruggeri, A.; Sollazzo, G.; Bosurgi, G. Distributed Services for Pavement Anomaly Detection in Smart Roads. In Proceedings of the 2024 IEEE International Symposium on Measurements & Networking (M&N), Rome, Italy, 2–5 July 2024; pp. 1–6. [Google Scholar]

- Barisic, L.; Levenberg, E.; Skar, A.; Boyd, A.; Zoulis, P. A Thermal Digital Twin for Condition Monitoring of Asphalt Roads; CRC Press: Boca Raton, FL, USA, 2021; pp. 709–713. [Google Scholar]

- Sotiriadis, G.; Kotzakolios, T.; Kostopoulos, V.; Gemou, M. A Digital Twin Assisted and Embedded Strain Gauge Monitoring System. Transp. Res. Procedia 2023, 72, 2038–2045. [Google Scholar] [CrossRef]

- Steyn, W.J.; Broekman, A. Development of a digital twin of a local road network: A case study. J. Test. Eval. 2022, 50, 2901–2915. [Google Scholar] [CrossRef]

- Meža, S.; Mauko Pranjic, A.; Vezočnik, R.; Osmokrović, I.; Lenart, S. Digital Twins and Road Construction Using Secondary Raw Materials. J. Adv. Transp. 2021, 2021, 8833058. [Google Scholar] [CrossRef]

- Marai, O.E.; Taleb, T.; Song, J. Roads Infrastructure Digital Twin: A Step Toward Smarter Cities Realization. IEEE Netw. 2021, 35, 136–143. [Google Scholar] [CrossRef]

- Wang, W.; Xu, X.; Peng, J.; Hu, W.; Wu, D. Fine-Grained Detection of Pavement Distress Based on Integrated Data Using Digital Twin. Appl. Sci. 2023, 13, 4549. [Google Scholar] [CrossRef]

- Sierra, C.; Paul, S.; Rahman, A.; Kulkarni, A. Development of a cognitive digital twin for pavement infrastructure health monitoring. Infrastructures 2022, 7, 113. [Google Scholar] [CrossRef]

- Sofia, H.; Anas, E.; Faïz, O. Mobile Mapping, Machine Learning and Digital Twin for Road Infrastructure Monitoring and Maintenance: Case Study of Mohammed VI Bridge in Morocco. In Proceedings of the 2020 IEEE International conference of Moroccan Geomatics (Morgeo), Casablanca, Morocco, 11–13 May 2020; pp. 1–6. [Google Scholar]

- Hidayat, F.; Supangkat, S.H.; Hanafi, K. Digital Twin of Road and Bridge Construction Monitoring and Maintenance. In Proceedings of the 2022 IEEE International Smart Cities Conference (ISC2), Pafos, Cyprus, 26–29 September 2022; pp. 1–7. [Google Scholar]

- Bosurgi, G.; Celauro, C.; Pellegrino, O.; Rustica, N.; Giuseppe, S. The BIM (Building Information Modeling)-Based Approach for Road Pavement Maintenance. In Proceedings of the 5th International Symposium on Asphalt Pavements & Environment (APE), Padua, Italy, 11–13 September 2019; Springer: Cham, Switzerland, 2020; pp. 480–490. [Google Scholar]

- Cao, T.; Wang, Y.; Liu, S. Pavement Crack Detection Based on 3D Edge Representation and Data Communication with Digital Twins. IEEE Trans. Intell. Transp. Syst. 2022, 24, 7697–7706. [Google Scholar] [CrossRef]

- D’Amico, F.; Bianchini Ciampoli, L.; Di Benedetto, A.; Bertolini, L.; Napolitano, A. Integrating Non-Destructive Surveys into a Preliminary BIM-Oriented Digital Model for Possible Future Application in Road Pavements Management. Infrastructures 2022, 7, 10. [Google Scholar] [CrossRef]

- Bertolini, L.; Giorgadze, I.M.; Vahdatikhaki, F.; D’Amico, F. A Semantic Digital Twinning Approach for the Management of Road Distress Data. ISPRS Ann. Photogramm. Remote Sens. Spat. Inf. Sci. 2024, X-4/W5-2024, 49–54. [Google Scholar] [CrossRef]

- Fox-Ivey, R.; Laurent, J.; Petitclerc, B. Using 3D Pavement Surveys to Create a Digital Twin of Your Runway or Highway. In Airfield and Highway Pavements 2021; Proceedings; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2021; pp. 180–192. [Google Scholar]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, W.; Luo, H. Building digital twins of existing highways using map data based on engineering expertise. Autom. Constr. 2022, 134, 104081. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, M.; Lu, L.; Wei, R.; Cavazzi, S.; Peck, M.; Brilakis, I. Scan-to-graph: Automatic generation and representation of highway geometric digital twins from point cloud data. Autom. Constr. 2024, 166, 105654. [Google Scholar] [CrossRef]

- Lukanen, E.O.; Stubstad, R.; Briggs, R.C.; Intertec, B. Temperature Predictions and Adjustment Factors for Asphalt Pavement; Turner-Fairbank Highway Research Center: McLean, VA, USA, 2000. [Google Scholar]

- Rajapaksha, M.M.C.; Athukorallage, B.; Senadheera, S.; James, D. Temporal and spatial temperature predictions for flexible pavement layers using numerical thermal analysis and verified with large datasets. Case Stud. Constr. Mater. 2023, 18, e02008. [Google Scholar] [CrossRef]

- Xu, B.; Dan, H.-C.; Li, L. Temperature prediction model of asphalt pavement in cold regions based on an improved BP neural network. Appl. Therm. Eng. 2017, 120, 568–580. [Google Scholar] [CrossRef]

- You, L.; Yan, K.; Liu, N. Assessing artificial neural network performance for predicting interlayer conditions and layer modulus of multi-layered flexible pavement. Front. Struct. Civ. Eng. 2020, 14, 487–500. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Talebsafa, M.; Motamedi, M.; Badroodi, S.K. Analytical evaluation of load movement on flexible pavement and selection of optimum neural network algorithm. KSCE J. Civ. Eng. 2015, 19, 1738–1746. [Google Scholar] [CrossRef]

- Ziyadi, M.; Al-Qadi, I.L. Efficient surrogate method for predicting pavement response to various tire configurations. Neural Comput. Appl. 2017, 28, 1355–1367. [Google Scholar] [CrossRef]

- Okte, E.; Al-Qadi, I.L. Prediction of flexible pavement 3-D finite element responses using Bayesian neural networks. Int. J. Pavement Eng. 2022, 23, 5066–5076. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Hernandez, J.A.; Gamez, A.; Ziyadi, M.; Gungor, O.E.; Kang, S. Impact of Wide-Base Tires on Pavements: A National Study. Transp. Res. Rec. 2018, 2672, 186–196. [Google Scholar] [CrossRef]

- Li, M.; Wang, H. Development of ANN-GA program for backcalculation of pavement moduli under FWD testing with viscoelastic and nonlinear parameters. Int. J. Pavement Eng. 2019, 20, 490–498. [Google Scholar] [CrossRef]

- Matchett, R. Digital Twins for Road Infrastructure; University of Pretoria: Pretoria, South Africa, 2022. [Google Scholar]

- Ansari, F.; Glawar, R.; Nemeth, T. PriMa: A prescriptive maintenance model for cyber-physical production systems. Int. J. Comput. Integr. Manuf. 2019, 32, 482–503. [Google Scholar] [CrossRef]

- Vasiliev, Y.E.; Fineeva, M.A.; Belyakov, A.B.; Varshavsky, S.V.; Caesar, A.A. Decision support system for street-road network objects repair. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1159, 012025. [Google Scholar] [CrossRef]

- Hadjidemetriou, G.M.; Masino, J.; Christodoulou, S.E.; Gauterin, F.; Brilakis, I. Comprehensive Decision Support System for Managing Asphalt Pavements. J. Transp. Eng. Part B: Pavements 2020, 146, 06020001. [Google Scholar] [CrossRef]

- Philip, B.; AlJassmi, H. A Bayesian decision support system for optimizing pavement management programs. Heliyon 2024, 10, e25625. [Google Scholar] [CrossRef]

- Abu Dabous, S.; Zeiada, W.; Zayed, T.; Al-Ruzouq, R. Sustainability-informed multi-criteria decision support framework for ranking and prioritising pavement sections. J. Clean. Prod. 2020, 244, 118755. [Google Scholar] [CrossRef]

- Pour, S.M.; Masoumi, A.M.; Dujardin, N.S. Towards a Technology-Driven Adaptive Decision Support System for Integrated Pavement and Maintenance strategies (TDADSS-IPM): Focus on risk assessment framework for climate change adaptation. Transp. Res. Procedia 2023, 72, 4468–4475. [Google Scholar] [CrossRef]

| Work | Year | Review Focus |

|---|---|---|

| [96] | 2024 | Explore DT applications in road pavement management. |

| [93] | 2024 | Transportation DTs for safety and mobility applications and architecture for a transportation DT (TDT). |

| [20] | 2024 | Overall Digital Twins of transportation infrastructure management. |

| [92] | 2024 | DT-ITS core considerations, progress, services development of DT-ITS concerning architectures. |

| [94] | 2024 | Transportation Operation and Maintenance adoption and general asset management framework. |

| [97] | 2023 | BIM applications in civil engineering using new Information and Communication Technologies (ICTs). |

| [24] | 2023 | Transportation infrastructure management DT concept definition, life cycle application, and technology. |

| [98] | 2022 | Predictive maintenance transportation motor vehicles. |

| [26] | 2022 | DT rail and road infrastructure networks. |

| [91] | 2022 | BIM and digital twins in the digitalisation of transportation. |

| [95] | 2022 | Digital twins of road bridges inspection. |

| [90] | 2022 | Underground infrastructure construction and Operation & Maintenance (O&M) on locating and mapping technology. |

| [89] | 2020 | General DT applications for maintenance. |

| Aspect | General Framework Possible Assumptions | Asphalt Pavement Asset Criticality | Challenge/Effect |

|---|---|---|---|

| Modelling material behaviour | Not available (analytical only)/Elastic assumptions | Account for asphalt responses (i.e., viscoelastic/plastic response, time &temperature dependency, stress dependency response) | Unrealistic behaviour, inaccurate deterioration, overlooking temperature/load type or pattern) |

| Lifecycle/Simulation data input | Constant loads of operational/environmental data | Sensor data preparation (time-based loading, distributed temperature, overloading, etc.) | Inaccurate distress prediction (i.e., deformation), degradation rates, scenario analysis (i.e., event-impact scenario) |

| Integrated predictive model techniques | One modelling approach | Combine underlying physics of asset material response and facilitate | Enhanced accuracy and less computational cost allow faster and long-term predictions. |

| Continuous model updating and validation | One-off model development and training | Periodic data-driven update (simulation progress, survey data, sensor response for validation) | Updated knowledge of deterioration mechanisms, long-term prediction |

| Sensor data | Place on critical points/represent the structure | Rely on physics-based virtual sensors, validation study sections, incorporate users/mobile feeder | Unapplicable due to linear horizontal nature/network level |

| Work | Methodologies | |||

|---|---|---|---|---|

| Data Acquisition | Model Type/Development/Approaches | Platform/Integration Strategies/Tools | Interaction Type/Output/Feedback | |

| [112] | Vehicle-line scan, Accelerometer | ML-Prediction: multi-ANN, XGBoost, etc. | BIM software (Autodesk Revit)/CDE, Visual programming | 3D model-Roughness IRI index visualisation |

| [117] | Set-temperature sensors (profile), weather station sensors | Statistical prediction, numerical analysis/ validation | Analytical/numerical software | Real-time temperature prediction |

| [118] | Strain sensor | Physics-based model | Numerical analysis software (LS-DYNA) | Strain, load prediction |

| [119] | Smartphone, UAV camera, CVV camera, infrared, LiDAR, temperature | Depth map modelling, multi-view stereo (MVSNet) | Cloud IoT platform | 3D model/real-time data streaming |

| [120] | Embedded (temperature, humidity, displacement, pressure, stress, strain) | 3D BIM model | Centralised data management, visualisation and collaboration platform | 3D model/real-time data streaming |

| [121] | Camera/Video, GPS, Gyroscope | Object detection model (SSD MobileNet V2) | Open-source cloud computing | Real-time data streaming, object detection |

| [127] | LiDAR, Camera | 3D Object crack segmentation (CNN), 3D feature extraction | Python-ML platform (TensorFlow software) | As-is 3D crack visualisation |

| [122] | UAV-Camera | Object Detection (cracks, potholes) based on (YOLOv5) | Photogrammetry/mapping software, Game engine, real-time 3D platform | As-is distress visualisation |

| [123] | UAV-Camera | Object segmentation crack (U-Net, VGG-16) | Reality modelling (ContextCapture software) | Distress detection |

| [124] | 3D LiDAR, GIS | Point cloud processing, parametric modelling | Bridge/road software (Civil 3D), plugin-integrated visualisation (Leica’s toolset for Revit), 3D Surveying software (Cyclone 3DR) | As-built 3D model/virtual assessment (flatness or distortion) |

| [125] | Camera, GPS camera | Spatial data analytics | BIM modelling, GIS software | 3D model GIS integration |

| [126] | NA | 3D object -inspection, lifecycle data integration | BIM Infra software | 3D Model-based data |

| [116] | Smartphone sensors/camera/GPS, edge computing | NA | Cloud-based storage/services/query platform | Condition indicators visualisation |

| [72] | Camera, LiDAR, GIS | Image processing, data analysis | GIS, point cloud computing software | Distress detection, quality index visualisation |

| [113] | UAV camera, GPS, Light Detection and Ranging, survey data | Parametric modelling, computer vision-based algorithms, AI clustering decision optimisation | Cloud computing platform. Game engine, real-time 3D platform | Mapped/visualised data support decision system |

| [128] | GPR, Light Detection and Ranging, Laser Profiler | 3D data processing, Parametric modelling | Design/visualisation software (civil, infra) | As-is 3D pavement model/distress visualisation |

| [129] | Equip vehicle-laser Measuring System, GPR surveys | Point cloud processing/reasoning/Cells and voxels classification, visualisation | Specialised point cloud computing software | As-is Surface reproducing/subsurface distress visualisation |

| [130] | GPS/GNSS, 3D scan-integrated inertial measurement units (IMUs)- | Geo-referencing, 3D points cloud processing | LDTM software, Cad viewer | As-is 3D surface modelling |

| [131] | Existing Map database, aerial images, derived point cloud | 3D data processing | 3D modelling, point cloud processing software, visual programming | 3D model element reconstruction/digitising |

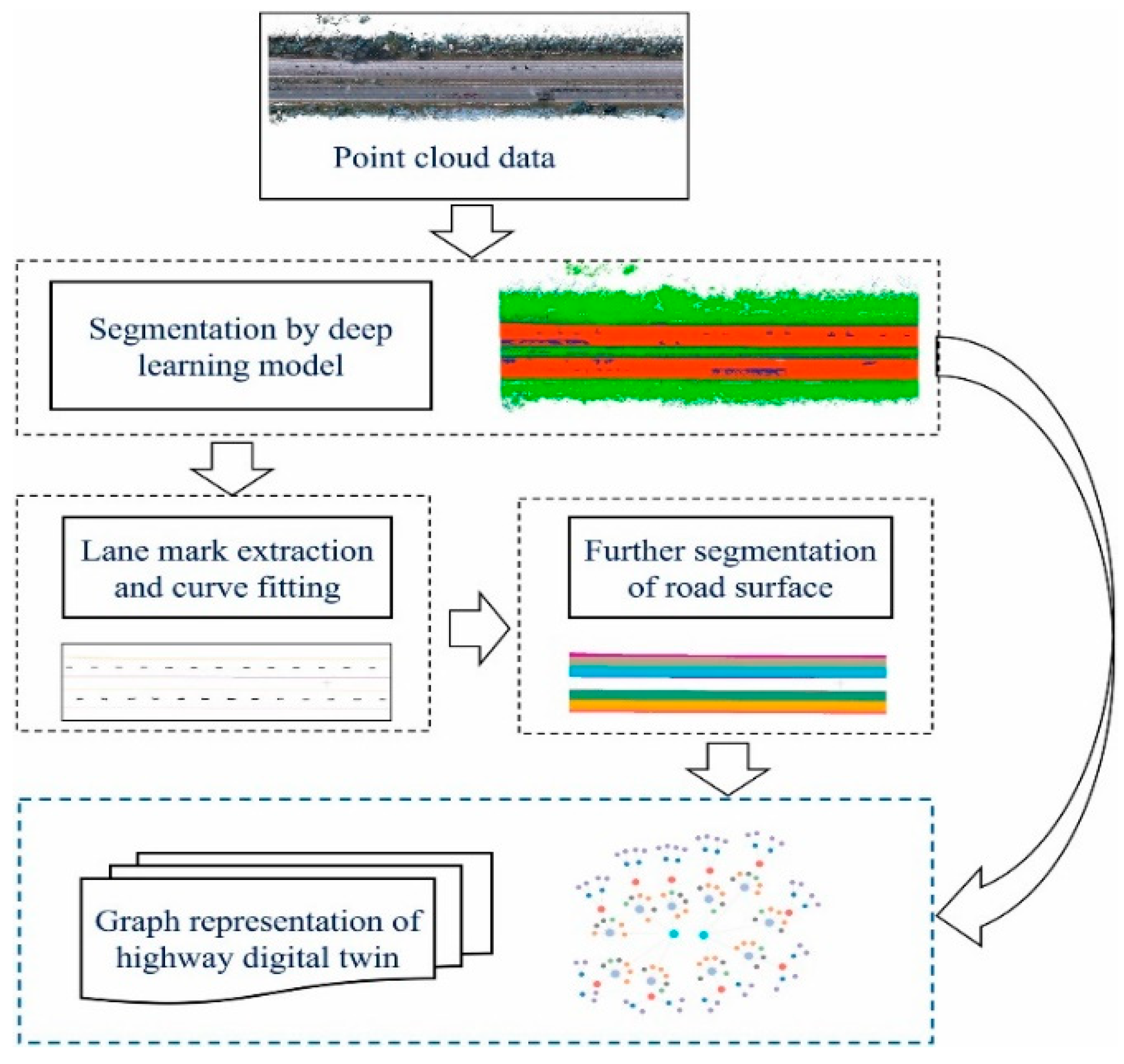

| [132] | 3D Point cloud data | Deep learning-segmentation, elements fitting | Point cloud processing software, Algorithm-Python | 3D Design element reconstruction/digitising |

| Work | Category | |||

|---|---|---|---|---|

| Current Condition Detection | 3D Model Creation/Visualisation | Support Monitoring Data | Analytical Prediction/Decision Support | |

| [116] | X | |||

| [112] | X | |||

| [72] | X | |||

| [128] | X | X | ||

| [115] | X | |||

| [117] | ||||

| [124] | X | X | ||

| [119] | X | |||

| [113] | X | X | ||

| [122] | X | |||

| [127] | X | X | ||

| [131] | X | |||

| [122] | X | X | ||

| [130] | X | |||

| [123] | X | |||

| [120] | X | X | ||

| [126] | X | |||

| [118] | X | |||

| [125] | X | |||

| [129] | X | X | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oditallah, M.; Alam, M.; Ekambaram, P.; Ranjha, S. Review and Insights Toward Cognitive Digital Twins in Pavement Assets for Construction 5.0. Infrastructures 2025, 10, 64. https://doi.org/10.3390/infrastructures10030064

Oditallah M, Alam M, Ekambaram P, Ranjha S. Review and Insights Toward Cognitive Digital Twins in Pavement Assets for Construction 5.0. Infrastructures. 2025; 10(3):64. https://doi.org/10.3390/infrastructures10030064

Chicago/Turabian StyleOditallah, Mohammad, Morshed Alam, Palaneeswaran Ekambaram, and Sagheer Ranjha. 2025. "Review and Insights Toward Cognitive Digital Twins in Pavement Assets for Construction 5.0" Infrastructures 10, no. 3: 64. https://doi.org/10.3390/infrastructures10030064

APA StyleOditallah, M., Alam, M., Ekambaram, P., & Ranjha, S. (2025). Review and Insights Toward Cognitive Digital Twins in Pavement Assets for Construction 5.0. Infrastructures, 10(3), 64. https://doi.org/10.3390/infrastructures10030064