Abstract

The aim of this study was to evaluate the influence of different ventilation systems in two aging cells. One cell featured transverse airflow starting from the top, while the other had a dual-flow system with vertical air motion from top to bottom and vice versa. In addition to monitoring weight loss during aging, chemical and physical analyses were conducted on various salamis to assess the influence of ventilation both between the two aging cells and among different positions of the salamis within the same cell. It was found that the dual-evaporator (DEV) cell behaved better than transverse flow (TFL) cell.

1. Introduction

The Italian regulation defines “salami” as the charcuterie product obtained from the meat of muscles belonging predominantly to pigs with the addition of salt and possibly meat from other animal species, minced and mixed with pork fat, added with spices, and stuffed into natural or synthetic casings [1,2]. Salamis are traditional food products from all parts of the world. The concentration of production, market opening, and standardization of norms and technologies lead to a flattening of quality and organoleptic characteristics, hindering the spread of typical regional salamis. Salamis are dried and cured in climatic conditions that lead to the development of natural fermentation and enzymatic phenomena that result in the gradual humidity reduction and biochemical changes that give to the products their typical organoleptic characteristics and ensure their preservation under environmental conditions [3]. The preparation techniques of salami involve several phases following slaughter: preparation and cooling of raw materials, preparation of the mixture, stuffing, tying, and ripening. After stuffing, the salami is subjected to a ripening phase; ripening plays an important role in preserving the quality of these meat products by improving their appearance and integrity due to the quality of the meat and microbial enzyme activity [4]. This step is one of the most important stages in salami production that clearly influences the characteristics of the final dry fermented pork products [5]. Some of the main quality parameters of the products such as weight loss, structural characteristics, and sensory properties are the result of chemical and microbiological transformations that occur during this phase [6]. As evidence of the centrality of this phase in the evolution of the qualitative characteristics of sausages, there are numerous bibliographic studies that link the ripening conditions to the evolution of product quality characteristics.

Aging consists of three different phases, which succeed each other over a period ranging from 15 to 90 days and beyond, distinguished by the temperature and relative humidity conditions of the environment and duration: warming, drying, and proper aging. Strictly speaking, the aging phase is the longest, varying from 4 to 10 weeks depending on the type of product, during which the biochemical reactions underlying maturation occur [7]. During the actual aging phase, the temperature is maintained around 10–14 °C and relative humidity at 65–75% [8]. On the outer surface of the skin, the maximum development of molds, besides regulating the water exchange between the superficial and internal parts of the product, partially causes deacidification with a rise in pH [9]. Several experimental tests reported in the literature have highlighted how inadequate aging conditions can jeopardize the final properties of aged sausages [10]. In particular, the effect of the ripening temperature and its influence on the pH evolution and consequently on water activity, microbial growth, and the consistency of the fermented sausages have been investigated multiple times [7]. Particularly interesting was the work conducted by Soyer et al. [11], who found that employing higher thermal ranges during aging resulted in better outcomes in terms of greater pH decrease, water activity, color improvement, and better lactic fermentation development. Another important parameter during aging is the airflow rate, studied during a project called DRIP (Dry Sausages Ripening Improved Project) funded by the European Union, whose experimental data seemed to indicate that alternating cycles of ventilation with high air speeds with cycles in which the product was left to rest led to better mold growth compared to what would be obtained with continuous air circulation. To ensure homogeneous conditions throughout the maturation process, a satisfactory technical solution to the problem can be provided by the increasing and ascending airflow in the maturation cells to maximize the uniformity and weight loss of the products. The aim of this study was to monitor and evaluate the performance of two air distribution systems installed in two conditioning cells for semi-industrial salami production, equipped with a system to control the microclimatic parameters.

2. Materials and Methods

2.1. Experimental Setup

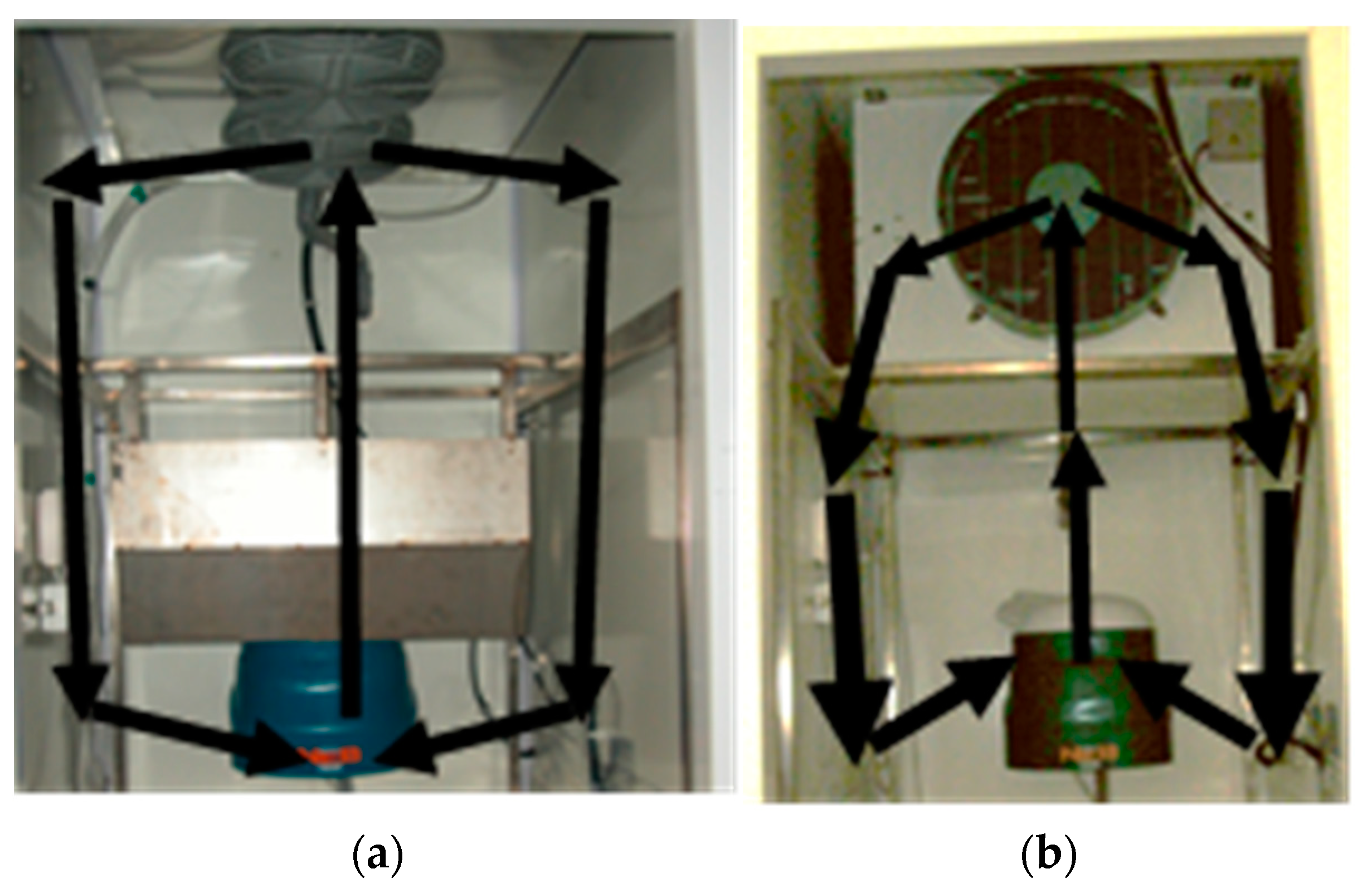

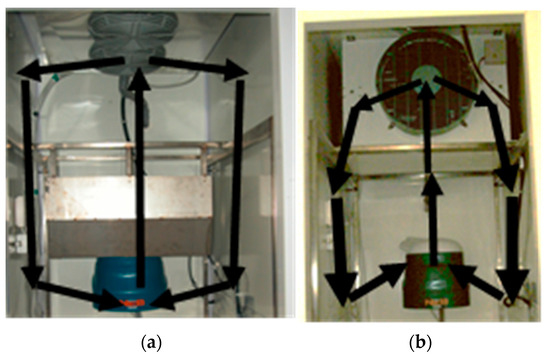

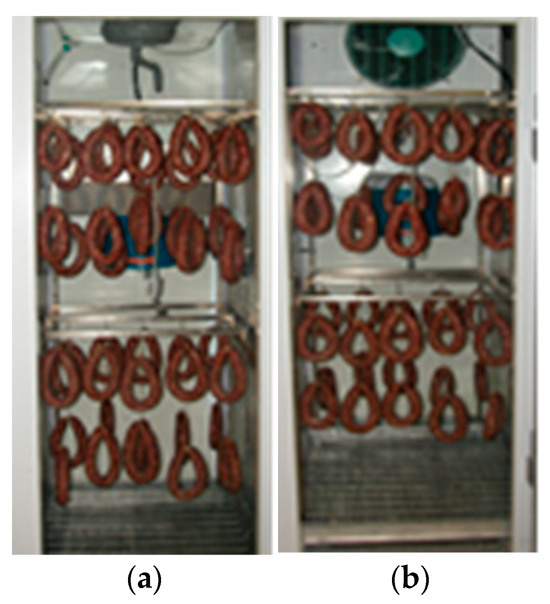

The setup was located in the Laboratory of Machinery and Plants for the Food Industries of the Department of DiSSPA at the University of Bari Aldo Moro and served two conditioning cells suitable for carrying out the necessary phases for salami production. The two cells were equipped with a system for controlling temperature, relative humidity, and CO2, and each of them had a different air cooling and circulation system: a dual-evaporator cell (DEV) (Figure 1a) that generates, along the two lateral walls, vertical air motion (air velocity below 1 m/s) from top to bottom and vice versa (bottom–up) in the center of the celland a traditional evaporator (Figure 1b) with transverse flow (TFL) and adjustable air velocity starting from 1 m/s.

Figure 1.

Details of the evaporators and air flows in the storage modules, as well as the electric resistors inserted in each module. (a) Dual-evaporator cell (DEV): from top to bottom air flows laterally. (b) Transverse flow (TFL) cell: from top to bottom air flows transversely.

Inside the cells, the temperature (0–50 °C), relative humidity (0–95 ± 5% R.H.), and carbon dioxide levels in the air (0–2000 ± 100 ppm) were measured. The latter varies due to the metabolic activity of bacteria and molds present on the food products. For the acquisition and digitization of analog signals from the sensors, two NI PCI-6024E (National Instruments, Austin, TX, USA) cards were used for their analog–digital features, along with an NI cDAQ-9172 (National Instruments, Austin, TX, USA) chassis equipped with modules for conditioning analog signals in current and voltage. The hardware was complemented by a DAC module for digital-to-analog conversion and some modules acting as low-side switches for controlling power loads. The graphical user interface of the software, specifically designed for this setup, allowed the following:

- Setting the desired temperature and humidity values within the refrigerated environment.

- Deactivation of unused compartments and monitoring of evaporator fans, where applicable.

- Data acquisition to assess conditions at rest and at the subsequent start-up of the system.

- Detection of any overpressure situations in the high- and low-pressure heat exchangers.

Additionally, an emergency stop button was provided for critical situations. During normal machine operation, the software allowed for saving all values from the sensors, those related to control variables, and parameters displayed on the interface for subsequent post-processing.

Furthermore, considering that the temperature in the experimental tests on salami would not be lower than 9 °C, electric resistance heaters were installed in each module, specifically chosen for their ease of operation, regulated by the management program of each cell. This was to make the temperature and relative humidity control system more flexible.

2.2. Production of Ripened Sausages

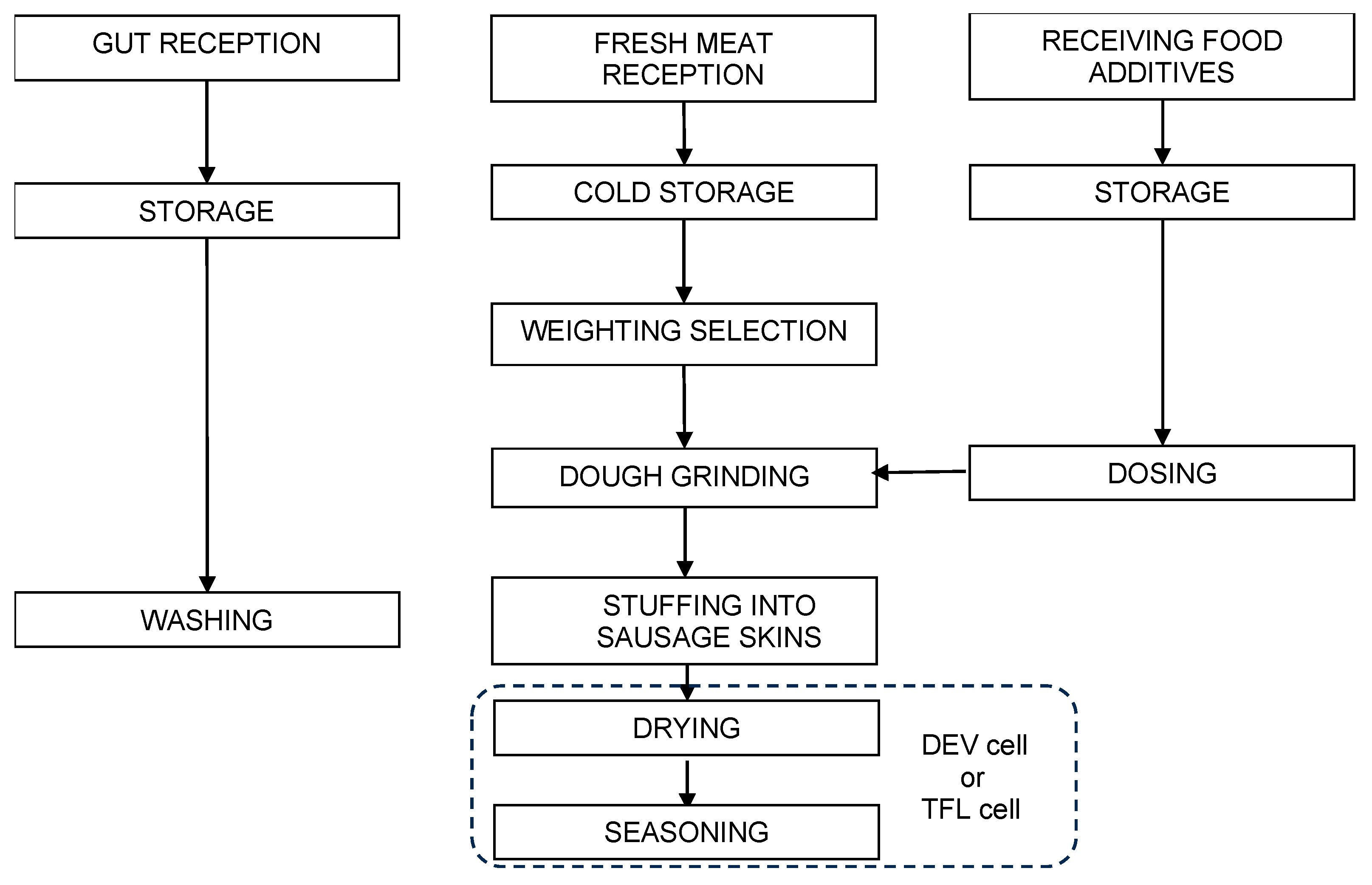

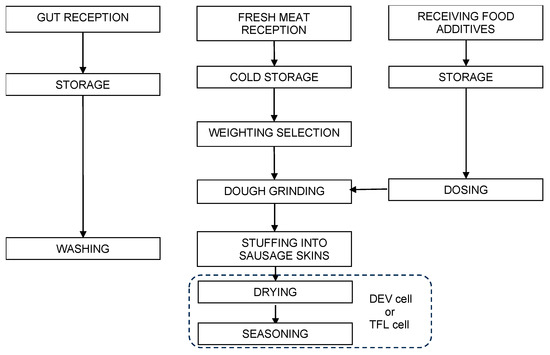

The samples of ripened sausages were produced at the “Salumi Martina Franca” facility (Martina Franca, Italy) following the typical production technology for aged sausages as depicted in Figure 2.

Figure 2.

Diagram of the process for producing the aged sausages under study.

In particular, the preparation involved mixing lean minced pork meat (81%), minced lard (15%), salt (2%), spices (2%), potassium nitrate, nitrite, and thickener. The resulting mixture had a moisture content of 60.47%, a fat content of 17.91%, and a protein content of 17.02%.

The mixing phase was carried out manually until achieving a homogeneous mass. After mixing, the mixture was stuffed into natural casings, and 70 samples were taken to the laboratory test facility for the subsequent phases.

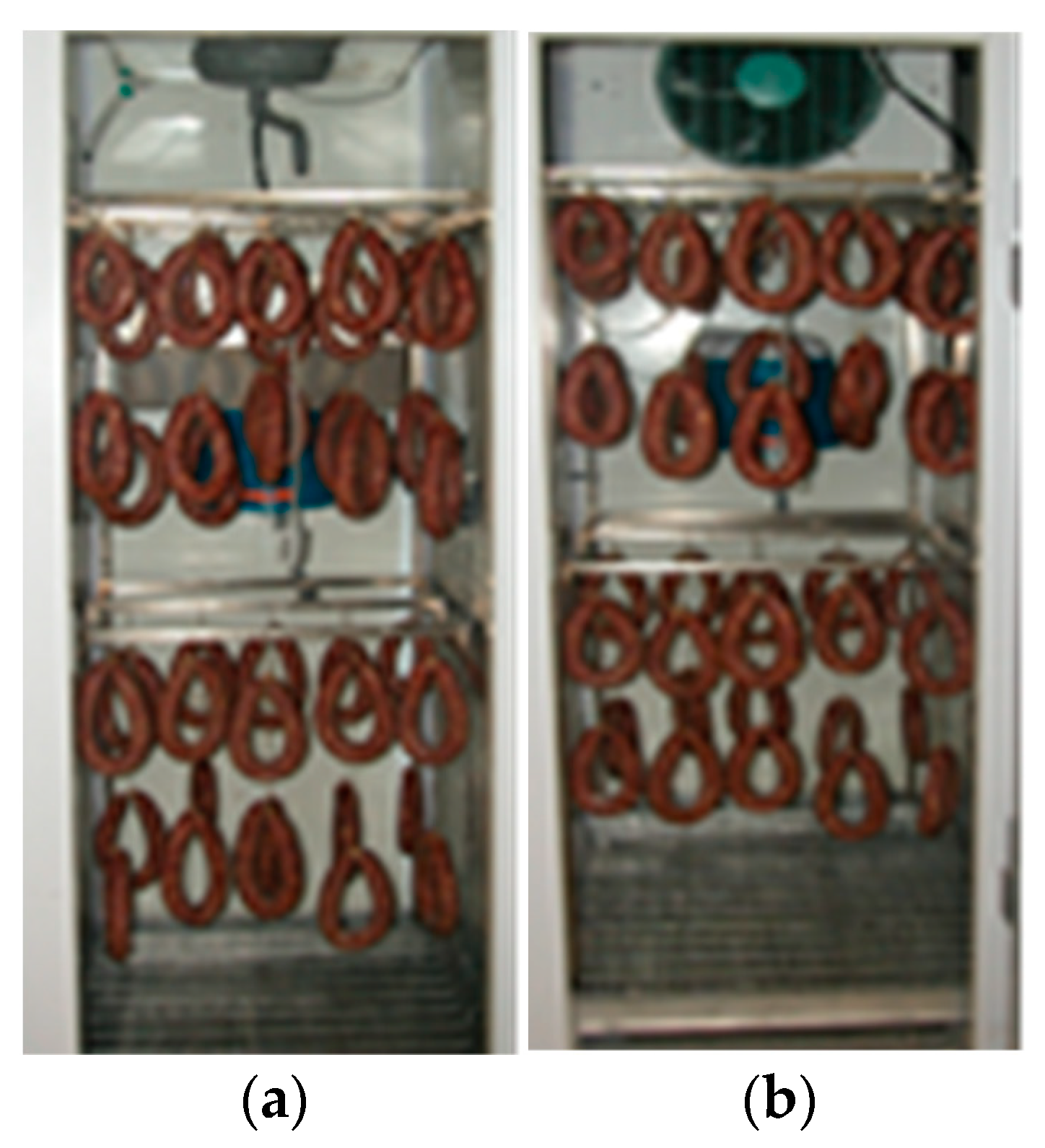

At this step, the sausages were divided into two different groups for the two different types of aging cells used. All the samples were individually weighed immediately before their introduction into the cells (time 0): 24 sausages were placed in the DEV cell, and 24 sausages were placed in the TFL cell, as shown in Figure 3. Each cell was divided into 4 zones: front top (FT), rear top (RT), front bottom (FB), rear bottom (RB). The remaining samples were analyzed in the laboratory.

Figure 3.

Arrangement of sausages in the two cells. (a) DEV cell; (b) TFL cell.

2.3. Evaluation of Weight Loss

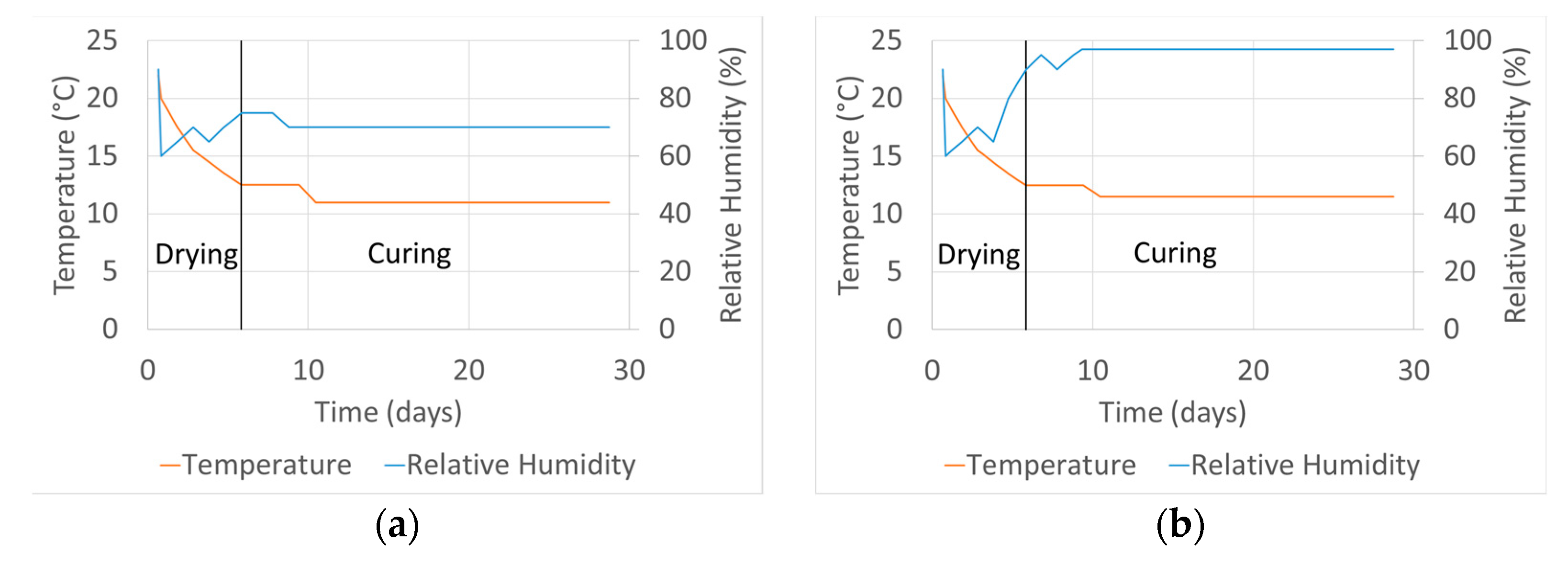

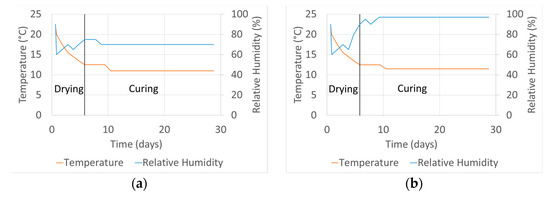

The evolution of the weight loss (%) was studied during the ripening period: the temperature and relative humidity were recorded for each cell and are shown in Figure 4.

Figure 4.

Temperature and humidity during the whole period in the two cells. (a) DEV cell; (b) TFL cell.

In Figure 4, it is evident that the values of temperature and relative humidity varied in each chamber adjusting the preservation microclimate to the conditioning phase (drying and curing) and to the state of the product, which, as expected, evolved differently in the two modules used. Specifically, these parameters were set according to the size of the products but were adjusted based on their pH. This was continuously monitored on salami samples located in different positions within the four zones of each chamber. In fact, the excessive reduction in pH can also be influenced by the air flow within the chamber and its penetration into the products [7]. Therefore, especially during the dripping and drying phases of the salami (drying phase in Figure 4), the chamber management program was designed to automatically compensate for excessive pH drops by increasing the relative humidity and gradually reducing the temperature to as low as 10 °C. The management program also set the downtime and the periods in which the chamber must ensure the maintenance of the temperature–humidity conditions.

Sampling and weighting the samples after 3, 10, 13, 15, 20, 22, 24, and 28 days of ripening, the weight loss was calculated as percentages of differences in weight of the whole sausages between day 0 and after each sampling time following the formula:

where W1 = weight (g) of the sample at the eight sampling times; W0 = weight (g) at the production.

2.4. Analytical Determinations

The pH determination was performed directly on the sample using a Basic 20 pH meter, equipped with a Codito 50 10T penetration conductometer from Crison (Barcelona, Spain) and a temperature compensator. The moisture, water activity, and ash content determinations were carried out according to AOAC methods [12], and the total protein content was calculated by multiplying the total nitrogen content, determined by the Kjeldahl method, by the factor 6.25. The fat content determination was performed on the dehydrated product using the Soxhlet procedure with ethyl ether as the extraction solvent. As regards the typical values of water activity for aged salami, it is generally below 0.90 [13].

2.5. Texture Profile Analysis (TPA)

The texture profile analysis (TPA) was conducted using a Texture Analyzer (Z1.0 TN, Zwick GmbH & Co. KG, Ulm, Germany) equipped with a 1 kN load cell.

The analysis was performed on 6 different ripened sausages from each cell. Approximately 7 slices with a thickness of about 1 cm were taken from each sausage and subjected to two compression cycles to 50% of their original height using a square compression probe (side 3.5 cm).

The procedure of the determination was the same as those reported in Difonzo et al. [14].

2.6. Statistical Analysis

The obtained data underwent ANOVA statistical analysis using Excel (https://www.microsoft.com/en-in/microsoft-365/excel (accessed on 24 August 2024), Microsoft, Redmond, WA, USA) statistic software functions. The different airflow within the cells and the vertical (top vs. bottom) and horizontal (front vs. rear) positioning of the sausages were considered independent variables. Means and standard deviations were calculated on 6 repetitions.

3. Results and Discussion

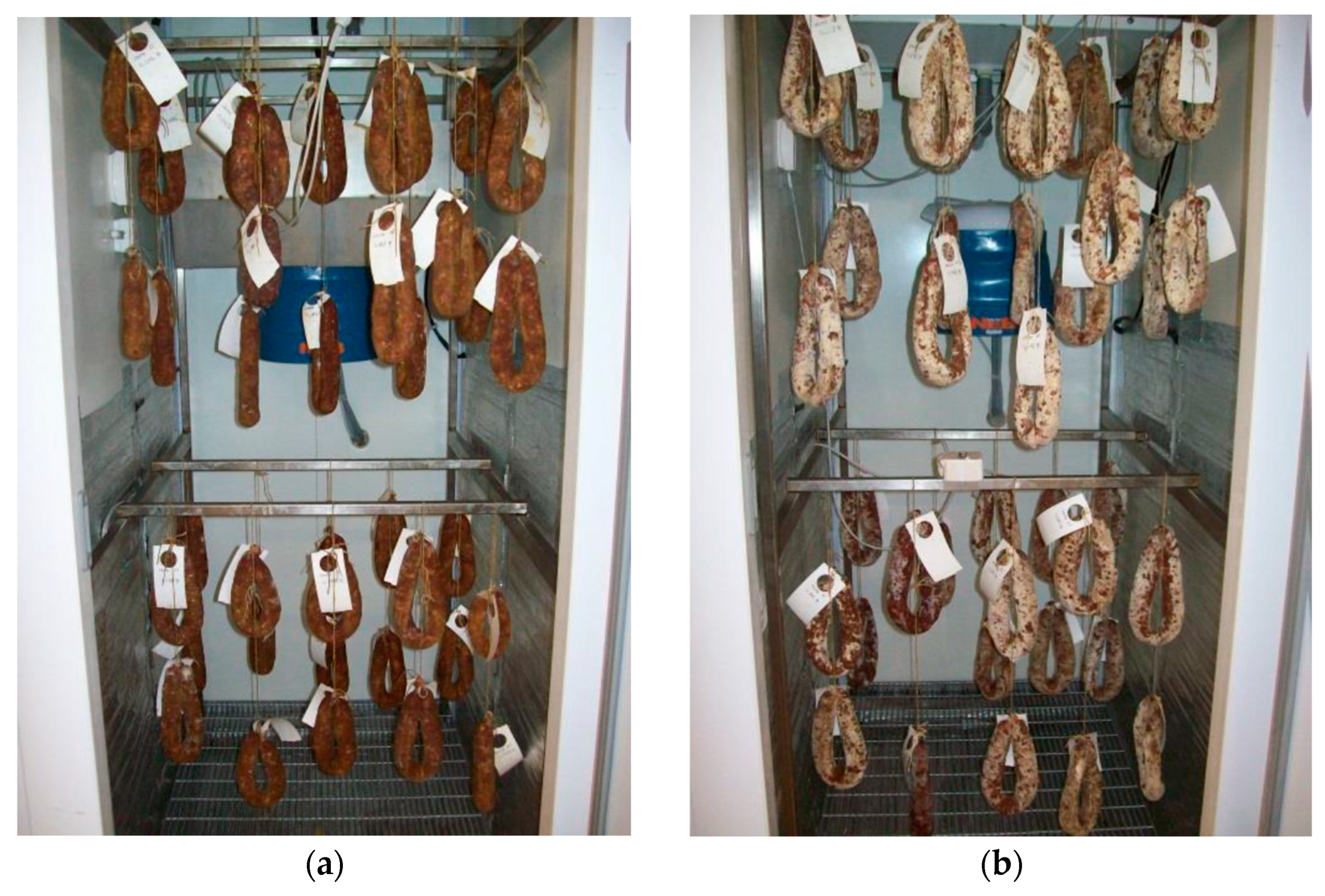

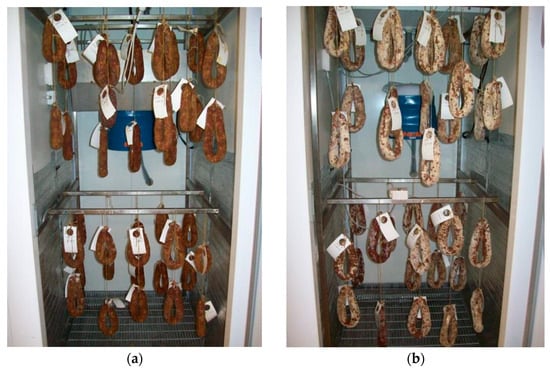

In Figure 5a,b, ripened sausages inside the study cells are shown at the end of the ripening period.

Figure 5.

Aged sausages at the end of the aging period: (a) DEV cell; (b) TFL cell.

The influence of the different ventilation systems on the external appearance of the sausages is evident. Particularly, the sausages from the TFL cell, characterized by transverse airflow starting from the top of the cell, appeared to be covered with a surface patina ranging in color from white to gray, indicative of characteristic fungal development not present, or present to a lesser extent, in the DEV cell, characterized by bidirectional airflow that develops a vertical motion of the air from top to bottom and vice versa. Specifically, in the TFL cell, the sausages placed in the lower part appeared to be less affected by mold development compared to those positioned in the upper part, highlighting the influence of sausage positioning within the cell. Based on this observation, the study of the chemical and textural characteristics of the sausages was conducted not only based on the aging cell but also based on vertical (top vs. bottom) and horizontal (front vs. rear) positioning.

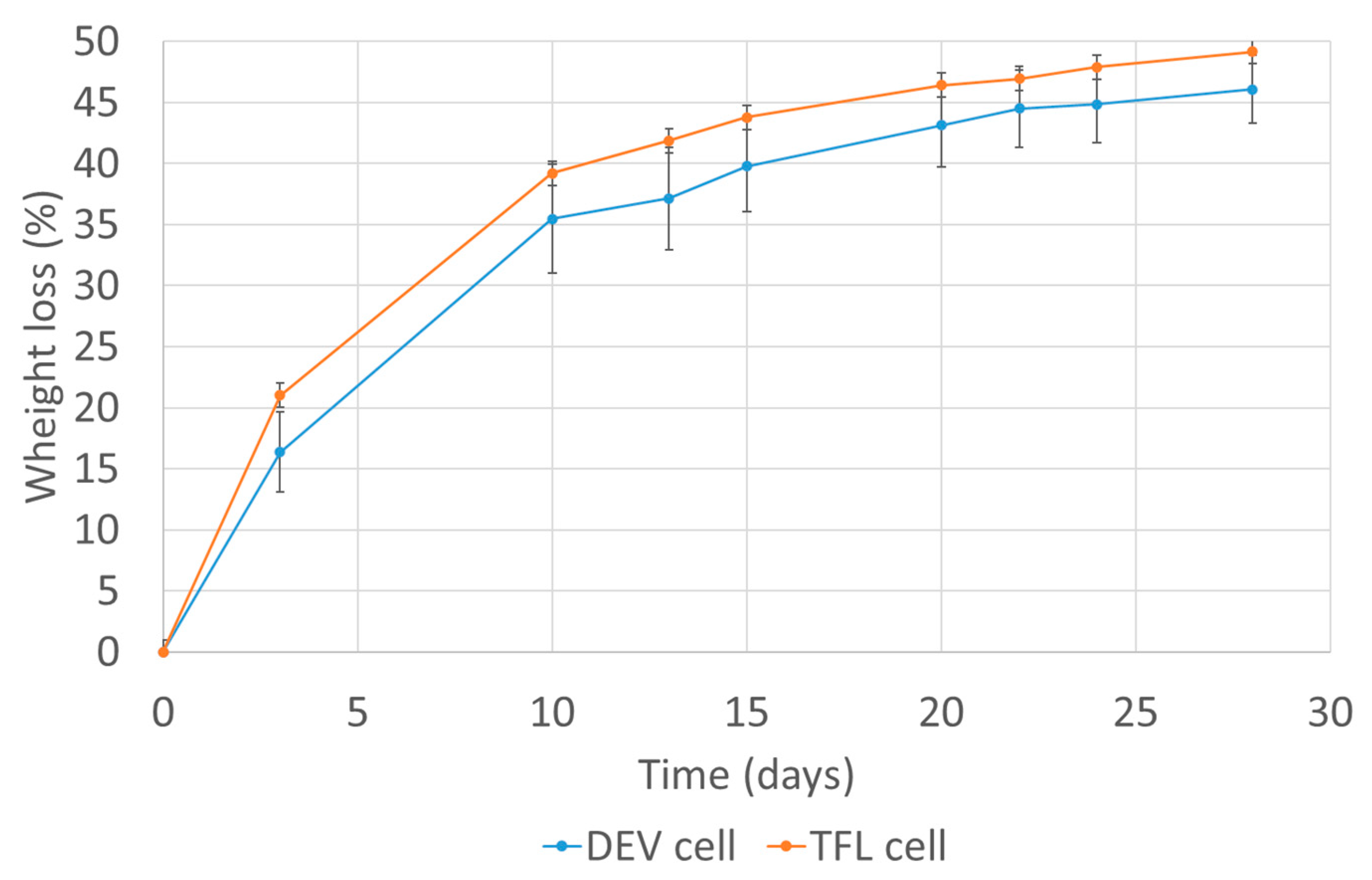

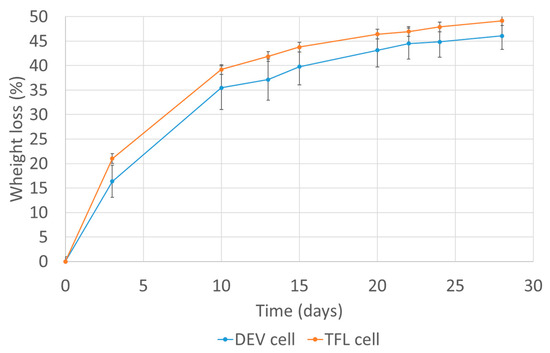

In Figure 6, the evolution of sausage weight loss during aging in the investigated cells is shown along with the results of the statistical analysis: all the averages showed significant differences (p < 0.05) between the two cells except at 10 days. A gradual dehydration of the products was observed, especially in the first 10 days of ripening. Subsequently, the process became less drastic, with less pronounced weight loss in the intermediate and final stages of the process. The different airflow significantly influenced the weight loss of the sausages. In the TFL cell, characterized by transverse airflow, the dehydration process was faster, with weight loss values already significantly higher at the first sampling time.

Figure 6.

Evolution of weight loss (%) of sausages during aging.

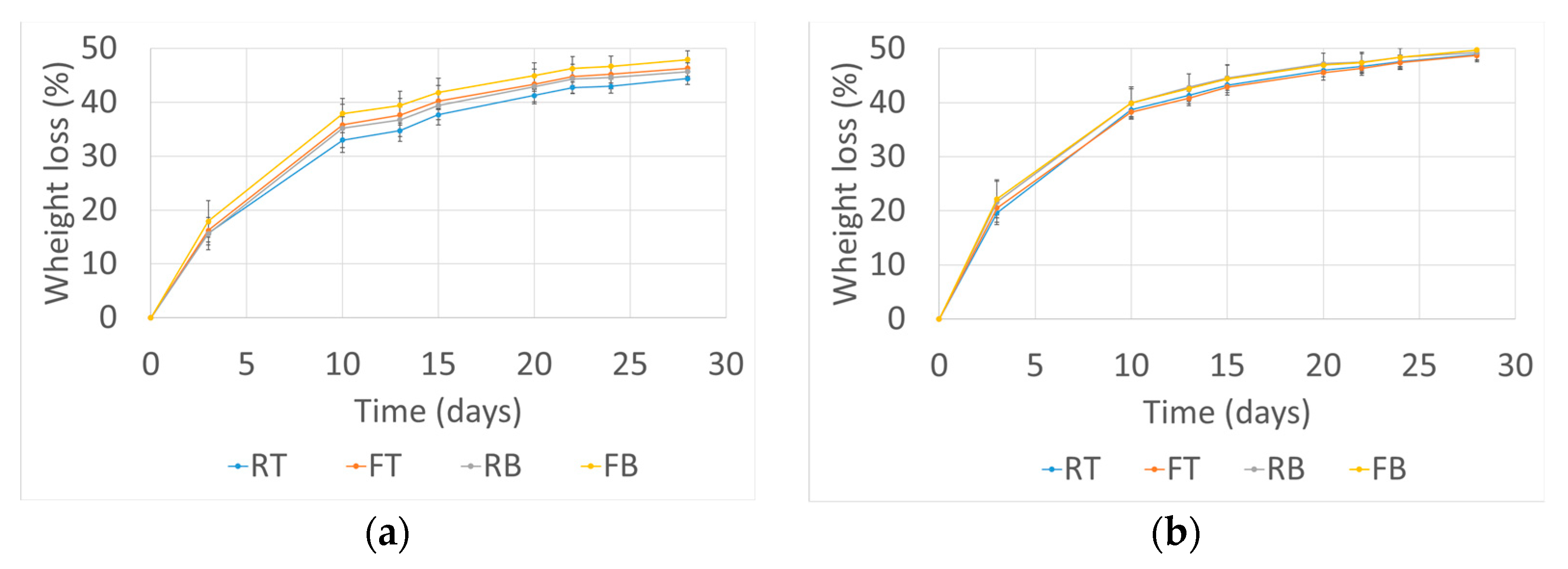

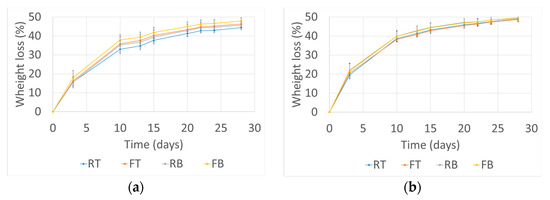

Table 1 presents the values of weight loss for the sausages recorded at different storage times, considering their positioning. From the data analysis, a different influence of the positioning of the sausages in the two investigated cells can be observed. Specifically, in the DEV cell, characterized by the bidirectional airflow system, a significant difference in weight loss was observed in different zones, except for the FT positioning, which showed a significantly similar trend to the RB positioning. This aspect is confirmed by the curves in Figure 7a,b. The positioning of the sausages significantly influenced the weight loss. In particular (Table 1), in the DEV cell (Figure 7a), heterogeneity was observed among the four positions, while in the TFL cell (Figure 7b), this heterogeneity was found between the upper and lower parts and was less significant.

Table 1.

Percentage values of weight loss of ripened sausages during the aging process in the two cells: identical letters “a, b, c, d, e” indicate non-significant differences (p < 0.05) *.

Figure 7.

Trend of weight loss in the two cells in relation to different positionings within them: (a) DEV cell; (b) TFL cell. FT: front top; RT: rear top; FB: front bottom; RB: rear bottom.

Indeed, from the first sampling, sausages placed in the front part exhibited a significantly higher weight loss compared to those positioned in the rear part, indicating a higher yield at the end of the aging phase. The vertical positioning studied in the DEV cell showed higher weight loss values in sausages placed in the lower part, with significant differences compared to the upper positioning at 10, 13, and 15 days. This difference was observed when grouping samples RT and FT on one side and samples RB and FB on the other and was consistent with the subsequent texture profile analysis (TPA) results, while the significant difference between front (FT and FB) and rear (RT and RB) did not correspond to the TPA data.

The evolution of weight loss during aging, influenced by both the aeration system and, in the cell with innovative airflow, the positioning of the sausages, represents an important parameter for the economic efficiency of the process (lower levels of weight loss correspond to higher yields during aging) and indicates a different dehydration process evolution during aging.

Regarding the TFL cell, in which the traditional type of aeration system was horizontally oriented, the anterior/posterior positioning of the sausages did not result in significant variations in weight loss, while the lower/upper positioning was significantly influential only in the early stages of aging. Therefore, at the end of the period (28 days), no significant differences related to the different positioning of the sausages were observed in this cell. This is also confirmed by the curves shown in Figure 8, which converge toward the end of the process (24 days and 28 days).

Figure 8.

Detail of the void spaces present inside some sausages in the TFL cell.

Table 2 shows the mean values and the results of the analysis concerning water activity, moisture, and pH determined on the samples of aged sausages in the two cells under investigation. The products aged in the TFL cell exhibited significantly lower water activity values (p < 0.01) compared to those aged in the DEV cell and lower than what is typically reported in the literature for this type of product. This finding is undoubtedly related to the different evolution of the dehydration process of the aged sausages within the two different cells under investigation, as evidenced by the different weight loss as well as the different percentages of humidity observed in the sausages at the end of the aging period.

Table 2.

Average values of water activity, moisture, and pH at the end of the process: all values are significantly (p < 0.01) influenced by the two cells.

The more uniform and homogeneous ventilation in the DEV chamber is also highlighted by the different trend in RH (relative humidity) between the chambers (Figure 4). In fact, especially during the drying phase, the management system in the DEV chamber responded with less abrupt and intense increases in RH compared to the TFL chamber. This is clear evidence that, in the products from the DEV chamber, the pH reduction was compatible with the level of dehydration. On the contrary, the pH in the TFL cell, also due to inadequate ventilation, suffered too high reductions forcing the intervention of the management system with a faster and more relevant RH increase throughout the cell (Figure 4b), resulting in a lower weight drop compared to the DEV cell as highlighted in Figure 6.

The structural characteristics (texture) of the sausages were evaluated using the texture profile analysis (TPA) procedure, a chewiness test that, through double compression of a standard thickness slice of the sausage, allows the expression of structural parameters such as hardness, chewiness, elasticity, cohesiveness, and gumminess. For approximately 50% of the sausages from the TFL cell, it was not possible to perform the test because the slice fractured after the first compression. The remaining data are, therefore, not reported as they were insufficient for statistical analysis.

As shown in Figure 8, void spaces were evident within the slice, probably due to non-uniform dehydration of the sausages. For the samples for which the test could be performed, a high standard deviation was observed, preventing effective statistical analysis. In relation to these latter data, the TFL cell, characterized by transverse airflow, produced sausages that were structurally unsuitable for commercialization. The experimental conditions applied (airflow rate, temperature, and humidity) were too harsh when applied to the transverse aeration system. In the DEV cell, characterized by a bi-flow aeration system, all the sausages successfully underwent TPA, and in no case were void spaces observed that compromised the execution of the test, thus allowing the examination of the evolution of structural characteristics based on sausage position.

Table 3 presents the results of the TPA conducted on the samples of sausages from the DEV cell according to their positioning. Specifically, the groups FT and RT were grouped and compared with the grouping FB-RB (top vs. bottom); the same comparison was made for the groupings FT-FB and RT-RB (front vs. rear) to highlight the differences between the different macro-zones of the cell. The texture parameters for which positioning showed a significant influence are displayed. From the analysis of the data in the table, the influence of vertical positioning on the texture of the aged sausages is evident. Sausages placed in the lower part of the cell exhibited greater hardness, gumminess, and chewiness compared to those positioned in the upper part. Conversely, horizontal positioning did not show a significant influence on the texture of the sausages under investigation.

Table 3.

Results of the TPA conducted on the samples of sausages from the DEV cell according to their positioning: equal letters “a, b, c, d, e, f, g, h, i” indicate non-significant differences (p < 0.05) *.

4. Conclusions

This study underscores the significant impact that different ventilation systems have on the maturation process and final quality of salami products. The distinct airflow patterns in the two aging cells: transverse flow (TFL) and dual-evaporator (DEV) produced notably different outcomes in terms of product appearance, weight loss, and chemical–physical properties. The TFL cell, characterized by a transverse airflow, demonstrated a more aggressive dehydration process leading to lower water activity, moisture, and pH values in the salamis compared to those aged in the DEV cell.

From a visual perspective, the sausages in the TFL cell developed a characteristic fungal surface patina, particularly pronounced in the upper zones, indicating a more robust mold growth facilitated by the airflow pattern. This contrasted with the more uniform but less intense mold development observed in the DEV cell in which the bidirectional airflow created more consistent conditions throughout the maturation process.

The weight loss data further highlight the influence of airflow direction and velocity on the drying efficiency. The TFL system led to faster and more uniform dehydration particularly in the upper sections of the cell, which could be advantageous in achieving certain desired textural properties. However, the harsher conditions in the TFL cell also resulted in structural issues such as void spaces within the sausages, which compromised their suitability for commercial sale. This finding suggests that, while the TFL system might accelerate the drying process, it may also require careful modulation of temperature and humidity to prevent product defects. Conversely, the DEV cell with its vertical airflow, allowed for a more controlled and less aggressive dehydration process. This led to more uniform textural properties and the successful completion of texture profile analysis (TPA) on all the samples. The lower incidence of structural defects in the DEV cell sausages suggests that this system may be more reliable for producing high-quality salamis, especially when consistent texture and structural integrity are critical.

Overall, the findings of this study indicate that, while the TFL cell may offer advantages in terms of drying efficiency, the DEV cell provides a more balanced environment for the maturation of salamis, potentially leading to better overall product quality. Future research could explore the optimization of airflow rates and environmental conditions within each system to further enhance the quality of dry-cured meat products. Additionally, a broader investigation into the energetic implications of each system could provide valuable insights for producers seeking to balance quality with cost efficiency.

Author Contributions

Conceptualization, F.G. and B.B.; methodology, F.G. and B.B.; software, F.C.; validation, F.G. and F.C.; formal analysis, F.G., F.C. and B.B.; investigation, F.C.; Data curation, F.G., G.L.F. and B.B.; Writing–original draft, F.C. and B.B.; Writing–review & editing, F.G.; Visualization, G.L.F.; Supervision, F.G. and B.B.; Funding acquisition, F.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, P.; Ali, U.; Aziz, T.; Wang, L.; Zhao, J.; Nabi, G.; Sameeh, M.Y.; Yu, Y.; Zhu, Y. Investigating the effect on biogenic amines, nitrite, and N-nitrosamine degradation in cultured sausage ripening through inoculation of Staphylococcus xylosus and lactic acid bacteria. Front. Microbiol. 2023, 14, 1156413. [Google Scholar] [CrossRef] [PubMed]

- Hao, M.; Wang, W.; Zhang, J.; Chen, L. Flavour Characteristics of Fermented Meat Products in China: A Review. Fermentation 2023, 9, 830. [Google Scholar] [CrossRef]

- Zanardi, E.; Novelli, E. Chapter 12: Italian salami. In Pork: Meat Quality and Processed Meat Products; Munekata, P.E.S., Pateiro, M., Franco, D., Lorenzo, J.M., Eds.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar] [CrossRef]

- Demeyer, D.; Stahnke, L. Quality control of fermented meat products. In Meat Processing: Improving Quality; Kerry, J., Ledward, D., Eds.; Woodhead: Cambridge, UK, 2002; pp. 359–393. [Google Scholar]

- Ambrosio, R.L.; Smaldone, G.; Di Paolo, M.; Vollano, L.; Ceruso, M.; Anastasio, A.; Marrone, R. Effects of Different Levels of Inclusion of Apulo-Calabrese Pig Meat on Microbiological, Physicochemical and Rheological Parameters of Salami during Ripening. Animals 2021, 11, 3060. [Google Scholar] [CrossRef] [PubMed]

- Giametta, F.; Sorrentino, E.; Lapenna, A.; La Fianza, G. Experimental study on optimizing cheese drying and ripening process. Int. J. Agric. Biol. Eng. 2012, 5, 74–82. [Google Scholar] [CrossRef]

- Sallan, S.; Yılmaz Oral, Z.F.; Kaya, M. A Review on the Role of Lactic Acid Bacteria in the Formation and Reduction of Volatile Nitrosamines in Fermented Sausages. Foods 2023, 12, 702. [Google Scholar] [CrossRef] [PubMed]

- Grazia, L.; Coloretti, F.; Zambonelli, C. Tecnologie dei Salumi; Edagricole: Bologna, Italy, 2011. [Google Scholar]

- Molina, J.R.G.; Frías-Celayeta, J.M.; Bolton, D.J.; Botinestean, C. A Comprehensive Review of Cured Meat Products in the Irish Market: Opportunities for Reformulation and Processing. Foods 2024, 13, 746. [Google Scholar] [CrossRef] [PubMed]

- Nout, M.J.R. Fermented foods and food safety. Food-Res. Int. 1994, 27, 291–298. [Google Scholar] [CrossRef]

- Soyer, A.; Hamdi Ertaş, A.; Üzümcüoğlu, Ü. Effect of processing conditions on the quality of naturally fermented turkish sausages (sucuks). Meat Sci. 2005, 69, 135–141. [Google Scholar] [CrossRef] [PubMed]

- AOAC International. Official Methods of Analysis of AOAC International, 16th ed.; Association of Analytical Communities: Arlington, VA, USA, 1995. [Google Scholar]

- Stangierski, J.; Rezler, R.; Kawecki, K. An Analysis of Changes in the Physicochemical and Mechanical Properties during the Storage of Smoked and Mould Salamis Made in Poland. Molecules 2023, 28, 5122. [Google Scholar] [CrossRef] [PubMed]

- Difonzo, G.; Totaro, M.P.; Caponio, F.; Pasqualone, A.; Summo, C. Olive Leaf Extract (OLE) Addition as Tool to Reduce Nitrate and Nitrite in Ripened Sausages. Foods 2022, 11, 451. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).