Analysis of Impact Crushing Characteristics of Steel Fiber Reinforced Recycled Aggregate Concrete Based on Fractal Theory

Abstract

:1. Introduction

1.1. Research Background

1.2. State of the Art

1.2.1. RAC

1.2.2. Steel Fiber Reinforced Recycled Aggregate Concrete (SFRRAC)

1.2.3. Fractal Theory

1.3. Research Content

2. Materials and Method

2.1. Raw Materials

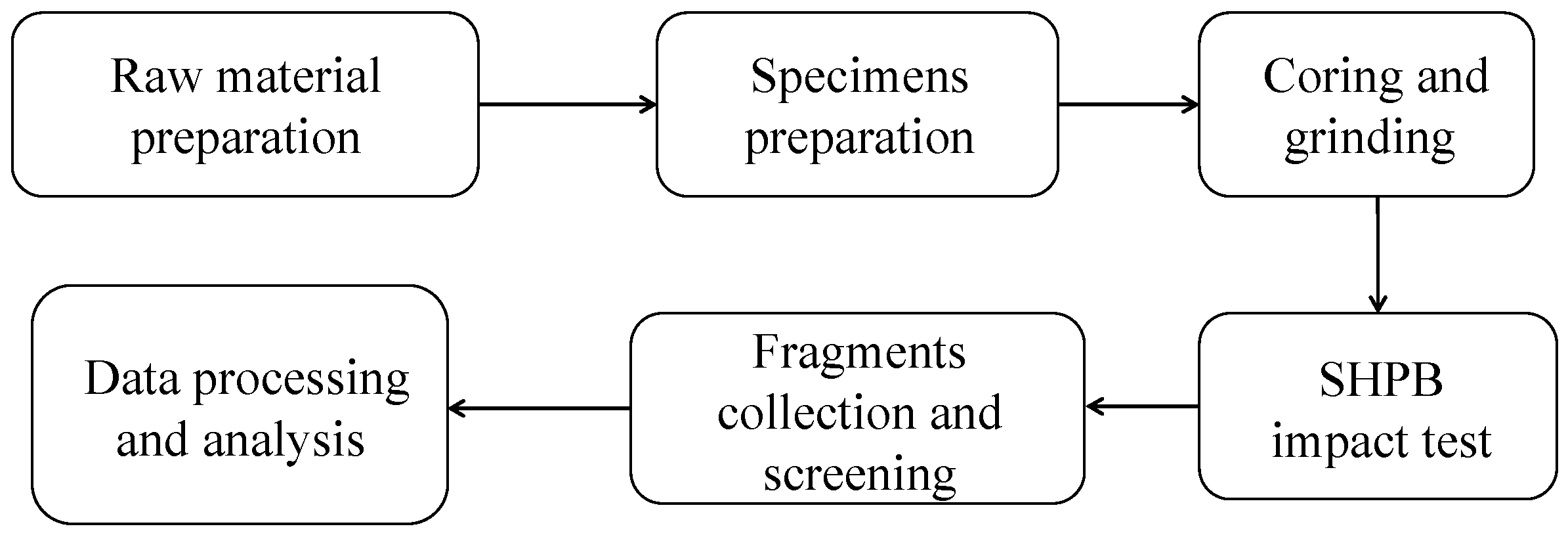

2.2. Method

2.2.1. Mix Proportion and Specimen Design

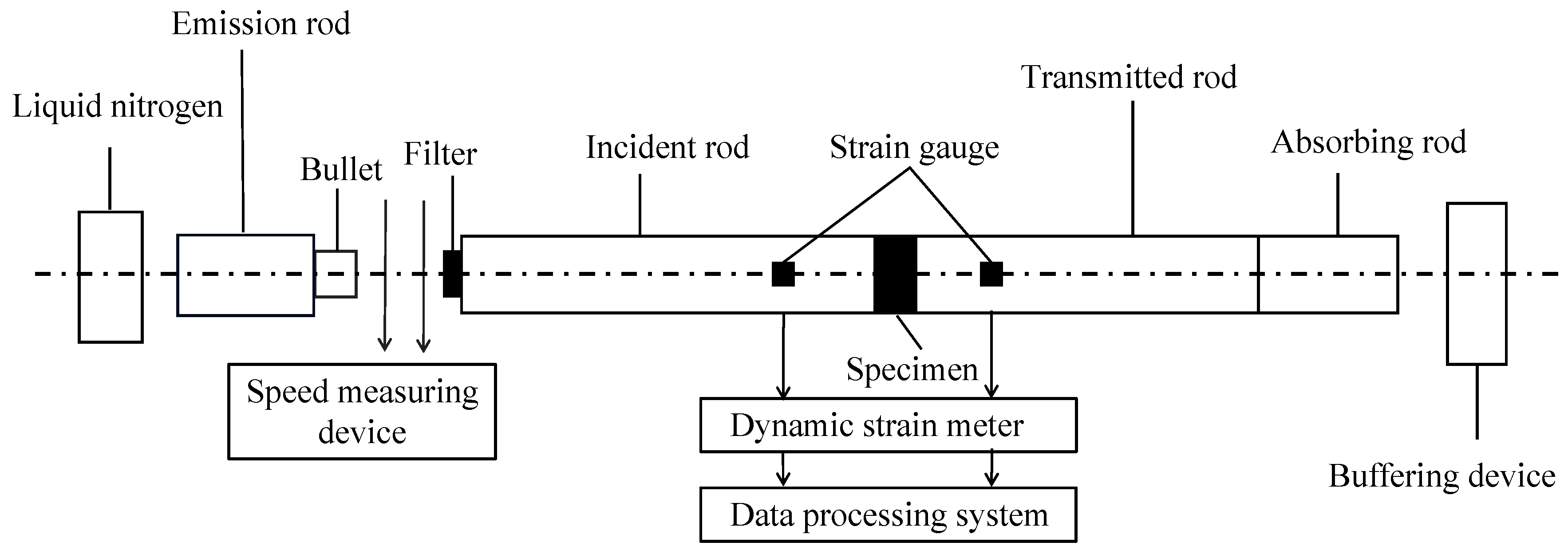

2.2.2. Test Method

3. Test Result

3.1. Distribution of Fragmentation Size

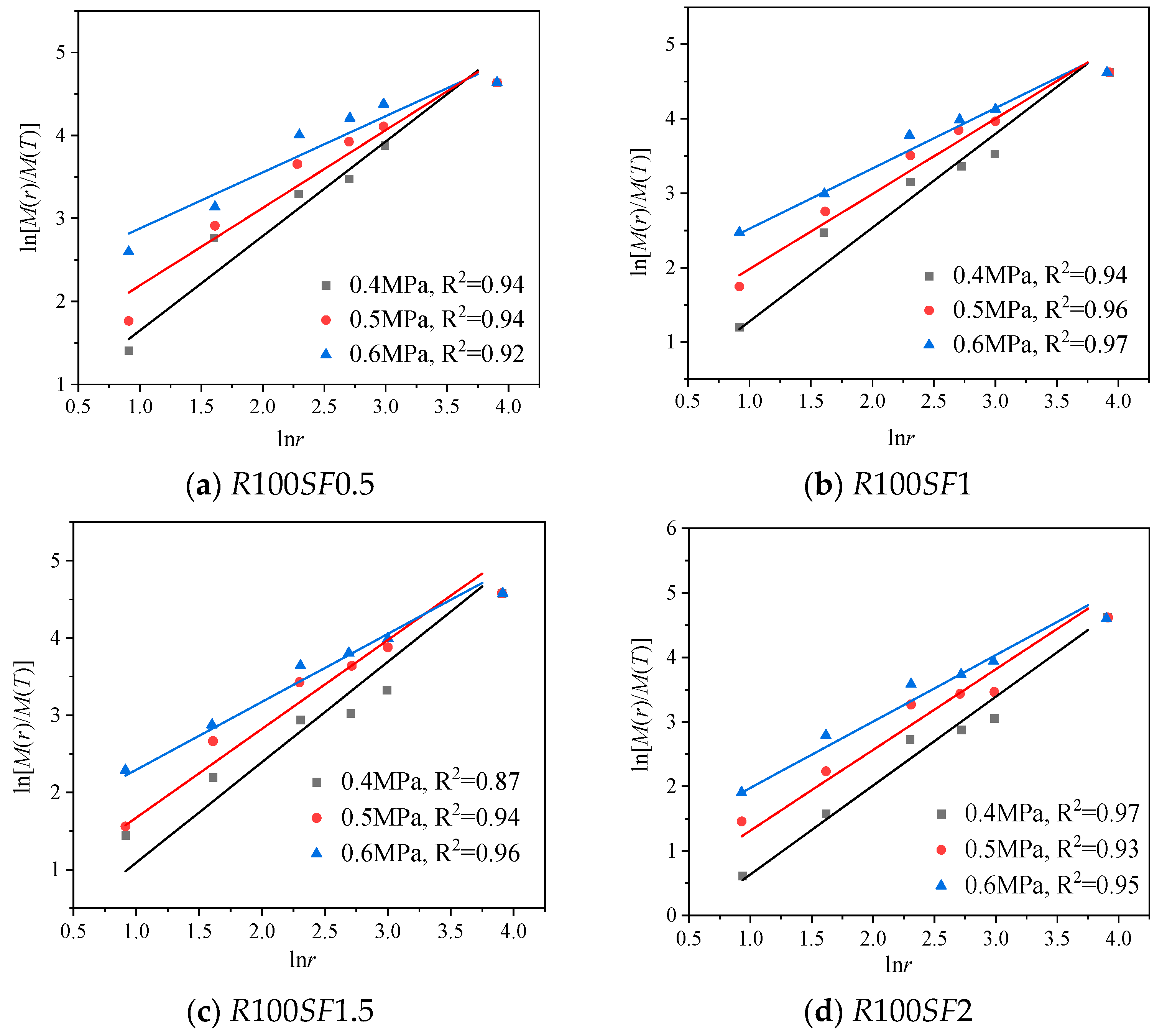

3.2. Calculation of Fractal Dimension of Fragments

4. Discussion

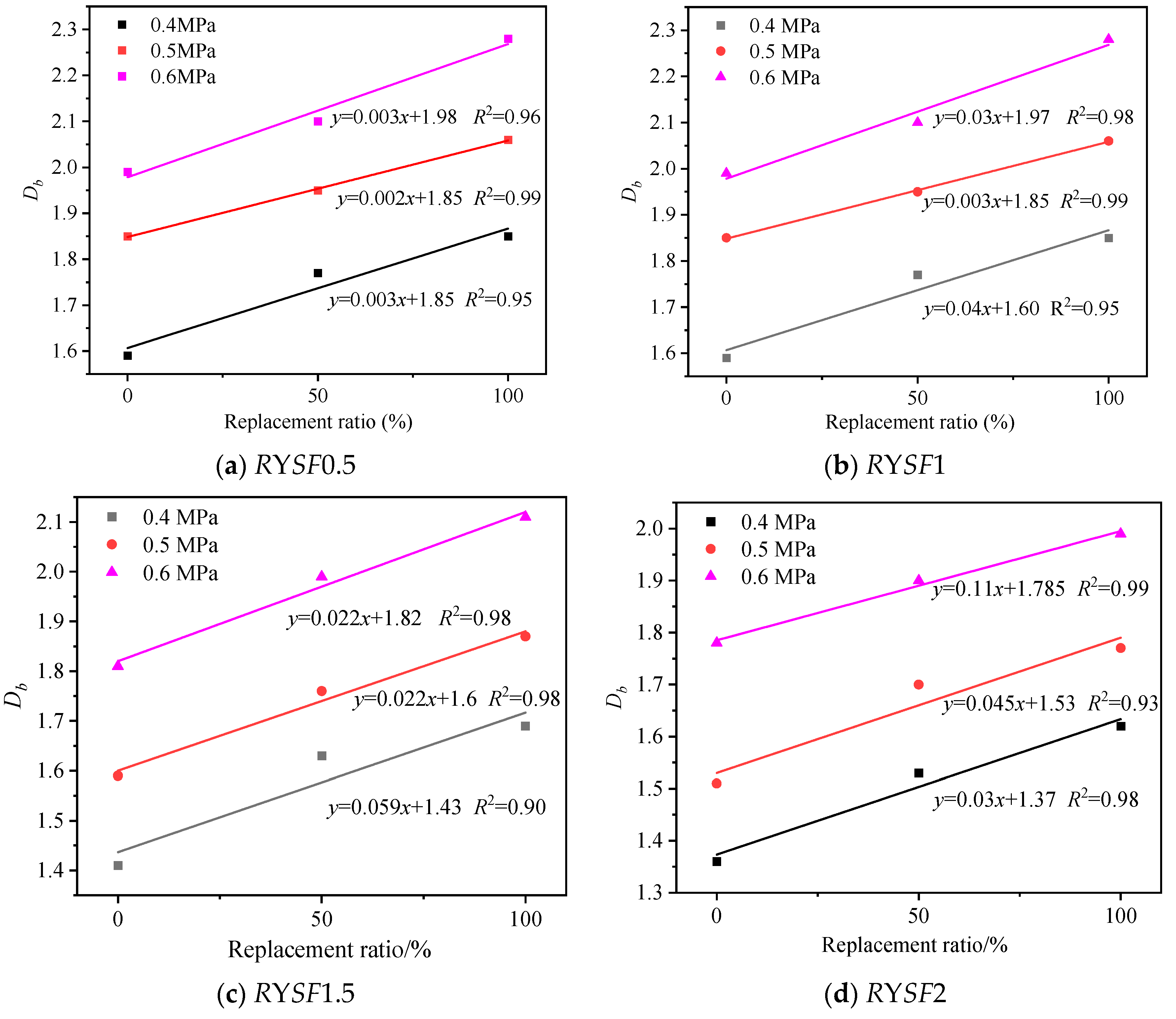

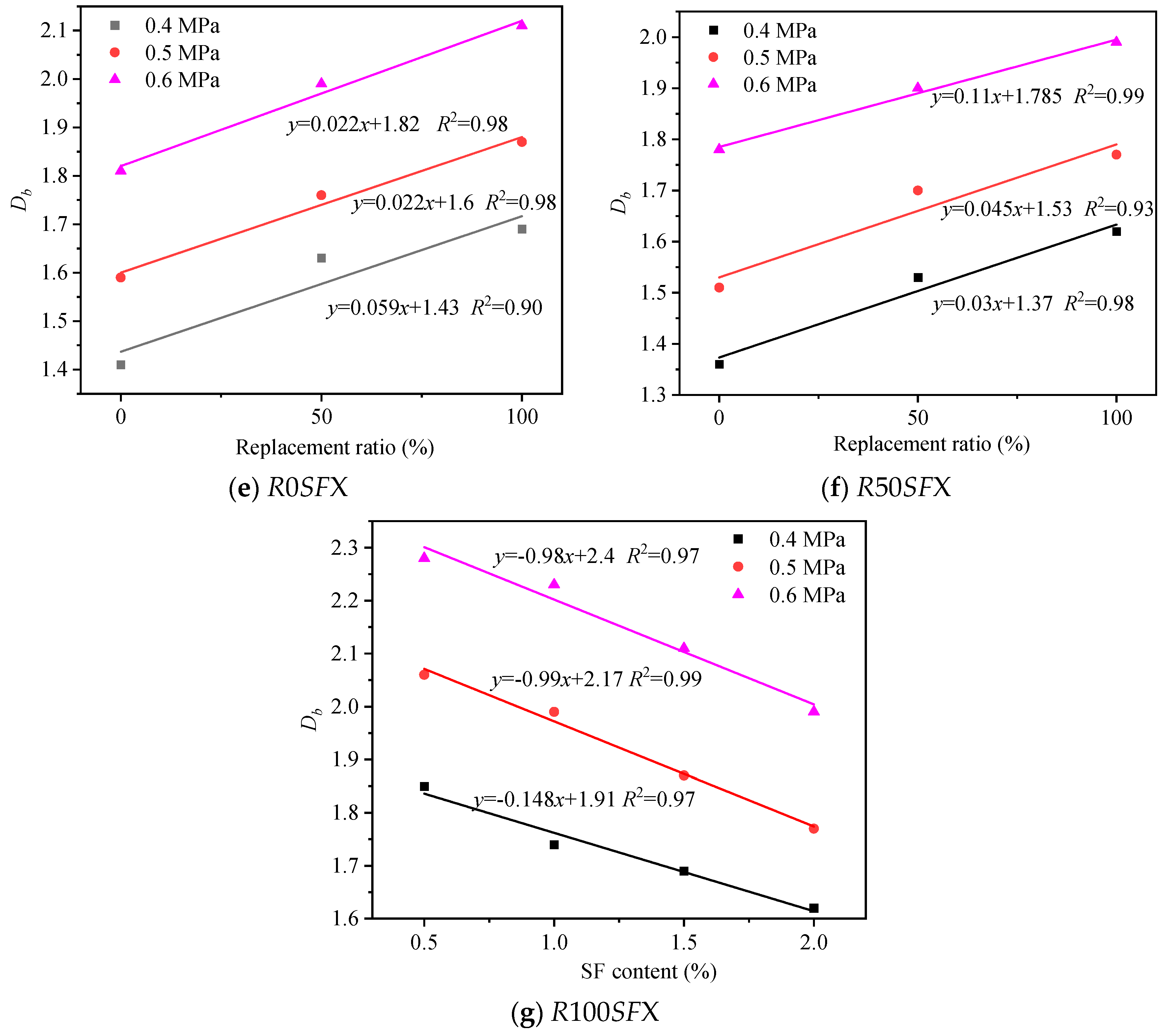

4.1. The Influence of Different Parameters on Fractal Dimension

4.2. The Relationship between Fractal Dimension and Energy Absorption for SFRRAC Specimens

5. Conclusions

- The fractal dimension can represent the degree of specimen fragmentation. The greater the fractal dimension, the higher the number of fragments of the specimens subjected to impact load, and the smaller the fragmentation size, indicating a higher degree of fragmentation;

- In the wake of the increases in impact pressure, the proportion of coarse particle size in the specimen fragments continuously decreases while the proportion of fine particle size gradually increases. As the replacement ratio grows, the degree of specimen fragmentation gradually increases, especially at the high pressure of 0.6 MPa, and the proportion of fine particle size of the fragments increases more significantly. As the SF content increases, the degree of specimen fragmentation decreases continuously under the same replacement ratio and impact pressure;

- As impact pressure rises, the fractal dimension increases between 1.36 and 2.28 for SFRRAC. Along with the replacement ratio increase, the fractal dimension increases continuously. When the SF content is 1.5%, the fractal dimension increase of up to 13.4% is the most evident. With the growth in SF content, the fractal dimension decreases;

- As impact pressure increases, the energy consumption increases. With the growth in replacement ratio, energy consumption, and fractal dimension are negatively correlated. In the wake of the increase in SF content, energy consumption is on the rise;

- In general, this study discusses the influence of different parameters on the fractal dimension and the relationship between energy consumption and the fractal dimension of SFRRAC. It provides an experimental basis for the application of SFRRAC in engineering structures under dynamic load. Currently, research on the impact-crushing characteristics of SFRRAC is relatively limited, and this study cannot be directly compared with other studies. However, this limitation also implies that the characteristics of impact fragmentation can be studied more deeply in the future. At the same time, different types of hybrid fibers can be introduced to explore the effects on the impact-crushing characteristics of RAC. This will help promote the wide application of RAC in construction engineering.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Niu, J.; Xu, P.; Deng, D.; Fan, Y. Investigation on eccentric compression performance of basalt fiber-reinforced recycled aggregate concrete-filled square steel tubular columns. Dev. Built Environ. 2024, 18, 100411. [Google Scholar] [CrossRef]

- Su, T.; Wang, C.; Cao, F.; Zou, Z.; Wang, C.; Wang, J.; Yi, H. An overview of bond behavior of recycled coarse aggregate concrete with steel bar. Rev. Adv. Mater. Sci. 2021, 60, 127–144. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Bai, W.; Wang, X.; Yuan, C.; Guan, J.; Cao, K.; Xie, C. Study on mechanical properties and meso-damage mechanism of carbon-polyvinyl alcohol hybrid fiber reinforced recycled coarse aggregate concrete under the coupling action of sodium sulfate and dry-wet cycles. Eng. Fract. Mech. 2024, 307, 110303. [Google Scholar] [CrossRef]

- Bai, W.; Suo, G.; Yuan, C.; Guan, J.; Xie, C.; Li, L. Study on multi-scale dynamic mechanical properties of metakaolin modified recycled aggregate concrete under coupling conditions of sulfate attack and dry-wet cycles. J. Build. Eng. 2024, 94, 109921. [Google Scholar] [CrossRef]

- Sorelli, L.; Meda, A.; Plizzari, G. Bending and uniaxial tensile tests on concrete reinforced with hybrid steel fibers. J. Mater. Civ. Eng. 2005, 17, 519–527. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Mari, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Zhang, W.; Ingham, J.M. Using recycled concrete aggregates in new zealand ready-mix Concrete production. J. Mater. Civ. Eng. 2010, 22, 443–450. [Google Scholar] [CrossRef]

- Ho, N.Y.; Lee, Y.P.; Lim, W.F.; Zayed, T.; Chew, K.C.; Low, G.L.; Ting, S.K. Efficient utilization of recycled concrete aggregate in structural concrete. J. Mater. Civ. Eng. 2013, 25, 318–327. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D. Compressive behavior of reinforced concrete columns with recycled aggregate under uniaxial loading. Eng. Struct. 2012, 41, 285–293. [Google Scholar] [CrossRef]

- Meng, E.; Yu, Y.; Yuan, J.; Qiao, K.; Su, Y. Triaxial compressive strength experiment study of recycled aggregate concrete after high temperatures. Constr. Build. Mater. 2017, 155, 542–549. [Google Scholar] [CrossRef]

- Meng, E.; Yu, Y.; Zhang, X.; Su, Y. Experimental and theoretical research on the mechanical performance of totally recycled concrete under triaxial compression after high temperatures. Constr. Build. Mater. 2020, 261, 120012. [Google Scholar] [CrossRef]

- Abdelgadir, A.; Gholamreza, F. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563. [Google Scholar]

- Roumiana, Z.; Francois, B.; Frederic, S. Assessment of the surface permeation properties of recycled aggregate concrete. Cem. Concr. Compos. 2003, 25, 223–232. [Google Scholar]

- Otsuki, N.; Miyazato, S.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone, strength, chloride, penetration and carbonation. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 84, 141–146. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Amnon, K. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar]

- Sasha, A.; Justin, H. The utilization of recycled concrete aggregate to produce controlled low-strength materials without using Portland cement. Cem. Concr. Compos. 2009, 31, 564–569. [Google Scholar]

- Kou, S.; Poon, C. Long-term mechanical and durability properties of recycled aggregate concrete prepared with the incorporation of fly ash. Cem. Concr. Compos. 2013, 37, 12–19. [Google Scholar] [CrossRef]

- Zhang, L.W.; Sojobi, A.O.; Liew, K.M. Sustainable CFRP-reinforced recycled concrete for cleaner eco-friendly construction. J. Clean. Prod. 2019, 233, 56–75. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Properties of concrete prepared with PVA-impregnated recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 649–654. [Google Scholar] [CrossRef]

- Zhang, X.; Niu, J.; Shen, W.; Deng, D.; Huang, Y. Analysis of axial compression performance of BFRRAC-filled square steel tubular column. Steel Compos. Struct. 2023, 49, 457–471. [Google Scholar]

- Zhang, X.; Shen, Y.; Fan, Y.; Gao, X. Experimental study on the triaxial compression mechanical performance of basalt fiber-reinforced recycled aggregate concrete after exposure to high temperature. Case Stud. Constr. Mater. 2024, 20, e03026. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.; Leite, M.B.; Toledo Filho, R.D. Compressive stress-strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Li, P.; Liu, Z.; Lu, Y.; Lin, C.; Ma, W. Mechanical behavior of steel fiber reinforced recycled aggregate concrete under dynamic triaxial compression. Compos. Struct. 2023, 320, 117161. [Google Scholar] [CrossRef]

- Gao, D.Y.; Zhang, L.J.; Nokken, M. Compressive behavior of steel fiber reinforced recycled coarse aggregate concrete designed with equivalent cubic compressive strength. Constr. Build. Mater. 2017, 141, 235–244. [Google Scholar] [CrossRef]

- Kazmi, S.M.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Axial stress-strain behavior of macro-synthetic fiber reinforced recycled aggregate concrete. Cem. Concr. Compos. 2019, 97, 341–356. [Google Scholar] [CrossRef]

- Omidinasab, F.; Goodarz, S.M.; Moghadam, A.S. Characterization and optimization of mechanical and impact properties of steel fiber reinforced recycled concrete. Int. J. Civ. Eng. 2022, 20, 41–55. [Google Scholar] [CrossRef]

- Sun, L.; Hao, Q.; Zhao, J.; Wu, D.; Yang, F. Stress strain behavior of hybrid steel-PVA fiber reinforced cementitious composites under uniaxial compression. Constr. Build. Mater. 2018, 188, 349–360. [Google Scholar] [CrossRef]

- Xia, D.T.; Xie, S.J.; Fu, M. Effects of maximum particle size of coarse aggregates and steel fiber contents on the mechanical properties and impact resistance of recycled aggregate concrete. Adv. Struct. Eng. 2022, 4, 3085–3098. [Google Scholar] [CrossRef]

- Lü, Q.; Qiu, Q.; Zheng, J.; Wang, J.; Zeng, Q. Fractal dimension of concrete incorporating silica fume and its correlations to pore structure, strength and permeability. Constr. Build. Mater. 2019, 228, 116986. [Google Scholar] [CrossRef]

- Gao, S.; Li, Q.Y.; Luo, J.L. Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete. Rev. Adv. Mater. Sci. 2021, 60, 663–677. [Google Scholar] [CrossRef]

- Xie, H.Z.; Yang, L.Y.; Zhu, H.N. Energy dissipation and fractal characteristics of basalt fiber reinforced concrete under impact loading. Structures 2022, 46, 654–663. [Google Scholar] [CrossRef]

- Konkol, J. A fractal model of cracking of cement matrix composites. Buildings 2020, 10, 52. [Google Scholar] [CrossRef]

- Wang, X.; Saifullah, H.A.; Nishikawa, H.; Nakarai, K. Effect of water cement ratio, aggregate type, and curing temperature on the fracture energy of concrete. Constr. Build. Mater. 2020, 259, 119646. [Google Scholar] [CrossRef]

- Zamen, S.; Dehghan-Niri, E. Fractal analysis of nonlinear ultrasonic waves in phase-space domain as a quantitative method for damage assessment of concrete structures. NDT E Int. 2020, 111, 102235. [Google Scholar] [CrossRef]

- Yin, Y.; Ren, Q.; Shen, L. Study on the effect of aggregate distribution on mechanical properties and damage cracks of concrete based on multifractal theory. Constr. Build. Mater. 2020, 262, 120086. [Google Scholar] [CrossRef]

- He, H.X.; Tian, S.Y.; Zhang, Y.Y. Refined fatigue damage assessment of RC beam based on fractal characteristics of cracks. Structures 2022, 46, 1595–1603. [Google Scholar] [CrossRef]

- Zarnaghi, V.N.; Fouroghi-Asl, A.; Nourani, V.; Ma, H. On the pore structures of lightweight self-compacting concrete containing silica fume. Constr. Build. Mater. 2018, 193, 557–564. [Google Scholar] [CrossRef]

- Han, X.; Wang, B.M.; Feng, J.J. Relationship between fractal feature and compressive strength of concrete based on MIP. Constr. Build. Mater. 2022, 332, 126504. [Google Scholar] [CrossRef]

- Ding, C.; Xu, T.; Chen, Q.; Su, C.; Zhao, P. Study on the relationship between fractal characteristics and mechanical properties of tensile fracture of reinforced concrete structures. KSCE J. Civ. Eng. 2022, 26, 2225–2233. [Google Scholar] [CrossRef]

- Li, Y.; Dang, F.; Zhou, M.; Ren, J. Analysis of Fractal and Energy Consumption Characteristics of Concrete under Impact Loading. Geofluids 2021, 2021, 2370363. [Google Scholar] [CrossRef]

- Yang, Y.A.; Li, X.L.; Yang, R.S.; Wang, J.G. Study on fractal characteristics and Fracture Mechanism of frozen Rock. Trans. Beijing Inst. Technol. 2020, 40, 632–639. [Google Scholar]

- Li, Y.; Zhai, Y.; Liu, X.; Liang, W. Research on fractal characteristics and energy dissipation of concrete suffered freeze thaw cycle action and impact loading. Materials 2019, 12, 12585. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, X.L.; Li, Q.H. Fractal characteristics of fire damaged ultrahigh toughness cementitious composite after impact loading. China Civ. Eng. J. 2019, 52, 44–55. [Google Scholar]

- Ren, W.B.; Xu, J.Y. Fractal characteristics of concrete fragmentation under impact loading. J. Mater. Civ. Eng. 2017, 29, 04016244. [Google Scholar] [CrossRef]

- Chrysanidis, T.A.; Panoskaltsis, V.P. Experimental investigation on cracking behavior of reinforced concrete tension ties. Case Stud. Constr. Mater. 2022, 16, e00810. [Google Scholar] [CrossRef]

- Carpinteri, A.; Brighenti, R. Fracture behaviour of plain and fiber-reinforced concrete with different water content under mixed mode loading. Mater. Des. 2010, 31, 2032–2042. [Google Scholar] [CrossRef]

- Akhavan, A.; Rajabipour, F. Quantifying the effects of crack width, tortuosity, and roughness on water permeability of cracked mortars. Cem. Concr. Res. 2012, 42, 313–320. [Google Scholar] [CrossRef]

- Woods, J.E.; Yang, Y.S.; Chen, P.C.; Lau, D.T.; Erochko, J. Automated crack detection and damage index calculation for RC structures using image analysis and fractal dimension. J. Struct. Eng. 2021, 147, 04021019. [Google Scholar] [CrossRef]

- Tang, S.W.; He, Z.; Cai, X.H.; Cai, R.J.; Zhou, W.; Li, Z.J.; Shao, H.Y.; Wu, T.; Chen, E. Volume and surface fractal dimensions of pore structure by NAD and LT-DSC in calcium sulfoaluminate cement paste. Constr. Build. Mater. 2017, 143, 395–418. [Google Scholar] [CrossRef]

- Shan, X.Y.; Li, Z.J. Fractal theory characteristics and its application on rock fragmentation. J. Hebei Inst. Technol. 2003, 25, 11–17. [Google Scholar]

| Length/mm | Diameter/mm | Tensile Strength/MPa | Elastic Modulus/GPa | Poisson Ratio |

|---|---|---|---|---|

| 13 | 0.22 | 3193 | 40–60 | 0.19–0.24 |

| Coarse Aggregate Type | Particle Size/mm | Apparent Density/(kg/m3) | Water Content/% | Water Absorption/% |

|---|---|---|---|---|

| Natural | 5~10 | 2798 | 0.7 | 0.1 |

| Recycle | 5~10 | 2486 | 1.8 | 4.5 |

| R (%) | W | SR (%) | C (kg/m3) | MW (kg/m3) | AW (kg/m3) | RCA (kg/m3) | NCA (kg/m3) | S (kg/m3) | FA (kg/m3) | WR (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.47 | 32 | 346 | 191 | 1.22 | 0.0 | 1224.9 | 577 | 69.2 | 2.04 |

| 50 | 0.47 | 32 | 346 | 191 | 28.17 | 612.5 | 612.5 | 577 | 69.2 | 2.04 |

| 100 | 0.47 | 32 | 346 | 191 | 55.12 | 1224.9 | 0.0 | 577 | 69.2 | 2.04 |

| Specimen NO. | Replacement Ratio (%) | SF (kg/m3) | Impact pressure (MPa) |

|---|---|---|---|

| R0SF0.5 | 0 | 39 | 0.4, 0.5, 0.6 |

| R0SF1 | 0 | 78 | 0.4, 0.5, 0.6 |

| R0SF1.5 | 0 | 117 | 0.4, 0.5, 0.6 |

| R0SF2 | 0 | 156 | 0.4, 0.5, 0.6 |

| R50SF0.5 | 50 | 39 | 0.4, 0.5, 0.6 |

| R50SF1 | 50 | 78 | 0.4, 0.5, 0.6 |

| R50SF1.5 | 50 | 117 | 0.4, 0.5, 0.6 |

| R50SF2 | 50 | 156 | 0.4, 0.5, 0.6 |

| R100SF0.5 | 100 | 39 | 0.4, 0.5, 0.6 |

| R100SF1 | 100 | 78 | 0.4, 0.5, 0.6 |

| R100SF1.5 | 100 | 117 | 0.4, 0.5, 0.6 |

| R100SF2 | 100 | 156 | 0.4, 0.5, 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Zhu, Y.; Wang, J.; Zhou, G.; Huang, Y. Analysis of Impact Crushing Characteristics of Steel Fiber Reinforced Recycled Aggregate Concrete Based on Fractal Theory. Fractal Fract. 2024, 8, 505. https://doi.org/10.3390/fractalfract8090505

Zhang X, Zhu Y, Wang J, Zhou G, Huang Y. Analysis of Impact Crushing Characteristics of Steel Fiber Reinforced Recycled Aggregate Concrete Based on Fractal Theory. Fractal and Fractional. 2024; 8(9):505. https://doi.org/10.3390/fractalfract8090505

Chicago/Turabian StyleZhang, Xianggang, Yanan Zhu, Junbo Wang, Gaoqiang Zhou, and Yajun Huang. 2024. "Analysis of Impact Crushing Characteristics of Steel Fiber Reinforced Recycled Aggregate Concrete Based on Fractal Theory" Fractal and Fractional 8, no. 9: 505. https://doi.org/10.3390/fractalfract8090505