Fractal Characterization of a Multi-Scale Pore Structure in Ultra-Deep Coal Seams

Abstract

:1. Introduction

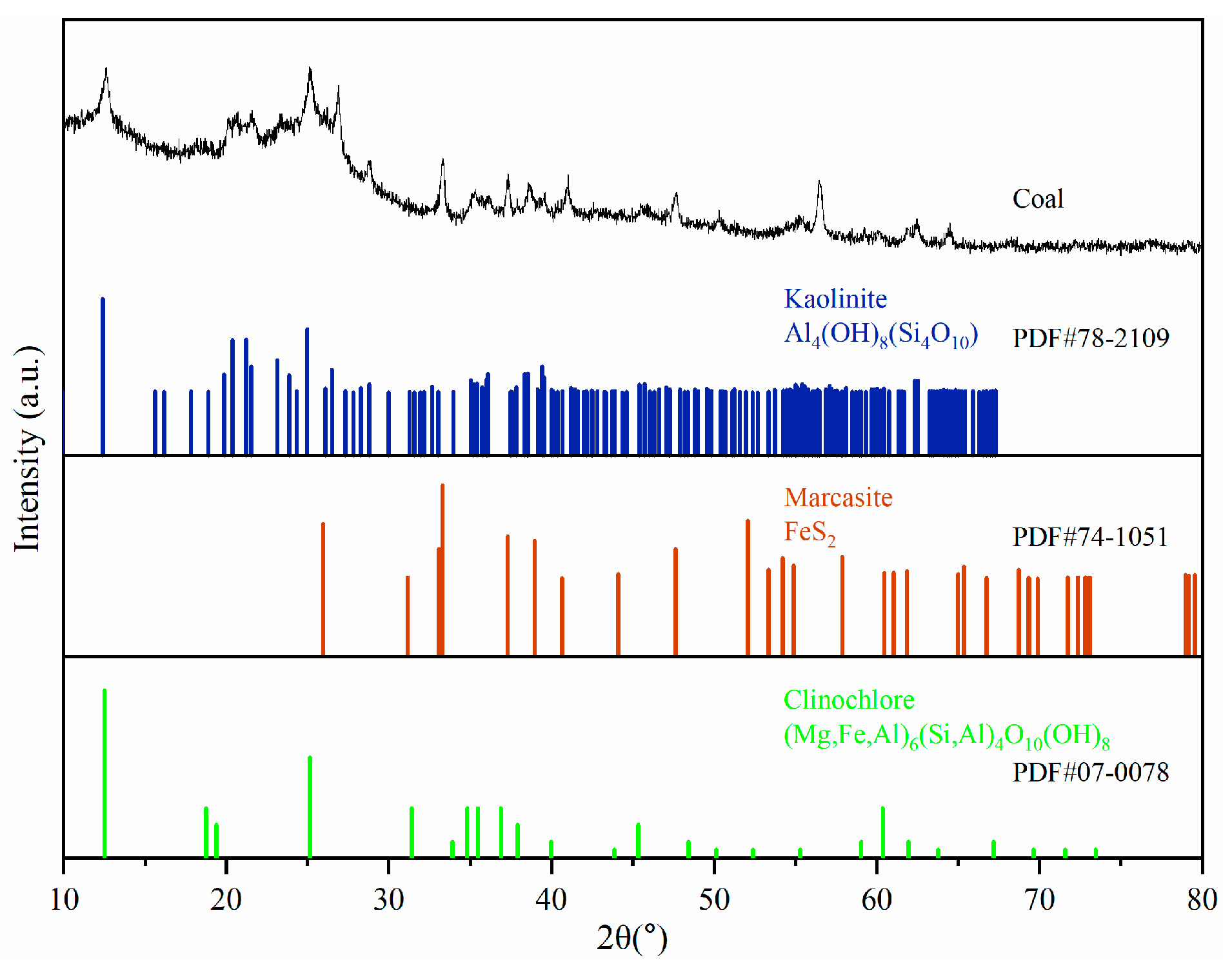

2. Samples and Methods

2.1. Samples

2.2. Experimental Methods

2.3. Fractal Theory

3. Results and Discussion

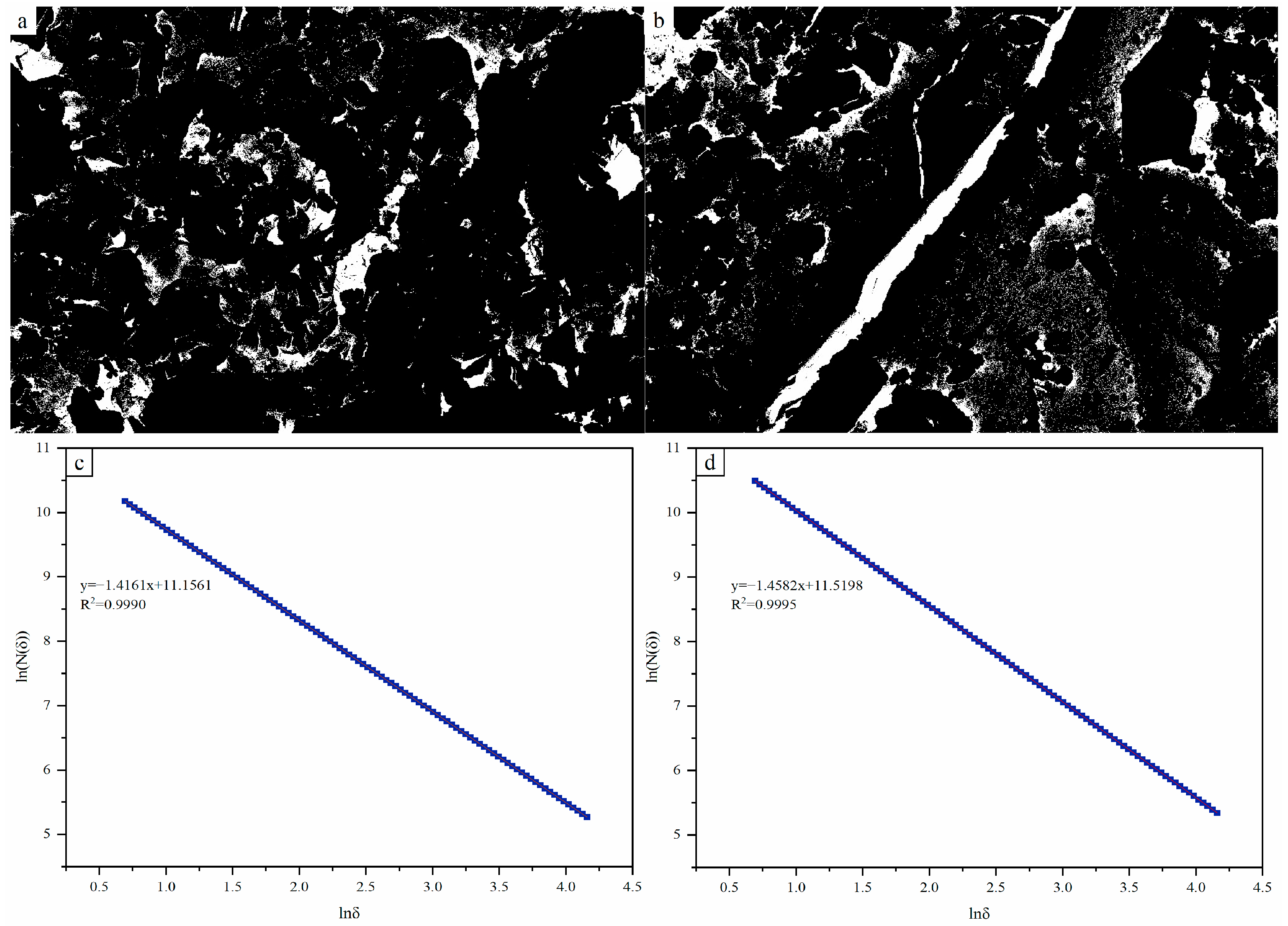

3.1. FE-SEM Results and Fractal Characteristics

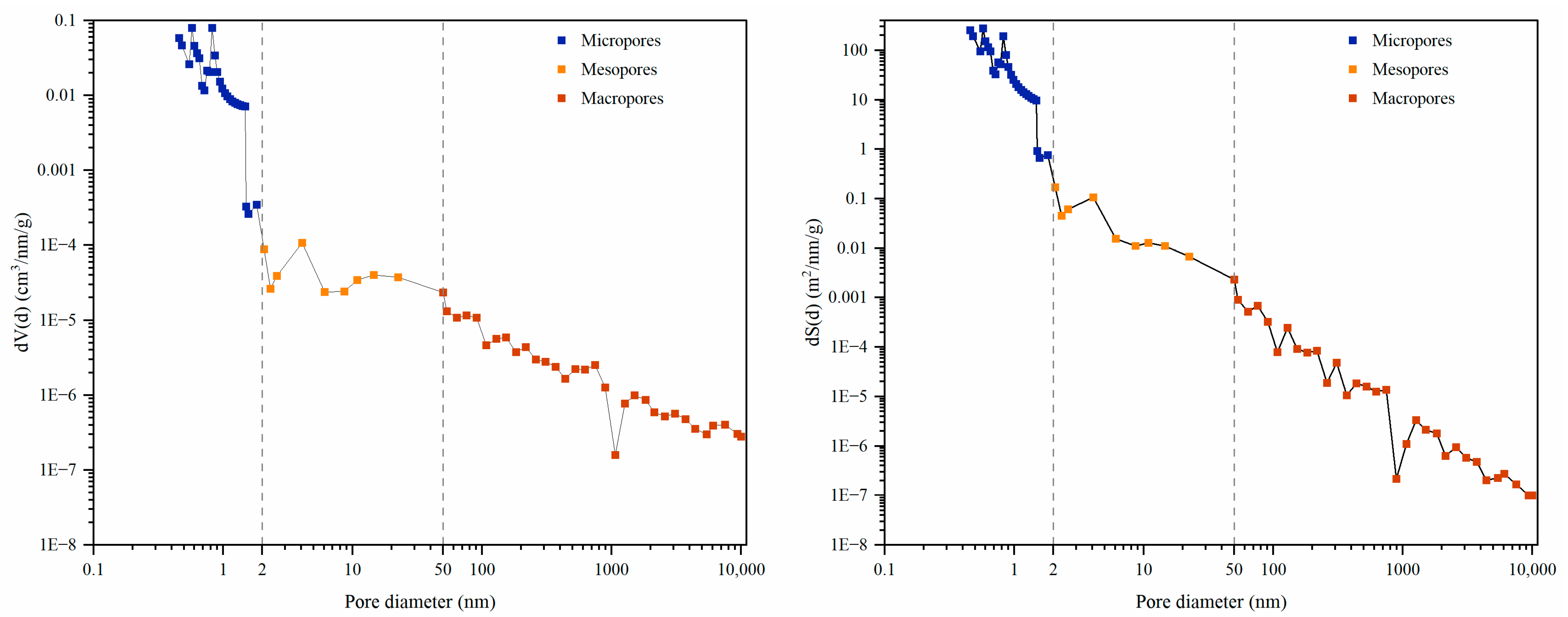

3.2. MIP Results and Fractal Characteristics

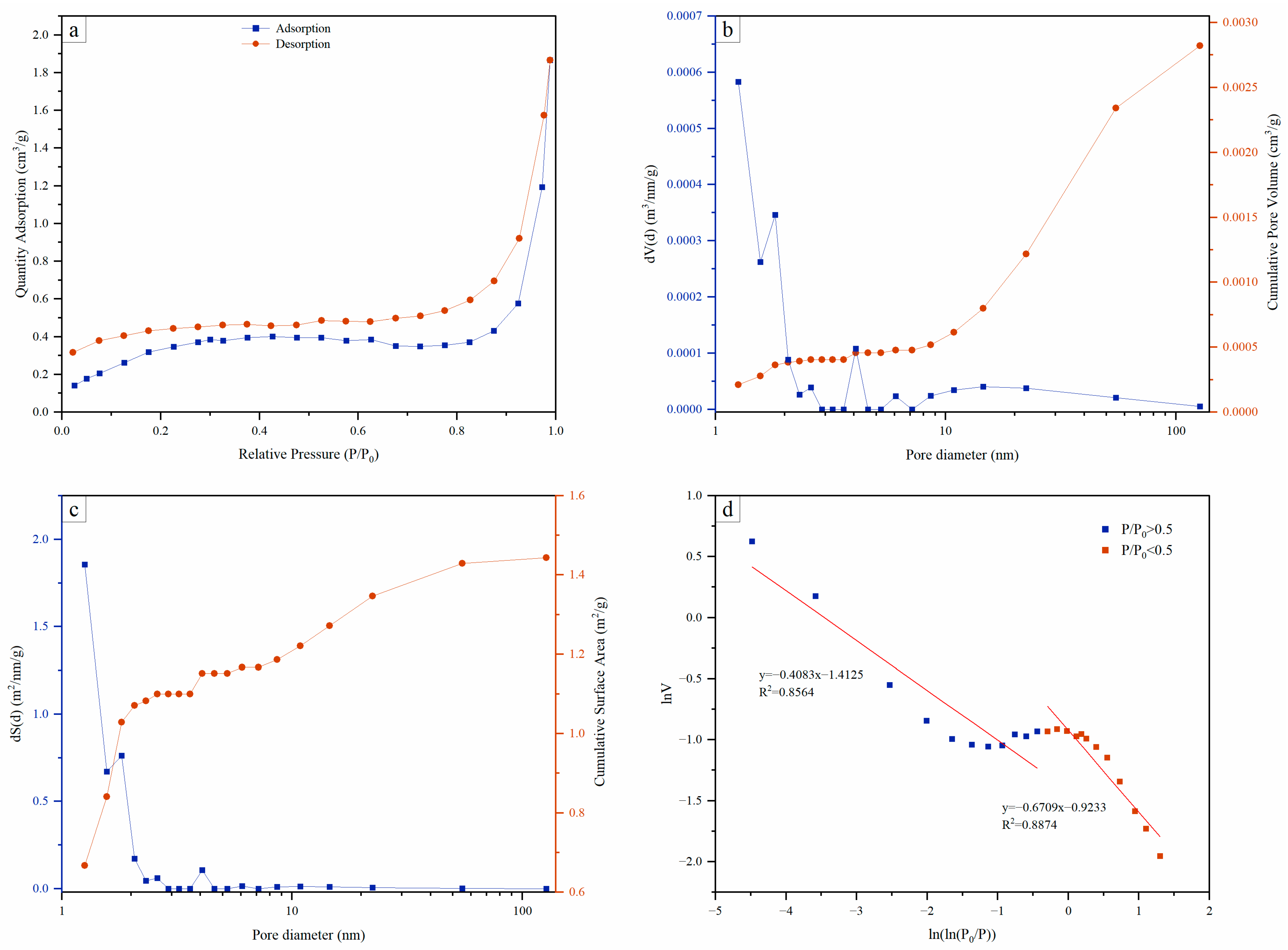

3.3. LT-N2GA Results and Fractal Characteristics

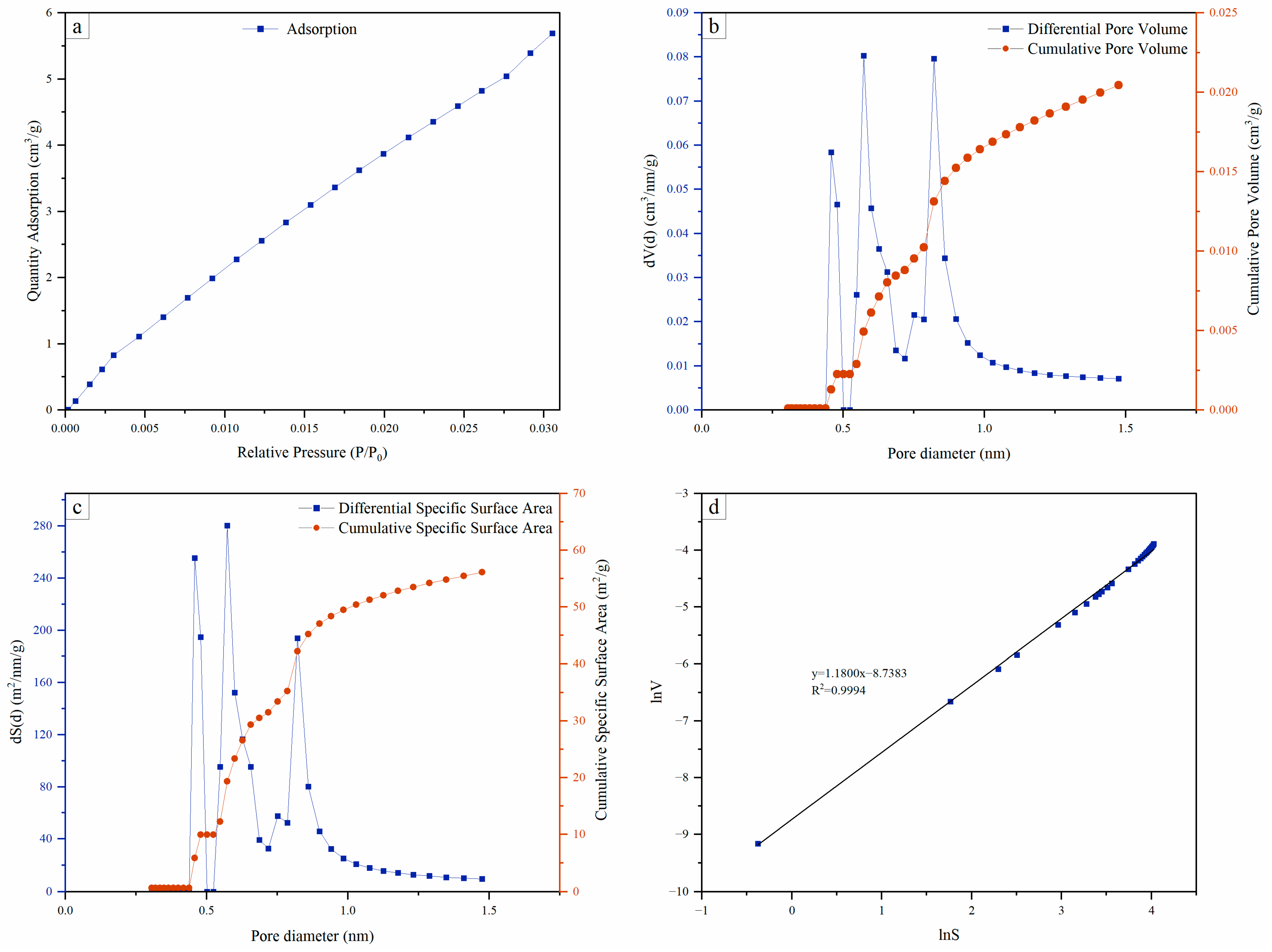

3.4. LP-CO2GA Results and Fractal Characteristics

3.5. Multi-Scale Pore Structure Characterization and Fractal Characteristics

3.6. Implication and Limitation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Jubori, A.; Johnston, S.; Boyer, C.; Lambert, S.W.; Bustos, O.A.; Pashin, J.C.; Wray, A. Coalbed Methane: Clean Energy for the World. Oilfield Rev. 2009, 21, 4–13. [Google Scholar]

- Liu, G.; Liu, H.; Xian, B.; Gao, D.; Wang, X.; Zhang, Z. Fuzzy Pattern Recognition Model of Geological Sweetspot for Coalbed Methane Development. Pet. Explor. Dev. 2023, 50, 924–933. [Google Scholar] [CrossRef]

- Lau, H.C.; Li, H.; Huang, S. Challenges and Opportunities of Coalbed Methane Development in China. Energy Fuels 2017, 31, 4588–4602. [Google Scholar] [CrossRef]

- Xian, B.; Liu, G.; Bi, Y.; Gao, D.; Wang, L.; Cao, Y.; Shi, B.; Zhang, Z.; Zhang, Z.; Tian, L.; et al. Coalbed Methane Recovery Enhanced by Screen Pipe Completion and Jet Flow Washing of Horizontal Well Double Tubular Strings. J. Nat. Gas Sci. Eng. 2022, 99, 104430. [Google Scholar] [CrossRef]

- Li, S.; Qin, Y.; Tang, D.; Shen, J.; Wang, J.; Chen, S. A Comprehensive Review of Deep Coalbed Methane and Recent Developments in China. Int. J. Coal Geol. 2023, 279, 104369. [Google Scholar] [CrossRef]

- Ren, J.; Song, Z.; Li, B.; Liu, J.; Lv, R.; Liu, G. Structure Feature and Evolution Mechanism of Pores in Different Metamorphism and Deformation Coals. Fuel 2021, 283, 119292. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Wang, X.; Wang, M.; Li, B.; Liu, H. Fractal Characterization on Three-Dimensional Fractur Tortuosity in Coal Based on CT Scanning. Fractals 2023, 31, 2350034. [Google Scholar] [CrossRef]

- Qin, L.; Zhai, C.; Liu, S.; Xu, J.; Wu, S.; Dong, R. Fractal Dimensions of Low Rank Coal Subjected to Liquid Nitrogen Freeze-Thaw Based on Nuclear Magnetic Resonance Applied for Coalbed Methane Recovery. Powder Technol. 2018, 325, 11–20. [Google Scholar] [CrossRef]

- Ji, X.; Song, D.; Zhao, H.; Li, Y.; He, K. Experimental Analysis of Pore and Permeability Characteristics of Coal by Low-Field NMR. Appl. Sci. 2018, 8, 1374. [Google Scholar] [CrossRef]

- Fu, H.; Tang, D.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.; Chen, B.; Zhang, C.; Wang, L. Characteristics of Pore Structure and Fractal Dimension of Low-Rank Coal: A Case Study of Lower Jurassic Xishanyao Coal in the Southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Zheng, S.; Liu, Y.; Huang, F.; Liu, S.; Sang, S.; Dai, X.; Wang, M. Pore Structure Evolution of Coal After Supercritical CO2–Water–Rock Treatment: A Multifractal Analysis. Fractal Fract. 2025, 9, 144. [Google Scholar] [CrossRef]

- Liu, D.; Qiu, F.; Liu, N.; Cai, Y.; Guo, Y.; Zhao, B.; Qiu, Y. Pore Structure Characterization and Its Significance for Gas Adsorption in Coals: A Comprehensive Review. Unconv. Resour. 2022, 2, 139–157. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; Fengli, L.; Jiegang, L. Structure and Fractal Characteristic of Micro- and Meso-Pores in Low, Middle-Rank Tectonic Deformed Coals by CO2 and N2 Adsorption. Microporous Mesoporous Mater. 2017, 253, 191–202. [Google Scholar] [CrossRef]

- Liu, X.; Nie, B. Fractal Characteristics of Coal Samples Utilizing Image Analysis and Gas Adsorption. Fuel 2016, 182, 314–322. [Google Scholar] [CrossRef]

- Yang, Y.; Wei, J.; Zhu, W.; Xu, D.; Bai, K.; Zhang, A.; Zhou, X.; Zeng, Q.; Wang, A.; Li, Y.; et al. Pore Structure Sensitivity to External Fluids for Coal Reservoir and Fracturing Initiation/Propagation Mechanism by Using the T1 ∼ T2 NMR Spectrum and Physical Simulation Experiment. Energy Fuels 2023, 37, 222–236. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, Z.; Cao, Y.; Wang, X.; Liu, H.; Li, B.; Si, N.; Guan, W. An Analogical Method on Fractal Dimension for Three-Dimensional Fracture Tortuosity in Coal Based on CT Scanning. Fractals 2023, 31, 2350072. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Chang, P.; Wang, X.; Lin, J. Fractal Characteristics for Coal Chemical Structure: Principle, Methodology and Implication. Chaos Solitons Fractals 2023, 173, 113699. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Liu, H.; Wang, X.; Lin, J.; Barakos, G.; Chang, P. Fractal Characterization on Methane Adsorption in Coal Molecular Structure. Phys. Fluids 2024, 36, 126611. [Google Scholar] [CrossRef]

- Feng, K.; Liu, G.; Zhang, Z.; Liu, H.; Lv, R.; Wang, X.; Chang, P.; Lin, J.; Barakos, G. Fractal Strategy for Improving Characterization of N2 Adsorption–Desorption in Mesopores. Fractal Fract. 2024, 8, 617. [Google Scholar] [CrossRef]

- Wei, Q.; Zheng, K.; Hu, B.; Li, X.; Feng, S.; Jiang, W.; Zhu, W.; Feng, W. Methane Adsorption Capacity of Deep-Buried Coals Based on Pore Structure in the Panji Deep Area of Huainan Coalfield, China. Energy Fuels 2021, 35, 4775–4790. [Google Scholar] [CrossRef]

- Wang, T.; Zhou, G.; Fan, L.; Zhang, D.; Shao, M.; Ding, R.; Li, Y.; Hu, H.; Deng, Z. Full-Scale Pore and Microfracture Characterization of Deep Coal Reservoirs: A Case Study of the Benxi Formation Coal in the Daning–Jixian Block, China. Int. J. Energy Res. 2024, 2024, 5772264. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, X.; Liu, J.; Pang, S.; Zhu, K.; Zheng, Z. Multi-Scale Quantitative Characterization of Three-Dimensional Pores and Fissures in Deep Coal and Study of the Evolution Laws. Constr. Build. Mater. 2024, 449, 138449. [Google Scholar] [CrossRef]

- Li, Q.; Wu, Y.; Qiao, L. Comprehensive Characterization and Metamorphic Control Analysis of Full Apertures in Different Coal Ranks within Deep Coal Seams. Appl. Sci. 2024, 14, 8566. [Google Scholar] [CrossRef]

- GB/T 212-2008; Proximate Analysis of Coal. Standardization Administration: Beijing, China, 2008.

- Sing, K.S.W. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Song, S.-B.; Liu, J.-F.; Yang, D.-S.; Ni, H.-Y.; Huang, B.-X.; Zhang, K.; Mao, X.-B. Pore Structure Characterization and Permeability Prediction of Coal Samples Based on SEM Images. J. Nat. Gas Sci. Eng. 2019, 67, 160–171. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of Gases in Multimolecular Layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The Determination of Pore Volume and Area Distributions in Porous Substances. I. Computations from Nitrogen Isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Marc Bustin, R. The Importance of Shale Composition and Pore Structure upon Gas Storage Potential of Shale Gas Reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Evans, R.; Marconi, U.M.B.; Tarazona, P. Capillary Condensation and Adsorption in Cylindrical and Slit-like Pores. J. Chem. Soc. Faraday Trans. 2 Mol. Chem. Phys. 1986, 82, 1763–1787. [Google Scholar] [CrossRef]

- Curtis, M.E.; Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Microstructural Investigation of Gas Shales in Two and Three Dimensions Using Nanometer-Scale Resolution Imaging. AAPG Bull. 2012, 96, 665–677. [Google Scholar] [CrossRef]

- Deng, G.; Zheng, R. Micropore Structure and Fractal Characteristics of Low-Permeability Coal Seams. Adv. Mater. Sci. Eng. 2018, 2018, 4186280. [Google Scholar] [CrossRef]

- You, L.; Chen, Q.; Kang, Y.; Yu, Y.; He, J. Evaluation of Formation Damage Using Microstructure Fractal in Shale Reservoirs. Fractals 2015, 23, 1540008. [Google Scholar] [CrossRef]

- Wang, G.; Ju, Y.; Bao, Y.; Yan, Z.; Li, X.; Bu, H.; Li, Q. Coal-Bearing Organic Shale Geological Evaluation of Huainan–Huaibei Coalfield, China. Available online: https://pubs.acs.org/doi/abs/10.1021/ef501285x (accessed on 28 December 2024).

- Song, H.; Min, L.; Jun, X.; Lushi, S.; Peisheng, L.; Sheng, S.; Xuexin, S. Fractal Characteristic of Three Chinese Coals. Fuel 2004, 83, 1307–1313. [Google Scholar] [CrossRef]

- Xie, H.; Wang, J.; Qan, P. Fractal Characters of Micropore Evolution in Marbles. Phys. Lett. A 1996, 218, 275–280. [Google Scholar] [CrossRef]

- Ye, Z.; Hou, E.; Duan, Z. Micrometer-Scale Pores and Fractures in Coals and the Effects of Tectonic Deformation on Permeability Based on Fractal Theory. AIP Adv. 2020, 10, 025118. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, S.; Tang, D.; Huang, W.; Pan, Z. Determining Fractal Dimensions of Coal Pores by FHH Model: Problems and Effects. J. Nat. Gas Sci. Eng. 2014, 21, 929–939. [Google Scholar] [CrossRef]

- Wood, D.A. Estimating Organic-Rich Shale Fractal Dimensions from Gas Adsorption Isotherms: Combining Different Methods Leads to More Reliable Values and Insight. Nat. Resour. Res. 2021, 30, 3551–3574. [Google Scholar] [CrossRef]

- Pfeifer, P.; Wu, Y.J.; Cole, M.W.; Krim, J. Multilayer Adsorption on a Fractally Rough Surface. Phys. Rev. Lett. 1989, 62, 1997–2000. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Wheeler, J.A. The Fractal Geometry of Nature. Am. J. Phys. 1983, 51, 286–287. [Google Scholar] [CrossRef]

- Li, Y.; Liu, W.; Song, D.; Ren, Z.; Wang, H.; Guo, X. Full-Scale Pore Characteristics in Coal and Their Influence on the Adsorption Capacity of Coalbed Methane. Environ. Sci. Pollut. Res. 2023, 30, 72187–72206. [Google Scholar] [CrossRef] [PubMed]

- Nie, B.; Liu, X.; Longlong, Y.; Meng, J.; Xiangchun, L. Pore Structure Characterization of Different Rank Coals Using Gas Adsorption and Scanning Electron Microscopy. Fuel 2015, 158, 908–917. [Google Scholar] [CrossRef]

- Bin, L.; Wei, Z.; Zhenhua, X.; Xiaojiao, C.; Yong, C. FTIR and XRD Microscopic Characterisation of Coal Samples with Different Degrees of Metamorphism. J. Mol. Struct. 2024, 1309, 138270. [Google Scholar] [CrossRef]

- Liu, L.; Ge, Z.; Zhou, Z.; Li, Z.; Deng, Q. Mineral Composition, Pore Structure and Mechanical Properties of Coal Measure Strata Rocks: A Case Study of Pingdingshan Coalfield. Sci. Total Environ. 2024, 952, 175944. [Google Scholar] [CrossRef]

- Dathe, A.; Eins, S.; Niemeyer, J.; Gerold, G. The Surface Fractal Dimension of the Soil–Pore Interface as Measured by Image Analysis. Geoderma 2001, 103, 203–229. [Google Scholar] [CrossRef]

- Jiao, K.; Yao, S.; Liu, C.; Gao, Y.; Wu, H.; Li, M.; Tang, Z. The Characterization and Quantitative Analysis of Nanopores in Unconventional Gas Reservoirs Utilizing FESEM–FIB and Image Processing: An Example from the Lower Silurian Longmaxi Shale, Upper Yangtze Region, China. Int. J. Coal Geol. 2014, 128–129, 1–11. [Google Scholar] [CrossRef]

- Liu, S.; Xue, H.; Zhao, M. Pore Structure and Fractal Characteristics of Coal Measure Shale in the Wuxiang Block in the Qinshui Basin. Processes 2023, 11, 3362. [Google Scholar] [CrossRef]

- Li, Z.; Liu, D.; Cai, Y.; Wang, Y.; Teng, J. Adsorption Pore Structure and Its Fractal Characteristics of Coals by N2 Adsorption/Desorption and FESEM Image Analyses. Fuel 2019, 257, 116031. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of Gases, with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Han, W.; Zhou, G.; Gao, D.; Zhang, Z.; Wei, Z.; Wang, H.; Yang, H. Experimental Analysis of the Pore Structure and Fractal Characteristics of Different Metamorphic Coal Based on Mercury Intrusion-nitrogen Adsorption Porosimetry. Powder Technol. 2020, 362, 386–398. [Google Scholar] [CrossRef]

- Wang, L.; Wu, S.; Han, S.; Hu, B.; Wang, Q.; Zhang, K.; Song, T. Fractal Analysis of Coal Pore Structure Based on Low-Pressure Gas Adsorption and Its Influence on Methane Adsorption Capacity: A Perspective from Micropore Filling Model. Energy Fuels 2024, 38, 4031–4046. [Google Scholar] [CrossRef]

- Jiang, J.; Yang, W.; Cheng, Y.; Zhao, K.; Zheng, S. Pore Structure Characterization of Coal Particles via MIP, N2 and CO2 Adsorption: Effect of Coalification on Nanopores Evolution. Powder Technol. 2019, 354, 136–148. [Google Scholar] [CrossRef]

- Wang, G.; Ju, Y.; Yan, Z.; Li, Q. Pore Structure Characteristics of Coal-Bearing Shale Using Fluid Invasion Methods: A Case Study in the Huainan–Huaibei Coalfield in China. Mar. Pet. Geol. 2015, 62, 1–13. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, S.; Elsworth, D.; Jiang, Y.; Zhu, J. Pore Structure Characterization of Coal by Synchrotron Small-Angle X-Ray Scattering and Transmission Electron Microscopy. Energy Fuels 2014, 28, 3704–3711. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R.; Saeedi, A.; Hinai, A.A. Evaluation of Pore Size Spectrum of Gas Shale Reservoirs Using Low Pressure Nitrogen Adsorption, Gas Expansion and Mercury Porosimetry: A Case Study from the Perth and Canning Basins, Western Australia. J. Pet. Sci. Eng. 2013, 112, 7–16. [Google Scholar] [CrossRef]

- Liu, X.; Kong, X.; Nie, B.; Song, D.; He, X.; Wang, L. Pore Fractal Dimensions of Bituminous Coal Reservoirs in North China and Their Impact on Gas Adsorption Capacity. Nat. Resour. Res. 2021, 30, 4585–4596. [Google Scholar] [CrossRef]

- Song, D.; Ji, X.; Li, Y.; Zhao, H.; Song, B.; He, K. Heterogeneous Development of Micropores in Medium-High Rank Coal and Its Relationship with Adsorption Capacity. Int. J. Coal Geol. 2020, 226, 103497. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Liu, H. Fractal Characteristics of Shales from a Shale Gas Reservoir in the Sichuan Basin, China. Fuel 2014, 115, 378–384. [Google Scholar] [CrossRef]

- Cai, Y.; Liu, D.; Pan, Z.; Yao, Y.; Li, J.; Qiu, Y. Pore Structure and Its Impact on CH4 Adsorption Capacity and Flow Capability of Bituminous and Subbituminous Coals from Northeast China. Fuel 2013, 103, 258–268. [Google Scholar] [CrossRef]

- Guo, F.; Liu, G.; Zhang, Z.; Lv, R.; Xian, B.; Lin, J.; Barakos, G.; Chang, P. A Fractal Adsorption Model on Methane in Coal with Temperature Effect Dependence. Fractal Fract. 2024, 8, 370. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Wang, X.; Lv, R.; Liu, H.; Lin, J.; Barakos, G.; Chang, P. A Fractal Langmuir Adsorption Equation on Coal: Principle, Methodology and Implication. Chem. Eng. J. 2024, 488, 150869. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, G.; Liu, H.; Wang, X.; Lin, J.; Barakos, G.; Chang, P. Fractal Dynamics Model of Gas Adsorption in Porous Media. Phys. Fluids 2025, 37, 016623. [Google Scholar] [CrossRef]

| ID | Mad (%) | Ad (%) | Vdaf (%) | FCad (%) |

|---|---|---|---|---|

| Gaogu-4 | 0.98 | 25.33 | 32.28 | 50.06 |

| Sample ID | PV (cm3/g) | SSA (m2/g) | ||||||

|---|---|---|---|---|---|---|---|---|

| Micropores | Mesopores | Macropores | Total | Micropores | Mesopores | Macropores | Total | |

| Gaogu-4 | 0.021 | 0.002 | 0.078 | 0.11 | 57.18 | 1.42 | 0.068 | 58.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Y.; Chen, F.; Ma, L.; Jiang, P.; Li, B.; Ren, J.; Lv, R.; Liu, G.; Song, Z.; Chang, P.; et al. Fractal Characterization of a Multi-Scale Pore Structure in Ultra-Deep Coal Seams. Fractal Fract. 2025, 9, 250. https://doi.org/10.3390/fractalfract9040250

Qu Y, Chen F, Ma L, Jiang P, Li B, Ren J, Lv R, Liu G, Song Z, Chang P, et al. Fractal Characterization of a Multi-Scale Pore Structure in Ultra-Deep Coal Seams. Fractal and Fractional. 2025; 9(4):250. https://doi.org/10.3390/fractalfract9040250

Chicago/Turabian StyleQu, Yanwei, Feng Chen, Lulu Ma, Peiwen Jiang, Bing Li, Jiangang Ren, Runsheng Lv, Gaofeng Liu, Zhimin Song, Ping Chang, and et al. 2025. "Fractal Characterization of a Multi-Scale Pore Structure in Ultra-Deep Coal Seams" Fractal and Fractional 9, no. 4: 250. https://doi.org/10.3390/fractalfract9040250

APA StyleQu, Y., Chen, F., Ma, L., Jiang, P., Li, B., Ren, J., Lv, R., Liu, G., Song, Z., Chang, P., & Barakos, G. (2025). Fractal Characterization of a Multi-Scale Pore Structure in Ultra-Deep Coal Seams. Fractal and Fractional, 9(4), 250. https://doi.org/10.3390/fractalfract9040250