Experimental Characterization of Fabric-Reinforced Cementitious Matrix (FRCM) Systems Applied on Calcarenite Stone: Adoption of Non-Standard Setup for Double-Shear Bond Tests

Abstract

:1. Introduction

2. Experimental Program

- BC is for BFRCM with cement-based mortar;

- BL is for BFRCM with hydraulic lime-based mortar;

- GC is for GFRCM with cement-based mortar;

- GL is for GFRCM with hydraulic lime-based mortar;

- DSB is for Double-Shear Bond test;

- n indicates the number of the specimen within each specimen group.

2.1. Characterization of Constituent Materials

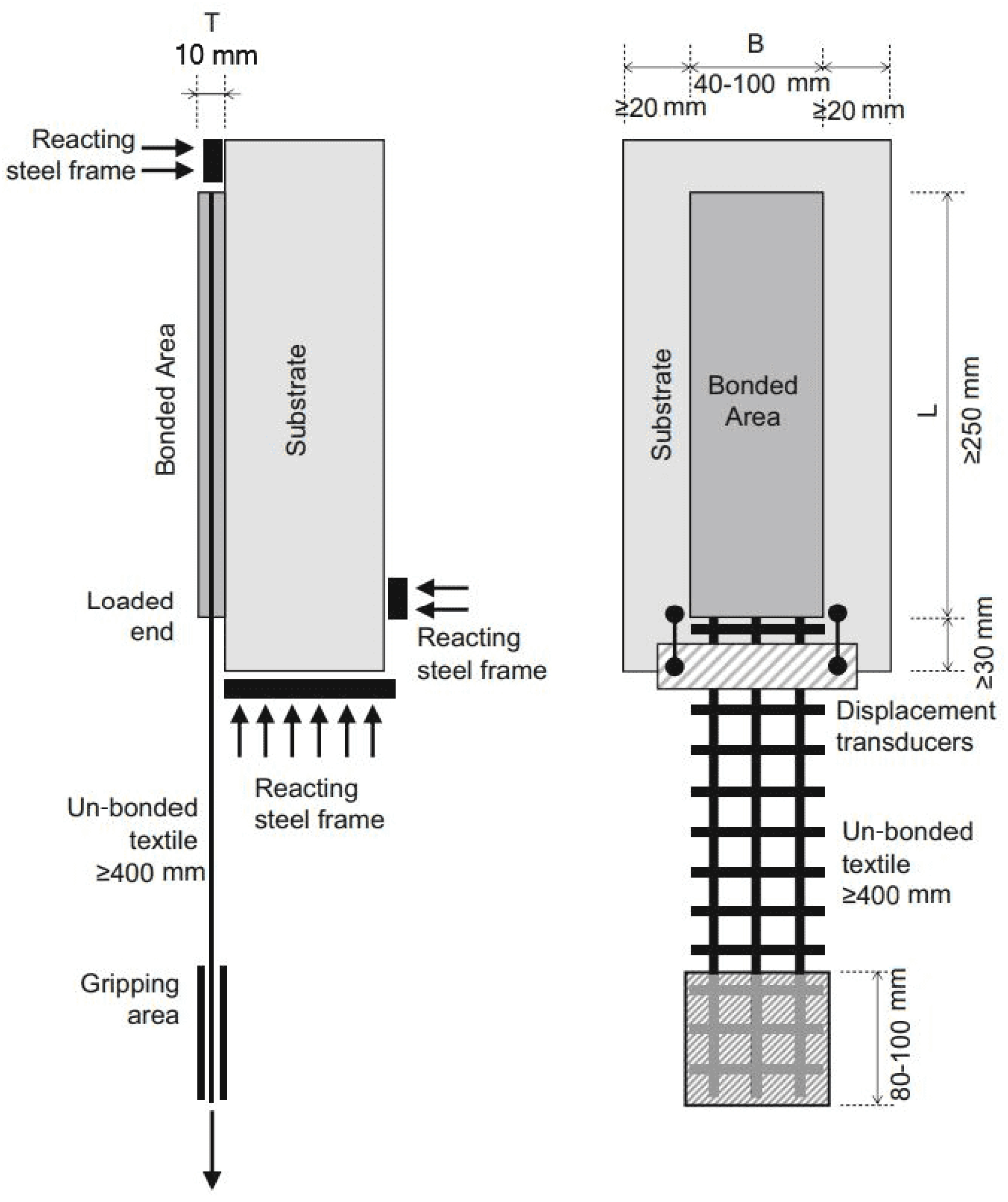

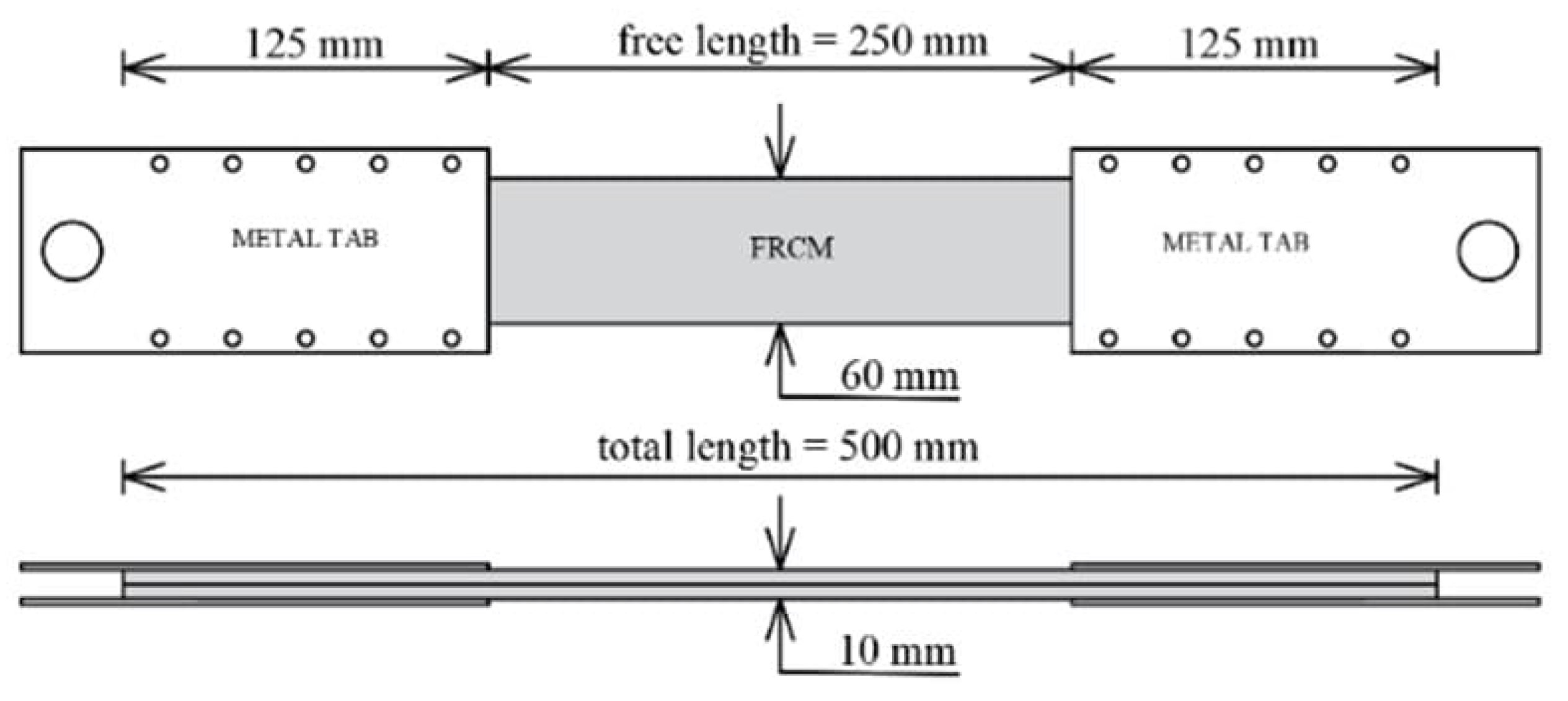

2.2. Specimens and Details for Double-Shear Bond Test Setup

3. Results from Material Characterization

4. Double-Shear Bond Experimental Tests: Main Results

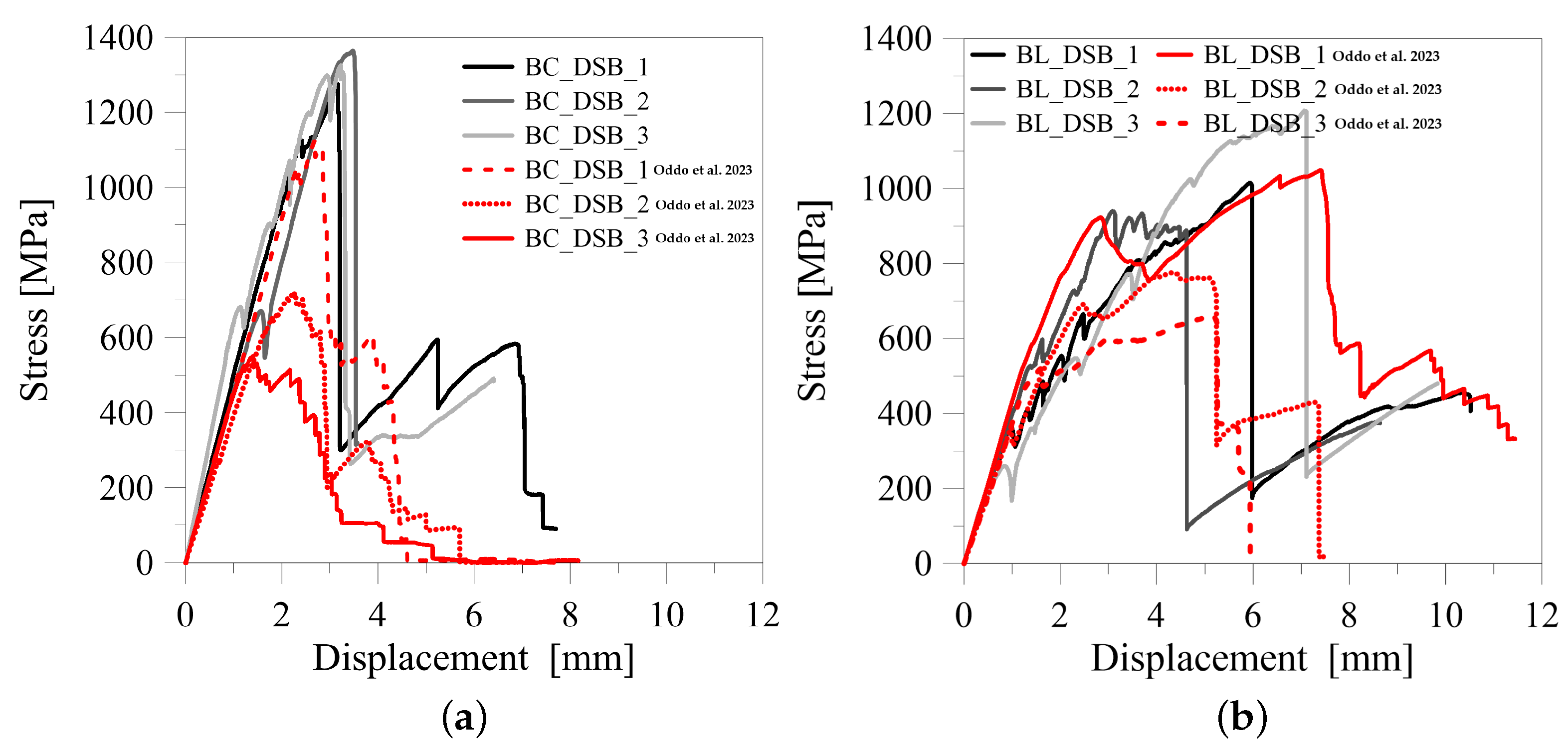

4.1. Stresses and Corresponding Displacements

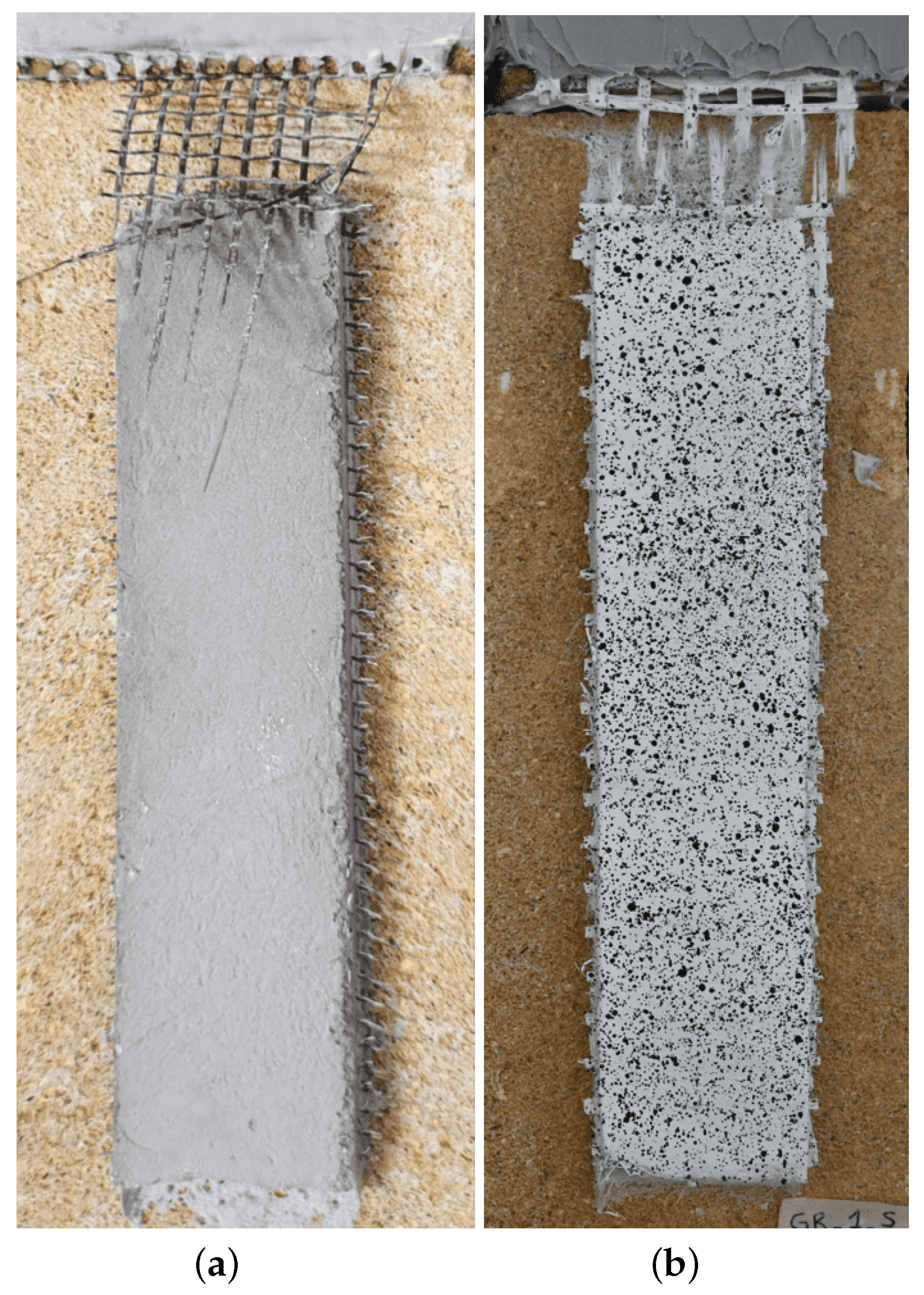

4.2. Failure Modes

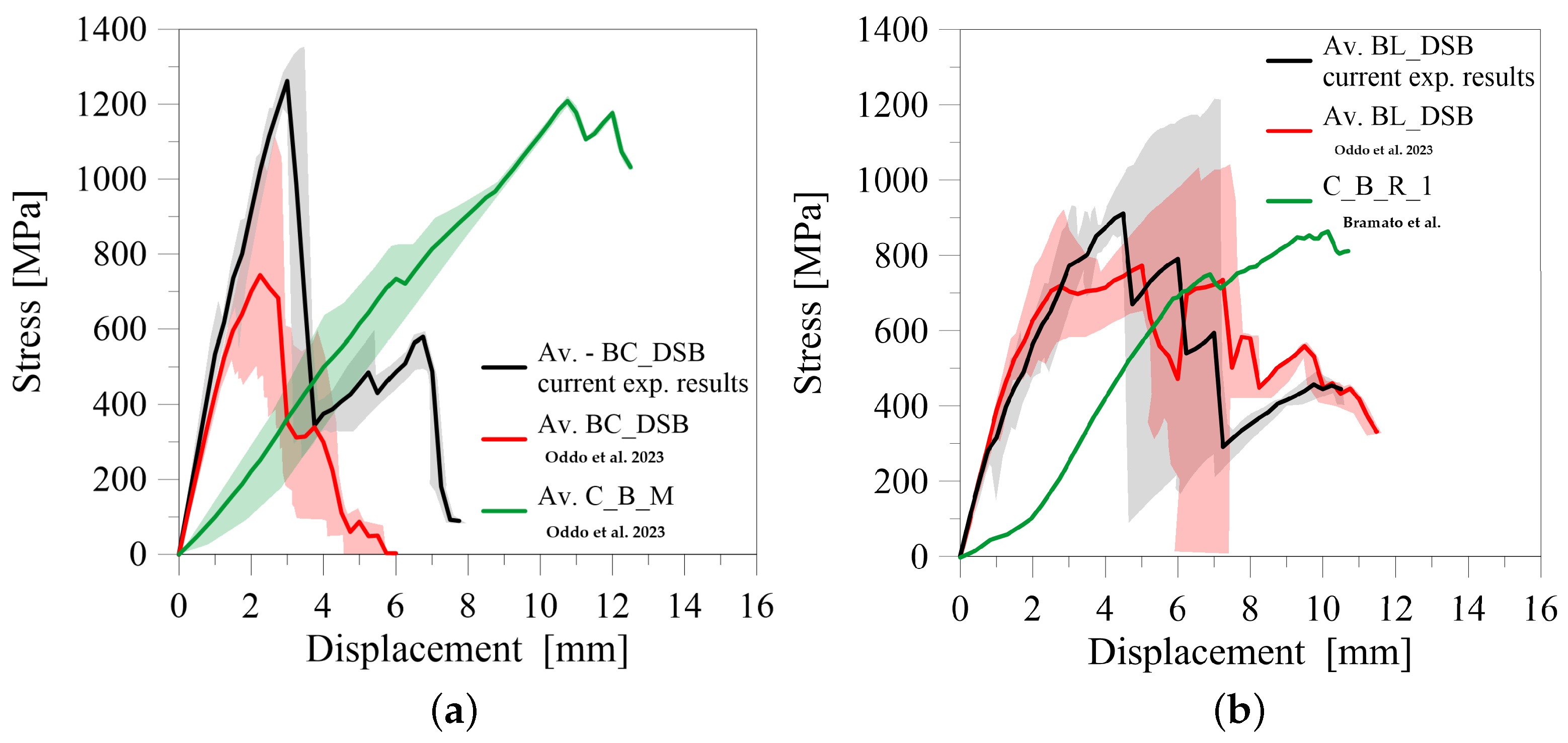

5. Comparisons and Discussion

6. Conclusions

- The type of mortar significantly affects bond properties at the fiber–mortar interface and thus, the behavior of FRCM systems. Coated basalt textiles exhibit limited adhesion with lime-based mortar, while glass textiles demonstrate good adhesion with lime-based mortar, and both glass and coated basalt textiles exhibit strong adhesion with cement-based mortar. The lime-based BFRCM facilitated gradual energy dissipation over abrupt failure modes, thereby avoiding the sudden energy release associated with fiber rupture and allowing for the energy-consuming mechanism of gradual fiber slippage.

- Experimental results show a minimal influence of the calcarenite support, primarily evident when significant interface mechanisms develop at the fiber–matrix level.

- Double-shear bond tests, with a non-standard setup configuration, proved to be repeatable and reproducible, especially in terms of peak strength. Low scatter is observed, except in cases such as specimens of GFRCM with lime-based mortar where manufacturing-related issues arise due to the sensitivity of dry fiber textiles to alignment problems. This sensitivity prevents the reinforcement system from effectively redistributing loads when the most stressed fiber yarns fail.

- The number of specimens tested herein is admittedly limited and more specimens should be tested to statistically validate the results; additionally, there is a size-dependent scattering effect (also present in other shear bond test configurations) that needs to be further investigated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cucuzza, R.; Domaneschi, M.; Camata, G.; Marano, G.C.; Formisano, A.; Brigante, D. FRCM retrofitting techniques for masonry walls: A literature review and some laboratory tests. Procedia Struct. Integr. 2023, 44, 2190–2197. [Google Scholar] [CrossRef]

- Yuan, Y.; Milani, G. Double shooting method for FRCM reinforced systems in debonding problems. Compos. Struct. 2024, 339, 118136. [Google Scholar] [CrossRef]

- Lignola, G.P.; Manfredi, G.; Prota, A. Effects of Defects on Masonry Confinement with Inorganic Matrix Composites. Materials 2023, 16, 4737. [Google Scholar] [CrossRef] [PubMed]

- Del Zoppo, M.; Di Ludovico, M.; Balsamo, A.; Prota, A. Fibre reinforced mortars for the out-of-plane strengthening of masonry walls. Procedia Struct. Integr. 2023, 44, 2158–2165. [Google Scholar] [CrossRef]

- D’Antino, T.; Bertolli, V.; Cagnoni, A.; Calabrese, A.S.; Poggi, C. Bending and shear behavior of historic walls strengthened with composite reinforced mortar. In Proceedings of the 11th International Conference on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), Rio de Janeiro, Brazil, 23–26 July 2023; Harries, K., Cardoso, D.C.T., Silva, F.A., Eds.; pp. 1–10. [Google Scholar]

- Maddaloni, G.; Cascardi, A.; Balsamo, A.; Di Ludovico, M.; Micelli, F.; Aiello, M.A.; Prota, A. Confinement of full-scale masonry columns with FRCM systems. Key Eng. Mater. 2017, 747, 374–381. [Google Scholar] [CrossRef]

- Aiello, M.A.; Cascardi, A.; Ombres, L.; Verre, S. Confinement of masonry columns with the FRCM-system: Theoretical and experimental investigation. Infrastructures 2020, 5, 101. [Google Scholar] [CrossRef]

- Di Ludovico, M.; Cascardi, A.; Balsamo, A.; Aiello, M.A. Uniaxial experimental tests on full-scale limestone masonry columns confined with glass and basalt FRCM systems. J. Compos. Constr. 2020, 24, 04020050. [Google Scholar] [CrossRef]

- Saidi, M.; Gabor, A. Use of distributed optical fibre as a strain sensor in textile reinforced cementitious matrix composites. Measurement 2019, 140, 323–333. [Google Scholar] [CrossRef]

- Grande, E.; Milani, G.; Imbimbo, M. Theoretical model for the study of the tensile behavior of FRCM reinforcements. Constr. Build. Mater. 2020, 236, 117617. [Google Scholar] [CrossRef]

- Reboul, N.; Saidi, M.; Mualla, S.; Homoro, O.; Amziane, S. Bond behaviour of Fibre Reinforced Polymers applied on masonry substrate: Analysis based on acoustic emission, digital image correlation and analytical modelling. Constr. Build. Mater. 2023, 403, 132921. [Google Scholar] [CrossRef]

- Rotunno, T.; Fagone, M.; Grande, E.; Milani, G. FRCM-to-masonry bonding behaviour in the case of curved surfaces: Experimental investigation. Compos. Struct. 2023, 313, 116913. [Google Scholar] [CrossRef]

- Bramato, G.; Leone, M.; Ceroni, F.; Oddo, M.C.; Minafò, G.; Aiello, M.A.; La Mendola, L. State of the art on bond between frcm systems and masonry/concrete substrate: Database analysis and improved models. Procedia Struct. Integr. 2023, 44, 2310–2317. [Google Scholar] [CrossRef]

- D’Ambrisi, A.; Feo, L.; Focacci, F. Experimental analysis on bond between PBO-FRCM strengthening materials and concrete. Compos. Part B Eng. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Sneed, L.; D’Antino, T.; Carloni, C.; Pellegrino, C. A comparison of the bond behavior of PBO-FRCM composites determined by double-lap and single-lap shear tests. Cem. Concr. Compos. 2015, 64, 37–48. [Google Scholar] [CrossRef]

- Olivito, R.S.; Codispoti, R.; Cevallos, O.A. Bond behavior of Flax-FRCM and PBO-FRCM composites applied on clay bricks: Experimental and theoretical study. Compos. Struct. 2016, 146, 221–231. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Nigro, E.; Pecce, M. Experimental tests on FRCM strengthening systems for tuff masonry elements. Constr. Build. Mater. 2017, 138, 114–133. [Google Scholar] [CrossRef]

- Leone, M.; Aiello, M.A.; Balsamo, A.; Carozzi, F.G.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P.; et al. Glass fabric reinforced cementitious matrix: Tensile properties and bond performance on masonry substrate. Compos. Part B Eng. 2017, 127, 196–214. [Google Scholar] [CrossRef]

- Garbin, E.; Panizza, M.; Valluzzi, M.R. Experimental Characterization of Glass and Carbon FRCMs for Masonry Retrofitting. ACI Spec. Publ. 2018, 324, 3.1–3.20. [Google Scholar]

- CSLLPP. Italian Standards: Guideline for the Identification, Qualification and Acceptance Control of Fibre Reinforced Cementitious Matrix (FRCM) Used for the Structural Consolidation of Existing Constructions; CSLLPP: Rome, Italy, 2018. [Google Scholar]

- De Felice, G.; Aiello, M.A.; Caggegi, C.; Ceroni, F.; De Santis, S.; Garbin, E.; Gattesco, N.; Hojdys, Ł.; Krajewski, P.; Kwiecień, A.; et al. Recommendation of RILEM Technical Committee 250-CSM: Test method for Textile Reinforced Mortar to substrate bond characterization. Mater. Struct. 2018, 51, 1–9. [Google Scholar] [CrossRef]

- Ascione, L.; de Felice, G.; De Santis, S. A qualification method for externally bonded Fibre Reinforced Cementitious Matrix (FRCM) strengthening systems. Compos. Part B Eng. 2015, 78, 497–506. [Google Scholar] [CrossRef]

- De Santis, S.; Hadad, H.A.; De Caso y Basalo, F.; de Felice, G.; Nanni, A. Acceptance criteria for tensile characterization of fabric-reinforced cementitious matrix systems for concrete and masonry repair. J. Compos. Constr. 2018, 22, 04018048. [Google Scholar] [CrossRef]

- Ekenel, M.; y Basalo, F.D.C.; Nanni, A. Acceptance criteria for concrete and masonry strengthening using fabric-reinforced cementitious matrix (FRCM) and steel reinforced grout (SRG) composites. ACI Spec. Publ. 2018, 324, 4.1–4.6. [Google Scholar]

- AC434:2013; AC434-ICC-Evaluation Service: Acceptance Criteria for Masonry and Concrete Strengthening Using Fiber-Reinforced Cementitious Matrix (FRCM) Composite Systems. ICC Evaluation. Services, Inc.: Los Angeles, CA, USA, 2013.

- Carozzi, F.G.; Arboleda, D.; Poggi, C.; Nanni, A. Direct shear bond tests of fabric-reinforced cementitious matrix materials. J. Compos. Constr. 2020, 24, 04019061. [Google Scholar] [CrossRef]

- Bellini, A.; Aiello, M.A.; Bencardino, F.; de Carvalho Bello, C.B.; Castori, G.; Cecchi, A.; Ceroni, F.; Corradi, M.; D’Antino, T.; De Santis, S.; et al. Influence of different set-up parameters on the bond behavior of FRCM composites. Constr. Build. Mater. 2021, 308, 124964. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; De Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.C.; Pellegrino, C.; Prota, A.; et al. Performance assessment of basalt FRCM for retrofit applications on masonry. Compos. Part B Eng. 2017, 128, 1–18. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; de Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecień, A.; Lignola, G.P.; Morganti, M.; Santandrea, M.; Valluzzi, M.R.; et al. Round Robin Test on tensile and bond behaviour of Steel Reinforced Grout systems. Compos. Part B Eng. 2017, 127, 100–120. [Google Scholar] [CrossRef]

- Accardi, M.; Cucchiara, C.; La Mendola, L. Bond behavior between CFRP strips and calcarenite stone. In Proceedings of the 6th International Conference on Fracture Mechanics of Concrete and Concrete Structures, Catania, Italy, 17–22 June 2007; pp. 17–22. [Google Scholar]

- Oddo, M.C.; Minafò, G.; La Mendola, L. Experimental investigation on tensile and shear bond behaviour of Basalt-FRCM composites for strengthening calcarenite masonry elements. Procedia Struct. Integr. 2023, 44, 2294–2301. [Google Scholar] [CrossRef]

- Bramato, G.; Leone, M.; Aiello, M.A. Bond behaviour of externally bonded BALSALT-FRCM system and calcareous stone. Procedia Struct. Integr. 2023, 44, 2302–2309. [Google Scholar] [CrossRef]

- Minafò, G.; La Mendola, L. Experimental investigation on the effect of mortar grade on the compressive behaviour of FRCM confined masonry columns. Compos. Part B Eng. 2018, 146, 1–12. [Google Scholar] [CrossRef]

- UNI EN ISO 13934-1; Determination of Tensile Strength of Textile Fabric with Universal Tensile Strength Test Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- UNI EN 1015-11; Methods of Test for Mortar for Masonry–Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. International Organization for Standardization: Geneva, Switzerland, 2001.

- RILEM Technical Committee 232-TDT (Wolfgang Brameshuber). Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete: Uniaxial tensile test: Test method to determine the load bearing behavior of tensile specimens made of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- Grande, E.; Milani, G. Interface modeling approach for the study of the bond behavior of FRCM strengthening systems. Compos. Part B Eng. 2018, 141, 221–233. [Google Scholar] [CrossRef]

- Nerilli, F.; Marfia, S.; Sacco, E. Nonlocal damage and interface modeling approach for the micro-scale analysis of FRCM. Comput. Struct. 2021, 254, 106582. [Google Scholar] [CrossRef]

- De Felice, G.; D’Antino, T.; De Santis, S.; Meriggi, P.; Roscini, F. Lessons learned on the tensile and bond behavior of fabric reinforced cementitious matrix (FRCM) composites. Front. Built Environ. 2020, 6, 5. [Google Scholar] [CrossRef]

- Calabrese, A.S.; D’Antino, T.; Colombi, P.; Poggi, C. Study of the influence of interface normal stresses on the bond behavior of FRCM composites using direct shear and modified beam tests. Constr. Build. Mater. 2020, 262, 120029. [Google Scholar] [CrossRef]

| Specimen ID | Number of Specimens | Fiber Type | Mortar Type |

|---|---|---|---|

| BC_DSB_n | 3 | Basalt | Cement-based |

| BL_DSB_n | 3 | Basalt | Lime-based |

| GC_DSB_n | 3 | Glass | Cement-based |

| GL_DSB_n | 3 | Glass | Lime-based |

| Fiber Grid | Average Tensile Strength [MPa] | Average Ultimate Strain [%] | Average Elastic Modulus [GPa] |

|---|---|---|---|

| Basalt | 1142.2 | 1.61 | 71.8 |

| COV | (14.3%) | (13.6%) | (5.7%) |

| Glass | 665.4 | 1.09 | 70.8 |

| COV | (10.2%) | (10.9%) | (9.7%) |

| Mortar Type | Average Flexural Strength [MPa] (COV) | Average Compressive Strength [MPa] (COV) |

|---|---|---|

| Cement-based (batch a) | 6.6 (6.1%) | 40.7 (1.2%) |

| Cement-based (batch b) | 6.2 (8.3%) | 35.6 (6.1%) |

| Lime-based (batch a) | 6.6 (6.1%) | 16.2 (9.3%) |

| Lime-based (batch b) | 4.3 (7.3%) | 18.1 (0.8%) |

| FRCM System | First Crack Stress [MPa] | Peak Stress [MPa] | Strain at Peak Stress [%] | Slope of Third Stage [GPa] | Exploitation Ratio of Fiber [-] |

|---|---|---|---|---|---|

| BC_TH | 995.4 | 1161.6 | 0.36 | nd | 1.02 |

| BL_TH | 562.5 | 1268.9 | 1.69 | 69.0 | 1.11 |

| GC_TH | 1100.2 | 1271.8 | 0.29 | nd | 1.91 |

| GL_TH | 695.9 | 1127.9 | 0.85 | 63.0 | 1.70 |

| Sample ID | Peak Strength [MPa] | Disp. at Peak Strength [mm] | Exploitation Ratio vs. Fibre [-] | Exploitation Ratio vs. Composite [-] | Failure Mode |

|---|---|---|---|---|---|

| BC_DSB_1 | 1274.3 | 3.17 | 1.12 | 1.10 | E2 |

| BC_DSB_2 | 1364.3 | 3.48 | 1.19 | 1.17 | E1 |

| BC_DSB_3 | 1324.5 | 3.23 | 1.16 | 1.14 | E1 |

| Average | 1321.0 | 3.29 | 1.16 | 1.14 | |

| COV | (2.8%) | (4.1%) | (2.8%) | (2.8%) | |

| BL_DSB_1 | 1015.0 | 5.94 | 0.89 | 0.80 | D/C |

| BL_DSB_2 | 939.6 | 3.11 | 0.82 | 0.74 | C/A |

| BL_DSB_3 | 1207.7 | 7.06 | 1.06 | 0.95 | C/A |

| Average | 1054.1 | 5.37 | 0.92 | 0.83 | |

| COV | (10.7%) | (31.0%) | (10.7%) | (10.7%) | |

| GC_DSB_1 | 712.9 | 3.67 | 1.07 | 0.56 | E1 |

| GC_DSB_2 | 279.6 * | 2.43 * | 0.42 * | 0.22 * | E1 |

| GC_DSB_3 | 558.8 | 2.69 | 0.84 | 0.44 | E1 |

| Average | 635.9 | 3.18 | 0.96 | 0.50 | |

| COV | (12.1%) | (15.3%) | (12.1%) | (12.1%) | |

| GL_DSB_1 | 394.6 | 1.17 | 0.59 | 0.35 | E1 |

| GL_DSB_2 | 447.8 | 1.79 | 0.67 | 0.40 | E1 |

| GL_DSB_3 | 129.0 | 0.94 | 0.19 | 0.11 | E1 |

| Average | 323.8 | 1.30 | 0.49 | 0.29 | |

| COV | (43.1%) | (27.8%) | (43.1%) | (43.1%) |

| Symbol for Failure Mode | Description |

|---|---|

| A | Cohesive debonding of the cementitious matrix at the contact layer with calcarenite stone |

| C | Debonding of the fabric fibers |

| D | Textile slippage in the cementitious matrix |

| E1 | Rupture of the textile out of the cementitious matrix |

| E2 | Rupture of the textile in the matrix |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oddo, M.C.; Cavaleri, L.; Papanicolaou, C.; La Mendola, L. Experimental Characterization of Fabric-Reinforced Cementitious Matrix (FRCM) Systems Applied on Calcarenite Stone: Adoption of Non-Standard Setup for Double-Shear Bond Tests. J. Compos. Sci. 2024, 8, 206. https://doi.org/10.3390/jcs8060206

Oddo MC, Cavaleri L, Papanicolaou C, La Mendola L. Experimental Characterization of Fabric-Reinforced Cementitious Matrix (FRCM) Systems Applied on Calcarenite Stone: Adoption of Non-Standard Setup for Double-Shear Bond Tests. Journal of Composites Science. 2024; 8(6):206. https://doi.org/10.3390/jcs8060206

Chicago/Turabian StyleOddo, Maria Concetta, Liborio Cavaleri, Catherine Papanicolaou, and Lidia La Mendola. 2024. "Experimental Characterization of Fabric-Reinforced Cementitious Matrix (FRCM) Systems Applied on Calcarenite Stone: Adoption of Non-Standard Setup for Double-Shear Bond Tests" Journal of Composites Science 8, no. 6: 206. https://doi.org/10.3390/jcs8060206