Design of an Overhead Crane in Steel, Aluminium and Composite Material Using the Prestress Method

Abstract

:1. Introduction

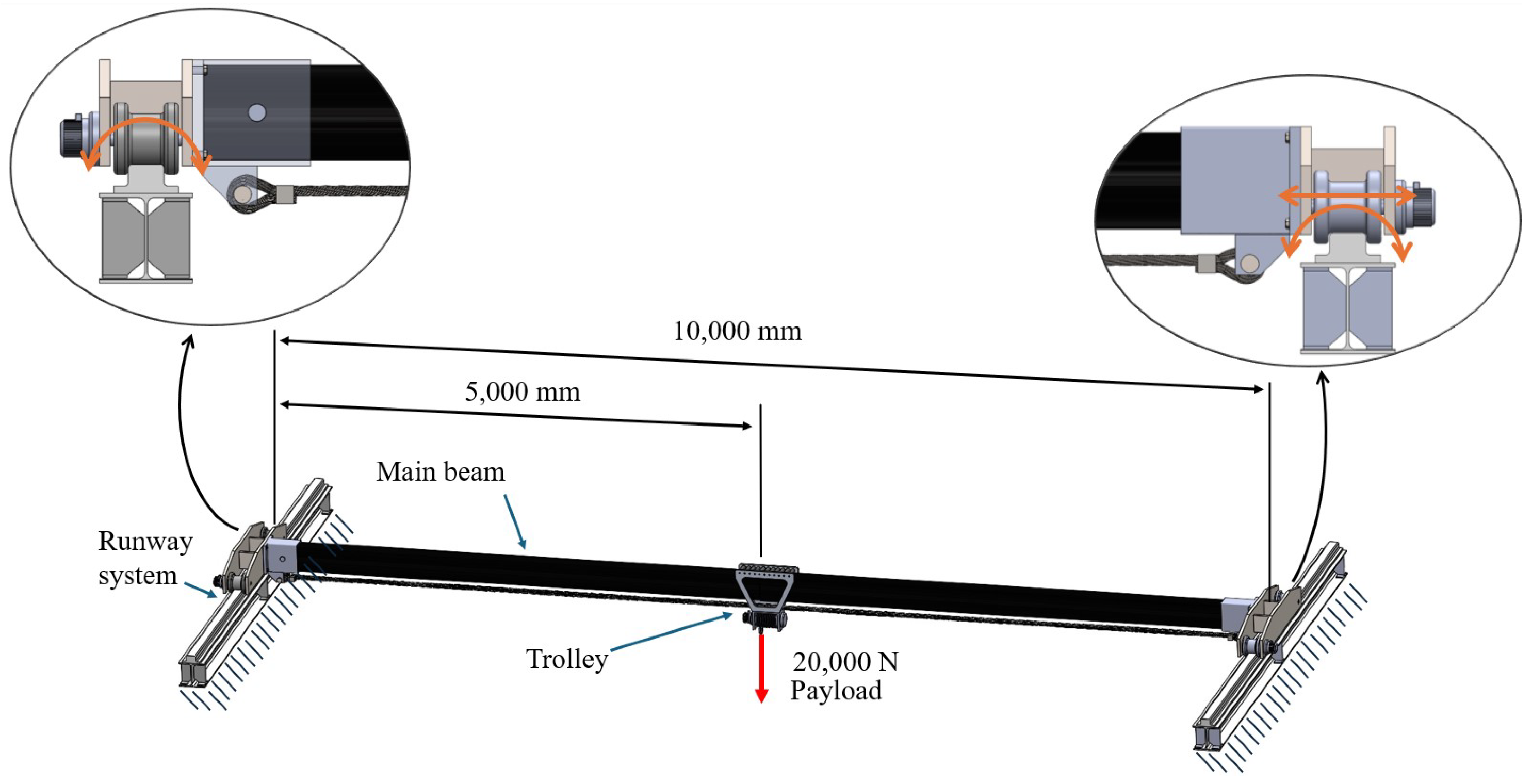

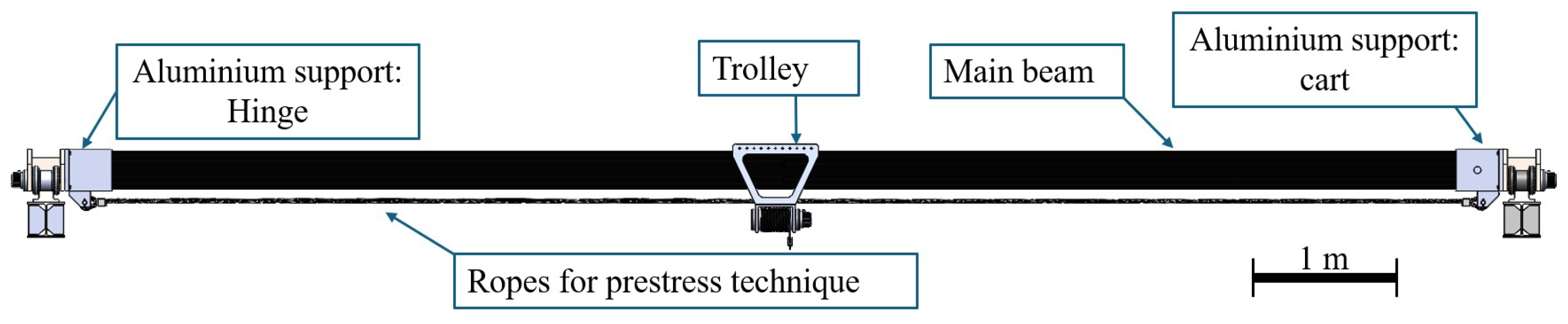

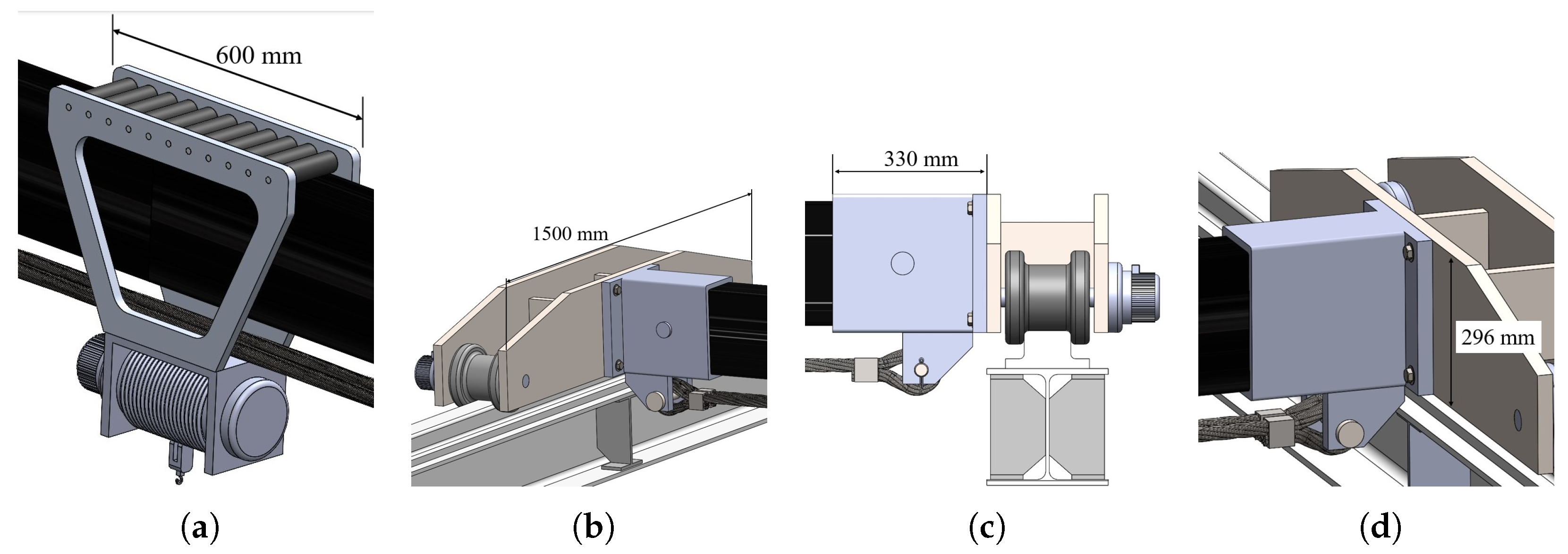

2. Description of the Overhead Crane

- A bridge structure that spans the width of the area where the crane operates. This element is typically a beam; it supports the runway system and provides a stable platform for the movement of the hoist and trolley.

- A runway system described as parallel steel beams secured to the building structure. This system ensures that the crane can move smoothly and safely along its designated path.

- End trucks mounted on either end of the bridge; they house the wheels or rollers that enable the crane to travel along the runway beams.

- The hoist assembly responsible for lifting and lowering loads. It consists of a motorized hoist unit mounted on the bridge, connected to a lifting mechanism.

- A trolley mounted on the bridge. It moves horizontally along the length of the bridge, and it provides lateral movement for positioning the hoist assembly precisely within the working area.

3. Design Methodology

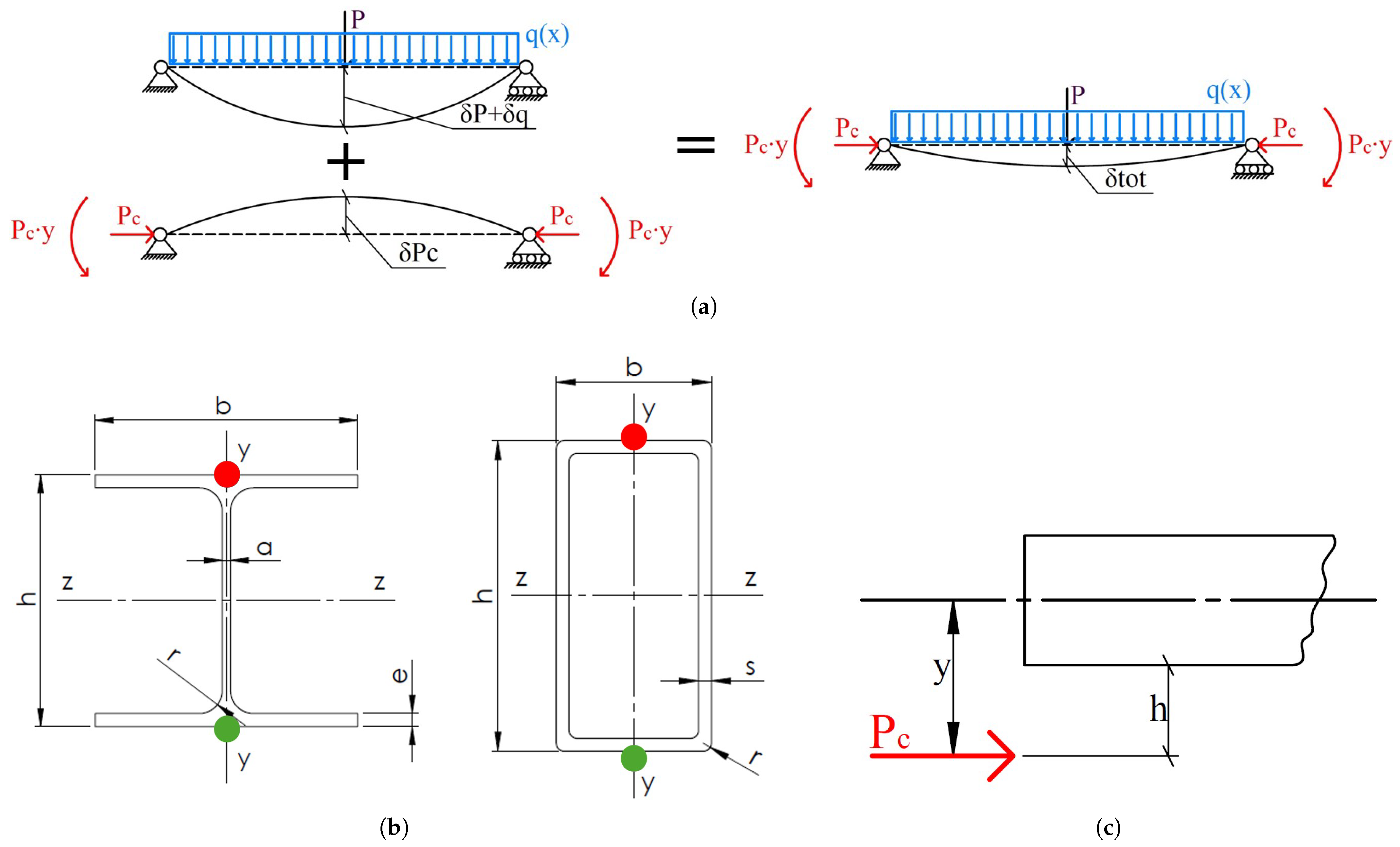

3.1. Analytical Design Theory

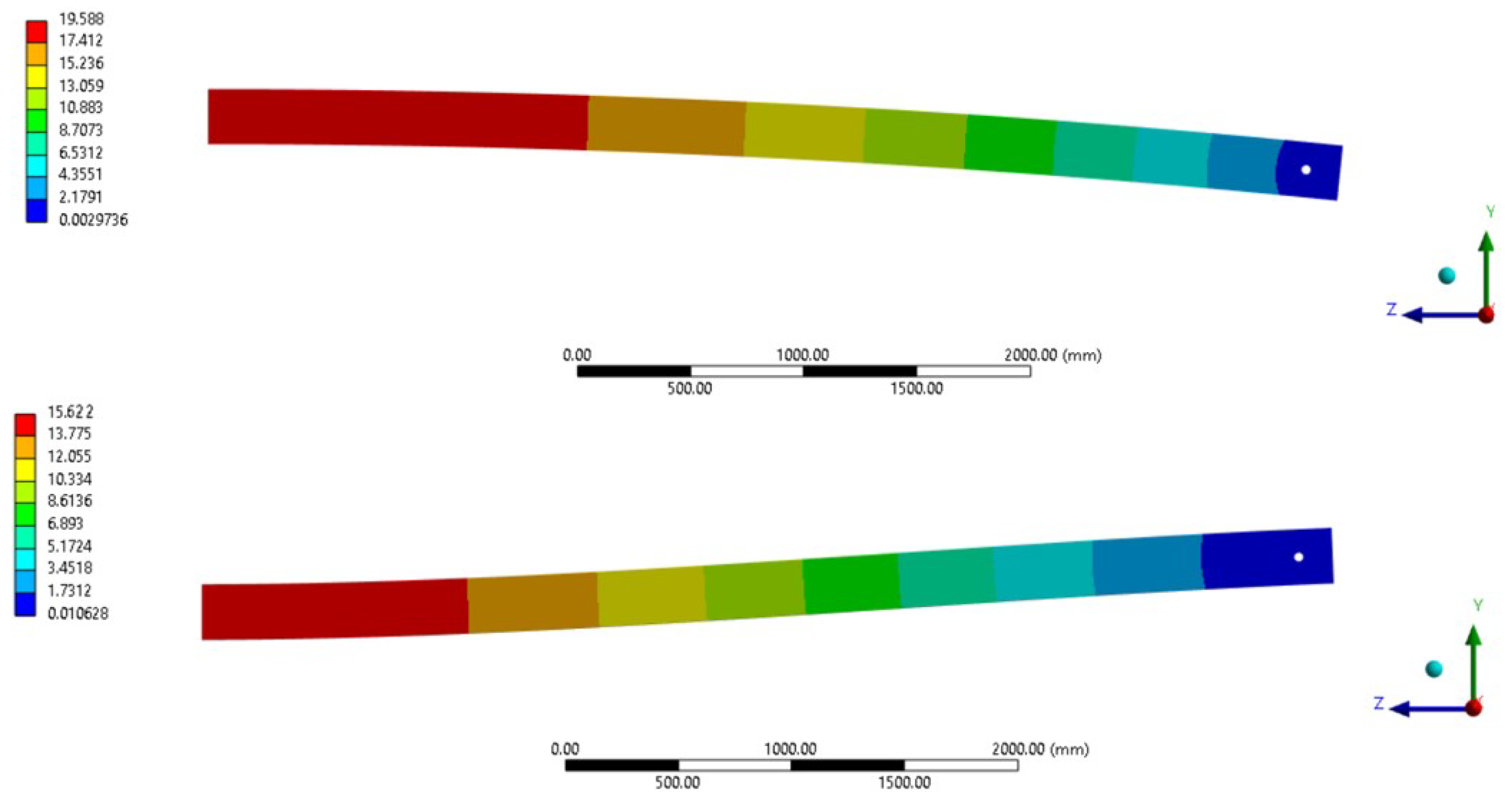

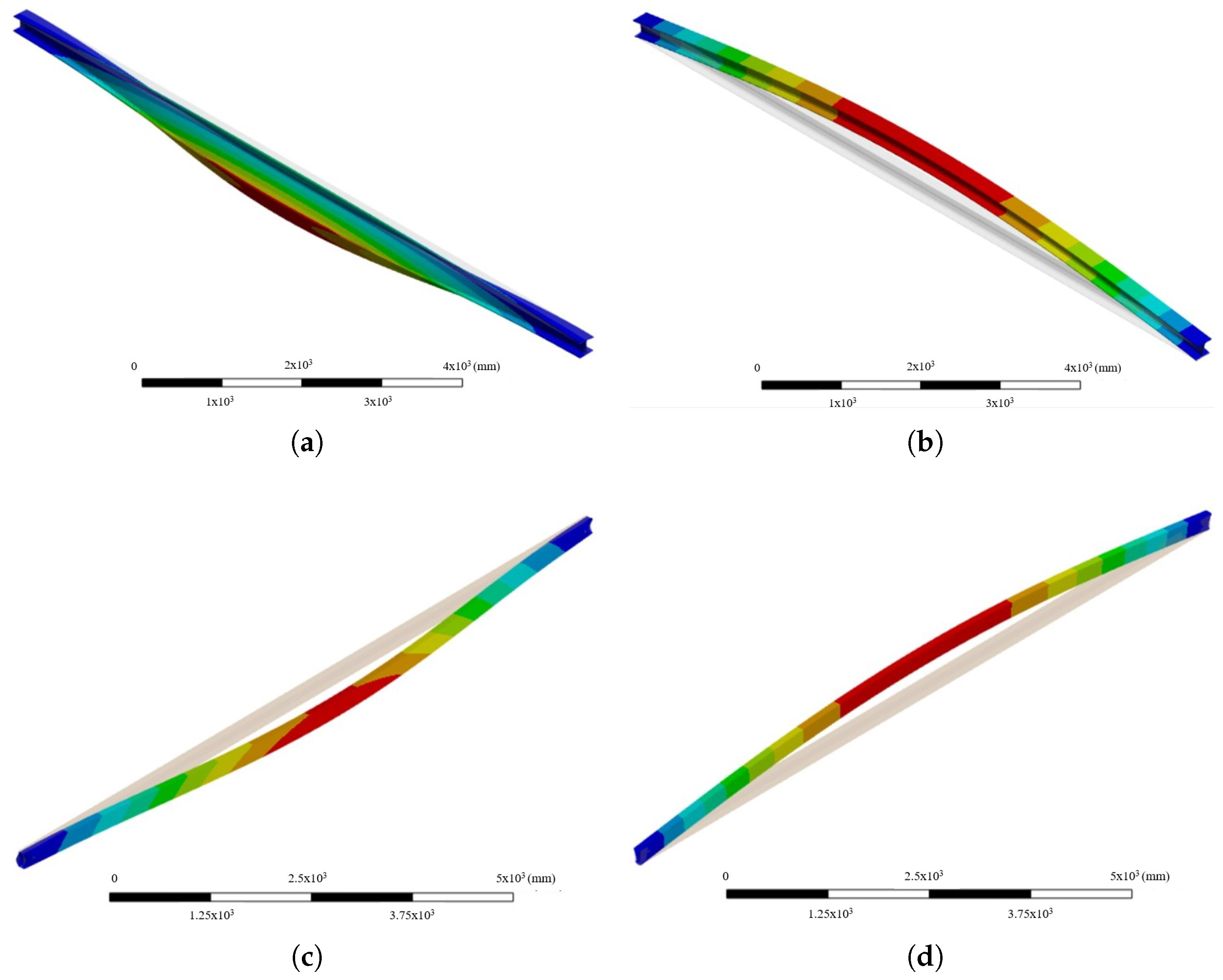

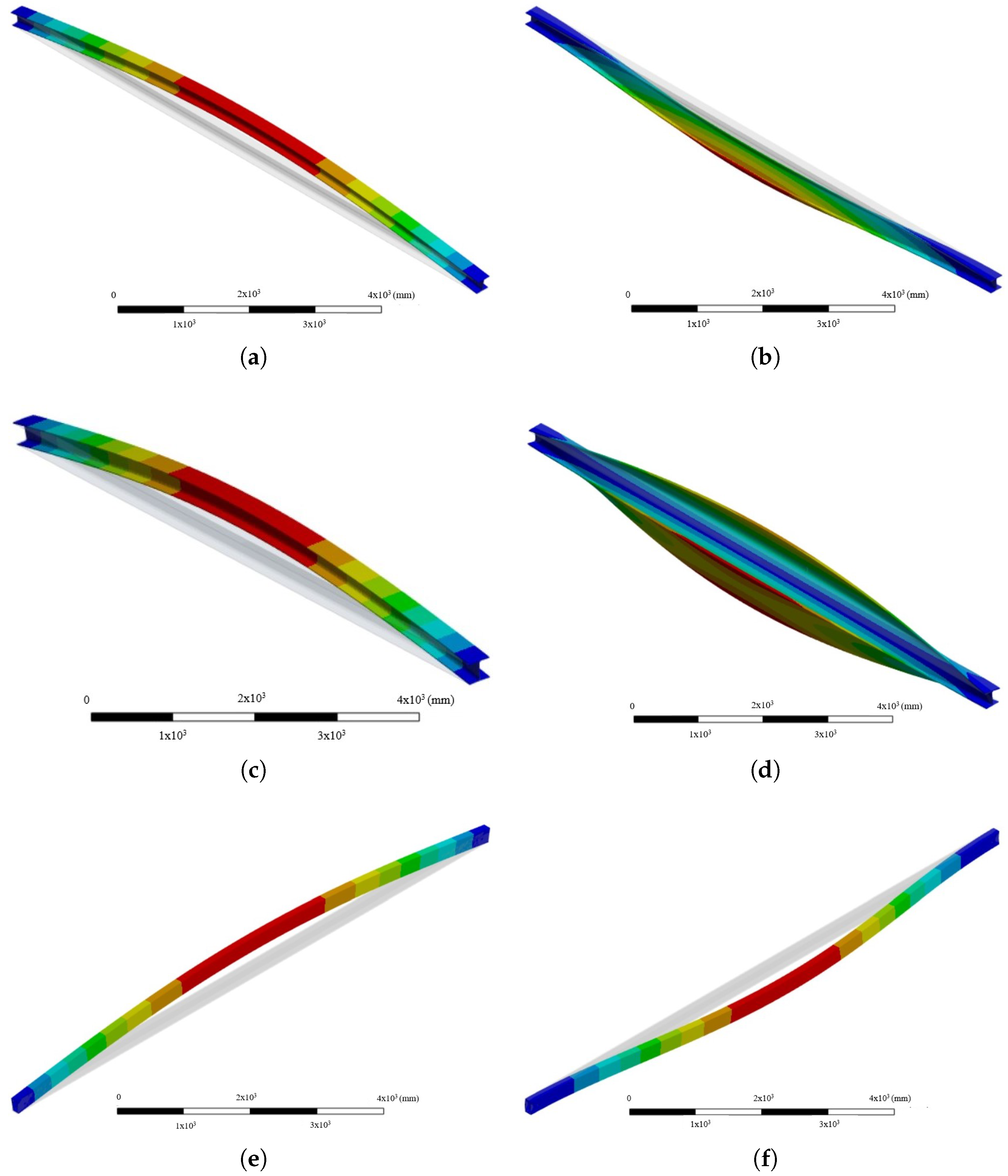

3.1.1. Evaluation of Stress and Displacement

3.1.2. Buckling Analysis

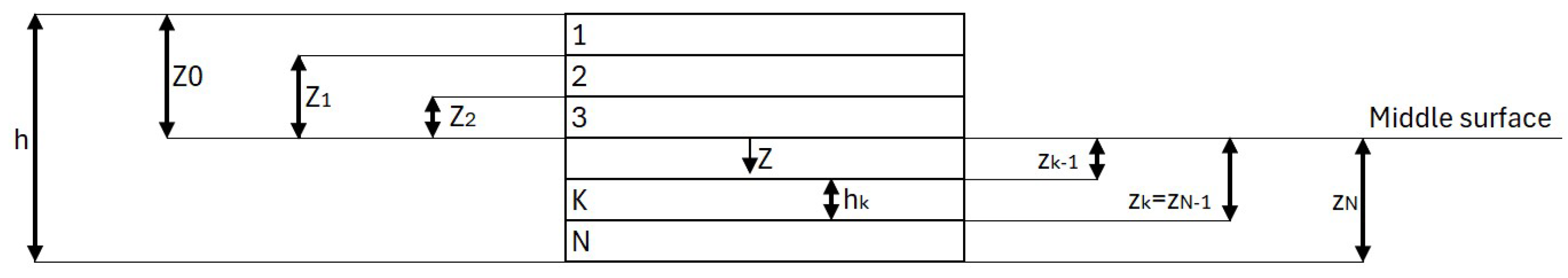

3.2. Description of the Adopted Material

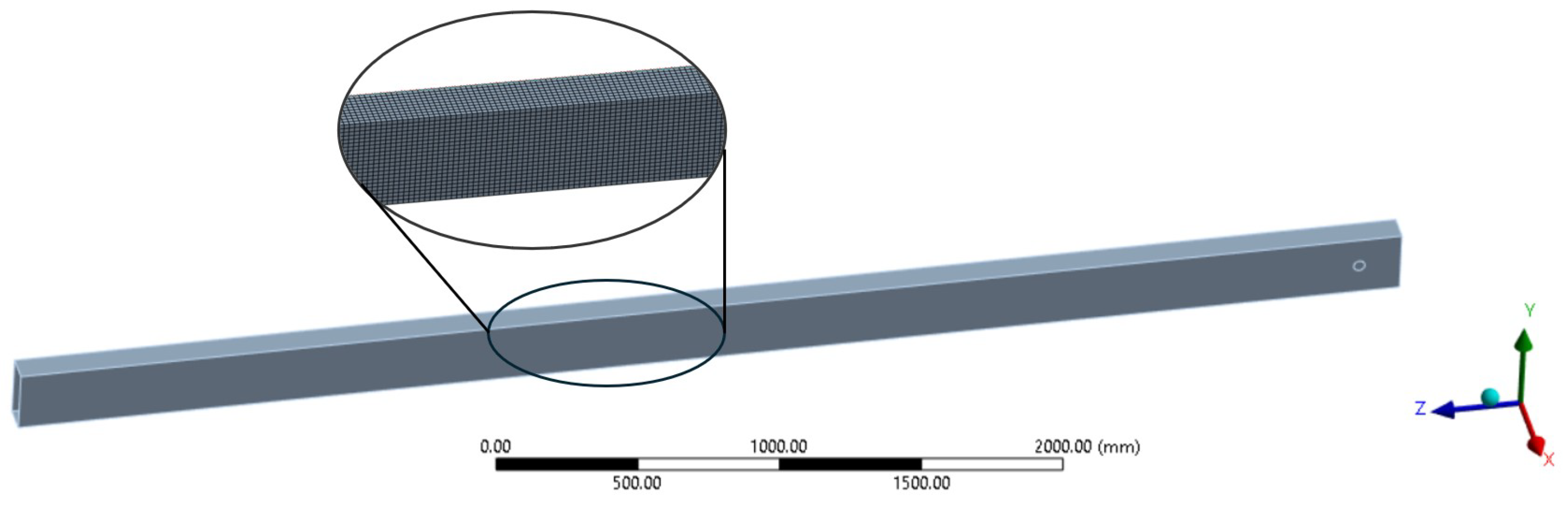

3.3. Design and FEM Analysis

4. Construction Methods

5. Results

6. Conclusions

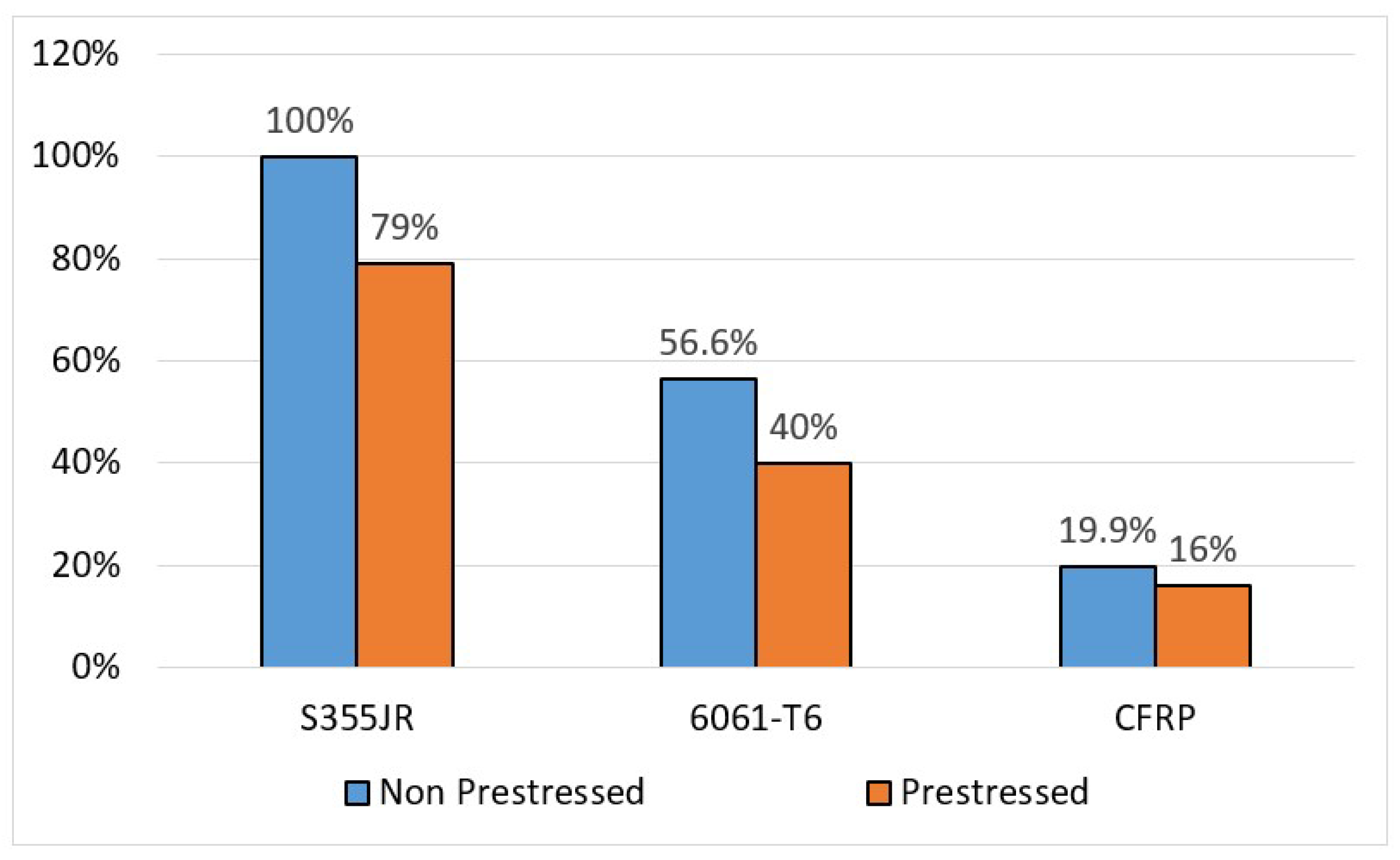

- The prestress methodology can be applied to the design of heavy industrial structures, offering benefits for lightweight design.

- The implementation of innovative materials, such as composite materials, can be adopted for these specific structures, achieving results similar to steel in terms of deflection but with a much lower density, and therefore, lower mass.

- The combination of the two methodologies can lead to a significant reduction in weight. For instance, when comparing the non-prestressed steel solution with the composite prestressed configuration, the latter weighs only 16% of the former.

- Electric motors powering the overhead crane require less effort.

- The lighter structure reduces inertia forces.

- The brake systems also benefit.

- The building itself, where the overhead crane is located, experiences less stress.

- The installation of the analyzed structure can be carried out with easier procedures compared to a heavier configuration.

- The successful implementation of these methodologies opens up possibilities for their application in other sectors of construction machinery. For instance, similar techniques could be adapted for different types of cranes, facilitating further advancements in the field.

Future Developments

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faruk, O.; Tjong, J.; Sain, M. (Eds.) Lightweight and Sustainable Materials for Automotive Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Mallick, P.K. (Ed.) Materials, Design and Manufacturing for Lightweight Vehicles; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar]

- Solazzi, L.; Assi, A.; Ceresoli, F. New design concept for an excavator arms by using composite material. Appl. Compos. Mater. 2018, 25, 601–617. [Google Scholar] [CrossRef]

- Santos, J.; Gouveia, R.M.; Silva, F.J.G. Designing a new sustainable approach to the change for lightweight materials in structural components used in truck industry. J. Clean. Prod. 2017, 164, 115–123. [Google Scholar] [CrossRef]

- Solazzi, L.; Scalmana, R. New design concept for a lifting platform made of composite material. Appl. Compos. Mater. 2013, 20, 615–626. [Google Scholar] [CrossRef]

- Bonopera, M.; Chang, K.C.; Lee, Z.K. State-of-the-art review on determining prestress losses in prestressed concrete girders. Appl. Sci. 2020, 10, 7257. [Google Scholar] [CrossRef]

- You, Z. Displacement control of prestressed structures. Comput. Methods Appl. Mech. Eng. 1997, 144, 51–59. [Google Scholar] [CrossRef]

- Kaur, H.; Jaspal, S. A review on external prestressing in concrete. Int. Res. J. Eng. Technol. 2017, 4, 1801–1805. [Google Scholar]

- Li, Z.M.; Qiao, P. Buckling and postbuckling of anisotropic laminated cylindrical shells under combined external pressure and axial compression in thermal environments. Compos. Struct. 2015, 119, 709–726. [Google Scholar] [CrossRef]

- Kumar, D.; Marchi, M.; Alam, S.B.; Kavka, C.; Koutsawa, Y.; Rauchs, G.; Belouettar, S. Multi-criteria decision making under uncertainties in composite materials selection and design. Compos. Struct. 2022, 279, 114680. [Google Scholar] [CrossRef]

- Solazzi, L. Feasibility study of a very big crawler crane using composite materials. Compos. Part C Open Access 2024, 13, 100430. [Google Scholar] [CrossRef]

- Suvorov, V.; Vasilyev, R.; Melnikov, B.; Kuznetsov, I.; Bahrami, M.R. Weight Reduction of a Ship Crane Truss Structure Made of Composites. Appl. Sci. 2023, 13, 8916. [Google Scholar] [CrossRef]

- Gąska, D.; Haniszewski, T. Modelling studies on the use of aluminium alloys in lightweight load-carrying crane structures. Transp. Probl. 2016, 11, 13–20. [Google Scholar] [CrossRef]

- Gu, J.P.; Qin, Y.X.; Xia, Y.Y.; Jiao, Q.Q.; Gao, H.B.; Zhang, Y.Y.; Zhang, H. Research on dynamic characteristics of composite towering structure. Int. J. Appl. Mech. 2021, 13, 2150096. [Google Scholar] [CrossRef]

- Alkin, C.; Imrak, C.E.; Kocabas, H. Solid modeling and finite element analysis of an overhead crane bridge. Acta Polytech. 2005, 45, 61–67. [Google Scholar] [CrossRef] [PubMed]

- Savković, M.M.; Bulatović, R.R.; Gašić, M.M.; Pavlović, G.V. Stepanović, A.Z. Optimization of the box section of the main girder of the single-girder bridge crane by applying biologically inspired algorithms. Eng. Struct. 2017, 148, 452–465. [Google Scholar] [CrossRef]

- Yildirim, Ş.; Emir, E. A new approach for dynamic analysis of overhead crane systems under moving loads. In CONTROLO 2016, Proceedings of the 12th Portuguese Conference on Automatic Control, Guimarães, Portugal, 14–16 September 2016; Springer International Publishing: Cham, Switzerland, 2017. [Google Scholar]

- Oellerich, J. Fundamentals for the Dimensioning and Optimization of Prestressed Segmented Girders for Application in Bridge Crane Systems; KIT Scientific Publishing: Karlsruhe, Germany, 2022; p. 242. [Google Scholar]

- Oellerich, J.; Büscher, K.J. Application of Segmented and Prestressed Supporting Structures in Bridge Crane Systems: Potentials and Challenges. Appl. Syst. Innov. 2023, 6, 105. [Google Scholar] [CrossRef]

- Solazzi, L.; Nicola, D. Jib crane lightweighting through composite material and prestressing technique. Compos. Struct. 2024, 343, 118283. [Google Scholar] [CrossRef]

- Solazzi, L.; Incerti, G.; Petrogalli, C. Estimation of the Dynamic Effect in the Lifting Operations of a Boom Crane. In Proceedings of the 28th European Conference on Modelling and Simulation, Brescia, Italy, 27–30 May 2014; pp. 309–315. [Google Scholar]

- Solazzi, L. Experimental and analytical study on elevating working platform. Procedia Eng. 2017, 199, 2597–2602. [Google Scholar] [CrossRef]

- Solazzi, L.; Buffoli, A. Fatigue design of hydraulic cylinder made of composite material. Compos. Struct. 2021, 277, 114647. [Google Scholar] [CrossRef]

- Nunziata, V. Strutture in Acciaio Precompresso; Dario Flaccovio: Palermo, Italy, 1999. [Google Scholar]

- Belletti, B.; Antonello, G. Behavior of prestressed steel beams. J. Ournal Struct. Eng. 2010, 136, 1131–1139. [Google Scholar] [CrossRef]

- Solazzi, L.; Buffoli, A.; Formicola, R. The multi-parametric weight optimization of a hydraulic actuator. Actuators 2020, 9, 60. [Google Scholar] [CrossRef]

- Öchsner, A. Classical Beam Theories of Structural Mechanics (Vol. 42); Springer: Cham, Switzerland, 2021. [Google Scholar]

- ISO 22986:2007(E); Cranes-Stiffness-Bridge and Gantry Cranes. International Organization for Standardization: Geneva, Switzerland, 2015.

- Jerath, S. Structural Stability Theory and Practice: Buckling of Columns, Beams, Plates, and Shells; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- da Silva, L.S.; Simoes, R.; Gervasio, H. Design of Steel Structures: Eurocode 3: Design of Steel Structures-General Rules and Rules for Buildings, 1st ed.; Wiley-Blackwell: Oxford, UK, 2013. [Google Scholar]

- Bloom, F.; Coffin, D. Handbook of Thin Plate Buckling and Postbuckling; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Falzon, B.G.; Aliabadi, M.F. Buckling and Postbuckling Structures: Experimental, Analytical and Numerical Studies (Vol. 1); World Scientific: Singapore, 2008. [Google Scholar]

- Dickel, T.; Klemens, H.P.; Rothert, H. Lateral torsional buckling coefficients. In Diagrams for Continuous Beams with Doubly Symmetric I-Sections; Vieweg: Braunschweig, Germany, 1991. [Google Scholar]

- Gonçalves, R. A geometrically exact approach to lateral-torsional buckling of thin-walled beams with deformable cross-section. Comput. Struct. 2012, 106, 9–19. [Google Scholar] [CrossRef]

- Piotrowski, R.; Szychowski, A. Lateral torsional buckling of steel beams elastically restrained at the support nodes. Appl. Sci. 2019, 9, 1944. [Google Scholar] [CrossRef]

- Trahair, N.S. Flexural-Torsional Buckling of Structures; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Han, H.; Dong, C. Buckling Analysis for Carbon and Glass Fibre Reinforced Hybrid Composite Stiffened Panels. J. Compos. Sci. 2024, 8, 34. [Google Scholar] [CrossRef]

- Wysmulski, P.; Katarzyna, F.; Przemyslaw, F. Buckling state analysis of compressed composite plates with cut-out. Compos. Struct. 2021, 274, 114345. [Google Scholar] [CrossRef]

- Belkacem, A.; Tahar, H.D.; Abderrezak, R.; Amine, B.M.; Mohamed, Z.; Boussad, A. Mechanical buckling analysis of hybrid laminated composite plates under different boundary conditions. Struct. Eng. Mech. Int. J. 2018, 66, 761–769. [Google Scholar]

- UNI EN 10027-1:2017; Designation Systems for Steels—Part 1: Steel Names. Ente Nazionale Italiano di Unificazione. 2017. Available online: https://store.uni.com (accessed on 3 September 2024).

- Ashby, M.F.; Cebon, D. Materials selection in mechanical design. Mrs Bull. 2005, 30, 995. [Google Scholar] [CrossRef]

- Collotta, M.; Solazzi, L.; Pandini, S.; Tomasoni, G. New design concept of a downhill mountain bike frame made of a natural composite material. Proc. Inst. Mech. Eng. Part P J. Sport. Eng. Technol. 2018, 232, 50–56. [Google Scholar] [CrossRef]

- Collotta, M.; Solazzi, L.; Pandini, S.; Tomasoni, G.; Alberti, M.; Donzella, G. Design and realization a skiff racing boat hull made of natural fibers reinforced composite. In AIP Conference Proceedings; AIP Publishing: New York, NY, USA, 2016; Volume 1736. [Google Scholar]

- Toray Composite Materials America Inc. M50J High Modulus Carbon Fiber. Available online: https://cdn.thomasnet.com/ccp/30164375/140079.pdf (accessed on 26 April 2024).

- Mates Italiana, Product Data Sheet: SX10. Available online: https://fileserver.mates.it/Prodotti/2_Matrici/TDS/Resine/Mates/SX10_DS.pdf (accessed on 26 April 2024).

- Jones, R.M. Mechanics of Composite Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Groenwold, A.A.; Haftka, R.T. Optimization with non-homogeneous failure criteria like Tsai–Wu for composite laminates. Struct. Multidiscip. Optim. 2006, 32, 183–190. [Google Scholar] [CrossRef]

- Aldoumani, N.; Giannetti, C.; Abdallah, Z.; Belblidia, F.; Khodaparast, H.H.; Friswell, M.I.; Sienz, J. Optimisation of the filament winding approach using a newly developed in-house uncertainty model. Eng 2020, 1, 8. [Google Scholar] [CrossRef]

- Solazzi, L. Reliability evaluation of critical local buckling load on the thin walled cylindrical shell made of composite material. Compos. Struct. 2022, 284, 115163. [Google Scholar] [CrossRef]

- de Jesus, A.M.; Matos, R.; Fontoura, B.F.; Rebelo, C.; da Silva, L.S.; Veljkovic, M. A comparison of the fatigue behavior between S355 and S690 steel grades. J. Constr. Steel Res. 2012, 79, 140–150. [Google Scholar] [CrossRef]

- Tiryakioğlu, M.; Eason, P.D.; Campbell, J. Fatigue life of ablation-cast 6061-T6 components. Mater. Sci. Eng. A 2013, 559, 447–452. [Google Scholar] [CrossRef]

- Vassilopoulos, A.P. (Ed.) Fatigue Life Prediction of Composites and Composite Structures; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Talreja, R.; Varna, J. (Eds.) Modeling Damage, Fatigue and Failure of Composite Materials; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Balasubramanian, M. Composite Materials and Processing; CRC press: Boca Raton, FL, USA, 2014; Volume 711. [Google Scholar]

- Covestro, A.G. Product Data Sheet: Solid Vulkollan®. Available online: https://solutions.covestro.com/-/media/covestro/solution-center/brands/downloads/imported/1582295025.pdf (accessed on 26 April 2024).

- Popp, J.; Drummer, D. Influence of the Textile Reinforcement on the Joint Formation of Pin-Joined Composite/Metal Parts. Appl. Compos. Mater. 2024, 31, 799–822. [Google Scholar] [CrossRef]

- Kovács, G.; Jozsef, F. Minimum cost design of overhead crane beam with box section strengthened by CFRP laminates. Struct. Eng. Mech. Int. J. 2017, 61, 475–481. [Google Scholar] [CrossRef]

| Material | Ultimate Tensile Strength | Yield Strength | Shear Modulus | Young’s Modulus | Density | Poisson’s Coefficient |

|---|---|---|---|---|---|---|

| − | [MPa] | [MPa] | [MPa] | [MPa] | [kg/m3] | |

| S355JR | 510 | 355 | 81,000 | 210,000 | 7800 | 0.29 |

| Al 6061-T6 | 310 | 275 | 27,000 | 69,000 | 2700 | 0.33 |

| Carbon Fibre | Epoxy Resin | |||

|---|---|---|---|---|

| Property | Symbol | Value | Symbol | Value |

| Density | 1880 kg/m3 | 1200 kg/m3 | ||

| Young modulus | 475 GPa | 3.3 GPa | ||

| Tensile strength | 4120 MPa | 65 MPa | ||

| Compressive strength | - | 120 MPa | ||

| Poisson ratio | 0.28 | 0.34 | ||

| Mechanical Property [MPa] | Symbol | Value |

|---|---|---|

| Longitudinal tensile elasticity modulus | 286,000 | |

| Transversal tensile elasticity modulus | 8160 | |

| Shear elasticity modulus | 3000 | |

| Longitudinal tensile strength | 2472 | |

| Transversal tensile strength | 45 | |

| Longitudinal compression strength | 880,000 | |

| Transversal compression strength | 99.2 | |

| Shear strength | S | 59 |

| [MPa] | [MPa] | [MPa] | |||

|---|---|---|---|---|---|

| CFRP | 215,000 | 46,000 | 17,250 | 0.36 | 0.08 |

| Material | Dimensions [mm] | Weight [kg] | Vertical Displacement [mm] () | |

|---|---|---|---|---|

| Analytical | Numerical | |||

| S355JR | HEA 280 | 758.66 | −17.88 | −18.24 |

| Al 6061-T6 | HEA 400 | 429.22 | −15.16 | −15.65 |

| CFRP | 300 × 150 × 11 | 151.4 | −18.74 | −19.55 |

| Material | Dimensions [mm] | Weight [kg] | Vertical Displacement [mm] | |||

|---|---|---|---|---|---|---|

| Without Payload () | With Payload () | |||||

| Analytical | Numerical | Analytical | Numerical | |||

| S355JR | HEA 240 | 599.32 | 10.26 | 10.20 | −15.31 | −15.64 |

| Al 6061-T6 | HEA 300 | 303.83 | 19.19 | 19.19 | −13.83 | −14.67 |

| CFRP | 244 × 122 × 11 | 121.69 | 19.52 | 19.58 | −14.80 | −15.62 |

| Material | Dimensions [mm] | Weight W [kg] | Payload P [kg] | Ratio [%] | |

|---|---|---|---|---|---|

| Non-prestressed configurations | S355JR | HEA 280 | 758.66 | 2038.74 | 37.21 |

| Al 6061-T6 | HEA 400 | 429.22 | 2038.74 | 21.05 | |

| CFRP | 300 × 150 × 11 | 151.4 | 2038.74 | 7.43 | |

| Prestressed configurations | S355JR | HEA 240 | 599.32 | 2038.74 | 29.39 |

| Al 6061-T6 | HEA 300 | 303.83 | 2038.74 | 14.91 | |

| CFRP | 244 × 122 × 11 | 121.69 | 2038.74 | 5.97 |

| S355JR | 6061-T6 | CFRP | |

|---|---|---|---|

| Weight [kg] | 758.66 | 429.22 | 151.40 |

| 100 | 56.6 | 19.9 |

| S355JR | 6061-T6 | CFRP | |

|---|---|---|---|

| Weight [kg] | 599.32 | 303.83 | 121.69 |

| 100 | 50.7 | 20.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solazzi, L.; Tomasi, I. Design of an Overhead Crane in Steel, Aluminium and Composite Material Using the Prestress Method. J. Compos. Sci. 2024, 8, 380. https://doi.org/10.3390/jcs8090380

Solazzi L, Tomasi I. Design of an Overhead Crane in Steel, Aluminium and Composite Material Using the Prestress Method. Journal of Composites Science. 2024; 8(9):380. https://doi.org/10.3390/jcs8090380

Chicago/Turabian StyleSolazzi, Luigi, and Ivan Tomasi. 2024. "Design of an Overhead Crane in Steel, Aluminium and Composite Material Using the Prestress Method" Journal of Composites Science 8, no. 9: 380. https://doi.org/10.3390/jcs8090380

APA StyleSolazzi, L., & Tomasi, I. (2024). Design of an Overhead Crane in Steel, Aluminium and Composite Material Using the Prestress Method. Journal of Composites Science, 8(9), 380. https://doi.org/10.3390/jcs8090380