Furnace Testing and Validation of a Hybrid Cooling Approach for Enhanced Turbine Blade Protection with a Thermal Barrier Coating in Advanced Gas Turbines

Abstract

:1. Introduction

2. Modified Furnace for Thermal Gradient Enhancement

3. Materials and Methods

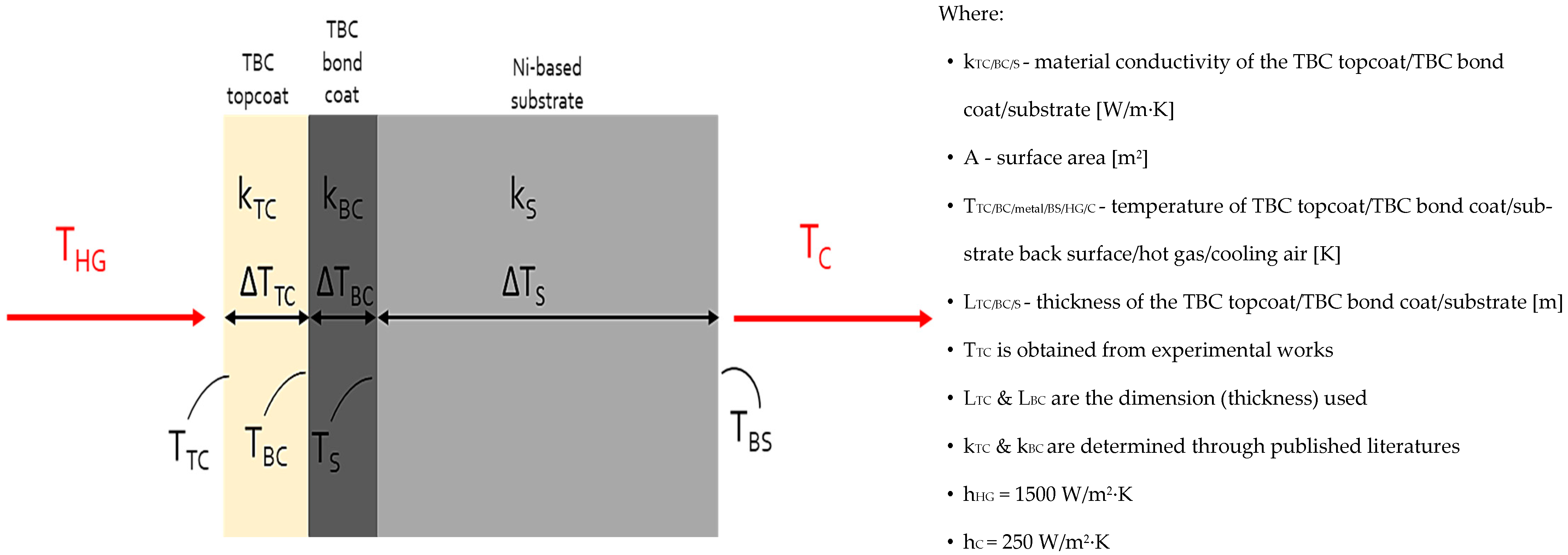

3.1. Thermal Gradient and Two-Dimensional Steady-State Thermal Analysis of Turbine Blades with Hybrid Cooling Systems

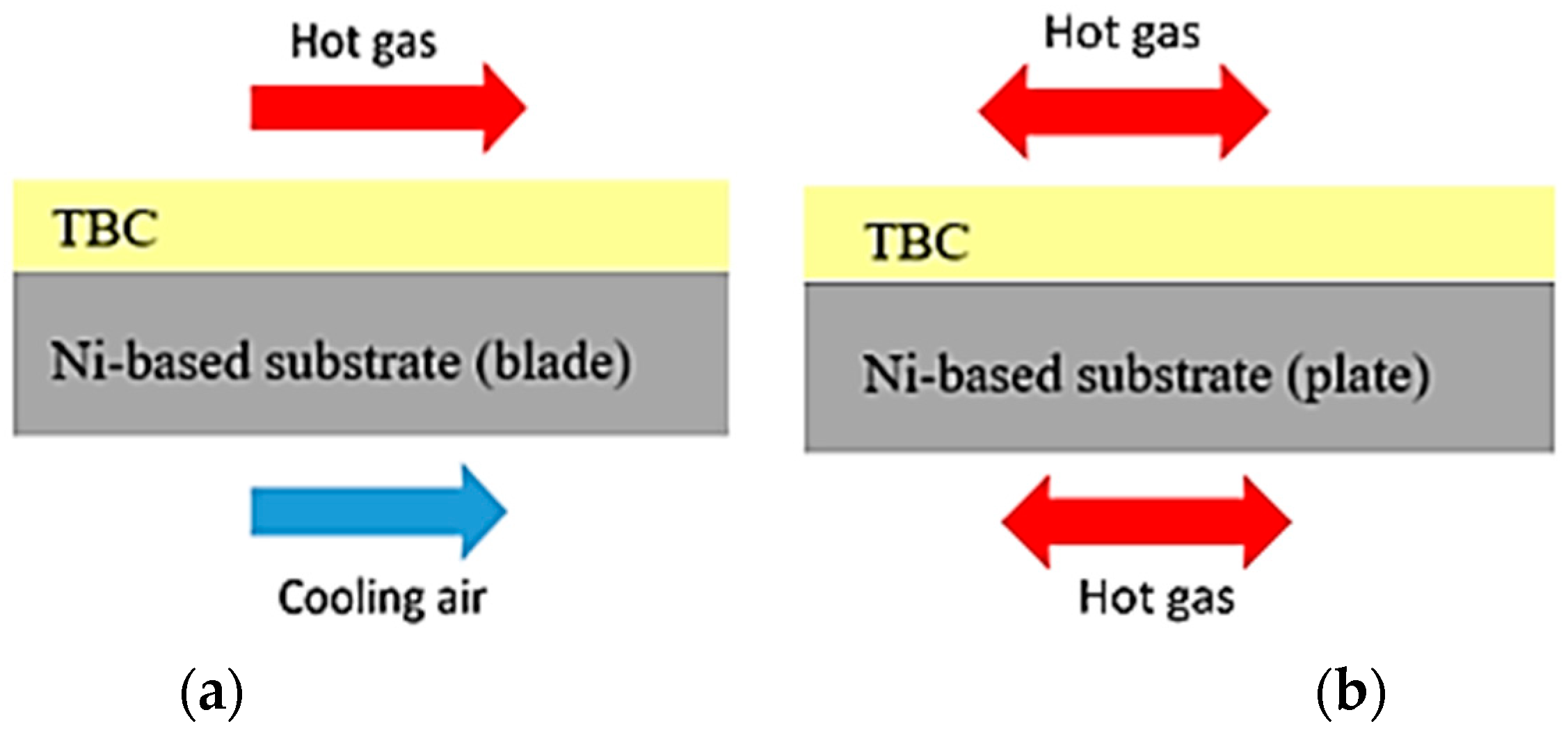

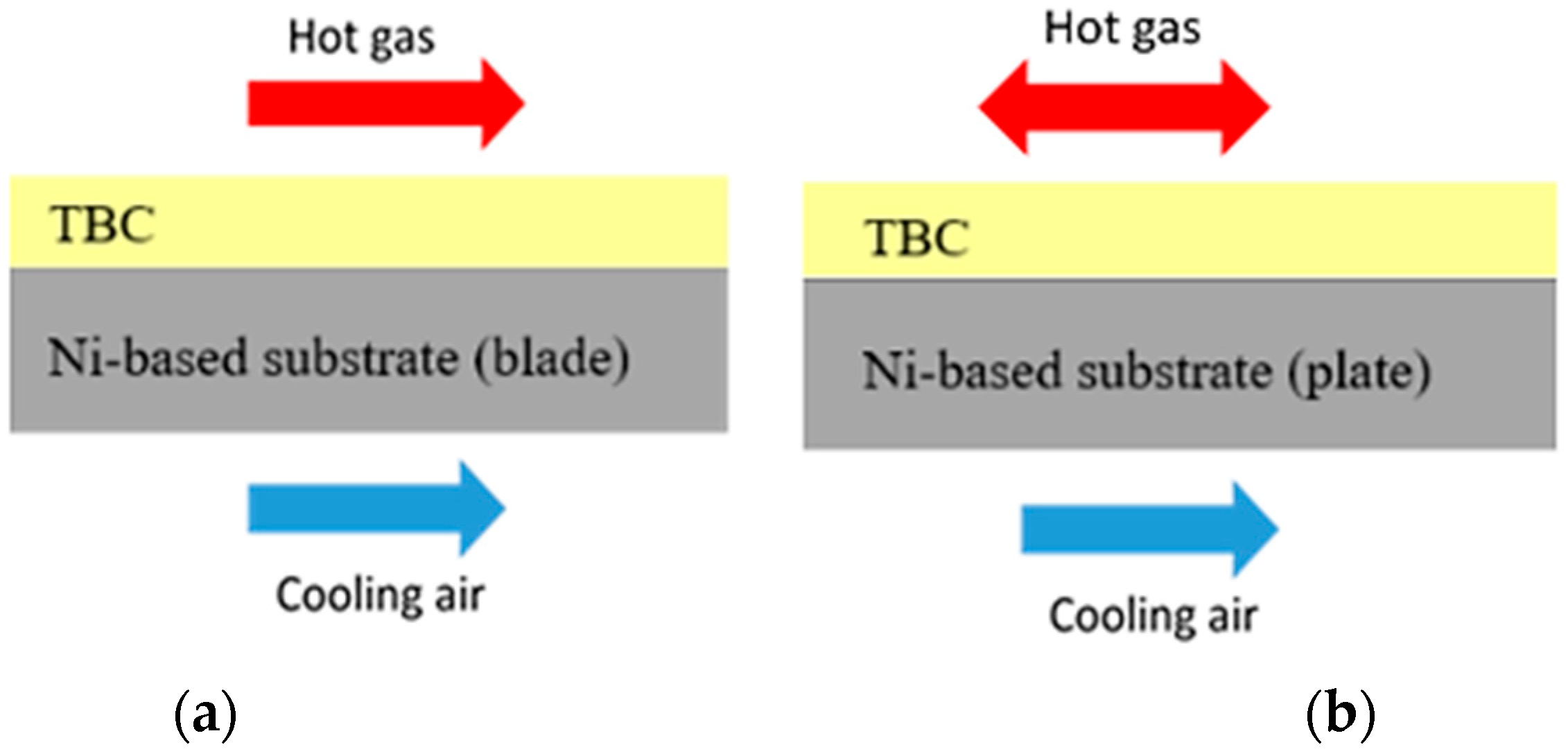

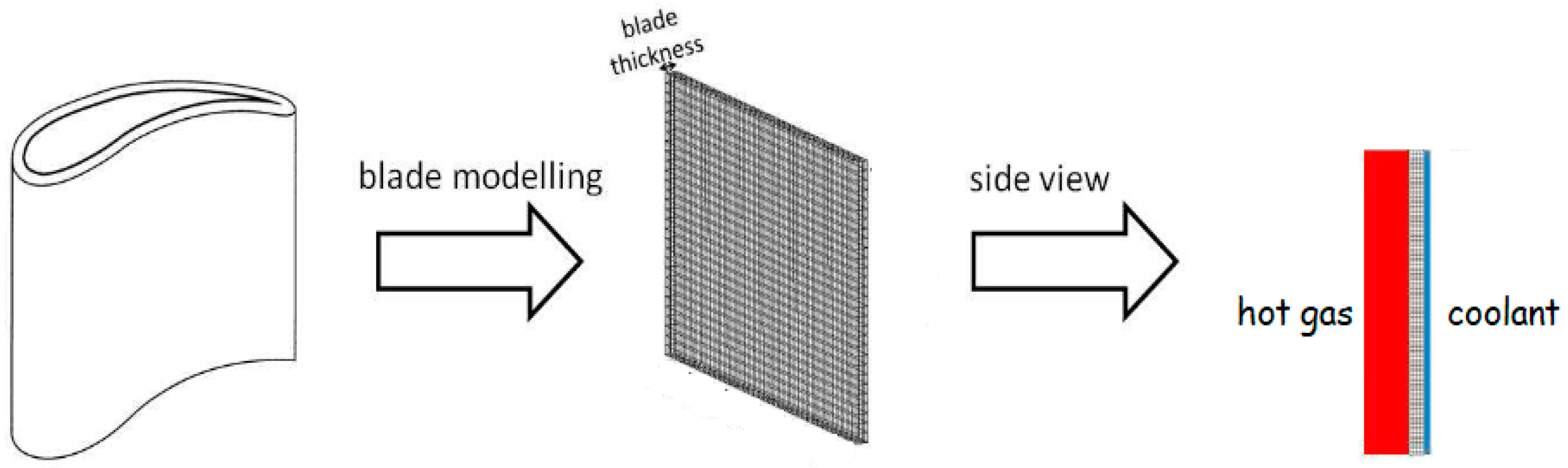

3.1.1. Thermal Gradient of the Actual Turbine Blade with the Hybrid Cooling

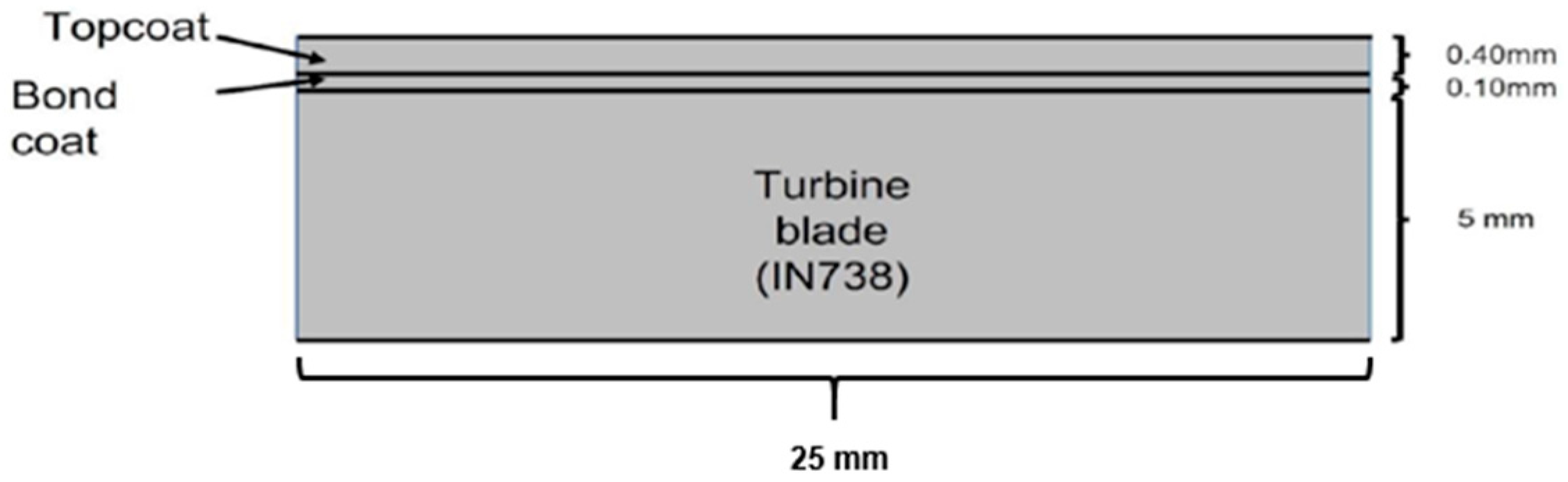

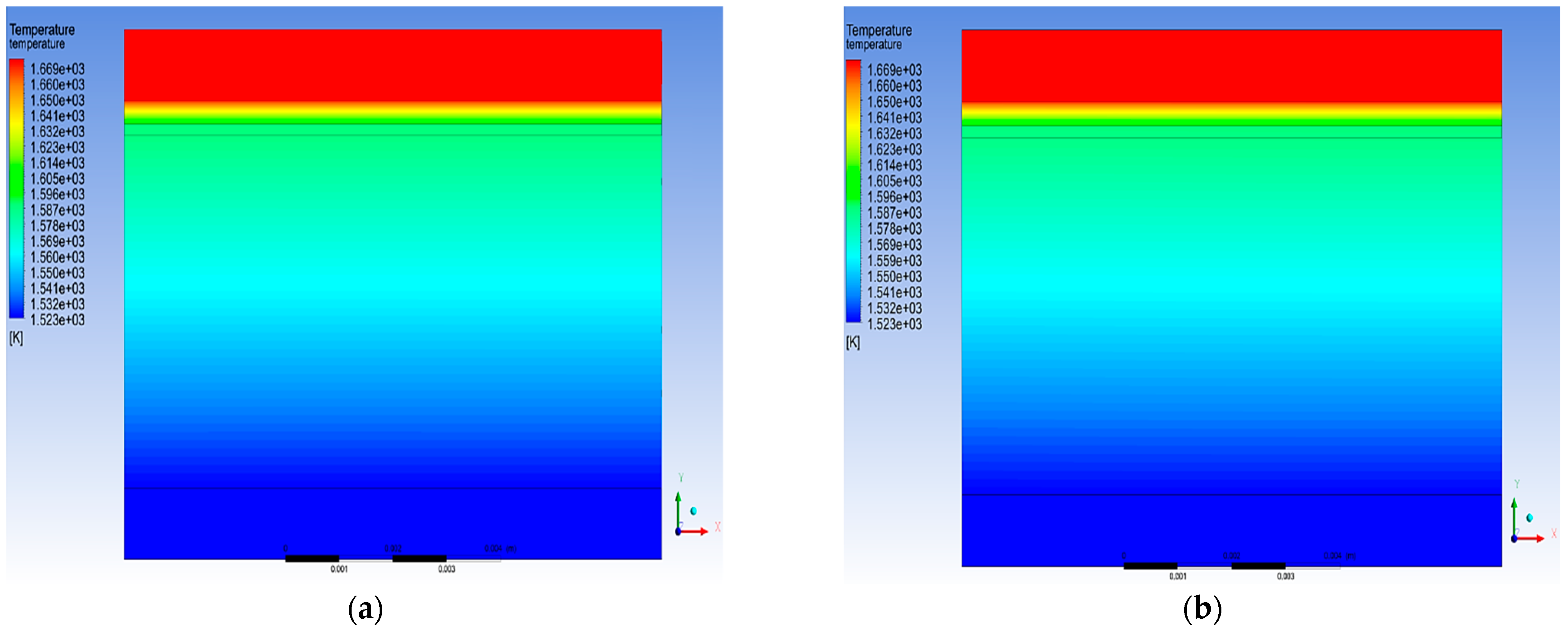

3.1.2. Two-Dimensional Steady-State Thermal Analysis of the Different Hot Gas Conditions

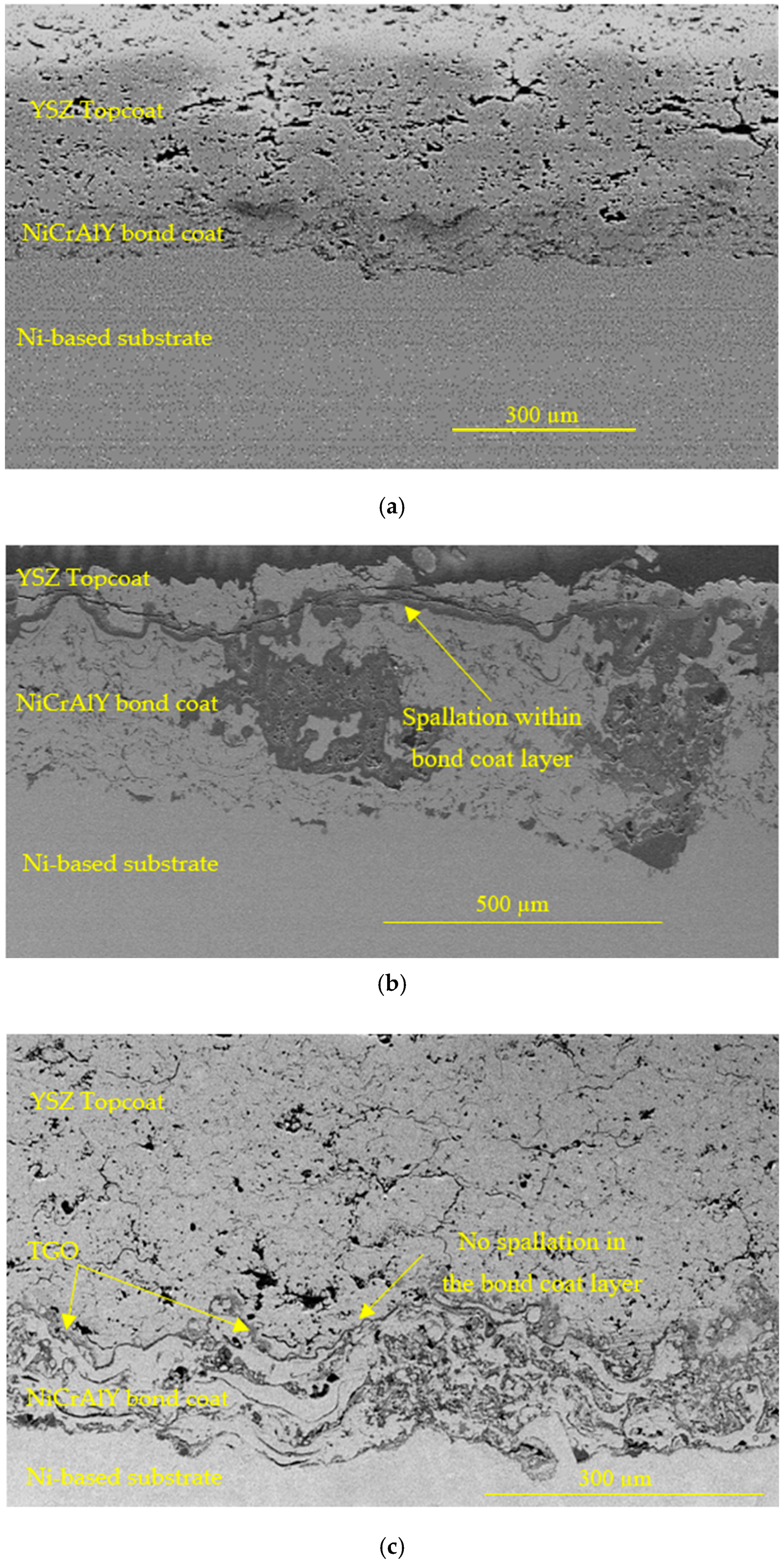

3.2. Experimental Analysis

3.2.1. Specimen Preparation

3.2.2. Isothermal Oxidation Test Using Modified Furnace

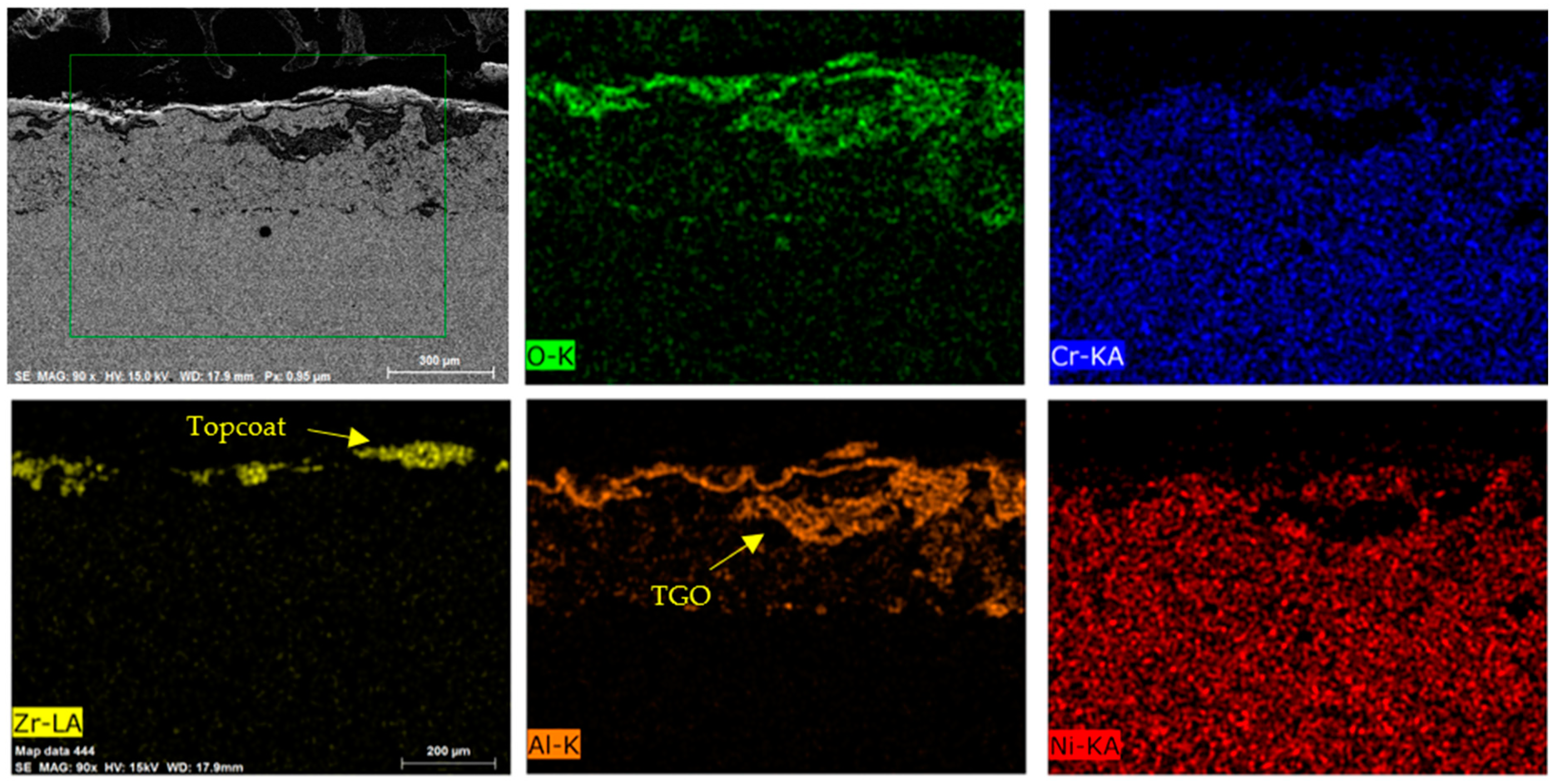

3.2.3. Specimen Characterization

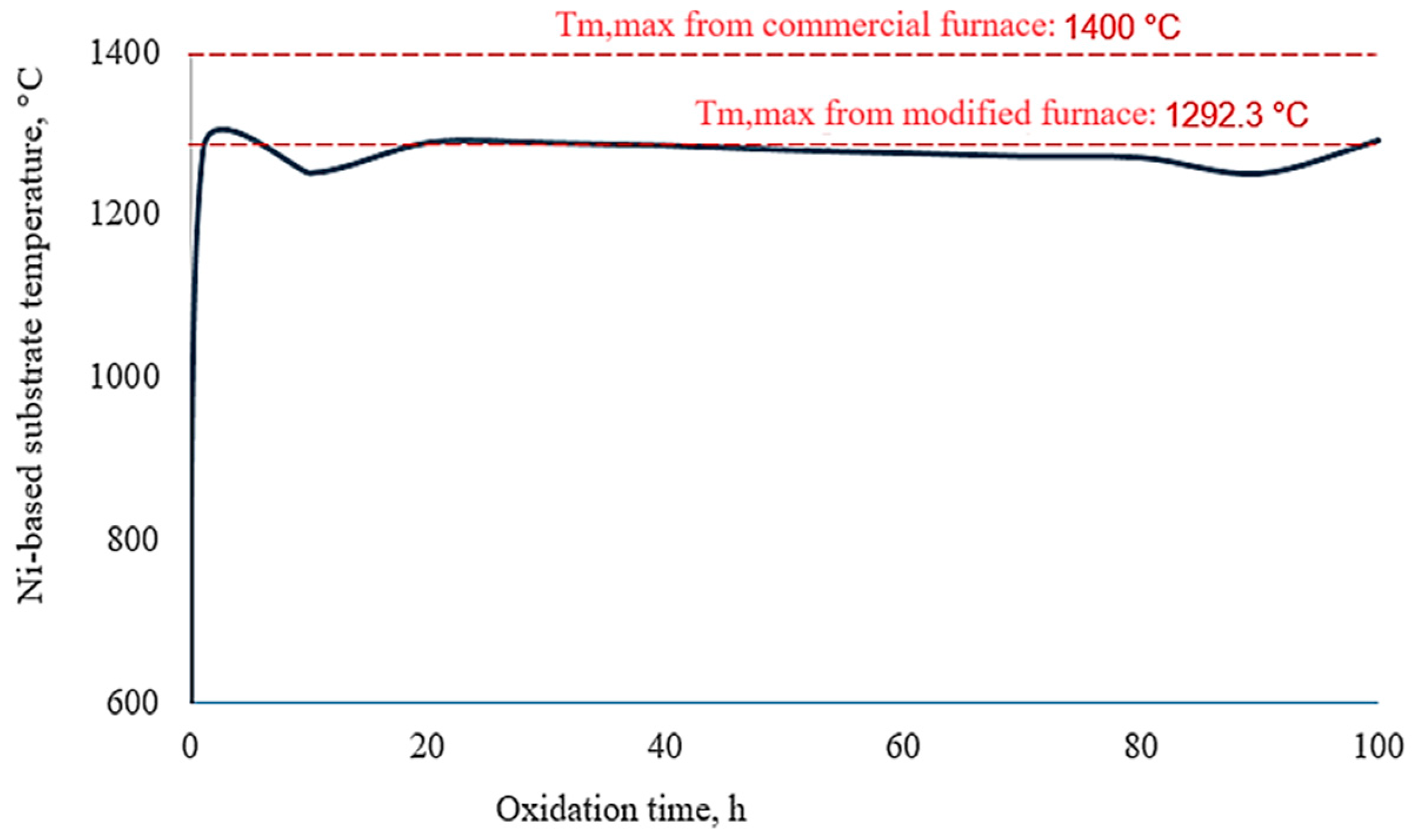

3.2.4. Determination of the Ni-Based Substrate Temperature

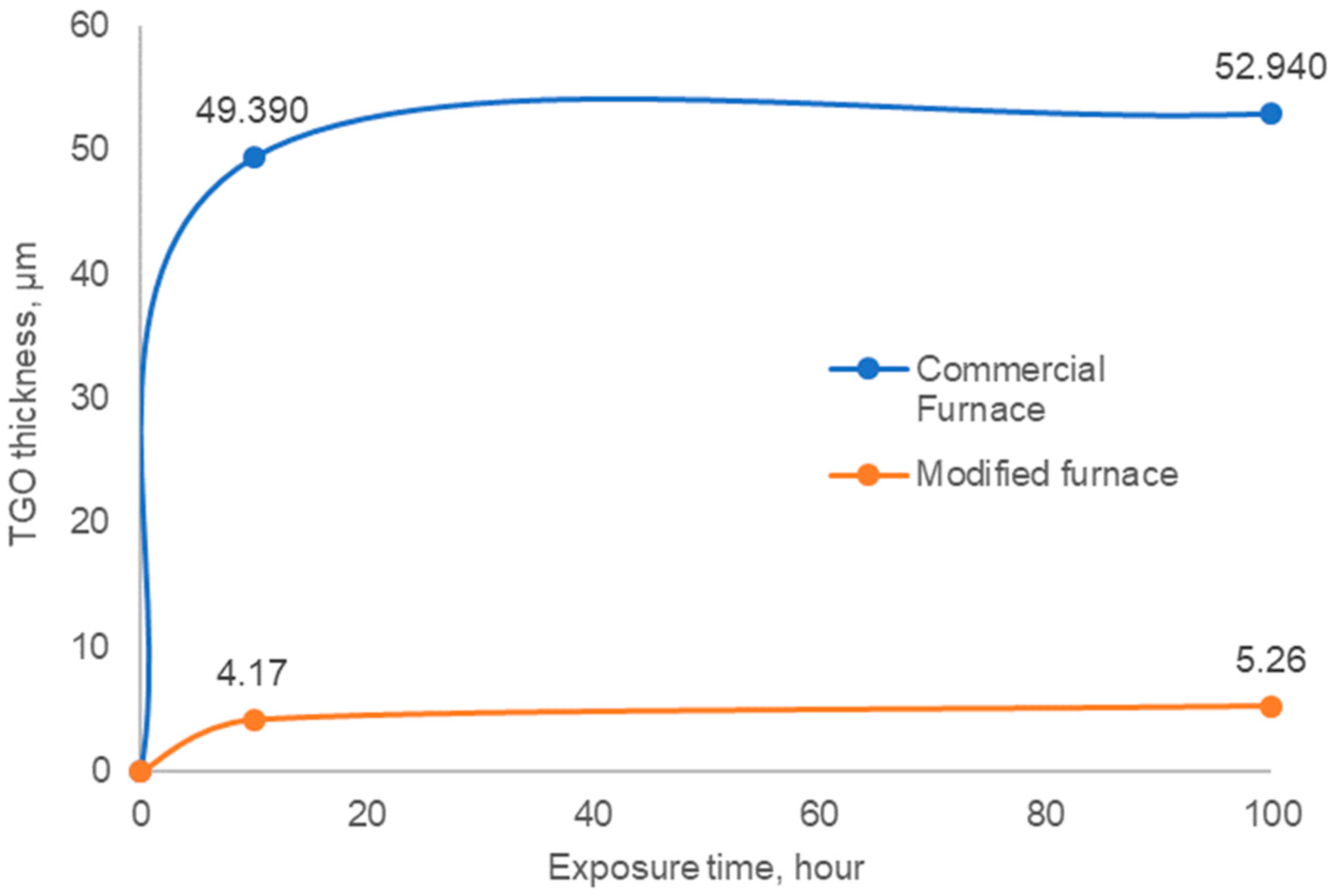

4. Results and Discussion

4.1. Effects of the Hot Gas Flows

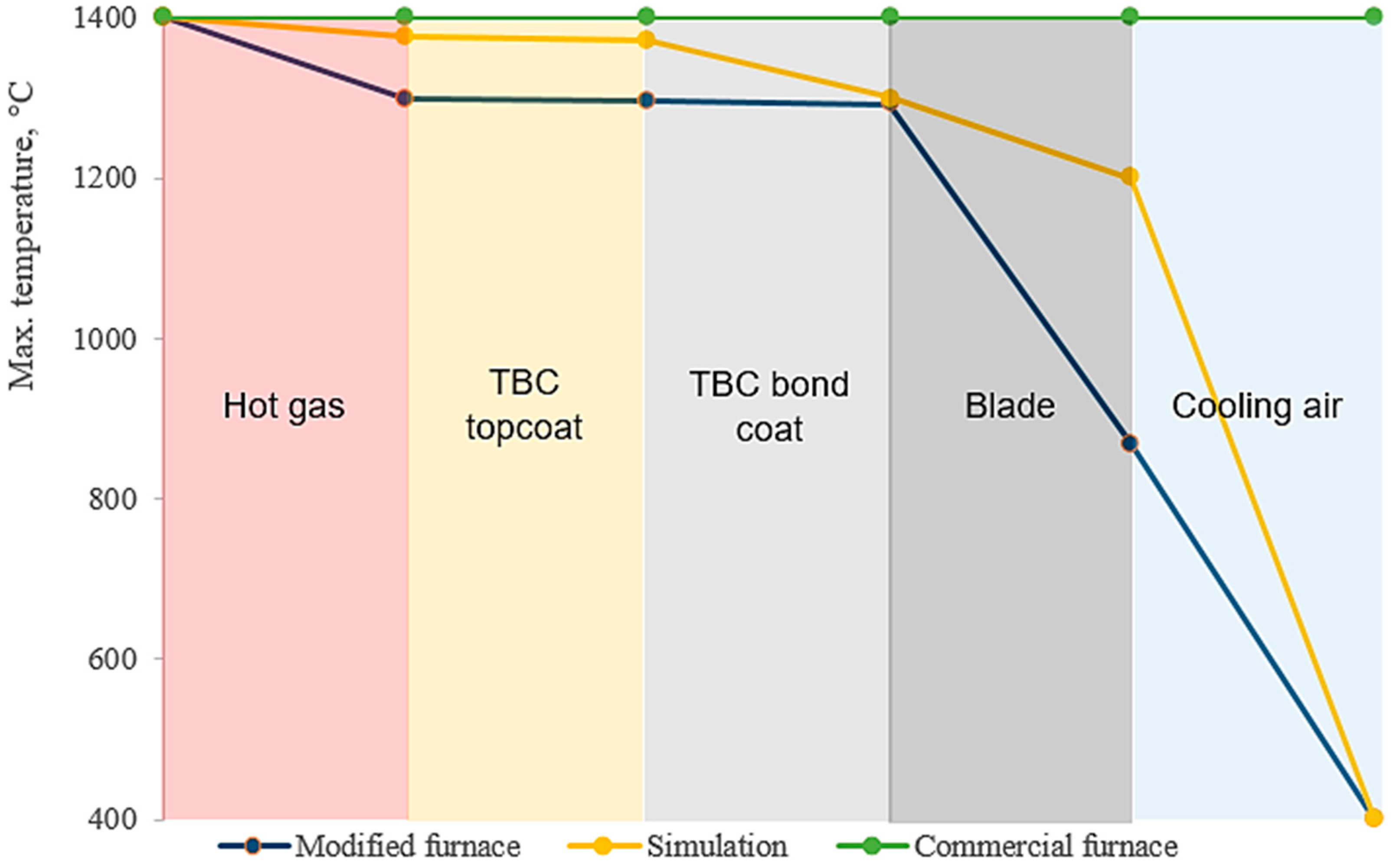

4.2. Reliability of the Developed Thermal Gradient

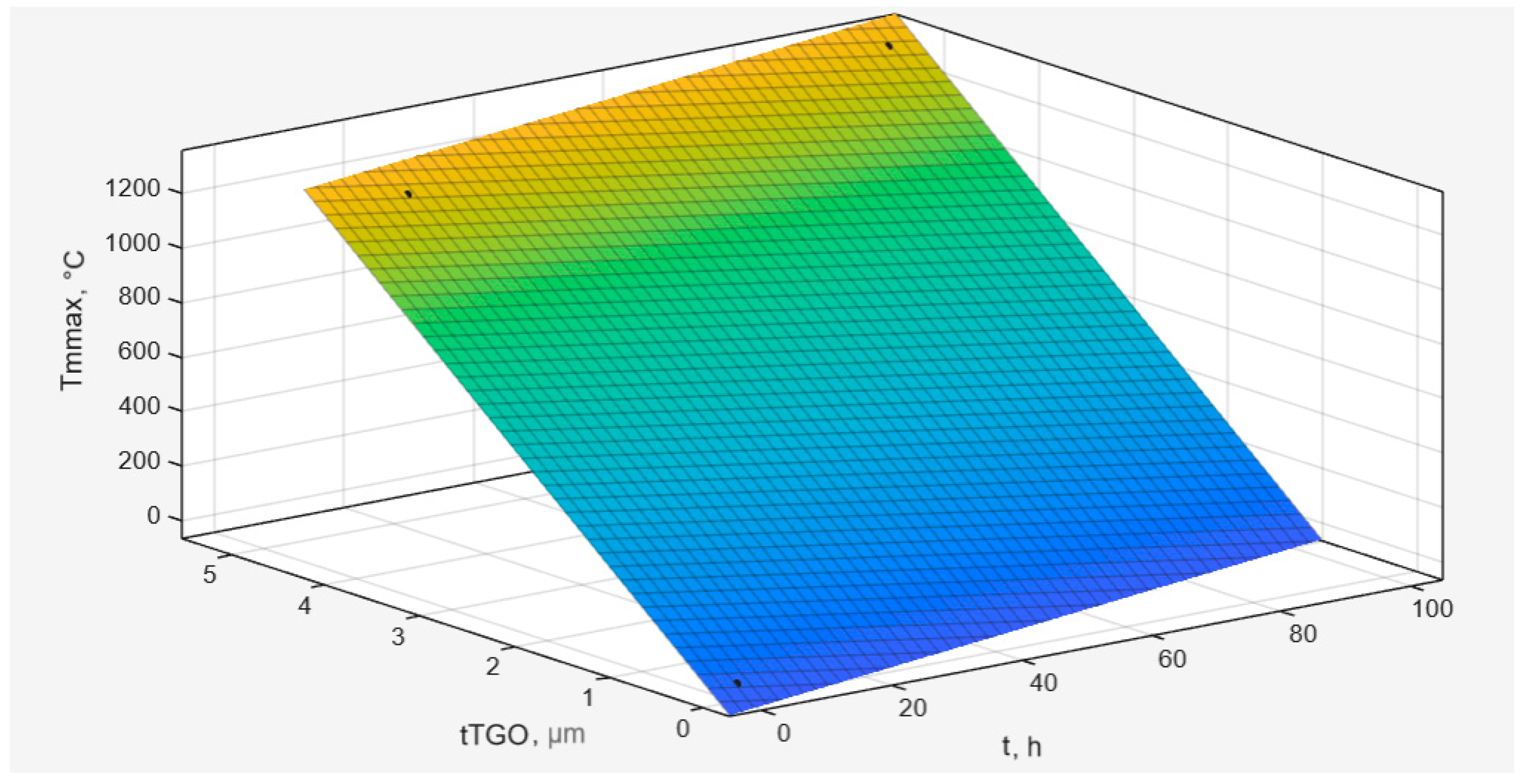

4.3. Temperature Model for Isothermal Oxidation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Olumayegun, O.; Wang, M.; Kelsall, G. Closed-cycle gas turbine for power generation: A state-of-the-art review. Fuel 2016, 180, 694–717. [Google Scholar] [CrossRef]

- Meng, Z.; Liu, Y.; Li, X.; He, X. The performance evaluation for thermal protection of turbine vane with film cooling and thermal barrier coating. Appl. Therm. Eng. 2022, 210, 118405. [Google Scholar] [CrossRef]

- Chowdhury, T.S.; Mohsin, F.T.; Tonni, M.M.; Mita, M.N.H.; Ehsan, M.M. A critical review on gas turbine cooling performance and failure analysis of turbine blades. Int. J. Thermofluids 2023, 18, 100329. [Google Scholar] [CrossRef]

- Wang, W.; Yan, Y.; Zhou, Y.; Cui, J. Review of advanced effusive cooling for gas turbine blades. Energies 2022, 15, 8568. [Google Scholar] [CrossRef]

- Vo, D.T.; Mai, T.D.; Kim, B.; Ryu, J. Numerical study on the influence of coolant temperature, pressure, and thermal barrier coating thickness on heat transfer in high-pressure blades. Int. J. Heat Mass Transf. 2022, 189, 122715. [Google Scholar] [CrossRef]

- Mohd Yunus, S.; Mahalingam, S.; Manap, A.; Mohd Afandi, N.; Satgunam, M. Test-rig simulation on hybrid thermal barrier coating assisted with cooling air system for advanced gas turbine under prolonged exposures—A review. Coatings 2021, 11, 560. [Google Scholar] [CrossRef]

- Doleker, K.M.; Ozgurluk, Y.; Ahlatci, H.; Karaoglanli, A.C. Evaluation of oxidation and thermal cyclic behavior of YSZ, Gd2Zr2O7 and YSZ/Gd2Zr2O7 TBCs. Surf. Coat. Technol. 2019, 371, 262–275. [Google Scholar] [CrossRef]

- Moon, S.W.; Kwon, H.M.; Kim, T.S.; Sohn, J.L. A novel coolant cooling method for enhancing the performance of the gas turbine combined cycle. Energy 2018, 160, 625–634. [Google Scholar] [CrossRef]

- Uysal, S.C.; Liese, E.; Nix, A.C.; Black, J. A thermodynamic model to quantify the impact of cooling improvements on gas turbine efficiency. J. Turbomach. 2018, 140, 031007. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Doleker, K.M.; Ozgurluk, Y. Interface failure behavior of yttria stabilized zirconia (YSZ), La2Zr2O7, Gd2Zr2O7, YSZ/La2Zr2O7 and YSZ/Gd2Zr2O7 thermal barrier coatings (TBCs) in thermal cyclic exposure. Mater. Charact. 2020, 159, 110072. [Google Scholar] [CrossRef]

- Shi, J.; Zhang, T.; Sun, B.; Wang, B.; Zhang, X.; Song, L. Isothermal oxidation and TGO growth behavior of NiCoCrAlY-YSZ thermal barrier coatings on a Ni-based superalloy. J. Alloys Compd. 2020, 844, 156093. [Google Scholar] [CrossRef]

- Mahade, S.; Ruelle, C.; Curry, N.; Holmberg, J.; Björklund, S.; Markocsan, N.; Nylén, P. Understanding the effect of material composition and microstructural design on the erosion behavior of plasma sprayed thermal barrier coatings. Appl. Surf. Sci. 2019, 488, 170–184. [Google Scholar] [CrossRef]

- Mohammadi, M.; Kobayashi, A.; Javadpour, S.; Jahromi, S.A.J. Evaluation of hot corrosion behaviors of Al2O3-YSZ composite TBC on gradient MCrAlY coatings in the presence of Na2SO4-NaVO3 salt. Vacuum 2019, 167, 547–553. [Google Scholar] [CrossRef]

- Lyu, G.; Kim, I.S.; Song, D.; Park, H.M.; Kim, J.S.; Song, T.; Myoung, S.; Jung, Y.G.; Zhang, J. Sintering behavior and phase transformation of YSZ-LZ composite coatings. Ceram. Int. 2020, 46, 1307–1313. [Google Scholar] [CrossRef]

- Lashmi, P.G.; Majithia, S.; Shwetha, V.; Balaji, N.; Aruna, S.T. Improved hot corrosion resistance of plasma sprayed YSZ/Gd2Zr2O7 thermal barrier coating over single layer YSZ. Mater. Charact. 2019, 147, 199–206. [Google Scholar] [CrossRef]

- Liu, F.; Song, W.; Zhou, X.; Huo, P.; Yuan, J.; Jiang, J.; Deng, L.; Dong, S.; Cao, X. Microstructures, thermophysical properties and thermal cycling behavior of LaZnAl11O19 thermal barrier coatings deposited by atmospheric plasma spraying. Inorg. Chem. Front. 2019, 6, 3302–3314. [Google Scholar] [CrossRef]

- Xiao, Y.Q.; Liu, Z.Y.; Zhu, W.; Peng, X.M. Reliability assessment and lifetime prediction of TBCs on gas turbine blades considering thermal mismatch and interfacial oxidation. Surf. Coat. Technol. 2021, 423, 127572. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Yildirim, B.; Welters, M. Correlation of thermal characteristics and microstructure of multilayer electron beam physical vapor deposition thermal barrier coatings. Thin Solid Film. 2020, 707, 138081. [Google Scholar] [CrossRef]

- Chen, H.F.; Zhang, C.; Liu, Y.C.; Song, P.; Li, W.X.; Yang, G.; Liu, B. Recent progress in thermal/environmental barrier coatings and their corrosion resistance. Rare Met. 2020, 39, 498–512. [Google Scholar] [CrossRef]

- Essa, S.K.; Chen, K.; Liu, R.; Wu, X.; Yao, M.X. Failure mechanisms of APS-YSZ-CoNiCrAlY thermal barrier coating under isothermal oxidation and solid particle erosion. J. Therm. Spray. Technol. 2021, 30, 424–441. [Google Scholar] [CrossRef]

- Góral, M.; Swadźba, R.; Kubaszek, T. TEM investigations of TGO formation during cyclic oxidation in two-and three-layered Thermal Barrier Coatings produced using LPPS, CVD and PS-PVD methods. Surf. Coat. Technol. 2020, 394, 125875. [Google Scholar] [CrossRef]

- Izadinia, M.; Soltani, R.; Sohi, M.H. Effect of segmented cracks on TGO growth and life of thick thermal barrier coating under isothermal oxidation conditions. Ceram. Int. 2020, 46, 7475–7481. [Google Scholar] [CrossRef]

- Paraschiv, A.; Banu, A.; Doicin, C.; Ionica, I. Isothermal oxidation behavior of plasma sprayed conventional and nanostructured ysz thermal barrier coatings. UPB Sci. Bull. Ser. B Chem. Mater. Sci. 2020, 82, 163–174. [Google Scholar]

- Yang, H.Z.; Zou, J.P.; Shi, Q.; Wang, D.; Dai, M.J.; Lin, S.S.; Chen, X.; Wang, W.; Xia, X.P. Comprehensive study on the microstructure evolution and oxidation resistance performance of NiCoCrAlYTa coating during isothermal oxidation at High temperature. Corros. Sci. 2020, 175, 108889. [Google Scholar] [CrossRef]

- Jonnalagadda, K.P.; Eriksson, R.; Li, X.H.; Peng, R.L. Fatigue life prediction of thermal barrier coatings using a simplified crack growth model. J. Eur. Ceram. Soc. 2019, 39, 1869–1876. [Google Scholar] [CrossRef]

- Karaoglanli, A.C.; Grund, T.; Turk, A.; Lampke, T. A comparative study of oxidation kinetics and thermal cyclic performance of thermal barrier coatings (TBCs). Surf. Coat. Technol. 2019, 371, 47–67. [Google Scholar] [CrossRef]

- Vorkötter, C.; Hagen, S.P.; Pintsuk, G.; Mack, D.E.; Virtanen, S.; Guillon, O.; Vaßen, R. Oxide dispersion strengthened bond coats with higher alumina content: Oxidation resistance and influence on thermal barrier coating lifetime. Oxid. Met. 2019, 92, 167–194. [Google Scholar] [CrossRef]

- Qiannan, T.; Yanrong, W.; Dasheng, W.; Shun, Y. Thermal oxidation description methodology of thermal barrier coatings on gas turbine blades considering service characteristics. Chin. J. Aeronaut. 2024, 37, 410–424. [Google Scholar]

- Fan, Y.; Fan, J.; Li, W.; Han, Y.; Lv, Y.; Cheng, H. Microstructure and ultra-high temperature isothermal oxidation behaviour of YSZ-particle-modified WSi2 coating. Surf. Coat. Technol. 2020, 397, 125982. [Google Scholar] [CrossRef]

- Nau, P.; Yin, Z.; Lammel, O.; Meier, W. Wall temperature measurements in gas turbine combustors with thermographic phosphors. J. Eng. Gas. Turbines Power 2019, 141, 041021. [Google Scholar] [CrossRef]

- Farhat, H.; Salvini, C. Novel gas turbine challenges to support the clean energy transition. Energies 2022, 15, 5474. [Google Scholar] [CrossRef]

- Li, J.; Ying, Y. Gas turbine gas path diagnosis under transient operating conditions: A steady state performance model based local optimization approach. Appl. Therm. Eng. 2020, 170, 115025. [Google Scholar] [CrossRef]

- Jude, S.A.A.; Jappes, J.W.; Adamkhan, M. Thermal barrier coatings for high-temperature application on superalloy substrates-A review. Mater. Today Proc. 2022, 60, 1670–1675. [Google Scholar] [CrossRef]

- Zhao, W.; Hu, Z.; Wang, L.; Wang, X.; Wu, Q.; Liu, R. Effect of Top-Coat Thickness and Interface Fluctuation on the Residual Stress in APS-TBCs. Coatings 2023, 13, 1659. [Google Scholar] [CrossRef]

- Ganji, D.K.; Rajyalakshmi, G. Influence of alloying compositions on the properties of nickel-based superalloys: A review. In Proceedings of the 1st National Conference on Advances in Mechanical Engineering (NCAME), Delhi, India, 16 March 2019; pp. 537–555. [Google Scholar]

- National Academies of Sciences, Division on Engineering, Physical Sciences, Aeronautics, Space Engineering Board and Committee on Advanced Technologies for Gas Turbines. Advanced Technologies for Gas Turbines; The National Academies Press: Washington, DC, USA, 2020. [Google Scholar]

- Gupta, S.; Chaube, A.; Verma, P. Review on Heat Transfer Augmentation Techniques: Application in Gas Turbine Blade Internal Cooling. J. Eng. Sci. Technol. Rev. 2012, 5, 57–62. [Google Scholar] [CrossRef]

- Radovic, M.; Lara-Curzio, E.; Trejo, R.M.; Wang, H.; Porter, W.D. Thermophysical Properties of YSZ and Ni-YSZ as a Function of Temperature and Porosity. Advan Solid. Oxide Fuel Cells II Ceram. Eng. Sci. Proc. 2006, 27, 79–85. [Google Scholar]

- Aabid, A.; Jyothi, J.; Zayan, J.M.; Khan, S.A. Experimental and numerical investigation on gas turbine blade with the application of thermal barrier coatings. Advan Mater. Res. 2019, 8, 275–293. [Google Scholar]

- Efe-Ononeme, O.E.; Ikpe, A.; Ariavie, G.O. Modal analysis of conventional gas turbine blade materials (Udimet 500 and IN738) for industrial applications. J. Eng. Technol. Appl. Sci. 2018, 3, 119–133. [Google Scholar] [CrossRef]

- Hu, L.; Wang, C.A.; Hu, Z.; Lu, S.; Sun, C.; Huang, Y. Porous yttria-stabilized zirconia ceramics with ultra-low thermal conductivity. Part II: Temperature dependence of thermophysical properties. J. Mater. Sci. 2011, 46, 623–628. [Google Scholar] [CrossRef]

- Souza, L.A.; Leal, E.M.; Costa, A.R.D.; Lima, M.S.F.D. Computational fluid dynamics and experimental analysis of a coated stainless steel gas turbine blade. Glob. J. Eng. Res. 2019, 19. Available online: https://repositorio.ufop.br/server/api/core/bitstreams/f4d5d8dc-5339-49fe-892e-301f1799d82b/content (accessed on 15 September 2023).

- Aabid, A.; Khan, S.A. Optimization of heat transfer on thermal barrier coated gas turbine blade. IOP Conf. Ser. Mater. Sci. Eng. 2018, 370, 012022. [Google Scholar] [CrossRef]

- Agrawal, V.; Khairnar, H.P. Analytical modeling of heat transfer coefficient analysis in dimensionless number of an electric parking brake using CFD. Int. J. Eng. 2023, 36, 276–288. [Google Scholar] [CrossRef]

- Pakseresht, A.; Sharifianjazi, F.; Esmaeilkhanian, A.; Bazli, L.; Nafchi, M.R.; Bazli, M.; Kirubaharan, K. Failure mechanisms and structure tailoring of YSZ and new candidates for thermal barrier coatings: A systematic review. Mater. Des. 2022, 222, 111044. [Google Scholar] [CrossRef]

- Smith, J.; Scheibel, J.; Classen, D.; Paschke, S.; Elbel, S.; Fick, K.; Carlson, D. Thermal barrier coating validation testing for industrial gas turbine combustion hardware. J. Eng. Gas Turbines Power 2016, 138, 031508. [Google Scholar] [CrossRef]

- Scheibel, J.; Smith, J.S. Gas Turbine Low Conductivity Thermal Barrier Coating Validation and Demonstration; European Turbine Network: Brussels, Belgium, 2016; p. 10. [Google Scholar]

- Plant, O.O. T-Point 2 Is a Proving Ground for Gas Turbine Advancements 2020. Available online: https://www.powermag.com/t-point-2-is-a-proving-ground-for-gas-turbine-advancements/ (accessed on 15 September 2023).

- Liu, S.; Zhang, X.; Wang, C.; Yin, C.; Rao, J.; Zhang, Y.; Losic, D. Long-term high-temperature resistant biotemplated composite coating for AZ91D magnesium alloy protection. J. Magnes. Alloy. 2022. [CrossRef]

- Saldanha, D.G.R.M. A Variational Principle for the Steady-State Heat Transfer Process in a Rigid Continuous Mixture. Math. Prob Eng. 2021, 2021, 6623995. [Google Scholar] [CrossRef]

- Hu, Z.C.; Liu, B.; Wang, L.; Cui, Y.H.; Wang, Y.W.; Ma, Y.D.; Sun, W.W.; Yang, Y. Research progress of failure mechanism of thermal barrier coatings at high temperature via finite element method. Coatings 2020, 10, 732. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, L.; Zhu, W. Experimental Simulators for the Service Environments of TBCs. In Thermal Barrier Coatings: Failure Theory and Evaluation Technology; Springer Nature Singapore: Singapore, 2022; pp. 879–934. [Google Scholar]

- Tao, S.; Yang, J.; Zhai, M.; Shao, F.; Zhong, X.; Zhao, H.; Zhuang, Y.; Ni, J.; Li, W.; Tao, S. Thermal stability of YSZ thick thermal barrier coatings deposited by suspension and atmospheric plasma spraying. Crystals 2020, 10, 984. [Google Scholar] [CrossRef]

- Musalek, R.; Tesar, T.; Medricky, J.; Lukac, F.; Lima, R.S. High-temperature cycling of plasma sprayed multilayered NiCrAlY/YSZ/GZO/YAG thermal barrier coatings prepared from liquid feedstocks. J. Therm. Spray Technol. 2021, 30, 81–96. [Google Scholar] [CrossRef]

- Iqbal, A.; Moskal, G. Recent development in advance ceramic materials and understanding the mechanisms of thermal barrier coatings degradation. Arch. Comput. Methods Eng. 2023, 30, 4855–4896. [Google Scholar] [CrossRef]

- Mondal, K.; Nuñez, L., III; Downey, C.M.; Van Rooyen, I.J. Thermal barrier coatings overview: Design, manufacturing, and applications in high-temperature industries. Ind. Eng. Chem. Res. 2021, 60, 6061–6077. [Google Scholar] [CrossRef]

- Wang, X.; Zhen, Z.; Huang, G.; Mu, R.; He, L.; Xu, Z. Thermal cycling of EB-PVD TBCs based on YSZ ceramic coat and diffusion aluminide bond coat. J. Alloys Compd. 2021, 873, 159720. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Hu, X.B. Segregation and microstructural evolution at interfaces of atmospheric plasma sprayed thermal barrier coatings during thermal cycling. J. Alloys Compd. 2021, 819, 153026. [Google Scholar] [CrossRef]

- Bao, Z.; Yao, H.; He, J.; Zhang, J. Interdiffusion between metallic coatings and single crystal superalloys and the strategies to constrain the interdiffusion. Therm. Barrier Coat. 2023, 87–118. [Google Scholar] [CrossRef]

- Archana, M.; Rao, C.J.; Ningshen, S.; Philip, J. High-temperature air and steam oxidation and oxide layer characteristics of Alloy 617. J. Mater. Eng. Perform. 2021, 30, 931–943. [Google Scholar] [CrossRef]

- Savitha, U.; Reddy, G.J.; Singh, V.; Gokhale, A.A.; Sundararaman, M. Additive laser deposition of compositionally graded NiCrAlY-YSZ multi-materials on IN625-NiCrAlY substrate. Mater. Charac 2020, 164, 110317. [Google Scholar]

- Mehtani, H.K.; Khan, M.I.; Jaya, B.N.; Parida, S.; Prasad, M.J.N.V.; Samajdar, I. The oxidation behavior of iron-chromium alloys: The defining role of substrate chemistry on kinetics, microstructure and mechanical properties of the oxide scale. J. Alloys Compd. 2021, 871, 159583. [Google Scholar] [CrossRef]

- Cui, S.; Liu, Y.; Wang, T.; Tieu, K.; Wang, L.; Zeng, D.; Li, Z.; Li, W. Tribological behavior comparisons of high chromium stainless and mild steels against high-speed steel and ceramics at high temperatures. Friction 2022, 10, 436–453. [Google Scholar] [CrossRef]

- Hu, Z.C.; Wang, L.; Zhuang, M.X.; Zhang, H.Y.; Li, G.S.; Liu, Y.; Wang, Y.; Yang, Y. Influence of internal oxidation of the bond-coat on the residual stress around the TGO and failure modes of the APS-TBCs: A finite element simulation study. Ceram. Int. 2021, 47, 5364–5373. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Joshi, S. Durability of gadolinium zirconate/YSZ double-layered thermal barrier coatings under different thermal cyclic test conditions. Materials 2019, 12, 2238. [Google Scholar] [CrossRef]

- Migas, D.; Moskal, G.; Maciąg, T. Thermal analysis of W-free Co–(Ni)–Al–Mo–Nb superalloys. J. Therm. Anal. Calorim. 2020, 142, 149–156. [Google Scholar] [CrossRef]

- Rame, J.; Utada, S.; Bortoluci Ormastroni, L.M.; Mataveli-Suave, L.; Menou, E.; Després, L.; Kontis, P.; Cormier, J. Platinum-containing new generation nickel-based superalloy for single crystalline applications. In Superalloys 2020. The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2020; pp. 71–81. [Google Scholar]

- Wen, Q.; Jing, F.; Zhang, C.; Tang, S.; Yang, J. Review of numerical simulation of TGO growth in thermal barrier coatings. Comput. Model. Eng. Sci. 2022, 132, 361–391. [Google Scholar] [CrossRef]

| No. | Potential Part | Specific Function |

|---|---|---|

| 1 | Air blower |

|

| 2 | Electric heater |

|

| 3 | Commercial furnace |

|

| 4 | Hot air blower pipe |

|

| Property | Hot Gas (1400 °C) | Topcoat (YSZ) | Bond Coat (NiCrAlY) | Turbine Blade Metal (In738) | Cooling Air (400 °C) |

|---|---|---|---|---|---|

| Density, kg/m3 | - | 2300 [38] | 7320 [39] | 8550 [40] | - |

| Specific heat capacity (J/kg.K) | - | 450 [41] | 764 [42] | 510 [40] | - |

| Thermal conductivity (W/m.K) | - | 2.4 [41] | 16.1 [42] | 14.3 [40] | - |

| Heat transfer coefficient (W/m2.K) | 2028 [43] | - | - | - | 11.5 [44] |

| Parameter | Value |

|---|---|

| Mainstream (hot gas) temperature, Tg | 1673.15 K |

| Mainstream (hot gas) pressure, Pg | 17 MPa |

| Coolant (cooling air) temperature, Tc | 673.15 K |

| Coolant (cooling air) pressure, Pc | 17 Mpa |

| Layer | Elemental Composition, wt. % | ||||

|---|---|---|---|---|---|

| Y | Zr | Ni | Cr | Al | |

| YSZ | 7.30 | 67.92 | 0.16 | 0.16 | 0.11 |

| NiCrAlY | 2.24 | - | 57.08 | 27.72 | 11.32 |

| Parameter | Unit | TBC Topcoat | TBC Bond Coat |

|---|---|---|---|

| Arc Current | Amps (A) | 575 | 550 |

| Primary plasma gas (Nitrogen, N2) | Normal litre per minute (NLPM) | 35 | 55 |

| Secondary plasma gas (Hydrogen, H2) | Normal litre per minute (NLPM) | 10.0 | 9.4 |

| Carrier gas (Argon, Ar) | Normal litre per minute (NLPM) | 3.0 | 4.0 |

| Powder feed rate | g/min | 55 | 40 |

| Spraying distance | mm | 90 | |

| Parameter | Unit | Input |

|---|---|---|

| Furnace temperature | °C | 1450.0 * |

| Inlet cooling air temperature | °C | 400.2 |

| Output cooling air temperature | °C | 424.8 |

| Cooling air flow rate | Nm3/h | 42.0 11.95 |

| Hz |

| Layer | Distance (mm) | Temperature, °C | |

|---|---|---|---|

| Flowing Hot Gas | Static Hot Gas | ||

| Hot gas | 0 | 1400.0 | 1400.0 |

| Topcoat/bond coat interface | 0.4 | 1367.2 | 1367.7 |

| Bond coat/metal substrate interface | 0.5 | 1337.3 | 1337.3 |

| Cooling air | 5.5 | 400.0 | 400.0 |

| Measurement Condition | Topcoat Temperature, °C | Bond Coat Temperature, °C | Tm,max, °C | Substrate Back Surface Temperature, °C |

|---|---|---|---|---|

| Simulation of the actual blade | 1377.0 | 1371.3 | 1300.0 | 1200.0 |

| Testing using a commercial furnace | 1400.0 | 1400.0 | 1400.0 | 1400.0 |

| Testing using a modified furnace | 1299.7 | 1296.2 | 1292.3 | 868.5 |

| Layer | Elemental Composition, wt. % | ||||

|---|---|---|---|---|---|

| Y | Zr | Ni | Cr | Al | |

| Modified furnace | 6.34 | 63.64 | - | 0.27 | 0.19 |

| Commercial furnace | 5.94 | 68.55 | 0.62 | 0.05 | 0.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohd Yunus, S.; Manap, A.; Satgunam, M.; Mahalingam, S.; Mohd Afandi, N. Furnace Testing and Validation of a Hybrid Cooling Approach for Enhanced Turbine Blade Protection with a Thermal Barrier Coating in Advanced Gas Turbines. Ceramics 2024, 7, 1340-1364. https://doi.org/10.3390/ceramics7040088

Mohd Yunus S, Manap A, Satgunam M, Mahalingam S, Mohd Afandi N. Furnace Testing and Validation of a Hybrid Cooling Approach for Enhanced Turbine Blade Protection with a Thermal Barrier Coating in Advanced Gas Turbines. Ceramics. 2024; 7(4):1340-1364. https://doi.org/10.3390/ceramics7040088

Chicago/Turabian StyleMohd Yunus, Salmi, Abreeza Manap, Meenaloshini Satgunam, Savisha Mahalingam, and Nurfanizan Mohd Afandi. 2024. "Furnace Testing and Validation of a Hybrid Cooling Approach for Enhanced Turbine Blade Protection with a Thermal Barrier Coating in Advanced Gas Turbines" Ceramics 7, no. 4: 1340-1364. https://doi.org/10.3390/ceramics7040088

APA StyleMohd Yunus, S., Manap, A., Satgunam, M., Mahalingam, S., & Mohd Afandi, N. (2024). Furnace Testing and Validation of a Hybrid Cooling Approach for Enhanced Turbine Blade Protection with a Thermal Barrier Coating in Advanced Gas Turbines. Ceramics, 7(4), 1340-1364. https://doi.org/10.3390/ceramics7040088