A Study on the Impact Erosion Effect of a Two-Phase Jet Field on a Wall at Different Impact Distances by Numerical Simulation

Abstract

1. Introduction

2. Determination of Mathematical Models

2.1. Basic Control Equations

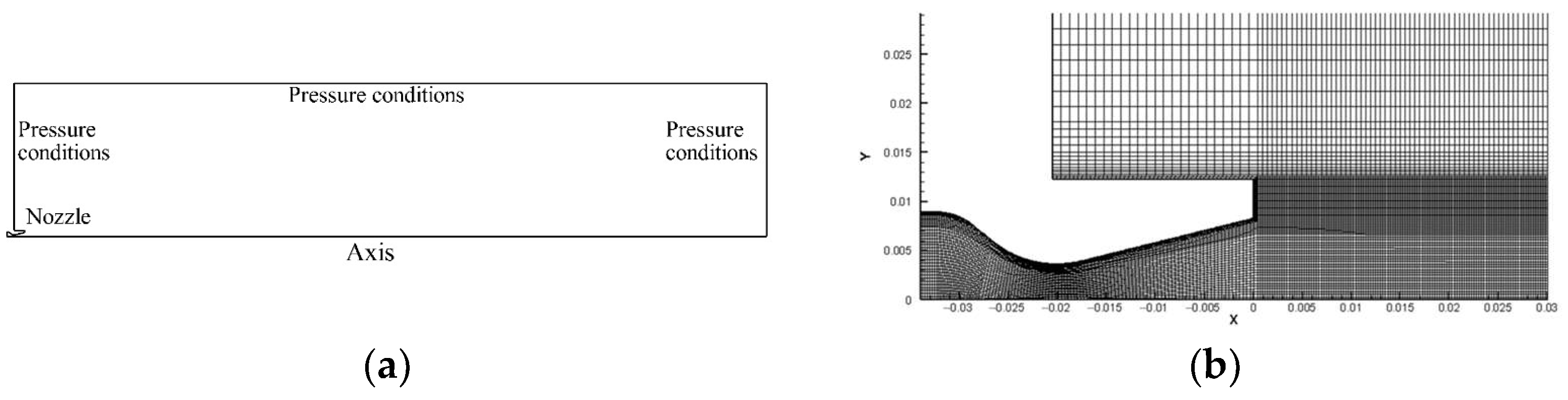

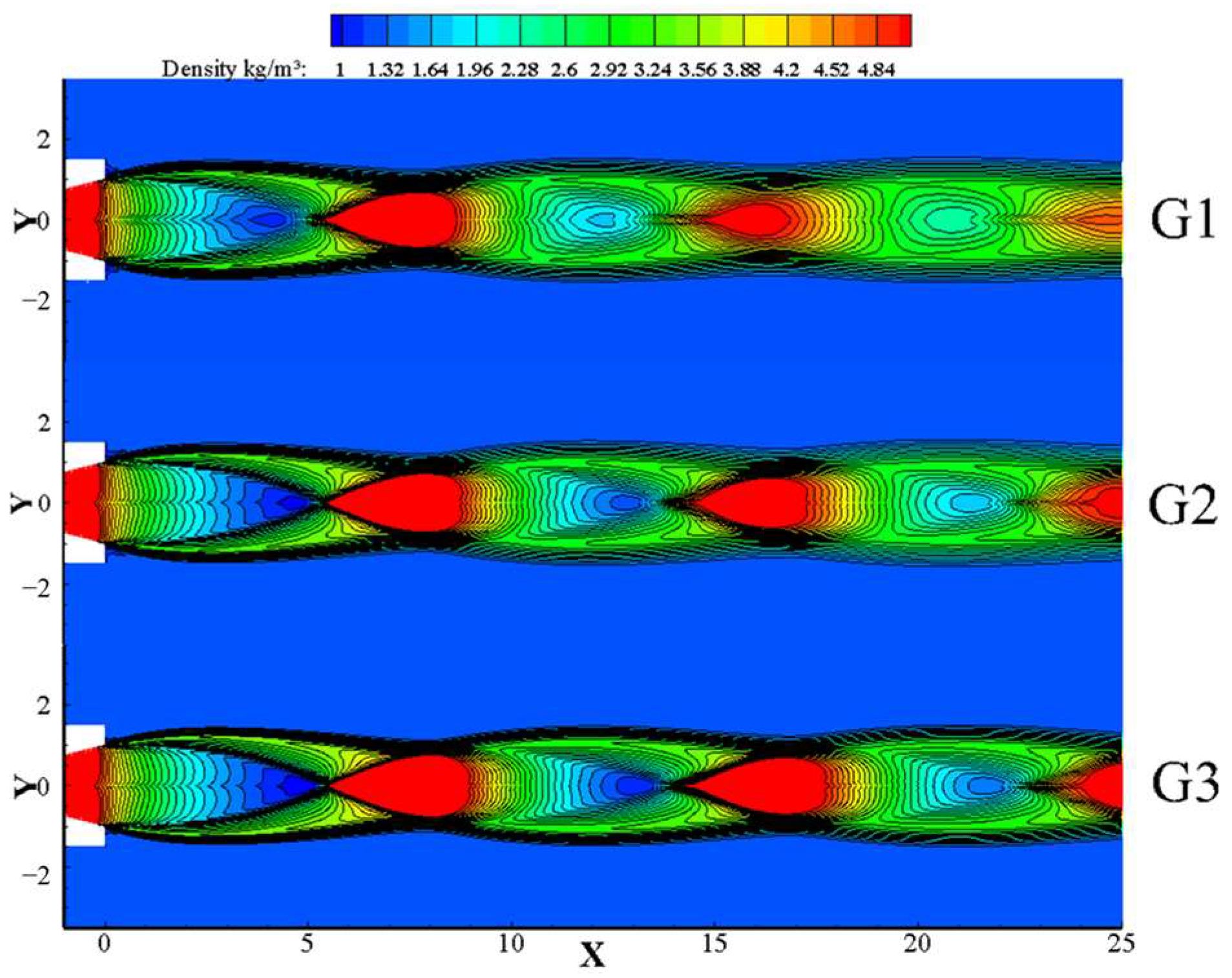

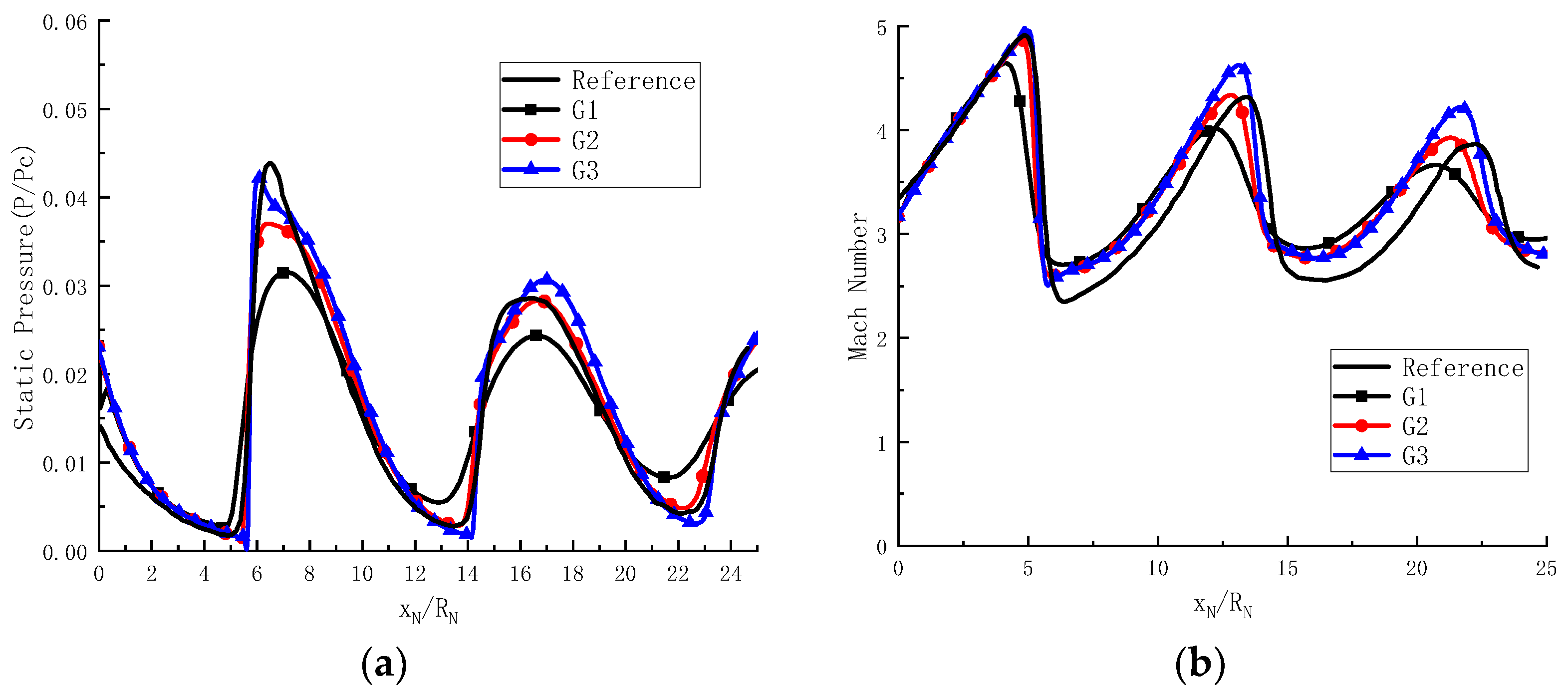

2.2. Determination of Grid Scale

2.3. Determination of Turbulence Model

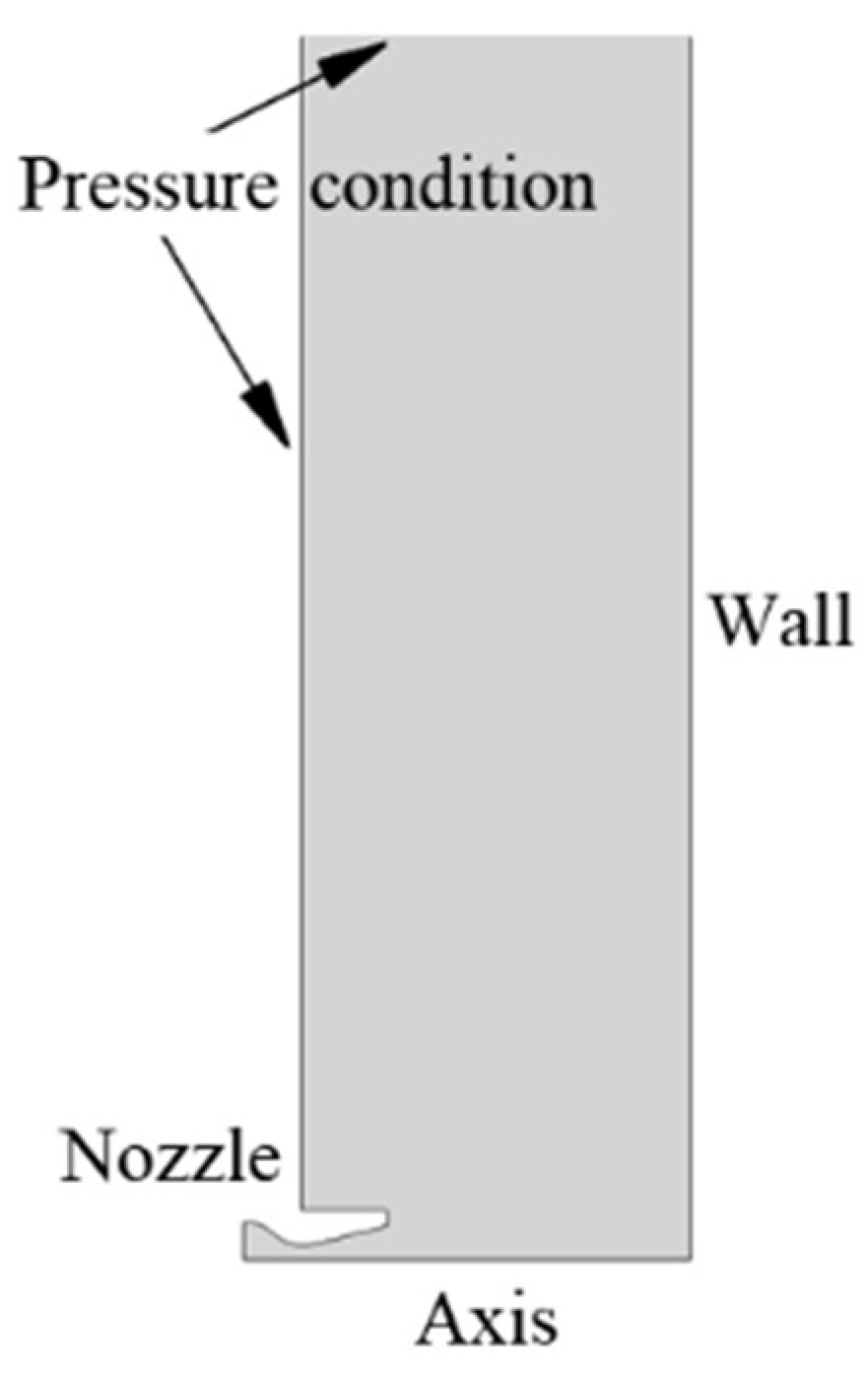

2.3.1. Physical Model

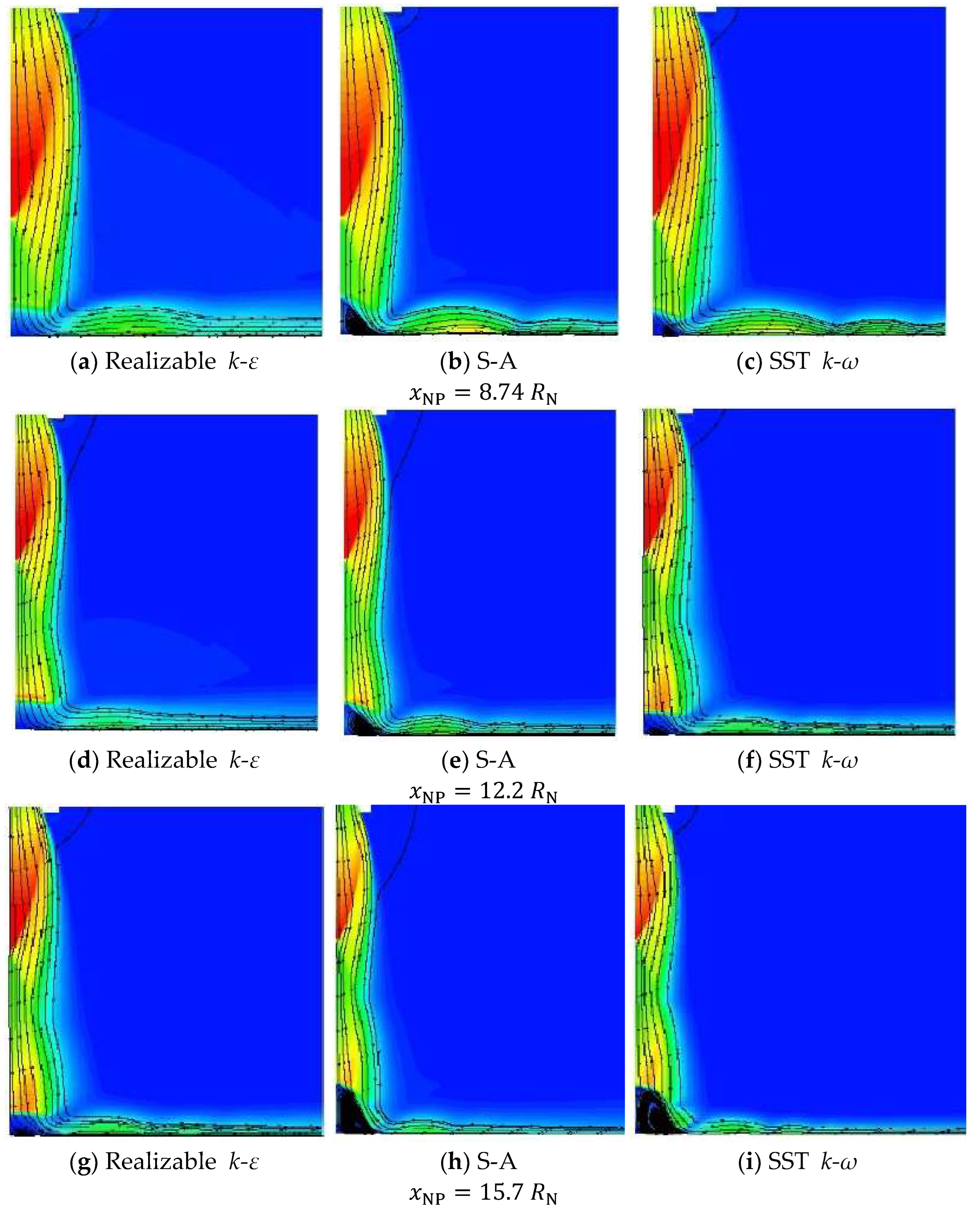

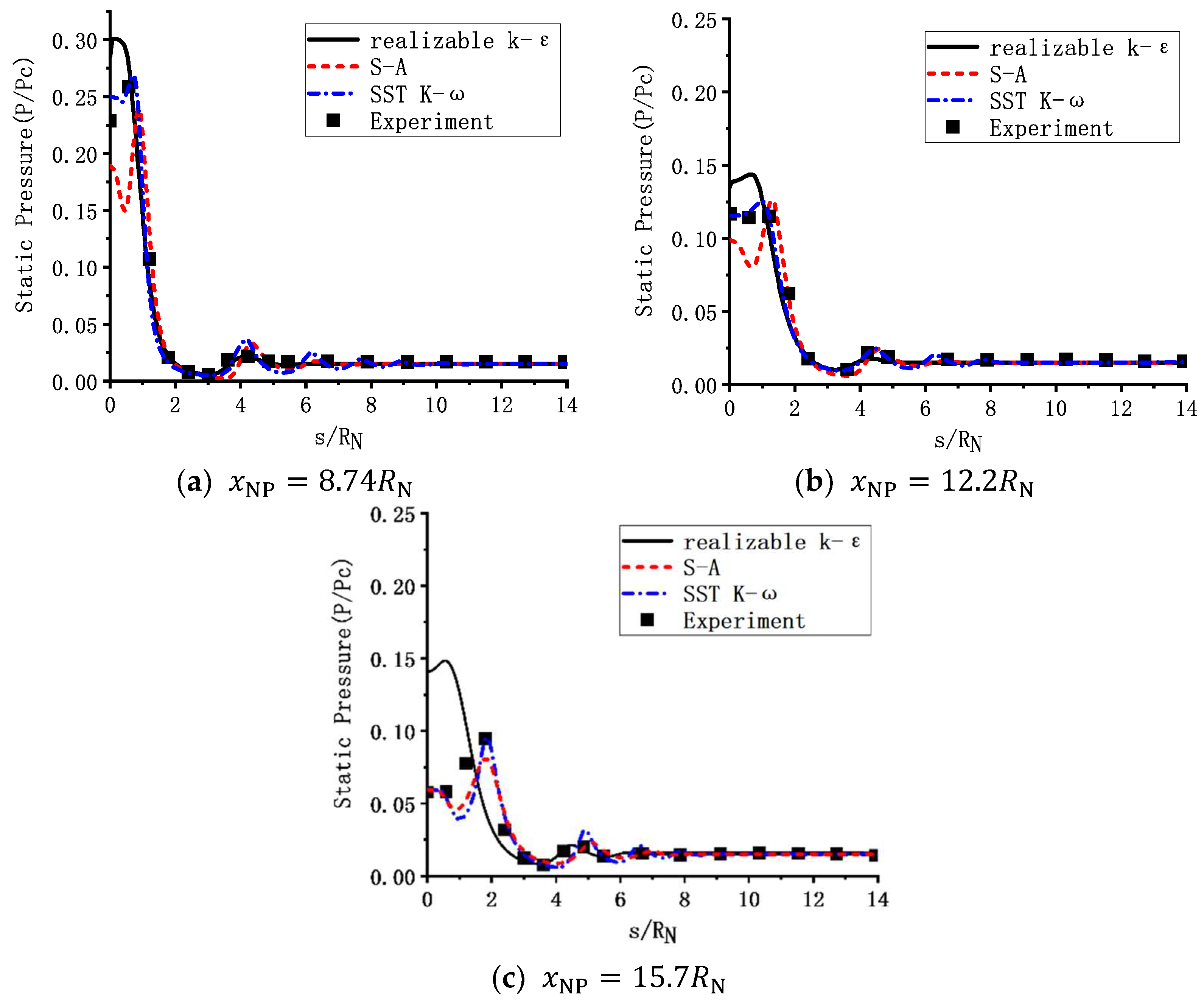

2.3.2. Comparative Analysis

3. Collision of Particles with Solid Bulkheads

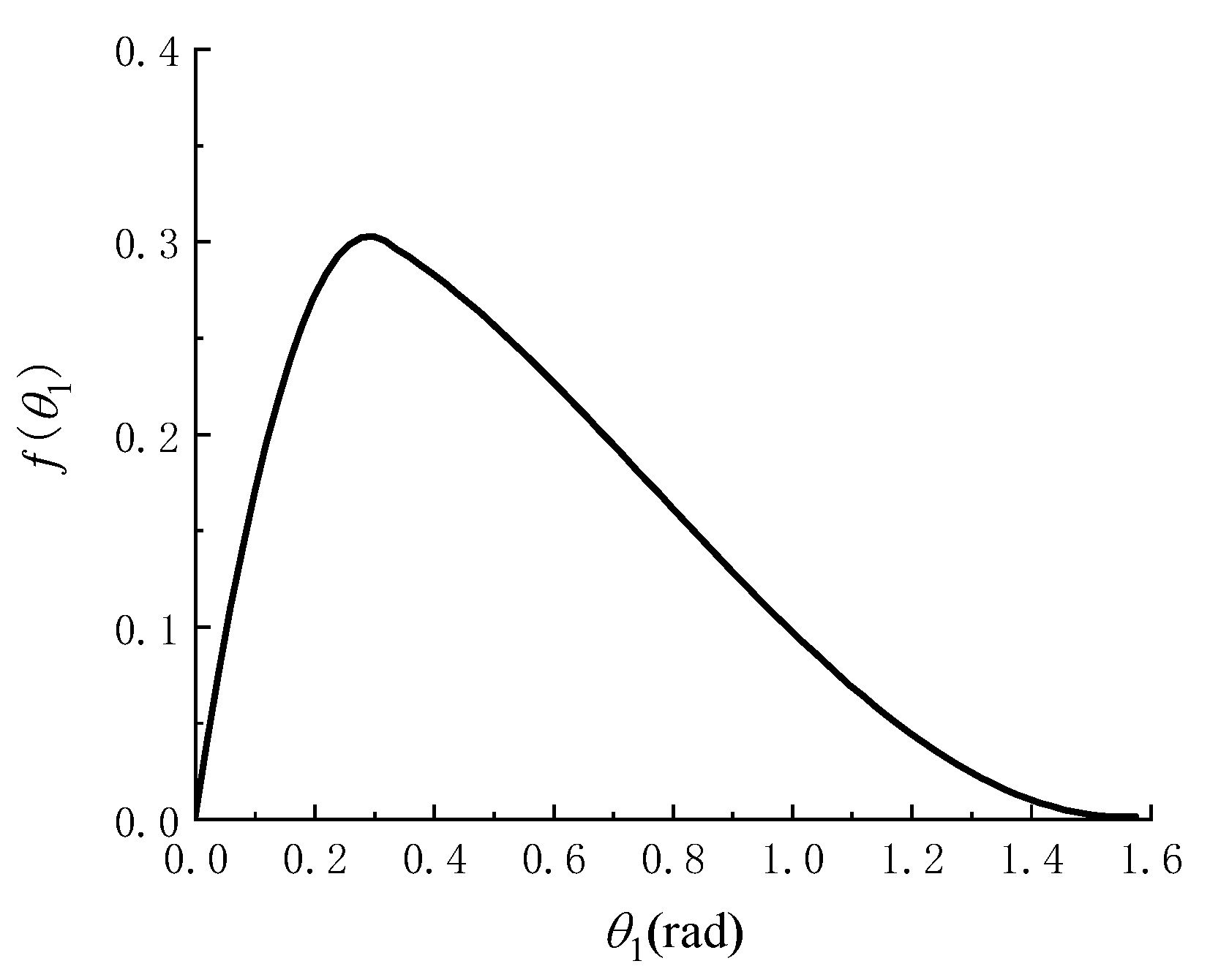

3.1. Particle Erosion and Deposition Model of Bulkhead

3.2. Calculation Condition Setting

4. Two-Phase Jet Field Analysis at Different Impact Distances

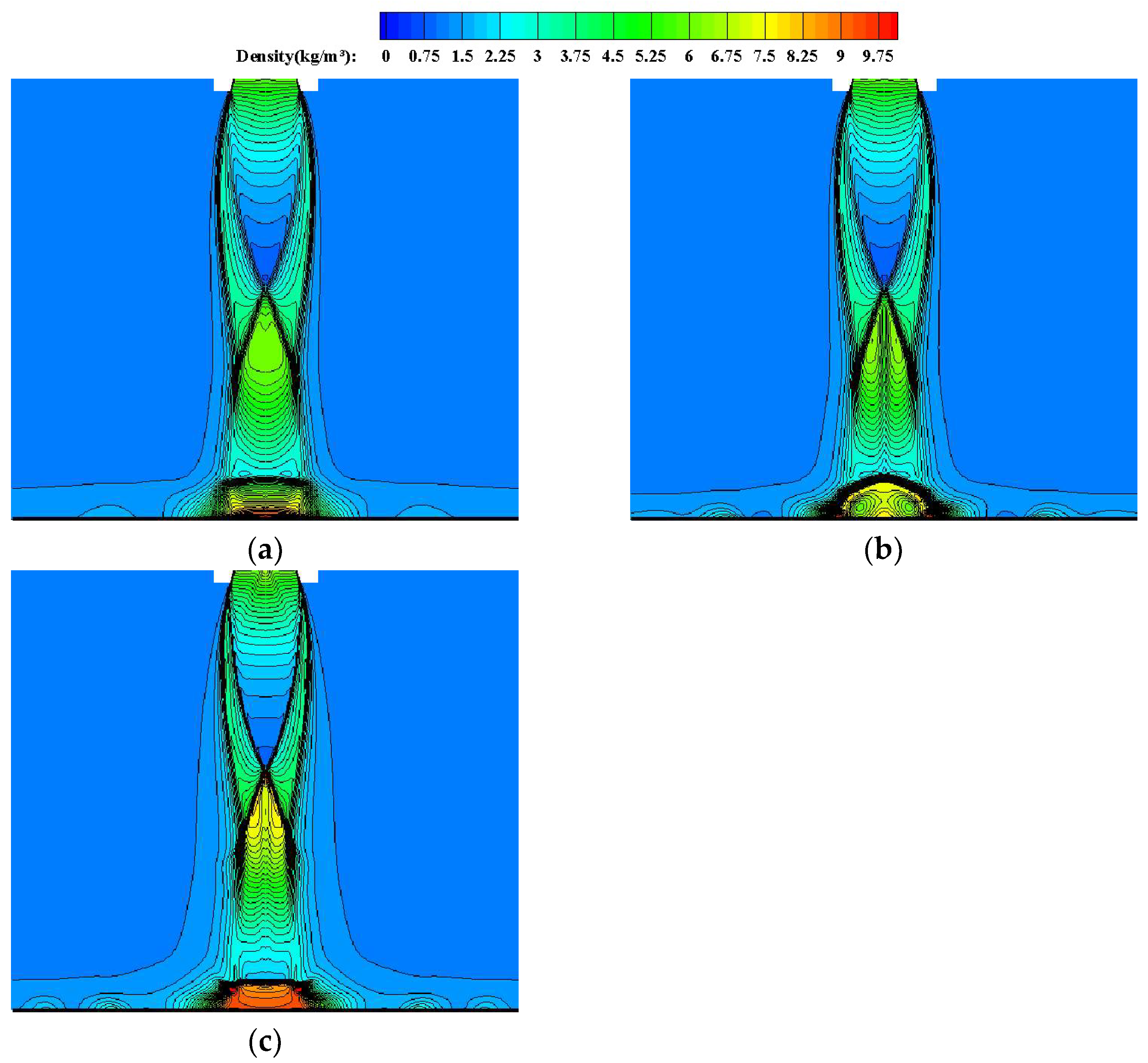

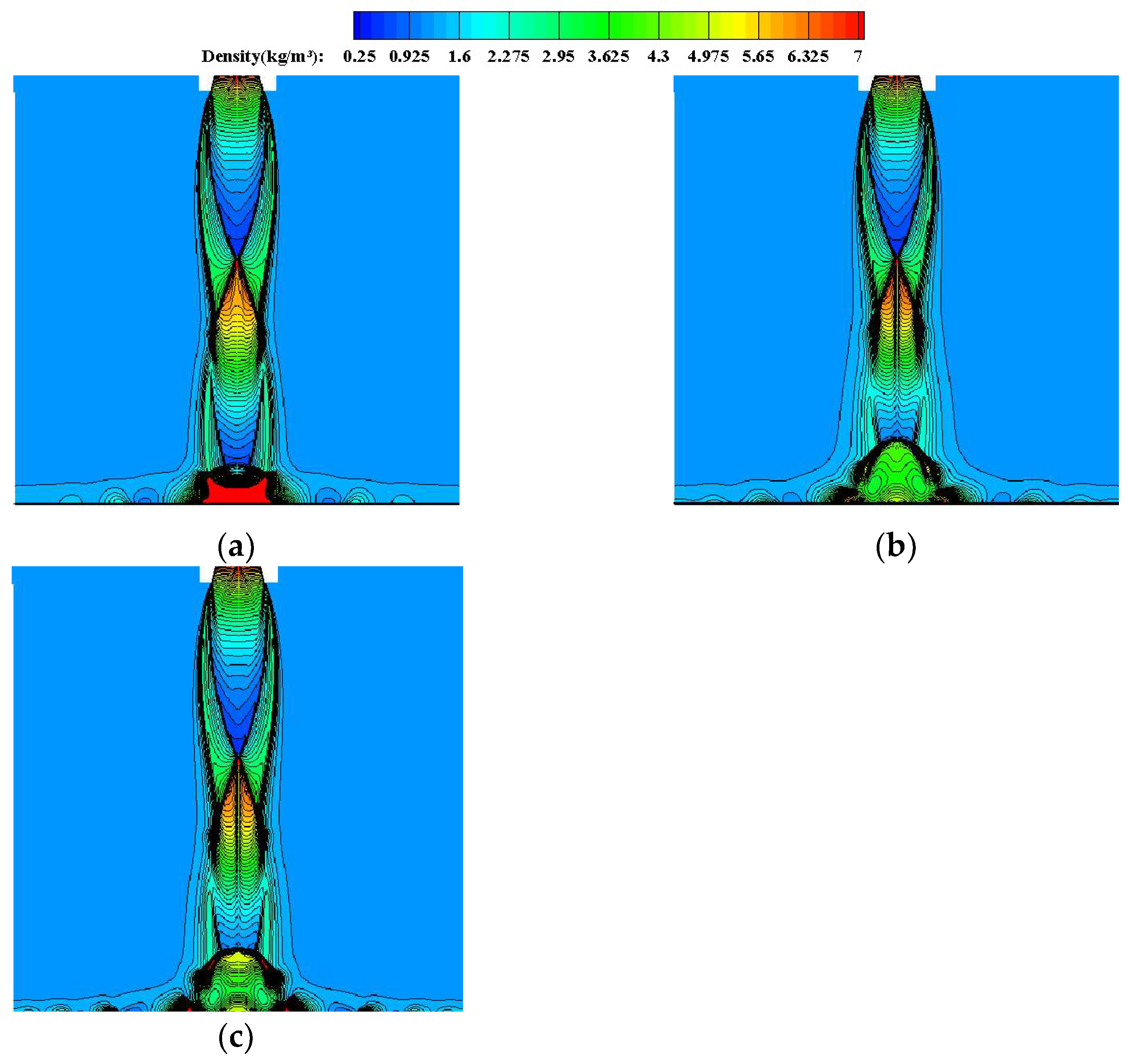

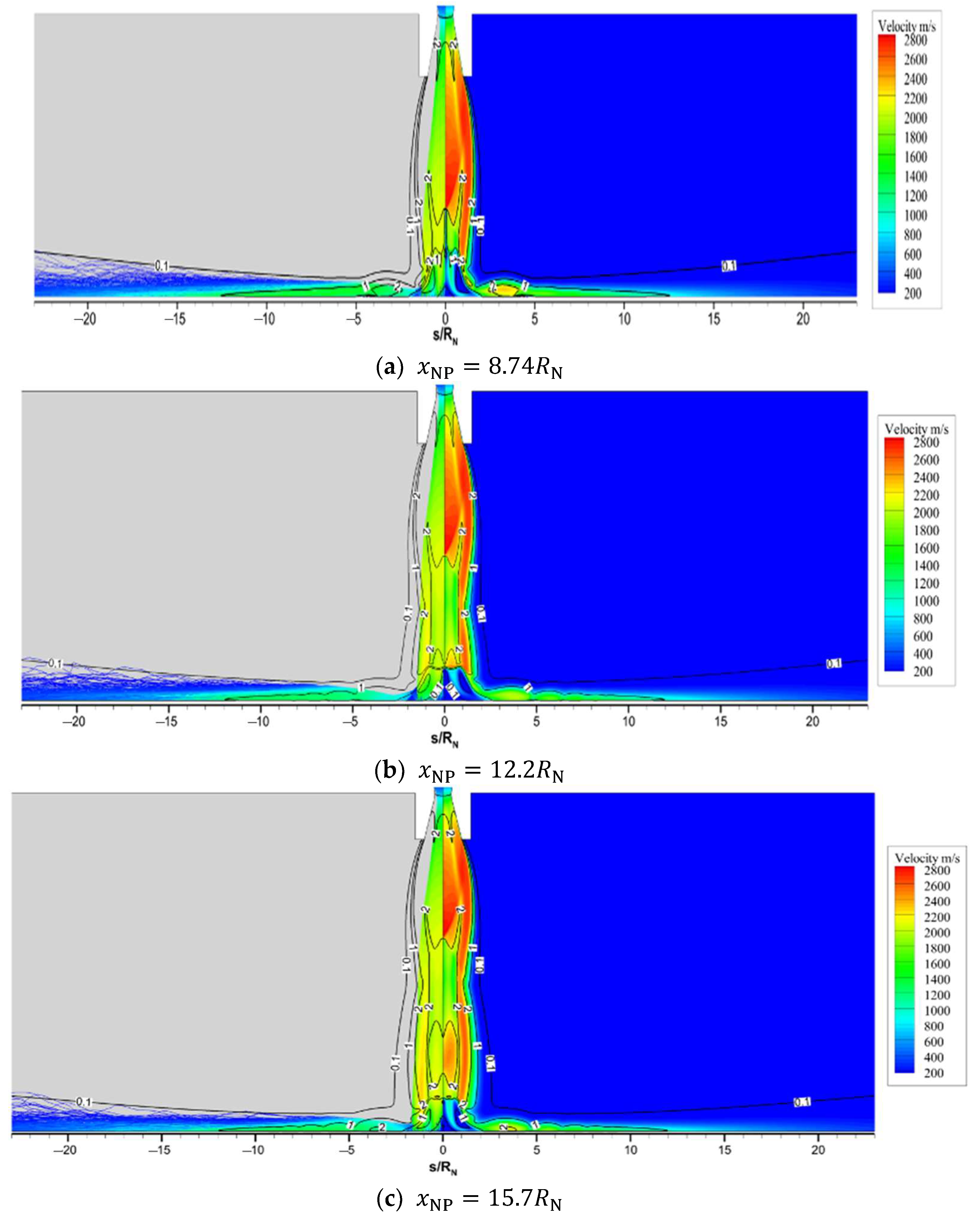

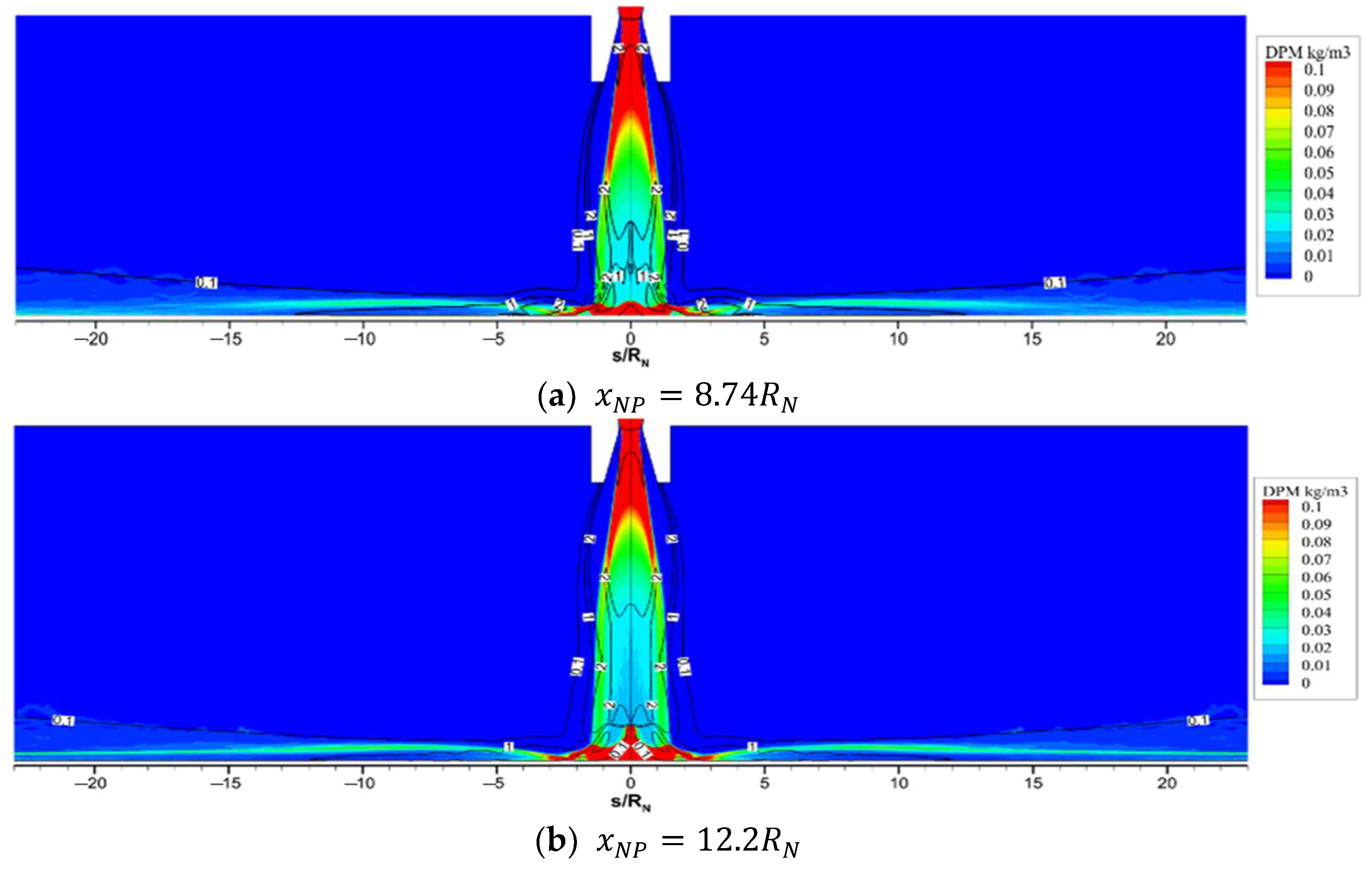

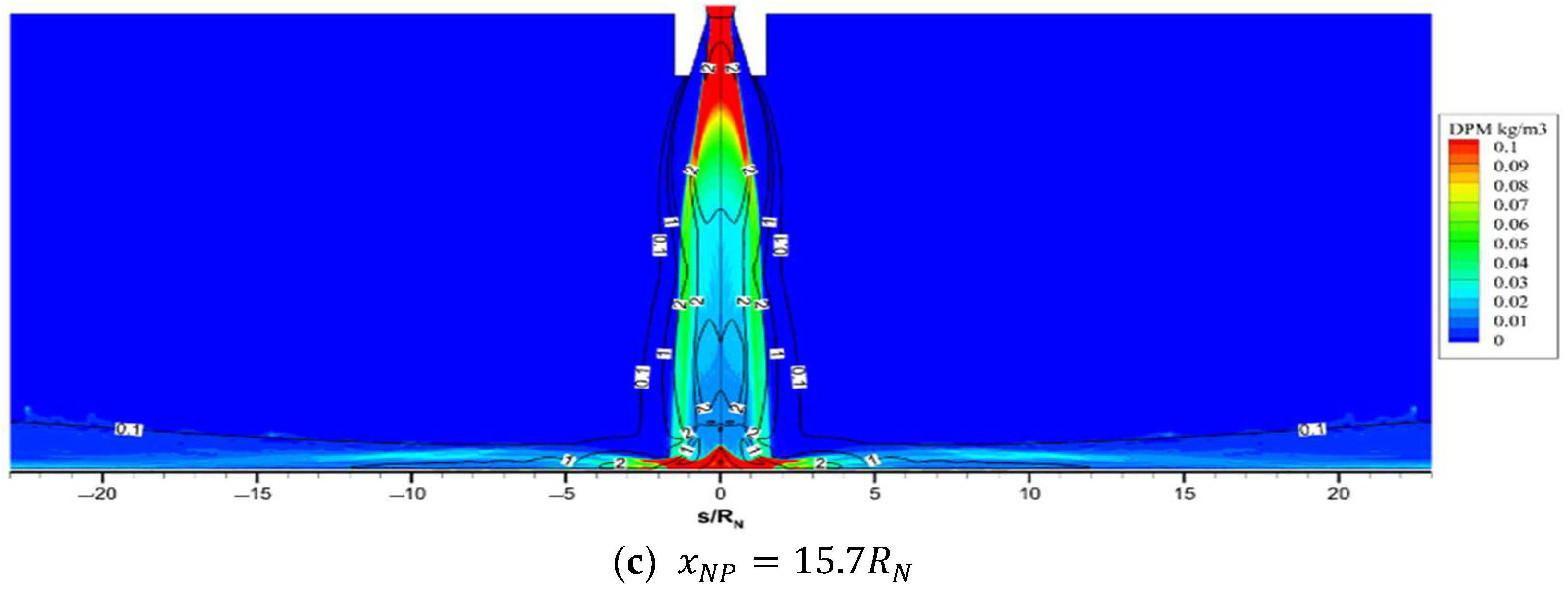

4.1. Study on Two-Phase Jet Fields

4.2. Study on the Erosion and Deposition of Particles on the Wall

5. Conclusions

- (1)

- Simulations were carried out using different grid sizes, and the simulation results were compared with previous experimental data. The grid size of the core area of the supersonic jet was selected as RN/24 by the calculation accuracy, and the resources and time consumption of the calculation were comprehensively considered.

- (2)

- The SST k-ω turbulence model was selected for the simulation. The SST k-ω model had more cycles of gas compression and expansion structures in the wall jet region than the other two turbulence models for different impact distances. The simulation of the static pressure distribution at the wall of the supersonic impact jet was closest to the experimental values.

- (3)

- The effects of different shock distances on the two-phase shock jet field of a solid rocket motor were investigated. In the shock jet field, the addition of the particle phase created a hysteresis effect on the airflow, changing the shock structure of the pure gas-phase flow field. The rebound of the particle phase at the wall caused the waves in front of the wall to move forward and the stagnation bubble structures to disappear in some cases.

- (4)

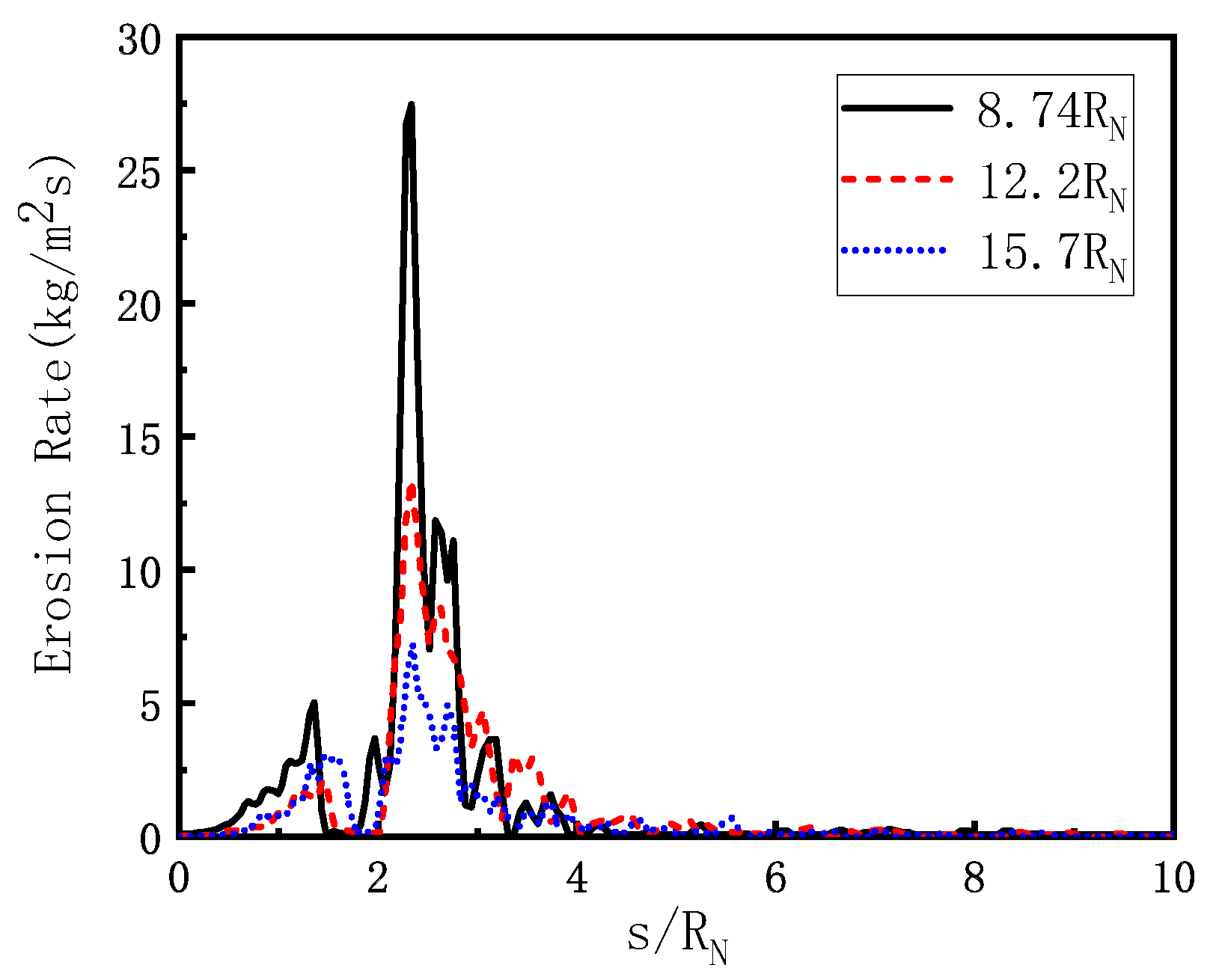

- The erosion rate of particles relative to the solid wall was affected by the particle phase aggregation degree and collision angle. The particle erosion rate at the jet axis was low due to the large incidence angle of particle collision. At the edge of the jet particle movement, the erosion rate of the accumulation area of the secondary collision between the particle and the wall was large. The deposition rate of the granular phase at the wall was mainly affected by the degree of particle aggregation. The increase in jet impact distance changed the distribution of particle phase aggregation, thereby changing the distribution of the wall particle erosion rate and deposition rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DeLuca, L.T.; Annovazzi, A. Survey of burning rate measurements in small solid rocket motors. FirePhysChem 2024, 4, 146–165. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Zou, G.; Dong, H.; Huo, Y. Pressure relief of underground ammunition storage under missile accidental ignition. Def. Technol. 2021, 17, 1081–1093. [Google Scholar] [CrossRef]

- Zhang, Y.; Yi, J.; Xie, X.; Chen, C.; Li, H.; Li, W.; Xu, Y.; Sun, Z.; Zhao, F. Numerical simulation of nano-aluminum ignition in oxygen and steam environments. FirePhysChem 2024, 4, 114–121. [Google Scholar] [CrossRef]

- Imaizumi, Y.; Kamiyama, K.; Matsuba, K.I. New analysis model of solid body formation in particle method for jet impingement and solidification in severe accidents of SFRs. Ann. Nucl. Energy 2024, 206, 110658. [Google Scholar] [CrossRef]

- Joshi, J.; Sahu, S.K. Effect of nozzle configurations and jet orientations on thermal performance of jet impingement on convex surface. Int. J. Therm. Sci. 2024, 203, 109171. [Google Scholar] [CrossRef]

- Cornaro, C.; Fleischer, A.S.; Goldstein, R.J. Flow visualization of a round jet impinging on cylindrical surfaces. Exp. Therm. Fluid Sci. 1999, 20, 66–78. [Google Scholar] [CrossRef]

- McDaniel, C.S.; Webb, B.W. Slot jet impingement heat transfer from circular cylinders. Int. J. Heat Mass Transfer. 2000, 43, 1975–1985. [Google Scholar] [CrossRef]

- Pachpute, S.; Premachandran, B. Experimental and numerical investigations of slot jet impingement with and without a semi-circular bottom confinement. Int. J. Heat Mass Transfer. 2017, 114, 866–890. [Google Scholar] [CrossRef]

- Cai, H.; Nie, W.; Hou, Z. Impact effect of liquid rocket motor exhaust plume on launching platform. J. Aerosp. Power. 2016, 31, 1995–2001. [Google Scholar]

- David, R.; Wallman, P.; Sanford, M. Characterization of rocket plume fluid dynamic environment using numerical & experiment approaches. AIAA J. 2013, 50, 527–539. [Google Scholar]

- Wang, G.; Xu, W.; Gao, Y. A study on erosive effect of two phase impinging jets on vertical plate. J. Ballist. 2009, 21, 10–14. [Google Scholar]

- Basu, S.; Saha, S.; Chakraborty, D. Numerical simulation of missile jet deflector. J. Spacecr. Rocket. 2017, 54, 930–935. [Google Scholar] [CrossRef]

- Shapiro, A.H. The Dynamics and Thermodynamics of Compressible Fluid Fow; Ascher, H., Ed.; Wiley: Hoboken, NJ, USA, 2017; Volume 2. [Google Scholar]

- Nicomedes, W.L.; Bathe, K.-J.; Moreira, F.J.S.; Mesquita, R.C. Overlapping finite elements for the Navier-Stokes equations. Comput. Struct. 2024, 299, 107343. [Google Scholar] [CrossRef]

- Cai, C.; Fan, L.; Wu, B. Numerical simulation of combustor temperature performance of a high-temperature high-speed heat-airflow simulation system. World J. Eng. 2016, 13, 422–431. [Google Scholar] [CrossRef]

- Clarkson, P.A.; Kruskal, M.D. New similarity reductions of the boussinesq equations. J. Math. Phys. 1989, 30, 2201–2213. [Google Scholar] [CrossRef]

- Du, J.; Navon, I.M.; Zhu, J.; Fang, F.; Alekseev, A.K. Reduced order modeling based on POD of a parabolized Navier–Stokes equations model II: Trust region POD 4D VAR data assimilation. Comput. Math. Appl. 2013, 65, 380–394. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, G.; Zhao, S.; Han, B. The influence of dusty size distribution model on propagation of electromagnetic waves in inhomogeneous plasma sheath. J. Phys. Conf. Ser. 2021, 1995, 012014. [Google Scholar] [CrossRef]

- Tsuboi, N.; Hayashi, A.K.; Fujiwara, T.; Arashi, K.; Kodama, M. Numerical simulation of a supersonic jet impingement on a ground. Proc. Soc. Automot. Eng. 1991, 246, 421–433. [Google Scholar]

- Song, G.; Zong, H.; Liang, H.; Su, Z.; Xie, L.; Zheng, X. Parametric study of high-frequency characteristics of plasma synthetic jet actuator. Plasma Sci. Technol. 2021, 23, 125503. [Google Scholar] [CrossRef]

- Li, J.; Jiang, Y. Numerical calculation on the influence of missile exhaust plume with mechanical properties to the double-launch box. Adv. Mat. Res. 2014, 978, 101–105. [Google Scholar] [CrossRef]

- Pattamatta, A.; Singh, G.; Mongia, H. Assessment of Turbulence Models for Free and Confined Impinging Jet Flows. In Proceedings of the 42nd AIAA Thermophysics Conference (AIAA), Honolulu, HI, USA, 27–30 June 2011. [Google Scholar]

- Aiister, F.; Martin, T.; David, H. A numerical investigation of solid particle erosion experienced within oilfield control valves. Wear 1998, 216, 184–193. [Google Scholar]

- Li, Z.; Xiang, H.; Zhang, X. Numerical simulation of jet flow field of composite propellant missile engine. J. Solid Rocket. Technol. 2014, 1, 37–42. [Google Scholar]

- Bing, X.; Liu, L. Numerical calculation of flow field in vertical launching gas exhaust system. J. Ordnance Equip. Eng. 2016, 37, 52–54. [Google Scholar]

- Li, Y.; Chen, L.; Jian, Z. Numerical study of two-phase nozzle flow with classified particles. J. Solid Rocket. Technol. 2003, 26, 32–34. [Google Scholar]

| Grid | Number of Meshes | Memory Footprint (MB) | Calculation Time (h) |

|---|---|---|---|

| G1 | 80,000 | 6.6 | 6 |

| G2 | 150,000 | 12.9 | 14 |

| G3 | 270,000 | 23.4 | 29 |

| Component | Quality Fraction | Component | Quality Fraction | Component | Quality Fraction |

|---|---|---|---|---|---|

| CO | 2.4412 × 10−1 | H2 | 1.5212 × 10−2 | OH | 6.1308 × 10−3 |

| CO2 | 5.7111 × 10−2 | H2O | 1.5973 × 10−1 | O2 | 2.7547 × 10−4 |

| Cl | 1.1398 × 10−2 | N2 | 1.3789 × 10−1 | H | 7.2076 × 10−4 |

| Cl2 | 5.6607 × 10−5 | O | 3.0101 × 10−4 | HCl | 1.8564 × 10−1 |

| Al2O3 | 1.814 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Dang, M.; Wang, Y. A Study on the Impact Erosion Effect of a Two-Phase Jet Field on a Wall at Different Impact Distances by Numerical Simulation. Fire 2024, 7, 312. https://doi.org/10.3390/fire7090312

Li Y, Dang M, Wang Y. A Study on the Impact Erosion Effect of a Two-Phase Jet Field on a Wall at Different Impact Distances by Numerical Simulation. Fire. 2024; 7(9):312. https://doi.org/10.3390/fire7090312

Chicago/Turabian StyleLi, Ying, Mingzhu Dang, and Yawei Wang. 2024. "A Study on the Impact Erosion Effect of a Two-Phase Jet Field on a Wall at Different Impact Distances by Numerical Simulation" Fire 7, no. 9: 312. https://doi.org/10.3390/fire7090312

APA StyleLi, Y., Dang, M., & Wang, Y. (2024). A Study on the Impact Erosion Effect of a Two-Phase Jet Field on a Wall at Different Impact Distances by Numerical Simulation. Fire, 7(9), 312. https://doi.org/10.3390/fire7090312