Examining the Existing Criteria for the Evaluation of Window Ejected Plume Attachment

Abstract

1. Introduction

1.1. The Existing Criteria for the Evaluation of Plume Attachment

1.2. Disagreements in Recent Studies

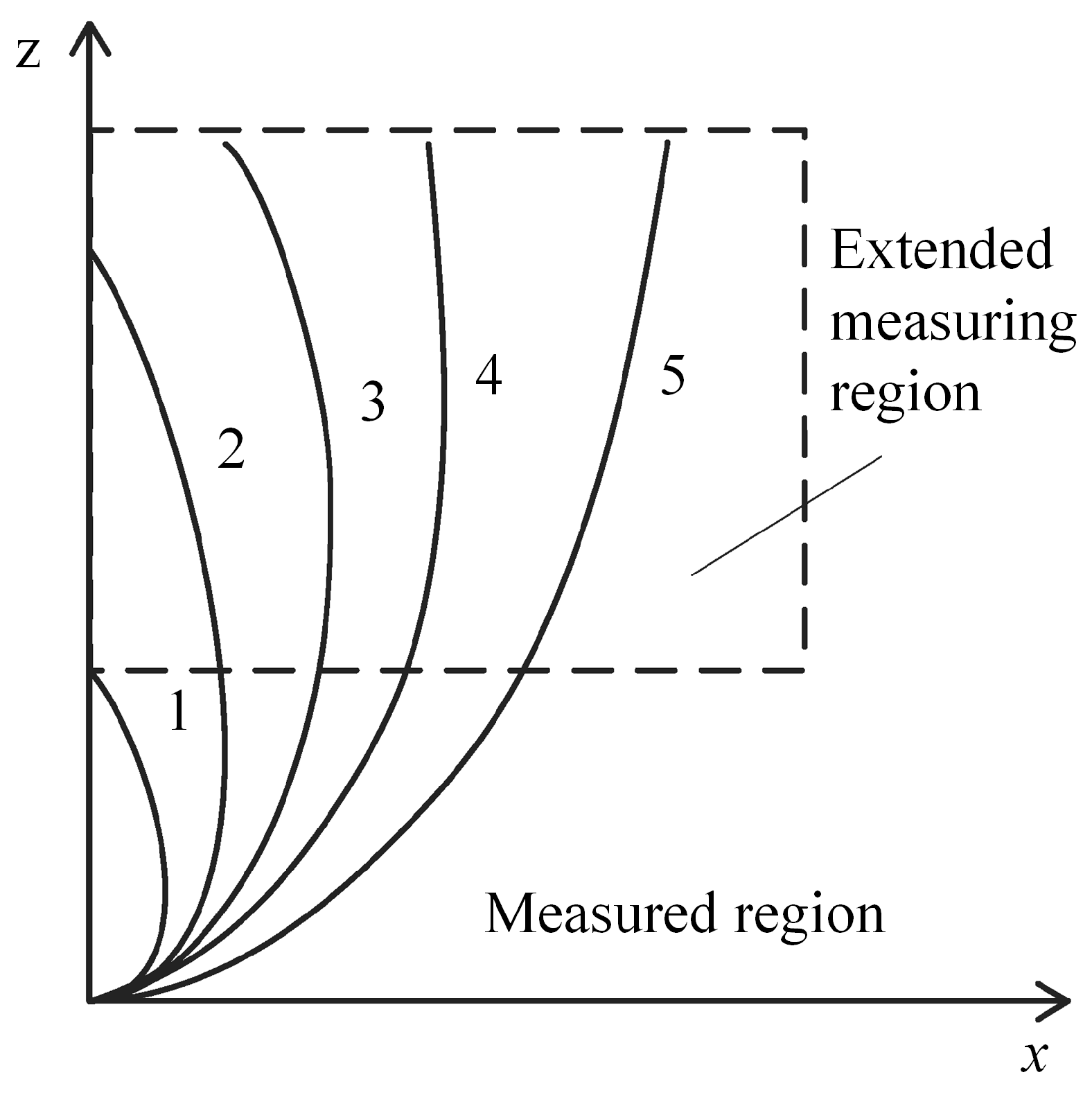

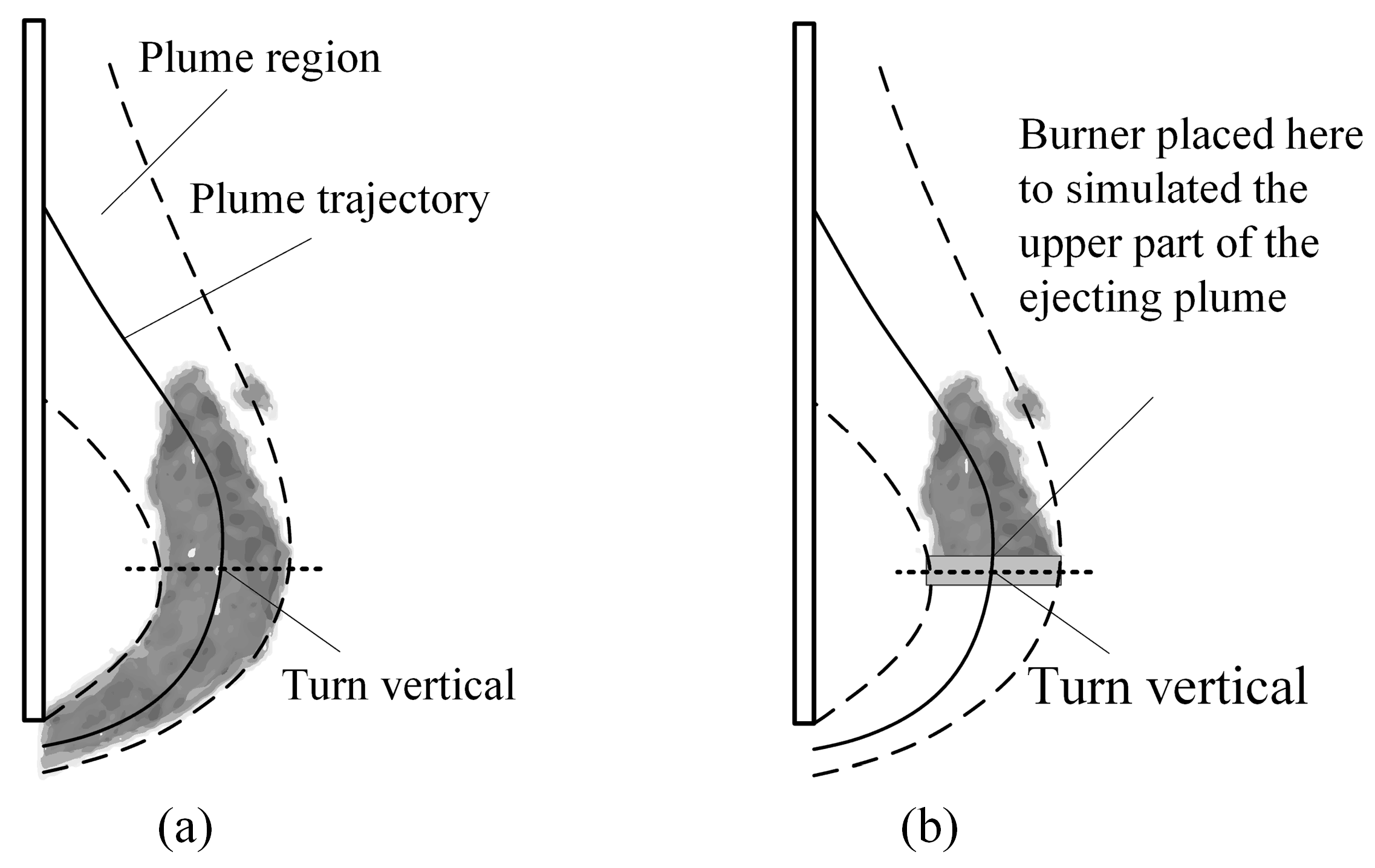

1.3. Simulating the Upper Part of Ejected Plume Using Square Pool Fires

2. Details of Experimental Apparatus and Simulation Conditions

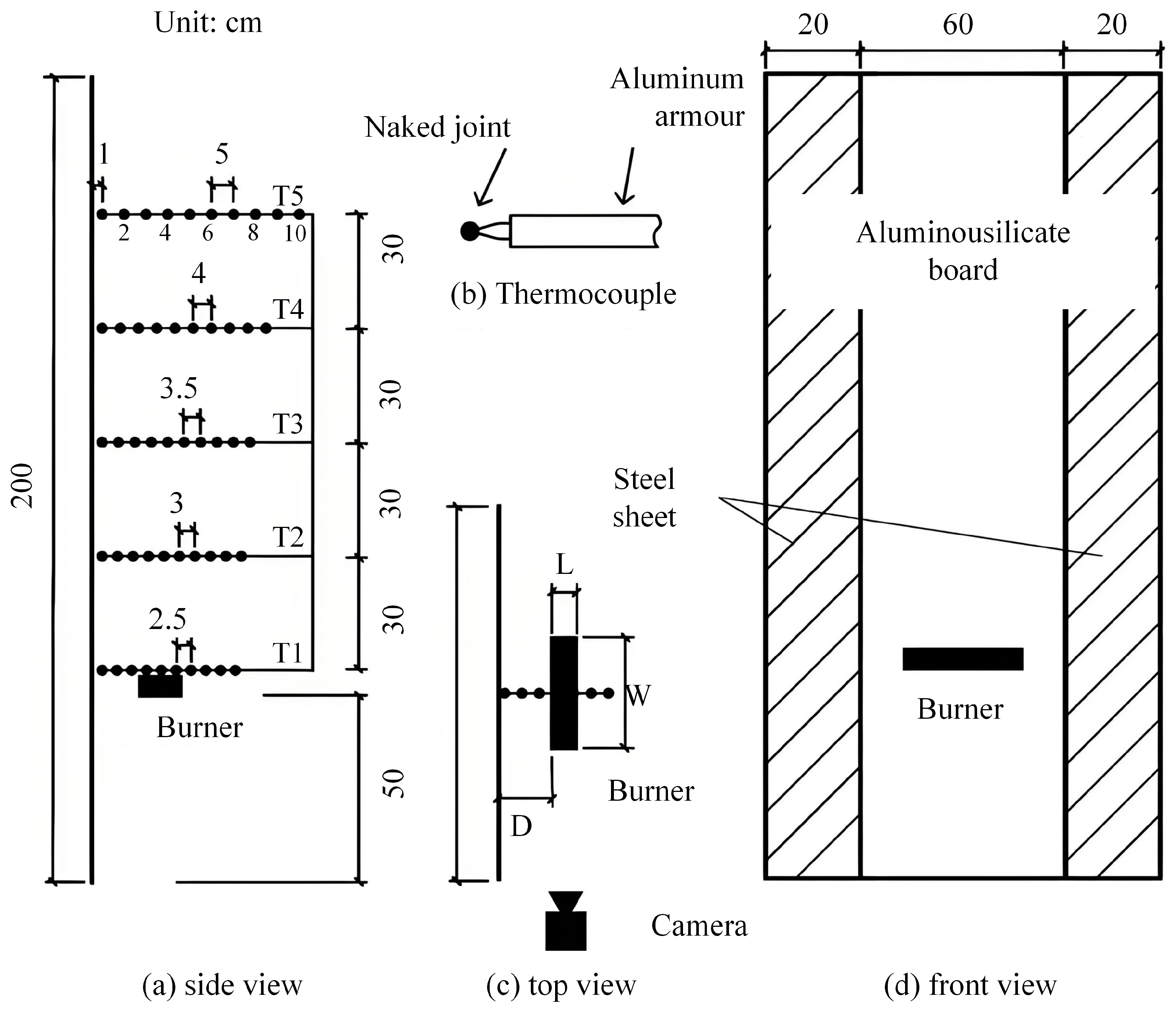

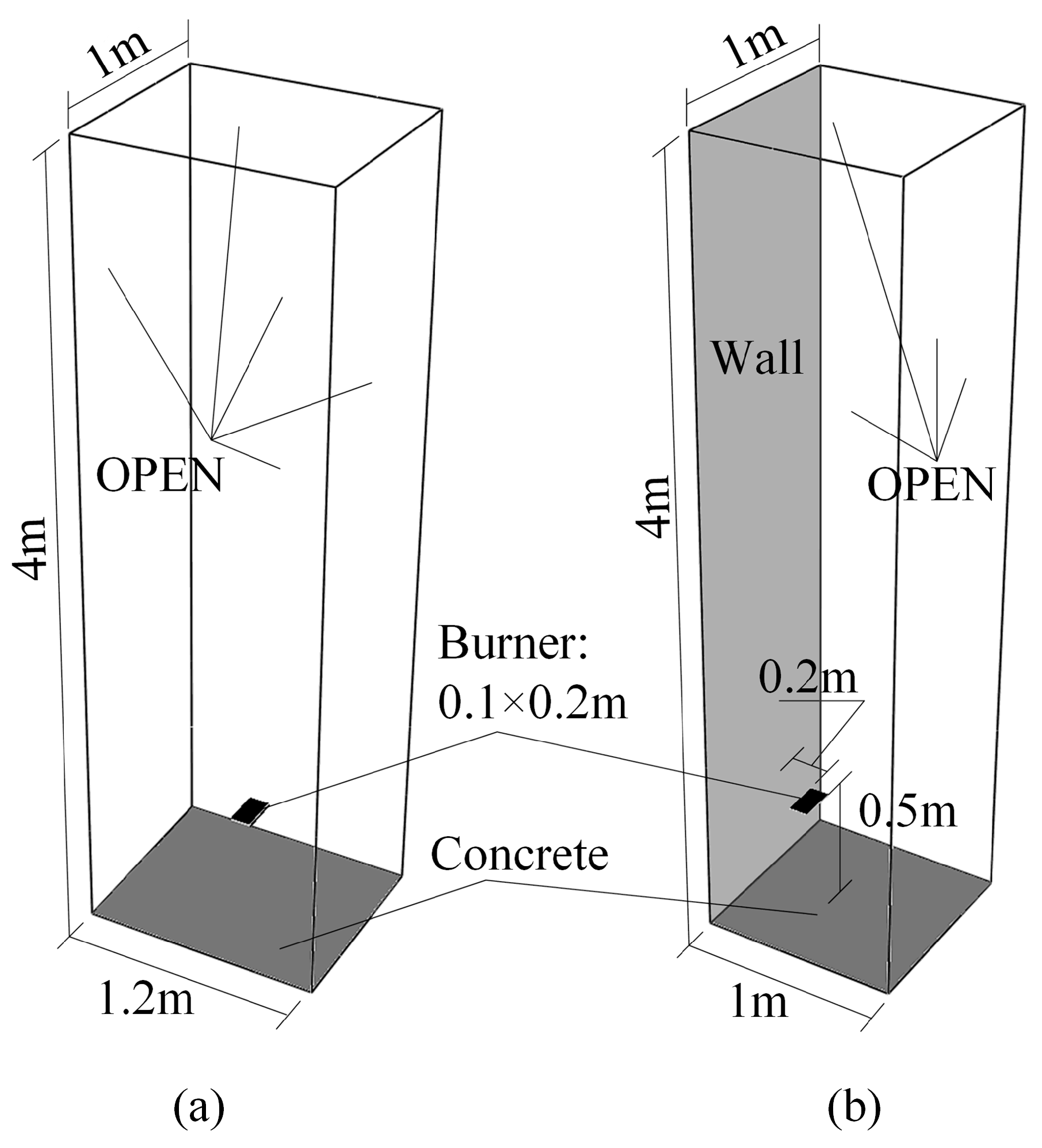

2.1. Experimental Apparatus

2.2. Simulation Conditions

3. Results and Discussion

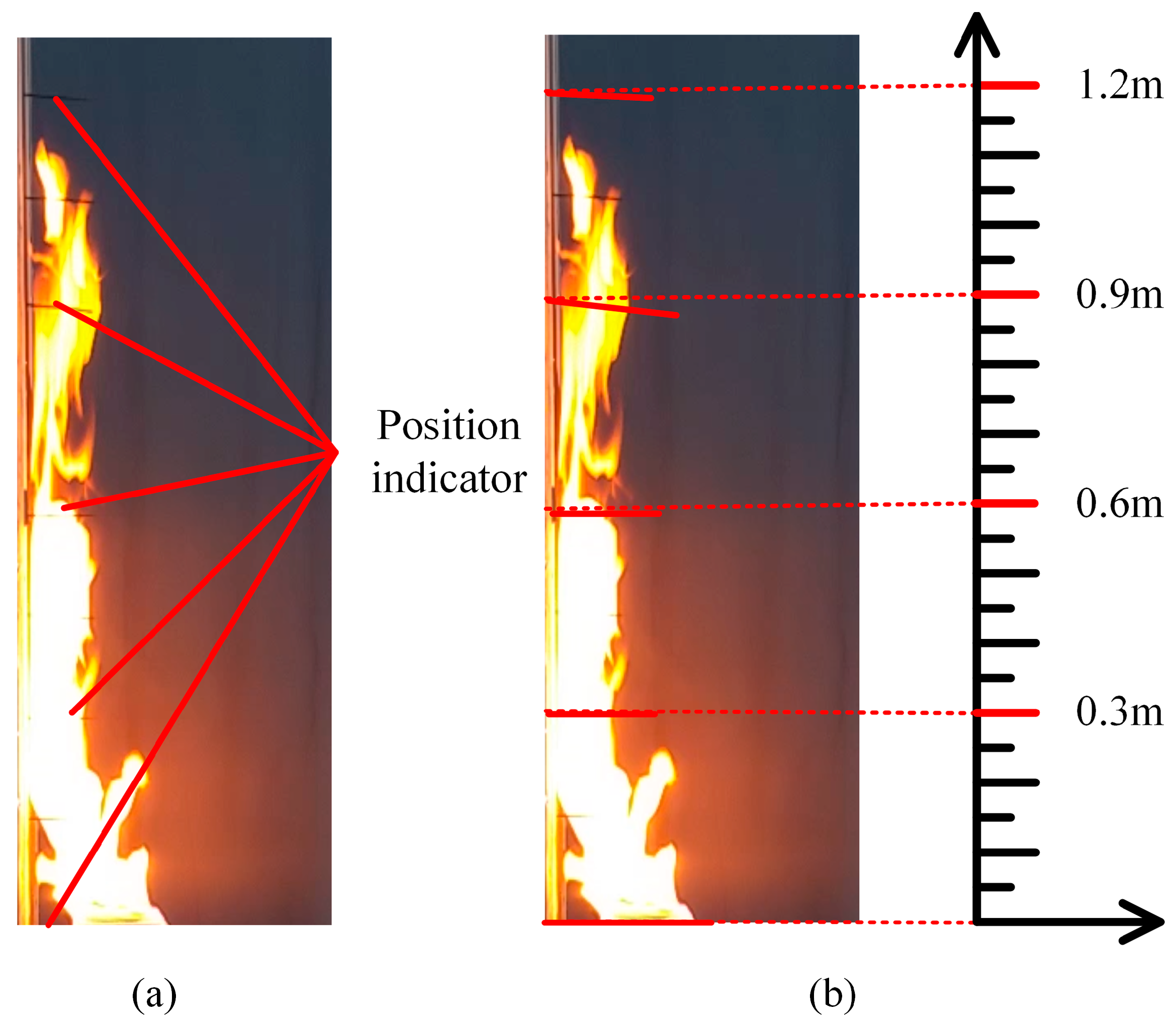

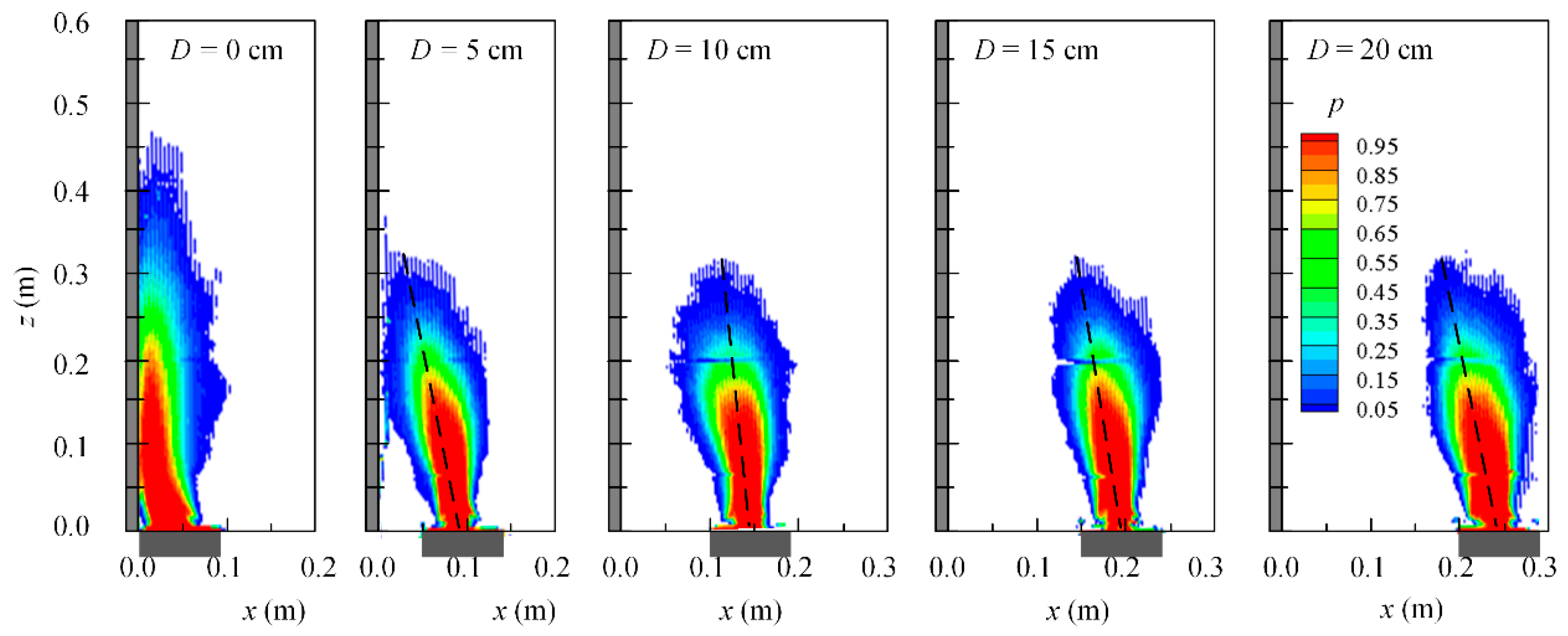

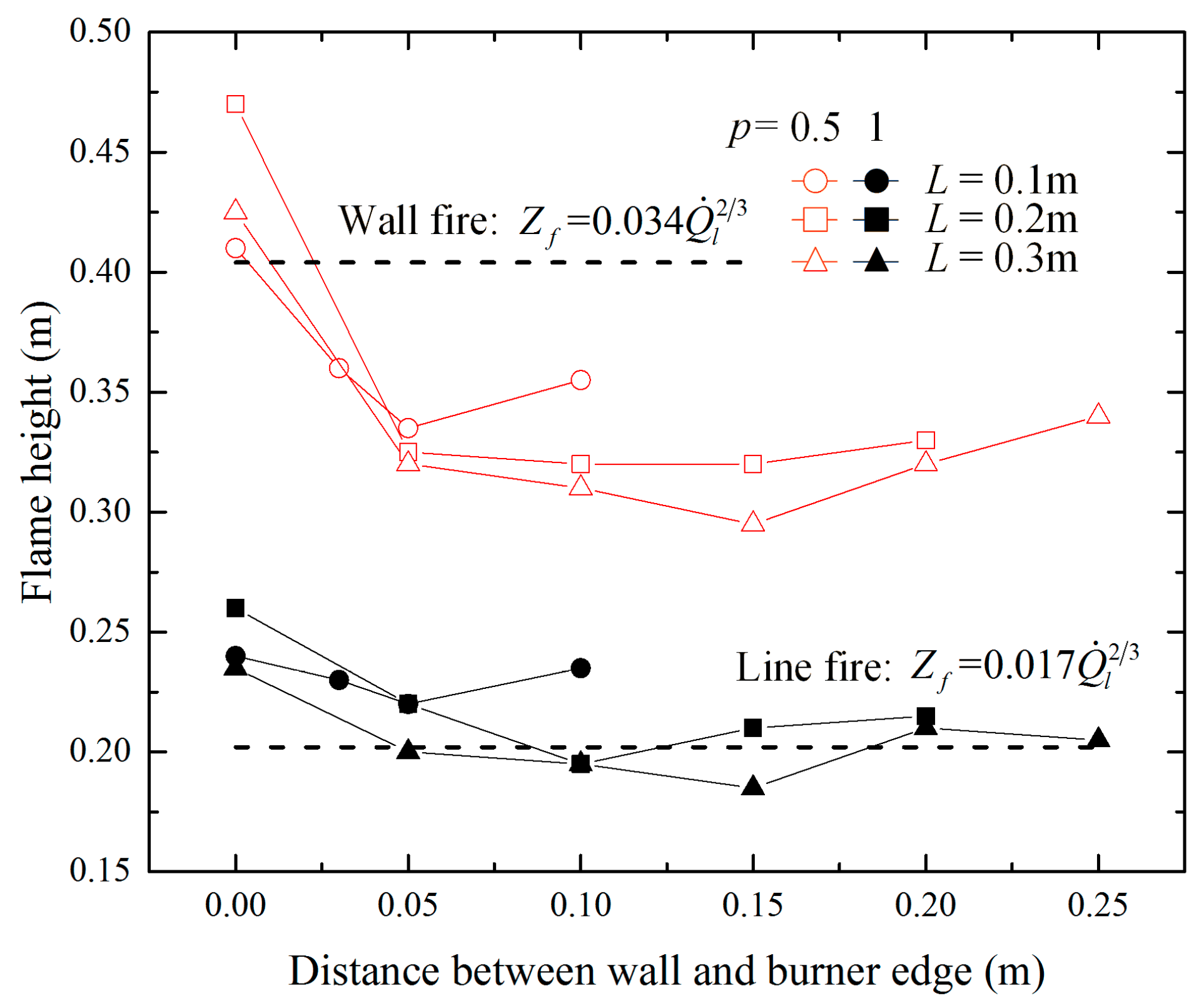

3.1. Flame Shape and Flame Height Obtained in Experiments

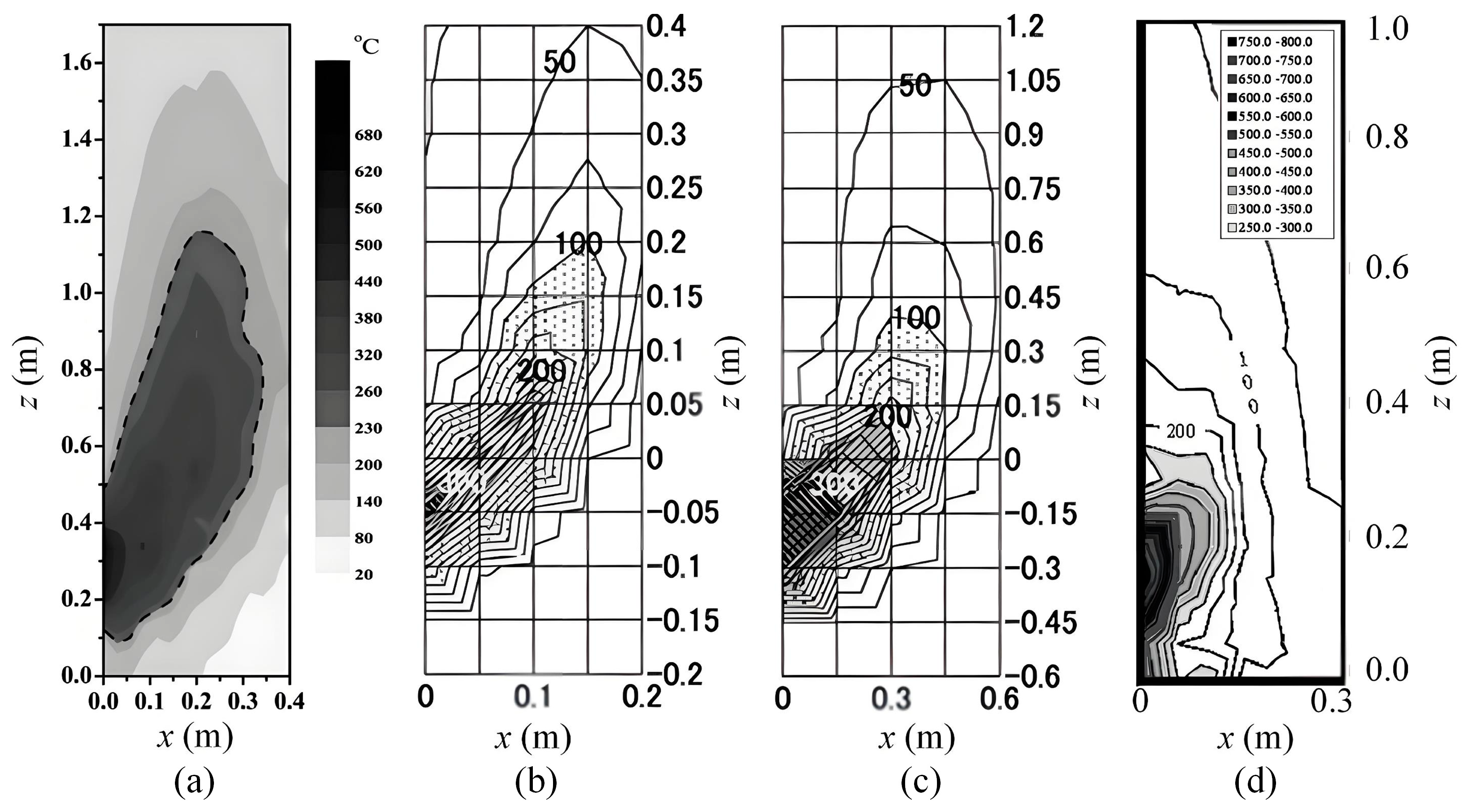

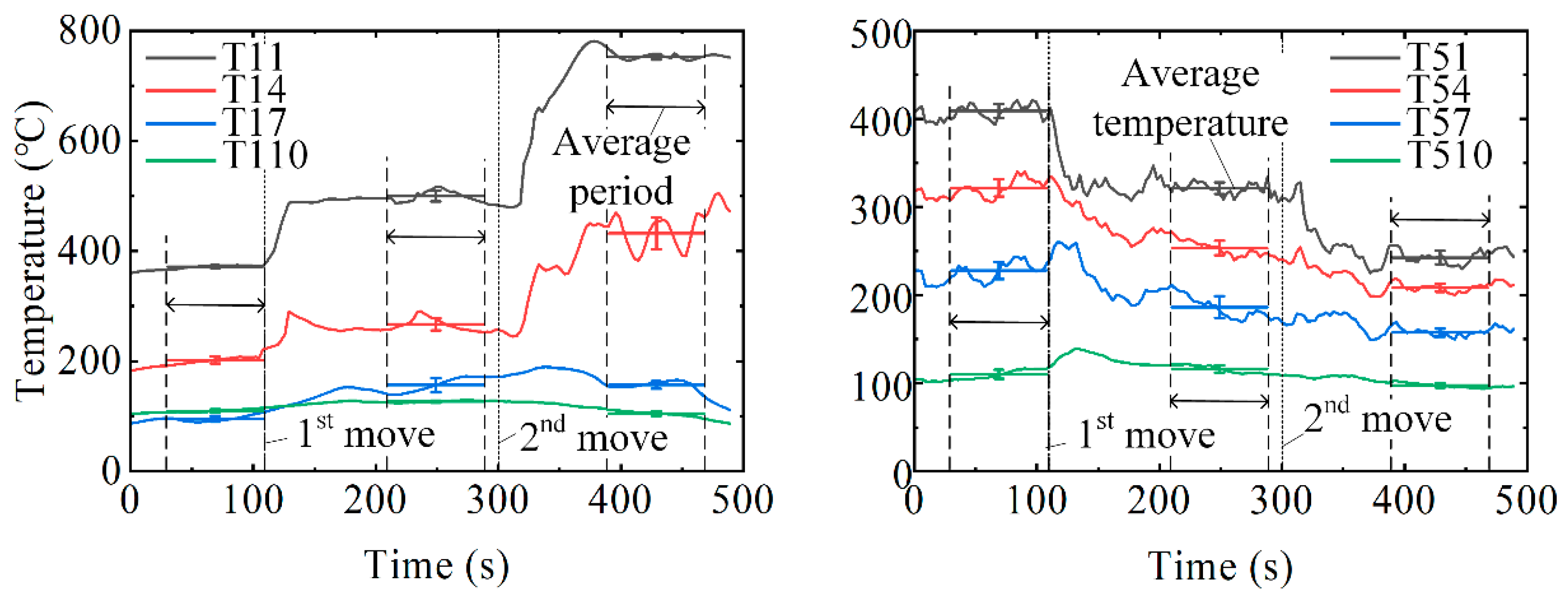

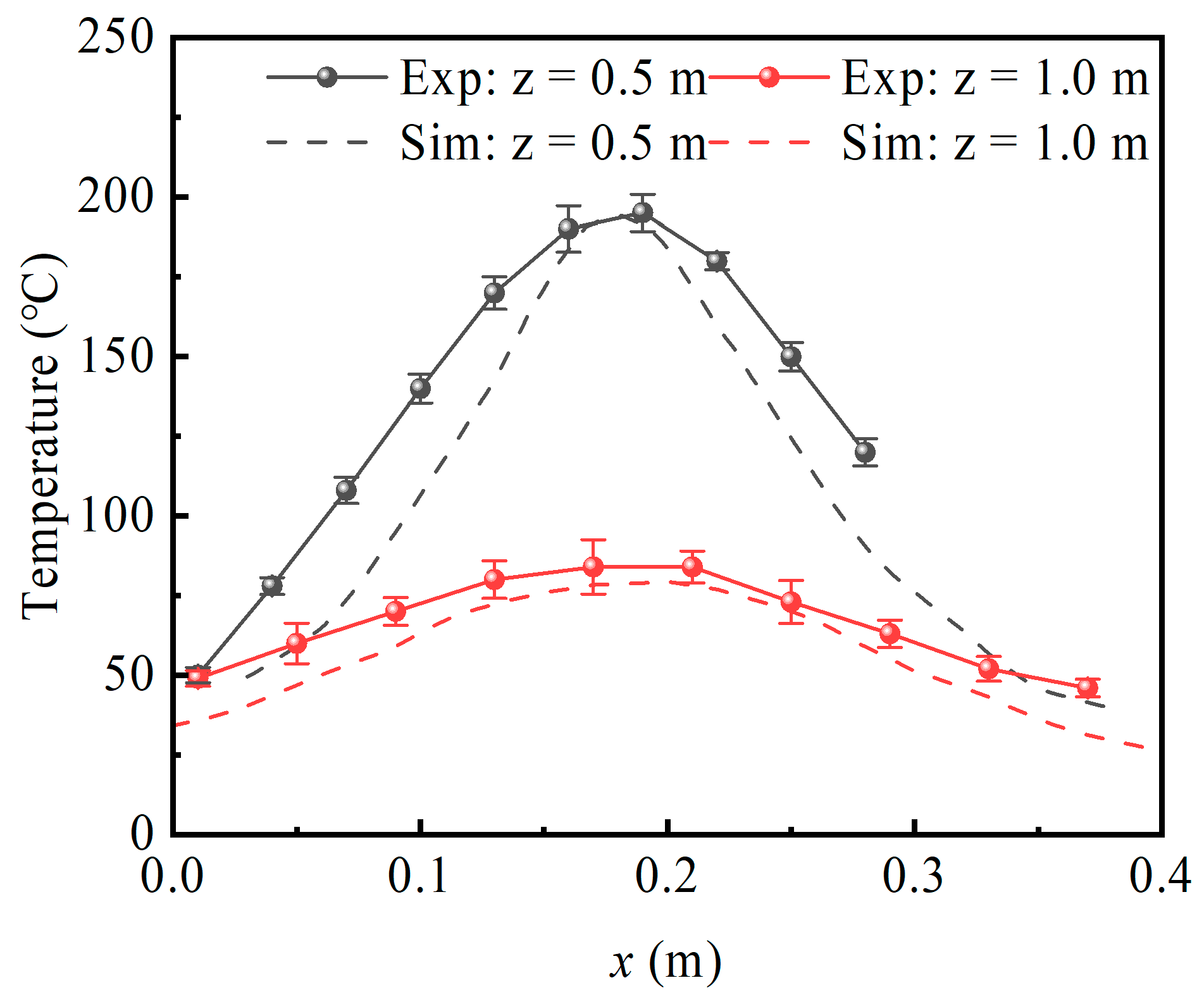

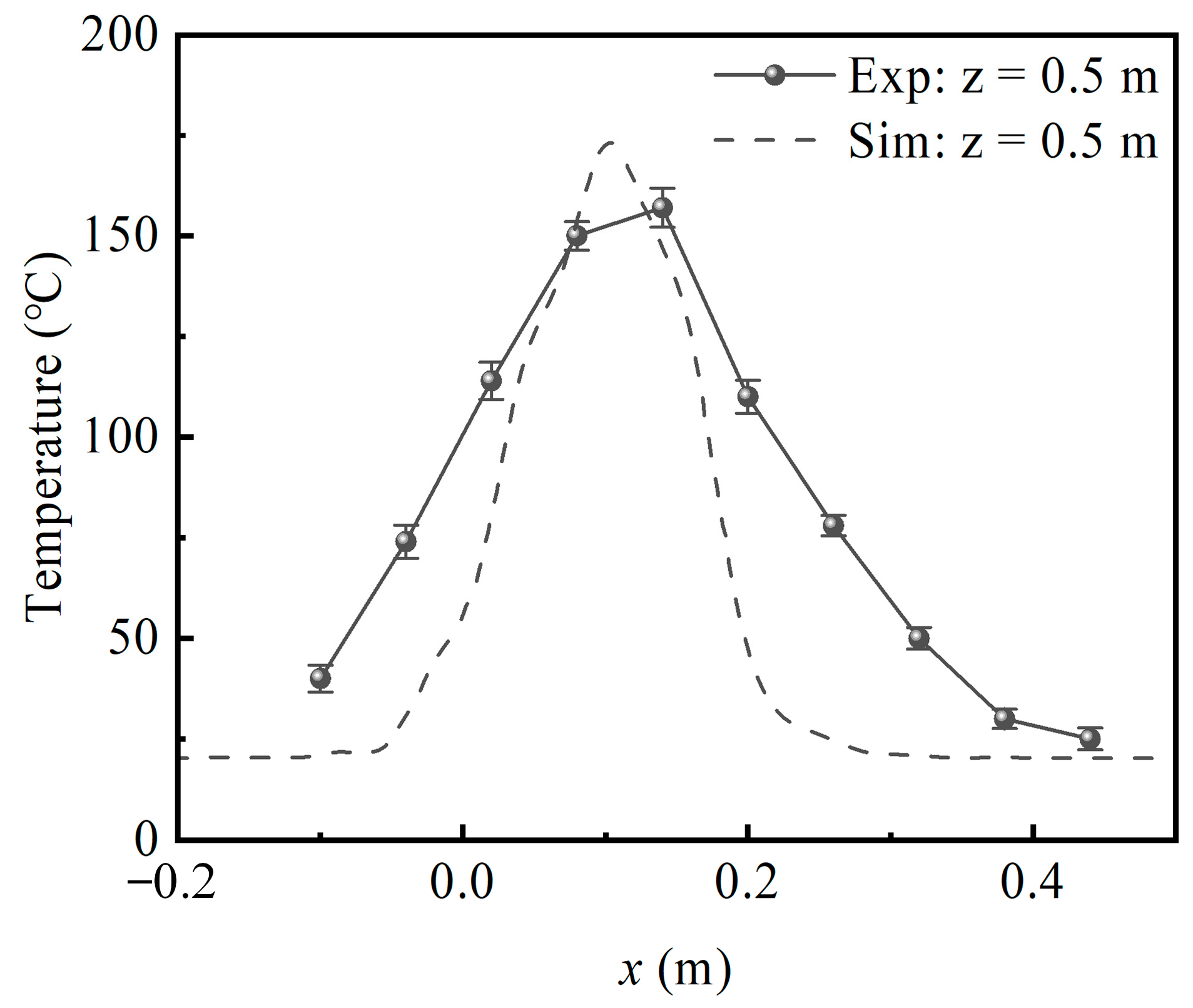

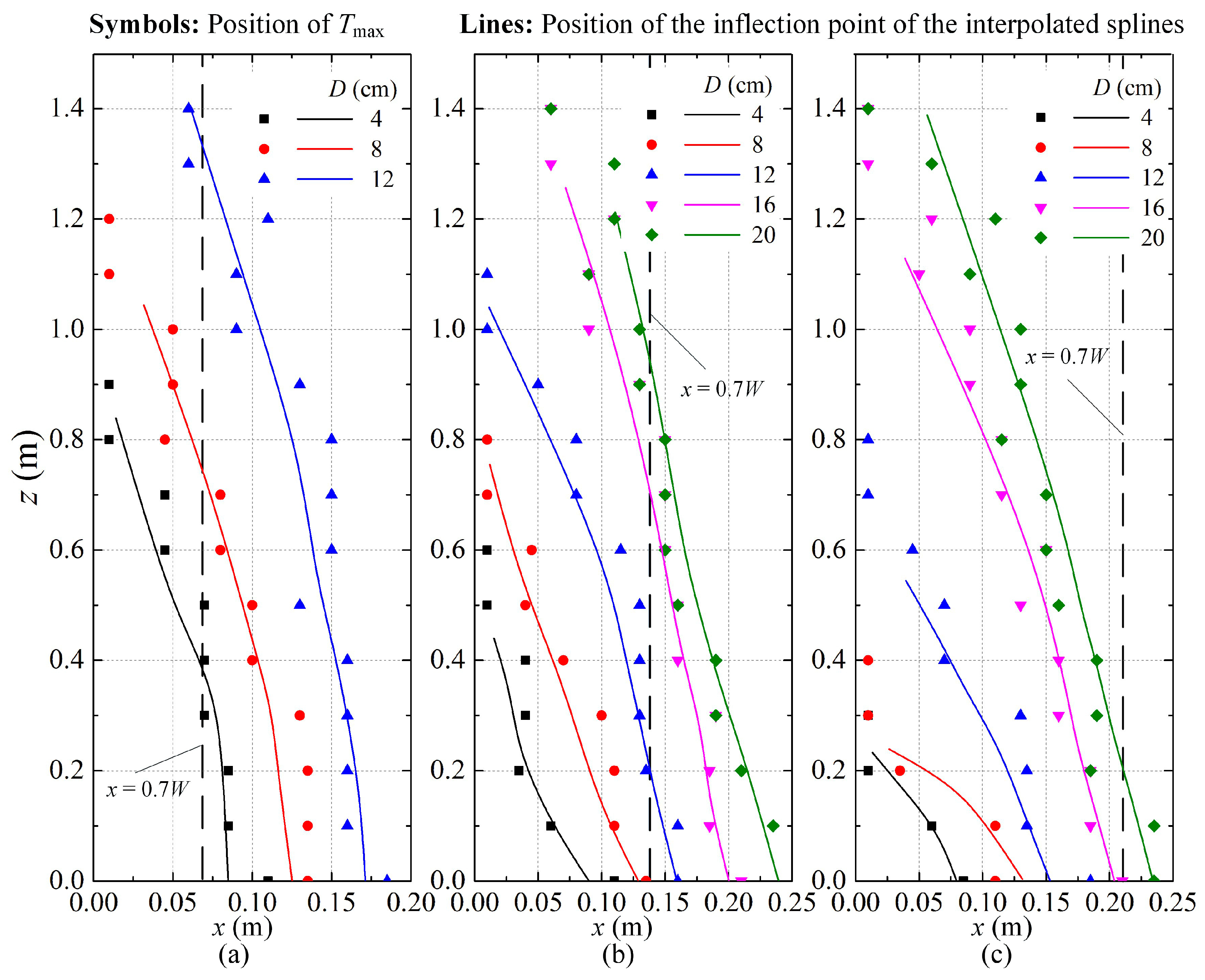

3.2. Time-Averaged Temperature Profile and Plume Trajectory

3.3. A Discussion on the Criteria for Evaluating Plume Attachment

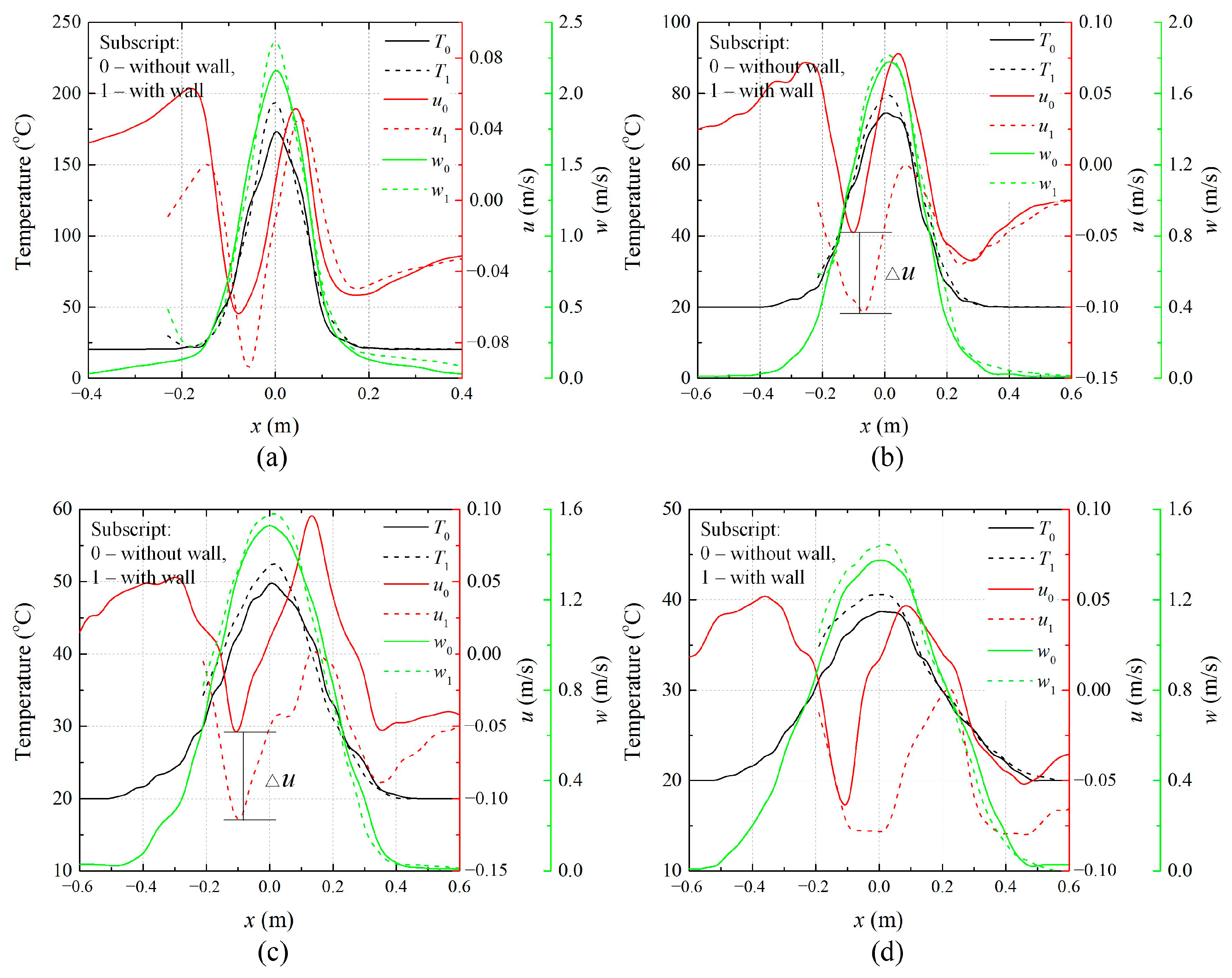

3.4. Velocity Generated by the Induced Pressure Difference

4. Conclusions

- The burner fire tilted to the wall even if LE. burner fire > 0.7W, which contradicts the existing criteria for estimating plume attachment. The reason is that the estimated effect of the induced pressure difference is lower in large fire scenarios.

- The induced pressure difference drives the plume toward the wall like a rigid body.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yokoi, S. Study on the Prevention of Fire-Spread Caused by Hot Upward Current; The Building Research Institute, Ministry of Construction: Tokyo, Japan, 1960. [Google Scholar]

- Yamaguchi, J.I.; Tanaka, T. Temperature Profiles of Window Jet Plume. Fire Sci. Technol. 2004, 24, 17–38. [Google Scholar] [CrossRef]

- Himoto, K.; Tsuchihashi, T.; Tanaka, Y.; Tanaka, T. Modeling the trajectory of window flames with regard to flow attachment to the adjacent wall. Fire Saf. J. 2009, 44, 250–258. [Google Scholar] [CrossRef]

- Harrison, R.; Spearpoint, M. The horizontal flow of gases below the spill edge of a balcony and an adhered thermal spill plume. Int. J. Heat Mass Transf. 2010, 53, 5792–5805. [Google Scholar] [CrossRef]

- Harrison, R. Entrainment of Air into Thermal Spill Plumes. Ph.D Thesis, University of Canterbury, Christchurch, New Zealand, 2009. [Google Scholar]

- Harrison, R.; Spearpoint, M. Physical scale modelling of adhered spill plume entrainment. Fire Saf. J. 2010, 45, 149–158. [Google Scholar] [CrossRef]

- Zhou, B.; Yoshioka, H.; Noguchi, T.; Ando, T. Experimental study on vertical temperature profile of buoyant window spill plume from intermediate-scale compartments. Fire Mater. 2020, 44, 516–529. [Google Scholar] [CrossRef]

- Lu, K.H.; Wang, Z.C.; Ding, Y.M.; Wang, J.; Zhang, J.P.; Delichatsios, M.A.; Hu, L.H. Flame behavior from an opening at different elevations on the facade wall of a fire compartment. Proc. Combust. Inst. 2021, 38, 4551–4559. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, X.; Lv, J.; Chen, X.; Fang, X.; Tang, F.; Ren, F.; Hu, L. Transverse and lateral temperature profiles of the window-ejected thermal plume along the facade. J. Build. Eng. 2023, 76, 107303. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, X.L.; Yi, J.W.; Sun, X.P.; Tang, F.; Ren, F.; Hu, L.H. Experimental study on vertical temperature of facade fire plume ejected from compartment constrained by adjacent single sidewall. Int. J. Therm. Sci. 2023, 193, 108470. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; Lin, Y.F.; Chen, Y.; Li, K.Y. Flame attachment effect on the distributions of flow, temperature and heat flux of inclined fire plume. Int. J. Heat Mass Transf. 2021, 174, 121313. [Google Scholar] [CrossRef]

- Xu, T.; Tang, F. Predicting the vertical buoyant spill -plume temperature along building facade with an external sloping facing wall. Int. J. Therm. Sci. 2020, 152, 106307. [Google Scholar] [CrossRef]

- Zhang, X.L.; Yang, Y.; Sun, X.P.; Ren, F.; Fang, X.; Hu, L.H. A reduced-scale experimental investigation of facade flame behavior ejected from a top-hung window of fire compartment. Proc. Combust. Inst. 2023, 39, 3673–3681. [Google Scholar] [CrossRef]

- Ji, J.; He, M.M.; Li, L.J.; Zhou, Y.L. Experimental and theoretical study on the characteristics of the spill plume in a compartment fire with high-low opposing openings. Int. J. Therm. Sci. 2023, 187, 108204. [Google Scholar] [CrossRef]

- Duny, M.; Dhima, D.; Wang, H.Y.; Garo, J.P.; Manescau, B. Impact of facade type on an ejected flame propagation from a compartment opening-Experimental and numerical studies. J. Build. Eng. 2022, 46, 103660. [Google Scholar] [CrossRef]

- Miao, L.; Chow, C.L. Thermal behavior of window plume generated by fully developed compartment fires in single-skin and double-skin façade scenarios. Int. J. Therm. Sci. 2020, 153, 106359. [Google Scholar] [CrossRef]

- Cui, Y.; Cheng, X.; Gong, L.; Li, L.; Zhang, H.; Zhao, Y. Effect of Opening Geometry on the Heat Transfer Characteristics for External Flames Impinging on an Exterior Wall. Exp. Heat Transf. 2014, 27, 213–230. [Google Scholar] [CrossRef]

- Yanagisawa, A.; Goto, D.; Ohmiya, Y.; Delichatsios, M.A.; Lee, Y.P.; Wakatsuki, K. Effect of a facing wall on façade flames. Fire Saf. Sci. 2009, 9, 801–811. [Google Scholar] [CrossRef]

- Lee, Y.-P.; Delichatsios, M.A.; Silcock, G.W.H. Heat fluxes and flame heights in façades from fires in enclosures of varying geometry. Proc. Combust. Inst. 2007, 31, 2521–2528. [Google Scholar] [CrossRef]

- Lee, Y.P.; Delichatsios, M.M.; Silcock, G.W.H. Heat Flux Distribution and Flame Shapes on the Inert Facade. Fire Saf. Sci. 2008, 9, 193–204. [Google Scholar] [CrossRef]

- Tang, F.; Hu, L.H.; Delichatsios, M.A.; Lu, K.H.; Zhu, W. Experimental study on flame height and temperature profile of buoyant window spill plume from an under-ventilated compartment fire. Int. J. Heat Mass Transf. 2012, 55, 93–101. [Google Scholar] [CrossRef]

- Beji, T.; Ukleja, S.; Zhang, J.; Delichatsios, M.A. Fire behaviour and external flames in corridor and tunnel-like enclosures. Fire Mater. 2012, 36, 636–647. [Google Scholar] [CrossRef]

- Ohmiya, Y.; Hori, Y.; Sagimori, K.; Wakamatsu, T. Predictive method for properties of flame ejected from an opening incorporating excess fuel. Power Demand Side Manag. 2000, 7, 688–694. [Google Scholar]

- Miao, L.; Yang, Y.; Chow, C.L. Experimental study on the variation regimes of window ejecting flame height. Fire Saf. J. 2019, 109, 102864. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, Z.; Gan, F.; Tao, H.; Zhao, J. Facade flame height ejected from window of a compartment fire under a single sidewall constraint boundary condition. Case Stud. Therm. Eng. 2023, 45, 103004. [Google Scholar] [CrossRef]

- Han, Y.; Sun, X.P.; Yang, Y.; Chen, X.T.; Lv, J.; Wang, X.H.; Zhang, X.L.; Hu, L.H. An experimental study of wall smoke pattern characteristics adjacent to fire source. Int. J. Therm. Sci. 2025, 214, 109865. [Google Scholar] [CrossRef]

- Fang, X.; Sun, X.; Tang, F.; Ren, F. Experimental investigation on morphology of window-ejected flame without facade effect. J. Build. Eng. 2024, 91, 109520. [Google Scholar] [CrossRef]

- Miao, L.; Chow, C.L. Influence of heat release rate and wall heat-blocking effect on the thermal plume ejected from compartment fire. Appl. Therm. Eng. 2018, 139, 585–597. [Google Scholar] [CrossRef]

- Himoto, K.; Tsuchihashi, T.; Tanaka, Y.; Tanaka, T. Modeling thermal behaviors of window flame ejected from a fire compartment. Fire Saf. J. 2009, 44, 230–240. [Google Scholar] [CrossRef]

- Sun, X.; Hu, L.; Lv, J.; Fang, X.; Chen, X.; Zhang, X. Experimental study on the heat flux profile upon the building facade of the window-ejected fire plume. Int. J. Heat Mass Transf. 2023, 214, 124391. [Google Scholar] [CrossRef]

- Sun, X.; Tang, F.; Lu, K.; Ren, F.; Shi, C.; Merci, B.; Hu, L. Fundamentals of window-ejected fire plumes from under-ventilated compartment fires: Recent progresses and perspectives. Prog. Energy Combust. Sci. 2023, 94, 101039. [Google Scholar] [CrossRef]

- Chen, Y.; Miao, Y.; Tao, S.; Li, Q.; Yuan, Y.; Zhang, X.; Hu, L. Flame structure and dynamics in pool fires of different geometries: Experimental and numerical investigation. Energy 2024, 304, 131996. [Google Scholar] [CrossRef]

- Li, Y.; Sun, X.; Chen, Y.; Hu, L.; Zhang, X. Experimental and numerical studies on flame radius, temperature profile and heat flux of axi-symmetric ceiling fires under various sub-atmospheric pressures. Int. J. Therm. Sci. 2025, 211, 109697. [Google Scholar] [CrossRef]

- McGrattan, K.; McDermott, R.; Weinschenk, C.; Forney, G. Fire Dynamics Simulator, Technical Reference Guide, 6th ed.; Special Publication (NIST SP); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. Automatica 1975, 11, 23–27. [Google Scholar] [CrossRef]

- Budnick, E.K.; Evans, D.D.; Nelson, H. Simplified Fire Growth Calculations. In Fire Protection Handbook; Natl Fire Protection Assn: Quincy, MA, USA, 1997. [Google Scholar]

| No. | L | W | D | HRRPUA * |

|---|---|---|---|---|

| cm | cm | cm | kW/m2 | |

| A1 | 8 | 10 | 0, 3, 5, 10 | 460 |

| A2 | 8 | 20 | 0, 5, 10, 15, 20 | |

| A3 | 8 | 30 | 0, 5, 10, 15, 20, 25 | |

| B1 | 10 | 10 | 0, 4, 8, 12, 16, 20 | 560 |

| B2 | 10 | 20 | ||

| B3 | 10 | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, J.; Nie, C.; Zheng, B.; Miao, L. Examining the Existing Criteria for the Evaluation of Window Ejected Plume Attachment. Fire 2025, 8, 168. https://doi.org/10.3390/fire8050168

Xing J, Nie C, Zheng B, Miao L. Examining the Existing Criteria for the Evaluation of Window Ejected Plume Attachment. Fire. 2025; 8(5):168. https://doi.org/10.3390/fire8050168

Chicago/Turabian StyleXing, Jianlong, Chaoting Nie, Bin Zheng, and Lei Miao. 2025. "Examining the Existing Criteria for the Evaluation of Window Ejected Plume Attachment" Fire 8, no. 5: 168. https://doi.org/10.3390/fire8050168

APA StyleXing, J., Nie, C., Zheng, B., & Miao, L. (2025). Examining the Existing Criteria for the Evaluation of Window Ejected Plume Attachment. Fire, 8(5), 168. https://doi.org/10.3390/fire8050168