Integrating a Centrifugal Extraction and Pipeline Transportation System to Improve Efficiency in Shrimp Harvesting Management

Abstract

1. Introduction

2. Material and Methods

2.1. Experimental Setup

- Preparatory phase (traditional netting method):

- (a)

- Prepare the necessary equipment, including nets, baskets, and sorting mechanisms.

- (b)

- Establish the designated area for shrimp receiving and sorting, equipped with appropriate chilling facilities.

- (c)

- Organize an 18-member workforce divided into two teams to ensure efficient workflow.

- Preparatory phase (centrifugal shrimp harvester):

- (a)

- Arrange essential equipment, including pipelines, machinery for white shrimp harvesting, electrical systems, and connectors.

- (b)

- Set up the designated area for shrimp receiving and sorting, complete with freezing and sorting mechanisms.

- (c)

- Deploy an 18-member workforce organized into two teams to optimize workflow.

- Initiation of experimental process (both methods):

- (a)

- Activate the sluice gate to guide shrimp towards the central area of the pond.

- (b)

- Employ the respective harvesting method—traditional netting or centrifugal harvesting—to extract shrimp from the collection pool.

- (c)

- Convey shrimp through the harvesting process using the designated method.

- Shrimp separation and monitoring (both methods):

- (a)

- Implement a dedicated mechanism for shrimp separation to isolate shrimp from the water.

- (b)

- Vigilantly monitor shrimp enumeration and movement throughout the harvesting process.

- Operational procedure of the centrifugal shrimp harvester (centrifugal method):

- (a)

- Securely connect the suction pipe to both the shrimp pond and the harvested shrimp pipe.

- (b)

- Ensure that air valves are closed to prevent air ingress.

- (c)

- Connect the discharge pipe to the 360 m transportation pipe without any air leaks.

- (d)

- Ensure proper positioning and connections between all pipes to prevent airlocks.

- (e)

- Install the shrimp water separator at the sourcing yard and connect it to the transportation pipe.

- (f)

- Activate the vacuum pump to initiate the suction system for water.

- (g)

- Start the main motor at a constant speed of 120 revolutions per minute (RPM).

- (h)

- Utilize the vacuum pump as needed to eliminate air pockets and ensure continuous water flow.

- (i)

- Open the suction channel in the shrimp pond to facilitate harvesting.

- (j)

- Adjust the inlet pipe and impeller speed as required, maintaining a constant impeller speed of 270 RPM.

- (k)

- Connect the suction pipe directly to the outlet pipe of the water suction point in the middle of the shrimp pond.

- (l)

- Operate the harvester at a constant speed of 270 RPM.

- Monitoring and quality grading (both methods):

- (a)

- Observe the efficient operation of each shrimp harvesting method.

- (b)

- Monitor the progress and quality of harvested shrimp throughout the process.

- (c)

- Assess and grade the quality of harvested shrimp, ensuring that only the highest-quality specimens are collected.

- Evaluation and data collection (both methods):

- (a)

- Analyze potential shrimp damage resulting from the harvesting process.

- (b)

- Conduct precise weighing of harvested white shrimp, Litopenaeus vannamei, to record essential data for further analysis.

- Achieving successful harvesting (both methods):

- (a)

- Complete the shrimp harvesting process using the chosen method.

- (b)

- Record the total quantity of harvested white shrimp, Litopenaeus vannamei, ensuring accurate measurement.

- Data analysis and conclusion (both methods):

- (a)

- Compare the efficiency and quality of shrimp harvested using the centrifugal shrimp harvester with those obtained through the traditional netting method.

- (b)

- Analyze data on shrimp liveliness, condition, size, weight, and quantity.

2.2. Measuring Tools and Equipment

- Inverter: Mitsubishi Electric, Model FR-A840-22K-1, with serial number K08857001. The primary motor drive is a 22 kW, 6-pole induction motor, SF-JV type, manufactured by Mitsubishi Electric Automation (Thailand) with the serial number A16.

- Vacuum Pump: ENVA Liquid Ring, Model 1EN015-03, with serial number 2025450. This is accompanied by a Vacuum Motor: ABB Germany, Model M2BAX90SA2, with serial number 8G1020360777864001.

- Clamp Meter: Model FLUKE 325, with serial number 463198MV.

- Ultrasonic Flow Meter: Manufactured by IMARI, Model CLM-700, with serial number 200323-H-81979116, made in Japan (12.445239104012108N, 102.33619210240366E).

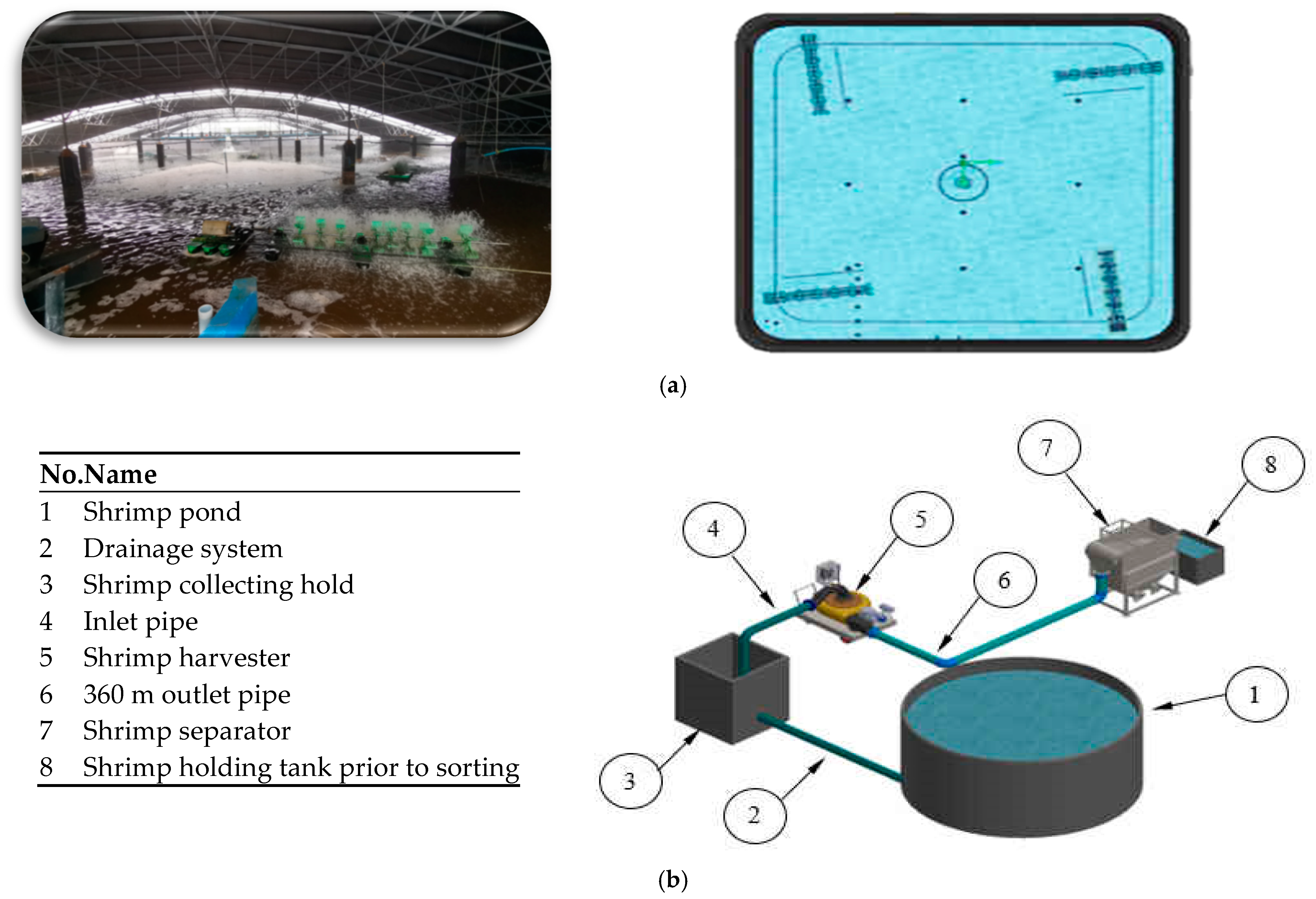

2.3. Hardware and System Configuration

2.4. Design and Quality Assessment of White Shrimp, Litopenaeus Vannamei

- Shrimp Number 1: These shrimp are lively and in overall good condition, with an average size of 20 pieces per kilogram.

- Shrimp Number 2: Similar to Shrimp Number 1, these shrimps also exhibit liveliness and good health, but they are slightly larger, averaging 30 pieces per kilogram.

- Shrimp Number 3: This category includes shrimp with a pale appearance and soft shells, indicating recent molting. Their shells have not fully hardened yet, making them vulnerable to damage. Insufficient calcium intake during the molting process can lead to wounds and weakened shell integrity. Newly molted shrimp may appear pale due to their soft shells, which are more susceptible to damage from strong impacts caused by interactions with other shrimp or equipment in a water-pumping pond.

- Shrimp Number 4: These shrimp may show signs of damage, such as broken necks, heads, and red bodies, which can occur during the harvesting process.

2.5. Shrimp Harvester Machine Using Centrifugal Technique

2.5.1. Centrifugal Force in a Bladeless Shrimp Harvester Design

2.5.2. Exploration and Development of the Centrifugal Shrimp Harvester Prototype

2.5.3. Shrimp Condition Transfer via Piping System

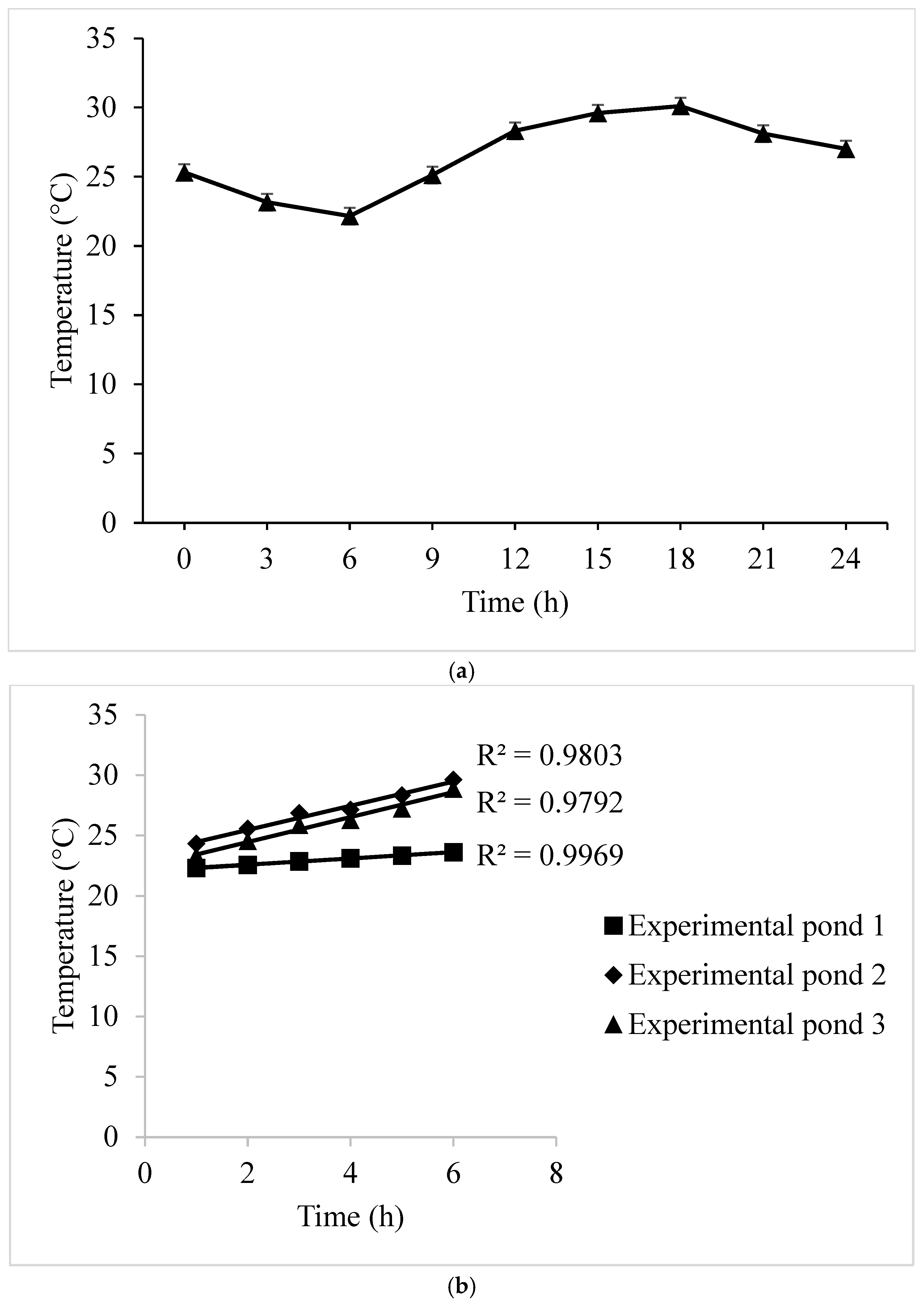

2.6. Operation of the Centrifugal Shrimp Harvester: Shrimp Transfer via a 360 m Pipeline

3. Results and Discussion

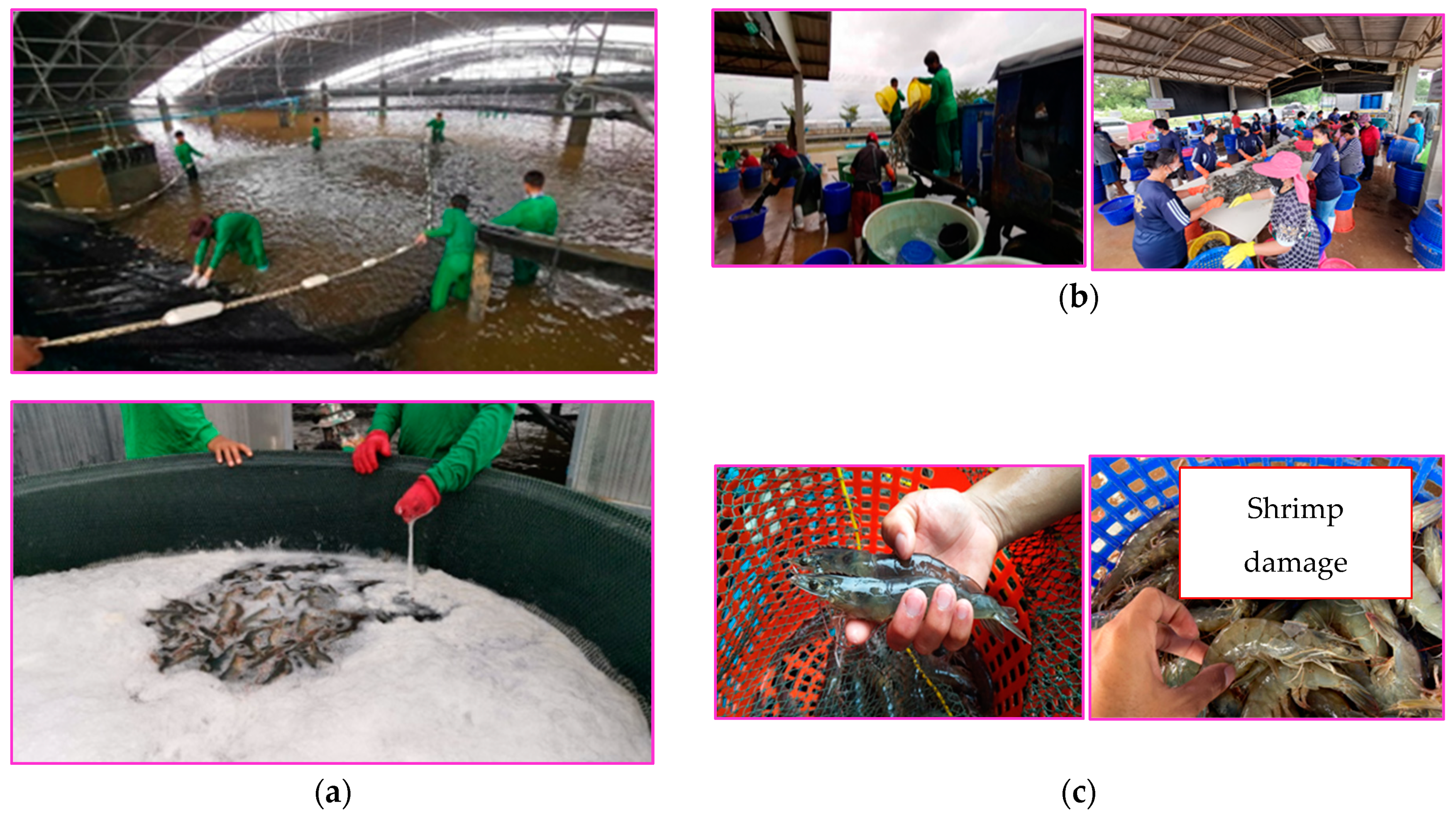

3.1. Traditional Shrimp Harvesting Using Netting Method

3.2. Operational Aspects of the Centrifugal Shrimp Harvester

3.3. Shrimp Quality Assessment Using the Centrifugal Shrimp Harvester

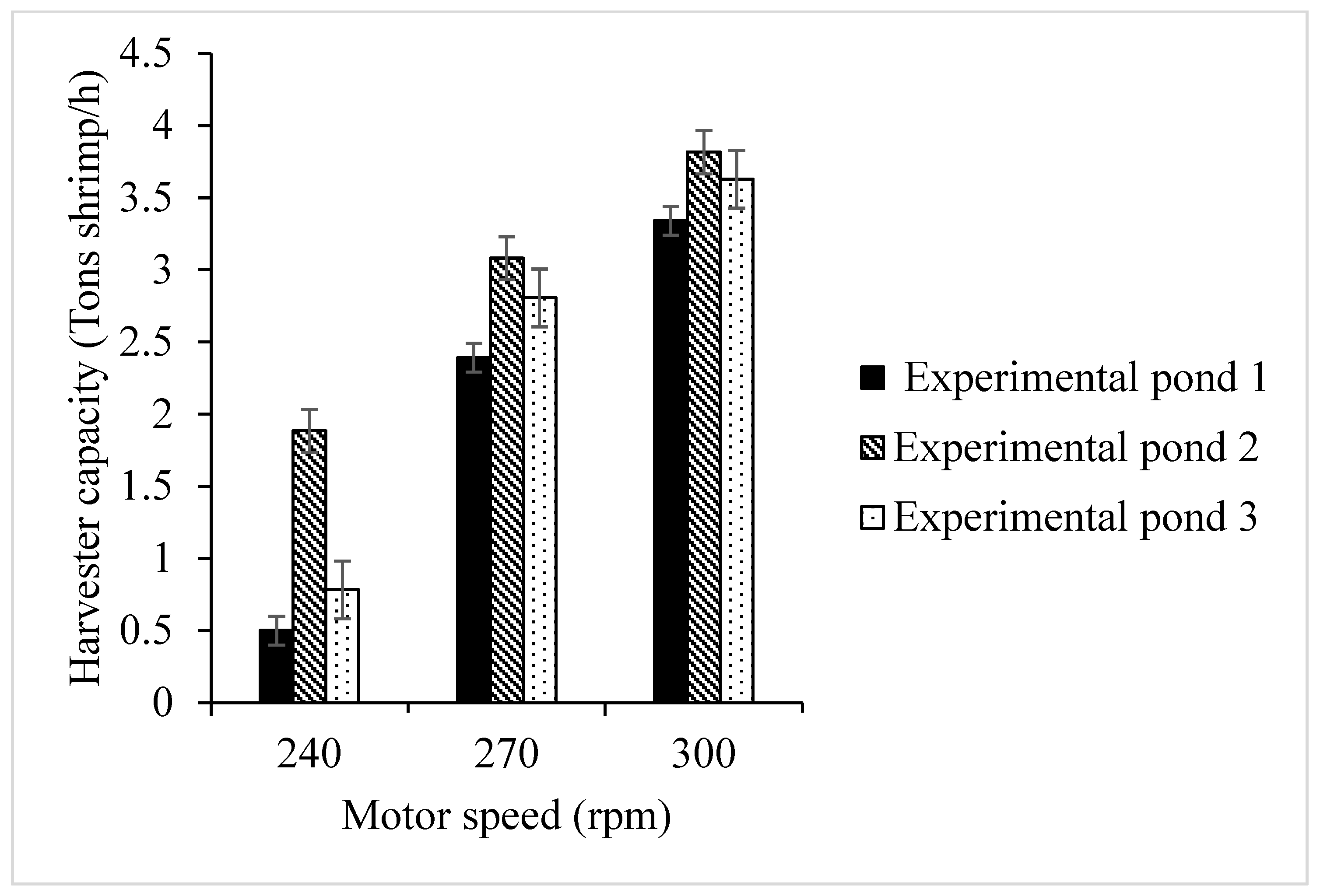

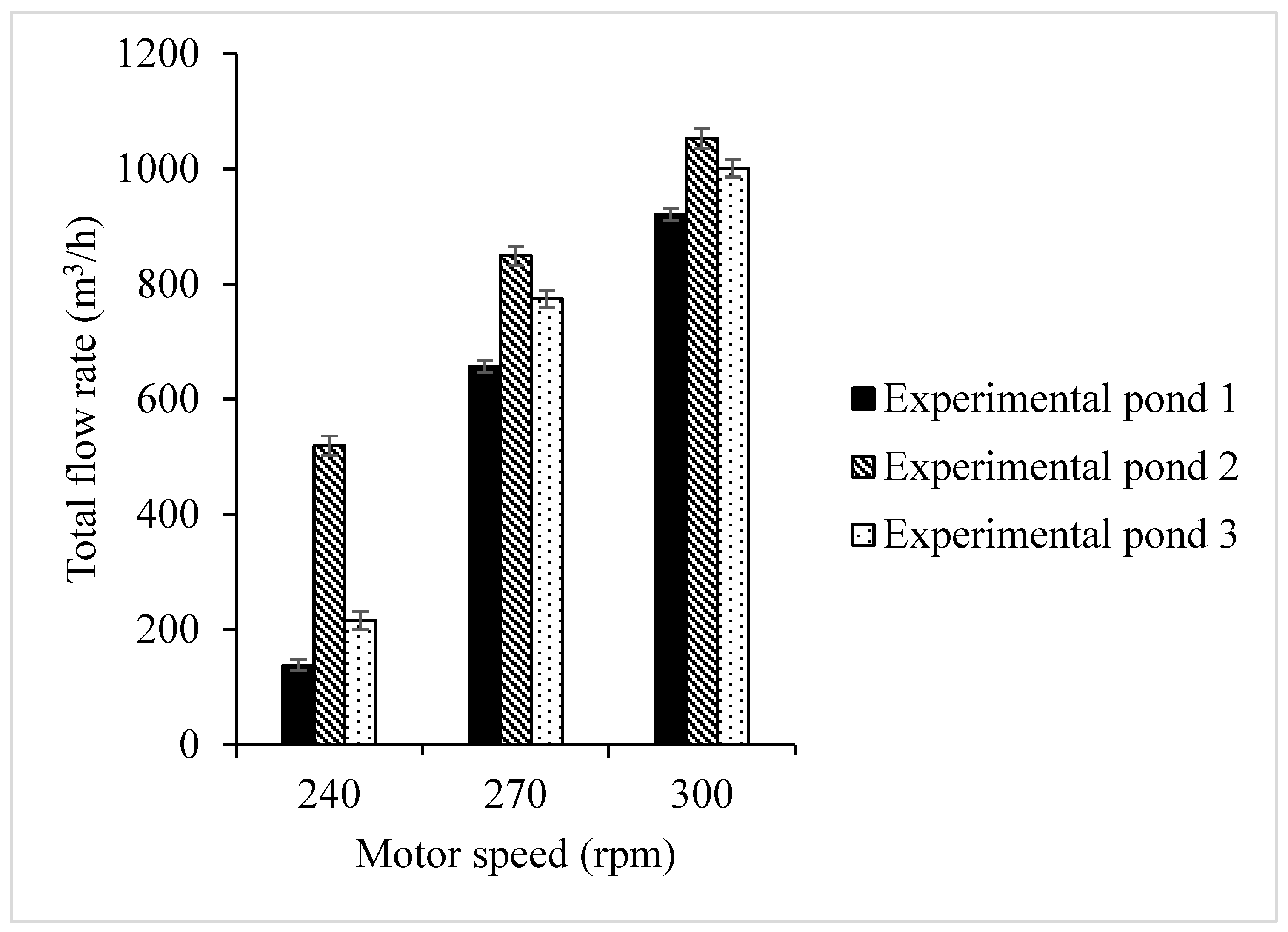

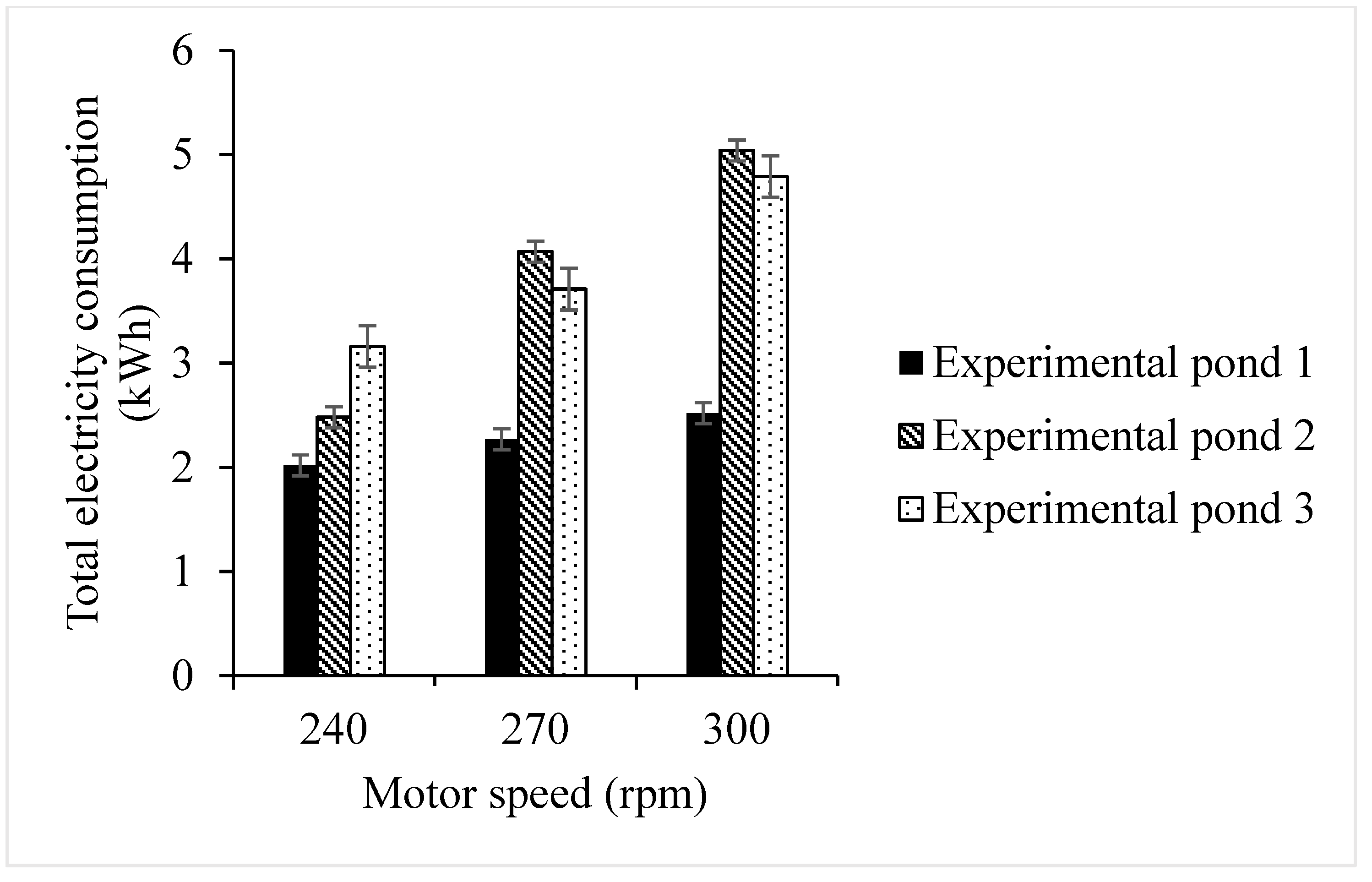

3.4. The Relationship Between Shrimp Catching Capacity, Flow Rate, Total Weight of Damaged Shrimp, and Electricity Consumption

3.5. Discussions

3.5.1. The Algorithm’s Structure, Parameters, or Decision-Making Process

- -

- Improved shrimp quality:

- -

- Reduced damage:

- -

- Enhanced efficiency and labor utilization:

3.5.2. Shrimp Quality and the Impact of Different Harvesting Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miao, W.; Wang, W. Trends of aquaculture production and trade: Carp, tilapia, and shrimp. Asian Fish. Sci. 2020, 33, 1–10. [Google Scholar] [CrossRef]

- Smith, M.D.; Roheim, C.A.; Crowder, L.B.; Halpern, B.S.; Turnipseed, M.; Anderson, J.L.; Asche, F.; Bourillón, L.; Guttormsen, A.G.; Khan, A.; et al. Tight coupling to ecosystems and dependence on common-pool resources threaten fisheries and aquaculture. Sustain. Glob. Seaf. 2010, 327, 784–786. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Li, G.; Wu, H.B.; Liu, X.G.; Yao, Y.H.; Tao, L.; Liu, H. An integrated recirculating aquaculture system (RAS) for land-based fish farming: The effects on water quality and fish production. Aquac. Eng. 2011, 45, 93–102. [Google Scholar] [CrossRef]

- Lin, Y.-F.; Jing, S.-R.; Lee, D.-Y. The potential use of constructed wetlands in a recirculating aquaculture system for shrimp culture. Environ. Pollut. 2003, 123, 107–113. [Google Scholar] [CrossRef]

- Tacon, A.G.J.; Metian, M. Fishing for feed or fishing for food: Increasing global competition for small pelagic forage fish. Ambio 2009, 38, 294–302. [Google Scholar]

- Hossain, M.S.; Uddin, M.J.; Fakhruddin, A.N.M. Impacts of shrimp farming on the coastal environment of Bangladesh and approach for management. Rev. Environ. Sci. Bio./Technol. 2013, 12, 313–332. [Google Scholar] [CrossRef]

- Boyd, C.E.; Tucker, C.S. Pond Aquaculture Water Quality Management; Springer Science + Business Media: New York, NY, USA, 1998; Available online: https://books.google.co.th/books?hl=en&lr=&id=2r8GCAAAQBAJ&oi=fnd&pg=PR11&dq=+Pond+aquaculture+water+quality+management.+Springer.2.%09Boyd,+C.+E.,+%26+Tucker,+C.+S.+(2018) (accessed on 20 March 2022).

- Pongsiri, M.J.; Roman, J.; Ezenwa, V.O.; Goldberg, T.L.; Koren, H.S.; Newbold, S.C.; Ostfeld, R.S.; Pattanayak, S.K.; Salkeld, D.J. Biodiversity Loss Affects Global Disease Ecology. BioScience 2009, 59, 945–954. [Google Scholar] [CrossRef]

- Faso, B. Food Security Situation Deteriorating in Northern Areas Due to Heightened Violence. GIEWS Update: Food and Agriculture Organization of the United Nations [FAO]. 2019. Available online: https://www.fao.org/3/ca5486en/ca5486en.pdf (accessed on 20 March 2022).

- Saha, S.K. Socio-economic and environmental impacts of shrimp farming in the south-western coastal region of Bangladesh. Int. J. Res. Land-Use Sustain. 2017, 3, 128–137. [Google Scholar]

- Dastidar, P.G.; Mallik, A.; Mandal, N. Contribution of shrimp disease research to the development of the shrimp aquaculture industry: An analysis of the research and innovation structure across the countries. Scientometrics 2013, 97, 659–674. [Google Scholar] [CrossRef]

- Smith, S.E.; Facelli, E.; Pope, S.; Andrew Smith, F. Plant performance in stressful environments: Interpreting new and established knowledge of the roles of arbuscular mycorrhizas. Plant Soil 2010, 326, 3–20. [Google Scholar] [CrossRef]

- Dierberg, F.E.; Kiattisimkul, W. Issues, impacts, and implications of shrimp aquaculture in Thailand. Environ. Manag. 1996, 20, 649–666. [Google Scholar] [CrossRef]

- Engle, C.R.; McNevin, A.; Racine, P.; Boyd, C.E.; Paungkaew, D.; Viriyatum, R.; Tinh, H.Q.; Minh, H.N. Economics of Sustainable Intensification of Aquaculture: Evidence from Shrimp Farms in Vietnam and Thailand. J. World Aquac. Soc. 2017, 48, 227–239. [Google Scholar] [CrossRef]

- Rashid, M.B.; Sheik, M.R.; Haque, A.J.M.E.; Siddique, M.A.B.; Habib, M.A.; Patwary, M.A.A. Salinity-induced change in green vegetation and land use patterns using remote sensing, NDVI, and GIS techniques: A case study on the southwestern coast of Bangladesh. Case Stud. Chem. Environ. Eng. 2023, 7, 100314. [Google Scholar] [CrossRef]

- Bush, S.R.; Van Zwieten, P.A.; Visser, L.; van Dijk, H.; Bosma, R.; de Boer, W.F.; Verdegem, M. Scenarios for resilient shrimp aquaculture in tropical coastal areas. Ecol. Soc. 2010, 15, 15. [Google Scholar] [CrossRef]

- Southeast Asian Fisheries Development Center, Marine Fishery Resources Development and Management Department. ASEAN Guidelines for Preventing the Entry of Fish and Fishery Products from IUU Fishing Activities into the Supply Chain. 2015. (SEAFDEC/MFRDMD/SP/29). Available online: https://asean.org/wp-content/uploads/2021/09/App-9-ASEAN-Guidelines-IUU-SSOM36th-AMAF-final.pdf (accessed on 20 March 2022).

- Pandey, N.; de Coninck, H.; Sagar, A.D. Beyond technology transfer: Innovation cooperation to advance sustainable development in developing countries. Wiley Interdiscip. Rev. Energy Environ. 2022, 11, e422. [Google Scholar] [CrossRef]

- Thoetrattanakiat, S.; Sangpradit, K. Effect of Fluid Velocity in Piping System Physical Properties for Shrimp Harvesting. In Proceedings of the 11th Rajamangala University of Technology International Conference on RMUT Driving Toward Innovation, Economy and Green Technology for Sustainable Development, Pattaya, Thailand, 18–20 May 2022; pp. 86–96. Available online: https://ird.rmutt.ac.th/wp-content/uploads/2022/06/E-Proceeding-RMUTCON-20201.pdf (accessed on 20 March 2023).

- Iryani, M.T.M.; Lv, A.; Sun, J.; Anirudhan, A.; Tan, M.P.; Danish-Daniel, M.; Sung, Y.Y. Effects of heat shock protein 70 knockdown on the tolerance of the brine shrimp Artemia franciscana to aquaculture-related stressors: Implications for aquatic animal health and production. Aquaculture 2022, 550, 737872. [Google Scholar] [CrossRef]

- Lima, L.C.S.d.; Carriero, R.; Souza, A.L.M.D.; Salim, A.P.A.d.A.; Ferreira, M.d.S.; Mano, S.B. Impact of production chain on defects of farmed shrimp (Penaeus vannamei). Ciência Rural 2023, 53, e20220269. [Google Scholar] [CrossRef]

- Yu, R.; Leung, P. Optimal harvesting strategies for a multi-cycle and multi-pond shrimp operation: A practical network model. Math. Comput. Simul. 2005, 68, 339–354. [Google Scholar] [CrossRef]

- Bayrak, G.; Cebeci, M. A PV based automation system for fish farms: An application study. In Proceedings of the 2011, 7th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 1–4 December 2011. [Google Scholar]

- Le, K.L.; Thap, L.V.; Hoai, N.T. An application of data envelopment analysis with the double bootstrapping technique to analyze cost and technical efficiency in aquaculture: Do credit constraints matter? Aquaculture 2020, 525, 735290. [Google Scholar] [CrossRef]

- Fotedar, S.; Evans, L. Health management during handling and live transport of crustaceans: A review. J. Invertebr. Pathol. 2011, 106, 143–152. [Google Scholar] [CrossRef]

- Huang, Z.; Guan, W.; Lyu, X.; Chen, R.; Wu, Y.; Zheng, G.; Mao, L. Impacts of long-time transportation on white leg shrimp (Penaeus vannamei) muscle quality and underlying biochemical mechanisms. J. Sci. Food Agric. 2023, 103, 7590–7599. [Google Scholar] [CrossRef]

- Stentiford, G.D.; Neil, D.M.; Peeler, E.J.; Shields, J.D.; Small, H.J.; Flegel, T.W.; Lightner, D.V. Disease will limit future food supply from the global crustacean fishery and aquaculture sectors. J. Invertebr. Pathol. 2012, 110, 141–157. [Google Scholar] [CrossRef]

- Yu, Q.; Liu, J.; Yang, J. Postharvest Preservation Technologies for Marine-Capture Shrimp: A Review. Food Bioprocess Technol. 2023, 16, 2343–2358. [Google Scholar] [CrossRef]

- Kring, N.A.; Fleckenstein, L.J.; Tierney, T.W.; Fisk, J.C.; Lawson, B.C.; Ray, A.J. The effects of stocking density and artificial substrate on production of Pacific white shrimp, Litopenaeus vannamei and water quality dynamics in greenhouse-based bio floc systems. Aquac. Eng. 2023, 101, 102322. [Google Scholar] [CrossRef]

- Jeyachandran, S.; Chellapandian, H.; Park, K.; Kwak, I.-S. A Review on the Involvement of Heat Shock Proteins (Extrinsic Chaperones) in Response to Stress Conditions in Aquatic Organisms. Antioxidants 2023, 12, 1444. [Google Scholar] [CrossRef]

- Pedrazzani, A.S.; Cozer, N.; Quintiliano, M.H.; Ostrensky, A. Insights into Decapod Sentience: Applying the General Welfare Index (GWI) for Whiteleg Shrimp (Penaeus vannamei—Boone, 1931) Reared in Aquaculture Grow-Out Ponds. Fishes 2024, 9, 440. [Google Scholar] [CrossRef]

- Radhakrishnan, K.; Sivaraman, I.; Krishnan, M. Evaluating input use efficiency in shrimp farming by stochastic production frontier approach. Aquac. Res. 2020, 51, 5309–5317. [Google Scholar] [CrossRef]

- Ghosh, A.K. Functionality of probiotics on the resistance capacity of shrimp against white spot syndrome virus (WSSV). Fish Shellfish. Immunol. 2023, 140, 108942. [Google Scholar] [CrossRef]

- Cong, C.; Pan, H.; Page, J.; Barthel, S.; Kalantari, Z. Modelling place-based nature-based solutions to promote urban carbon neutrality. Ambio 2023, 52, 1297–1313. [Google Scholar] [CrossRef]

- Qin, Y.; Zhou, M.; Hao, Y.; Huang, X.; Tong, D.; Huang, L.; Zhu, T. Amplified positive effects on air quality, health, and renewable energy under China’s carbon neutral target. Nat. Geosci. 2024, 17, 411–418. [Google Scholar] [CrossRef]

- Ren, Q.; Pei, J. Do green financial and non-financial policies achieve the carbon neutrality target? Environ. Sci. Pollut. Res. 2023, 30, 97965–97976. [Google Scholar] [CrossRef] [PubMed]

- Fan, X.; Jiang, X.; Deng, N. Immersive technology: A meta-analysis of augmented/virtual reality applications and their impact on tourism experience. Tour. Manag. 2022, 91, 104534. [Google Scholar] [CrossRef]

| Shrimp Number | Liveliness | Condition | Size (Pieces/kg) | Reason | Traditional Netting Method | Shrimp Harvester Machine with 360 m Transportation by Pipe | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Shrimp Weight (kg) | Shrimp Quantity (Pieces) | Percent (%) | Shrimp Weight (kg) | Shrimp Quantity (Pieces) | Percent (%) | |||||

| 1 | High | Good | 20 | Shrimp exhibiting high liveliness and good overall condition. | 3532.17 | 70,643.4 | 78.47 | 2897.05 | 57,940 | 81.66 |

| 2 | High | Good | 30 | Shrimp displaying high liveliness and good overall condition. | 462.80 | 13,884.00 | 15.42 | 399.42 | 11,983 | 16.88 |

| 3 | Moderate | Soft-shelled | 25 | Shrimp showing moderate liveliness with soft-shelled condition due to recent molting; harvesting method induces stress and disturbance in shrimp | 122.23 | 3055.75 | 3.39 | 41.2 | 1029 | 1.45 |

| 4 | Low | Damaged | 25 | Shrimp with low liveliness and damaged condition, potentially due to harvesting methods. | 97.80 | 2445.00 | 2.72 | 0.337 | 9 | 0.01 |

| Total | 4215.00 | 90,028.15 | 100.00 | 3338 | 70,962 | 100.00 | ||||

| Total harvesting time | 253 min | 60 min | ||||||||

| No. | Pond Geometry and Components | Parameters |

|---|---|---|

| 1 | Fluid properties: | |

| Density, kg/m3 | 999.79 | |

| Viscosity, Pa·s | 0.0017912 | |

| Thermal conductivity, W/(m·K) | 0.56104 | |

| Specific heat, J/(kg·K) | 4219.90 | |

| 2 | Condition of aerators: | |

| Inlet velocity, cm/s | 38 | |

| Temperature, K | 273.16 | |

| Environment pressure, kPa | 101.32 | |

| 3 | Summary of the comparative analysis: | |

| Pump flow rate, ft3/min | 31.38 | |

| Selected target filling levels, ft3 | 2075 | |

| Total pumping duration, min | 36.92 | |

| Total electricity consumption, kWhr | 2.52 | |

| 4 | Technical Specification: | |

| Inlet size, mm | 250 | |

| Outlet size | 250 | |

| Max. Pump output, m3/h | 750 | |

| Max. Pump head (TDH), m | 9 | |

| Max. Pump suction, m | 3 | |

| Power Pump, Hp | 30 | |

| Vacuum Pump, Hp | 2 |

| Items | Initial Point | Final Point |

|---|---|---|

| Shrimp quantity (kg) | 3338 | 3338 |

| Shrimp size (pieces/kg) | 20–30 | 20–30 |

| Temperature (°C) | 29.60 | 31.20 |

| Dissolved oxygen (ppm) | 6.11 | 5.20 |

| Flow rate (m3/h) | 400 | 400 |

| Transfer time (h) | 7:00 AM | 8:00 AM |

| Impeller speed (rpm) | 300 | 300 |

| Biomass density (kg/m3) | 8.345 | 8.345 |

| Harvester capacity (tons shrimp/h) | 3.338 | 3.338 |

| Motor Speed (rpm) | Experimental Pond 1 | Experimental Pond 2 | Experimental Pond 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Harvester Capacity (Tons Shrimp/h) | Total Flow Rate (m3/h) | Total Weight of Damaged Shrimps (kg) | Total Electricity Consumption (kW·h) | Harvester Capacity (Tons Shrimp/h) | Total Flow Rate (m3/h) | Total Weight of Damaged Shrimps (kg) | Total Electricity Consumption (kW·h) | Harvester Capacity (Tons Shrimp/h) | Total Flow Rate (m3/h) | Total Weight of Damaged Shrimps (kg) | Total Electricity Consumption (kW·h) | |

| 240 | 0.501 ± 0.001 | 138 ± 1 | 0.051 ± 0.001 | 2.02 ± 0.01 | 1.884 ± 0.001 | 519 ± 1 | 0.063 ± 0.001 | 2.48 ± 0.02 | 0.783 ± 0.002 | 216 ± 1 | 0.089 ± 0.001 | 3.16 ± 0.03 |

| 270 | 2.391 ± 0.003 | 657 ± 2 | 0.238 ± 0.001 | 2.27 ± 0.02 | 3.081 ± 0.002 | 849 ± 2 | 0.103 ± 0.001 | 4.07 ± 0.02 | 2.806 ± 0.001 | 774 ± 1 | 0.776 ± 0.002 | 3.71 ± 0.01 |

| 300 | 3.338 ± 0.002 | 921 ± 4 | 0.334 ± 0.002 | 2.52 ± 0.02 | 3.816 ± 0.002 | 1053 ± 2 | 0.668 ± 0.001 | 5.04 ± 0.02 | 3.627 ± 0.002 | 1001 ± 1 | 1.002 ± 0.002 | 4.79 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thoetrattanakiat, S.; Sangpradit, K.; Samseemoung, G. Integrating a Centrifugal Extraction and Pipeline Transportation System to Improve Efficiency in Shrimp Harvesting Management. AgriEngineering 2025, 7, 128. https://doi.org/10.3390/agriengineering7050128

Thoetrattanakiat S, Sangpradit K, Samseemoung G. Integrating a Centrifugal Extraction and Pipeline Transportation System to Improve Efficiency in Shrimp Harvesting Management. AgriEngineering. 2025; 7(5):128. https://doi.org/10.3390/agriengineering7050128

Chicago/Turabian StyleThoetrattanakiat, Songphon, Kiattisak Sangpradit, and Grianggai Samseemoung. 2025. "Integrating a Centrifugal Extraction and Pipeline Transportation System to Improve Efficiency in Shrimp Harvesting Management" AgriEngineering 7, no. 5: 128. https://doi.org/10.3390/agriengineering7050128

APA StyleThoetrattanakiat, S., Sangpradit, K., & Samseemoung, G. (2025). Integrating a Centrifugal Extraction and Pipeline Transportation System to Improve Efficiency in Shrimp Harvesting Management. AgriEngineering, 7(5), 128. https://doi.org/10.3390/agriengineering7050128