Fault Classification of 3D-Printing Operations Using Different Types of Machine and Deep Learning Techniques

Abstract

:1. Introduction

2. Related Work

2.1. Monitoring the AM Process

2.2. Data-Driven Classification Model

3. Methodology

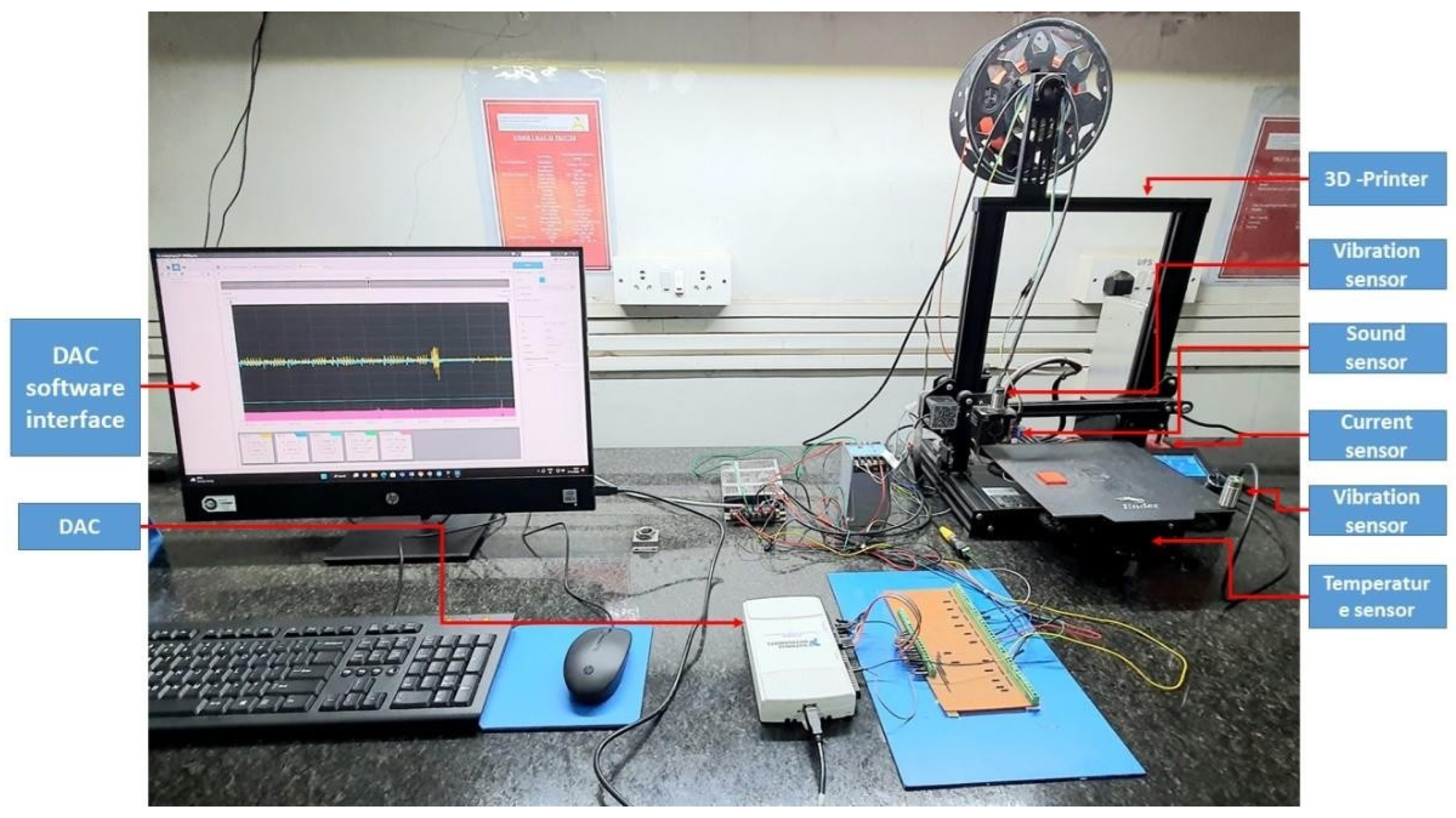

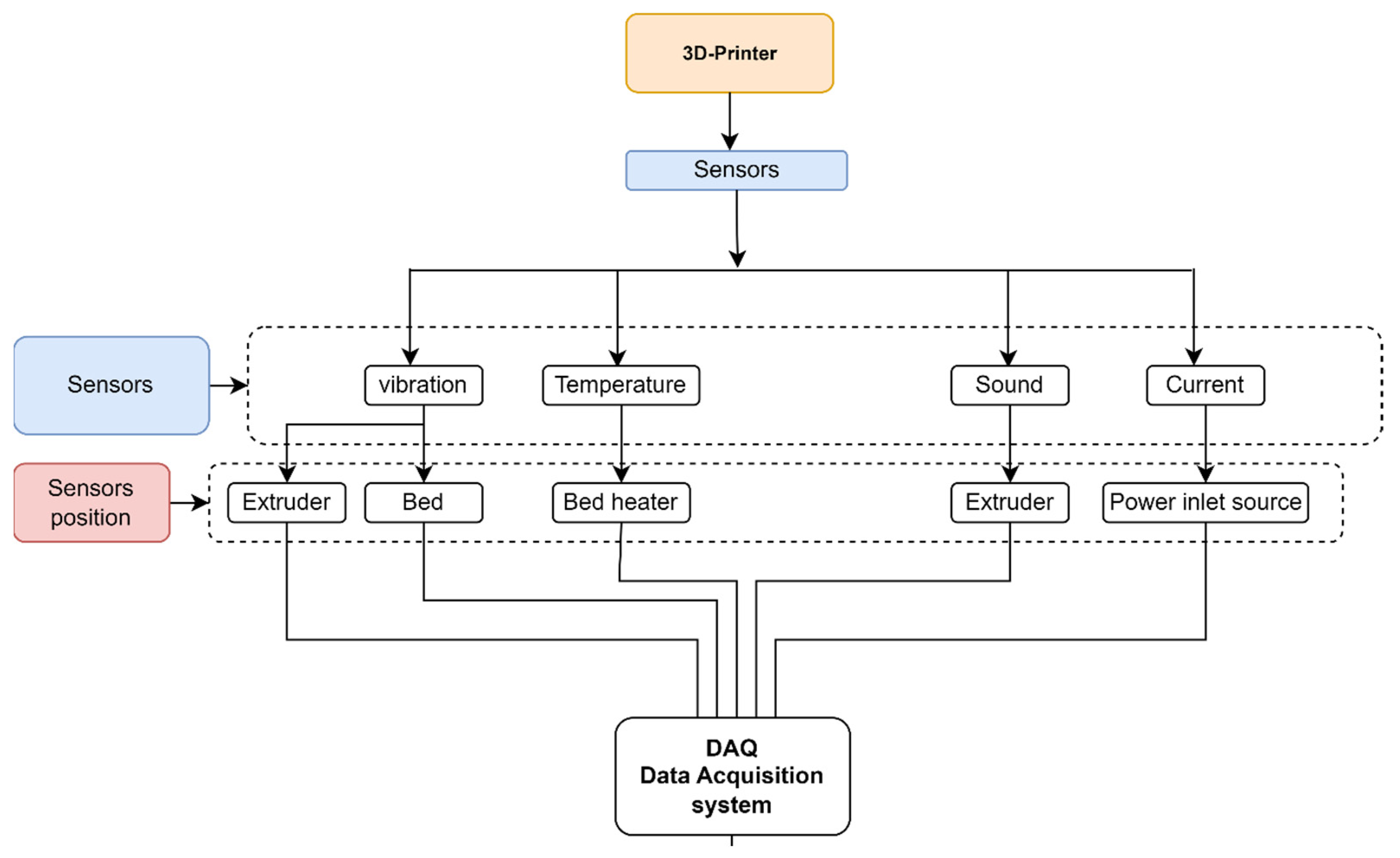

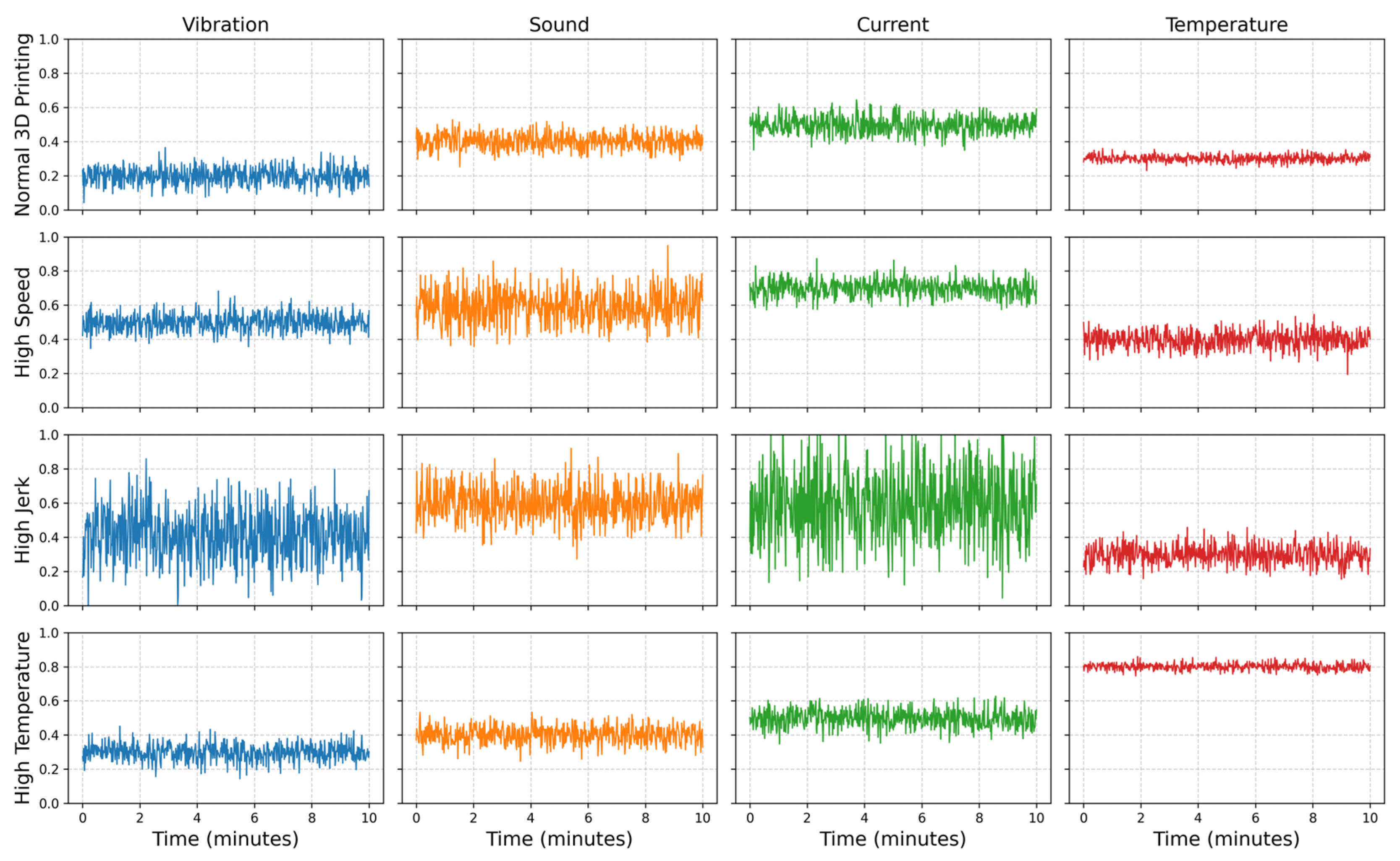

3.1. Experimentation and Data Acquisition

3.2. Models Used for the Fault Classification

4. Results and Discussion

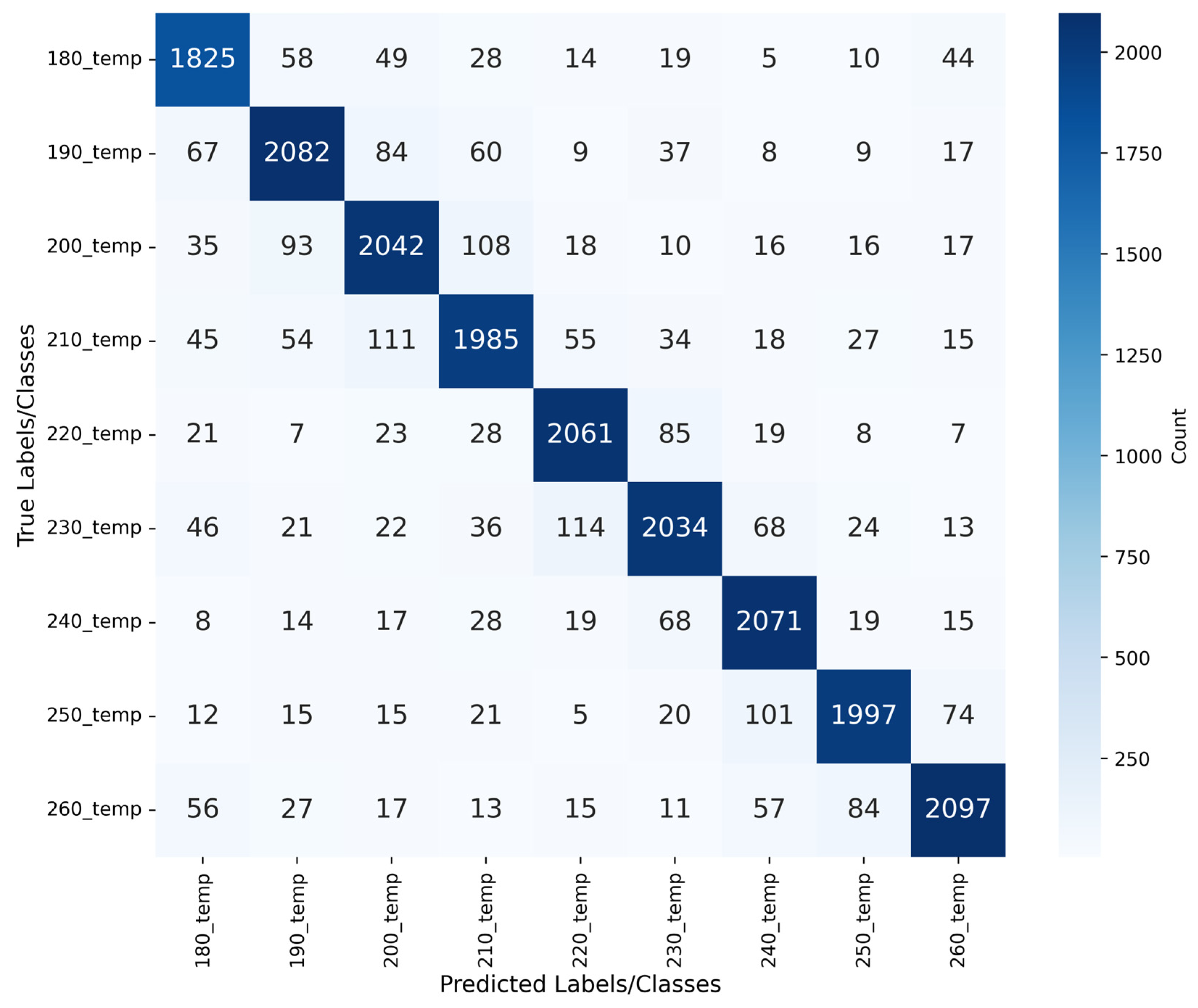

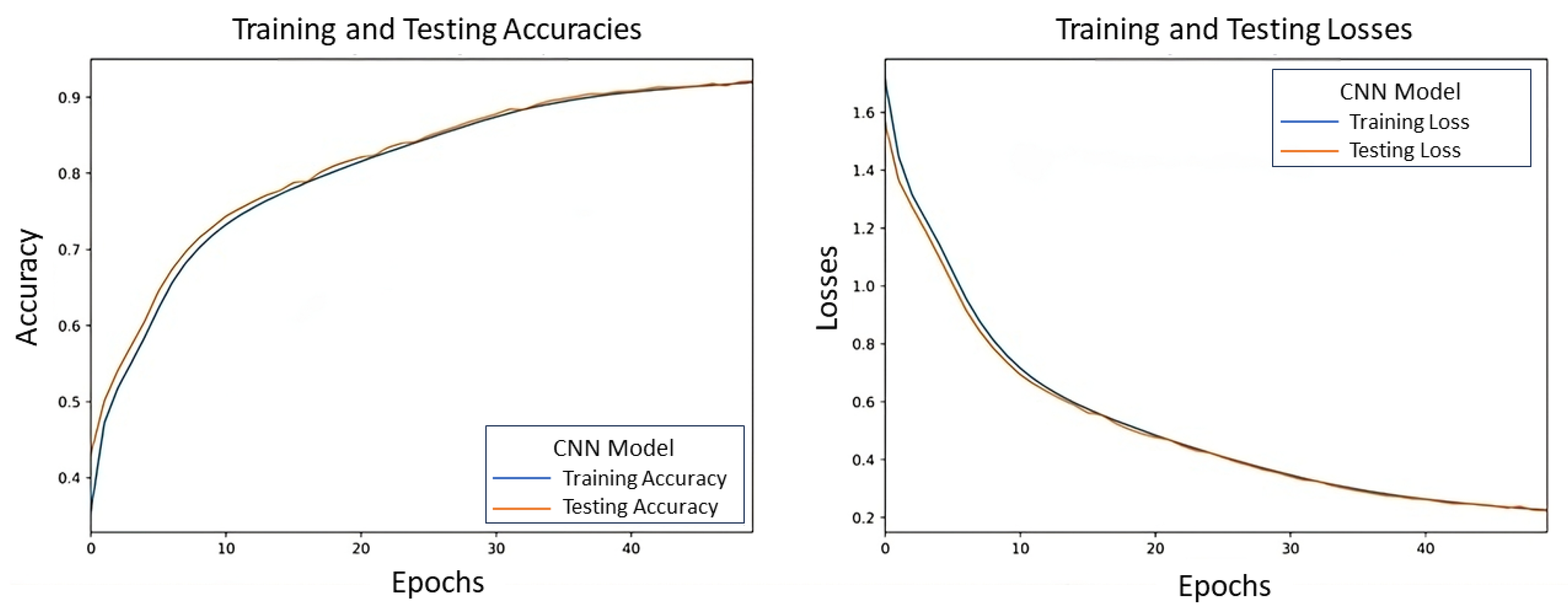

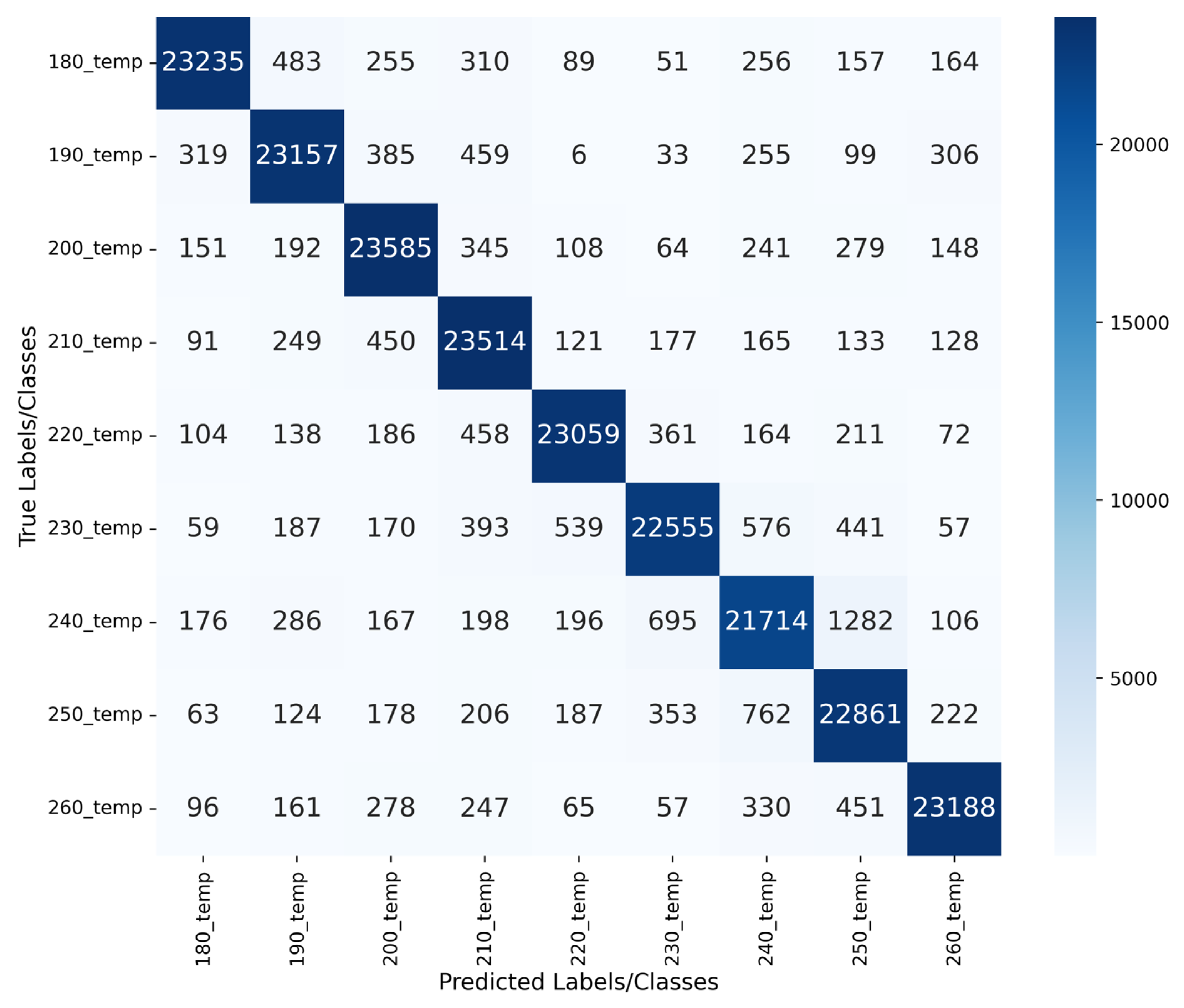

4.1. Model Performance for the Variable Printing Temperature Conditions

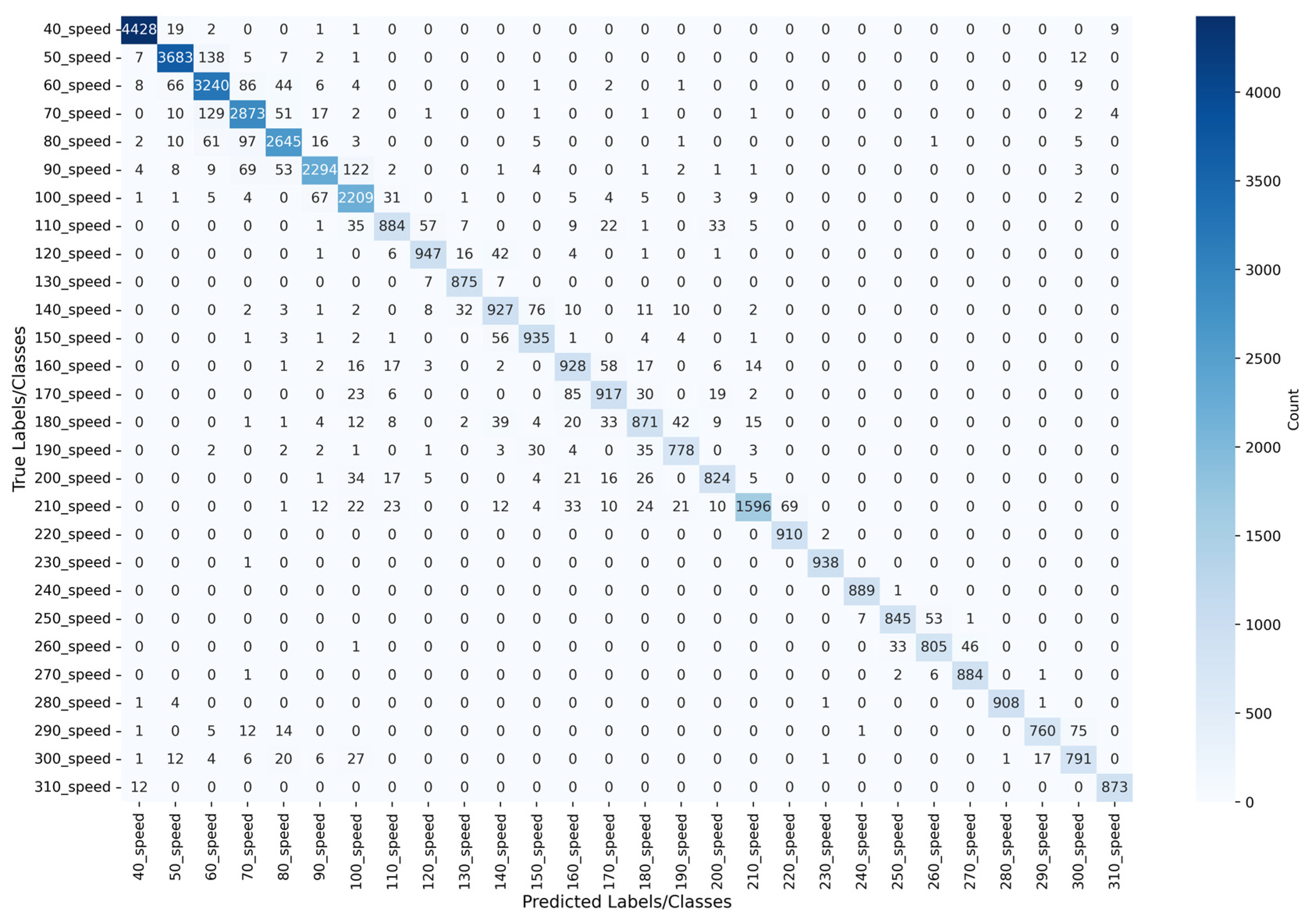

4.2. Model Performance for the Variable Printing Speed Conditions

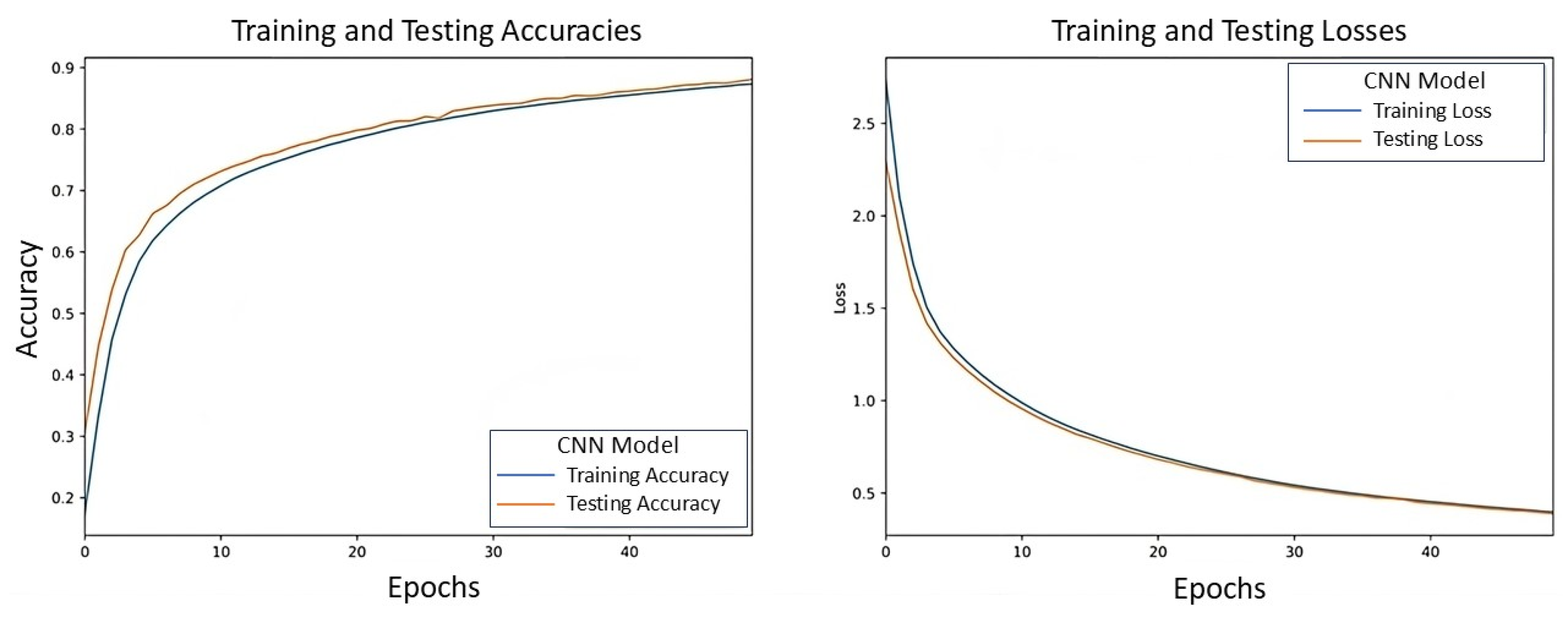

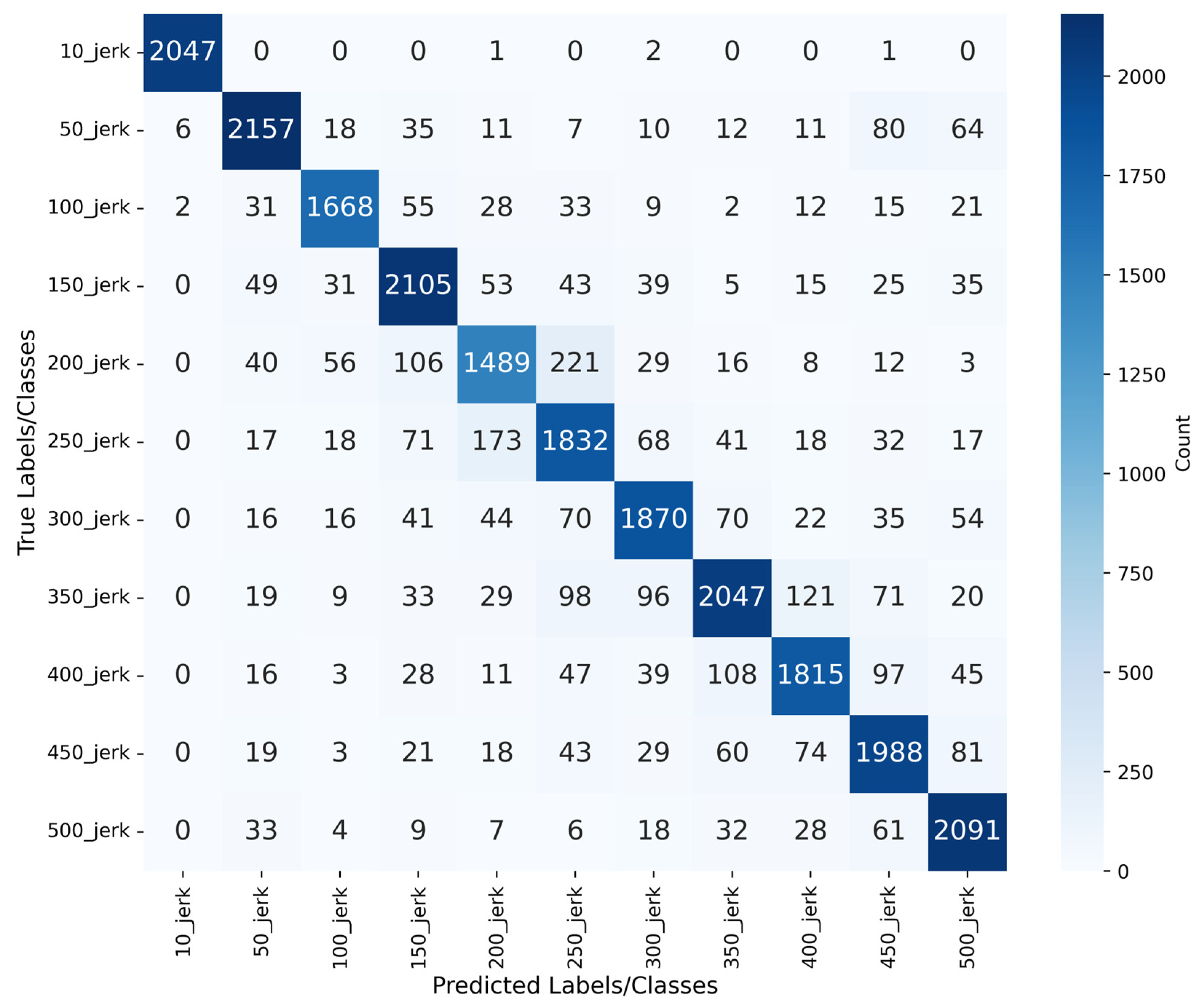

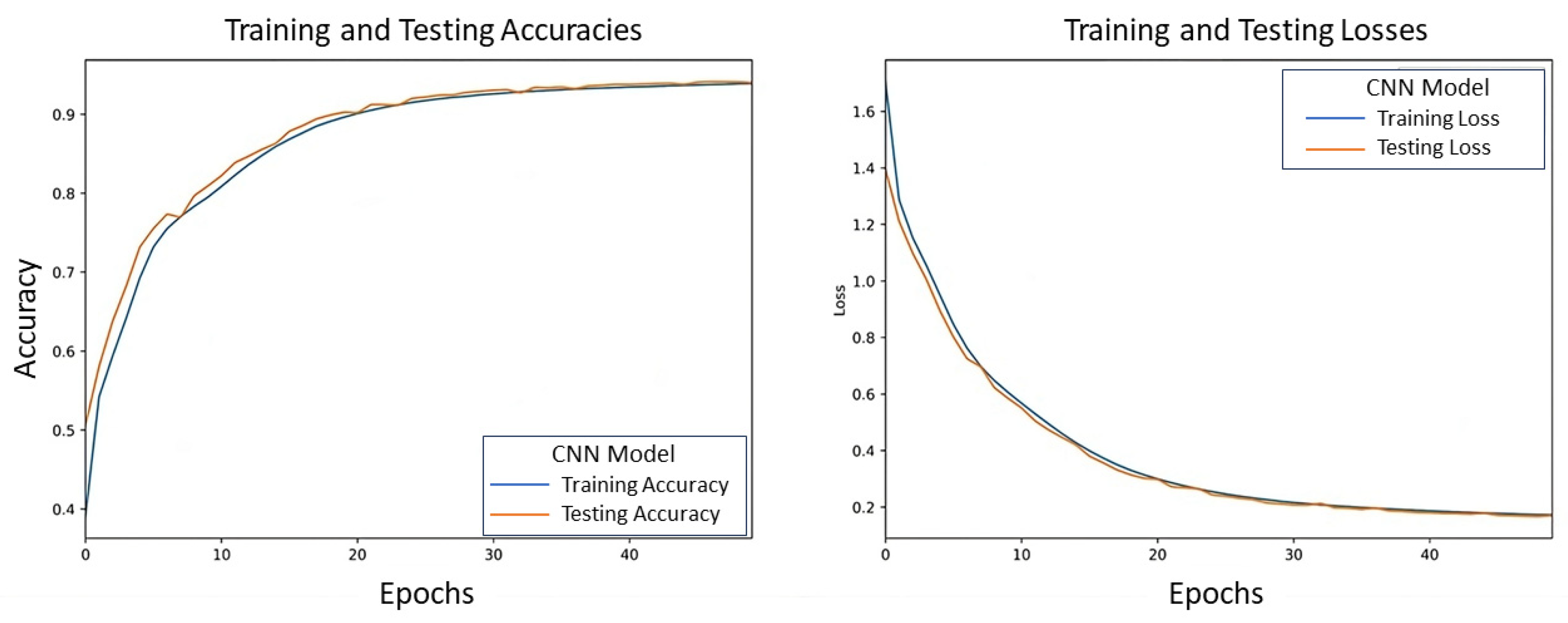

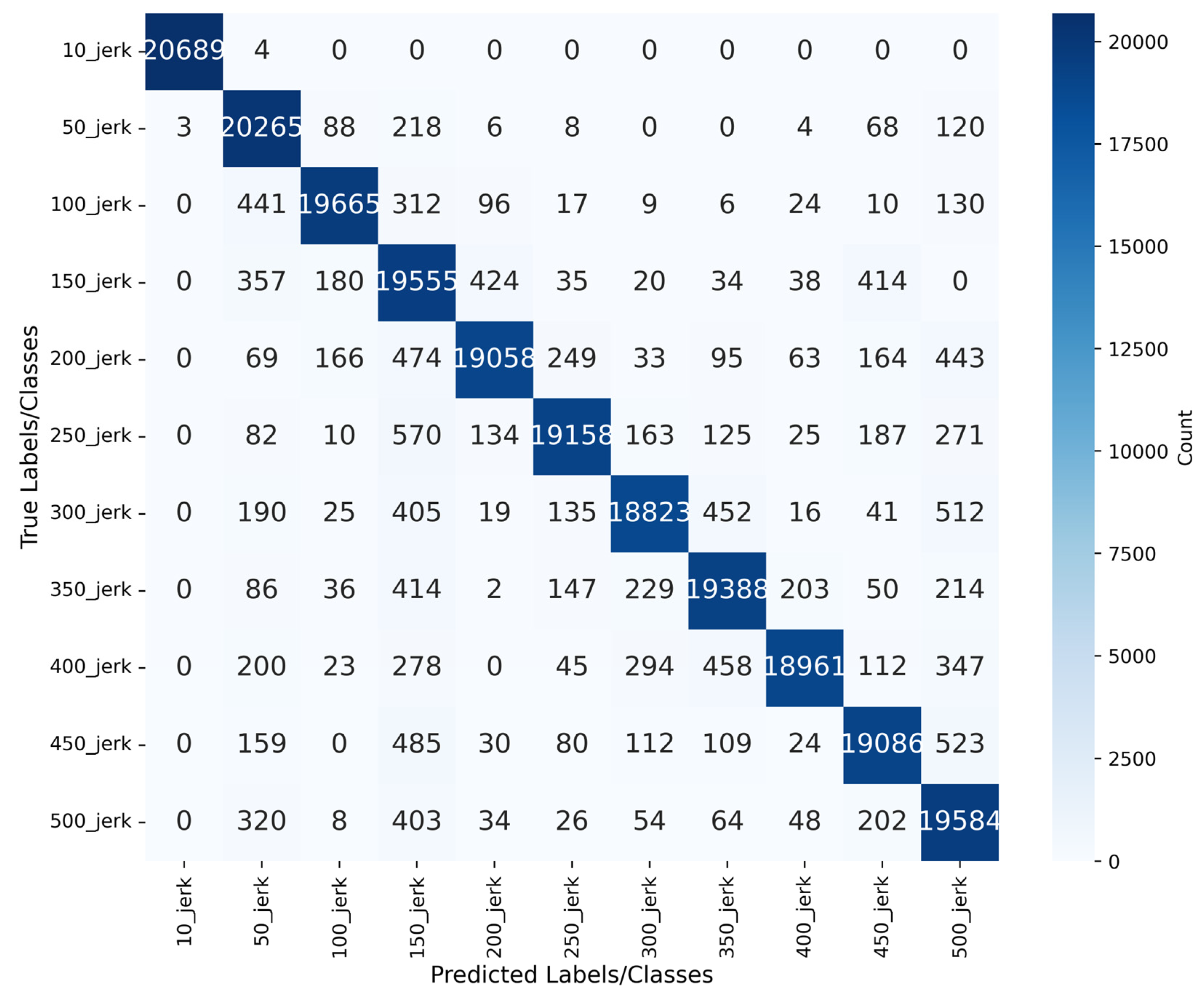

4.3. Model Performance for the Variable Printing Jerk Conditions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bogue, R. 3D Printing: The Dawn of a New Era in Manufacturing? Assem. Autom. 2013, 33, 307–311. [Google Scholar] [CrossRef]

- MarketsandMarkets. 3D Printing Market. Available online: https://www.marketsandmarkets.com/Market-Reports/3d-printing-market-1276.html (accessed on 20 April 2024).

- Yan, X.; Bethers, B.; Chen, H.; Xiao, S.; Lin, S.; Tran, B.; Jiang, L.; Yang, Y. Recent Advancements in Biomimetic 3D Printing Materials with Enhanced Mechanical Properties. Front. Mater. 2021, 8, 735220. [Google Scholar] [CrossRef]

- Schiller, G.J. Additive Manufacturing for Aerospace. In Proceedings of the IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Rouf, S.; Malik, A.; Singh, N.; Raina, A.; Naveed, N.; Siddiqui, M.I.H.; Haq, M.I.U. Additive Manufacturing Technologies: Industrial and Medical Applications. Sustain. Oper. Comput. 2022, 3, 100107. [Google Scholar] [CrossRef]

- Sayyad, S.; Kumar, S.; Bongale, A.; Kamat, P.; Patil, S.; Kotecha, K. Data-Driven Remaining Useful Life Estimation for Milling Process: Sensors, Algorithms, Datasets, and Future Directions. IEEE Access 2021, 9, 110255–110286. [Google Scholar] [CrossRef]

- Gunaydin, K.; Türkmen, H. Common FDM 3D Printing Defects. In Proceedings of the International Congress on 3D Printing (Additive Manufacturing) Technologies and Digital Industry, Antalya, Turkey, 19–21 April 2018. [Google Scholar]

- Galati, M.; Minetola, P. On the Measure of the Aesthetic Quality of 3D Printed Plastic Parts. Int. J. Interact. Des. Manuf. 2019, 14, 381–392. [Google Scholar] [CrossRef]

- Carolo, L. Gaps in 3D Prints: How to Fix & Avoid Them. All3DP. 5 December 2023. Available online: https://all3dp.com/2/gaps-in-3d-print-top-layer-gaps-between-lines/ (accessed on 5 May 2024).

- Sampedro, G.A.R.; Agron, D.J.S.; Amaizu, G.C.; Kim, D.-S.; Lee, J.-M. Design of an In-Process Quality Monitoring Strategy for FDM-Type 3D Printer Using Deep Learning. Appl. Sci. 2022, 12, 8753. [Google Scholar] [CrossRef]

- Manufactur3D. Common Problems in 3D Printing & How to Resolve Them–Part I. Manufactur3D. 3 December 2018. Available online: https://manufactur3dmag.com/common-problems-in-3d-printing-how-to-resolve-them-part-i/ (accessed on 5 May 2024).

- Kousiatza, C.; Karalekas, D. In-Situ Monitoring of Strain and Temperature Distributions During the Fused Deposition Modeling Process. Mater. Des. 2016, 97, 400–406. [Google Scholar] [CrossRef]

- Sammaiah, P.; Rushmamanisha, K.; Praveenadevi, N.; Reddy, I.R. The influence of process parameters on the surface roughness of the 3d printed part in FDM process. IOP Conf. Ser. Mater. Sci. Eng. 2020, 981, 042021. [Google Scholar] [CrossRef]

- Rao, P.K.; Liu, J.; Roberson, D.; Kong, Z.; Williams, C. Online Real-Time Quality Monitoring in Additive Manufacturing Processes Using Heterogeneous Sensors. J. Manuf. Sci. Eng. 2015, 137, 061007. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Jin, C. Introduction to Cyber Manufacturing. Manuf. Lett. 2016, 8, 11–15. [Google Scholar] [CrossRef]

- Long, J.; Sun, Z.; Li, C.; Hong, Y.; Bai, Y.; Zhang, S. A novel sparse echo autoencoder network for data-driven fault diagnosis of delta 3-D printers. IEEE Trans. Instrum. Meas. 2019, 69, 683–692. [Google Scholar] [CrossRef]

- Banadaki, Y.; Razaviarab, N.; Fekrmandi, H.; Sharifi, S. Toward Enabling a Reliable Quality Monitoring System for Additive Manufacturing Process Using Deep Convolutional Neural Networks. arXiv 2020, arXiv:2003.08749. [Google Scholar]

- Zhang, Z.; Fidan, I.; Allen, M. Detection of Material Extrusion In-Process Failures via Deep Learning. Inventions 2020, 5, 25. [Google Scholar] [CrossRef]

- Langeland, S.A. Automatic Error Detection in 3D Printing Using Computer Vision. Master’s Thesis, The University of Bergen, Bergen, Norway, 2020. Available online: https://bora.uib.no/bora-xmlui/handle/1956/22384 (accessed on 15 May 2024).

- Stoyanov, S.; Bailey, C. Machine Learning for Additive Manufacturing of Electronics. In Proceedings of the 2017 40th International Spring Seminar on Electronics Technology (ISSE), Sofia, Bulgaria, 10–14 May 2017. [Google Scholar]

- Misal, A.; Karandikar, H.; Sayyad, S.; Bongale, A.; Kumar, S.; Warke, V. Milling Tool Wear Estimation Using Machine Learning with Feature Extraction Approach. In Proceedings of the 2024 MIT Art, Design and Technology School of Computing International Conference (MITADTSoCiCon), Pune, India, 25–27 April 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Wan, J.; Canedo, A.; Al Faruque, M.A. Cyber–Physical Codesign at the Functional Level for Multidomain Automotive Systems. IEEE Syst. J. 2015, 11, 2949–2959. [Google Scholar] [CrossRef]

- Dey, A. Machine Learning Algorithms: A Review. Int. J. Comput. Sci. Inf. Technol. 2016, 7, 1174–1179. [Google Scholar]

- Westphal, E.; Seitz, H. Machine learning for the intelligent analysis of 3D printing conditions using environmental sensor data to support quality assurance. Addit. Manuf. 2022, 50, 102535. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Z.; Shi, J.; Wu, D. Prediction of Surface Roughness in Extrusion-Based Additive Manufacturing with Machine Learning. Robot. Comput. Manuf. 2019, 57, 488–495. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, J.; Li, M.; Wang, X. Real-Time Monitoring of Fused Deposition Modeling Using Thermal Imaging and Deep Learning. J. Manuf. Process. 2020, 54, 276–283. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, C.S.; Kim, S.M.; Lee, S.W. Development of Data-Driven In-Situ Monitoring and Diagnosis System of Fused Deposition Modeling (FDM) Process Based on Support Vector Machine Algorithm. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 479–486. [Google Scholar] [CrossRef]

- Olowe, M.; Ogunsanya, M.; Best, B.; Hanif, Y.; Bajaj, S.; Vakkalagadda, V.; Fatoki, O.; Desai, S. Spectral Features Analysis for Print Quality Prediction in Additive Manufacturing: An Acoustics-Based Approach. Sensors 2024, 24, 4864. [Google Scholar] [CrossRef]

- Okaro, I.A.; Jayasinghe, S.; Sutcliffe, C.; Black, K.; Paoletti, P.; Green, P.L. Automatic Fault Detection for Laser Powder-Bed Fusion Using Semi-Supervised Machine Learning. Addit. Manuf. 2019, 27, 42–53. [Google Scholar] [CrossRef]

| Author | Data Collected Type | Additive Manufacturing—Approach Applied | Model Applied | Summary of the Work | Accuracy |

|---|---|---|---|---|---|

| R. Zhang et al. [26] | Thermal image data | Fused deposition Modeling | Deep learning | Developed a thermal imaging-based method for real-time monitoring of temperature and layer bonding to detect defects in AM parts. | 81% |

| Danielle Jaye S. Agron et al. [27] | Sensor | SLS | ANN | The research offers a model for monitoring and regulating oxygen levels in SLA. | 96% |

| J. Kim et al. [28] | Acoustic emission and accelerometer Data | FDM | Support vector machine (SVM) | Data-driven models for real-time fault diagnosis in FDM processes, focusing on loose bolts in the nozzle head. | 82.5% to 87.5%. |

| M. Olowe et al. [29] | Acoustic emission sensor | FDM | Gradient boosting | Used AE data to develop a machine learning-driven system for diagnosing FDM process conditions. | 91% |

| Ikenna A. Okaro et al. [30] | Sensor | L-PBF | Machine learning—semi-supervised learning | The semi-supervised approach is used | 77% |

| Sr. No. | Specification | Details |

|---|---|---|

| 1 | Printer name | Ender 3 by Creality |

| 2 | Print technology | Fused deposition modeling (FDM) |

| 3 | Build volume | 220 × 220 × 250 mm |

| 4 | Layer resolution | 0.1–0.4 mm |

| 5 | Nozzle diameter | 0.4 mm |

| 6 | Print speed | 40–60 mm/s |

| 7 | Maximum nozzle temperature | 255 °C |

| 8 | Maximum bed temperature | 110 °C |

| Sr. No. | Features | Description |

|---|---|---|

| 1 | Channels | 16 analog input channels, 2 analog output channels |

| 2 | Analog input | 16-bit resolution |

| 3 | Analog output | 16-bit resolution |

| 4 | Sampling rate | Up to 250 kS/s (kilo-samples per second) per channel |

| 5 | Input range | ±10 V, ±5 V, ±1 V, ±0.2 V, and others (configurable) |

| 6 | Output range | ±10 V |

| 7 | Input type | Differential and single ended |

| 8 | Connector type | 68-pin SCSI connector |

| 9 | DAQ software | Compatible with NI-DAQExpress and LabVIEW |

| 10 | Temperature range | Operating: 0 to 55 °C; Storage: −20 to 70 °C |

| Sr. No. | Specification | Value/Range |

|---|---|---|

| 1 | Extruder/nozzle temperature | 180–220 °C |

| 2 | Bed temperature | 40–60 °C |

| 3 | Print speed | 30–90 mm/s |

| 4 | Layer height | 0.1–0.3 mm |

| 5 | Nozzle size | 0.4 mm (standard) |

| 6 | Retraction speed | 25–45 mm/s |

| 7 | Infill percentage | 10–40% |

| 8 | Infill pattern | Grid, triangles, honeycomb |

| Sr. No. | Variable Operating Parameters | Normal Operating Value | Variable Operating Range | Variation Step Size |

|---|---|---|---|---|

| 1 | Temperature | 200 to 220 °C | 180 to 260 °C | 10 °C |

| 2 | Printing speed | 50 to 100 mm/s | 40 to 310 mm/s | 10 mm/s |

| 3 | Jerk | 10 m/ s3 | 10 to 500 m/s3 | 50 m/ s3 |

| Sr. No | Normal and Induced Fault Conditions | Finished Product | Faults |

|---|---|---|---|

| 1 | Normal conditions |   | No fault |

| 2 | High printing speed |   | Poor infill, elephant foot |

| 3 | High jerk value |   | Poor infill, level shift |

| 4 | High extrusion temperature |   | Overheating, poor surface finish |

| Layer | Type | Parameters | Description |

|---|---|---|---|

| Input layer | 1D input | input_shape = (sequence_length, num_features) | Input layer for 1D sequence data |

| Convolutional layer 1 | 1D conv | filters = 32, kernel_size = 3, activation = ‘relu’ | First convolutional layer |

| Max pooling layer 1 | 1D max pool | pool_size = 2 | Reduces dimensionality and extracts features |

| Convolutional layer 2 | 1D conv | filters = 64, kernel_size = 3, activation = ‘relu’ | Second convolutional layer |

| Max pooling layer 2 | 1D max pool | pool_size = 2 | Further reduces dimensionality |

| Convolutional layer 3 | 1D conv | filters = 128, kernel_size = 3, activation = ‘relu’ | Third convolutional layer |

| Max pooling layer 3 | 1D max pool | pool_size = 2 | Further reduces dimensionality |

| Flatten | Flatten | - | Flattens the output for the Dense layer |

| Dense layer 1 | Dense | units = 128, activation = ‘relu’ | Fully connected layer for feature extraction |

| Dropout layer | Dropout | rate = 0.5 | Regularization to prevent overfitting |

| Dense layer 2 | Dense | units = num_classes, activation = ‘softmax’ | Output layer for classification |

| Model Used | Precision | Recall | F1-Scores | Accuracy |

|---|---|---|---|---|

| K-nearest neighbors classifier | 0.73 | 0.73 | 0.73 | 0.73 |

| Extra-tree classifier | 0.89 | 0.89 | 0.89 | 0.89 |

| Decision tree classifier | 0.89 | 0.89 | 0.89 | 0.89 |

| Random forest classifier | 0.90 | 0.90 | 0.90 | 0.90 |

| Convolutional neural network | 0.92 | 0.92 | 0.92 | 0.92 |

| Model Used | Precision | Recall | F1-Scores | Accuracy |

|---|---|---|---|---|

| K-nearest neighbors classifier | 0.68 | 0.68 | 0.68 | 0.68 |

| Extra-tree classifier | 0.92 | 0.93 | 0.92 | 0.92 |

| Decision tree classifier | 0.90 | 0.90 | 0.90 | 0.90 |

| Random forest classifier | 0.91 | 0.92 | 0.92 | 0.92 |

| Convolutional neural network | 0.93 | 0.93 | 0.93 | 0.93 |

| Model Used | Precision | Recall | F1-Scores | Accuracy |

|---|---|---|---|---|

| K-nearest neighbors classifier | 0.74 | 0.73 | 0.73 | 0.73 |

| Extra-tree classifier | 0.89 | 0.89 | 0.89 | 0.81 |

| Decision tree classifier | 0.88 | 0.88 | 0.88 | 0.88 |

| Random forest classifier | 0.91 | 0.91 | 0.91 | 0.91 |

| Convolutional neural network | 0.94 | 0.94 | 0.94 | 0.94 |

| Model Used | Variable Parameter | Precision | Recall | F1-Scores | Accuracy |

|---|---|---|---|---|---|

| K-nearest neighbors classifier | Temp | 0.73 | 0.73 | 0.73 | 0.73 |

| Speed | 0.68 | 0.68 | 0.68 | 0.68 | |

| Jerk | 0.74 | 0.73 | 0.73 | 0.73 | |

| Extra-tree classifier | Temp | 0.89 | 0.89 | 0.89 | 0.89 |

| Speed | 0.93 | 0.93 | 0.93 | 0.93 | |

| Jerk | 0.89 | 0.89 | 0.89 | 0.81 | |

| Decision tree classifier | Temp | 0.89 | 0.89 | 0.89 | 0.89 |

| Speed | 0.90 | 0.90 | 0.90 | 0.90 | |

| Jerk | 0.88 | 0.88 | 0.88 | 0.88 | |

| Random forest classifier | Temp | 0.90 | 0.90 | 0.90 | 0.90 |

| Speed | 0.91 | 0.92 | 0.92 | 0.92 | |

| Jerk | 0.91 | 0.91 | 0.91 | 0.91 | |

| Convolutional neural network | Temp | 0.92 | 0.92 | 0.92 | 0.92 |

| Speed | 0.93 | 0.93 | 0.93 | 0.93 | |

| Jerk | 0.94 | 0.94 | 0.94 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, S.; Sayyad, S.; Bongale, A. Fault Classification of 3D-Printing Operations Using Different Types of Machine and Deep Learning Techniques. AI 2024, 5, 1759-1778. https://doi.org/10.3390/ai5040087

Kumar S, Sayyad S, Bongale A. Fault Classification of 3D-Printing Operations Using Different Types of Machine and Deep Learning Techniques. AI. 2024; 5(4):1759-1778. https://doi.org/10.3390/ai5040087

Chicago/Turabian StyleKumar, Satish, Sameer Sayyad, and Arunkumar Bongale. 2024. "Fault Classification of 3D-Printing Operations Using Different Types of Machine and Deep Learning Techniques" AI 5, no. 4: 1759-1778. https://doi.org/10.3390/ai5040087

APA StyleKumar, S., Sayyad, S., & Bongale, A. (2024). Fault Classification of 3D-Printing Operations Using Different Types of Machine and Deep Learning Techniques. AI, 5(4), 1759-1778. https://doi.org/10.3390/ai5040087