Experimental Study on the Use of Polyurethane Elastomers to Enhance Structural Performance of A36 Steel Sheets Under Near-Field Detonation

Abstract

:1. Introduction

- Polyurethane elastomer is a cheaper and more readily available material compared to polyurea;

- Polyurethane can take hours to cure, whereas polyurea cures almost instantly, making each suitable for different scenarios. For example, it is easier to produce sandwich elements with polyurethane;

- Polyurethane is more resistant to UV exposure, making it more appropriate for outdoor environments;

- Polyurethane requires greater control over moisture during fabrication, making it more suitable for use with dry materials such as metals.

2. Materials and Methods

- Coating A36 Steel Sheets with Polyurethane Elastomer;

- Near-Field Blast Tests;

- Blast Intensity of the Experiments Compared with Real Events;

- Method for Measuring Peak Displacement;

- Uncertainties in Displacement Measurement.

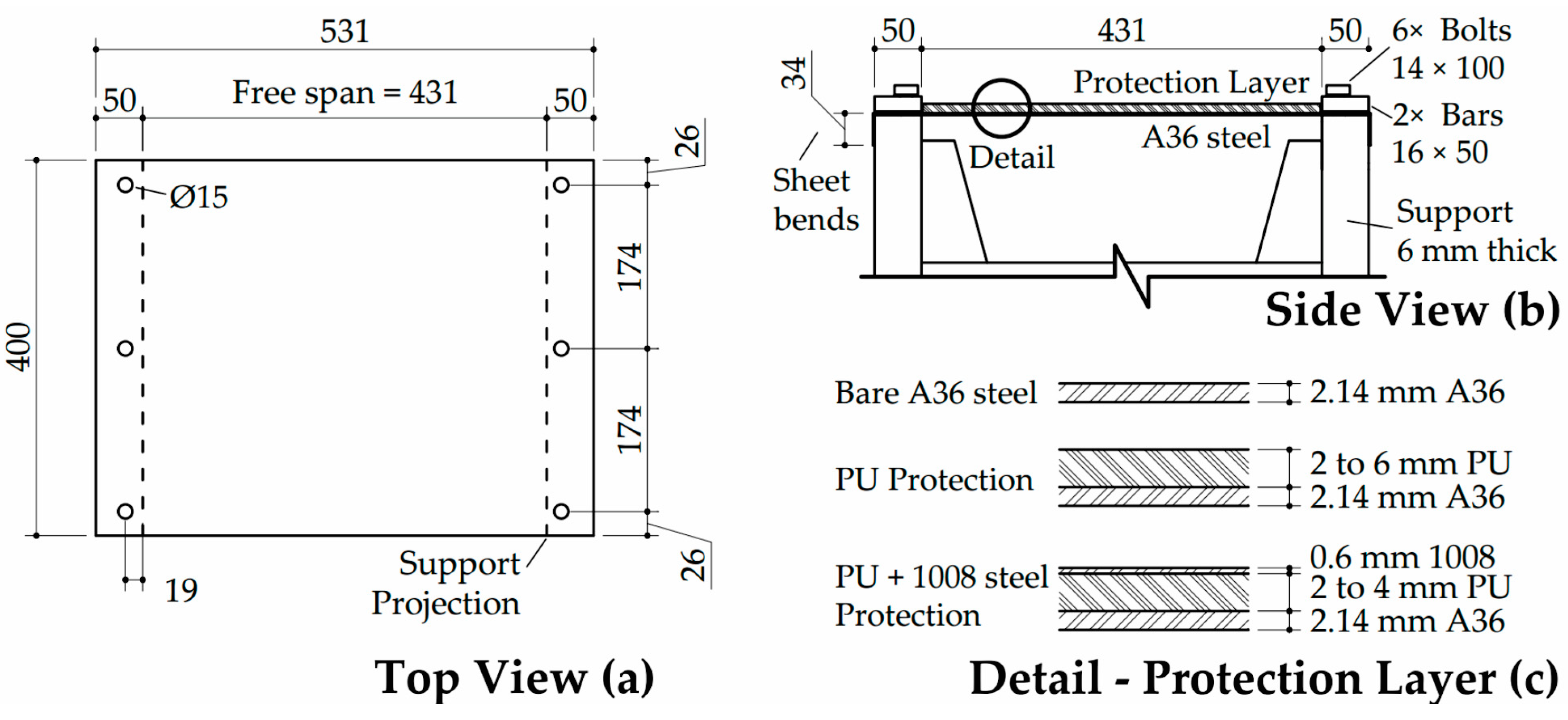

2.1. Coating A36 Steel Sheets with Polyurethane Elastomer

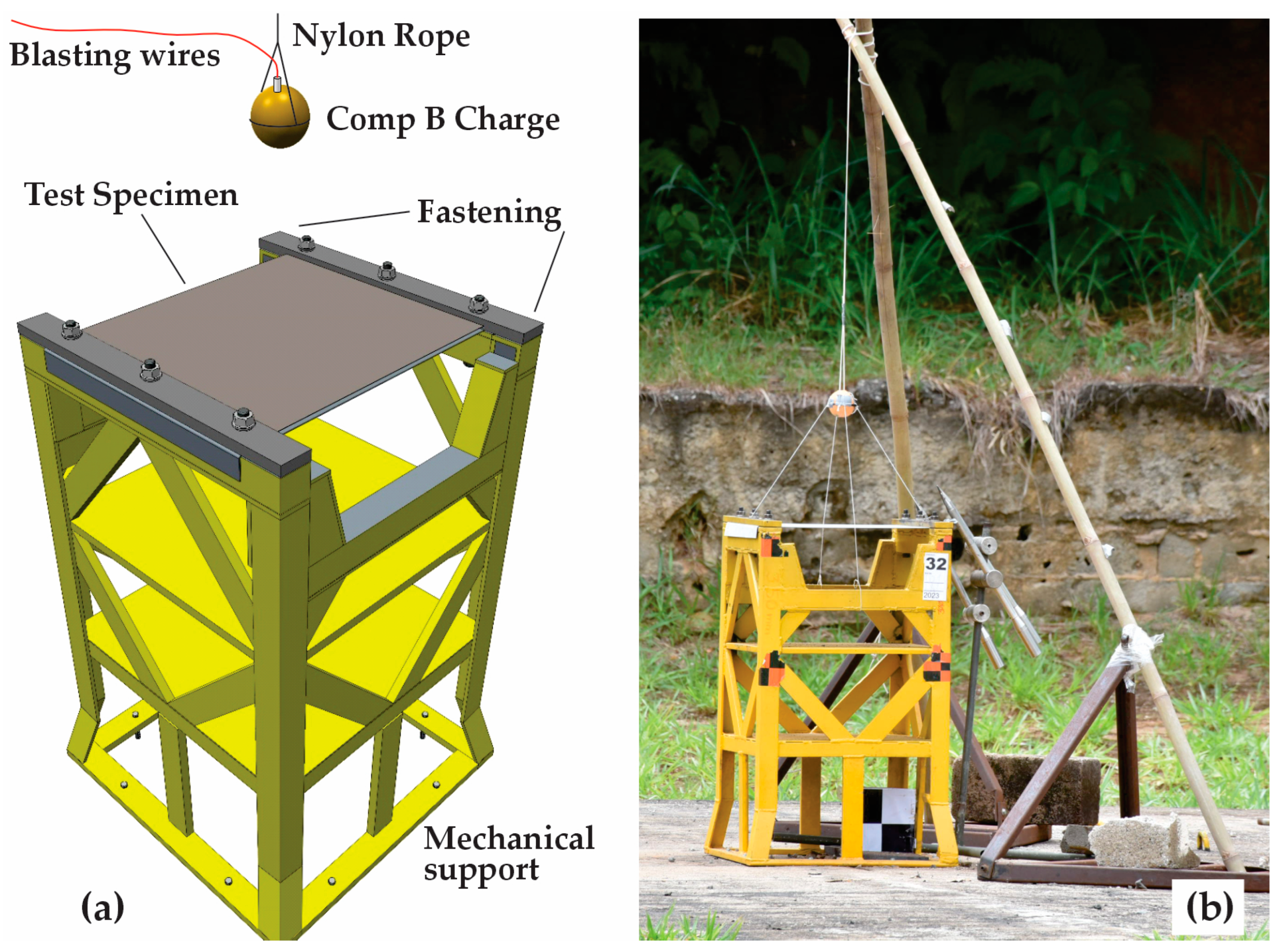

2.2. Near-Field Blast Tests

2.3. Blast Intensity of the Experiments Compared with Real Events

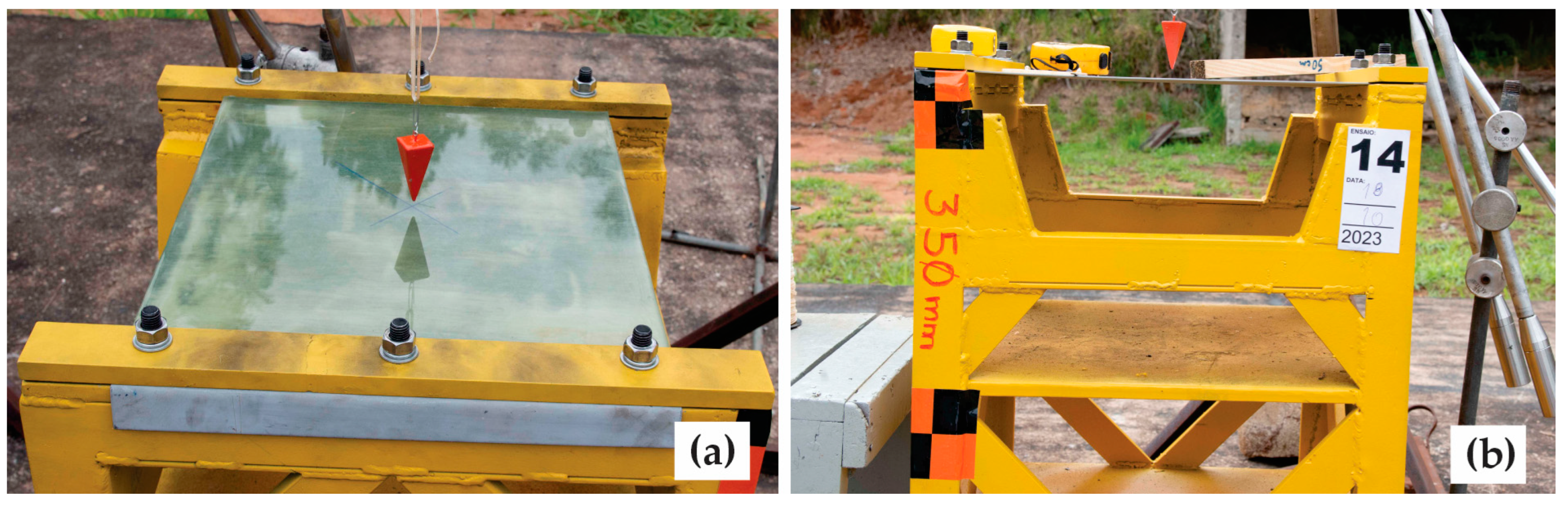

2.4. Method of Measuring the Peak Displacement

2.5. Uncertainties in Displacement Measurement

3. Results

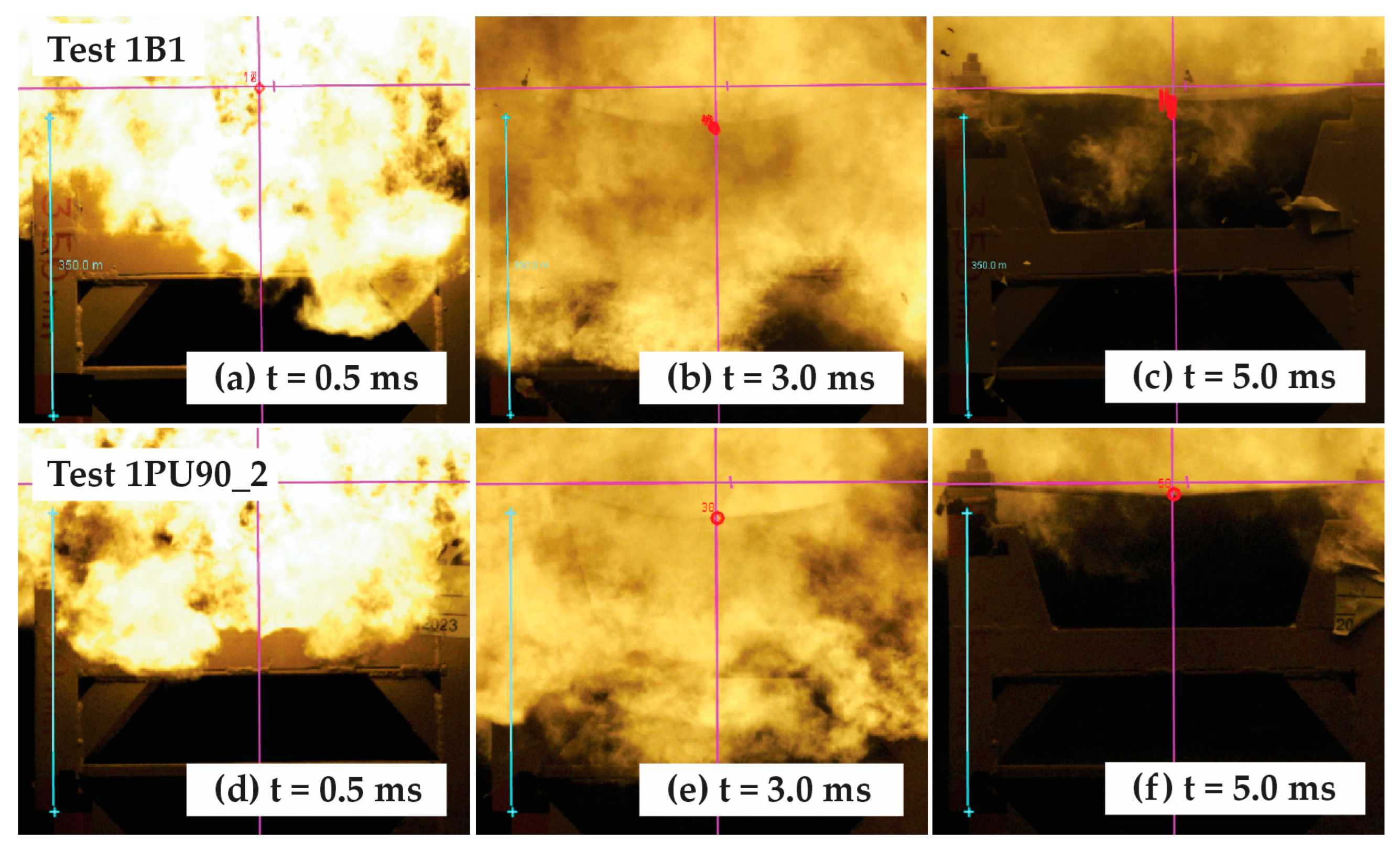

3.1. Blast Near-Field Tests Results

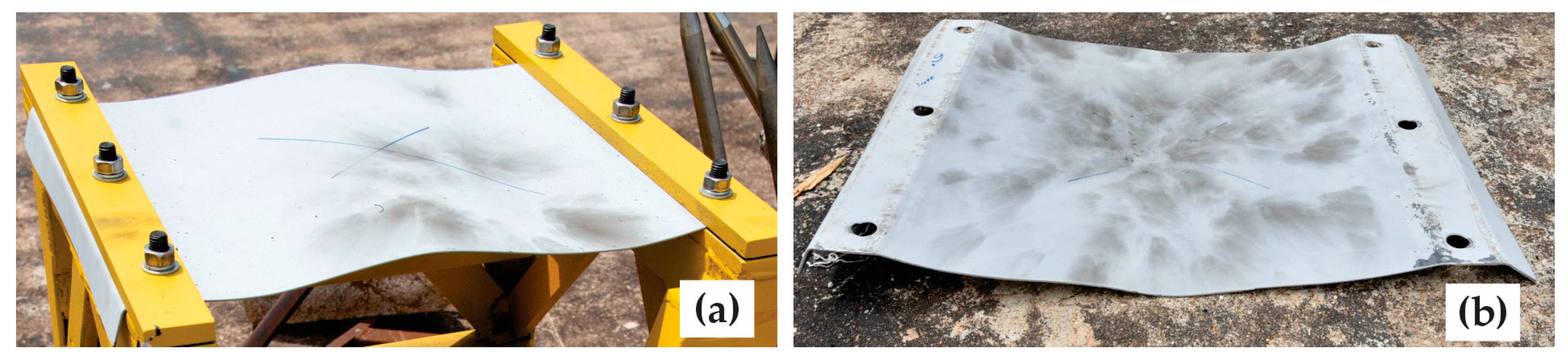

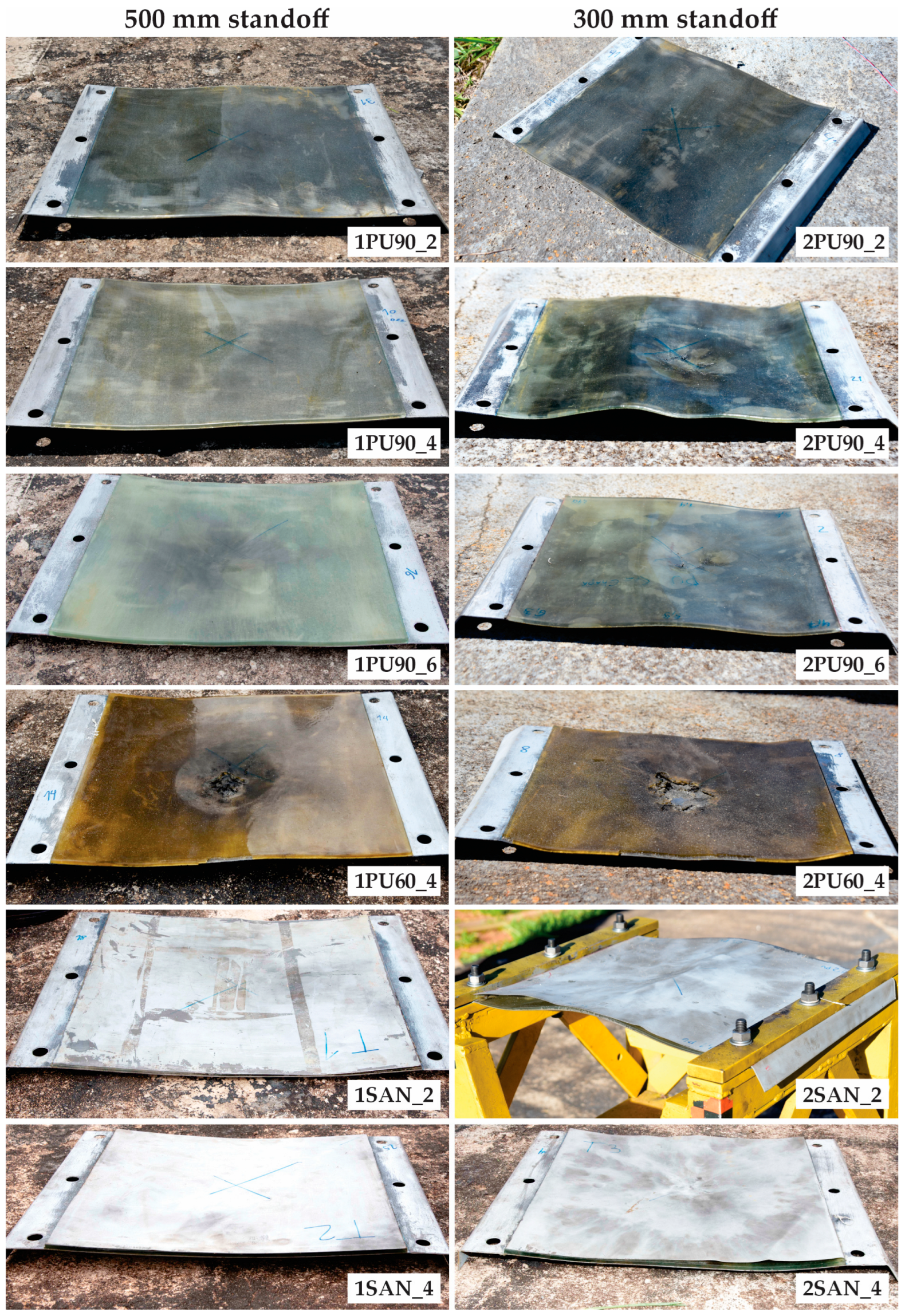

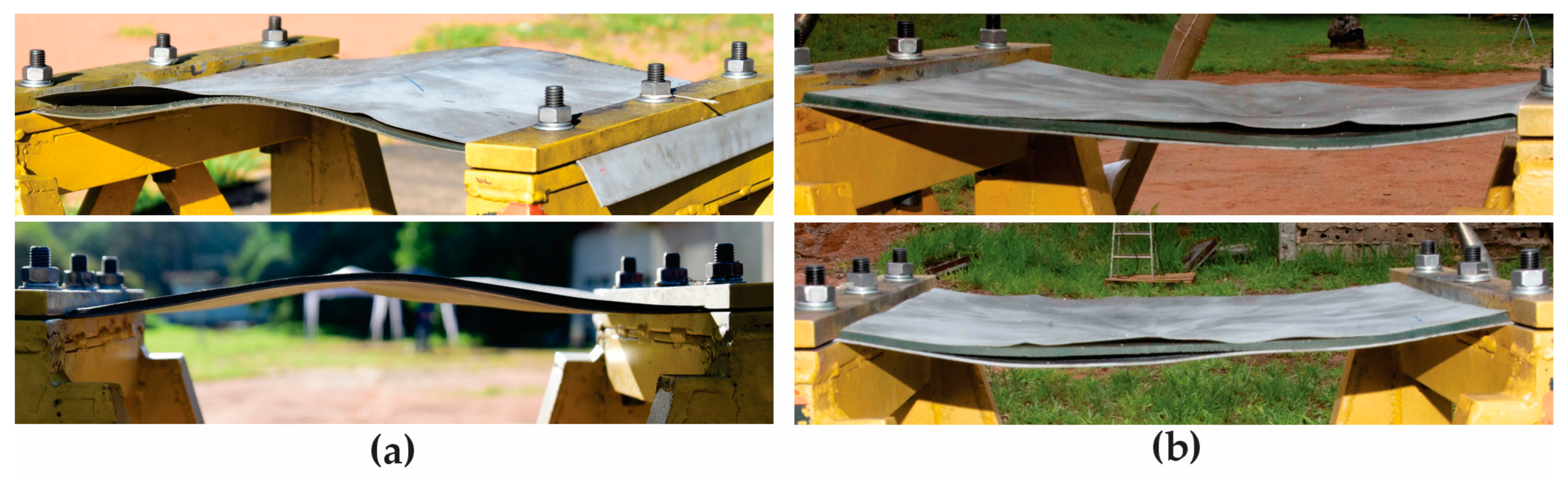

3.2. Visual Results of the Specimens

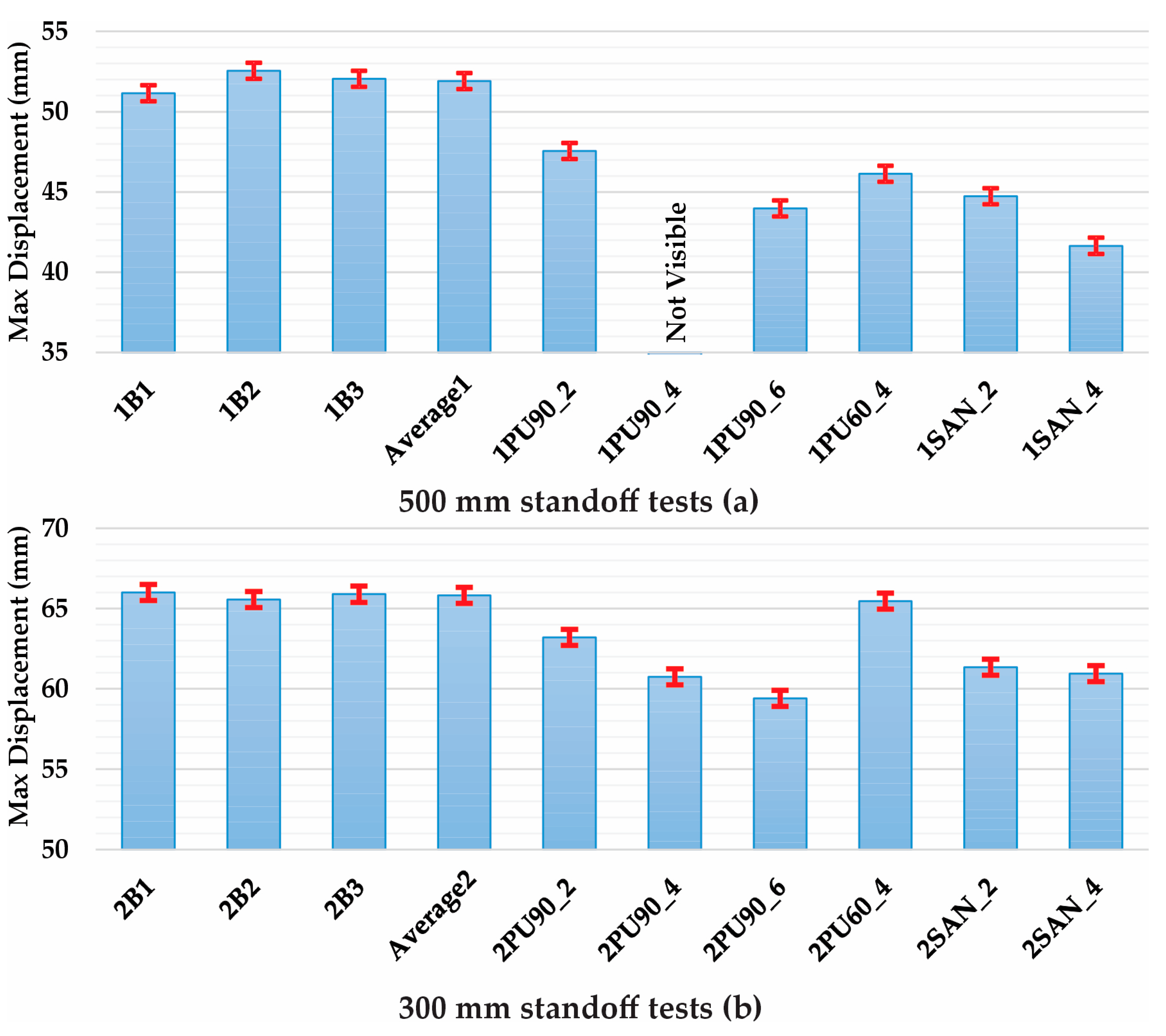

3.3. Maximum Displacement

4. Discussion

4.1. Results Discussion

4.2. Contextualization and Practical Application

5. Conclusions

- This study tested the use of polyurethane elastomer as reinforcement for steel sheets subjected to near-field blast loads. According to the consulted references, this combination had never been tested before and introduced a more cost-effective material that may be suitable in different scenarios when compared to other materials previously studied, such as polyurea;

- Eighteen near-field blast tests were conducted on 2 mm A36 steel sheets at 300 mm and 500 mm standoff distances using 334 g of Composition B. Sheets retrofitted with 2–6 mm of Shore A 60 or 90 polyurethane elastomer showed a reduction in maximum displacement ranging from 5% to 20% compared to unprotected sheets. For the 500 mm distance, the best performance was observed with the sandwich configuration, while at 300 mm, the greatest reduction occurred with the thickest polyurethane layer. Overall, Shore A 90 elastomer provided better results than Shore A 60;

- Polyurethane elastomer showed protective performance similar to that reported for polyurea in a referenced study but offers broader practical applications. Due to its longer curing time, UV resistance, low density, and self-leveling properties, it is suitable for use in sandwich panels, steel floor panels, flat steel roof decks, metallic bunkers, casemates, removable steel frames, and military assets such as hangars, radar stations, transport vehicles, and armored tanks. However, it is not suitable for use on vertically fixed frames due to the flow of the uncured material, or on wet surfaces during curing due to its unintended reaction with water;

- Future work to advance the field should include testing polyurethane elastomer with different steel profiles and various steel grades. Additionally, analyzing the propagation of vibrations within the structure and their potential influence on the delamination process would be essential to ensure effective adhesion between layers, particularly under extreme loading conditions. This aspect affected the performance of the sandwich configuration tested at the 300 mm standoff distance. Moreover, the present results serve as valuable primary data for the validation of numerical simulations, such as those based on Finite Element Methods, and can support future studies and research in this field.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nazarian, A.; Presser, C. Forensic analysis methodology for thermal and chemical characterization of homemade explosives. Thermochim. Acta 2014, 576, 60–70. [Google Scholar] [CrossRef]

- United Nations. International Ammunition Technical Guidelines—IATG 01.08, 3rd ed.; United Nations: New York, NY, USA, 2021; Available online: https://data.unsaferguard.org/iatg/en/IATG-01.80-Formulae-ammunition-management-IATG-V.3.pdf (accessed on 3 April 2025).

- USDOD. Structures to Resist the Effects of Accidental Explosions—UFC 3-340-02; United States Department of Defense (USDOD): Washington, DC, USA, 2008; p. 1943. Available online: https://www.wbdg.org/FFC/DOD/UFC/ARCHIVES/ufc_3_340_02.pdf (accessed on 3 April 2025).

- Mendonça, F.B.; Urgessa, G.S.; Almeida, L.E.N.; Rocco, J.A.F.F. Damage diagram of blast test results for determining reinforced concrete slab response for varying scaled distance, concrete strength and reinforcement ratio. An. Acad. Bras. Ciênc. 2021, 93, e20200511. [Google Scholar] [CrossRef] [PubMed]

- Barsoum, R.G. Elastomeric Polymers with High Rate Sensitivity—Applications in Blast, Shockwave, and Penetration Mechanics; William Andrew: Oxford, UK, 2015; Available online: https://www.sciencedirect.com/book/9780323354004/elastomeric-polymers-with-high-rate-sensitivity (accessed on 3 April 2025).

- Oertel, G. Polyurethane Handbook; Hanser Publishers: Munich, Germany, 1985; p. 629. [Google Scholar] [CrossRef]

- Cartman, L. Handbook of Polyurethane; NY Research Press: New York, NY, USA, 2015. [Google Scholar]

- Souza, F.M.d.; Kahol, P.K. Introduction to polyurethane chemistry. In Renewable Polyols and Isocyanates; Gupta, R.K., Ed.; ACS Symposium Series: Washington, DC, USA, 2021; pp. 1–24. [Google Scholar] [CrossRef]

- Oertel, G. Polyurethane Handbook: Chemistry, Raw Materials, Processing, Application, Properties, Subsequent ed.; Hanser Pub Inc.: Cincinnati, OH, USA, 1994. [Google Scholar]

- Zu, X.; Chen, T.; Cai, Y.; Huang, Z.; Xiao, Q. Blast resistance of a masonry wall coated with a polyurea elastomer. Coatings 2022, 12, 1744. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, R.; Wang, X.; Lyu, P.; Ju, J.; Gao, F.; Yan, S. Study of blast mitigation performance and fracture mechanism of polyurea under contact explosion. Polymers 2022, 14, 3458. [Google Scholar] [CrossRef]

- Yue, Z.; Zhou, J.; Kong, X.; Xu, Y.; Chen, Y.; Wang, B.; Huang, Y.; Wang, P. Anti-blast performance of polyurea-coated concrete arch structures. Polymers 2023, 15, 1263. [Google Scholar] [CrossRef]

- Fatt, H.S.H.; Ouyang, X.; Dinan, R.J. Blast response of walls retrofitted with elastomer coatings. In Structures Under Shock and Impact VIII; Force Protection Branch, Air Force Research Laboratory, Tyndall Air Force Base: Tyndall AFB, FL, USA, 2004; Available online: https://apps.dtic.mil/sti/tr/pdf/ADA589006.pdf (accessed on 3 April 2025).

- Davidson, J.; Porter, J.; Dinan, R.; Hammons, M.; Connell, J. Explosive testing of polymer retrofit masonry walls. J. Perform. Constr. Facil. 2004, 18, 100–107. [Google Scholar] [CrossRef]

- Wu, G.; Ji, C.; Wang, X.; Gao, F.Y.; Zhao, C.X.; Liu, Y.J.; Yang, G.L. Blast response of clay brick masonry unit walls unreinforced and reinforced with polyurea elastomer. Def. Technol. 2022, 18, 643–662. [Google Scholar] [CrossRef]

- Santos, A.P.; Chiquito, M.; Castedo, R.; López, L.; Gomes, G.; Mota, C.; Fangueiro, R.; Mingote, J.L. Experimental and numerical study of polyurea coating systems for blast mitigation of concrete masonry walls. Eng. Struct. 2023, 284, 116006. [Google Scholar] [CrossRef]

- Lyu, P.; Fang, Z.; Wang, X.; Huang, W.; Zhang, R.; Sang, Y.; Sun, P. Explosion Test and Numerical Simulation of Coated Reinforced Concrete Slab Based on BLAST Mitigation Polyurea Coating Performance. Materials 2022, 15, 2607. [Google Scholar] [CrossRef]

- Chen, Y.S.; Wang, B.; Zhang, B.; Zheng, Q.; Zhou, J.N.; Jin, F.N.; Fan, H.L. Polyurea coating for foamed concrete panel: An efficient way to resist explosion. Def. Technol. 2020, 16, 136–149. [Google Scholar] [CrossRef]

- Zhu, H.; Wang, X.; Wang, Y.; Wu, G.; Cao, Y.; Ji, C. Dynamic responses of aluminum alloy plates coated with polyurea elastomer subjected to repeated blast loads: Experimental and numerical investigation. Thin-Walled Struct. 2023, 189, 110912. [Google Scholar] [CrossRef]

- Zhu, H.; Ji, C.; Feng, K.; Tu, J.; Wang, X.; Zhao, C. Polyurea elastomer for enhancing blast resistance of structures: Recent advances and challenges ahead. Thin-Walled Struct. 2024, 200, 111938. [Google Scholar] [CrossRef]

- Jamil, A.; Guan, Z.W.; Cantwell, W.J.; Zhang, X.F.; Langdon, G.S.; Wang, Q.Y. Blast response of aluminium/thermoplastic polyurethane sandwich panels—Experimental work and numerical analysis. Int. J. Impact Eng. 2019, 127, 31–40. [Google Scholar] [CrossRef]

- Bahei-El-Din, Y.A.; Dvorak, G.J. Behavior of sandwich plates reinforced with polyurethane/polyurea interlayers under blast loads. J. Sandw. Struct. Mater. 2007, 9, 261–281. [Google Scholar] [CrossRef]

- Kannan, K.; Ponnalagu, A. Blast effect on layered polyurethane foam. Int. J. Impact Eng. 2024, 187, 104894. [Google Scholar] [CrossRef]

- Mostafa, H.E.; El-Dakhakhni, W.W.; Mekky, W.F. Use of reinforced rigid polyurethane foam for blast hazard mitigation. J. Reinf. Plast. Compos. 2010, 29, 3048–3057. [Google Scholar] [CrossRef]

- Jia, S.; Wang, C.; Xu, W.; Ma, D.; Qi, F. Experimental investigation on weak shock wave mitigation characteristics of flexible polyurethane foam and polyurea. Def. Technol. 2024, 31, 179–191. [Google Scholar] [CrossRef]

- Freidenberg, A.; Lee, C.W.; Durant, B.; Nesterenko, V.F.; Stewart, L.K.; Hegemier, G.A. Characterization of the Blast Simulator elastomer material using a pseudo-elastic rubber model. Int. J. Impact Eng. 2013, 60, 58–66. [Google Scholar] [CrossRef]

- Somarathna, H.M.C.C.; Raman, S.N.; Badri, K.H.; Mutalib, A.A. Mechanical characterization of polyurethane elastomers: For retrofitting application against blast effects. In Proceedings of the SMAR 2015: Third Conference on Smart Monitoring, Assessment & Rehabilitation of Civil Structures, Antalya, Turkey, 7–9 September 2015; Available online: https://plus.empa.ch/smar-conferences-data/SMAR_2015_Proceedings/papers/48.pdf (accessed on 3 April 2025).

- Chattopadhyay, D.K.; Raju, K.V.S.N. Structural engineering of polyurethane coatings for high performance applications. Prog. Polym. Sci. 2007, 32, 352–418. [Google Scholar] [CrossRef]

- Somarathna, H.M.C.C.; Raman, S.N.; Mutalib, A.A.; Badri, K.H. Elastomeric polymers for blast and ballistic retrofitting of structures. J. Teknol. Sci. Eng. 2015, 76, 1–13. [Google Scholar] [CrossRef]

- Knox, K.J.; Hammons, M.I.; Lewis, T.T.; Porter, J.R. Polymer Materials for Structural Retrofit; Force Protection Branch, Air Expeditionary Forces, Technology Division, Air Force Research Laboratory: Tyndall AFB, FL, USA, 2000; Available online: http://userfile.alephnetwork.com/files/b2gmarekt_vendor/Polymer_Retrofit_Paper-1.pdf (accessed on 3 April 2025).

- Davidson, J.S.; Fisher, J.W.; Hammons, M.I.; Porter, J.R.; Dinan, R.J. Failure mechanisms of polymer-reinforced concrete masonry walls subjected to blast. J. Struct. Eng. 2005, 131, 1194–1205. [Google Scholar] [CrossRef]

- Mohotti, D.; Fernando, P.; Weerasinghe, D.; Remennikov, A. Evaluation of effectiveness of polymer coatings in reducing blast-induced deformation of steel plates. Def. Technol. 2021, 17, 1895–1904. [Google Scholar] [CrossRef]

- Woods, G. The ICI Polyurethanes Book, 2nd ed.; Wiley: New York, NY, USA, 1991; p. 362. [Google Scholar] [CrossRef]

- Companhia Siderúrgica Nacional. Aços Planos Laminados a Quente (Hot-Rolled Flat Steel Sheets). Available online: https://www.csn.com.br/homepage/acos-planos/laminados-a-quente/ (accessed on 3 April 2025).

- Preedawiphat, P.; Mahayotsanun, N.; Sa-ngoen, K.; Noipitak, M.; Tuengsook, P.; Sucharitpwatskul, S.; Dohda, K. Mechanical investigations of ASTM A36 welded steels with stainless steel cladding. Coatings 2020, 10, 844. [Google Scholar] [CrossRef]

- Cormie, D.; Geoff, M. Blast Effects on Buildings, 2nd ed.; Thomas Telford: London, UK, 2009. [Google Scholar]

- Celpan Industria e Comercio de Plásticos Ltda. Elastômeros Poliuretano—Peças Técnicas (Polyurethane Elastomer Technical Parts). Available online: https://www.celpan.com.br/plasticos/poliuretano/elastomeros-pecas-tecnicas/ (accessed on 3 April 2025).

- Usinas Siderúrgicas de Minas Gerais S.A., Laminados a Frio (Cold-Rolled Steel). Available online: https://www.usiminas.com/wp-content/uploads/2020/05/LAMINADOSFRIO-PORT.pdf (accessed on 3 April 2025).

- Augusto, A.S.; Urgessa, G.; Amorim, C.B.; Lopes Júnior, R.E.; Mendonça, F.B.; Rocco, J.A.F.F.; Iha, K. Experimental Characterization of Cast Explosive Charges Used in Studies of Blast Effects on Structures. CivilEng 2025, 6, 20. [Google Scholar] [CrossRef]

- Phantom. PHANTOM VEO 640/VEO 440 High-Speed Camera Datasheet; Phantom: Wayne, NJ, USA, 2024; p. 4. Available online: https://www.phantomhighspeed.com/products/cameras/veo/veo640 (accessed on 3 April 2025).

- Kingery, C.N.; Bulmash, G. Technical Report ARBRL TR-02555—Airblast Parameters from TNT Spherical Air Burst and Hemispherical Surface Burst; Aberdeen Proving Ground, Army Armament and Development Center, Ballistic Research Laboratory: Aberdeen Proving Ground, MD, USA, 1984. [Google Scholar]

- Jeremić, R.; Bajić, Z. An approach to determining the TNT equivalent of high explosives. Sci. Tech. Rev. 2006, 56, 58–62. Available online: http://www.vti.mod.gov.rs/ntp/rad2006/1-06/jere/jere.pdf (accessed on 3 April 2025).

- Kinney, G.F.; Graham, K.J. Explosive Shocks in Air, 2nd ed.; Springer Science+Business Media, LLC: New York, NY, USA, 1985; p. 269. [Google Scholar] [CrossRef]

- Mendonça, F.B.; Urgessa, G.S.; Domingues, M.G.; Iha, K.; Rocco, J.A.F.F. Efeitos do EPS na leitura de pico de pressão refletida em ensaio de campo com explosivo militar. Spectrum 2023, 24, 49–53. [Google Scholar] [CrossRef]

- Panowicz, R.; Konarzewski, M.; Trypolin, M. Analysis of criteria for determining a TNT equivalent. J. Mech. Eng. 2017, 63, 666–672. [Google Scholar] [CrossRef]

- Hyde, D.W. Conventional Weapons Effect (CONWEP)—Application of TM5-855-1; Department of the Army: Vicksburg, MS, USA, 1988; Available online: https://apps.dtic.mil/sti/pdfs/ADA195867.pdf (accessed on 3 April 2025).

- National Academies; Department of Homeland Security. IED Attack—Improvised Explosive Devices; Department of Homeland Security: Washington, DC, USA, 2009. Available online: https://www.dhs.gov/xlibrary/assets/prep_ied_fact_sheet.pdf (accessed on 3 April 2025).

- Rigby, S.E.; Knighton, R.; Clarke, S.D.; Tyas, A. Reflected near-field blast pressure measurements using high-speed video. Exp. Mech. 2020, 60, 875–888. [Google Scholar] [CrossRef]

- Tyas, A. Blast loading from high explosive detonation: What we know and don’t know. In Proceedings of the 13th International Conference on Shock and Impact Loads on Structures, Guangzhou, China, 14–15 December 2019. [Google Scholar]

- Tyas, A. Experimental measurement of pressure loading from near-field blast events: Techniques, findings and future challenges. Proceedings 2018, 2, 471. [Google Scholar] [CrossRef]

- Brown, D.; Christian, W.; Hanson, R.M. Tracker 6.2.0: Video Analysis and Modelling Tool. Available online: https://opensourcephysics.github.io/tracker-website/ (accessed on 3 April 2025).

- Rastogi, P.K. Photomechanics (Topics in Applied Physics); Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Yield strength | MPa | 328 |

| Tensile strength | MPa | 467 |

| Dynamic yield strength | MPa | 394 |

| Dynamic tensile strength | MPa | 490 |

| Elongation (50 mm gauge) | % | 27 |

| Young’s Modulus | GPa | 200 |

| Poisson’s ratio | - | 0.26 |

| Density | g/cm3 | 7.85 |

| Parameter | Unit | Test Standard | 60 Shore A | 90 Shore A |

|---|---|---|---|---|

| Hardness | Shore A | ASTM D 2240 | 60 | 90 |

| Tensile strength | MPa | ASTM D 412 | 13 | 28 |

| 100% modulus | MPa | ASTM D 412 | 2 | 10 |

| 300% modulus | MPa | ASTM D 412 | 3 | 14 |

| Elongation | % | ASTM D 412 | 990 | 475 |

| Tear strength | kN/m | ASTM D 624 | 31 | 76 |

| Permanent deformation | % | ASTM D 395 | 50 | 40 |

| Resilience (Bashore) | % | ASTM D 2632 | 35 | 26 |

| Abrasion resistance | mm3 | DIN 53516 | 80 | 45 |

| Density | g/cm3 | ASTM D 792 | 1.10 | 1.15 |

| ID Code | Nominal Protection | A36 Sheet Mass | PU Mass | PU Thickness | 1008 Sheet Mass | Total Mass |

|---|---|---|---|---|---|---|

| (g) | (g) | (mm) | (g) | (g) | ||

| Used in 500 mm standoff distance blast tests | ||||||

| 1B1 | Bare | 3856 | 0 | 0.0 | 0 | 3856 |

| 1B2 | Bare | 3881 | 0 | 0.0 | 0 | 3881 |

| 1B3 | Bare | 3845 | 0 | 0.0 | 0 | 3845 |

| 1PU90_2 | 2 mm of PU Shore 90 | 3871 | 416 | 2.1 | 0 | 4287 |

| 1PU90_4 | 4 mm of PU Shore 90 | 3836 | 823 | 4.1 | 0 | 4658 |

| 1PU90_6 | 6 mm of PU Shore 90 | 3882 | 1226 | 6.2 | 0 | 5108 |

| 1PU60_4 | 4 mm of PU Shore 60 | 3849 | 809 | 4.3 | 0 | 4658 |

| 1SAN_2 | 2 mm of PU 90 + 1008 sheet | 3813 | 416 | 2.1 | 804 | 5033 |

| 1SAN_4 | 4 mm of PU 90 + 1008 sheet | 3836 | 725 | 3.7 | 803 | 5364 |

| Used in 300 mm standoff distance blast tests | ||||||

| 2B1 | Bare | 3871 | 0 | 0.0 | 0 | 3871 |

| 2B2 | Bare | 3808 | 0 | 0.0 | 0 | 3808 |

| 2B3 | Bare | 3868 | 0 | 0.0 | 0 | 3868 |

| 2PU90_2 | 2 mm of PU Shore 90 | 3876 | 416 | 2.1 | 0 | 4292 |

| 2PU90_4 | 4 mm of PU Shore 90 | 3814 | 829 | 4.2 | 0 | 4643 |

| 2PU90_6 | 6 mm of PU Shore 90 | 3840 | 1175 | 5.9 | 0 | 5015 |

| 2PU60_4 | 4 mm of PU Shore 60 | 3819 | 822 | 4.3 | 0 | 4641 |

| 2SAN_2 | 2 mm of PU 90 + 1008 sheet | 3850 | 383 | 1.9 | 803 | 5036 |

| 2SAN_4 | 4 mm of PU 90 + 1008 sheet | 3819 | 772 | 3.9 | 804 | 5395 |

| Charge | TNT Equiv. | Dist. | Scaled Dist. | P 1 | Ref. 2 |

|---|---|---|---|---|---|

| (kg) | (m) | (m/kg 1/3) | (bar) | ||

| Test 334 g Comp B | 0.43 | 0.50 | 0.6624 | 22.54 | [45] |

| Hand grenade | 0.10 | 0.30 | 0.6463 | 23.69 | [46] |

| Explosive vest bomb | 9.00 | 1.38 | 0.6634 | 22.47 | [47] |

| Parcel bomb | 23.00 | 1.89 | 0.6646 | 22.39 | [47] |

| Airdropped 230 kg bomb | 99.00 | 3.07 | 0.6636 | 22.46 | [46] |

| Car bomb | 226.00 | 4.04 | 0.6633 | 22.48 | [47] |

| Airdropped 920 kg bomb | 429.00 | 5.01 | 0.6643 | 22.41 | [46] |

| Van bomb | 1815.00 | 8.01 | 0.6567 | 22.94 | [47] |

| Test 334 g Comp B | 0.43 | 0.30 | 0.3975 | 58.06 | [45] |

| Hand grenade | 0.10 | 0.18 | 0.3975 | 58.06 | [46] |

| Explosive vest bomb | 9.00 | 0.83 | 0.3990 | 57.69 | [47] |

| Parcel bomb | 23.00 | 1.13 | 0.3973 | 58.09 | [47] |

| Airdropped 230 kg bomb | 99.00 | 1.84 | 0.3977 | 57.99 | [46] |

| Car bomb | 226.00 | 2.42 | 0.3973 | 58.10 | [47] |

| Airdropped 920 kg bomb | 429.00 | 3.00 | 0.3978 | 57.99 | [46] |

| Van bomb | 1815.00 | 4.85 | 0.3976 | 58.03 | [47] |

| Main Parameters | Uncertainties | ||||||

|---|---|---|---|---|---|---|---|

| L | f | D | Pixel | Parallax | Resolution | Calibration | Total 1 |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 45,000 | 200 | 55 | 0.83 | ±0.2 | ±0.4 | ±0.1 | ±0.5 |

| ID Code | Protection Used | Maximum Displacement | Max Displacement Reduction 1 | Percentual Reduction 1 |

|---|---|---|---|---|

| (mm) | (mm) | (%) | ||

| 500 mm standoff distance tests | ||||

| 1B1 | Bare | 51.2 ± 0.5 | 0.8 ± 0.7 | 1 ± 1% |

| 1B2 | Bare | 52.5 ± 0.5 | 0.6 ± 0.7 | 1 ± 1% |

| 1B3 | Bare | 52.0 ± 0.5 | 0.1 ± 0.7 | 0 ± 1% |

| Average1 2 | Bare Average | 51.9 ± 0.5 | 0.0 ± 0.7 | 0 ± 1% |

| 1PU90_2 | 2 mm of PU Shore 90 | 47.6 ± 0.5 | 4.3 ± 0.7 | 8 ± 1% |

| 1PU90_4 | 4 mm of PU Shore 90 | Not visible | ||

| 1PU90_6 | 6 mm of PU Shore 90 | 44.0 ± 0.5 | 7.9 ± 0.7 | 15 ± 1% |

| 1PU60_4 | 4 mm of PU Shore 60 | 46.1 ± 0.5 | 5.8 ± 0.7 | 11 ± 1% |

| 1SAN_2 | 2 mm of PU 90 + 1008 sheet | 44.7 ± 0.5 | 7.2 ± 0.7 | 14 ± 1% |

| 1SAN_4 | 4 mm of PU 90 + 1008 sheet | 41.6 ± 0.5 | 10.3 ± 0.7 | 20 ± 1% |

| 300 mm standoff distance tests | ||||

| 2B1 | Bare | 66.0 ± 0.5 | 0.2 ± 0.7 | 0 ± 1% |

| 2B2 | Bare | 65.6 ± 0.5 | 0.3 ± 0.7 | 0 ± 1% |

| 2B3 | Bare | 65.9 ± 0.5 | 0.1 ± 0.7 | 0 ± 1% |

| Average2 2 | Bare Average | 65.8 ± 0.5 | 0.0 ± 0.7 | 0 ± 1% |

| 2PU90_2 | 2 mm of PU Shore 90 | 63.2 ± 0.5 | 2.6 ± 0.7 | 4 ± 1% |

| 2PU90_4 | 4 mm of PU Shore 90 | 60.8 ± 0.5 | 5.1 ± 0.7 | 8 ± 1% |

| 2PU90_6 | 6 mm of PU Shore 90 | 59.4 ± 0.5 | 6.4 ± 0.7 | 10 ± 1% |

| 2PU60_4 | 4 mm of PU Shore 60 | 65.5 ± 0.5 | 0.4 ± 0.7 | 1 ± 1% |

| 2SAN_2 | 2 mm of PU 90 + 1008 sheet | 61.4 ± 0.5 | 4.5 ± 0.7 | 7 ± 1% |

| 2SAN_4 | 4 mm of PU 90 + 1008 sheet | 60.9 ± 0.5 | 4.9 ± 0.7 | 7 ± 1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Augusto, A.S.; Urgessa, G.; Rocco, J.A.F.F.; Mendonça, F.B.; Iha, K. Experimental Study on the Use of Polyurethane Elastomers to Enhance Structural Performance of A36 Steel Sheets Under Near-Field Detonation. Appl. Mech. 2025, 6, 28. https://doi.org/10.3390/applmech6020028

Augusto AS, Urgessa G, Rocco JAFF, Mendonça FB, Iha K. Experimental Study on the Use of Polyurethane Elastomers to Enhance Structural Performance of A36 Steel Sheets Under Near-Field Detonation. Applied Mechanics. 2025; 6(2):28. https://doi.org/10.3390/applmech6020028

Chicago/Turabian StyleAugusto, Anselmo S., Girum Urgessa, José A. F. F. Rocco, Fausto B. Mendonça, and Koshun Iha. 2025. "Experimental Study on the Use of Polyurethane Elastomers to Enhance Structural Performance of A36 Steel Sheets Under Near-Field Detonation" Applied Mechanics 6, no. 2: 28. https://doi.org/10.3390/applmech6020028

APA StyleAugusto, A. S., Urgessa, G., Rocco, J. A. F. F., Mendonça, F. B., & Iha, K. (2025). Experimental Study on the Use of Polyurethane Elastomers to Enhance Structural Performance of A36 Steel Sheets Under Near-Field Detonation. Applied Mechanics, 6(2), 28. https://doi.org/10.3390/applmech6020028