Abstract

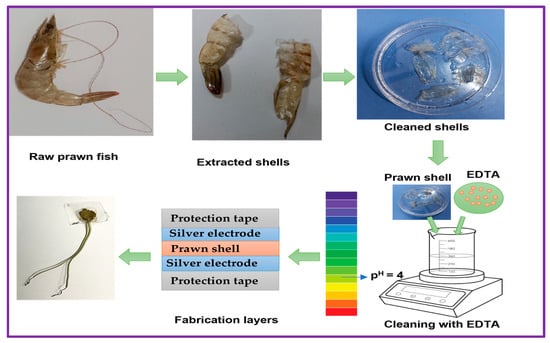

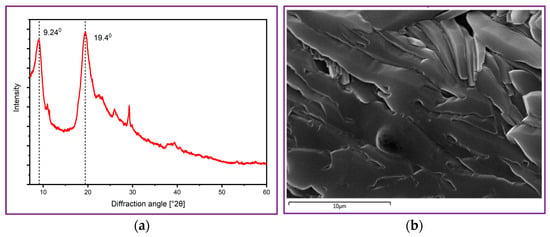

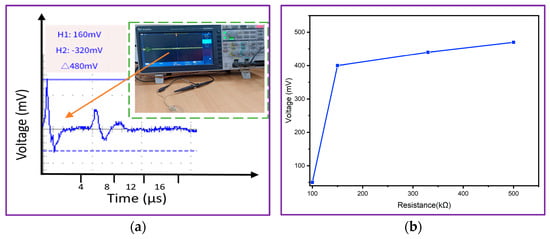

In this work, a biocompatible and fully sustainable, self-poled green energy harvester is designed from the exoskeleton of prawn fish. The prawn shells (PSs) are collected from the biowaste of a local seafood processing plant. Shell surfaces are properly cleaned with DI water to remove any loose debris or contaminants. A strong chelating agent, e Ethylenediaminetetraacetic acid (EDTA), that can effectively bind to metal ions is used to remove the mineral content and metal ions from the shell surface. Any trapped water content on the PSs’ surface is dissipated by keeping the sample at room temperature for 24 h. The PSs contain 20–50% calcium carbonate, 20–40% protein and 15–40% chitin, where the chitin nanofiber acts as an active piezoelectric element. The X-ray diffraction peak obtained at 2θ0 = 9.240 and 19.40 confirms the presence of crystalline intersheet α-chitin and intrasheet β-chitin that possess piezoelectricity. The PS energy harvester with a very small surface area “10 mm × 8 mm” fabricated as silver-prawn shell-silver layer, generates 480 mV output voltage only by finger taping longitudinally on its surface. By optimizing the electrical load, the piezoelectric generator can generate 470 mV output across 500 kΩ and harvest 441.8 nW of output power at applied mechanical stress only by finger taping at 2 Hz.

1. Introduction

Self-powered devices have now become inherently necessary for regular life to avoid the limitations of battery-operated devices. Batteries have a limited lifetime and require recharging periodically, which is difficult where power sources are not available or where devices are placed in difficult-to-access locations. Thus, self-powering devices can overcome the limitations of battery-operated devices and increase real-time application abilities. Nowadays, most researchers focus their attention on clean energy harvesting due to the increasing levels of global pollution [1]. Ambient mechanical energy is an abundant, free and unused energy source that dissipates in terms of force, pressure, and vibration from industrial machines [2]. Research and development for converting mechanical energy into electrical energy has been accelerated by three methods viz. (1) electrostatic, (2) electromagnetic and (3) piezoelectric; the piezoelectric energy conversion method is widely used due to its self-generating ability, high electromechanical coupling factor, lightweight, flexibility, etc., [3,4]. However, the selection of appropriate material for harvesting energy is a crucial task to maintain its flexibility, efficiency, ease of availability and eco-friendliness. Although several organic and inorganic piezoelectric materials have been widely explored and utilized, for instance, PZT, KNN, PVDF, and ZnO, some of them are toxic, non-ecofriendly, non-biocompatible, non-biodegradable and most importantly not easily available. In addition, the synthesis and fabrication of piezoelectric sensors require long and hazardous chemical processes. Moreover, to enhance the piezoelectric property, sometimes high electrical poling is required, which is a tedious and challenging task for the manufacturers [5].

Therefore, exploring alternative materials, especially those that are eco-friendly, nontoxic, biocompatible, and cost-effective, has now become prominent. Materials that are derived from biowaste sources can be sustainable and cost-effective. Biological materials exhibit highly ordered structures but low symmetry with a lack of an inversion center. Thus, the majority of biomolecules possess an inherent piezoelectric property. Guerin et al. surveyed the piezoelectric behavior of different biological sources, such as viruses, egg shells, fish bladder, fiber silk, glycine, collagen, and chitin, and harvested an extensive amount of output voltage [6]. Karan et al. fabricated a bio-inspired piezoelectric energy harvester from the abundant membrane of calcified egg shell. The thin, porous membrane is a rich source of collagenized fibrous that contributes to piezoelectricity for energy generation [7].

In this paper, a piezoelectric energy harvester fabricated from prawn shells is investigated as it avails chitin nanofibers in its surfaces. The crystalline structure is confirmed via P-XRD analysis. The shell surface morphology is studied using FESEM. Finally, the piezoelectric output voltage generated by the harvester is optimized with different electrical loads to achieve maximum output voltage.

2. Materials and Methods

2.1. Sample Preparation and Device Fabrication

The sample collection and harvester fabrication process are described below:

- The shells are collected from the biowaste of a local sea food processing plant;

- The shells are first cleaned with DI water to remove any loose debris or contaminants;

- The shells are cut into pieces and cleaned in an 8 M EDTA solution at room temperature using a magnetic stirrer at 700 rpm and pH 4. EDTA is a strong chelating agent that can effectively bind to metal ions and facilitate their removal from the shell’s surface;

- A small surface area of “10 mm × 8 mm” is used for the energy harvester fabrication;

- A conductive silver paste is used as the top and bottom electrodes and is deposited using the brush painting method. Moreover, two copper lead wire are connected for external electrical interfacing. The energy harvester fabrication process is shown in Figure 1.

2.2. Characterization

The prawn shell film is characterized by using X-ray diffraction to confirm the presence of crystalline structure. The prawn shell contains 20–50% calcium carbonate, 20–40% protein and 15–40% chitin, where the chitin nanofiber acts as an active piezoelectric element [8]. As shown in Figure 2a, the two diffraction peaks at 9.240 and 19.40 confirms the presence of the crystalline element intersheet α-chitin and intrasheet β-chitin which possess inherent piezoelectric properties that are responsible for piezoelectricity of prawn shell [9]. Field Emission Scanning Electron Microscope (FESEM) view of the prawn shell surface is shown in Figure 2b. The shell surface is composed of multiple layers overlapping each other.

3. Results and Discussion

The harvester output is an AC voltage measured using a Digital Storage Oscilloscope (Tektronix TBS 2000 series) after the application of mechanical stress. Mechanical stress is employed with simple finger taping at a frequency of 2 Hz. On each finger taping, 480 mV of open-circuit output voltage is obtained, as shown in Figure 3a. Furthermore, to obtain an optimum output, the harvester output is tested with varying load resistances from a range of 150 kΩ to 500 kΩ, as shown in Figure 3b. The output voltage of 470 mV is obtained across a 500 kΩ load with a harvested power of 441.8 nW at each finger tap.

4. Conclusions

The piezoelectric property of prawn exoskeleton film was studied. The X-ray diffraction peak obtained at 9.240 and 19.40 confirmed the presence of crystalline chitin nanofibers that contributes to the piezoelectric activity. An output voltage of 470 mV was obtained across 500 kΩ and 441.8 nW of output power was harvested. Besides being used as an energy harvester, it can also be used as a sensor for motion monitoring, impact monitoring, etc.

Author Contributions

Conceptualization, H.K.; methodology, experiment and writing—original draft preparation, H.K. and R.K.; writing—review and editing, U.S. and M.P.G.; supervision, U.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The authors would like to thank the Department of Science and Technology (DST), India, as one of the authors is an INSPIRE Fellow. The authors also thank Parasharam M. Shirage, Department of MEMS, Indian Institute of Technology, Indore, India, for their support in sample characterization.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bairagi, S.; Ghosh, S.; Ali, S.W. A fully sustainable, self-poled, bio-waste based piezoelectric nanogenerator: Electricity generation from pomelo fruit membrane. Sci. Rep. 2020, 10, 12121. [Google Scholar] [CrossRef] [PubMed]

- Montazer, B.; Sarma, U. Design and optimization of quadrilateral shaped pvdf cantilever for efficient conversion of energy from ambient vibration. IEEE Sens. J. 2018, 18, 3977–3988. [Google Scholar] [CrossRef]

- Montazer, B.; Sarma, U. Modeling and Analysis the Effect of PZT Area on Square Shaped Substrate for Power Enhancement in MEMS Piezoelectric Energy Harvester. J. Circuits Syst. Comput. 2017, 26, 1750128. [Google Scholar] [CrossRef]

- Khatun, H.; Hazarika, S.; Sarma, U. Aluminium Plate Surface Defect Detection and CLassification based on Piezoelectric Transducers. In Proceedings of the 2021 IEEE 18th India Council International Conference, INDICON 2021, Guwahati, India, 19–21 December 2021. [Google Scholar]

- Ghosh, S.K.; Mandal, D.; Ghosh, S.K.; Mandal, D. High-performance bio-piezoelectric nanogenerator made with fish scale. Appl. Phys. Lett. 2016, 109, 103701. [Google Scholar] [CrossRef]

- Guerin, S.; Tofail, S.A.M.; Thompson, D. Organic piezoelectric materials: Milestones and potential. NPG Asia Mater. 2019, 11, 10. [Google Scholar] [CrossRef]

- Karan, S.K.; Maiti, S.; Paria, S.; Maitra, A.; Si, S.K.; Kim, J.K.; Khatua, B.B. A new insight towards eggshell membrane as high energy conversion efficient bio-piezoelectric energy harvester. Mater. Today Energy 2018, 9, 114–125. [Google Scholar] [CrossRef]

- Kumar, S.; Dipankar Mandal, G. Bio-assembled, piezoelectric prawn shell made self-powered wearable sensor for non-invasive physiological signal monitoring. Appl. Phys. Lett. 2017, 110, 123701. [Google Scholar]

- Marimuthu, R.; Ravichandran, S.; Suresh, A. Piezoelectric Property from Processed Prawn Shells. Chem. Sci. Rev. Lett. 2020, 9, 933–940. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).