Abstract

Recent developments in architectural materials emphasize the importance of antibacterial and thermal insulation functions due to the prevalence of diseases such as COVID-19 and influenza. There is a growing expectation for the implementation of constructed glass that possesses antibacterial properties. Low-emissivity (Low-E) glass, known for its ability to reduce infrared radiation penetration through windows, is a focal point of our ongoing research. In this study, we continued our preliminary investigations into the development of Low-E glass by preparing copper/aluminum-doped zinc oxide (Cu/AZO) films on glass substrates through in-line sputtering. Copper was incorporated to provide antibacterial functionality, while aluminum-doped zinc oxide was chosen for its high visible optical transmission, which is crucial for architectural glass, and its low electrical resistivity indicative of thermal insulation properties. A vacuum annealing process was subsequently applied to the Cu/AZO films on glass. The evaluation of these films involved measuring electrical resistivity that correlates with emissivity, as well as assessing average visible transmission and antibacterial effectiveness according to the JIS Z2801:2000 standard. The results of these tests reveal that the vacuum-annealed Cu/AZO films on glass exhibited commendable antibacterial and thermal insulation properties. Specifically, the antibacterial index (R) was determined to be 8.75; the emissivity, calculated from the measured electrical resistivity, was found to be 0.18; and the average visible transmission was recorded at 52.78%. These findings underscore the potential of Cu/AZO films in advancing the functionality of architectural glass.

1. Introduction

In public spaces, numerous bacteria and viruses are present in facilities and equipment. These pathogens are transmitted through contact and potentially become a source of infection. Recent research has focused on the use of copper metal materials for sterilization purposes [1,2,3,4,5]. The literature demonstrates that copper surfaces exhibit reduced bacterial adhesion, thus confirming the outstanding antibacterial properties of copper and its alloys [2].

Among various building materials, low-emissivity (Low-E) glass is distinguished by its high transmittance in the visible light spectrum and high reflectivity in the infrared band. The utilization of Low-E glass not only facilitates optimal indoor lighting but also ensures effective thermal insulation, therefore making it a staple in the construction of green buildings [6,7,8,9]. Presently, the radiation coefficient of Low-E glass available in the market serves as a crucial metric for consumers when selecting these products. The lower the emissivity of the glass, the greater its capability to insulate against heat.

In everyday environments, such as public facilities, including libraries and medical institutions, as well as in vehicles, such as buses and MRT systems, glass building materials are extensively used. Glass surfaces in public buildings are contacted by numerous individuals. If these glass materials offer both sterilization and thermal insulation properties, the safety, illumination, and comfort of the interior spaces can be significantly enhanced. Similarly, in public transportation, the glass surfaces that passengers frequently touch have antibacterial properties to prevent bacterial transmission. This functionality is beneficial and essential for maintaining public health and safety, highlighting yet another critical application of Low-E glass.

Based on the previous research result regarding the application of copper/aluminum-doped zinc oxide (Cu/AZO) films to energy-saving glass, we employed linear sputtering techniques to deposit Cu/AZO films. Additionally, we introduced a vacuum annealing process aimed at enhancing the material properties of the samples. The vacuum annealing step was effective in improving the electrical properties of the materials. The experimental analysis involved comprehensive measurements of the electrical, optical, and antibacterial properties of the Cu/AZO films post-vacuum annealing. These assessments were critical in determining the efficacy of the vacuum annealing process in optimizing the performance of Cu/AZO films for application in energy-saving glass solutions.

2. Experiment

Cu/AZO thin films were fabricated on borosilicate glass substrates using a linear sputtering system. Initially, the substrates were methodically cleaned through sequential ultrasonic baths in acetone, isopropyl alcohol, and purified water, followed by drying under a stream of nitrogen. The resulting Cu and AZO layers had thicknesses of 10 nm and 500 nm, respectively. The deposition process began with the application of an AZO thin film onto the glass substrate through in-line sputtering. The AZO layer was deposited using an AZO target material (ZnO:Al2O3 = 98.5%:1.5% by weight) at a direct current (DC) power setting of 2500 W, an argon (Ar) flow rate of 250 cm3/min (sccm), and a working pressure of 3 mTorr. Subsequently, a Cu film was deposited on top of the partially deposited AZO film to form the Cu/AZO film. This copper layer was sputtered from a Cu target (99.9% Cu by weight) using a DC power of 1000 W, an Ar flow rate of 250 sccm, and a working pressure of 3 mTorr. We used a vacuum heating system to perform vacuum annealing treatment on the sample. Treatment conditions: annealing time of 1 h and temperature condition of 300 degrees.

The optical transmittance of the Cu/AZO film across the visible spectrum was analyzed using a UV-visible spectrophotometer (Model U-2800A, Hitachi, Tokyo, Japan), specifically within the wavelength range of 400 to 800 nm. The electrical properties, including resistivity, carrier mobility, and carrier concentration, were determined using a Hall measurement system (Model HMS-3000, Ecopia, Gyeonggi-do, Republic of Korea). Additionally, the antibacterial activity of the Cu/AZO film against Escherichia coli ATCC 8739 (E. coli) was assessed following the JIS Z 2801:2010 standard [10] to evaluate its effectiveness in inhibiting bacterial growth on its surface.

3. Results and Discussion

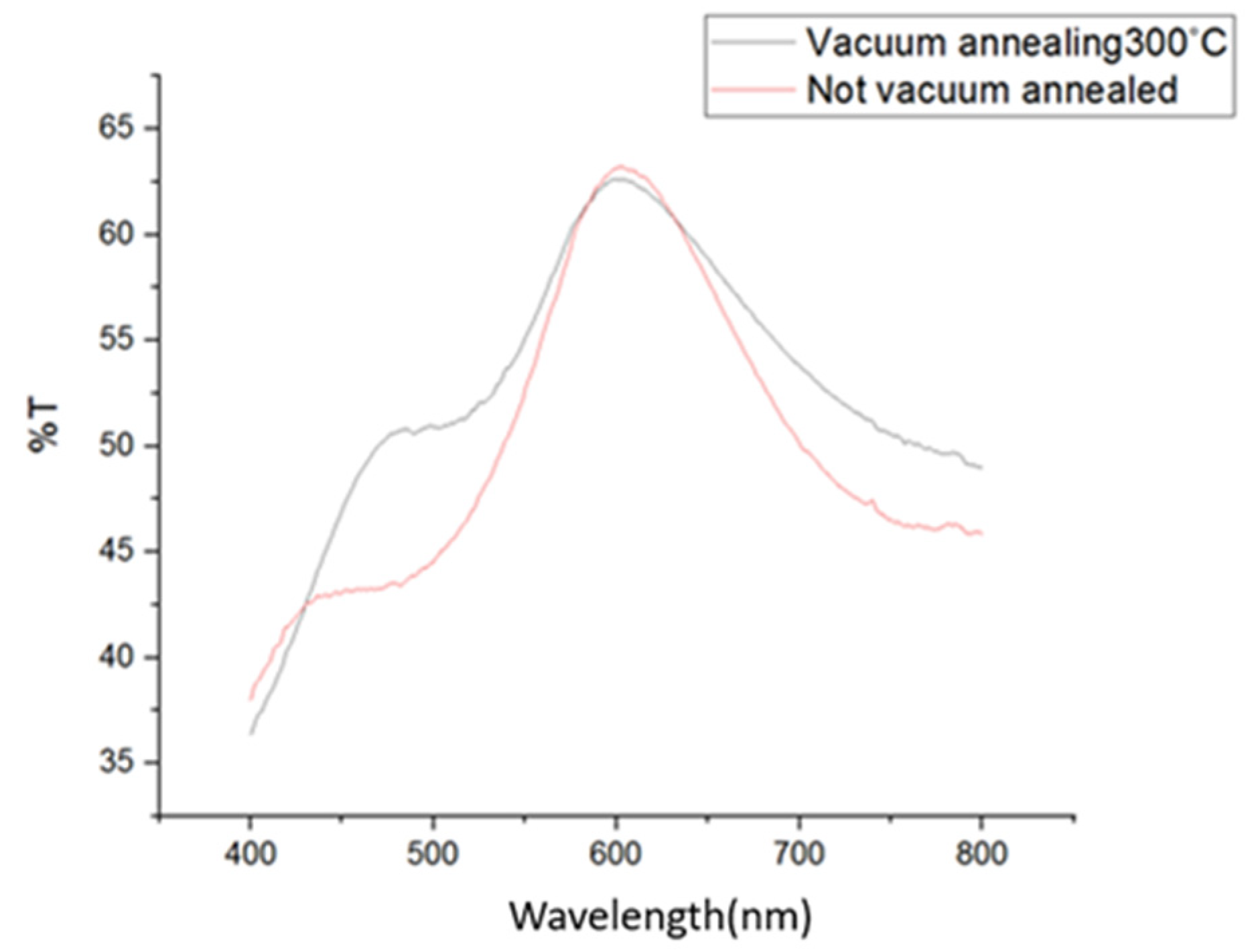

Figure 1 presents the optical transmission spectra of both vacuum-annealed Cu/AZO films and untreated Cu/AZO films. The spectra reveal differences in the visible light transmittance between the two types of films. The data showed that vacuum annealing positively affected the optical properties, as demonstrated by the higher average transmittance recorded for the annealed films. Specifically, the average transmittance of the Cu/AZO films processed by vacuum annealing at 300 degrees Celsius was 52.78%, compared to 50.11% for the untreated films. This improvement in visible light transmittance post-annealing is demonstrated in Figure 1.

Figure 1.

Visible light cross-transmittance of vacuum-annealed 300-degree Cu/AZO samples and unannealed Cu/AZO samples.

Table 1 details the electrical and optical properties of both the Cu/AZO and untreated Cu/AZO films produced by the vacuum annealing process, providing a comprehensive comparison of their performance characteristics. This information is crucial for understanding the impact of the annealing process on the functionality of the films in various applications.

Table 1.

Structural, electrical, antibacterial, and optical properties of vacuum-annealed Cu/AZO samples at 300 °C and untreated Cu/AZO samples.

Table 1 indicates significant differences in the resistivity and emissivity values between the Cu/AZO films before and after vacuum annealing at 300 degrees Celsius. Specifically, the resistivity of the untreated Cu/AZO films was recorded at 1.314 × 10−3 Ω-cm, whereas the vacuum-annealed Cu/AZO films exhibit a higher resistivity of 9.033 × 10−3 Ω-cm. Additionally, the emissivity of the Cu/AZO films decreases from 0.29 in the untreated state to 0.18 after undergoing vacuum annealing.

The reduction in emissivity observed in the annealed films suggests that vacuum annealing enhances the thermal insulation properties of the Cu/AZO films. This enhancement is likely due to modifications in the film’s microstructure and surface characteristics induced by the annealing process, which in turn affect its ability to emit infrared radiation, therefore improving its thermal insulation performance. Such findings underscore the potential benefits of vacuum annealing in optimizing the functional properties of Cu/AZO films for applications requiring efficient thermal management.

Table 1 also displays the antibacterial activity values of Cu/AZO films both before and after undergoing vacuum annealing at 300 °C. The antibacterial activity value of the unannealed Cu/AZO films was 8.66, while the value for the Cu/AZO films vacuum-annealed was 8.75. These values are significantly above the threshold of ≥2.0 as stipulated by the JIS Z 2801:2010 standard, confirming that both sets of films exhibit effective antibacterial properties. The enhanced antibacterial activity in the vacuum-annealed films is attributed to the contact-killing mechanism, a well-documented antimicrobial effect of copper [11,12]. This mechanism involves the release of copper ions that interact with bacterial cells, leading to the disruption of cell membranes, the generation of reactive oxygen species, and, ultimately, the damage to cellular DNA. The slight increase in antibacterial activity following vacuum annealing is caused by changes in the surface structure or the increased availability of copper ions at the surface, which enhances the contact interaction between the copper and microbial cells. These results underscore the dual functionality of Cu/AZO films, offering both improved thermal insulation and effective antimicrobial properties, making them highly suitable for applications in environments where hygiene and temperature control are critical.

4. Conclusions

In this article, for the Cu/AZO samples after the vacuum annealing process, the electrical properties and antibacterial properties were enhanced compared with untreated Cu/AZO. The Cu/AZO sample produced by the vacuum annealing process has low emissivity and high antibacterial properties.

Author Contributions

Conceptualization, investigation, funding acquisition, project administration and methodology, Shang-Chou Chang; validation, formal analysis, writing—review and editing, Shang-Chou Chang and Jian-Syun Wu; resources, Jian-Syun Wu. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science and Technology Commission of Taiwan for financial support under contract no. NSTC 112-2637-E-168-002.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

This work was partially supported by the Green Energy Technology Research Center of Kunshan University.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hans, M.; Mathews, S.; Mücklich, F.; Solioz, M. Physicochemical properties of copper important for its antibacterial activity and development of a unified model. Biointerphases 2016, 11, 018902. [Google Scholar] [CrossRef] [PubMed]

- Casey, A.L.; Karpanen, T.J.; Adams, D.; Lambert, P.A.; Nightingale, P.; Miruszenko, L.; Elliott, T.S. A comparative study to evaluate surface microbial contamination associated with copper-containing and stainless steel pens used by nurses in the critical care unit. Am. J. Infect. Control 2011, 39, e52–e54. [Google Scholar] [CrossRef] [PubMed]

- Rtimi, S.; Dionysiou, D.D.; Pillai, S.C.; Kiwi, J. Advances in catalytic/photocatalytic bacterial inactivation by nano Ag and Cu coated surfaces and medical devices. Appl. Catal. B Environ. 2019, 240, 291–318. [Google Scholar] [CrossRef]

- Ondok, V.; Musil, J.; Meissner, M.; Čerstvý, R.; Fajfrlík, K. Two-functional DC sputtered Cu-containing TiO2 thin films. J. Photochem. Photobiol. A Chem. 2010, 209, 158–162. [Google Scholar] [CrossRef]

- Prado, J.V.; Esparza, M.M.; Vidal, A.R. Adherence to copper and stainless steel metal coupons of common nosocomial bacterial strains. Rev. Med. Chile 2013, 141, 291–297. [Google Scholar]

- Horiuchi, T.; Yoshimura, K. Solar heat gain coefficient and heat transmission coefficient of Al-doped ZnO thin-film coated low-emissivity glass. J. Ceram. Soc. Jpn. 2020, 128, 220–223. [Google Scholar] [CrossRef]

- Lee, S.Y. Low Emissivity Property of Amorphous Oxide Multilayer (SIZO/Ag/SIZO) Structure. Trans. Electr. Electron. Mater. 2017, 18, 13–15. [Google Scholar] [CrossRef][Green Version]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef]

- Hagen, E.; Rubens, H. Über Beziehungen des Reflexions- und Emissionsvermögens der Metalle zu ihrem elektrischen Leitvermögen. Ann. Phys. 1903, 4, 873–901. [Google Scholar] [CrossRef]

- JIS Z 2801:2010; Antimicrobial Products—Test for Antimicrobial Activity and Efficacy. Japanese Standards Association: Tokyo, Japan, 2010.

- Grass, G.; Rensing, C.; Solioz, M. Metallic copper as an antimicrobial surface. Appl. Environ. Microbiol. 2011, 77, 1541–1547. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Mettlach, N.; Nguyen, N.; Sun, Y.M.; White, J.M. Copper oxide reduction through vacuum annealing. Appl. Surf. Sci. 2003, 206, 102–109. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).