Abstract

As ore quality declines in KGHM mines after continuous exploitation, it becomes increasingly relevant to extract as much economic value as possible from the mined ore while limiting the environmental impact. The recovery of cobalt from converter slag is a possible extraction route that can increase economic output at a limited environmental and logistic cost. Life cycle assessment (LCA) is used to assess the environmental impact of copper exploitation and to compare that impact with the estimated impact of cobalt extraction in the Lubin mine. In most impact categories, Co extraction would be responsible for less than 0.2% of the impact, while increasing economic output by 3.38%. Economic allocation shows that cobalt recovery is environmentally pertinent.

1. Introduction

As the production of high-tech devices such as electric cars, smartphones, and laptops increases, the demand for cobalt will follow suit. Additionally, cobalt is part of the list of critical raw materials published by the European Commission [1]. Because these materials are economically important and are at high supply risk, being able to produce them inside the confines of the EU is of political and economic importance.

The KGHM Polska Miedź S.A. Group is an international organization, specializing in exploration, mining, and metallurgy. It has its activities in Europe, South America, North America, and Asia [2]. The main assets are localized in Poland, where there are operating three underground mines (Lubin, Polkowice-Sieroszowice and Rudna), three metallurgical plants (Legnica Copper Smelter and Refinery, Głogów I Smelter, and Głogów II Smelter), and Wire Rod Plant (Cedynia). The other activities are located in the USA (Robinson mine, Carlota), Chile (Sierra Gorda Mine, Franke), and Canada (Ajax, Sudbury, Victoria) [2].

Polish copper mines produce annually 449.4 kt of copper from extracted ore (data for 2019). KGHM also recovers associated minerals. The production in 2019 was 1400 t of silver, 674 kg of gold, 28,510 t of lead, 1993 t of nickel sulfate, 75.76 t of selenium, and 8.34 t of rhenium. Polkowice-Sieroszowice mine is also a significant producer of rock salt (68.28 kt) [3]. Smelters in Głogów and Legnica produced 565.6 kt of electrolytic copper in 2019 (418.3 kt from KGHM’s concentrates and 147.3 kt from externally purchased concentrates) [2]. Cedynia Wire Rod Plant produced 250.7 kt of copper wire rod and 15.5 kt of oxygen-free copper rod [2,4].

KGHM’s economic resources equal 1,181 Mt of ore, which contains 23,173 kt of copper, and 70 kt of silver [3]. KGHM was recognized as a potential cobalt supplier in this part of Europe [5]. Cobalt occurs as an accompanying metal in the KGHM deposits, with prospective resources equal to 93.48 kt. The largest prospective resources of Co (41.94 kt) are observed for the Lubin-Małomice deposit operated by Lubin mine [3].

It should be noted the exploitation of copper in the Lubin mine of KGHM in Poland is becoming less profitable over the years because of the depletion of the ore, from 1.09% Cu content in 2007 to 0.92% currently [6]. Poorer ore has negative economic and environmental consequences, as more ore needs to be processed for the same amount of refined product, increasing the power requirement as ore quality lowers [7]. For this reason, it becomes imperative to try to maximize the economic output of a mine while limiting environmental impacts. For example, mines managed by KGHM produce silver as a by-product of copper exploitation, increasing economic output at a relatively low environmental cost. By the same logic, cobalt could be extracted from converter slags from the Legnica smelter.

2. Materials and Methods

Life cycle assessment was used to assess the environmental impacts of copper exploitation in the Lubin mine. Modeling was carried out in Simapro v9.1.1.1. The ReCiPe method (2016) was used in a hierarchic configuration to assess impact. Emission data came from the Ecoinvent 3 data set. The functional unit was the production of 1 t of refined (99.9%) copper.

The life cycle inventory is shown in Table S1 (cf. Supplementary Material). Inventory data were collected via several methods:

- KGHM reports;

- Extrapolation of data from peer-reviewed literature on the Lubin operation;

- Estimations.

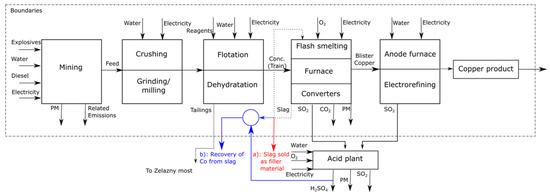

The mine operation flowsheet is in Figure 1. The LCA was considered cradle-to-gate: the extraction and use of raw materials was considered; however, the use and end-of-life phases of the refined copper product were not taken into account. Some emissions and aspects of the mining process were not taken into account in the assessment either because of a lack of data or being outside the scope of the research:

Figure 1.

Schematic flowsheet of the copper refining process with LCA boundaries.

- Recovery of the SO2 emissions for sulfuric acid production;

- Slag sold as a building material;

- Tailings sent to the Żelazny Most containment facility;

- Production of secondary products (lead, selenium, nickel sulfate, rhenium, gold).

Two scenarios are considered: the current operation of the Lubin mine, in which slag is sold as filler materials, and a potential scenario where the converter slag goes through a sulfuric acid roasting process with leaching for cobalt recovery [8].

3. Results

3.1. Comparison of Lubin and the Average Ore Grade of KGHM Mines

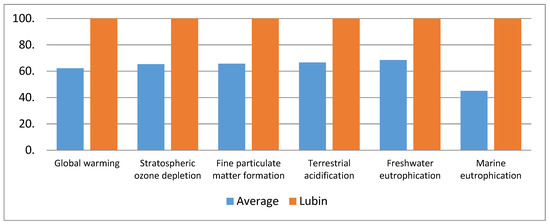

To show the importance of ore grade in terms of environmental impacts, the impact of the exploitation of the Lubin mine (0.92% Cu) was compared to the average ore grade in KGHM mines (1.40% Cu). The impact categories were considered following previously published methodologies [9]: global warming potential, terrestrial acidification, eutrophication, stratospheric ozone depletion, and particulate matter formation. The results are given in Figure 2.

Figure 2.

Comparison of the environmental impacts of the exploitation of copper in the Lubin mine compared to the average impact of KGHM mines.

As expected for the ore grade difference, the Lubin installations must extract around 50% more ore to obtain the same amount of copper, leading to more important impacts, as seen in Figure 2.

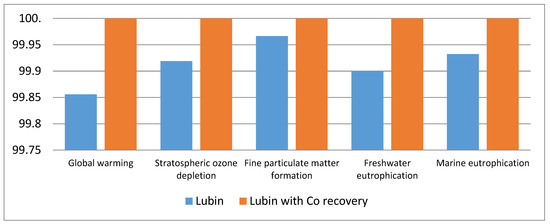

3.2. Impact of Cobalt Recovery

The impact of the Lubin exploitation with cobalt recovery, whose inventory estimation is given in Table S1, is compared with the traditional exploitation of the mine in Figure 3. As evidenced by the scale of the ordinates axis, the differences are almost negligible.

Figure 3.

Comparison of Lubin exploitation with and without cobalt recovery from converter slag.

3.3. Economic Output

Measurements from KGHM of the ore composition and the recovery rate of each element (Cu, Ag, and Co) are given in Table 1.

Table 1.

Amount of copper, silver, and cobalt recovered from the exploitation of the Lubin mine. Values are given from the London Metal Exchange prices at the date of writing (12 March 2021).

The added value of cobalt in the basic economic estimation corresponds to an increase of 3.38% in the initial value of the copper and silver produced by the Lubin mine.

4. Conclusions

From this preliminary study, it appears that the impact of cobalt exploitation from converter slag has a very low environmental impact compared to the value the cobalt adds. It is therefore environmentally pertinent. However, this study should be expanded with more robust data from KGHM, especially for the impact of slag recovery, to decidedly state the environmental pertinence. In further studies, the economic rentability of the cobalt recovery process in KGHM will be assessed to make a thorough case for the implementation of the process.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/environsciproc2021009033/s1, Table S1: Life cycle inventory of copper exploitation.

Author Contributions

A.M. and W.K. conceived and designed the experiments; A.M. performed the experiments; A.M., W.K., G.L. and H.W. analyzed the data; A.M. and W.K contributed reagents/materials/analysis tools; A.M., W.K., G.L. and H.W. wrote the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted in the context of the PULSATEC project and funded by the European Regional Development Fund (ERDF)—grant number 045-4-08-105) as well as the Walloon Region.

Conflicts of Interest

The authors declare no conflict of interest. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- European Commission. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020DC0474 (accessed on 15 April 2021).

- KGHM. Integrated Report 2019. Available online: https://kghm.com/en/investors/results-center/integrated-reports (accessed on 15 April 2021).

- Szuflicki, M.; Malon, A.; Tymińskiego, M. Bilans zasobów złóż kopalin w Polsce wg stanu na 31 XII 2019 r; PAŃSTWOWY INSTYTUT GEOLOGICZNY: Warszawa, Poland, 2020. [Google Scholar]

- KGHM Official Website. Available online: https://kghm.com/ (accessed on 15 April 2021).

- Pązik, P.M.; Chmielewski, T.; Glass, H.J.; Kowalczuk, P.B. World production and possible recovery of cobalt from the Kupferschiefer stratiform copper ore. In Proceedings of the Mineral Engineering Conference (MEC2016), Swieradow-Zdroj, Poland, 25–28 September 2016. [Google Scholar]

- Micon International Ltd. Technical Report on the Copper-Silver Production Operations of KGHM Polska Miedź S.A. In The Legnica-Glogów Copper Belt Area of Southwestern Poland; Report No. 5/2013; The Management Board of KGHM Polska Miedź S.A.: Toronto, ON, Canada, February 2013. [Google Scholar]

- Norgate, T.; Haque, N. Energy and greenhouse gas impacts of mining and mineral processing op.erations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Sukla, L.B.; Panda, S.C.; Jena, P.K. Recovery of cobalt, nickel and copper from converter slag through roasting with ammonium sulphate and sulphuric acid. Hydrometallurgy 1986, 16, 153–165. [Google Scholar] [CrossRef]

- Santero, N.; Hendry, J. Harmonization of LCA methodologies for the metal and mining industry. Int. J. Life Cycle Assess 2016, 21, 1543–1553. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).