Predicting the Compression Capacity of Screw Piles in Sand Using Machine Learning Trained on Finite Element Analysis

Abstract

1. Introduction

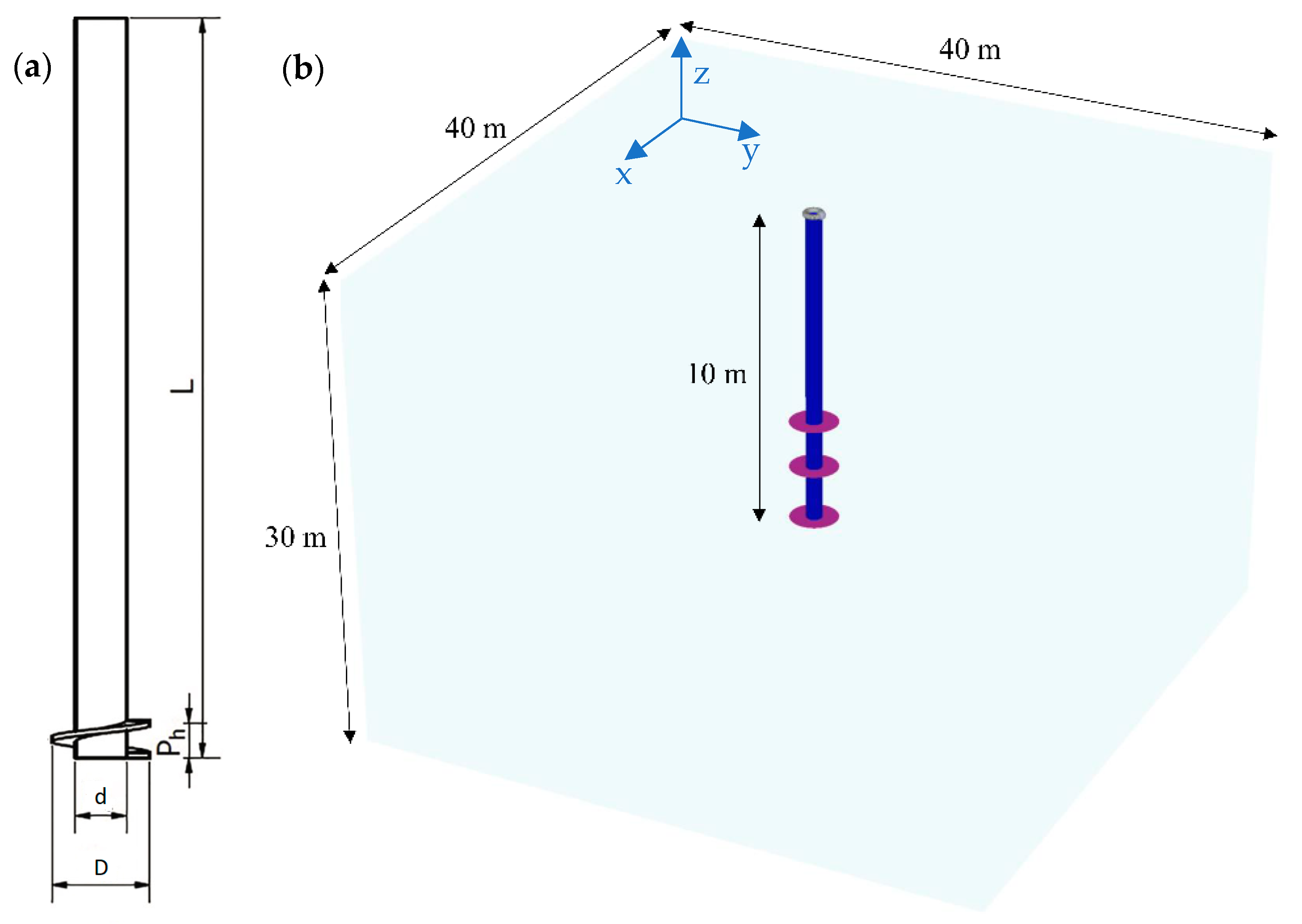

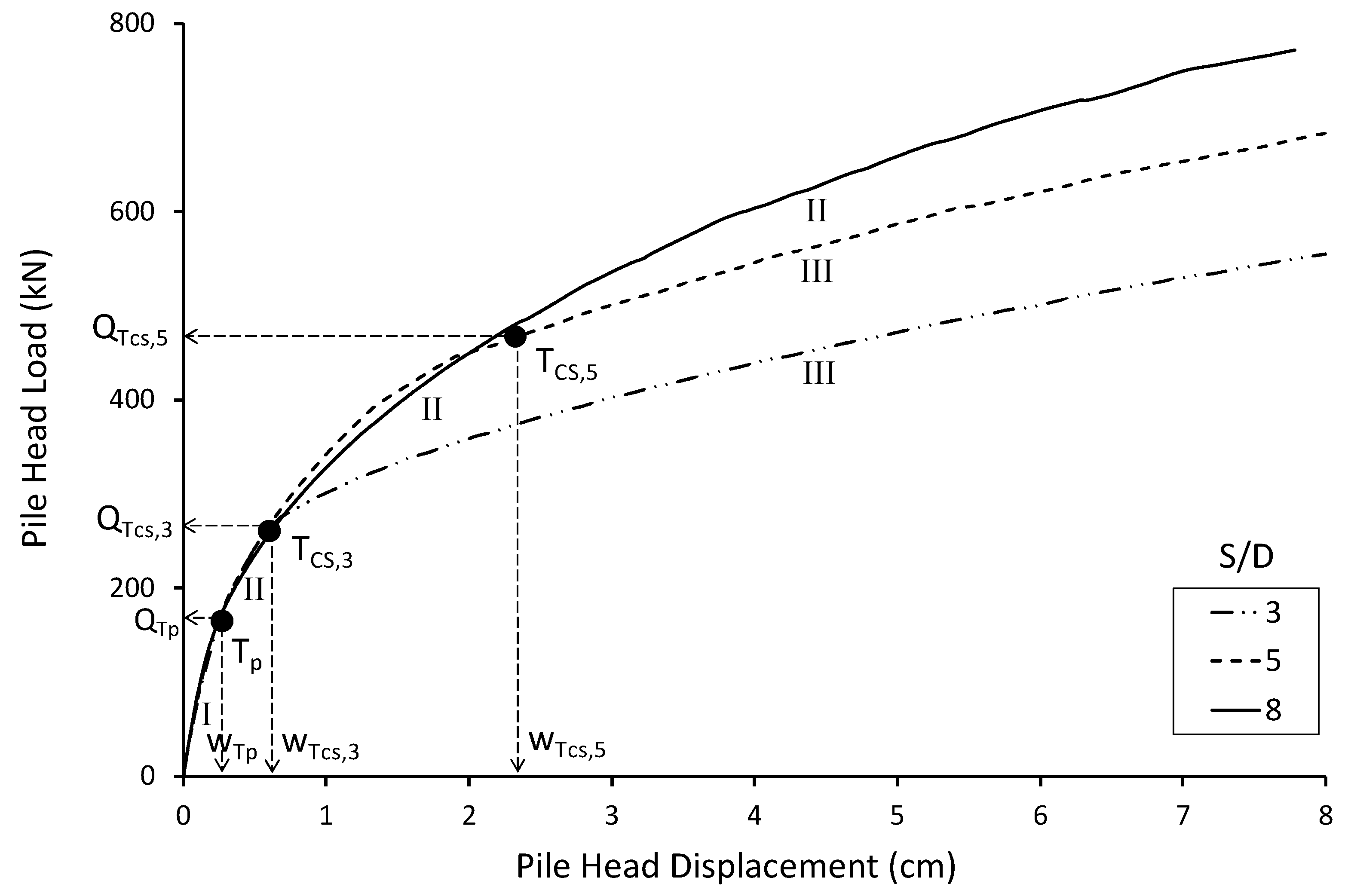

2. 3D FE Modelling

2.1. Methodology

2.2. Validation

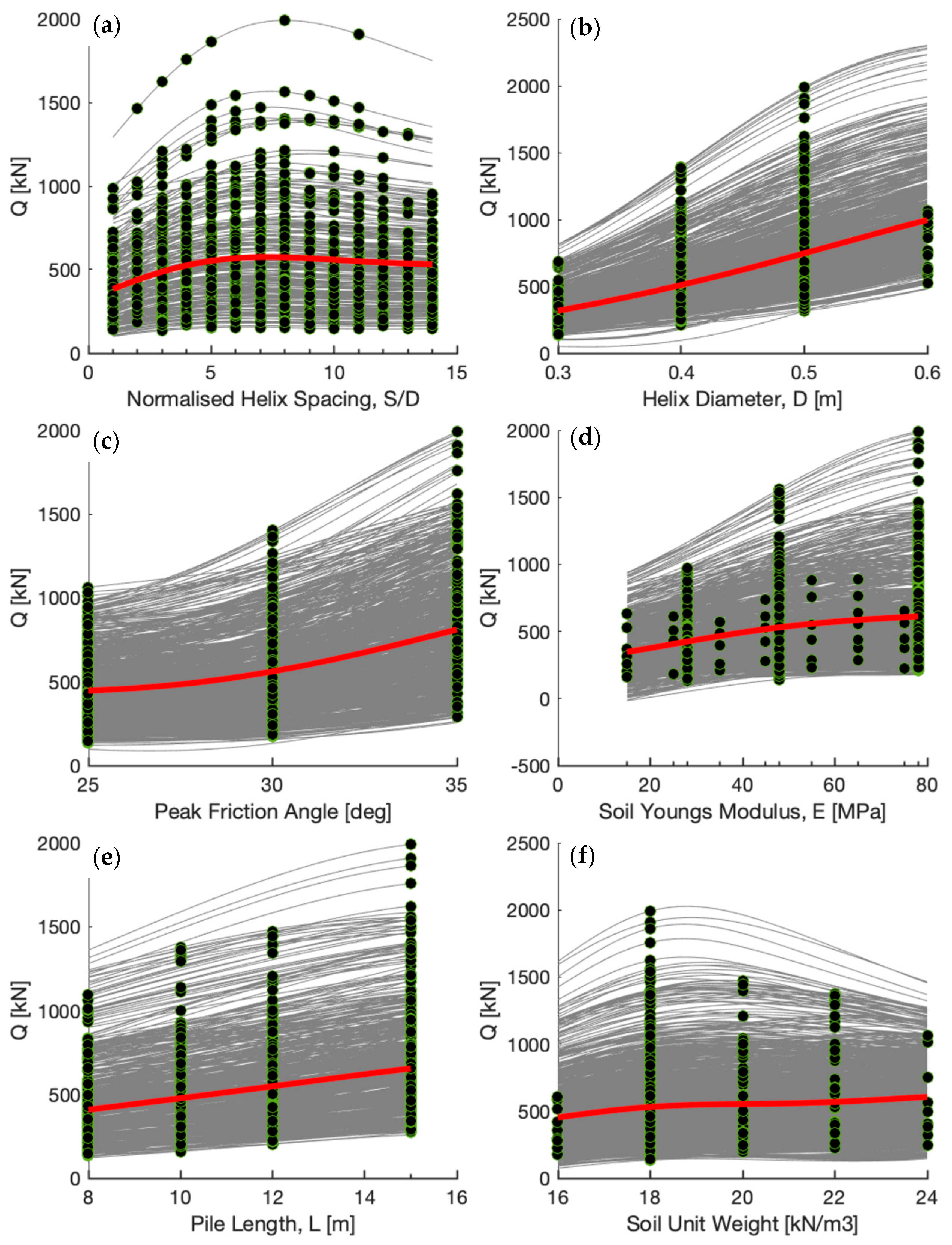

2.3. Developing 3DFE Dataset

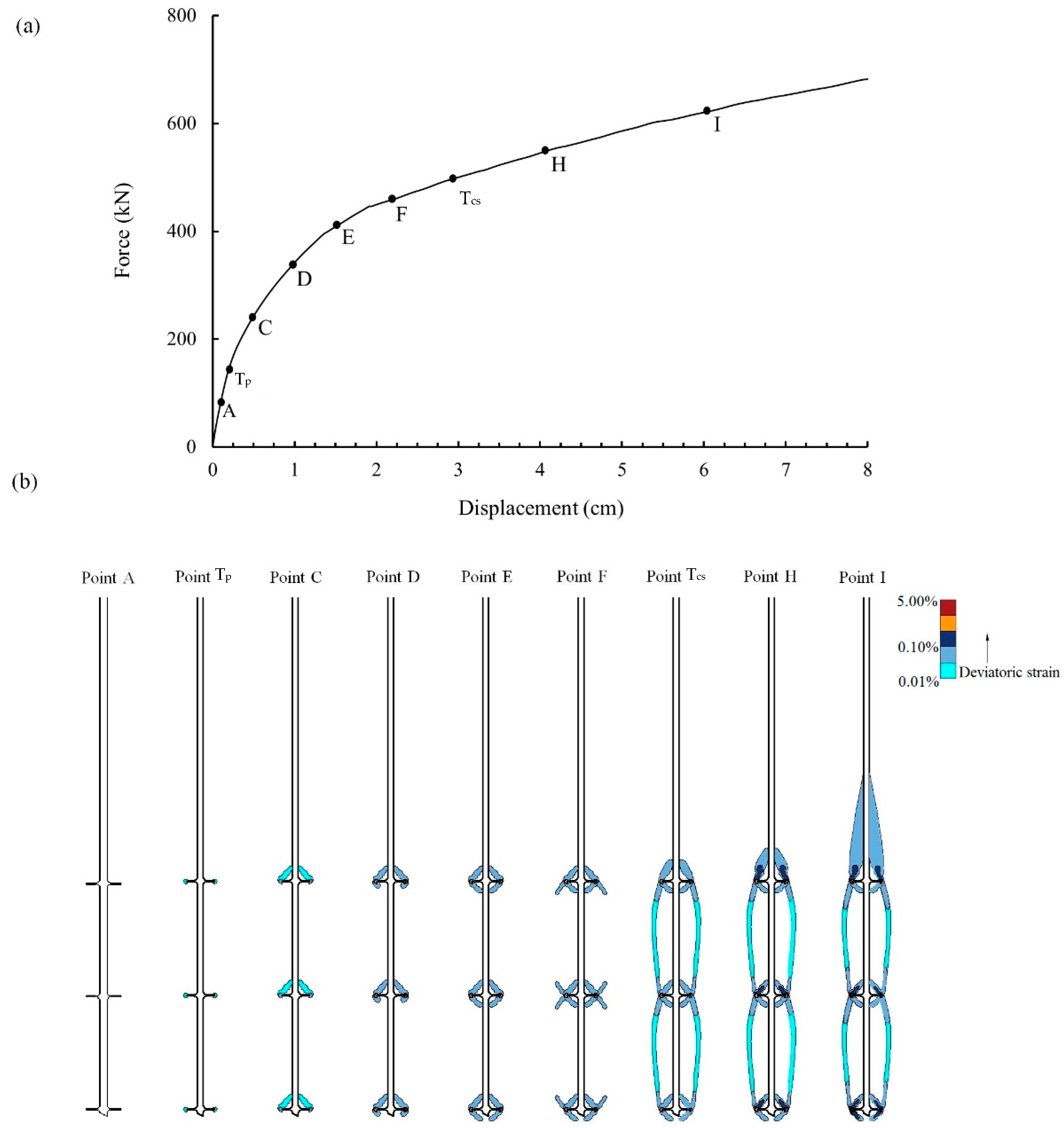

3. FE Modelling Results

4. Application of Machine Learning Methods to Predict Compression Capacity

4.1. Training and Testing Datasets

4.2. Machine Learning Models

- Linear regression models: Simple and multiple linear regression, enabling the modelling of relationships between predictors and a continuous response variable.

- Support vector machines (SVM) with various kernel functions (linear, quadratic, cubic, and Gaussian).

- Decision trees and ensembles: Including regression trees, bagged trees, boosted trees, and random forests.

- Gaussian process regression (GPR): With different kernel functions (squared exponential, Matern, rational quadratic, etc.).

- Neural networks: Bilayer and trilayer basic feedforward neural networks which can model complex, non-linear relationships through hidden layers.

5. Results and Discussion

- The linear elastic perfectly plastic constitutive soil model was used for the 3DFE analysis. This model is the most widely used constitutive model for soil behavior, but it has limitations compared to more advanced models. Its advantages include its straightforward formulation, making it easy to understand simple input parameters which are intuitive and easy to obtain from common soil tests, and it is computationally efficient compared to more complex models. However, it should be noted that significant drawbacks include its inability to accurately capture the soil strength as described by critical state soil mechanics, its inability to capture nonlinear stress–strain behavior, and its inability to account for the evolution of soil fabric anisotropy under loading. Future work will focus on the use of more advanced soil models, such as the SANISAND family of models, to provide more accurate predictions of the soil response. It should also be noted that the 3DFE analysis used in this paper did not include installation effects, which have been shown to have a significant influence on the response of screw piles, particularly regarding the pullout resistance [2,26].

- The database 3DFE model was initially developed in an adhoc manner and therefore not optimized to provide the best ML training outcomes with the minimum number of models. Potential biases exist within the dataset where sample points may be clustered around certain input features. Better planning at an early stage and using approaches such as Latin hypercube, Sobol sampling, or active learning approaches may require fewer FE models to achieve similar ML model accuracy. Future work will explore the use of different sampling strategies to optimize the production of training data and the training of the ML models.

- All the 3DFE models analyzed in this paper assumed dry homogenous sand. Future work will explore the effect of water table depth and layered soils on the compression capacity [27].

- Future work will also focus on using physics informed machine learning approaches and incorporating multi-modal data, for example low-fidelity theoretical models along with high-fidelity 3DFE models and experimental field test data, similar to the approach suggested in Surysentana et al. [28].

6. Conclusions

- Out of the 27 different machine learning models tested, Gaussian process regression models offered the best performance when ranked based on MAE on the test dataset. The ML models offered an almost 10-fold improvement in RMSE when compared with traditional theoretical methods.

- The best performing model ranked based on MAE (test) and RMSE (test) was the rational quadratic Gaussian process regression (RQGPR). This model was explored further. Training the model using subsets of the full training database indicated very good predictions could be obtained using only 200 randomly selected training samples (3DFE models), and only marginal improvements were seen once the number of training samples increased beyond 600. Similar accuracy could potentially be achieved with less training data through improved parameter space sampling methods such as Latin hypercube sampling or the Sobol methods.

- Further insights into the factors affecting the screw pile capacity were obtained through conditional expectation plots which indicate an inter-helix spacing of ~6 helix diameters may be optimum.

- Traditional theoretical methods used for screw pile design suffer from an inability to fully capture the complex soil-structure interaction which occurs in multi-helix screw piles. This paper shows the potential for ML models as a design tool which can have significantly higher accuracy than traditional design approaches. Future work will focus on training ML models on multi-modal data including field test results.

- The database developed in this paper and used for training and trained ML models has been made available open access on Github (https://github.com/igoed1/Screw-pile-3DFE-and-ML-models.git).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Perko, H.A. Helical Piles: A Practical Guide to Design and Installation; John Wiley & Sons, Inc.: Denver, CO, USA, 2009. [Google Scholar] [CrossRef]

- Sharif, Y.U.; Brown, M.J.; Cerfontaine, B.; Davidson, C.; Ciantia, M.; Knappett, J.; Brennan, A.; Ball, J.D.; Augarde, C.; Coombs, W.; et al. Effects of screw pile installation on installation requirements and in-service performance using the Discrete Element Method. Can. Geotech. J. 2021, 58, 1334–1350. [Google Scholar] [CrossRef]

- Lutenegger, A.J. Screw piles and helical anchors—What we know and what we don’t know: An academic perspective. In Proceedings of the International Symposium on Screw Piles for Energy Applications, West Park Dundee, UK, 27–28 May 2019. [Google Scholar]

- Livneh, B.; El Naggar, M.H. Axial testing and numerical modeling of square shaft helical piles under compressive and tensile loading. Can. Geotech. J. 2008, 45, 1142–1155. [Google Scholar]

- Alwalan, M.F.; El Naggar, M.H. Load-transfer mechanism of helical piles under compressive and impact loading. Int. J. Geomech. 2021, 21, 04021082. [Google Scholar]

- Zhang, D. Predicting Capacity of Helical Screw Piles in Alberta Soils. MSc. Thesis, University of Alberta, Edmonton, AB, Canada, 1999. [Google Scholar]

- Donal, J.; Calyton, P.E. Basic Helical Screw Pile Design. ECP Torque Anchor Brand of Helical Screw Piles; Earth Contact Products: Olathe, Kansas, 2005; pp. 1–28. [Google Scholar]

- Livro. Helical Pile Engineering Handbook, 7th ed.; Helical Pier Systems: Nisku, AB, Canada, 2010; pp. 20–28. Available online: www.helicalpiersystems.com (accessed on 9 July 2024).

- Salhi, L.; Nait-Rabah, O.; Deyrat, C.; Roos, C. Numerical modeling of single helical pile behavior under compressive loading in sand. Electron. J. Geotech. Eng. 2013, 18, 4319–4338. [Google Scholar]

- Knappet, J.A.; Brown, M.J.; Brennan, A.J.; Hamilton, L. Optimising the compressive behaviour of screw piles in sand for marine renewable energy applications. In Proceedings of the DFI/EFFC 11th International Conference on Piling and Deep Foundations, Stockholm Fair, Stockholm, Sweden, 21–23 May 2014. [Google Scholar]

- Elsherbiny, Z.H.; El Naggar, M.H. Axial compressive capacity of helical piles from field tests and numerical study. Can. Geotech. J. 2013, 50, 1191–1203. [Google Scholar]

- Samui, P. Prediction of friction capacity of driven piles in clay using the support vector machine. Can. Geotech. J. 2008, 45, 288–295. [Google Scholar]

- Liu, Y.; Liang, S.; Wu, J.; Fu, N. Prediction method of vertical ultimate bearing capacity of single pile based on support vector machine. Adv. Mater. Res. 2011, 168–170, 2278–2282. [Google Scholar]

- Zhang, M.; Liang, L.; Song, H.; Li, Y.; Peng, W. Intelligent prediction for side friction of large-diameter and super-long steel pipe pile based on support vector machine. Appl. Mech. Mater. 2012, 170–173, 747–750. [Google Scholar]

- Kordjazi, A.; Pooya Nejad, F.; Jaksa, M.B. Prediction of ultimate axial load-carrying capacity of piles using a support vector machine based on CPT data. Comput. Geotech. 2014, 55, 91–102. [Google Scholar] [CrossRef]

- Kardani, N.; Zhou, A.; Nazem, M.; Shen, S.L. Estimation of Bearing Capacity of Piles in Cohesionless Soil Using Optimised Machine Learning Approaches. Geotech. Geol. Eng. 2020, 38, 2271–2291. [Google Scholar] [CrossRef]

- Wang, B.; Moayedi, H.; Nguyen, H.; Foong, L.K.; Rashid, A.S.A. Feasibility of a novel predictive technique based on artificial neural network optimized with particle swarm optimization estimating pullout bearing capacity of helical piles. Eng. Comput. 2020, 36, 1315–1324. [Google Scholar]

- Wang, L.; Wu, M.; Chen, H.; Hao, D.; Tian, Y.; Qi, C. Efficient Machine Learning Models for the Uplift Behavior of Helical Anchors in Dense Sand for Wind Energy Harvesting. Appl. Sci. 2022, 12, 10397. [Google Scholar] [CrossRef]

- Peres, M.S.; Schiavon, J.A.; Ribeiro, D.B. A Machine Learning-Based Approach for Predicting Installation Torque of Helical Piles from SPT Data. Buildings 2024, 14, 1326. [Google Scholar] [CrossRef]

- Brinkgrevee, R.B.J.; Broere, W.; Waterman, D. Plaxis V8, Reference Manual; Delft University of Technology and PLAXIS: Delft, The Netherlands, 2002. [Google Scholar]

- Sakr, M. Installation and performance characteristics of high capacity helical piles in cohesionless soils. DFI J. 2011, 5, 39–57. [Google Scholar]

- Mitsch, M.P.; Clemence, S.P. The uplift capacity of helix anchors in sand. In Proceedings of the Uplift Behavior of Anchor Foundations in Soil: A Session Sponsored by the Geotech; American Society of Civil Engineers: Reston, VA, USA, 1985. [Google Scholar]

- Mohajerani, A.; Bosnjak, D.; Bromwich, D. Analysis and design methods of screw piles: A review. Soils Found. 2016, 56, 115–128. [Google Scholar]

- Matlab. Available online: https://uk.mathworks.com/help/stats/regression-learner-app (accessed on 25 June 2024).

- Sheil, B.B.; Suryasentana, S.K.; Mooney, M.A.; Zhu, H. Machine learning to inform tunnelling operations: Recent advances and future trends. Proc. ICE–Smart Infrastruct. Constr. 2020, 173, 74–95. [Google Scholar] [CrossRef]

- Cerfontaine, B.; White, D.; Kwa, K.; Gourvenec, S.; Knappett, J.; Brown, M. Anchor geotechnics for floating offshore wind: Current technologies and future innovations. Ocean Eng. 2023, 279, 114327. [Google Scholar] [CrossRef]

- Yan, G.; Li, Z.; Galindo Torres, S.A.; Scheuermann, A.; Li, L. Transient Two-Phase Flow in Porous Media: A Literature Review and Engineering Application in Geotechnics. Geotechnics 2022, 2, 32–90. [Google Scholar] [CrossRef]

- Suryentana, S.; Sheil, B.; Stuyts, B. Practical Approach for Data-Efficient Metamodeling and Real-Time Modeling of Monopiles Using Physics-Informed Multifidelity Data Fusion. J. Geotech. Geoenviron. Eng. 2024, 150, 06024005. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Poisson ratio, υ | 0.33 |

| Pile unit weight, γ (kN/m3) | 78 |

| Modulus of elasticity of pile, Ep (GPa) | 210 |

| Parameters | Values |

|---|---|

| Internal friction angle, ϕ (deg) | 35 |

| Dilation angle, (deg) | 0 |

| Cohesion, c (kPa) | 0.1 |

| Poisson ratio, υ | 0.3 |

| Unit weight, γ (kPa) | 18 |

| Modulus of elasticity, E (MPa) | 50 |

| Parameters | Values |

|---|---|

| Internal friction angle, ϕ (deg) | 25 |

| Dilation angle, (deg) | 0 |

| Cohesion, c (kPa) | 0.1 |

| Poisson ratio, υ | 0.3 |

| Unit weight, γ (kPa) | 20 |

| Modulus of elasticity, E (MPa) | 50 |

| Layers | Depth to (m) | γ′ (kN/m3) | c (kPa) | ϕ (deg) | E (MPa) |

|---|---|---|---|---|---|

| Stiff brown sandy clayey silt | 2.4 | 17.3 | 10 | 28 | 100 |

| Very stiff brown clayey silt | 4.1 | 17.5 | 21 | 27 | 85 |

| Stiff grey clayey silt | 5.8 | 16.5 | 9 | 23 | 100 |

| Very stiff grey sandy clayey silt | 7.3 | 15 | 20 | 30 | 400 |

| Dense grey silt | >7.3 | 17 | 19 | 34 | 65 |

| Soil Input Parameters | Values |

|---|---|

| Internal friction angle, ϕ (deg) | 30 |

| Dilation angle, (deg) | 0 |

| Cohesion, c (kPa) | 0 |

| Poisson ratio, υ | 0.33 |

| Unit weight, γ (kPa) | 18 |

| Modulus of elasticity, E (MPa) | 48 |

| Feature Number | Feature | Value |

|---|---|---|

| 1 | Unit weight, γ (kN/m3) | 16, 18, 20, 22 |

| 2 | Internal friction angle, ϕ (deg) | 25, 30, 35 |

| 3 | Modulus of elasticity, E (MPa) | 18, 48, 78 |

| 4 | Number of helix plates, n | 2, 3 |

| 5 | Pile length, L (m) | 8, 10, 12, 15 |

| 6 | Helix diameter, D (m) | 0.3, 0.4, 0.5 |

| 7 | Inter–helix spacing ratio, S/D | 1–14 |

| Hyperparameter | Setting |

|---|---|

| Basis Function | Constant |

| Use Isotropic Kernel | Yes |

| Kernel Scale | Automatic |

| Signal Standard Deviation | Automatic |

| Sigma | Automatic |

| Standardize Data | Yes |

| Optimize Numeric Parameters | Yes |

| Hyperparameter | Setting |

|---|---|

| Number of Fully Connected Layers | Default = 1, Bilayered = 2, Trilayered = 3 |

| Layer Size (all layers) | Default = 10, Medium NN = 25, Wide NN = 100 |

| Activation | ReLu |

| Iteration Limit | 1000 |

| Regularization Strength (Lambda) | 0 |

| Standardize Data | Yes |

| Optimize Numeric Parameters | Yes |

| Model Type | RMSE (Validation) | R-Squared (Validation) | MAE (Validation) | MAE (Test) | RMSE (Test) | R-Squared (Test) | Training Time (s) |

|---|---|---|---|---|---|---|---|

| Rational Quadratic GPR | 33.1 | 0.99 | 16.2 | 14.5 | 30.0 | 0.99 | 130.0 |

| Matern 5/2 GPR | 33.0 | 0.99 | 16.1 | 14.6 | 30.3 | 0.99 | 71.5 |

| Squared Exponential GPR | 34.5 | 0.99 | 18.1 | 16.3 | 30.9 | 0.99 | 48.0 |

| Trilayered Neural Network | 45.9 | 0.97 | 25.5 | 23.1 | 35.8 | 0.98 | 132.2 |

| Medium Neural Network | 74.4 | 0.93 | 41.0 | 22.3 | 36.1 | 0.98 | 95.4 |

| Exponential GPR | 38.6 | 0.98 | 17.9 | 16.0 | 36.5 | 0.98 | 74.5 |

| Bilayered Neural Network | 56.0 | 0.96 | 34.1 | 22.1 | 37.0 | 0.98 | 116.9 |

| Wide Neural Network | 43.5 | 0.98 | 20.2 | 19.2 | 38.1 | 0.98 | 114.4 |

| Cubic SVM | 41.7 | 0.98 | 22.9 | 21.5 | 38.7 | 0.98 | 12.3 |

| Medium Gaussian SVM | 43.1 | 0.98 | 24.1 | 21.4 | 39.5 | 0.98 | 9.7 |

| Least Squares Regression | 59.8 | 0.96 | 39.6 | 33.9 | 54.4 | 0.96 | 119.6 |

| Quadratic SVM | 57.5 | 0.96 | 35.1 | 36.2 | 60.3 | 0.96 | 9.1 |

| Fine Tree | 77.2 | 0.93 | 44.4 | 37.7 | 67.6 | 0.94 | 4.8 |

| Narrow Neural Network | 71.2 | 0.94 | 42.3 | 42.8 | 68.9 | 0.94 | 91.4 |

| Boosted Trees | 74.7 | 0.93 | 47.1 | 44.3 | 73.9 | 0.93 | 16.9 |

| Bagged Trees | 76.5 | 0.93 | 47.7 | 46.2 | 77.2 | 0.93 | 18.4 |

| Interactions Linear | 71.3 | 0.94 | 47.6 | 50.3 | 77.7 | 0.93 | 7.2 |

| Stepwise Linear | 71.8 | 0.94 | 47.9 | 50.5 | 78.1 | 0.93 | 117.6 |

| Coarse Gaussian SVM | 89.6 | 0.90 | 50.8 | 49.6 | 91.3 | 0.90 | 9.5 |

| Medium Tree | 99.8 | 0.88 | 66.5 | 64.5 | 100.6 | 0.88 | 7.2 |

| Linear | 109.8 | 0.85 | 76.9 | 80.5 | 117.6 | 0.83 | 8.4 |

| Efficient Linear Least Squares | 111.5 | 0.85 | 77.1 | 80.1 | 118.0 | 0.83 | 11.8 |

| Fine Gaussian SVM | 124.9 | 0.81 | 69.8 | 61.6 | 119.7 | 0.83 | 8.6 |

| Linear SVM | 116.6 | 0.83 | 71.1 | 73.7 | 122.8 | 0.82 | 7.7 |

| Robust Linear | 127.2 | 0.80 | 72.6 | 73.2 | 131.2 | 0.79 | 5.8 |

| Coarse Tree | 136.6 | 0.8 | 94.8 | 93.9 | 140.3 | 0.8 | 6.7 |

| SVM Kernel | 243.4 | 0.3 | 163.5 | 134.4 | 224.1 | 0.4 | 119.8 |

| Efficient Linear SVM | 234.4 | 0.3 | 173.7 | 170.9 | 230.6 | 0.4 | 11.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Igoe, D.; Zahedi, P.; Soltani-Jigheh, H. Predicting the Compression Capacity of Screw Piles in Sand Using Machine Learning Trained on Finite Element Analysis. Geotechnics 2024, 4, 807-823. https://doi.org/10.3390/geotechnics4030042

Igoe D, Zahedi P, Soltani-Jigheh H. Predicting the Compression Capacity of Screw Piles in Sand Using Machine Learning Trained on Finite Element Analysis. Geotechnics. 2024; 4(3):807-823. https://doi.org/10.3390/geotechnics4030042

Chicago/Turabian StyleIgoe, David, Pouya Zahedi, and Hossein Soltani-Jigheh. 2024. "Predicting the Compression Capacity of Screw Piles in Sand Using Machine Learning Trained on Finite Element Analysis" Geotechnics 4, no. 3: 807-823. https://doi.org/10.3390/geotechnics4030042

APA StyleIgoe, D., Zahedi, P., & Soltani-Jigheh, H. (2024). Predicting the Compression Capacity of Screw Piles in Sand Using Machine Learning Trained on Finite Element Analysis. Geotechnics, 4(3), 807-823. https://doi.org/10.3390/geotechnics4030042