Lubricity and Wear of Alternative Engine Fuels and Lubricants

A special issue of Applied Sciences (ISSN 2076-3417). This special issue belongs to the section "Energy Science and Technology".

Deadline for manuscript submissions: closed (20 October 2022) | Viewed by 5362

Special Issue Editors

Interests: tribochemistry; tribology environmental design; boundary lubrication; special lubricants

Special Issues, Collections and Topics in MDPI journals

Interests: tribological methods and techniques for enhancing efficiency; design methodologies for mechanical components and devices; acoustic emissions for tribological diagnosis; application of machine learning, AI, and neural networks in tribological systems; energy and materials in manufacturing and transportation; biomedical engineering devices and applications; water systems and resource management

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

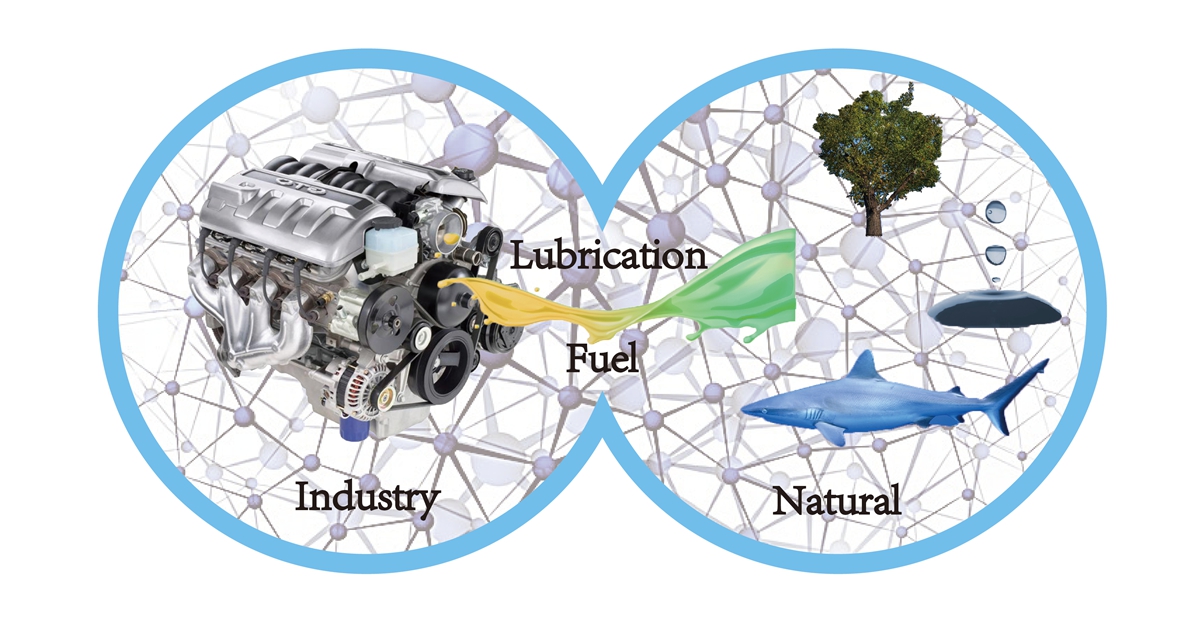

Advanced alternative fuels provide an essential mechanism for reaching global aspirations of peak CO2 emissions and net-zero carbon, driving research and development. There are many opportunities for the development of sustainable fuels, but equally many challenges.

Low heating value, high corrosion rates, and dilution of lubricant oil are just some of the hurdles that must be overcome and drive innovation. A detailed understanding of the tribological properties of alternative fuels forms an essential intellectual aspect for saving energy, increasing the reliability of engine technology, in the selection and optimisation of synthetic processing and the determination of the molecular groups for alternative engine fuels.

What is clear is that there will be a lasting and continuous need for liquid fuels in transportation and other applications. This Special Issue invites contributions on the latest developments and new perspectives on the tribological aspects of alternative fuels in engines from the wider community. Topics will cover but are not be limited to:

- Preparation of alternative engine fuels ;

- Physical and chemical properties of alternative engine fuels;

- Cavitation and erosion of fuel pump;

- Lubricity of alternative engine fuels;

- Selection and application of green lubricants in engines;

- Molecular simulation of wear mechanism of alternative engine fuels;

- Tribo-measurement of alternative engine fuels;

- Tribo-catalyzation on rubbing surfaces;

- Exhaust emissions of alternative engine fuels;

- The role of soot in friction and wear;

Corrosion behavior of alternative engine fuels (metals, polymers, and other materials)

Prof. Dr. Xianguo Hu

Prof. Dr. Karl Dearn

Prof. Dr. Tianxia Liu

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Applied Sciences is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- alternative engine fuels

- bio-oil

- biodiesel

- tribology

- biodegradation

- tribochemistry

- corrosion

- exhaust emission

- solid lubricant

- green lubricant