Intelligent Production and Manufacturing Systems

A special issue of Applied Sciences (ISSN 2076-3417). This special issue belongs to the section "Applied Industrial Technologies".

Deadline for manuscript submissions: closed (29 February 2024) | Viewed by 5854

Special Issue Editors

Interests: intelligent manufacturing; high-performance machining; process planning

Interests: supply chain management; sustainable manufacturing; intelligent manufacturing; advanced manufacturing

2. Key Laboratory of Advanced Manufacturing Technology of Zhejiang Province, School of Mechanical Engineering, Zhejiang University, Hangzhou 310027, China

Interests: additive manufacturing; process planning; robotics

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

We invite submissions to the Special Issue on Intelligent Production and Manufacturing Systems.

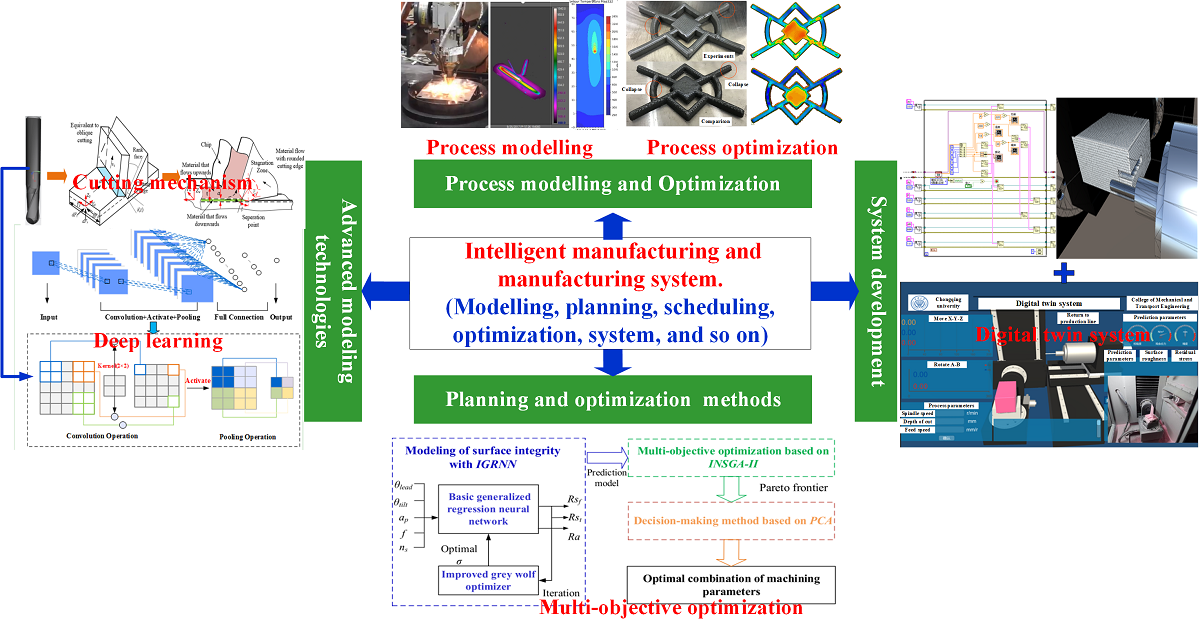

Intelligent manufacturing integrates new-generation information technologies (Digital twin, deep learning, and so on) and advanced manufacturing technologies. It has been the trend in manufacturing technologies. Presently, a huge number of researchers have been dedicated to this area. Therefore, “Intelligent manufacturing and manufacturing system”, has been proposed and aims to cover the recent advances and future perspectives related to intelligent manufacturing, including manufacturing systems, supply chains, process planning and scheduling in the machining process, and additive manufacturing. The Special Issue welcomes outstanding research papers and review articles devoted to innovative methods for advanced modeling, planning, optimization, control, and monitoring technologies with the help of new-generation information technologies in the field of intelligent manufacturing and manufacturing systems.

In particular, the topics of interest include but are not limited to:

- Intelligent manufacturing;

- Digital twin in manufacturing;

- Supply chain;

- Manufacturing system;

- Intelligent tool design;

- Process planning;

- Process optimization;

- Production scheduling;

- Modeling of the machining process;

- Additive manufacturing.

Dr. Sibao Wang

Dr. Ning Liu

Dr. Kai Ren

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Applied Sciences is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- intelligent manufacturing

- supply chain

- digital twin

- sustainable manufacturing

- manufacturing process modelling and optimization