Recent Advances in Drilling Fluid Technologies

A special issue of Applied Sciences (ISSN 2076-3417). This special issue belongs to the section "Earth Sciences".

Deadline for manuscript submissions: closed (20 March 2025) | Viewed by 4028

Special Issue Editors

Interests: drilling technology; competition and workover; drilling and completion fluids; waste management; deep well waste injection

Special Issues, Collections and Topics in MDPI journals

Interests: drilling technology; drilling fluids; environmental protection; waste management; well control

Interests: drilling technology; well cementing; drilling and completion fluids; environmental protection in petroleum engineering; waste management; deep well waste injection

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

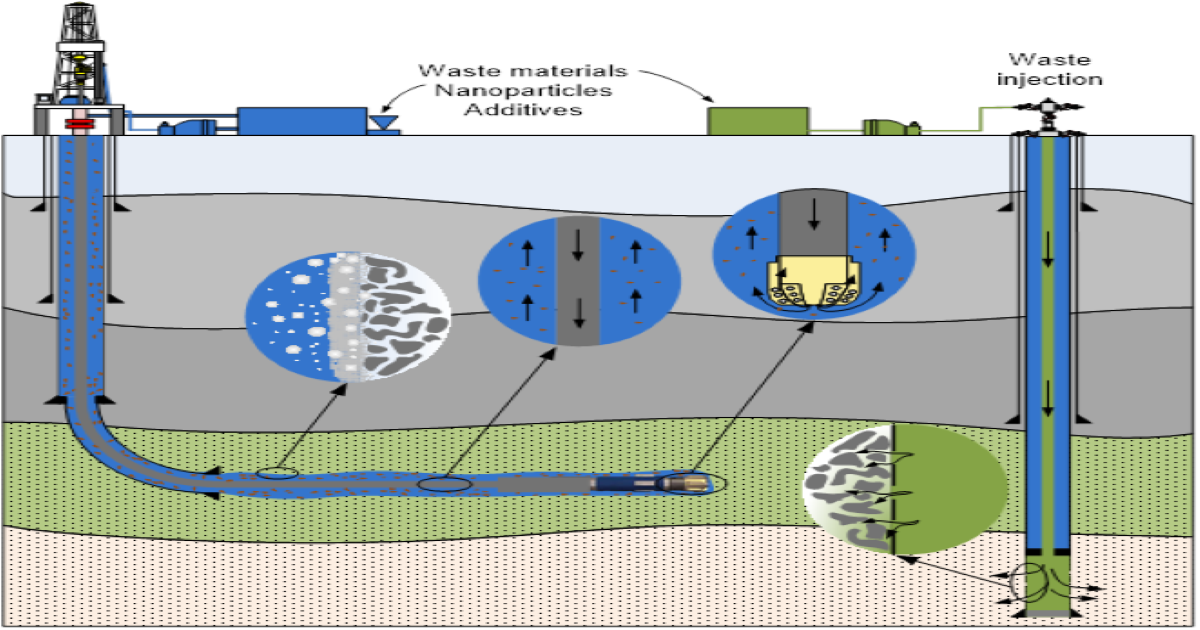

Drilling fluid (mud) is an important type of fluid that must fulfill numerous important functions during drilling operations. By circulating through the well, the mud continuously removes cuttings, lubricates drilling tools, and improves wellbore stability, which enables drilling to be carried out in increasingly demanding areas through various types of rocks. Since some commercially available additives used for the optimization of drilling fluid constitute non-degradable and environmentally hazardous materials, in the last few years, research has aimed to apply a green approach and the concept of circular economy in mud design to determine whether different biodegradable waste materials can be used as efficient drilling fluid additives. Also, for drilling through unconventional reservoirs (e.g., shales), the industry is exploring the possibility of replacing existing conventional materials with those that have the ability to plug nanopores in rocks with very low permeability.

It is evident that the industry of drilling fluids has undergone significant development over the last few years, so we encourage researchers to submit scientific papers (original research or review) that present current advances in drilling fluid optimization. In addition, within the framework of this Special Issue, all other types of fluids used during drilling, completion, and workover, as well as hydraulic fracturing, are acceptable. The preferred subjects for this Special Issue include drilling fluid property optimization, testing, additives, cuttings removal, biodegradable materials, the use of waste, nanoparticles, formation damage, cement slurries, hydraulic fracturing fluids, and others.

Dr. Borivoje Pašić

Dr. Petar Mijić

Prof. Dr. Nediljka Gaurina-Međimurec

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Applied Sciences is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- drilling fluid

- additives

- waste materials

- nanoparticles

- hydraulics

- rheology

- cutting removal

- lost circulation

- formation damage

- hydraulic fracturing

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- e-Book format: Special Issues with more than 10 articles can be published as dedicated e-books, ensuring wide and rapid dissemination.

Further information on MDPI's Special Issue policies can be found here.