Innovative Functional Textiles (Closed)

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Applications".

Viewed by 43198Editors

Interests: sustainable sportswear materials; eco-friendly market survey; social network analysis; protective smart sportswear;

Special Issues, Collections and Topics in MDPI journals

Interests: battery/super capacitor/fuel-cell; CCS (carbon dioxide capture & sequestration); super absorbent polymer; hybrid interface design for composites

Special Issues, Collections and Topics in MDPI journals

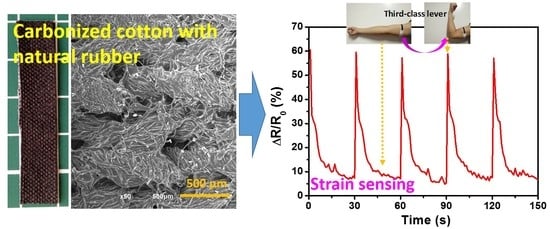

Interests: smart materials & textiles; conductive textiles with carbon nanofiber and graphene; 3D printing textile; smart clothing

Topical Collection Information

Dear Colleagues,

During the past seventy years, fiber and textile industry have undergone the revolutionary changes and seen the most significant innovations in their history. The most important innovations come with the advent of information industry and biotechnology industry. The fiber- and textile-based structures are highly desirable for human wears that are expected to be light-weighted, durable, flexible, and conformable. The well- established and cost-effective fiber and textile production processes enable these materials to convert into one-, two- and three-dimensional fiber assemblies (yarns, fabrics, and products). The fusion of textiles and information technology or biotechnology has the potential to combine the positive attributes of each technology with the flexible, wearable, and continuous nature of fiber assemblies. Thus, the hierarchical nature of the fibrous structures makes it suitable for the application of electronically- and biologically-relevant fields.

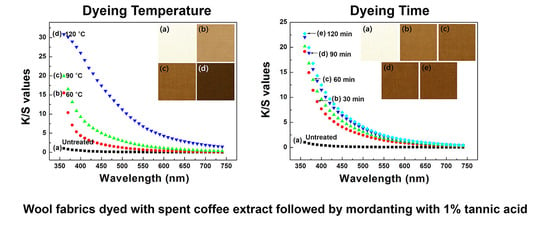

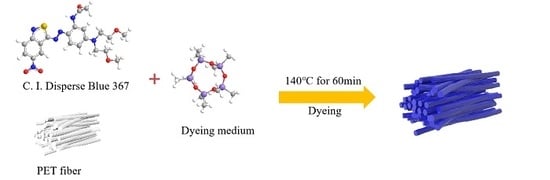

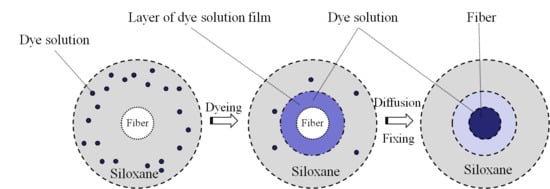

This Special Issue, “Innovative Functional Textiles”, aims to be a collection of high-quality original/review papers focusing on recent progresses on: (a) Smart electronic polymers and textiles; (b) Graphene based conductive polymers and textiles; (c) Fibers and textiles in energy technology ; (d) Fibretronics: Electronic polymers and textiles; (e) Polymer/textiles composites for energy generation and storage; (f) Biomedical polymers and textiles; (g) Photonic polymers and textiles; (h) Sustainable textile materials & processing; (i) Eco-friendly dyeing and finishing technology ; (j) 3D/4D printing of conductive polymer composites.

Other potentially interesting topics are also welcome and not limited to the above lists, if the intended submissions are generally in the category of functional textiles.

Dr. Kyung Wha Oh

Prof. Seung Geol Lee

Prof. Sunhee Lee

Dr. Sohee Lee

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- Nano- and micro-fibers and assembles

- Graphene based conductive polymers and textiles

- Fibers and textiles in energy technology

- Fibretronics: Electronic polymers and textiles

- Polymer/textiles composites for energy generation and storage

- Biomedical polymers and textiles

- Photonic polymers and textiles

- Sustainable textile materials & processing

- Eco-friendly dyeing and finishing technology

- 3D/4D printing of conductive polymer composites

Related Special Issue

- Innovative Functional Textiles in Polymers (31 articles - displayed below)