Highly Stable and Efficient Performance of Binder-Free Symmetric Supercapacitor Fabricated with Electroactive Polymer Synthesized via Interfacial Polymerization

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.2.1. Synthesis of PANI–DBSA

2.2.2. Structural Characterization

2.2.3. Electrochemical Characterization

3. Results

3.1. Structural Characterization

3.2. Cyclic Voltammetry

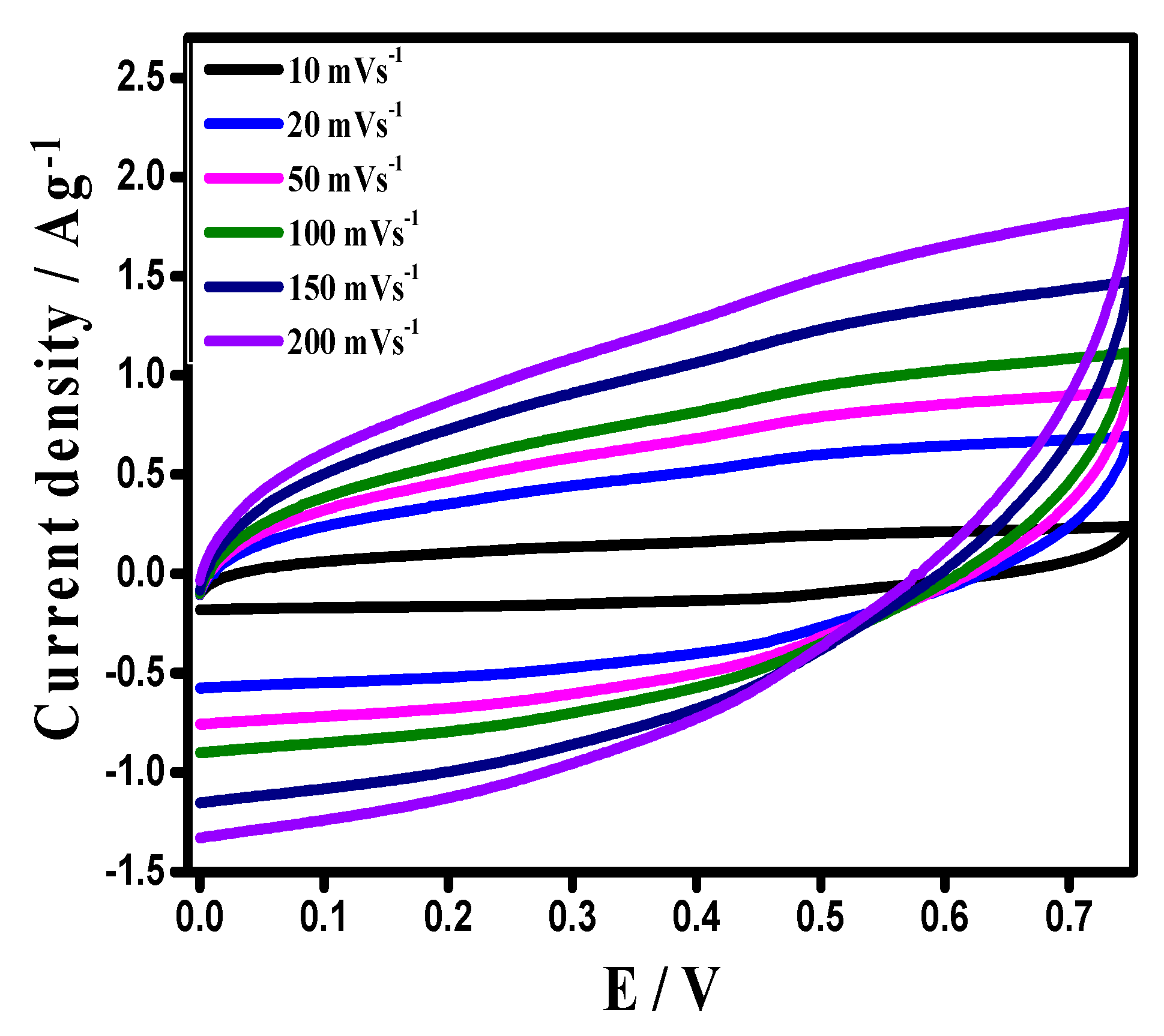

3.3. Galvanostatic Charge Discharge (GCD)

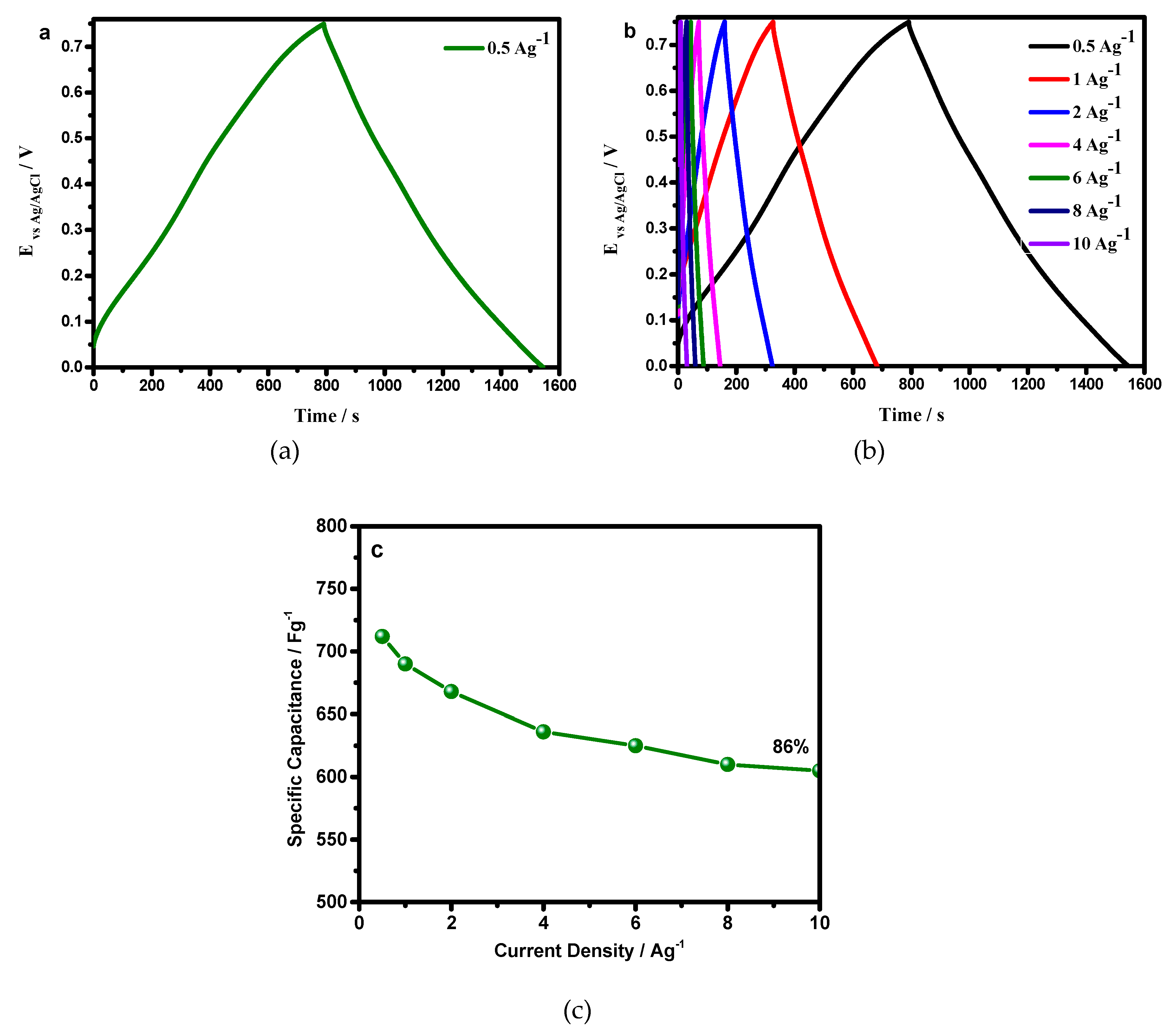

3.4. Electrochemical Impedance Spectroscopy (EIS)

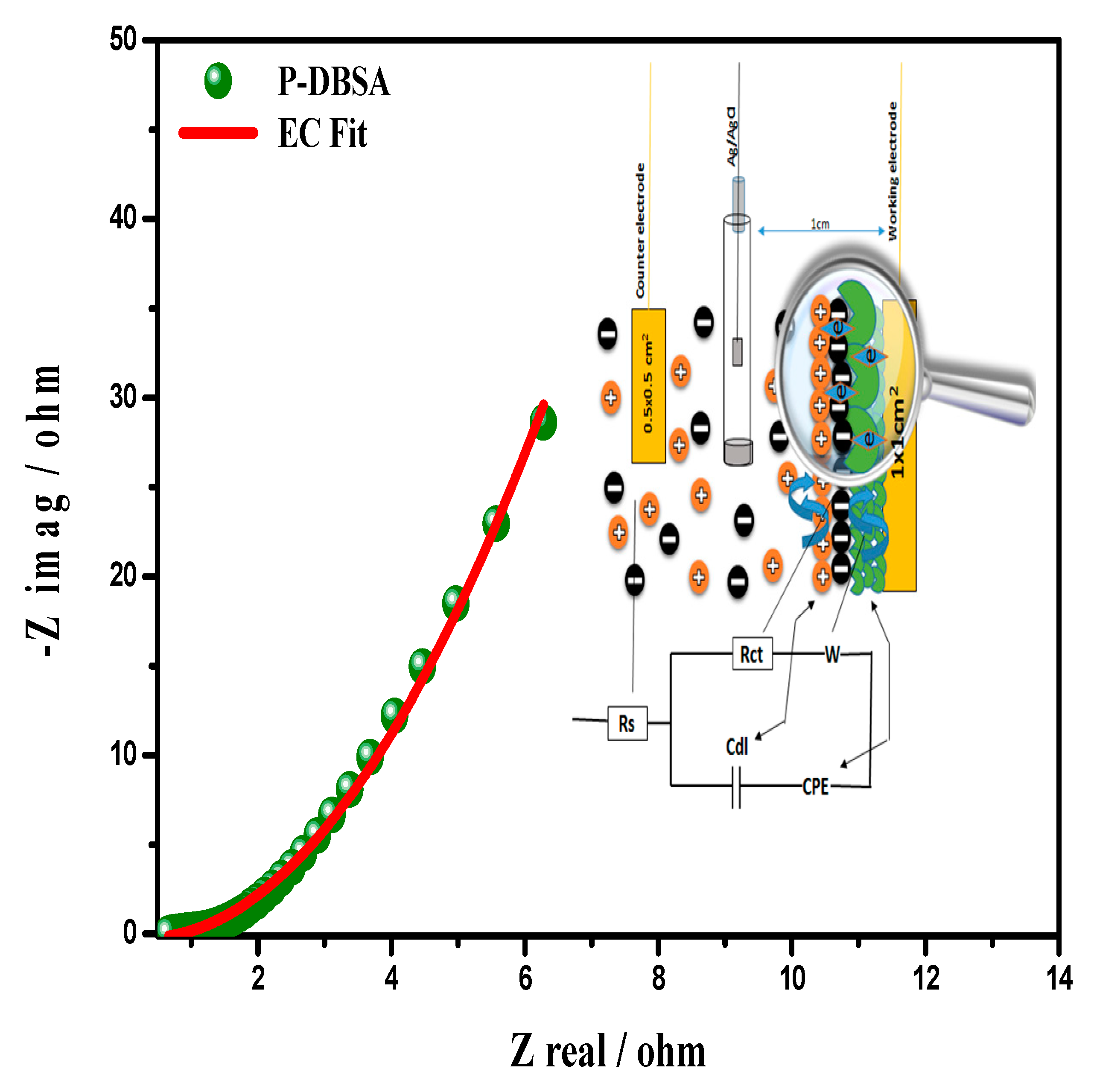

3.5. Application of the Synthesized PANI–DBSA in a Symmetric Supercapacitor

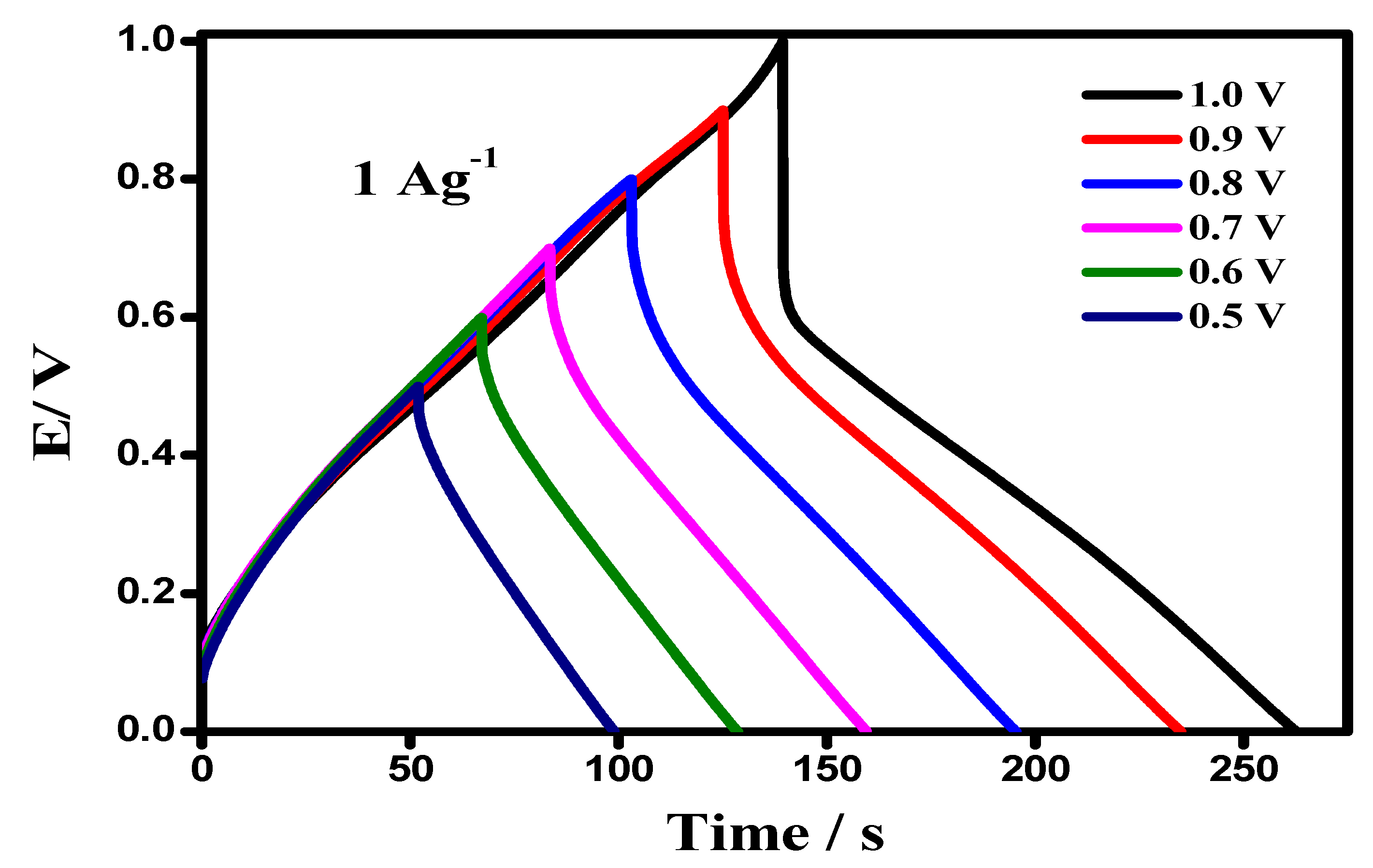

3.6. Charge Storage Mechanism of a Supercapacitor Device

| Positive: | Pani + nA- + ne+ ‹—› | Pani + (ne+) ⁞⁞ nA- | [EDLC behavior] |

| Negative: | Paniox + ne- ‹—› | Panired + nA- + nH+ | [PSC behavior] |

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Simon, P.; Gogotsi, Y. Materials for electrochemical capacitors. Nat. Mater. 2008, 7, 845–854. [Google Scholar] [CrossRef]

- Park, H.W.; Kim, T.; Huh, J.; Kang, M.; Lee, J.E.; Yoon, H. Anisotropic growth control of polyaniline nanostructures and their morphology-dependent electrochemical characteristics. ACS Nano 2012, 6, 7624–7633. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Xing, W.; Duan, J.; Hu, X.; Qiao, S.Z. Nanostructured morphology control for efficient supercapacitor electrodes. J. Mater. Chem. 2013, 1, 2941–2954. [Google Scholar] [CrossRef]

- Jiang, H.; Lee, S.P.; Li, C. 3D carbon based nanostructures for advanced supercapacitors. Energy Environ. Sci. 2013, 6, 41–53. [Google Scholar] [CrossRef]

- Béguin, F.; Presser, V.; Balducci, A.; Frackowiak, E. Carbons and Electrolytes for Advanced Supercapacitors. Adv. Mater. 2014, 26, 2219–2251. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Li, Z.; Zhong, M.; Kowalewski, T.; Matyjaszewski, K. Templated Synthesis of Nitrogen-Enriched Nanoporous Carbon Materials from Porogenic Organic Precursors Prepared by ATRP. Angew. Chem. Int. Ed. 2014, 126, 4038–4041. [Google Scholar] [CrossRef]

- Winter, M.; Brodd, R.J. What Are Batteries, Fuel Cells, and Supercapacitors? Chem. Rev. 2004, 104, 4245–4270. [Google Scholar] [CrossRef] [Green Version]

- Hallik, A.; Alumaa, A.; Kurig, H.; Jänes, A.; Lust, E.; Tamm, J. On the porosity of polypyrrole films. Synth. Met. 2007, 157, 1085–1090. [Google Scholar] [CrossRef]

- Hallik, A.; Alumaa, A.; Tamm, J.; Sammelselg, V.; Väärtnõu, M.; Jänes, A.; Lust, E. Analysis of electrochemical impedance of polypyrrole| sulfate and polypyrrole| perchlorate films. Synth. Met. 2006, 156, 488–494. [Google Scholar] [CrossRef]

- Thakur, A.; Choudhary, R.; Sartale, S.; Desai, M. Polythiophene-carbon nanotubes composites as energy storage materials for supercapacitor application. In Proceedings of the AIP Conference Proceedings, Bikaner, India, 30–31 October 2015. [Google Scholar]

- Tran, H.D.; Wang, Y.; D’Arcy, J.M.; Kaner, R.B. Toward an Understanding of the Formation of Conducting Polymer Nanofibers. ACS Nano 2008, 2, 1841–1848. [Google Scholar] [CrossRef]

- Shi, Y.; Pan, L.; Liu, B.; Wang, Y.; Cui, Y.; Bao, Z.; Yu, G. Nanostructured conductive polypyrrole hydrogels as high-performance, flexible supercapacitor electrodes. J. Mater. Chem. 2014, 2, 6086–6091. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Rao Chepuri, R.K.; Vijayan, M. Performance of conducting polyaniline-DBSA and polyaniline-DBSA/Fe3O4 composites as electrode materials for aqueous redox supercapacitors. Appl. Polym. Sci. 2011, 122, 1510–1518. [Google Scholar] [CrossRef]

- Bilal, S.; Gul, S.; Holze, R.; Shah, A.A. An impressive emulsion polymerization route for the synthesis of highly soluble and conducting polyaniline salts. Synth. Met. 2015, 206, 131–144. [Google Scholar] [CrossRef]

- Ullah, R.; Bilal, S.; Ali, K.; Shah, A.A. Synthesis and characterization of polyaniline doped with Cu II chloride by inverse emulsion polymerization. Synth. Met. 2014, 198, 113–117. [Google Scholar] [CrossRef]

- Bilal, S.; Gul, S.; Ali, K.; Shah, A.A. Synthesis and characterization of completely soluble and highly thermally stable PANI-DBSA salts. Synth. Met. 2012, 162, 2259–2266. [Google Scholar] [CrossRef]

- Shreepathi, S.; Holze, R. Spectroelectrochemical investigations of soluble polyaniline synthesized via new inverse emulsion pathway. Chem. Mater. 2005, 17, 4078–4085. [Google Scholar] [CrossRef]

- Huang, J.; Virji, S.; Weiller, B.H.; Kaner, R.B. Polyaniline Nanofibers: Facile Synthesis and Chemical Sensors. J. Am. Chem. Soc. 2003, 125, 314–315. [Google Scholar] [CrossRef] [Green Version]

- Yuan, R.; Wang, H.; Ji, T.; Mu, L.; Chen, L.; Zhu, Y.; Zhu, J. Superhydrophobic polyaniline hollow spheres with mesoporous brain-like convex-fold shell textures. J. Mater. Chem. 2015, 3, 19299–19303. [Google Scholar] [CrossRef]

- Nuraje, N.; Su, K.; Yang, N.I.; Matsui, H. Liquid/Liquid Interfacial Polymerization to Grow Single Crystalline Nanoneedles of Various Conducting Polymers. ACS Nano 2008, 2, 502–506. [Google Scholar] [CrossRef]

- Chen, J.; Chao, D.; Lu, X.; Zhang, W. A facile one-step synthesis of PTSA-doped tetraaniline nanostructure/magnetite nanoparticles via self-assembly method. Mater. Lett. 2007, 61, 1419–1423. [Google Scholar] [CrossRef]

- Huang, J.; Kaner, R.B. A General Chemical Route to Polyaniline Nanofibers. J. Am. Chem. Soc. 2004, 126, 851–855. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.; Mao, H.; Zhang, W. Fabrication of DBSA-doped polyaniline nanorods by interfacial polymerization. J. Appl. Polym. Sci. 2008, 109, 2842–2847. [Google Scholar] [CrossRef]

- Ma, H.; Luo, Y.; Yang, S.; Li, Y.; Cao, F.; Gong, J. Synthesis of Aligned Polyaniline Belts by Interfacial Control Approach. J. Phys. Chem. C 2011, 115, 12048–12053. [Google Scholar] [CrossRef]

- Ji, T.; Cao, W.; Chen, L.; Mu, L.; Wang, H.; Gong, X.; Lu, X.; Zhu, J. A non-fullerene acceptor with a fully fused backbone for efficient polymer solar cells with a high open-circuit voltage. J. Mater. Chem. 2016, 4, 6290–6294. [Google Scholar] [CrossRef]

- Ho, S.K.; Hsieh, H.T.; Kuo, W.C.; Lee, W.S.; Lin, J.J.; Huang, J.L. Effect of aniline formaldehyde resin on the conjugation length and structure of doped polyaniline: Spectral studies. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 3116–3125. [Google Scholar] [CrossRef]

- Stejskal, J.; Hlavatá, D.; Holler, P.; Trchová, M.; Prokeš, J.; Sapurina, I. Polyaniline prepared in the presence of various acids: a conductivity study. Polym. Int. 2004, 53, 294–300. [Google Scholar] [CrossRef]

- Shah, A.-U.-H.A.; Kamran, M.; Bilal, S.; Ullah, R. Cost Effective Chemical Oxidative Synthesis of Soluble and Electroactive Polyaniline Salt and Its Application as Anticorrosive Agent for Steel. Materials 2019, 12, 1527. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, D.; Deng, J.; Duan, X.; Guo, J.; Liu, P. Improving cyclic stability of polyaniline by thermal crosslinking as electrode material for supercapacitors. RSC Adv. 2015, 5, 78545–78552. [Google Scholar] [CrossRef]

- Gawli, Y.; Banerjee, A.; Dhakras, D.; Deo, M.; Bulani, D.; Wadgaonkar, P.; Shelke, M.; Ogale, S. 3D Polyaniline Architecture by Concurrent Inorganic and Organic Acid Doping for Superior and Robust High Rate Supercapacitor Performance. Sci. Rep. 2016, 6, 21002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tissera, N.D.; Wijesena, R.N.; Rathnayake, S.; de Silva, R.M.; de Silva, K.M.N. Heterogeneous in Situ Polymerization of Polyaniline (PANI) Nanofibers on Cotton Textiles: Improved Electrical Conductivity, Electrical Switching, and Tuning Properties. Carbohydr. Polym. 2018, 186, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Chao, D.; Lu, X.; Zhang, W. Novel Interfacial Polymerization for Radially Oriented Polyaniline Nanofibers. Mater. Lett. 2007, 61, 1419–1423. [Google Scholar] [CrossRef]

- Oueiny, C.; Berlioz, S.; Perrin, F.X. Assembly of Polyaniline Nanotubes by Interfacial Polymerization for Corrosion Protection. Phys. Chem. Chem. Phys. 2016, 18, 3504–3509. [Google Scholar] [CrossRef]

- Ji, T.; Cao, W.; Chen, L.; Mu, L.; Wang, H.; Gong, X.; Lu, X.; Zhu, J. Confined Molecular Motion across Liquid/Liquid Interfaces in a Triphasic Reaction towards Free-Standing Conductive Polymer Tube Arrays. J. Mater. Chem. 2016, 4, 6290–6294. [Google Scholar] [CrossRef]

- Zhai, Y.; Dou, Y.; Zhao, D.; Fulvio, P.F.; Mayes, R.T.; Dai, S. Carbon Materials for Chemical Capacitive Energy Storage. Adv. Mater. 2011, 23, 4828–4850. [Google Scholar] [CrossRef]

- Wu, W.; Pan, D.; Li, Y.; Zhao, G.; Jing, L.; Chen, S. Facile Fabrication of Polyaniline Nanotubes Using the Self-Assembly Behavior Based on the Hydrogen Bonding: A Mechanistic Study and Application in High-Performance Electrochemical Supercapacitor Electrode. Electrochim. Acta 2015, 152, 126–134. [Google Scholar] [CrossRef]

- Guan, L.; Yu, L.; Chen, G.Z. Capacitive and Non-Capacitive Faradaic Charge Storage. Electrochim. Acta 2016, 206, 464–478. [Google Scholar] [CrossRef]

- Jiang, H.; Ma, J.; Li, C. Polyaniline–MnO2 Coaxial Nanofiber with Hierarchical Structure for High-Performance Supercapacitors. J. Mater. Chem. 2012, 22, 16939. [Google Scholar] [CrossRef]

- Biswas, S.; Drzal, L.T. Multi Layered Nanoarchitecture of Graphene Nanosheets and Polypyrrole Nanowires for High Performance Supercapacitor Electrodes. Chem. Mater. 2010, 22, 5667–5671. [Google Scholar] [CrossRef]

- Kötz, R.; Carlen, M. Principles and Applications of Electrochemical Capacitors. Electrochim. Acta 2000, 45, 2483–2498. [Google Scholar] [CrossRef]

- National Physical Laboratory Kaye and Laby Table of Physical and Chemical Constants. Available online: http://www.kayelaby.npl.co.uk/atomic_and_nuclear_physics/4_2/4_2_1.html (accessed on 9 May 2019).

- Zhang, D.; Zheng, L.; Ma, Y.; Lei, L.; Li, Q.; Li, Y.; Luo, H.; Hao, Y. Synthesis of Nitrogen- and Sulfur-Codoped 3D Cubic-Ordered Mesoporous Carbon with Superior Performance in Supercapacitors. ACS Appl. Mater. Interfaces 2014, 6, 2657–2665. [Google Scholar] [CrossRef]

- Gür, T.M. Review of electrical energy storage technologies, materials and systems: challenges and prospects for large-scale grid storage. Energ. Environ. Sci. 2018, 11, 2696–2767. [Google Scholar]

- Hu, C.; Chu, C. Electrochemical Impedance Characterization of Polyaniline-Coated Graphite Electrodes for Electrochemical Capacitors—Effects of Film Coverage/Thickness and Anions. J. Electroanal. Chem. 2001, 503, 105–116. [Google Scholar] [CrossRef]

- Sivakkumar, S.R.; Kim, W.J.; Choi, J.A.; MacFarlane, D.R.; Forsyth, M.; Kim, D.W. Electrochemical Performance of Polyaniline Nanofibres and Polyaniline/Multi-Walled Carbon Nanotube Composite as an Electrode Material for Aqueous Redox Supercapacitors. J. Power Sources 2007, 171, 1062–1068. [Google Scholar] [CrossRef]

- Yan, J.; Wei, T.; Fan, Z.; Qian, W.; Zhang, M.; Shen, X.; Wei, F. Preparation of Graphene Nanosheet/Carbon Nanotube/Polyaniline Composite as Electrode Material for Supercapacitors. J. Power Sources 2010, 195, 3041–3045. [Google Scholar] [CrossRef]

| Synthesis Method | Electrolyte | Cs in Fg−1 (Current Density/Scan Rate) | % Retention (# Cycles) | Ref |

|---|---|---|---|---|

| Interfacial polymerization | 1 M H2SO4 | 548 (0.18 Ag−1) | 75 (1000) | [29] |

| Self-Assembly | 1 M H2SO4 | 274 (1 Ag−1) | 89 (1300) | [18] |

| Self-Assembly | 1 M H2SO4 | 350 (1 Ag−1) | 99 (500) | [18] |

| Soft template | 1 M H2SO4 | 450 (0.5 Ag−1) | 83 (10K) | |

| Self-Assembly | 1 M H2SO4 | 455 (1 mVs−1) | 65 (1300) | [32] |

| Self-Assembly | 1 M H2SO4 | 625 (1 Ag−1) | 77 (500) | [33] |

| Mechanochemical polymerization | 1 M H2SO4 | 333 (1 Ag−1) | 85 (1000) | [34] |

| Interfacial polymerization | 1 M H2SO4 | 712 (0.5 Ag−1) | 100 (5000) | This Work |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fahim, M.; Shah, A.u.H.A.; Bilal, S. Highly Stable and Efficient Performance of Binder-Free Symmetric Supercapacitor Fabricated with Electroactive Polymer Synthesized via Interfacial Polymerization. Materials 2019, 12, 1626. https://doi.org/10.3390/ma12101626

Fahim M, Shah AuHA, Bilal S. Highly Stable and Efficient Performance of Binder-Free Symmetric Supercapacitor Fabricated with Electroactive Polymer Synthesized via Interfacial Polymerization. Materials. 2019; 12(10):1626. https://doi.org/10.3390/ma12101626

Chicago/Turabian StyleFahim, Muhammad, Anwar ul Haq Ali Shah, and Salma Bilal. 2019. "Highly Stable and Efficient Performance of Binder-Free Symmetric Supercapacitor Fabricated with Electroactive Polymer Synthesized via Interfacial Polymerization" Materials 12, no. 10: 1626. https://doi.org/10.3390/ma12101626