Quick Green Scan: A Methodology for Improving Green Performance in Terms of Manufacturing Processes

Abstract

:1. Introduction

- A more quick and integrated approach is needed for the improvement and green or sustainability assessment on the aggregated level against two scenarios: The sustainability should encompass economic, social, environmental and other relevant considerations.

- Referring to the previously mentioned point, the green assessment methodology must also be sufficiently generic and broad to cover as much of the detail as possible that would be covered in a comprehensive procedure. Moreover, this methodology must be usable in a straightforward manner by company decision-makers (users). The production process involves multiple sub-processes represented by various kinds of performance data. Various in-operations manufacturing technologies need to be based upon procedures for simplifying green or sustainability assessment in order to easily compare with the baseline scenario.

- There is no unanimity yet as to which criteria and indicators or which method is better to use in green evaluation. In addition, there is a lack of a science-based methodology to describe specific manufacturing processes to generate inventory [16] data in a unified manner for whole manufacturing companies.

- The time devoted to performance evaluation is usually quite limited and the cost required to implement one of these later-mentioned tools is high,

- SMEs producing heating devices begin to consider technological changes (based on Best Available Technology) in manufacturing processes with respect to green measurements, since Best Available Technology (BAT) has been successfully implemented in terms of costs and benefits.

- How to establish a methodology to evaluate an improvement of green manufacturing processes’ performance based on the Life Cycle Assessment-based indicators framework and linguistic scale (fuzzy numbers) and to provide comparison of the performance for the baseline and improvement scenario?

- How to establish an overall Life Cycle Assessment-based indicators framework for manufacturing processes and integration with linguistic scale?

- How the proposed methodology can be applied to a company producing heating devices to assess and compare performances for both scenarios?

- By addressing the above challenges, a structured green scan (Q-G-S) methodology for assessing performance of manufacturing processes in a company producing heating devices is proposed. This methodology integrates a Life Cycle Assessment-based indicator framework as well as linguistic scale (fuzzy numbers) to evaluate the degree of company greening.

2. Theoretical Background

2.1. Need to Improve “Green” Performance

2.2. Tools and Key (Green or Sustainable) Manufacturing Indicators Used to Assess Company Performance

- Specific improvements initiatives;

- The power of information technology;

- Determination of the possibility to measure green manufacturing performance based on LCA methodology and fuzzy numbers.

- the provision of a tool to easily assess the progress made at each manufacturing process, differentiating the improvements obtained due to sustainable outcomes from each workstation of the manufacturing process

3. Materials and Methods

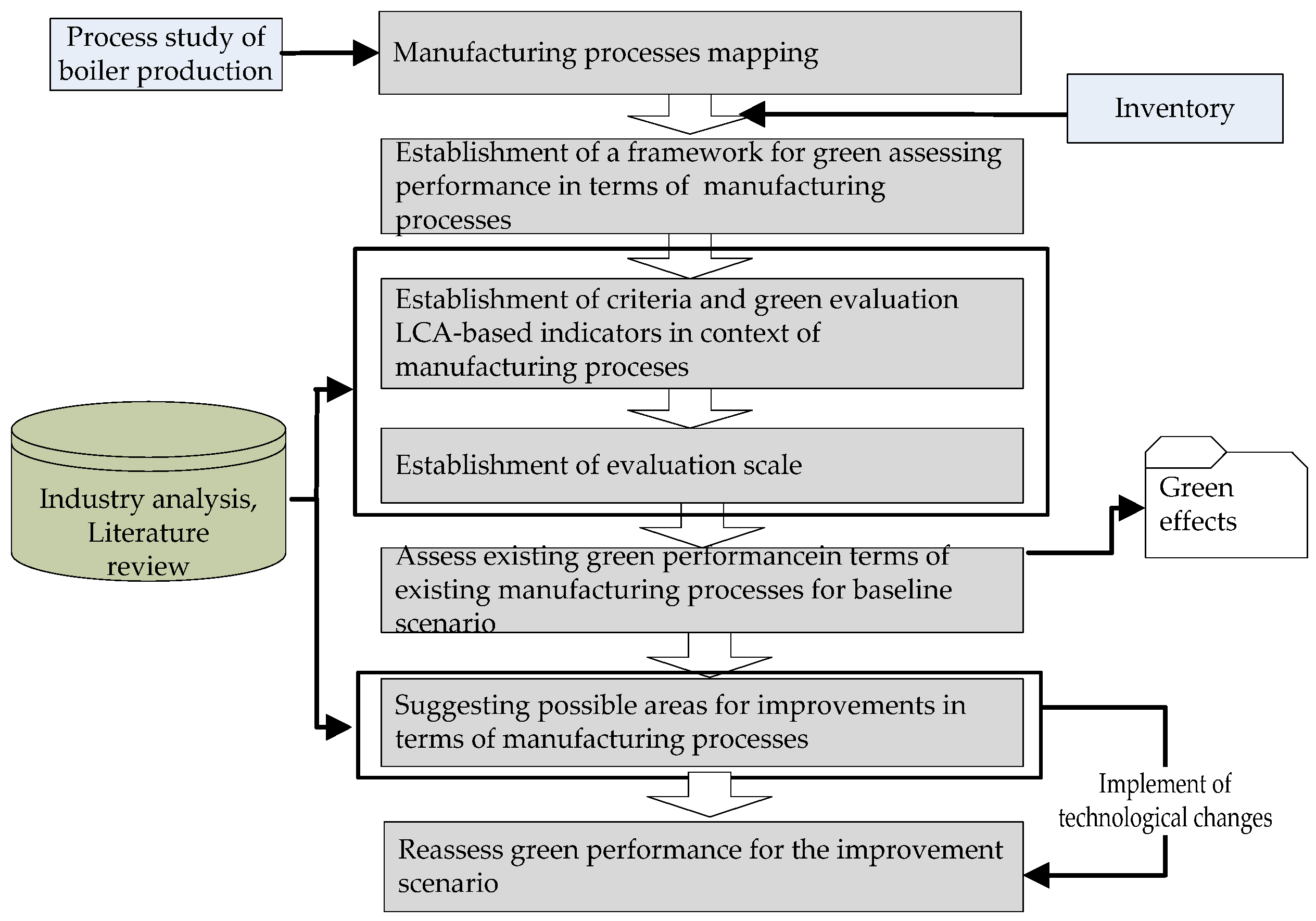

3.1. The Methodological Approach

3.1.1. Definition of the Criteria and Indicators for Evaluation of Defined Scenarios

- (1)

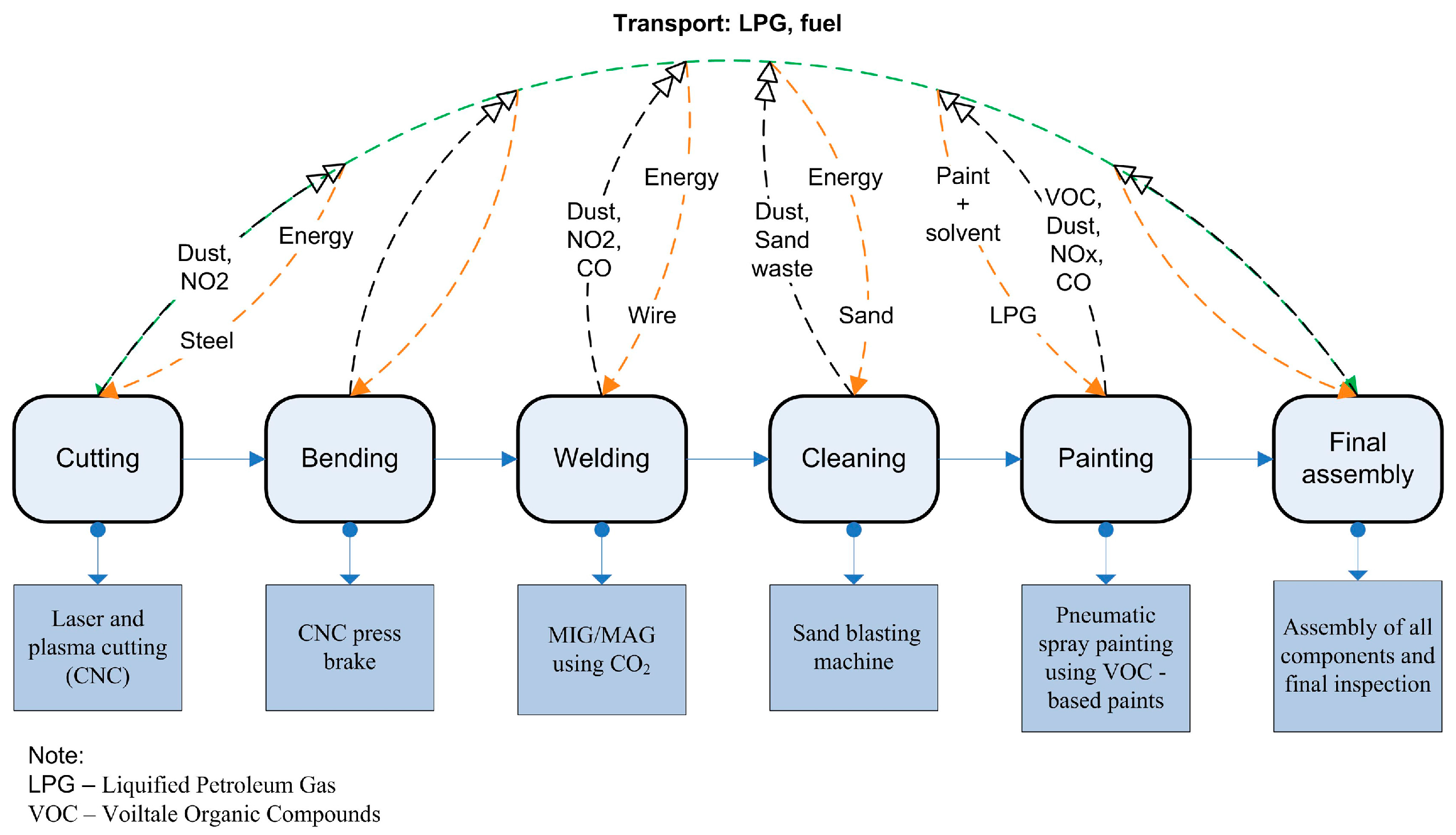

- Principle of life cycle assessment (LCA). The green or sustainable performance evaluation should consider the manufacturing life cycle of a boiler, including cutting, welding, cleaning, and painting. Therefore, the development of selection indicators should be based on the principle of LCA. Although in many investment decisions, social factors are often ignored by industry, the social impact is not separately assessed in this study, but economic factors, including labor safety and political stability, are among the factors that can be considered. Sustainability requires incorporating social and environmental objectives or constraints while undertaking this reconfiguration [4].

- (2)

- Principle of “green technology” development or technology upgrading. Technology upgrading can be interpreted as the adoption of a greener technology helping a company to remain environmentally sound [6]. The selection of materials is also significant in reducing the environmental load. For example, recyclable components used to manufacture products enhance green performance. Materials with a high recoverability rate, which are safe, reliable and environmentally friendly, should be used. Efforts are made to lower the energy consumption through the use of energy-saving technologies and manufacturing techniques. The indicator framework should be constantly improved with the development and deployment of new technologies and equipment in the boiler sector over time. In addition, during the operation phase, sustainability objectives might change according to related domestic environmental laws and regulations, and governmental environmental policies. Thus, with advancements in manufacturing technologies or technology upgrading, relevant indicators are more likely to emerge/be introduced, representing a state of company performance. For criteria assigned in boiler production, BAT technologies were applied based on the studies of field research of the author [61].

- (3)

- Principle of pollution prevention. The evaluation indicators system must protrude the idea of pollution prevention. It does not have to cover all the factors of environmental performance in boiler production. Nevertheless, it is necessary to take account of resource consumption (e.g., energy and steel, sand), environmental impact (e.g., dust, and scraps), socioeconomic impact (e.g., health and safety, production cost) in the production process. In this way, it would be possible to demonstrate that green or sustainable performance could be effectively evaluated through implementing the technology improvement scenario for boiler manufacture.

- (4)

- The main goal of this paper is to establish a methodology to evaluate the sustainability level of manufacturing processes by identifying and defining indicators that contribute to the manufacturing process sustainability.

3.1.2. Establishment of Evaluation Scales

3.2. Research Methodology

- Draw process mapping with the recognition of environmental problems that can be identified in the manufacturing processes. This step includes collecting and analyzing inventory data to establish the material flow diagram. This inventory analysis collects all data of manufacturing processes and relates it to the functional unit of the study, it examines the inputs and outputs (materials and energy consumed, produced waste) during the manufacturing processes from and to the environment.

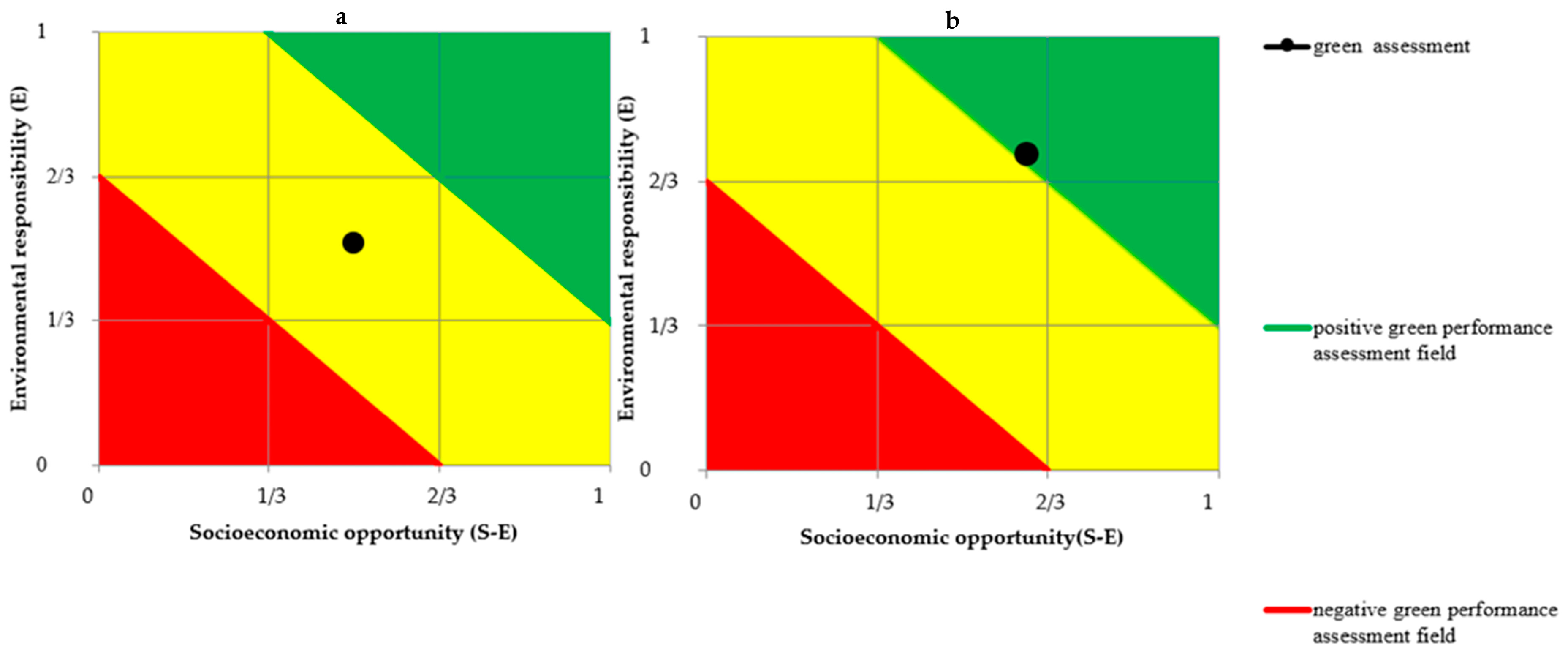

- Establish a set of the LCA-based indicators for the evaluation of green performance in the context of manufacturing processes. The potential indicators are divided into two groups of criteria: internal and external. An internal criterion is represented by environmental responsibility performance. An external criterion is demonstrated by socioeconomic opportunity performance. Environmental responsibility performance indicators are useful to help the company to decrease its overall environmental impacts. Socioeconomic indicators include cost of production, investment cost, healthy work environment, and social commitment. Indicators are particularly appropriate when manufacturing performance indicators to be analyzed and compared represent the outcomes of specific present and future improvement actions taken by the company.

- Establish evaluation scales for comparing and assessing company performance in terms of manufacturing processes. Initial linguistics scales for evaluation of a set of criteria shown in Table 2 are applied. Then, the scale is translated into fuzzy numbers.

- Assess green performance of existing manufacturing processes (baseline scenario) using the initial linguistics scales and their fuzzy numbers.

- Suggest possible areas for improvement in terms of technological changes in existing manufacturing processes. These improvements encompass technological solutions for mitigating pollution and their design characteristics, including the in-process, or in-plant modifications. This stage describes or analyzes the original state of equipment and pollution produced by the operations.

- Reassess green performance of the improved manufacturing processes as performed in step 4 (improvement scenario). By implementing green techniques and technologies from the perspective of environmental concern, green effects of proposed solutions are also presented.

3.3. Process Mapping and Original State of Pollution in the Company

3.4. Setting LCA-Based Indicators for Green Assessment

3.5. Suggesting Possible Areas for Improvements in Terms of Manufacturing Processes and Their Green Concerns

- Material costs: costs are determined by multiplying the amount of the particular materials by their specific prices and summing up the results;

- Labor costs: labor costs are calculated in the man-hours required by each machine: labor cost per year is multiplied by (1 + f)/average hours per year, where f is a social cost of labor;

- Energy costs: electricity and fuel costs are included in the calculation. The energy consumption of each examined process is allocated to each quantity center by machine-hour. Energy is often subsumed under the term of material. The energy costs are treated as part of the material costs;

- Waste management costs: waste costs are all expenses which occur in the context of handling waste losses within a particular quantity center;

- Emission cost: emissions (CO, NO2, dust, VOC, NOx) are calculated similar to the waste.

3.6. Assess Green Performance of Existing and Improvement Manufacturing Processes

4. Results

5. Discussion

6. Conclusions

Conflicts of Interest

References

- Rusinko, C.A. Green Manufacturing: An Evaluation of Environmentally Sustainable Manufacturing Practices and Their Impact on Competitive Outcomes. IEEE Eng. Manag. 2007, 54, 445–453. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean. Prod. 2016, in press. [Google Scholar] [CrossRef]

- Cheung, W.M.; Marsh, R.; Griffin, P.W.; Newnes, L.B.; Mileham, A.R.; Lanham, J.D. Towards cleaner production: A roadmap for predicting product end-of-life costs at early design concept. J. Clean. Prod. 2015, 87, 431–441. [Google Scholar] [CrossRef] [Green Version]

- Rosen, M.A.; Kishawy, H.A. Sustainable Manufacturing and Design: Concepts, Practices and Needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Wu, N. IoT-enabled Real-time Production Performance Analysis and Exception Diagnosis Model. IEEE TASE 2016, 13, 1318–1332. [Google Scholar] [CrossRef]

- Zhang, Y.; Qian, C.; Lv, J.; Liu, Y. Agent and cyber-physical system based self-organizing and self-adaptive intelligent shopfloor. IEEE Trans. Ind. Inf. 2016. [Google Scholar] [CrossRef]

- Chien, M.-K. Influences of green supply chain management practices on organizational sustainable performance. Int. J. Environ. Monit. Prot. 2014, 1, 12–23. [Google Scholar]

- Rao, P. Greening production: A South-East Asian experience. Int. J. Oper. Prod. Manag. 2004, 24, 289–320. [Google Scholar] [CrossRef]

- Wu, R.; Yang, D.; Chen, J. Social Life Cycle Assessment Revisited. Sustainability 2014, 6, 4200–4226. [Google Scholar] [CrossRef]

- Ajukumar, V.N.; Gandhi, O.P. Evaluation of green maintenance initiatives in design and development of mechanical systems using an integrated approach. J. Clean. Prod. 2013, 51, 34–46. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Genève, Switzerland, 1997. [Google Scholar]

- Toro, J.; Requena, I.; Duarte, O.; Zamorano, M. A qualitative method proposal to improve environmental impact assessment. Environ. Impact. Assess. 2013, 43, 9–20. [Google Scholar] [CrossRef]

- Hui, I.K.; He, L.; Dang, C. Environmental impact assessment in an uncertain environment. Int. J. Prod. Res. 2002, 40, 373–388. [Google Scholar] [CrossRef]

- Höjer, M.; Ahlroth, S.; Dreborg, K.H.; Ekvall, T.; Finnveden, G.; Hjelm, O.; Hochschorner, E.; Nilsson, M.; Palm, V. Scenarios in selected tools for environmental systems analysis. J. Clean. Prod. 2008, 16, 1958–1970. [Google Scholar] [CrossRef]

- Sendra, C.; Gabarrell, X.; Vicent, T. Material flow analysis adapted to an industrial area. J. Clean. Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Mani, M.; Madan, J.; Leeb, J.H.; Lyons, K.W.; Gupta, S.K. Sustainability characterization for manufacturing processes. Int. J. Prod. Res. 2014, 52, 5895–5912. [Google Scholar] [CrossRef]

- Baines, T.; Brown, S.; Benedettini, O.; Ball, P. Examining green production and its role within the competitive strategy of manufacturers. J. Ind. Eng. Manag. 2012, 5, 53–87. [Google Scholar] [CrossRef] [Green Version]

- Figge, F.; Hahn, T. Is green and profitable sustainable? Assessing the trade-off between economic and environmental aspects. Int. J. Prod. Econ. 2012, 140, 92–102. [Google Scholar] [CrossRef]

- Wong, C.W.Y.; Lai, K.; Shangc, K.; Lud, C.; Leunge, T.K.P. Green operations and the moderating role of environmental management capability of suppliers on manufacturing firm performance. Int. J. Prod. Econ. 2012, 140, 283–294. [Google Scholar] [CrossRef]

- Salvado, J.A.; de Castro, G.M.G.; Navas-Lopez, J.E. Green corporate image: moderating the connection between environmental product innovation and firm performance. J. Clean. Prod. 2014, 83, 356–365. [Google Scholar] [CrossRef]

- Florida, R. Lean and Green: The move to environmentally conscious manufacturing. Calif. Manag. Rev. 1996, 39, 80–105. [Google Scholar] [CrossRef]

- Gungorand, A.; Gupta, S.M. Issues in environmentally conscious manufacturing and product recovery: A survey. Comput. Ind. Eng. 1999, 36, 811–853. [Google Scholar] [CrossRef]

- Plehn, J.; Züst, R.; Kimura, F.; Sproedt, A.; Schönsleben, P. A method for determining a functional unit to measure environmental performance in manufacturing systems. CIRP Ann. Manuf. Technol. 2012, 61, 415–418. [Google Scholar] [CrossRef]

- Sarkis, J. Manufacturing’s role in corporate environmental sustainability: Concerns for the new millennium. Int. J. Oper. Prod. Manag. 2001, 2, 666–686. [Google Scholar] [CrossRef]

- Kroes, J.; Subramanian, R.; Subramanyam, R. Operational Compliance Levers, Environmental Performance, and Firm Performance under Cap and Trade Regulation. M&SOM-Manuf. Serv. Oper. Manag. 2012, 14, 186–201. [Google Scholar]

- Li, B. Study on Performance Evaluation of Enterprise Green Manufacturing Based on Fussy Integral. Int. Rev. Comput. Softw. 2012, 7, 773–778. [Google Scholar]

- Ambec, S.; Lanoie, P. Does It Pay to Be Green? A Systematic Overview. Acad. Manag. Perspect. 2008, 22, 45–62. [Google Scholar]

- Li, C.; Liu, F.; Tan, X.; Du, Y. A methodology for selecting a green technology portfolio based on synergy. Int. J. Prod. Res. 2010, 48, 7289–7302. [Google Scholar] [CrossRef]

- Drira, A.; Pierreval, H.; Hajri-Gabouj, S. Facility layout problems: A survey. Annu. Rev. Control. 2007, 31, 255–267. [Google Scholar] [CrossRef]

- Deif, A.M. A system model for green manufacturing. J. Clean. Prod. 2011, 19, 1553–1559. [Google Scholar] [CrossRef]

- Linke, B.; Corman, G.J.; Dornfeld, D.A.; Tonissen, S. Sustainability indicators for discrete manufacturing processes applied to grinding technology. J. Manuf. Syst. 2013, 32, 556–563. [Google Scholar] [CrossRef]

- Woerlen, C. Meta-Evaluation of Climate Mitigation Evaluations; Case Study: Poland’s Heating Sector. Study for the Climate Change Evaluation Community of Practice. Available online: https://www.climate-eval.org/sites/default/files/studies/Meta-Evaluation%20-%20Poland%20Case%20Study.pdf (accessed on 11 September 2016).

- Pons, O.; de al Fluente, A.; Aguado, A. The Use of MIVES as a Sustainability Assessment MCDM Method for Architecture and Civil Engineering Applications. Sustainability 2016, 8, 460. [Google Scholar] [CrossRef] [Green Version]

- Fan, C.; Carrell, J.; Zhang, H.C. An investigation of indicators for measuring sustainable manufacturing. In Proceedings of the International Symposium on Sustainable Systems and Technology, Washington, DC, USA, 19–21 May 2010.

- Feng, S.; Joung, C. An overview of a proposed measurement infrastructure for sustainable manufacturing. In Proceedings of the 7th Global Conference on Sustainable Manufacturing, Madras, India, 2–4 December 2009; pp. 1–6.

- Lerkkasemsan, N.; Achenie, L.E.K. Life Cycle Costs and Life Cycle Assessment for the Harvesting, Conversion, and the Use of Switchgrass to Produce Electricity. Int. J. Chem. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Schau, E.M.; Traverso, M.; Lehmann, A.; Finkbeiner, M. Life Cycle Costing in Sustainability Assessment—A Case Study of Remanufactured Alternators. Sustainability 2011, 3, 2268–2288. [Google Scholar] [CrossRef]

- Sulga, M. Life Cycle Assessment (LCA) Based Environmental Impact Minimization of Solid Fuel Boilers in Lithuanian Industry. Environ. Res. Eng. Manag. 2011, 4, 74–84. [Google Scholar]

- Glavic, P.; Lukman, R. Review of sustainability terms and their definitions. J. Clean. Prod. 2007, 1, 1875–1885. [Google Scholar] [CrossRef]

- De Benedetto, L.; Klemes, J. The Environmental Performance Strategy Map: An integrated LCA approach to support the strategic decision-making process. J. Clean. Prod. 2009, 17, 900–906. [Google Scholar] [CrossRef]

- Brander, M.; Tipper, R.; Hutchison, C.; Davis, G. Consequential and Attributional Approaches to LCA: A Guide to Policy Makers with Specific Reference to Greenhouse Gas LCA of Biofuels; Technical Paper TP-090403-A; Ecometrica Press: Edinburgh, UK, 2009; Available online: http://www.ecometrica.com/assets//approachesto_LCA3_technical.pdf (accessed on 11 September 2016).

- Ekvall, T.; Weidema, B.P. System Boundaries and Input Data in Consequential Life Cycle Inventory Analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Finnveden, G.A.; Hauschild, M.Z.; Ekvall, T.C.; Guine, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a product. J. Clean. Prod. 2004, 13, 687–697. [Google Scholar] [CrossRef]

- Pacca, S. Life-Cycle Assessment (LCA) as a Management Tool: An Emphasis on Electricity Generation, Global Climate Change, and Sustainability. In Handbook of Input-Output Economics in Industrial Ecology. Eco Efficiency Indicator in Industry and Science; Suh, S., Ed.; Springer: Dordrecht, The Netherlands, 2009; Volume 23, pp. 247–261. [Google Scholar]

- Kluczek, A. Assessment of the Eco-Efficiency of Manufacturing Processes Based on MFA-LCA-MFCA Methods. Available online: http://omicron.ch.tuiasi.ro/EEMJ/pdfs/accepted/561_521_Kluczek_14.pdf (accessed on 6 January 2016).

- Westkämper, E.; Alting, A. Life Cycle Management and Assessment: Approaches and Visions towards Sustainable Manufacturing. CIRP Ann. Manuf. Technol. 2000, 49, 501–552. [Google Scholar] [CrossRef]

- Schmidt, W.; Sullivan, J. Weighting in life cycle assessment in a global context. Int. J. Life Cycle Assess. 2002, 7, 5–10. [Google Scholar] [CrossRef]

- Wang, X.; Chan, H.K.; Yee, R.W.Y.; Diaz-Rainey, I. Two-stage fuzzy-AHP model for risk assessment of implementing green initiatives in the fashion supply chain. Int. J. Prod. Econ. 2012, 135, 595–606. [Google Scholar] [CrossRef]

- Vinodh, S.; Shivraman, K.R.; Viswesh, S. AHP-based lean concept selection in a manufacturing organization. J. Manuf. Technol. Manag. 2012, 23, 124–136. [Google Scholar] [CrossRef]

- Hauff, M.; Wilderer, P.A. Industrial ecology: Engineered representation of sustainability. Sustain. Sci. 2008, 3, 103–115. [Google Scholar] [CrossRef]

- Sudarsan, R.; Sriram, R.D.; Narayanan, A.; Sarkar, P.; Lee, J.H.; Lyons, K.W.; Kemmerer, S.J. Sustainable Manufacturing: Metrics, Standards, and Infrastructure. In Proceedings of the 2010 IEEE Conference on Automation Science and Engineering, Toronto, ON, USA, 21–24 August 2010; pp. 144–149.

- Singh, R.K.; Murty, H.R.; Gupta, S.K.; Dikshit, A.K. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- Moldavska, A.; Welo, T. On the Applicability of Sustainability Assessment Tools in Manufacturing. Procedia CIRP 2015, 29, 621–626. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, H.; Sutherland, J. Development of an environmental performance assessment method for manufacturing process plans. Int. J. Adv. Manuf. Technol. 2012, 58, 783–790. [Google Scholar] [CrossRef]

- Lu, T.; Gupta, A.; Jayal, A.D.; Badurdeen, F.; Feng, S.C.; Dillon, O.W.; Jawahir, I.S. A Framework of Product and Process Metrics for Sustainable Manufacturing. In Proceedings of the Eighth International Conference on Sustainable Manufacturing, Abu Dhabi, UAE, 22–24 November 2010.

- Ziout, A.; Azab, A.; Altarazi, S.; Maraghy, W.H. Multi-criteria decision support for sustainability assessment of manufacturing system reuse. CIRP J. Manuf. Sci. Technol. 2013, 6, 59–69. [Google Scholar] [CrossRef]

- Chhipi-Shrestha, G.K.; Hewage, K.; Sadiq, R. “Socializing” sustainability: A critical review on current development status of social life cycle impact assessment method. Clean Technol. Environ. Policy 2015, 17, 579–596. [Google Scholar] [CrossRef]

- Gazi, A.; Skevis, G.; Founti, M.A. Energy efficiency and environmental assessment of a typical marble quarry and processing plant. J. Clean. Prod. 2012, 32, 10–21. [Google Scholar] [CrossRef]

- Tyteca, D.; Carlens, J.; Berkhout, F.; Hertin, J.; Wehrmeyer, W.; Wagner, M. Corporate environmental performance evaluation: Evidence from MEPI Project. Bus. Strategy Environ. 2002, 11, 1–13. [Google Scholar] [CrossRef]

- Kluczek, A. Application of best available techniques in an enterprise producing heating devices. J. Clean. Prod. 2014, 83, 444–453. [Google Scholar] [CrossRef]

- Jolly, D. The issue of weighting in technology portfolio management. Technovation 2003, 23, 383–391. [Google Scholar] [CrossRef]

- Jolly, D. Development of a two-dimensional scale for evaluating technologies in high-tech companies: An empirical examination. J. Eng. Technol. Manag. 2012, 29, 307–329. [Google Scholar] [CrossRef]

- Gladysz, B.; Santarek, K. An assessment of technologies with wide range of impact. A case of RFID. Procedia Manuf. 2015, 3, 1966–1973. [Google Scholar] [CrossRef]

- Zimmermann, H. Fuzzy Sets Theory and Its Applications, 2nd ed.; Kluwer Academic Publishers: Boston, MA, USA, 1991. [Google Scholar]

- Papajorgji, P.; Guimarães, A.M.; Guarracino, M.R. Enterprise Business Modeling, Optimization Techniques, and Flexible Information Systems; IGI Global: Hershey, PA, USA, 2013; pp. 30–41. [Google Scholar]

- Fasangarhi, M.; Roudsari, F.H. The Fuzzy Evaluation of E-Commerce Customer Satisfaction. World Appl. Sci. J. 2008, 4, 164–168. [Google Scholar]

- A Study to Examine the Costs and Benefits of the ELV Directive—Final Report Annexes. Annex 5—Environmental Impacts Analysed and Characterisation Factors. Available online: http://ec.europa.eu/environment/waste/pdf/study/annex5.pdf (accessed on 11 September 2016).

- Rączka, J. The cost-effectiveness analysis—A superior alternative to the cost-benefit analysis of environmental infrastructure investments. In Proceedings of the Fifth European Conference on Evaluation of the Structural Funds “Challenges for Evaluation in an Enlarged Europe”, Budapest, Hungary, 26–27 June 2003.

- Soltani, A.; Sadiq, R.; Hewage, K. Selecting sustainable waste-to-energy technologies for municipal solid waste treatment: A game theory approach for group decision-making. J. Clean. Prod. 2016, 113, 388–399. [Google Scholar] [CrossRef]

- Rogowski, W. Account of Investment Efficiency; Kluwer: Cracow, Poland, 2008. (In Polish) [Google Scholar]

- Kluczek, A. Application of multi-criteria approach for sustainability assessment of manufacturing processes. Manag. Prod. Eng. Rev. 2016, 7, 62–78. [Google Scholar] [CrossRef]

- Pfeiffer, W.; Metze, G.; Scheider, W.; Amler, R. Technologie Portfolio zum Management Strategischer Zukunftschaeftsfelder, 6th ed.; Vanden-hoeck & Ruprecht: Goettingen, Germany, 1991; p. 102. [Google Scholar]

- Anderson, R. Mid-Course Correction: Towards a Sustainable Enterprise: The Interface Model; Chelsea Green Publishing Company: White River Junction, VT, USA, 1998. [Google Scholar]

| External Criterion: Environmental Responsibility | Low Value |  | High Value | ||

| E1. Non-energy efficiency (EE) | Very low | Low | Medium | High | Very high |

| E2. Material intensity | Very weak | Weak | Medium | Strong | Very strong |

| E3. Produced waste consumption/wastes generated and disposed | Very weak | Weak | Medium | Strong | Very strong |

| E4. Terrestrial acidification | Very negative | Negative | Neutral | Positive | Very positive |

| E5. Global Warming Potential (GWP) | Very negative | Negative | Neutral | Positive | Very positive |

| E6. Respiratory effects | Very poor | Poor | Medium | Favorable | Very favorable |

| Internal Criterion: Socioeconomic Opportunity | Lowest Opportunity |  | Highest Opportunity | ||

| SE1. Dynamic generation cost (DGC) | Very low | Low | Medium | High | Very high |

| SE2. Work environment footprint/Health and safety | Very negative | Negative | Neutral | Positive | Very positive |

| SE3. Environmental investment cost (average % of sales) | Very low | Low | Medium | High | Very high |

| SE4. Cost of protection of human health impairment | Very decreasing | Decreasing | Medium | Increasing | Very increasing |

| Linguistic Scale | Very Low (VL) | Low (L) | Medium (M) | High (H) | Very High (VH) |

|---|---|---|---|---|---|

| Triangular fuzzy number (li; mi; ui) | (0; 0; 0.25) | (0; 0.25; 0.5) | (0.25; 0.5; 0.75) | (0.5; 0.75; 1) | (0.75; 1; 1) |

| Existing Manufacturing Processes | T1 | T2 | T3 | T4 | Total | Improved Manufacturing Process | T1 | T2 | T3 | T4 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Input | Input | ||||||||||

| Steel | 150,000 | 0 | 0 | 0 | 150,000 | Steel | 150,000 | 0 | 0 | 0 | 150,000 |

| Sand [kg/year] | 0 | 0 | 258,384 | 0 | 258,384 | Shots [kg/year] | 0 | 0 | 4200 | 0 | 4200 |

| Electricity [kWh/year] | 60,500 | 36,300 | 2,640 * | 1,080 | 100,520 | Electricity [kWh/year] | 26,400 | 89,700 | 2200 * | 47,520 | 165,820 |

| Electricity [MJ/year] | 217,800 | 130,680 | 9504 * | 3888 | 361,872 | Electricity [MJ/year] | 95,040 | 322,920 | 7920 * | 171,072 | 596,952 |

| Fuel [MJ/year] | 0 | 0 | 0 | 0 | 0 | Fuel [MJ/year] | 0 | 0 | 0 | 1,021,200 | 1,021,200 |

| Paints [kg/year] | 0 | 0 | 0 | 2500 | 2500 | Paints [kg/year] | 0 | 0 | 0 | 2500 | 2500 |

| Solvent [kg/year] | 0 | 0 | 0 | 502.00 | 502 | Solvent [kg/year] | 0 | 0 | 0 | 502.00 | 502 |

| Welding wire [kg/year] | 0 | 15,648 | 0 | 0 | 15,648 | Welding wire [kg/year] | 0 | 15,648 | 0 | 0 | 15,648 |

| Output | 0 | Output | 0 | ||||||||

| CO [kg/year] | 0 | 62.6 | 0 | 7.2 | 69.8 | CO [kg/year] | 0 | 62.6 | 0 | 7.2 | 69.8 |

| NO2 [kg/year] | 336 | 7.8 | 0 | 0 | 347 | NO2 [kg/year] | 336 | 7.8 | 0 | 0 | 343.8 |

| Dust [kg/year] | 7.2 | 60.3 | 335 | 0 | 402.5 | Dust [kg/year] | 3.6 | 30.3 | 8.3 | 0 | 42.2 |

| VOC [kg/year] | 0 | 0 | 0 | 1465 | 1465 | VOC [kg/year] | 0 | 0 | 0 | 1465 | 1465 |

| NOx [kg/year] | 0 | 0 | 0 | 54 | 54 | NOx | 0 | 0 | 0 | 54 | 54 |

| Waste | Waste | ||||||||||

| Steel scrap [kg/year] | 12,000 | 0 | 0 | 0 | 12,000 | Steel scrap [kg/year] | 9000 | 0 | 0 | 0 | 9000 |

| Waste paint and varnish [kg/year] | 0 | 0 | 0 | 350 | 350 | Waste paint and varnish [kg/year] | 0 | 0 | 0 | 350 | 350 |

| Welding wastes [kg/year] | 0 | 100 | 0 | 0 | 100 | Welding wastes [kg/year] | 0 | 100 | 0 | 0 | 100 |

| Degreasing wastes [kg/year] | 0 | 0 | 100 | 0 | 100 | Degreasing wastes [kg/year] | 0 | 0 | 100 | 0 | 100 |

| Waste blasting material [kg/year] | 0 | 0 | 258,384 | 0 | 258,384 | Waste blasting material [kg/year] | 0 | 0 | 4200 | 0 | 4200 |

| Reducing Greening (Adverse Impacts) | Neutral—Status Quo (Maintenance) or Mitigating Performance Impacts | Enhancing Sustainability—(Positive Impact) | |

|---|---|---|---|

|  | ||

| Objective (focusing on “attending green” “Attaining Suitability”) | Facilitating parameters of green manufacturing/Guiding assessment criteria (bold) and example actions/opportunities (dot points) for incorporation into company | ||

| Minimization of energy consumption | Large increase in energy use in technologies with no measures | No significant increase in energy use, no change in manufacturing technologies in terms of energy use, minimization of energy consumption in production technologies | Reduction in energy consumption with measures taken to mitigate or reduce |

|

|

| |

| Minimization contribution to greenhouse gas emissions (GHG) | Significant contribution to increased GHG emissions over life of project with no measures taken to mitigate or reduce | No change and/or minimizing project contribution to GHG emissions | Reductions in GHG emissions/changes |

|

|

| |

| Minimization of air emissions | Increase in air emissions and their impacts in local environment | No significant change or ongoing impact due to project and/or minimization of air emissions and impacts on a local scale | Reduction in air emissions and impacts on a local scale |

|

|

| |

| Waste minimization and use of recycled materials; land contamination | No control measures to minimize waste to landfill and/or incorporate recycled or recyclable materials and to the creation of land contamination | Control measures in place to manage waste and/or minimization of waste to landfill | Use of recyclable materials |

|

|

| |

| Minimization of social impacts of processes and production technology infrastructure | No mechanisms to identify the opportunities, health impacts and social risks | Mechanisms to identify and mitigate the accidents potential social risks | Mechanisms to identify and mitigate the accidents and potential social risks, inc., adverse social impacts; significant changes in health and safety issues |

|

|

| |

| Practice of environmental guidelines/standards; maintenance practices including safety concerns waste disposal programs; availability of maintenance support in the form of tools and personnel |

|

|

|

| Increase in economic operational efficiency |

|

|

|

| Criterion: Environmental Responsibility | Major Contributors/Description |

| E1. Non-renewable energy | Total energy consumption [MJ/year]; Energy from different sources is considered: electricity, natural gas. Liquefied petroleum gas (LPG) for transport is included. Energy takes into account the energy demand per functional unit for the processes undergoing comparison. |

| E2. Material intensity | All form of material consumption expressed in kg per material cost in US dollars. In the study, material intensity includes restricted substances, especially important for cleaning or blasting (e.g., solvent, sand). |

| E3. Produced waste | Waste is considered as a useful quantitative indicator for measuring amounts that are finally disposed of at landfill. All wastes from production are both disposed and recycled [kg/year], e.g., waste blasting material. |

| E4. Terrestrial acidification | Acidification is caused by releases of protons in the terrestrial. In this study, the contributors to acidification were NO2, NOx, where acidification potential was calculated in SO2 equivalents based on the appropriate conversion factors between different substances. SO2 equivalence factors is 0.70 kg eq SO2 [68]. Transportation of air emissions has not been included. |

| E5. Global Warming Potential (GWP) | The contributors to global warming were found to be CO2, where GWP is calculated using Equation (3): CO2 = Ʃ (emission factor (kg/m3 × GWP of GHGs)) × fuel (m3)/1000, (3) CO2 equivalent emissions are determined by multiplying the quantity of energy emitted by its GWP emissions relative to its source (for a time horizon of 100 years). Considered over a time span of 100 years, GWP values for these gases (CO2, N2O and CH4) are 1; 310 and 21 respectively [68]. Thus, the propane (LPG) emission factors for the above-mentioned gases emitted to the atmosphere during the combustion of natural gas are 1530; 0.23; 0.03 (kg/m3) respectively. |

| E6. Respiratory effects | Respiratory effects are caused by inorganic substances and CO. However, VOCs are the contributor to human toxicity. In this study, emissions, as the sum of VOC components, CO and dust (silica particles) have resulted in respiratory effects and are measured in kg into air. |

| Criterion: Socioeconomic Opportunity | Major Contributors/Description |

| SE1. Dynamic generation cost (DGC) | DGC shows what is the technical cost of obtaining an environmental effect unit (product), expressed in United States Dollars (USD) per unit of environmental effects. It is a ratio between discounted costs and discounted benefits. It is a dynamic index used widely in German banks and applied in Poland [69]. Additionally, the DGC indicator employs the Net Present Value (NPV) and Life Cycle Costing (LCC) expressed as all costs associated with the life cycle of boilers manufacturing [33]. Based on the data available in Table 7 and Table 8, DGC may be calculated using (4):

|

| SE2. Work environment footprint/Health and safety footprint | Absence from work due to accidents or work conditions; calculated as absence from work per worker in a given year divided by number of employees (90 persons). |

| SE3. Environmental investment cost (average % of sales) [%] | Investment costs describes the necessary monetary investment for new machines, tools or upgrading the existing ones. The investment also does not include the costs for equipment, coolant, and worker training. |

| SE4. Cost of protection of human health [USD/yearly] | Cost of protection of human health is expressed as the cost of avoiding air emissions (CO, NOx, VOC, CO2, dust) and waste disposed in the context of handling emissions within a particular quantity center |

| T1 | T2 | T3 | T4 | |||||

| Environmental Responsibility | Baseline Scenario | Improvement Scenario | Baseline Scenario | Improvement Scenario | Baseline Scenario | Improvement Scenario | Baseline Scenario | Improvement Scenario |

| E1. | 217,800 | 95,040 | 130,680 | 322,920 | 9504 | 7920 | 3888 | 171,072 |

| E2. | 1.17 | 1.17 | 0.07 | 0.07 | 0.82 | 0.52 | 0.03 | 0.03 |

| E3. | 12,000 | 9000 | 100 | 100 | 358,384 | 4300 | 350 | 350 |

| E4 | 235.2 | 235.2 | 5.46 | 5.46 | 0 | 0 | 37.8 | 37.8 |

| E5. | 38,720 | 16,896 | 23,232 | 57,408 | 1690 | 1408 | 691.20 | 30,477.8 * |

| E6. | 7.2 | 3.6 | 122.9 | 92.5 | 335 | 8.3 | 1472.2 | 1472.2 |

| Socioeconomic Opportunity | T1 | T2 | T3 | T4 | ||||

| SE1. | 759.58 | 806.21 | 1304.41 | 1312.72 | 486.29 | 110.51 | 556.66 | 785.87 |

| SE2. | 0.03 | 0.02 | 0.03 | 0.01 | 0.01 | 0 | 0.06 | 0 |

| SE3. | Cannot be determined | 3.7 ** | Cannot be determined | 0.4 ** | Cannot be determined | 1.2 ** | Cannot be determined | 2 ** |

| SE4. | 56.96 | 60.41 | 21.94 | 32.07 | 4.14 | 32.07 | 2779.54 | 2776.86 |

| Manuf. Processes | Implement Green Techniques and Technologies | Current Situation and the Implemention Approaches of Green Manufacturing and Effects |

|---|---|---|

| T1 |

| Current situation: Sheets steel is cut using plasma by a computer controlled system which accurately produces the shapes designed in computer-aided design, computer-aided manufacturing system. Green effects: Workplaces converted from plasma to laser cutting machine with a separate ventilation system (filtering system) will reduce:

|

| T2 |

| Current situation: Cut steel sheets are bent using Computer Numerical Control (CNC) presses. The press is equipped with a laser sensing mechanism to guide the material during the bending process. Green effects: The installation of ventilation systems will reduce:

|

| T3 |

| Current situation: Welding of the boiler bodies with semiautomatic welders using the metal inert gas, metal active gas method (MIG/MAG) shielded with CO2. A SpG3S-wire electrode is used as the welding material. Stations are equipped with jigs and fixtures, and lift points. |

| Green effects: Install a dust-free, shot blasting booth with a closed circuit steel shot system: The shot blast booth will be equipped with an integral filter absorbing dust emissions. | ||

The new shot blasting installations will eliminate:

| ||

| T4 |

| Current situation: The process of applying paint is preceded by thorough cleaning of the boiler bodies: sandblasting, scrubbing, wiping, and sometimes degreasing. The solvent-based paint is applied pneumatically. Pneumatic spray painting uses compressed air, dispersing the coating material. |

| Green effects: Ventilation systems installed in these booths capture up to 1465 kg/year of VOC rich emissions. | ||

| Installation of paint spraying and drying booths requires more electricity (46,440 MJ/year) for paint application from the base scenario (1080 MJ/year). |

| Process/Operational Cost | Electricity | Fuel | Materials | Labor | Waste | Emission | Total Production Cost [KEt] |

|---|---|---|---|---|---|---|---|

| Improvement scenario | |||||||

| T1 | 5016 | 0 | 128,500 | 4687.50 | −2340 | 56.96 | 138,203.50 |

| T2 | 18,747.30 | 8932 | 212,966.40 | 7812.50 | 100 | 21.94 | 248,458.20 |

| T3 | 1672 | 0 | 8106 | 6250 | 15.71 | 4,14 | 16,028.00 |

| T4 | 9028 | 32,000 | 93,962.60 | 6250 | 29 | 2779.54 | 141,240.60 |

| Baseline scenario | |||||||

| T1’ | 11,495 | 0 | 128,500 | 4687.5 | −3120 | 60.41 | 144,682.50 |

| T2’ | 6897 | 8932 | 212,966.4 | 7812.5 | 100 | 32.07 | 236,872.03 |

| T3’ | 6897 | 8932 | 212,966.40 | 7812.50 | 100 | 32.07 | 92,626.6 |

| T4’ | 205.20 | 0 | 93,962.60 | 6250 | 29 | 2776.86 | 106,029.52 |

| Baseline Scenario (a) | Improvement Scenario (b) | ||||

|---|---|---|---|---|---|

| Linguistic Scale | TFN | Linguistic Scale | TFN | ||

| Environmental responsibility | E1 | (M; H, M) | (0.25; 0.75; 0.75) | (M; L; M) | (0.25; 0.75; 0.75) |

| E2 | (H; M; H) | (0.5; 0.5; 1) | (H; H; H) | (0.5; 0.75; 1) | |

| E3 | (M; M; M) | (0.25; 0.5; 0.75) | (M; VH; M) M) | (0.25; 1; 0.75) | |

| E4 | (H; VH; VH) | (0.5; 1; 1) | (H; VH; VH) | (0.5; 1; 1) | |

| E5 | (NL; M; L) | (0; 0.5; 0.5) | (M; H; H) | (0.25; 0.75; 1) | |

| E6 | (L; NL; NL) | (0; 0; 0.25) | (VH; VH; VH) | (0.75; 1; 1) | |

| Socioeconomic opportunity | SE1 | (VH; H; H) | (0.75; 0.75; 1) | (M; H; M) | (0.25; 0.75; 0.75) |

| SE2 | (NL; NL; NL) | (0; 0; 0.25) | (VH; VH; VH) | (0.25; 0.5; 0.75) | |

| SE3 | (L; L; L) | (0; 0.25; 0.5) | (M; H; H) | (0.25; 0.75;1) | |

| SE4 | (H; VH; H) | (0.5; 1; 1) | (M; H; H) | (0.25; 0.75; 1) | |

| Fuzzy mean evaluation (li; mi; ui) | E1–E6 | (0.25; 0.542; 0.708) | (0.417; 0.792; 0.917) | ||

| SE1–SE4 | (0.313; 0.50; 0.688) | (0.25; 0.688; 0.875) | |||

| Crisp value w | (0.510; 0.500) | (0.729; 0.625) | |||

© 2017 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kluczek, A. Quick Green Scan: A Methodology for Improving Green Performance in Terms of Manufacturing Processes. Sustainability 2017, 9, 88. https://doi.org/10.3390/su9010088

Kluczek A. Quick Green Scan: A Methodology for Improving Green Performance in Terms of Manufacturing Processes. Sustainability. 2017; 9(1):88. https://doi.org/10.3390/su9010088

Chicago/Turabian StyleKluczek, Aldona. 2017. "Quick Green Scan: A Methodology for Improving Green Performance in Terms of Manufacturing Processes" Sustainability 9, no. 1: 88. https://doi.org/10.3390/su9010088