Hydrogen Generation from Catalytic Steam Reforming of Acetic Acid by Ni/Attapulgite Catalysts

Abstract

:1. Introduction

2. Results and Discussion

2.1. Catalyst Characterizations

2.1.1. XRD Analysis

2.1.2. N2 Adsorption–Desorption Analysis

2.1.3. TEM Analysis of Reduced Catalysts

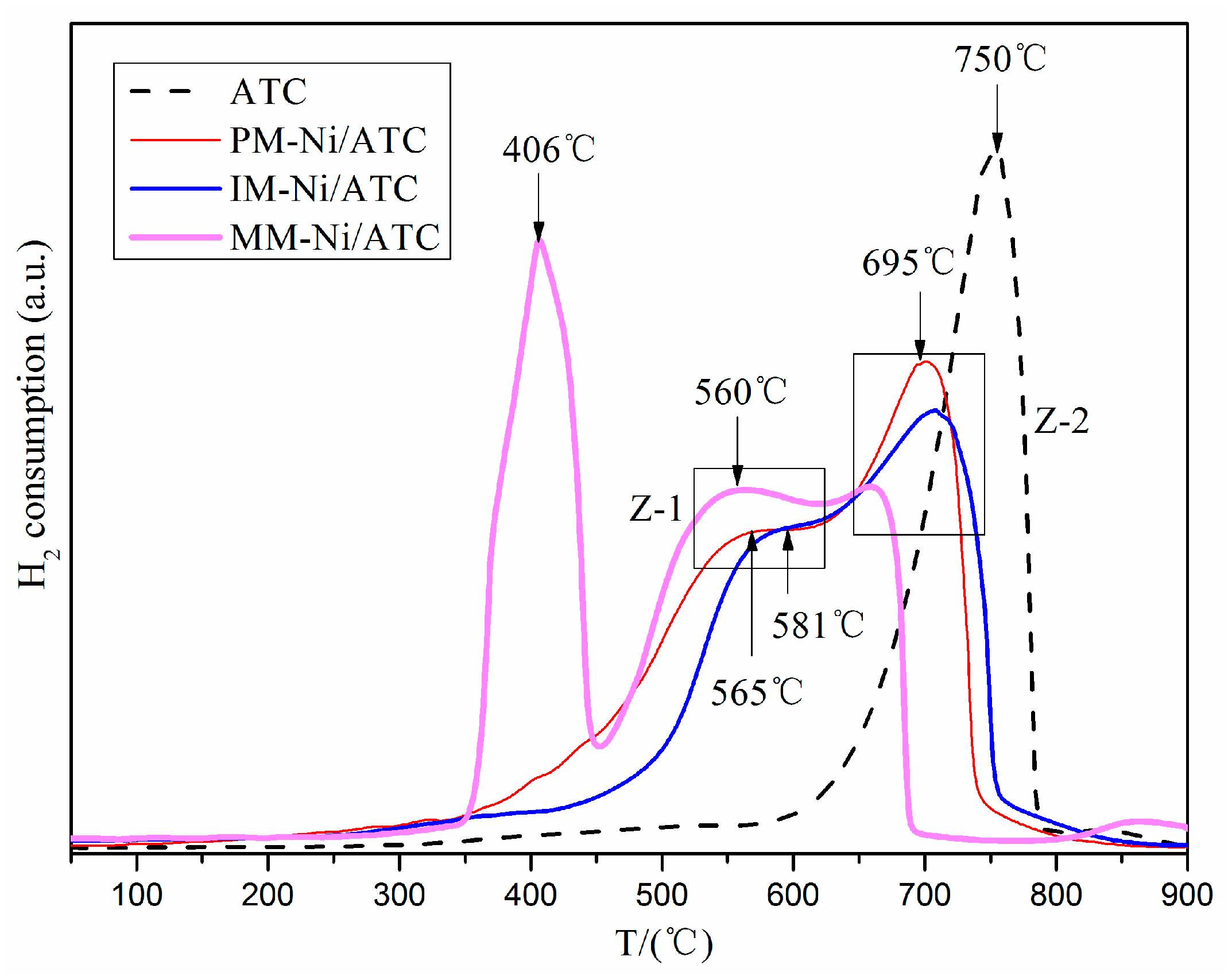

2.1.4. H2-TPR Test of Fresh Catalysts

2.2. Catalytic Performance

2.3. Characterization of Spent Catalysts at 650 °C

2.3.1. Thermogravimetric Analysis of Spent Catalysts

2.3.2. TEM Analysis of Spent Catalysts

3. Experiment Methods

3.1. Preparation of Catalysts

3.2. Characterizations

3.3. Catalytic Performance Test

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Song, C. Global challenges and strategies for control, conversion and utilization of CO2, for sustainable development involving energy, catalysis, adsorption and chemical processing. Catal. Today 2006, 115, 2–32. [Google Scholar] [CrossRef]

- Goltsov, V.A.; Veziroglu, T.N.; Goltsova, L.F. Hydrogen civilization of the future—A new conception of the IAHE. Int. J. Hydrog. Energy 2006, 31, 153–159. [Google Scholar] [CrossRef]

- Centi, G.; Perathoner, S. Opportunities and prospects in the chemical recycling of carbon dioxide to fuels. Catal. Today 2009, 148, 191–205. [Google Scholar] [CrossRef]

- Hosseini, S.E.; Wahid, M.A. Hydrogen Production from Renewable and Sustainable Energy Resources: Promising Green Energy Carrier for Clean Development. Renew. Sustain. Energy Rev. 2015, 57, 850–866. [Google Scholar] [CrossRef]

- Ayalur Chattanathan, S.; Adhikari, S.; Abdoulmoumine, N. A review on current status of hydrogen production from bio-oil. Renew. Sustain. Energy Rev. 2012, 16, 2366–2372. [Google Scholar] [CrossRef]

- Trane, R.; Dahl, S.; Skjøth-Rasmussen, M.S.; Jensen, A.D. Catalytic steam reforming of bio-oil. Int. J. Hydrog. Energy 2012, 37, 6447–6472. [Google Scholar] [CrossRef]

- Chen, T.; Wu, C.; Liu, R. Steam reforming of bio-oil from rice husks fast pyrolysis for hydrogen production. Bioresour. Technol. 2011, 102, 9236–9240. [Google Scholar] [CrossRef] [PubMed]

- Garcia, L.; French, R.; Czernik, S.; Chornet, E. Catalytic steam reforming of bio-oils for the production of hydrogen: Effects of catalyst composition. Appl. Catal. A Gen. 2000, 201, 225–239. [Google Scholar] [CrossRef]

- Galdámez, J.R.; García, L.; Bilbao, R. Hydrogen Production by Steam Reforming of Bio-Oil Using Coprecipitated Ni–Al Catalysts. Acetic Acid as a Model Compound. Energy 2005, 19, 1133–1142. [Google Scholar] [CrossRef]

- Park, H.J.; Heo, H.S.; Jeon, J.K.; Kim, J.; Ryoo, R. Highly valuable chemicals production from catalytic upgrading of radiata pine sawdust-derived pyrolytic vapors over mesoporous MFI zeolites. Appl. Catal. B Environ. 2010, 95, 365–373. [Google Scholar] [CrossRef]

- Nava, R.; Pawelec, B.; Castaño, P.; Alvarez-Galvan, M.C.; Loricera, C.V.; Fierro, J.L.G. Upgrading of bio-liquids on different mesoporous silica-supported CoMo catalysts. Appl. Catal. B Environ. 2009, 92, 154–167. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Wang, S.R.; Liao, Y.F.; Zhou, J.S.; Gu, Y.L.; Cen, K.F. Research on biomass fast pyrolysis for liquid fuel. Biomass Bioenergy 2004, 26, 455–462. [Google Scholar] [CrossRef]

- Resende, K.A.; Ávila-Neto, C.N.; Rabelo-Neto, R.C.; Noronha, F.B.; Hori, C.E. Hydrogen production by reforming of acetic acid using La–Ni type perovskites partially substituted with Sm and Pr. Catal. Today 2015, 242, 71–79. [Google Scholar] [CrossRef]

- Hu, X.; Lu, G.X. Comparative study of alumina-supported transition metal catalysts for hydrogen generation by steam reforming of acetic acid. Appl. Catal. B Environ. 2010, 99, 289–297. [Google Scholar] [CrossRef]

- Goicoechea, S.; Kraleva, E.; Sokolov, S.; Schneider, M.; Pohl, M.M.; Kockmann, N.; Ehrich, H. Support effect on structure and performance of Co and Ni catalysts for steam reforming of acetic acid. Appl. Catal. A Gen. 2016, 514, 182–191. [Google Scholar] [CrossRef]

- Assaf, P.G.M.; Nogueira, F.G.E.; Assaf, E.M. Ni and Co catalysts supported on alumina applied to steam reforming of acetic acid: Representative compound for the aqueous phase of bio-oil derived from biomass. Catal. Today 2013, 213, 2–8. [Google Scholar] [CrossRef]

- Li, Z.K.; Hu, X.; Zhang, L.J.; Liu, S.M.; Lu, G.X. Steam reforming of acetic acid over Ni/ZrO2 catalysts: Effects of nickel loading and particle size on product distribution and coke formation. Appl. Catal. A Gen. 2012, 417, 281–289. [Google Scholar] [CrossRef]

- Vagia, E.C.; Lemonidou, A.A. Investigations on the properties of ceria-zirconia-supported Ni and Rh catalysts and their performance in acetic acid steam reforming. J. Catal. 2010, 269, 388–396. [Google Scholar] [CrossRef]

- Thaicharoensutcharittham, S.; Meeyoo, V.; Kitiyanan, B.; Rangsunvigit, P.; Rirksomboon, T. Hydrogen production by steam reforming of acetic acid over Ni-based catalysts. Catal. Today 2011, 164, 257–261. [Google Scholar] [CrossRef]

- Wang, S.R.; Li, X.B.; Long, G.; Luo, Z.Y. Experimental research on acetic acid steam reforming over Co-Fe catalysts and subsequent density functional theory studies. Int. J. Hydrog. Energy 2012, 37, 11122–11131. [Google Scholar] [CrossRef]

- Hu, X.; Lu, G. Acetic acid steam reforming to hydrogen over Co-Ce/Al2O3 and Co-La/Al2O3 catalysts-The promotion effect of Ce and La addition. Catal. Commun. 2010, 12, 50–53. [Google Scholar] [CrossRef]

- Mohanty, P.; Patel, M.; Pant, K.K. Hydrogen production from steam reforming of acetic acid over Cu-Zn supported calcium aluminate. Bioresour. Technol. 2012, 123, 558–565. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.B.; Wang, N.; Yang, L.; Li, M.; Huang, L.H. Ni-Co bimetallic MgO-based catalysts for hydrogen production via steam reforming of acetic acid from bio-oil. Int. J. Hydrog. Energy 2014, 39, 18688–18694. [Google Scholar] [CrossRef]

- Zhong, X.Y.; Xie, W.; Wang, N.; Duan, Y.P.; Shang, R.S.; Huang, L.H. Dolomite-Derived Ni-Based Catalysts with Fe Modification for Hydrogen Production via Auto-Thermal Reforming of Acetic Acid. Catalysts 2016, 6, 85. [Google Scholar] [CrossRef]

- Basagiannis, A.C.; Verykios, X.E. Reforming reactions of acetic acid on nickel catalysts over a wide temperature range. Appl. Catal. A Gen. 2006, 308, 182–193. [Google Scholar] [CrossRef]

- Esteves, L.M.; Brijaldo, M.H.; Passos, F.B. Decomposition of acetic acid for hydrogen production over Pd/Al2O3 and Pd/TiO2: Influence of metal precursor. J. Mol. Catal. A Chem. 2016, 442, 275–288. [Google Scholar] [CrossRef]

- Brijaldo, M.H.; Rojas, H.A.; Martínez, J.J.; Passos, F.B. Effect of support on acetic acid decomposition over palladium catalysts. J. Catal. 2015, 331, 63–75. [Google Scholar] [CrossRef]

- Takanabe, K.; Aika, K.I.; Seshan, K.; Lefferts, L. Catalyst deactivation during steam reforming of acetic acid over Pt/ZrO2. Chem. Eng. J. 2006, 120, 133–137. [Google Scholar] [CrossRef]

- Takanabe, K.; Aika, K.I.; Inazu, K.; Baba, T.; Seshan, K.; Lefferts, L. Steam reforming of acetic acid as a biomass derived oxygenate: Bifunctional pathway for hydrogen formation over Pt/ZrO2 catalysts. J. Catal. 2006, 243, 263–269. [Google Scholar] [CrossRef]

- Lemonidou, A.A.; Vagia, E.C.; Lercher, J.A. Acetic Acid Reforming over Rh Supported on La2O3/CeO2–ZrO2: Catalytic Performance and Reaction Pathway Analysis. ACS Catal. 2013, 3, 1919–1928. [Google Scholar] [CrossRef]

- Basagiannis, A.C.; Verykios, X.E. Influence of the carrier on steam reforming of acetic acid over Ru-based catalysts. Appl. Catal. B Environ. 2008, 82, 77–88. [Google Scholar] [CrossRef]

- Bimbela, F.; Oliva, M.; Ruiz, J.; Garcıa, L.; Arauzo, J. Hydrogen production by catalytic steam reforming of acetic acid, a model compound of biomass pyrolysis liquids. J. Anal. Appl. Pyrolysis 2007, 79, 112–120. [Google Scholar] [CrossRef]

- Medrano, J.A.; Oliva, M.; Ruiz, J.; Garcıa, L.; Arauzo, J. Catalytic steam reforming of model compounds of biomass pyrolysis liquids in fluidized bed reactor with modified Ni/Al catalysts. J. Anal. Appl. Pyrolysis 2009, 85, 214–225. [Google Scholar] [CrossRef]

- Ma, H.Y.; Zeng, L.; Tian, H.; Li, D.; Wang, X.; Li, X.Y.; Gong, J.L. Efficient hydrogen production from ethanol steam reforming over La-modified ordered mesoporous Ni-based catalysts. Appl. Catal. B Environ. 2016, 181, 321–331. [Google Scholar] [CrossRef]

- Fermoso, J.; Gil, M.V.; Rubiera, F.; Chen, D. Multifunctional Pd/Ni-Co Catalyst for Hydrogen Production by Chemical Looping Coupled With Steam Reforming of Acetic Acid. Chemsuschem 2014, 7, 3063–3077. [Google Scholar] [CrossRef] [PubMed]

- Rossetti, I.; Lasso, J.; Finocchio, E.; Ramis, G.; Nichele, V.; Signoretto, M.; Michele, A.D. TiO2-supported catalysts for the steam reforming of ethanol. Appl. Catal. A Gen. 2014, 477, 42–53. [Google Scholar] [CrossRef]

- Wang, Y.S.; Chen, M.Q.; Liu, S.M.; Yang, Z.L.; Shen, C.P.; Liu, K. Hydrogen production via catalytic steam reforming of bio-oil model compounds over NiO-Fe2O3-loaded palygouskite. J. Fuel Chem. Technol. 2015, 43, 1470–1475. [Google Scholar]

- Dancini-Pontes, I.; Desouza, M.; Silva, F.A.; Scaliante, M.H.N.O.; Alonso, C.G.; Bianchi, G.S.; Neto, A.M.; Pereira, G.M.; Fernandes-Machado, N.R.C. Influence of the CeO2 and Nb2O5 supports and the inert gas in ethanol steam reforming for H2 production. Chem. Eng. J. 2015, 273, 66–74. [Google Scholar] [CrossRef]

- Nichele, V.; Signoretto, M.; Pinna, F.; Menegazzo, F.; Rossetti, I.; Cruciani, G.; Cerrato, G.; Michele, A.D. Ni/ZrO2 catalysts in ethanol steam reforming: Inhibition of coke formation by CaO-doping. Appl. Catal. B Environ. 2014, 150–151, 12–20. [Google Scholar] [CrossRef]

- Haryanto, A.; Fernando, S.; Murali, N.; Adhikari, S. Current Status of Hydrogen Production Techniques by Steam Reforming of Ethanol: A Review. Energy Fuels 2005, 19, 2098–2106. [Google Scholar] [CrossRef]

- Luo, X.; Hong, Y.; Wang, F.C.; Hao, S.Q.; Pang, C.H.; Lester, E.; Wu, T. Development of nano NixMgyO solid solutions with outstanding anti-carbon deposition capability for the steam reforming of methanol. Appl. Catal. B Environ. 2016, 194, 84–97. [Google Scholar] [CrossRef]

- Silva, F.A.D.; Pontes, I.D.; Wurzler, G.T.; Alonso, C.G.; Neto, A.M.; Scaliante, M.H.N.; Souza, M.D.; Fernandes-Machado, N.R.C. Production of hydrogen from bioethanol in Cu-Ni/NbxOy catalysts obtained by different preparation methods. Int. J. Hydrog. Energy 2016, 41, 8111–8119. [Google Scholar] [CrossRef]

- Sun, Z.M.; Bai, C.H.; Zheng, S.L.; Yang, X.P.; Frost, R.L. A comparative study of different porous amorphous silica minerals supported TiO2 catalysts. Appl. Catal. A Gen. 2013, 458, 103–110. [Google Scholar] [CrossRef]

- Fagherazzi, G.; Benedetti, A.; Polizzi, S.; Mario, A.D.; Pinna, F.; Signoretto, M.; Pernicone, N. Structural investigation on the stoichiometry of β-PdHx in Pd/SiO2 catalysts as a function of metal dispersion. Catal. Lett. 1995, 32, 293–303. [Google Scholar] [CrossRef]

- Asencios, Y.J.O.; Rodella, C.B.; Assaf, E.M. Oxidative reforming of model biogas over NiO-Y2O3-ZrO2 catalysts. Appl. Catal. B Environ. 2013, 132–133, 1–12. [Google Scholar] [CrossRef]

- Nogueira, F.G.E.; Assaf, P.G.M.; Carvalho, H.W.P.; Assaf, E.M. Catalytic steam reforming of acetic acid as a model compound of bio-oil. Appl. Catal. B Environ. 2014, 160–161, 188–199. [Google Scholar] [CrossRef]

- Cao, J.L.; Shao, G.S.; Wang, Y.; Liu, Y.P.; Yuan, Z.Y. CuO catalysts supported on attapulgite clay for low-temperature CO oxidation. Catal. Commun. 2008, 9, 2555–2559. [Google Scholar] [CrossRef]

- Yuan, Z.Y.; Ren, T.Z.; Vantomme, A.; Su, B.L. Facile and Generalized Preparation of Hierarchically Mesoporous-Macroporous Binary Metal Oxide Materials. Chem. Mater. 2004, 16, 5096–5106. [Google Scholar] [CrossRef]

- Li, X.Y.; Zhang, D.Y.; Liu, X.Q.; Shi, L.Y.; Sun, L.B. A tandem demetalization-desilication strategy to enhance the porosity of attapulgite for adsorption and catalysis. Chem. Eng. Sci. 2015, 141, 184–194. [Google Scholar] [CrossRef]

- Li, X.Z.; Hu, Z.L.; Zhao, X.B.; Lu, X.W. Ce1−xSmxO2−δ-attapulgite nanocomposites: Synthesis via simple microwave approach and investigation of its catalytic activity. J. Rare Earths 2013, 31, 1157–1162. [Google Scholar] [CrossRef]

- Chary, K.V.R.; Rao, P.V.R.; Vishwanathan, V. Synthesis and high performance of ceria supported nickel catalysts for hydrodechlorination reaction. Catal. Commun. 2006, 7, 974–978. [Google Scholar] [CrossRef]

- Wang, T.; Ma, H.Y.; Zeng, L.; Li, D.; Tian, H.; Xiao, S.N.; Gong, J.L. Highly loaded Ni-based catalysts for low temperature ethanol steam reforming. Nanoscale 2016, 8, 10177–10187. [Google Scholar] [CrossRef] [PubMed]

- Bengaard, H.S.; Nørskov, J.K.; Sehested, J.; Clausen, B.S.; Nielsen, L.P.; Molenbroke, A.M.; Rostrup-Nielsen, J.R. Steam Reforming and Graphite Formation on Ni Catalysts. J. Catal. 2002, 209, 365–384. [Google Scholar] [CrossRef]

- Yang, X.X.; Wang, Y.J.; Wang, Y.H. Significantly Improved Catalytic Performance of Ni-Based MgO Catalyst in Steam Reforming of Phenol by Inducing Mesostructure. Catalysts 2015, 5, 1721–1736. [Google Scholar] [CrossRef]

- Cheng, F.; Dupont, V. Nickel catalyst auto-reduction during steam reforming of bio-oil model compound acetic acid. Int. J. Hydrog. Energy 2013, 38, 15160–15172. [Google Scholar] [CrossRef]

- Zhang, C.X.; Li, S.R.; Wu, G.W.; Gong, J.L. Synthesis of stable Ni-CeO2 catalysts via ball-milling for ethanol steam reforming. Catal. Today 2014, 233, 53–60. [Google Scholar] [CrossRef]

- Vicente, J.; Ereña, J.; Montero, C.; Azkoiti, M.J.; Bibao, J.; Gayubo, A.G. Reaction pathway for ethanol steam reforming on a Ni/SiO2 catalyst including coke formation. Int. J. Hydrog. Energy 2014, 39, 18820–18834. [Google Scholar] [CrossRef]

- Calles, J.A.; Carrero, A.; Vizcaíno, A.J.; García-Moreno, L. Hydrogen production by glycerol steam reforming over SBA-15-supported nickel catalysts: Effect of alkaline earth promoters on activity and stability. Catal. Today 2014, 227, 198–206. [Google Scholar] [CrossRef]

- Li, S.D.; Ji, G.B.; Huang, Z.G.; Zhang, F.M.; Du, Y.W. Synthesis of chaoite-like macrotubes at low temperature and ambient pressure. Carbon 2007, 45, 2946–2950. [Google Scholar] [CrossRef]

- Xu, Q.L.; Lan, P.; Zhang, B.Z.; Ren, Z.Z.; Yan, Y.J. Hydrogen Production via Catalytic Steam Reforming of Fast Pyrolysis Bio-oil in a Fluidized-Bed Reactor. Energy Fuels 2010, 24, 6456–6462. [Google Scholar] [CrossRef]

- Pimenidou, P.; Rickett, G.; Dupont, V.; Twigg, M.V. Chemical looping reforming of waste cooking oil in packed bed reactor. Bioresour. Technol. 2010, 101, 6389–6397. [Google Scholar] [CrossRef] [PubMed]

| Catalysts | dNi a (nm) | Sbet (m2/g) | Vpore b (cm3/g) | Dpore b (nm) | Dm (%) |

|---|---|---|---|---|---|

| ATC (Attapulgite Clay) | - | 40.6 | 0.10 | 10.5 | - |

| (precipitation method) PM-Ni/ATC | 13.5 | 65.2 | 0.12 | 8.9 | 7.5 |

| (impregnation method) IM-Ni/ATC | 20.2 | 65.3 | 0.12 | 9.1 | 5.0 |

| MM-Ni/ATC | 37.0 | 68.9 | 0.15 | 9.9 | 2.7 |

| Catalysts | XAA (%) | (%) | Selectivity (%) | |||

|---|---|---|---|---|---|---|

| CO | CO2 | CH4 | ||||

| 550 °C | PM-Ni/ATC | 61.8 | 54.5 | 44.8 | 48.0 | 7.2 |

| IM-Ni/ATC | 59.6 | 43.3 | 50.8 | 39.1 | 10.1 | |

| MM-Ni/ATC | 59.0 | 53.3 | 54.1 | 33.9 | 12.0 | |

| 650 °C | PM-Ni/ATC | 75.0 | 67.8 | 42.4 | 41.7 | 15.8 |

| IM-Ni/ATC | 86.5 | 70.9 | 36.1 | 39.1 | 24.8 | |

| MM-Ni/ATC | 76.5 | 65.4 | 40.0 | 41.9 | 18.1 | |

| Status | PM-Ni/ATC | IM-Ni/ATC | MM-Ni/ATC |

|---|---|---|---|

| Reduced | 13.0 | 17.3 | 34.7 |

| Spent | 23.8 | 32.3 | 83.1 |

| Samples | SiO2 | Al2O3 | CaO | MgO | K2O | NiO | Fe2O3 | TiO2 |

|---|---|---|---|---|---|---|---|---|

| ATC | 41.6 | 5.8 | 26.6 | 19.4 | 1.9 | / | 4.0 | 0.7 |

| PM-Ni/ATC | 55.7 | 8.7 | 3.3 | 6.4 | 2.4 | 18.8 | 4.1 | 0.6 |

| IM-Ni/ATC | 51.3 | 4.3 | 9.5 | 13.0 | 0.7 | 17.5 | 3.2 | 0.4 |

| MM-Ni/ATC | 50.6 | 6.1 | 9.5 | 11.3 | 0.8 | 16.9 | 4.1 | 0.6 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Chen, M.; Liang, T.; Yang, Z.; Yang, J.; Liu, S. Hydrogen Generation from Catalytic Steam Reforming of Acetic Acid by Ni/Attapulgite Catalysts. Catalysts 2016, 6, 172. https://doi.org/10.3390/catal6110172

Wang Y, Chen M, Liang T, Yang Z, Yang J, Liu S. Hydrogen Generation from Catalytic Steam Reforming of Acetic Acid by Ni/Attapulgite Catalysts. Catalysts. 2016; 6(11):172. https://doi.org/10.3390/catal6110172

Chicago/Turabian StyleWang, Yishuang, Mingqiang Chen, Tian Liang, Zhonglian Yang, Jie Yang, and Shaomin Liu. 2016. "Hydrogen Generation from Catalytic Steam Reforming of Acetic Acid by Ni/Attapulgite Catalysts" Catalysts 6, no. 11: 172. https://doi.org/10.3390/catal6110172

APA StyleWang, Y., Chen, M., Liang, T., Yang, Z., Yang, J., & Liu, S. (2016). Hydrogen Generation from Catalytic Steam Reforming of Acetic Acid by Ni/Attapulgite Catalysts. Catalysts, 6(11), 172. https://doi.org/10.3390/catal6110172