Sustainable Route for Synthesis of All-Silica SOD Zeolite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis

2.3. Characterization

3. Results and Discussion

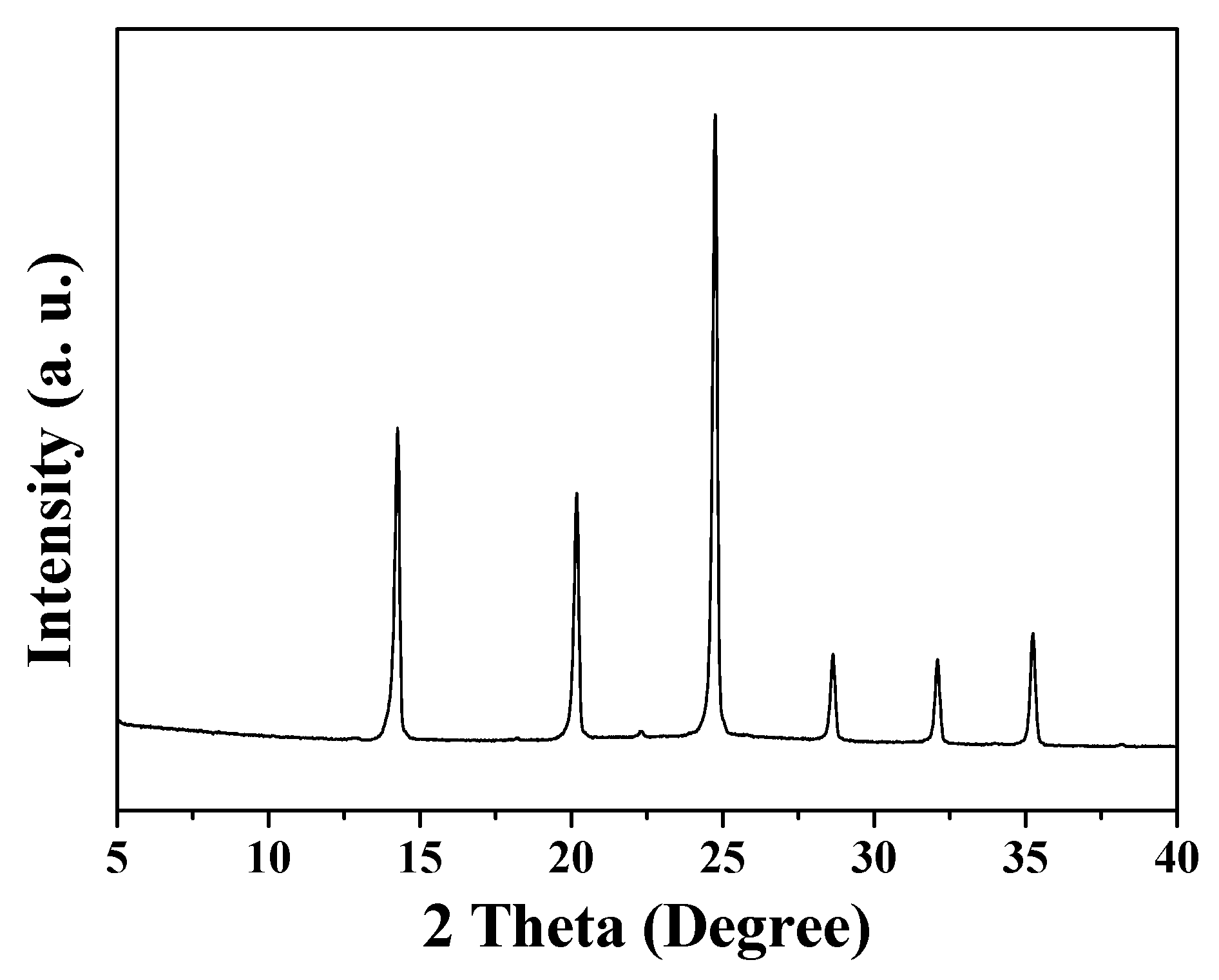

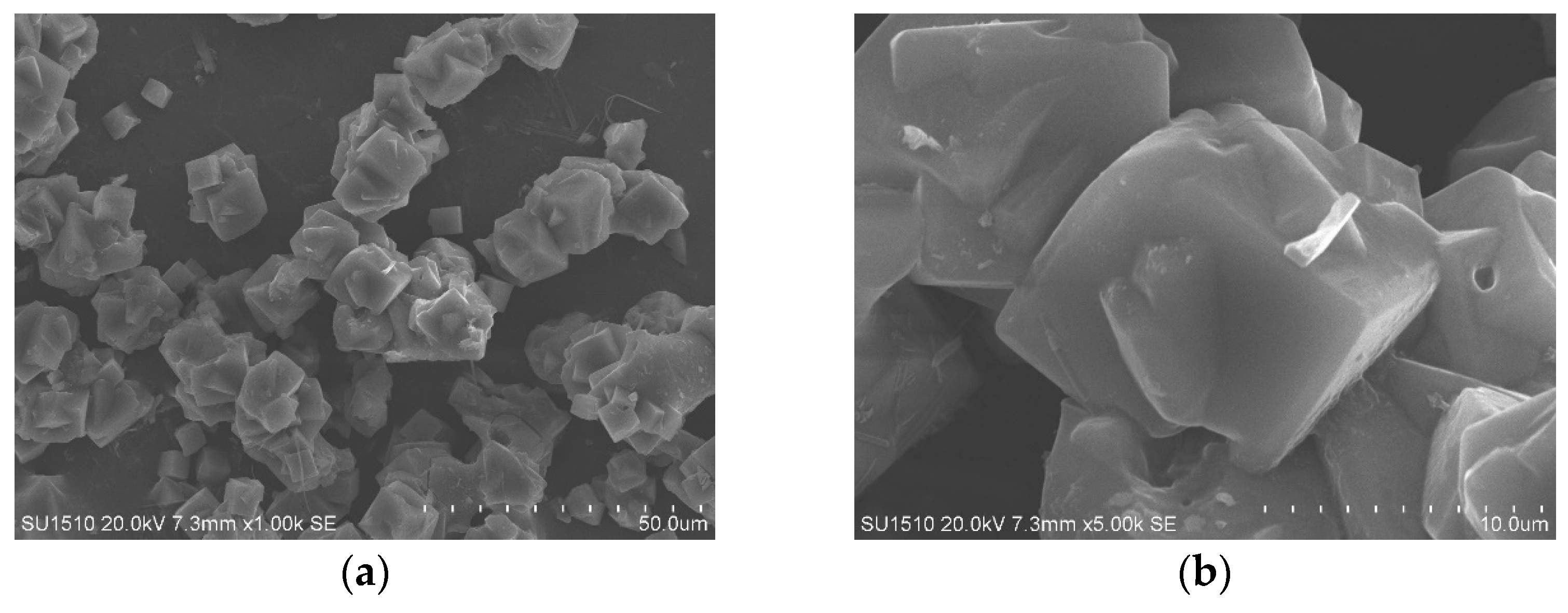

3.1. Synthesis and Characterization of S–Si–SOD Zeolite

3.2. Critical Factors for Synthesizing S–Si–SOD Zeolite

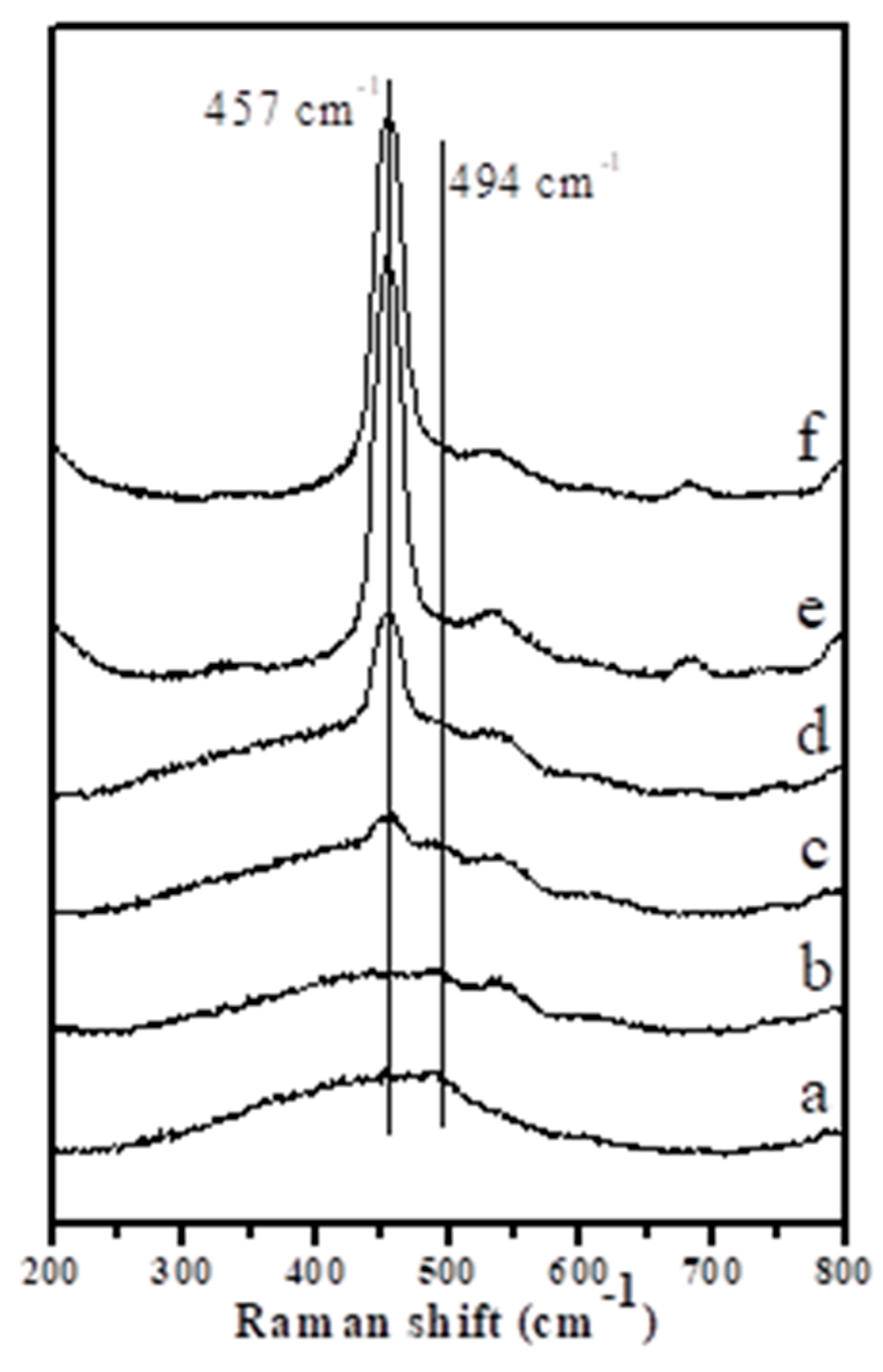

3.3. Crystallization Process of S–Si–SOD Zeolite

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, Q.M.; Meng, X.J.; Gao, X.H.; Xiao, F.-S. Solvent-free synthesis of zeolites: Mechanism and utility. Acc. Chem. Res. 2018, 51, 1396–1403. [Google Scholar] [CrossRef] [PubMed]

- Li, S.Y.; Li, J.F.; Dong, M.; Fan, W.B.; Zhao, T.S.; Wang, J.G.; Fan, W.B. Strategies to control zeolite particle morphology. Chem. Soc. Rev. 2019, 48, 885–907. [Google Scholar] [CrossRef] [PubMed]

- Davis, M.E.; Lobo, R.F. Zeolite and molecular sieve synthesis. Chem. Mater. 1992, 4, 756–768. [Google Scholar] [CrossRef]

- Corma, A. Inorganic solid acids and their use in acid-catalyzed hydrocarbon reactions. Chem. Rev. 1995, 95, 559–614. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, F.F.; Pan, D.H.; Ma, J.H. A hierarchically micro-meso-macroporous zeolite CaA for methanol conversion to dimethyl ether. Crystals 2016, 6, 155. [Google Scholar] [CrossRef]

- Cui, Y.C.; Yan, Z.; Li, M.L.; Zhu, J.; Zhu, L.F.; Yao, H.; Cao, X.B. Solvent-free synthesis of all-silica Beta zeolite in the presence of tetraethylammonium bromide. Crystals 2018, 8, 73. [Google Scholar]

- Wu, Q.M.; Hong, X.; Zhu, L.F.; Meng, X.J.; Han, S.H.; Zhang, J.; Liu, X.L.; Jin, C.H.; Xiao, F.S. Generalized ionothermal synthesis of silica-based zeolites. Microporous Mesoporous Mater. 2019, 286, 163–168. [Google Scholar] [CrossRef]

- Vattipalli, V.; Paracha, A.M.; Hu, W.G.; Chen, H.Y.; Fan, W. Broadening the scope for fluoride-free synthesis of siliceous zeolites. Angew. Chem. Int. Ed. 2018, 57, 3607–3611. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.L.; Luo, Q. Solid state NMR spectroscopy studies of the nature of structure direction of OSDAs in pure-silica zeolites ZSM-5 and Beta. J. Phy. Chem. C 2017, 121, 13211–13217. [Google Scholar] [CrossRef]

- Zhu, Z.G.; Xu, H.; Jiang, J.G.; Wu, H.H.; Wu, P. Hydrophobic nanosized all-silica Beta zeolite: Efficient synthesis and adsorption application. ACS Appl. Mater. Interfaces 2017, 9, 27273–27283. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Jiang, Y.W.; Chen, B.B.; Shi, C.; Li, Y.B.; Wang, C.Y.; Han, S.C.; Pan, S.X.; Wang, L.; Meng, X.J.; et al. Exceptional activity for formaldehyde combustion using siliceous Beta zeolite as a catalyst support. Catal. Today 2019. [Google Scholar] [CrossRef]

- Liu, Y.T.; Tian, T. Fabrication of diatomite/silicalite-1 composites and their property for VOCs adsorption. Materials 2019, 12, 551. [Google Scholar] [CrossRef] [PubMed]

- Lew, C.M.; Li, Z.J.; Li, S.; Hwang, S.J.; Liu, Y.; Medina, D.I.; Sun, M.W.; Wang, J.L.; Davis, M.E.; Yan, Y.S. Pure-silica-zeolite MFI and MEL low-dielectric-constant films with fluoro-organic-functionalization. Adv. Funct. Mater. 2008, 18, 3454–3460. [Google Scholar] [CrossRef]

- Bibby, D.M.; Dale, M.P. Synthesis of silica-sodalite from non-aqueous systems. Nature 1985, 317, 157–158. [Google Scholar] [CrossRef]

- Yang, X.B.; Albrecht, D.; Caro, J. Solvothermal synthesis and silica-sodalite: Effects of water, germanium and fluoride. Microporous Mesoporous Mater. 2007, 100, 95–102. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Cui, M.; Zhang, Y.F.; Zheng, J.Q.; Lv, T.M.; Gao, W.Y.; Liu, X.Y.; Meng, C.G. Study on the synthesis of FER and SOD in the presence of ethylene glycol and the oxidation transformation of ethylene glycol in a confined region of zeolites. J. Alloys Compd. 2017, 244, 158–163. [Google Scholar] [CrossRef]

- Werthmann, U.; Marler, B.; Gies, H. Pyrrolidine silica sodalite and ethylamine sodalite-two new silica sodalite materials synthesized from different solid silica sources. Microporous Mesoporous Mater. 2000, 39, 549–562. [Google Scholar] [CrossRef]

- Morris, R.E.; James, S.L. Solventless synthesis of zeolites. Angew. Chem. Int. Ed. 2013, 52, 2163–2165. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.M.; Wang, X.; Qi, G.D.; Guo, Q.; Pan, S.X.; Meng, X.J.; Xu, J.; Deng, F.; Fan, F.T.; Feng, Z.C.; et al. Sustainable synthesis of zeolites without addition of both organotemplates and solvents. J. Am. Chem. Soc. 2014, 136, 4019–4025. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.F.; Zhang, J.; Wang, L.; Wu, Q.M.; Bian, C.Q.; Pan, S.X.; Meng, X.J.; Xiao, F.S. Solvent-free synthesis of titanosilicate zeolites. J. Mater. Chem. A 2015, 3, 14093–14095. [Google Scholar] [CrossRef]

- Yu, X.; Zhou, C.H.; Chen, X.Q.; Gao, P.; Qiu, M.H.; Xue, W.J.; Yang, C.G.; Zhao, H.Q.; Liu, H.J.; Liu, Z.Y.; et al. Facile solvent-free synthesis of hollow fiber catalyst assembled by c-axis oriented ZSM-5 crystals. ChemCatChem 2018, 10, 5619–5626. [Google Scholar] [CrossRef]

- Gao, W.Z.; Amoo, C.C.; Zhang, G.H.; Javed, M.; Mazonde, B.; Lu, C.X.; Yang, R.Q.; Xing, C.; Tsubaki, N. Insight into solvent-free synthesis of MOR zeolite and its laboratory scale production. Microporous Mesoporous Mater. 2019, 280, 187–194. [Google Scholar] [CrossRef]

| Run | Na2O/SiO2 | EG/SiO2 | Temperature (°C) | Time (h) | Products a |

|---|---|---|---|---|---|

| 1 | 0.01 | 1.5 | 200 | 24 | Amor |

| 2 | 0.04 | 1.5 | 200 | 24 | SOD + Amor |

| 3 | 0.06 | 1.5 | 200 | 24 | SOD |

| 4 | 0.11 | 1.5 | 200 | 24 | SOD + Amor |

| 5 | 0.06 | 0 | 200 | 24 | Q + Amor |

| 6 | 0.06 | 1.0 | 200 | 24 | SOD + Amor |

| 7 | 0.06 | 1.5 | 160 | 24 | Amor |

| 8 | 0.06 | 1.5 | 230 | 12 | SOD |

| 9 b | 0.06 | 1.5 | 200 | 3 | SOD |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhai, H.; Bian, C.; Yu, Y.; Zhu, L.; Guo, L.; Wang, X.; Yu, Q.; Zhu, J.; Cao, X. Sustainable Route for Synthesis of All-Silica SOD Zeolite. Crystals 2019, 9, 338. https://doi.org/10.3390/cryst9070338

Zhai H, Bian C, Yu Y, Zhu L, Guo L, Wang X, Yu Q, Zhu J, Cao X. Sustainable Route for Synthesis of All-Silica SOD Zeolite. Crystals. 2019; 9(7):338. https://doi.org/10.3390/cryst9070338

Chicago/Turabian StyleZhai, Hangling, Chaoqun Bian, Yuxia Yu, Longfeng Zhu, Lingfeng Guo, Xiao Wang, Qinqin Yu, Jie Zhu, and Xuebo Cao. 2019. "Sustainable Route for Synthesis of All-Silica SOD Zeolite" Crystals 9, no. 7: 338. https://doi.org/10.3390/cryst9070338