Direct Micromachining of Microfluidic Channels on Biodegradable Materials Using Laser Ablation

Abstract

:1. Introduction

2. Materials and Methods

2.1. PGS Synthesis

2.2. APS Synthesis

2.3. PDMS Synthesisar

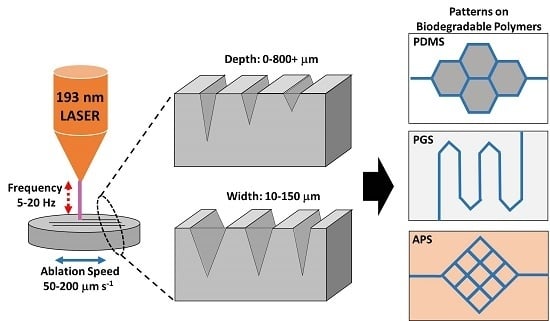

2.4. Laser Ablation System

2.5. Surface Topography Measurement

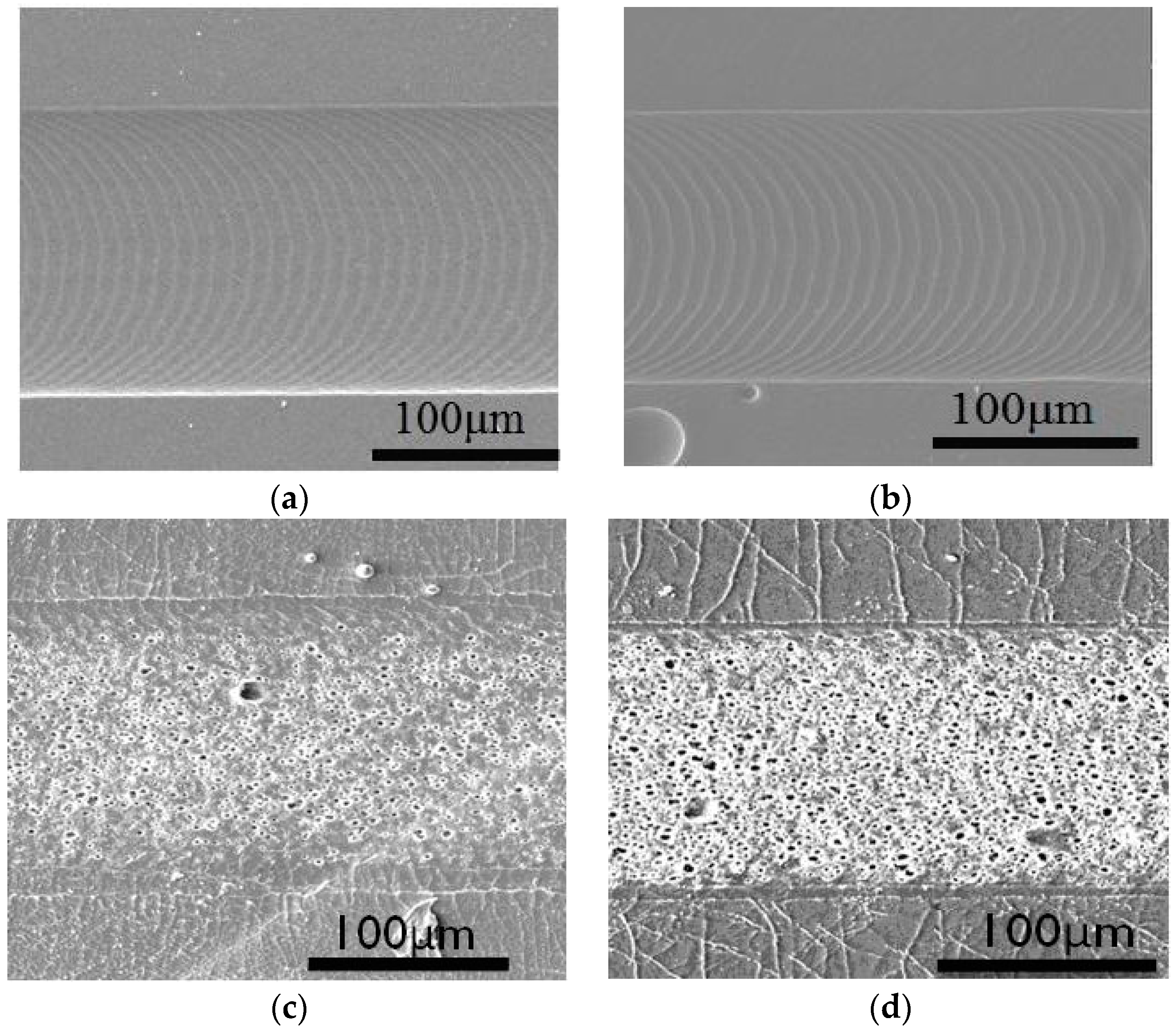

2.6. Field Emission Scanning Electron Microscope (FE-SEM) Image

2.7. Fabrication of Microfluidic Device

2.8. Hydrodynamics Simulation of Micropatterns

3. Results and Discussions

3.1. Influence of Laser Fluence toward Polymer Patterning

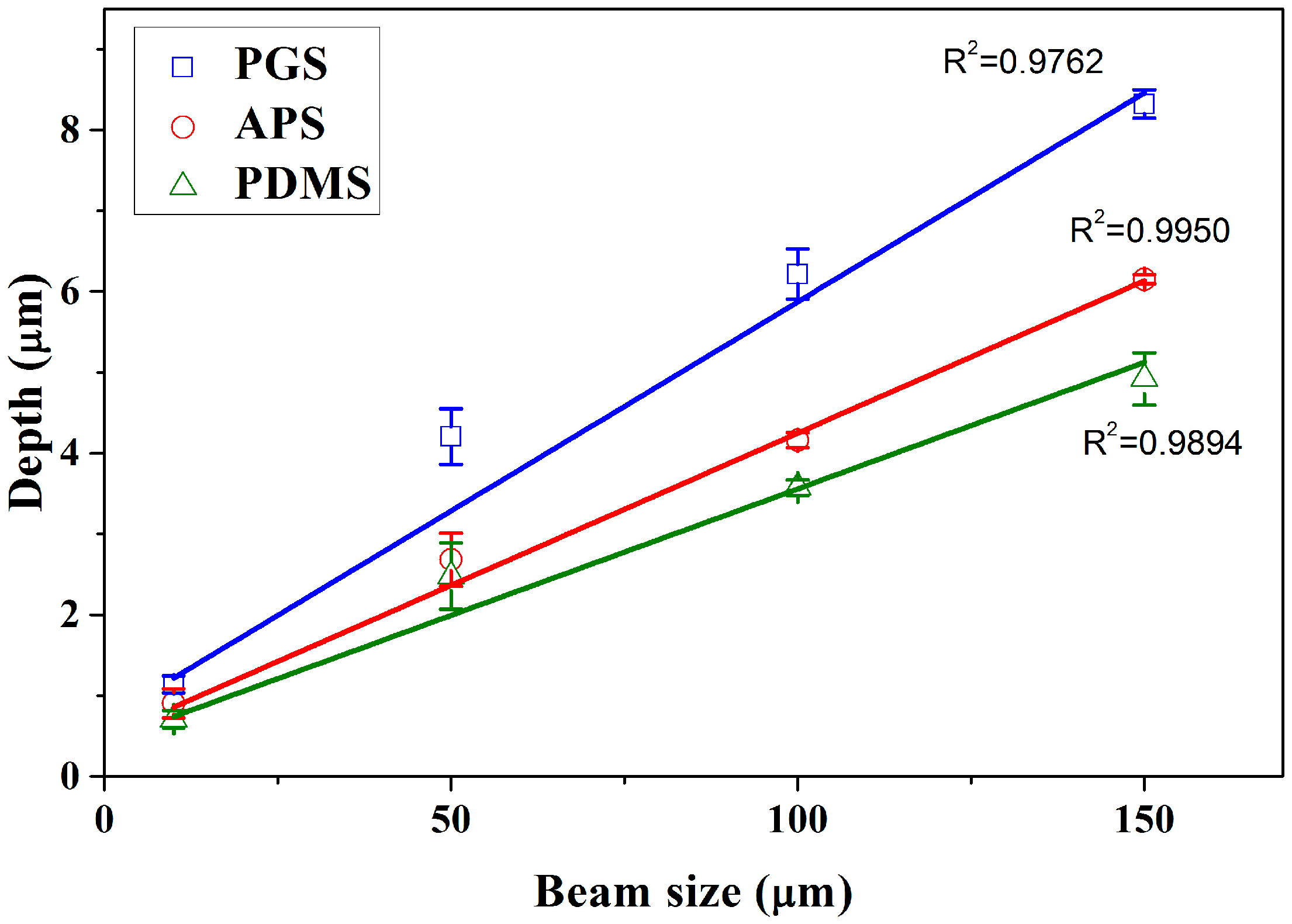

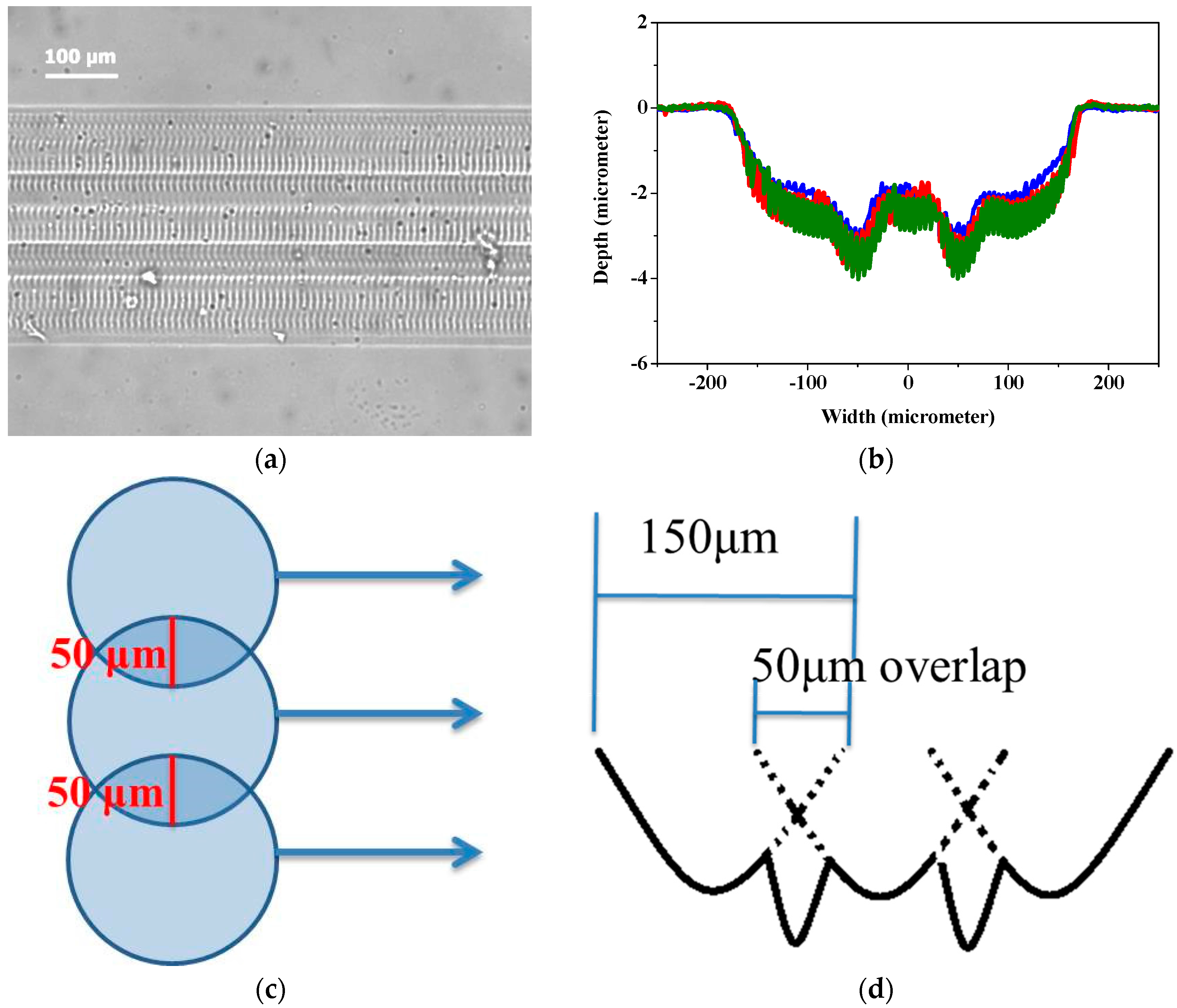

3.2. Control of Channel Widths and Depths

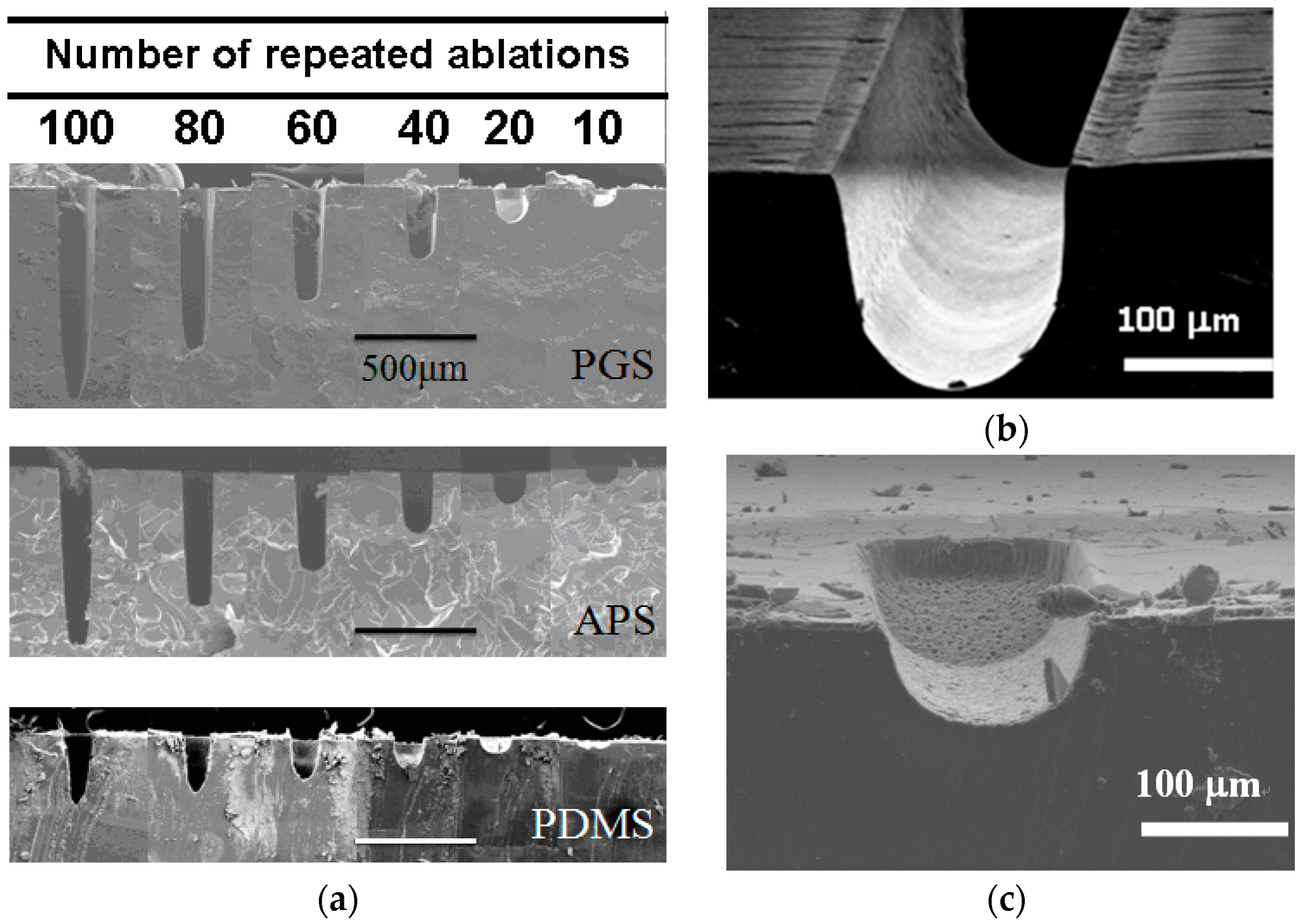

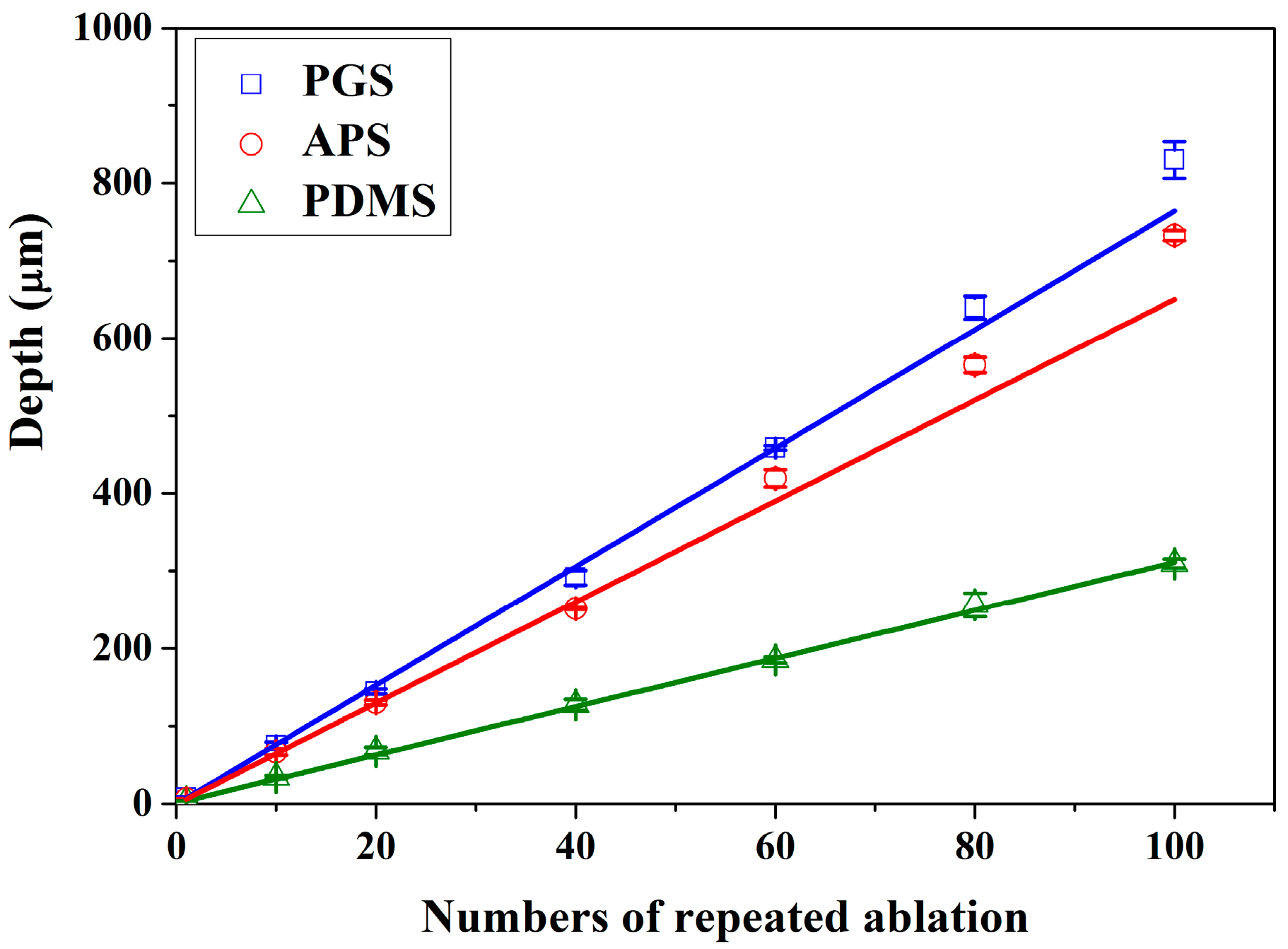

3.3. Repeated Ablation to Vary Channel Depth

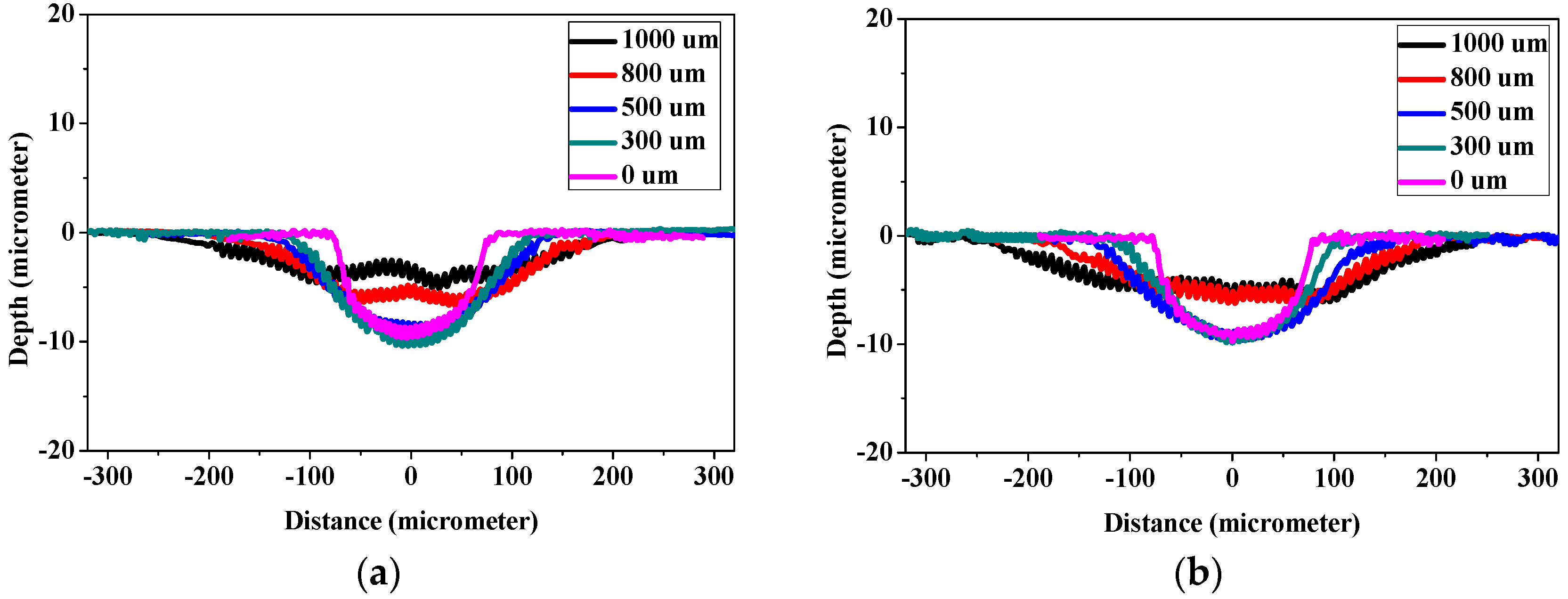

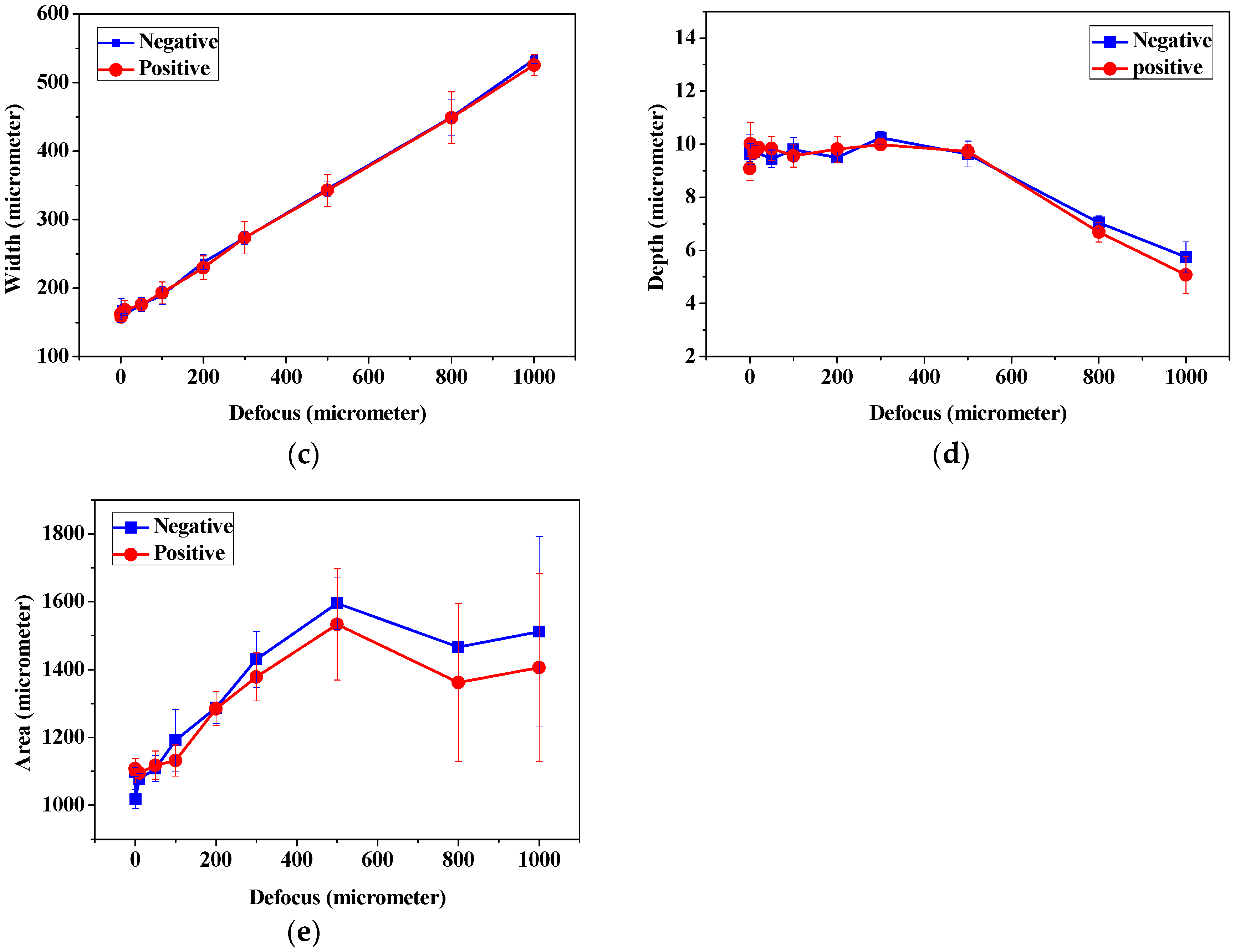

3.4. The Relation between Defocus Distance and Ablation Efficiency

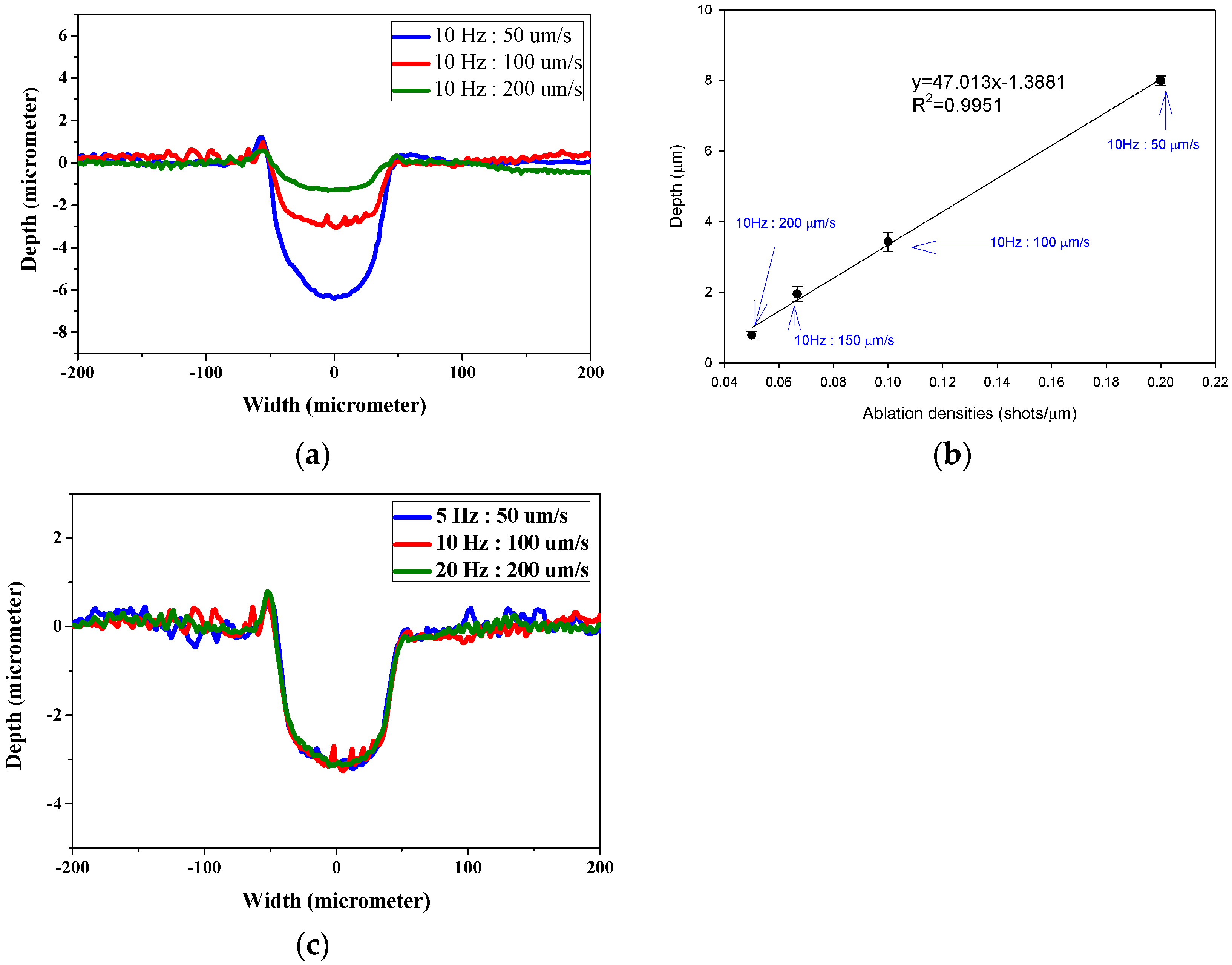

3.5. The Influence of Laser Firing Frequency and Ablation Progression Speed to Channel Depth

3.6. Hydrodynamic Simulation of Laser Patterned Channels

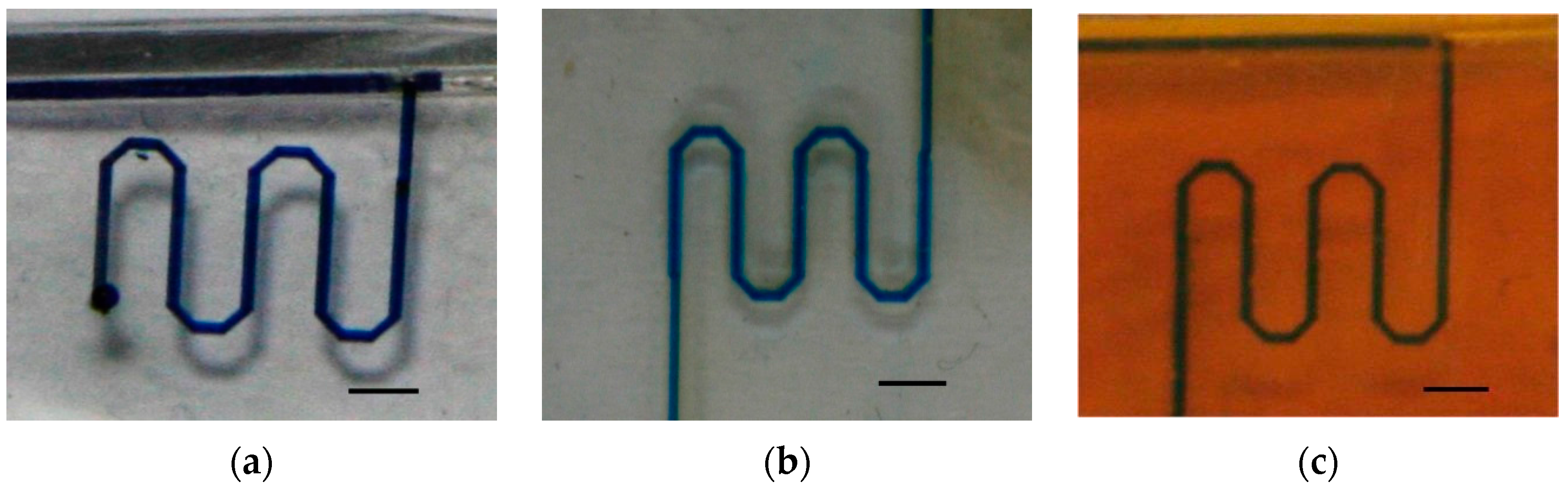

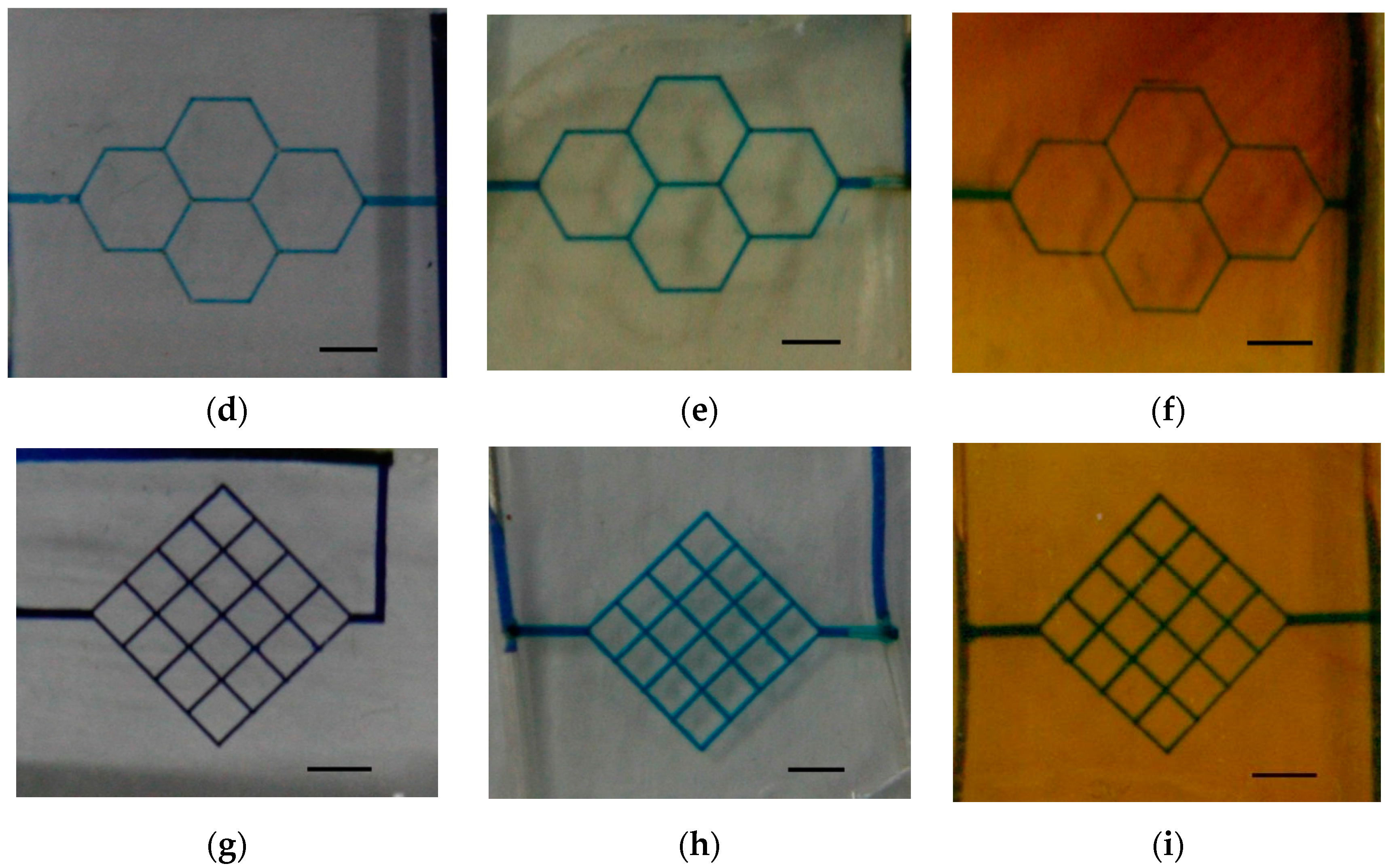

3.7. The Fabrication of Simple Microfluidic Systems via Laser Ablation

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bong-Hwan, K.; Jong-Bok, K. Fabrication of a high aspect ratio thick silicon wafer mold and electroplating using flipchip bonding for mems applications. J. Micromech. Microeng. 2009, 19, 065024. [Google Scholar]

- Marasso, S.L.; Canavese, G.; Cocuzza, M. Cost efficient master fabrication process on copper substrates. Microelectron. Eng. 2011, 88, 2322–2324. [Google Scholar] [CrossRef]

- Ho, C.-H.; Chin, K.-P.; Yang, C.-R.; Wu, H.-M.; Chen, S.-L. Ultrathick su-8 mold formation and removal, and its application to the fabrication of liga-like micromotors with embedded roots. Sens. Actuators A Phys. 2002, 102, 130–138. [Google Scholar] [CrossRef]

- Chang, H.-K.; Kim, Y.-K. Uv-liga process for high aspect ratio structure using stress barrier and c-shaped etch hole. Sens. Actuators A Phys. 2000, 84, 342–350. [Google Scholar] [CrossRef]

- Xia, Y.; Whitesides, G.M. Soft lithography. Angew. Chem. Int. Ed. 1998, 37, 550–575. [Google Scholar] [CrossRef]

- Xia, Y.; Kim, E.; Zhao, X.-M.; Rogers, J.; Prentiss, M.; Whitesides, G. Complex optical surfaces formed by replica molding against elastomeric masters. Science 1996, 273, 347–349. [Google Scholar] [CrossRef] [PubMed]

- Fidkowski, C.; Kaazempur-Mofrad, M.R.; Borenstein, J.; Vacanti, J.P.; Langer, R.; Wang, Y. Endothelialized microvasculature based on a biodegradable elastomer. Tissue Eng. 2005, 11, 302–309. [Google Scholar] [CrossRef] [PubMed]

- Bettinger, C.J.; Weinberg, E.J.; Kulig, K.M.; Vacanti, J.P.; Wang, Y.; Borenstein, J.T.; Langer, R. Three-dimensional microfluidic tissue-engineering scaffolds using a flexible biodegradable polymer. Adv. Mater. 2005, 18, 165–169. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Bettinger, C.J.; Langer, R.S.; Borenstein, J.T. Biodegradable microfluidic scaffolds for tissue engineering from amino alcohol-based poly(ester amide) elastomers. Organogenesis 2010, 6, 212–216. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Zhou, L.; Wang, X.; Li, X.; Zeng, X. Micropen direct-write deposition of polyimide. Microelectron. Eng. 2009, 86, 1989–1993. [Google Scholar] [CrossRef]

- King, K.R.; Wang, C.C.J.; Kaazempur-Mofrad, M.R.; Vacanti, J.P.; Borenstein, J.T. Biodegradable microfluidics. Adv. Mater. 2004, 16, 2007–2012. [Google Scholar] [CrossRef]

- Brayfield, C.A.; Marra, K.G.; Leonard, J.P.; Tracy Cui, X.; Gerlach, J.C. Excimer laser channel creation in polyethersulfone hollow fibers for compartmentalized in vitro neuronal cell culture scaffolds. Acta Biomater. 2008, 4, 244–255. [Google Scholar] [CrossRef] [PubMed]

- Holmes, A.S.; Saidam, S.M. Sacrificial layer process with laser-driven release for batch assembly operations. J. Microelectromech. Syst. 1998, 7, 416–422. [Google Scholar] [CrossRef]

- Ke, K.; Hasselbrink, E.F.; Hunt, A.J. Rapidly prototyped three-dimensional nanofluidic channel networks in glass substrates. Anal. Chem. 2005, 77, 5083–5088. [Google Scholar] [CrossRef] [PubMed]

- Costa, L.; Terekhov, A.; Rajput, D.; Hofmeister, W.; Jowhar, D.; Wright, G.; Janetopoulos, C. Femtosecond laser machined microfluidic devices for imaging of cells during chemotaxis. J. Laser Appl. 2011, 23, 1.3614405. [Google Scholar] [CrossRef] [PubMed]

- Arutinov, G.; Mastrangeli, M.; Smits, E.C.P.; van Heck, G.; den Toonder, J.M.J.; Dietzel, A. Foil-to-foil system integration through capillary self-alignment directed by laser patterning. J. Microelectromech. Syst. 2015, 24, 126–133. [Google Scholar] [CrossRef]

- Gari, A.; Edsger, C.P.S.; Massimo, M.; Arutinov, G.; Smits, E.C.P.; Mastrangeli, M.; van Heck, G.; van den Brand, J.; Schoo, H.F.M.; Dietzel, A. Capillary self-alignment of mesoscopic foil components for sensor-systems-in-foil. J. Micromech. Microeng. 2012, 22, 115022. [Google Scholar]

- Römer, G.R.B.E.; Cerro, D.A.D.; Pohl, R.; Chang, B.; Liimatainen, V.; Zhou, Q.; Veld, A.J.H.I. Picosecond laser machining of metallic and polymer substrates for fluidic driven self-alignment. Phys. Procedia 2012, 39, 628–635. [Google Scholar] [CrossRef]

- Schmid, M.; Wegener, K. Additive manufacturing: Polymers applicable for laser sintering (ls). Procedia Eng. 2016, 149, 457–464. [Google Scholar] [CrossRef]

- Lippert, T. Laser application of polymers. In Polymers and Light; Lippert, T.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2004; Volume 168, pp. 51–246. [Google Scholar]

- Dutta Majumdar, J.; Manna, I. Laser processing of materials. Sadhana 2003, 28, 495–562. [Google Scholar] [CrossRef]

- Jansen, E.D.; Frenz, M.; Kadipasaoglu, K.A.; Pfefer, T.J.; Altermatt, H.J.; Motamedi, M.; Welch, A.J. Laser–tissue interaction during transmyocardial laser revascularization. Ann. Thorac. Surg. 1997, 63, 640–647. [Google Scholar] [CrossRef]

- Mangirdas, M.; Holger, G.; Albertas, Ž.; Vytautas, P.; Domas, P.; Roaldas, G. A femtosecond laser-induced two-photon photopolymerization technique for structuring microlenses. J. Opt. 2010, 12, 035204. [Google Scholar]

- Samant, A.N.; Dahotre, N.B. Laser machining of structural ceramics—A review. J. Eur. Ceram. Soc. 2009, 29, 969–993. [Google Scholar] [CrossRef]

- Miller, P.; Aggarwal, R.; Doraiswamy, A.; Lin, Y.; Lee, Y.-S.; Narayan, R. Laser micromachining for biomedical applications. JOM 2009, 61, 35–40. [Google Scholar] [CrossRef]

- Korte, F.; Nolte, S.; Chichkov, B.N.; Bauer, T.; Kamlage, G.; Wagner, T.; Fallnich, C.; Welling, H. Far-field and near-field material processing with. Femtosecond laser pulses. Appl. Phys. A 1999, 69, S7–S11. [Google Scholar] [CrossRef]

- Liao, Y.; Song, J.; Li, E.; Luo, Y.; Shen, Y.; Chen, D.; Cheng, Y.; Xu, Z.; Sugioka, K.; Midorikawa, K. Rapid prototyping of three-dimensional microfluidic mixers in glass by femtosecond laser direct writing. Lab Chip 2012, 12, 746–749. [Google Scholar] [CrossRef] [PubMed]

- Jensen, M.F.; Noerholm, M.; Christensen, L.H.; Geschke, O. Microstructure fabrication with a CO2 laser system: Characterization and fabrication of cavities produced by raster scanning of the laser beam. Lab Chip 2003, 3, 302–307. [Google Scholar] [CrossRef] [PubMed]

- Wagner, F.; Hoffmann, P. Novel structure formation in poly(ethylene therephthalate) by scanning excimer laser ablation. Appl. Surf. Sci. 2000, 154–155, 627–632. [Google Scholar] [CrossRef]

- Khan Malek, C. Laser processing for bio-microfluidics applications (part i). Anal. Bioanal. Chem. 2006, 385, 1351–1361. [Google Scholar] [CrossRef] [PubMed]

- Sugioka, K.; Hanada, Y.; Midorikawa, K. 3d integration of microcomponents in a single glass chip by femtosecond laser direct writing for biochemical analysis. Appl. Surf. Sci. 2007, 253, 6595–6598. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast laser-reliable tools for advance materials processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Fu, L.-M.; Ju, W.-J.; Yang, R.-J.; Wang, Y.-N. Rapid prototyping of glass-based microfluidic chips utilizing two-pass defocused CO2 laser beam method. Microfluid. Nanofluid. 2013, 14, 479–487. [Google Scholar] [CrossRef]

- Klank, H.; Kutter, J.P.; Geschke, O. CO2-laser micromachining and back-end processing for rapid production of pmma-based microfluidic systems. Lab Chip 2002, 2, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Li, S.; Wu, J.; Wen, W.; Li, W.; Alici, G. A simple and cost-effective method for fabrication of integrated electronic-microfluidic devices using a laser-patterned pdms layer. Microfluid. Nanofluid. 2012, 12, 751–760. [Google Scholar] [CrossRef]

- Liu, H.-B.; Gong, H.-Q. Templateless prototyping of polydimethylsiloxane microfluidic structures using a pulsed CO2 laser. J. Micromech. Microeng. 2009, 19, 037002. [Google Scholar] [CrossRef]

- Chung, C.K.; Lin, S.L.; Chang, K.C.; Wang, H.Y. Fabrication and simulation of pdms assisted CO2 laser ablation. In Proceedings of the 2010 5th IEEE International Conference on Nano/Micro Engineered and Molecular Systems (NEMS), Xiamen, China, 20–23 January 2010; pp. 650–653. [Google Scholar]

- Chen, C.-C.; Lin, P.-H.; Chung, C.-K. Microfluidic chip for plasma separation from undiluted human whole blood samples using low voltage contactless dielectrophoresis and capillary force. Lab Chip 2014, 14, 1996–2001. [Google Scholar] [CrossRef] [PubMed]

- Ziya, I.; Guler, M.T.; Berkan, A.; Ismail, B.; Caglar, E. Rapid fabrication of microfluidic pdms devices from reusable pdms molds using laser ablation. J. Micromech. Microeng. 2016, 26, 035008. [Google Scholar]

- Wang, H.-W.; Cheng, C.-W.; Li, C.-W.; Chang, H.-W.; Wu, P.-H.; Wang, G.-J. Fabrication of pillared plga microvessel scaffold using femtosecond laser ablation. Int. J. Nanomed. 2012, 7, 1865–1873. [Google Scholar] [CrossRef] [PubMed]

- Zainuddin; Chirila, T.V.; Barnard, Z.; Watson, G.S.; Toh, C.; Blakey, I.; Whittaker, A.K.; Hill, D.J.T. F2 excimer laser (157 nm) radiation modification and surface ablation of phema hydrogels and the effects on bioactivity: Surface attachment and proliferation of human corneal epithelial cells. Radiat. Phys. Chem. 2011, 80, 219–229. [Google Scholar] [CrossRef]

- Wang, Y.; Ameer, G.A.; Sheppard, B.J.; Langer, R. A tough biodegradable elastomer. Nat. Biotechnol. 2002, 20, 602–606. [Google Scholar] [CrossRef] [PubMed]

- Bettinger, C.J.; Bruggeman, J.P.; Borenstein, J.T.; Langer, R.S. Amino alcohol-based degradable poly(ester amide) elastomers. Biomaterials 2008, 29, 2315–2325. [Google Scholar] [CrossRef] [PubMed]

- Engelmayr, G.C.; Cheng, M.; Bettinger, C.J.; Borenstein, J.T.; Langer, R.; Freed, L.E. Accordion-like honeycombs for tissue engineering of cardiac anisotropy. Nat. Mater. 2008, 7, 1003–1010. [Google Scholar] [CrossRef] [PubMed]

- Tatyana, S.; Ahmed, H. Scaling mechanisms of vapour/plasma shielding from laser-produced plasmas to magnetic fusion regimes. Nucl. Fusion 2014, 54, 023044. [Google Scholar]

- Voiculescu, I.; Li, F.; Liu, F.; Zhang, X.; Cancel, L.M.; Tarbell, J.M.; Khademhosseini, A. Study of long-term viability of endothelial cells for lab-on-a-chip devices. Sens. Actuators B Chem. 2013, 182, 696–705. [Google Scholar] [CrossRef]

- Okuyama, T.; Yamazoe, H.; Mochizuki, N.; Khademhosseini, A.; Suzuki, H.; Fukuda, J. Preparation of arrays of cell spheroids and spheroid-monolayer cocultures within a microfluidic device. J. Biosci. Bioeng. 2010, 110, 572–576. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.; Shao, H.; Reiner, T.; Issadore, D.; Weissleder, R.; Lee, H. Microfluidic Cell Sorter (μFCS) for On-chip Capture and Analysis of Single Cells. Adv. Healthc. Mater. 2012, 1, 432–436. [Google Scholar] [CrossRef] [PubMed]

| Parameter | Value |

|---|---|

| Laser wavelength | 193 nm |

| Pulse Width | 4 ns |

| Ablation progression speed | 50–200 μm s−1 |

| Frequency of laser shots | 5–20 Hz |

| Laser energy | 6 and 9 J cm−2 |

| Beam size | 10–150 μm |

| Repeated ablations | 1–100 times |

| Defocus distance | 0–1000 μm |

| Beam Size | PGS | APS | PDMS |

|---|---|---|---|

| 10 | 8 ± 1 | 11 ± 2 | 12 ± 2 |

| 50 | 48 ± 3 | 52 ± 3 | 52 ± 3 |

| 100 | 97 ± 5 | 104 ± 6 | 102 ± 6 |

| 150 | 156 ± 9 | 157 ± 7 | 157 ± 7 |

| Flow Rate (Q) | 0.05 μL min−1 | 0.1 μL min−1 | 0.2 μL min−1 | |

|---|---|---|---|---|

| Squared |  |  |  |  |

| U-shaped |  |  |  | |

| Circular |  |  |  |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, Y.-K.; Chen, S.-C.; Huang, W.-L.; Hsu, K.-P.; Gorday, K.A.V.; Wang, T.; Wang, J. Direct Micromachining of Microfluidic Channels on Biodegradable Materials Using Laser Ablation. Polymers 2017, 9, 242. https://doi.org/10.3390/polym9070242

Hsieh Y-K, Chen S-C, Huang W-L, Hsu K-P, Gorday KAV, Wang T, Wang J. Direct Micromachining of Microfluidic Channels on Biodegradable Materials Using Laser Ablation. Polymers. 2017; 9(7):242. https://doi.org/10.3390/polym9070242

Chicago/Turabian StyleHsieh, Yi-Kong, Shiau-Chen Chen, Wen-Ling Huang, Kai-Ping Hsu, Kaiser Alejandro Villalobos Gorday, Tsinghai Wang, and Jane Wang. 2017. "Direct Micromachining of Microfluidic Channels on Biodegradable Materials Using Laser Ablation" Polymers 9, no. 7: 242. https://doi.org/10.3390/polym9070242