Optimized Subsurface Irrigation System (OPSIS): Beyond Traditional Subsurface Irrigation

Abstract

:1. Introduction

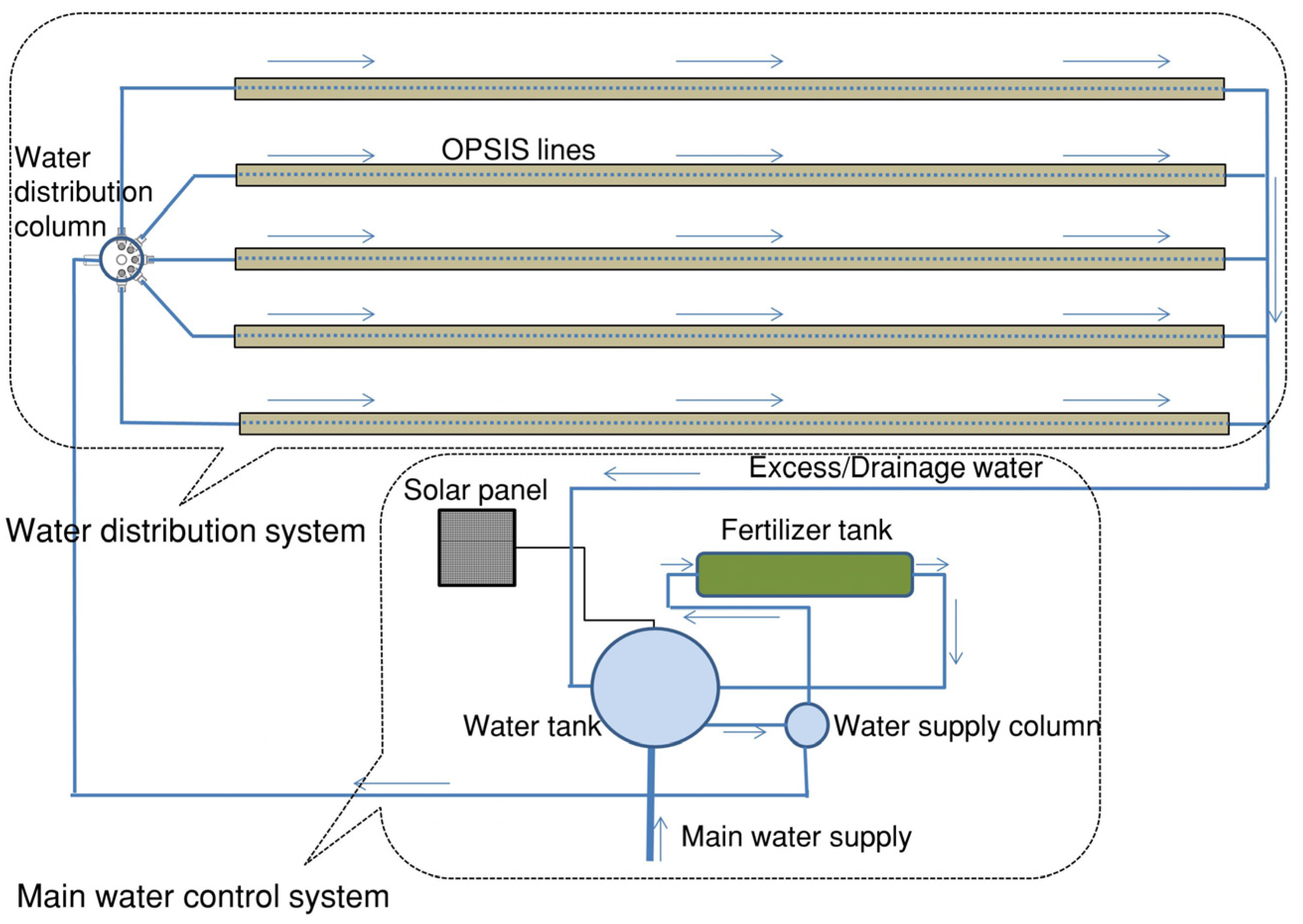

Optimized Subsurface Irrigation System (OPSIS)

2. Technical Details of OPSIS

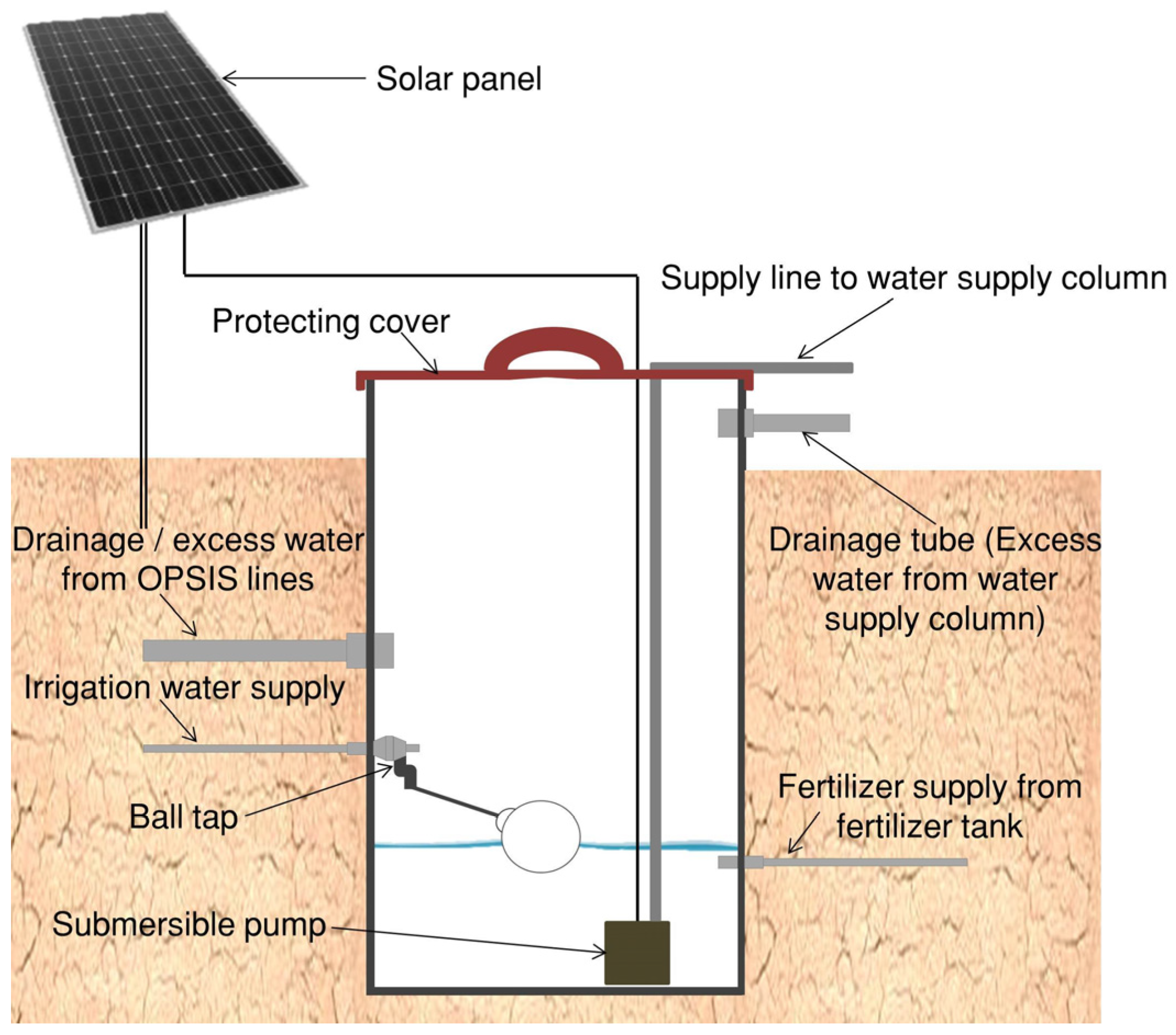

2.1. Main Water Control System

2.1.1. Water Tank

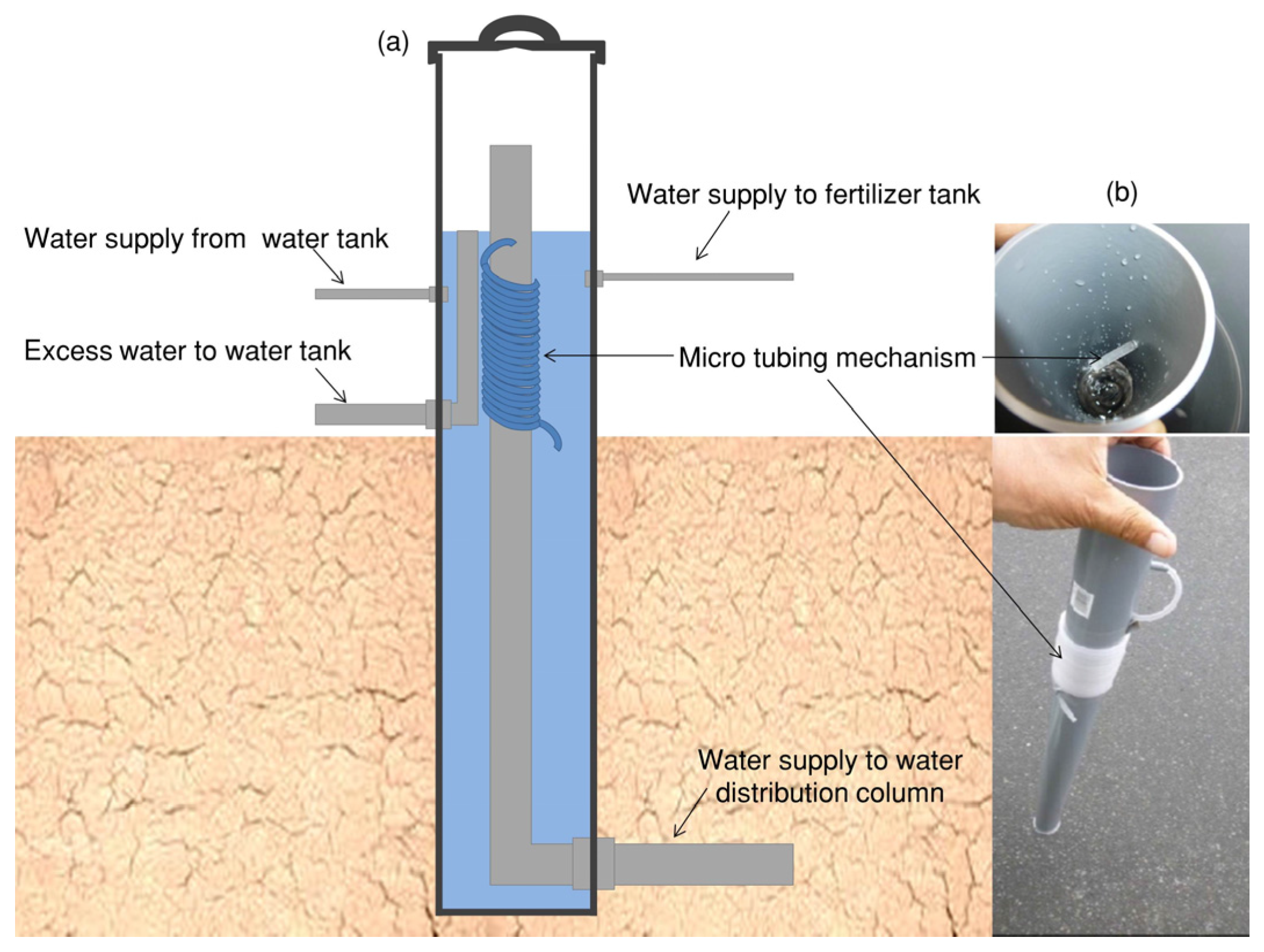

2.1.2. Water Supply Column

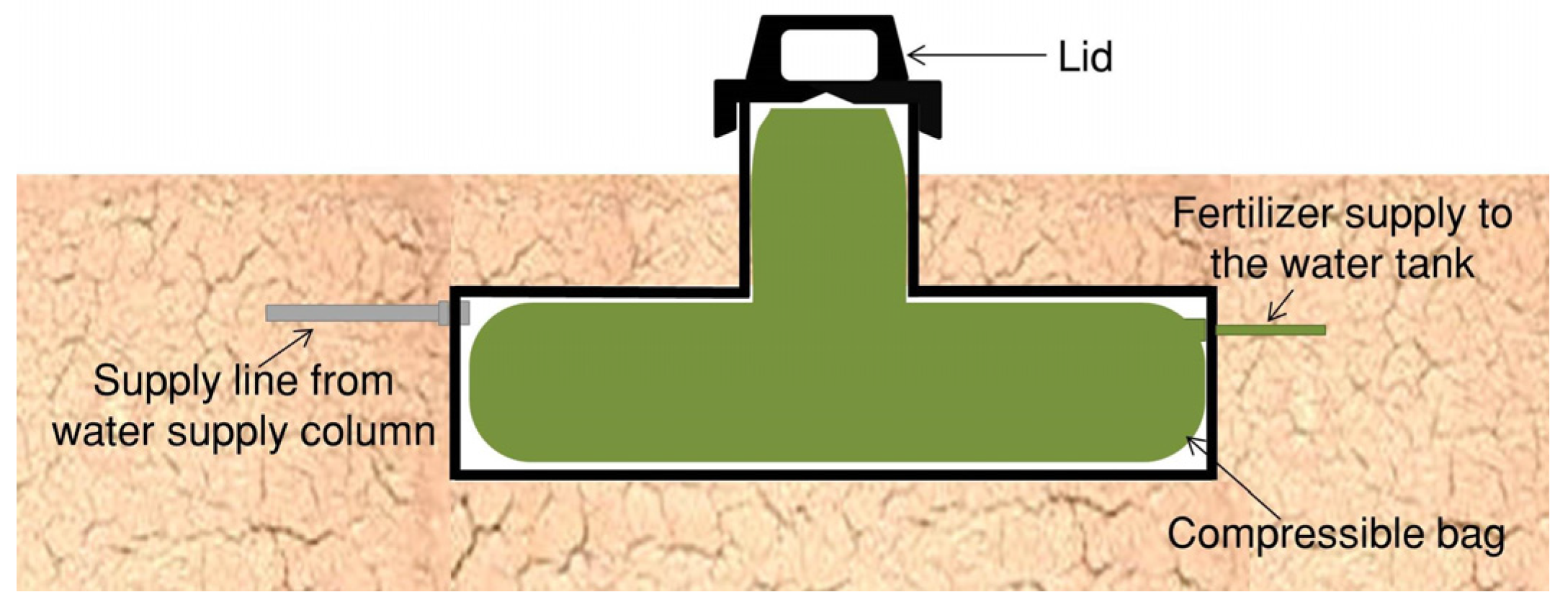

2.1.3. Fertilizer Tank

2.2. Water Distribution System

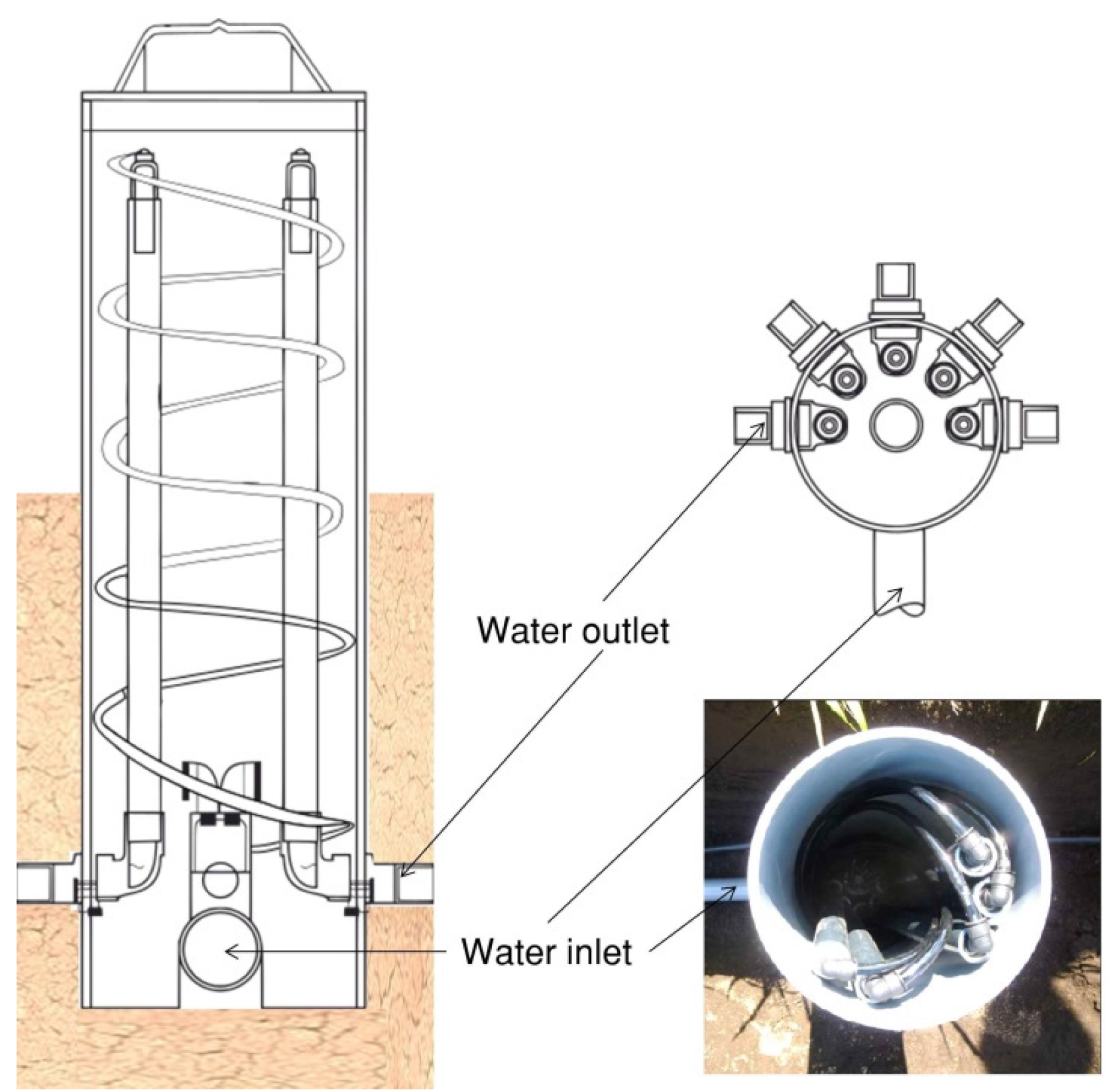

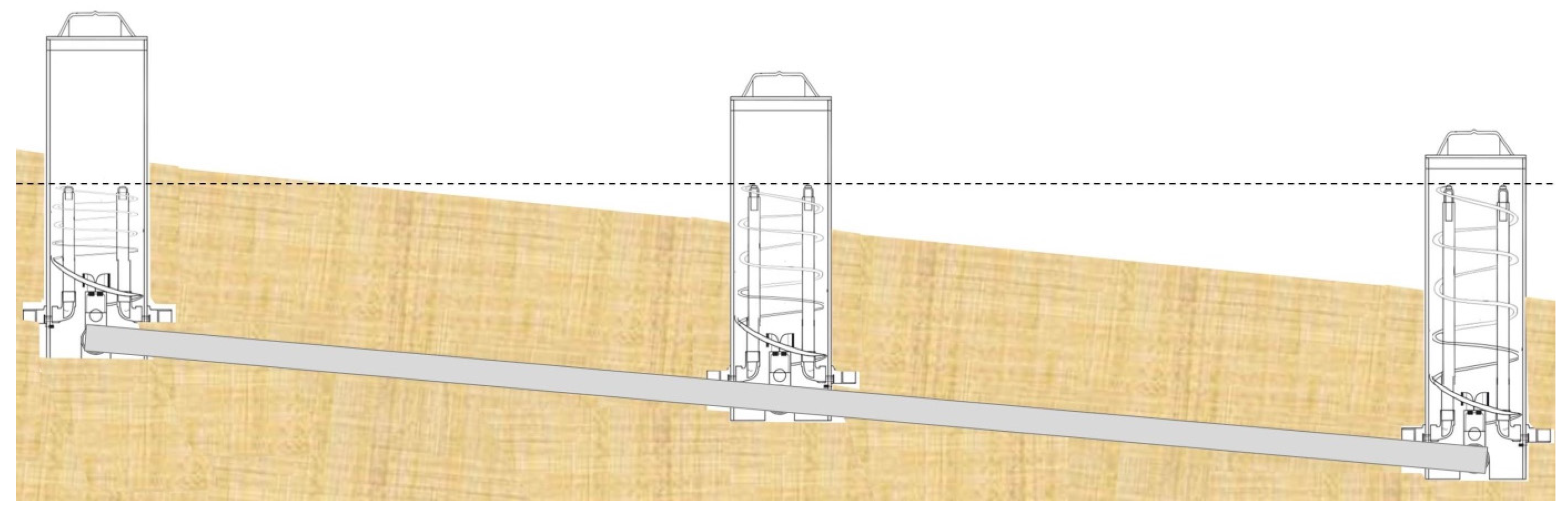

2.2.1. Water Distribution Column

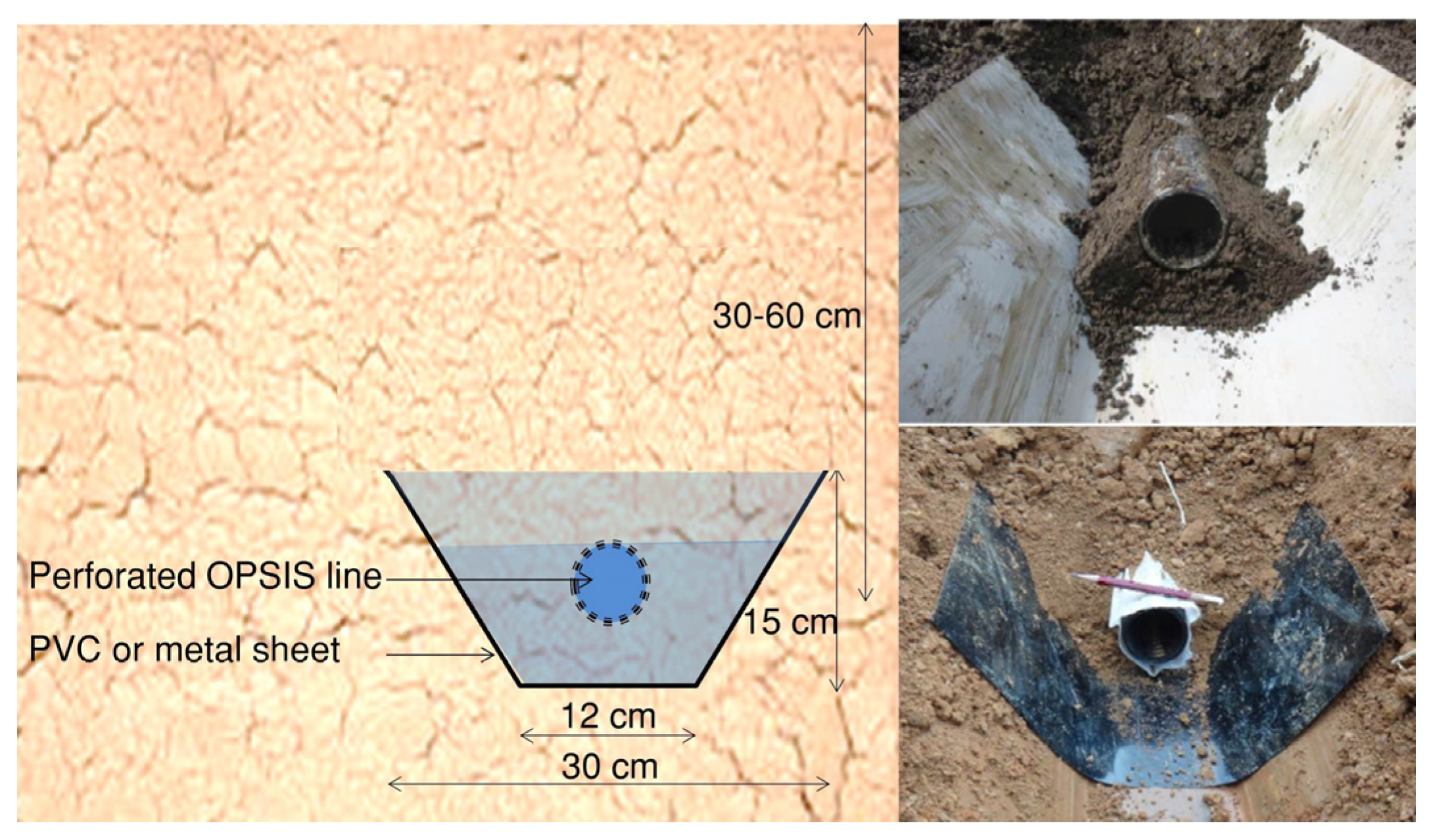

2.2.2. Perforated OPSIS Lines

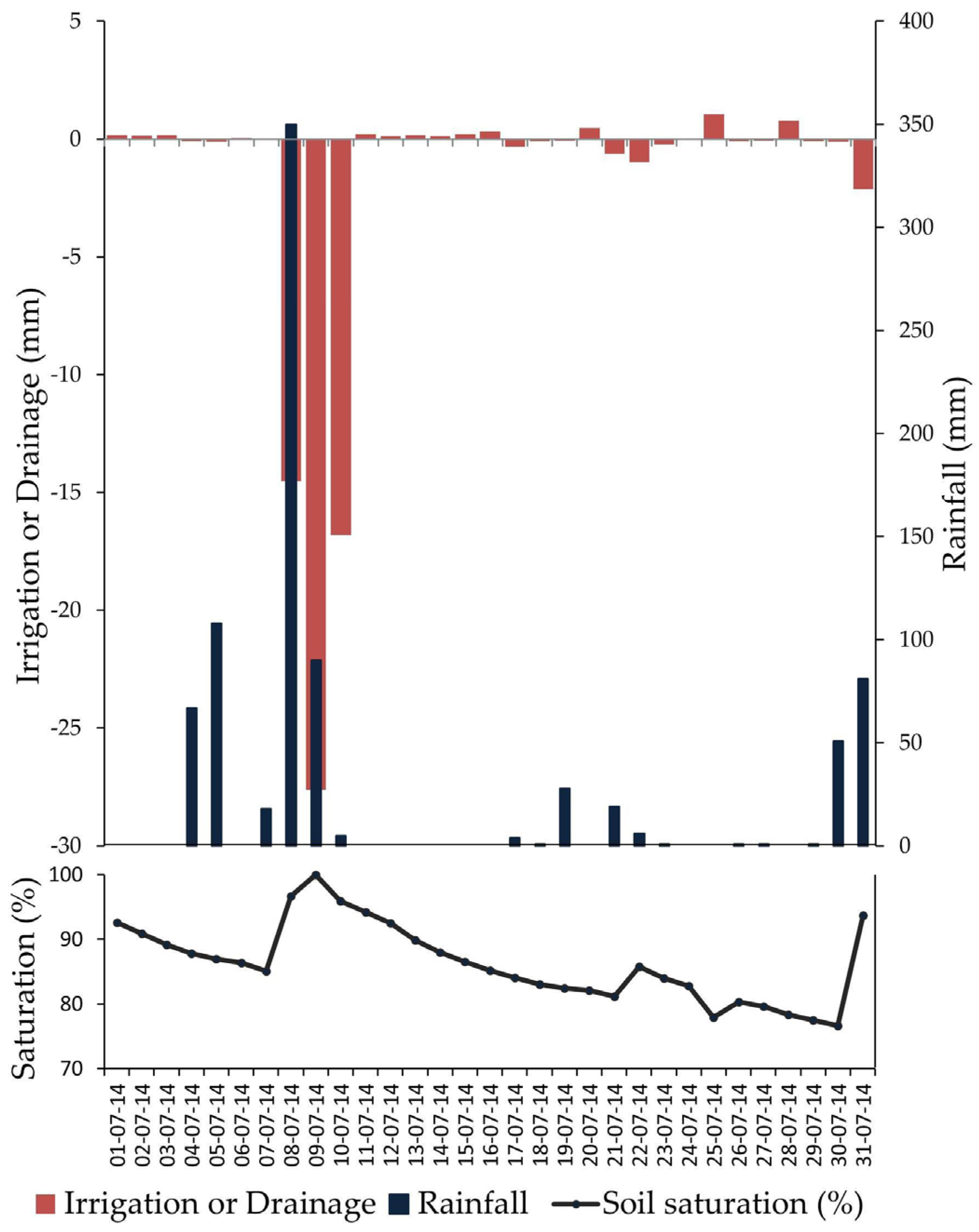

2.3. OPSIS can Act as a Drainage System

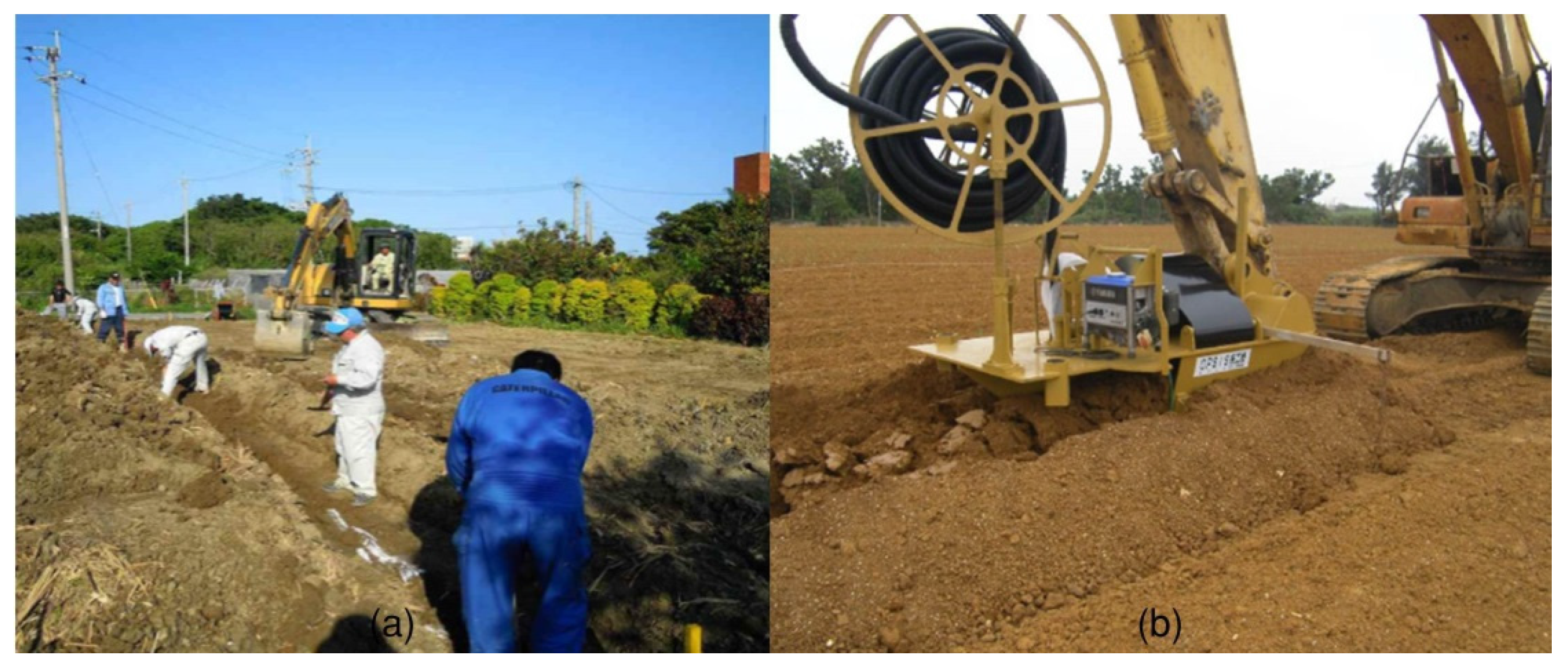

2.4. System Installation

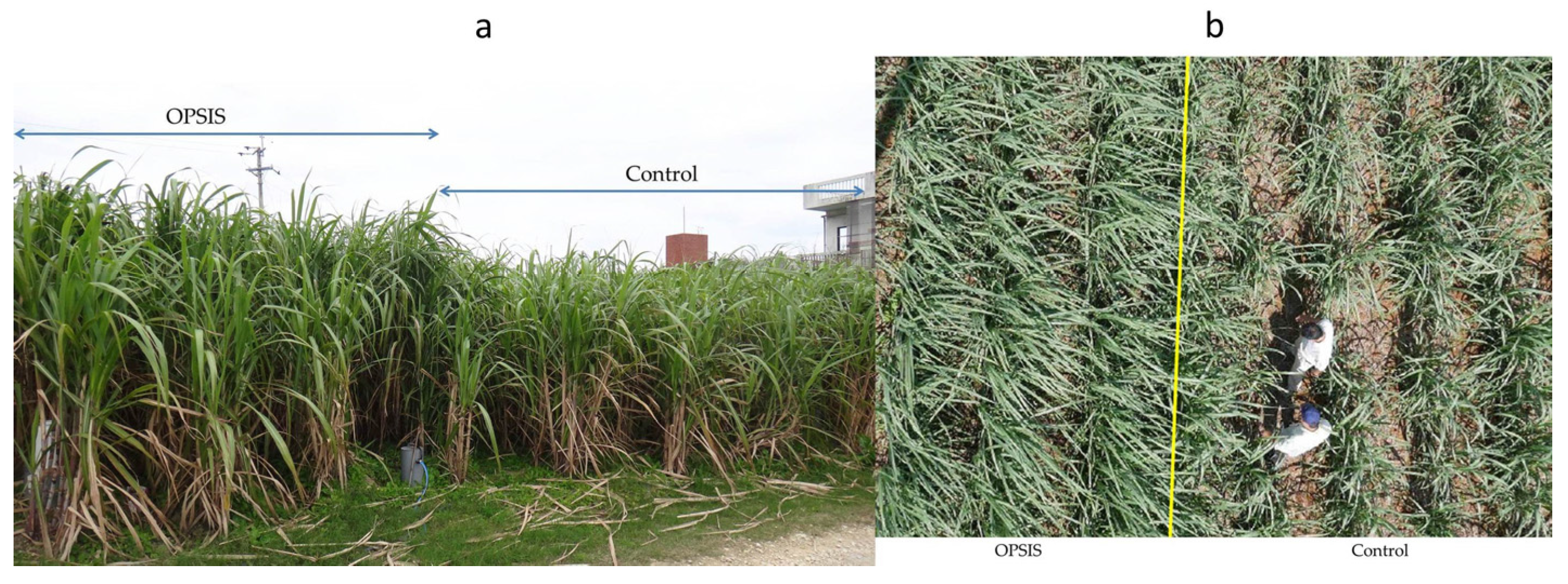

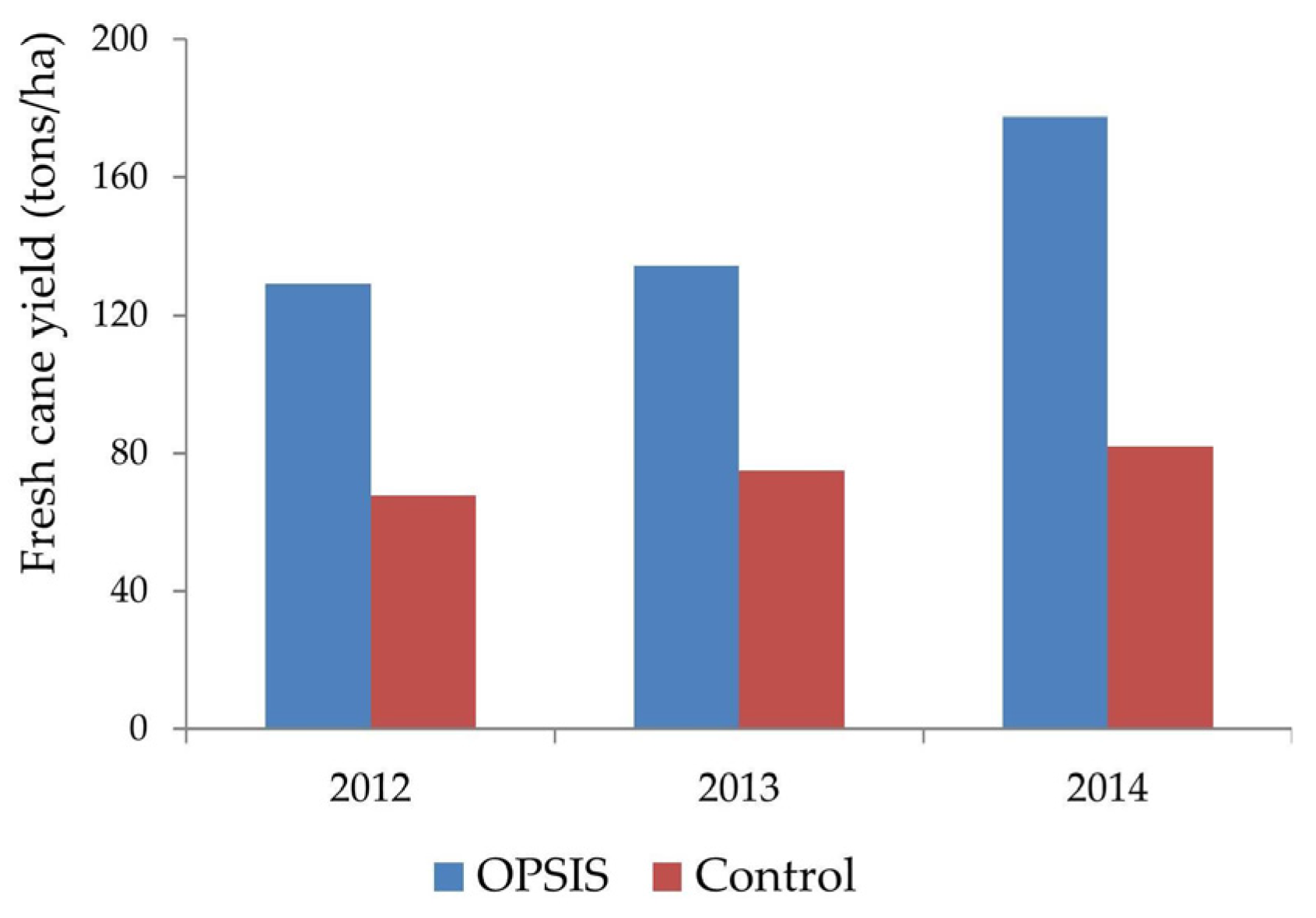

2.5. Field Testing of OPSIS

3. Discussion

3.1. Special Features of OPSIS

3.1.1. Water-Saving Irrigation Method

3.1.2. Ensures Uniform Water Distribution

3.1.3. Ensures Good Crop Yields

3.1.4. Ensures Sanitary Field Conditions

3.1.5. Enables Fertigation

3.1.6. Minimal Operational Costs

3.1.7. No Clogging

3.1.8. Long Durability

3.1.9. Drainage System

3.1.10. Environmentally-Friendly Technology

3.2. Limitations of OPSIS

4. Recommendations

Author Contributions

Conflicts of Interest

References

- FAO. Status and trends in land and water resources. In The State of the World’s Land and Water Resources for Food and Agriculture (SOLAW): Managing Systems at Risk; Routledge: London, UK, 2011; Chapter 1; pp. 19–62. [Google Scholar]

- IPCC. Food security and food production systems. In Climate Change 2014: Impacts, Adaptation, and Vulnerability. Working Group II Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Technical Report for Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014; Chapter 7; pp. 485–534. [Google Scholar]

- Webber, H.; Gaiser, T.; Ewert, F. What role can crop models play in supporting climate change adaptation decisions to enhance food security in Sub-Saharan Africa? Agric. Syst. 2014, 127, 161–177. [Google Scholar] [CrossRef]

- Roudier, P.; Sultan, B.; Quirion, P.; Berg, A. The impact of future climate change on West African crop yields: What does the recent literature say? Glob. Environ. Chang. 2011, 21, 1073–1083. [Google Scholar] [CrossRef]

- Sharma, B.; Molden, D.; Cook, S. Water use efficiency in agriculture: Measurement, current situation and trends. In Managing Water and Fertilizer for Sustainable Agricultural Intensification, 1st ed.; Drechsel, P., Heffer, P., Magen, H., Mikkelsen, R., Wichelns, D., Eds.; International Fertilizer Industry Association (IFA), International Water Management Institute (IWMI), International Plant Nutrition Institute (IPNI) and International Potash Institute (IPI): Paris, France, 2015; Chapter 3; pp. 39–64. [Google Scholar]

- Ali, M.H. Water application methods. In Practices of Irrigation and On-farm Water Management; Springer Science: Berlin, Germany, 2011; Volume 2. [Google Scholar] [CrossRef]

- Van Lier, H.N.; Pereira, L.S.; Steiner, F.R. CIGR Handbook of Agricultural Engineering. Am. Soc. Agric. Eng. 1999, 1, 297–369. [Google Scholar]

- Strelkoff, T.S.; Clemmens, A.J. Hydraulics of surface systems. In Design and Operation of Farm Irrigation Systems; Hoffman, G.J., Evans, R.G., Jensen, M.E., Martin, D.L., Elliott, R.L., Eds.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; Chapter 13; pp. 436–498. [Google Scholar]

- Martin, D.L.; Heermann, D.F.; Madison, M. Hydraulics of sprinkler and microirrigation systems. In Design and Operation of Farm Irrigation Systems; Hoffman, G.J., Evans, R.G., Jensen, M.E., Martin, D.L., Elliott, R.L., Eds.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; Chapter 15; pp. 532–556. [Google Scholar]

- Mikkelsen, R.; Hartz, T.K.; Rusan, M.J.M. Challenges of increasing water and nutrient efficiency in irrigated agriculture. In Managing Water and Fertilizer for Sustainable Agricultural Intensification, 1st ed.; Drechsel, P., Heffer, P., Magen, H., Mikkelsen, R., Wichelns, D., Eds.; International Fertilizer Industry Association (IFA), International Water Management Institute (IWMI), International Plant Nutrition Institute (IPNI) and International Potash Institute (IPI): Paris, France, 2015; Chapter 8; pp. 168–186. [Google Scholar]

- Evans, R.G.; Wu, I.; Smajstrala, A.G. Microirrigation Systems. In Design and Operation of Farm Irrigation Systems; Hoffman, G.J., Evans, R.G., Jensen, M.E., Martin, D.L., Elliott, R.L., Eds.; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007; Chapter 17; pp. 632–679. [Google Scholar]

- Payero, J.O.; Yonts, C.D.; Irmak, S. Advantages and Disadvantages of Subsurface Drip Irrigation; Nebraska Extension, Institute of Agriculture and Extension, University of Nebraska-Lincoln: Lincoln, NE, USA, 2005. [Google Scholar]

- Lamm, F.R.; Camp, C.R. Subsurface drip irrigation. In Micro Irrigation for Crop Production—Design, Operation and Management; Lamm, F.R., Ayars, J.E., Nakayama, F.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; Chapter 13; pp. 473–551. [Google Scholar]

- Li, J.; Chen, L.; Li, Y.; Liu, Y. Field Evaluation of Emitter Clogging in Subsurface Drip Irrigation Systems. In Proceedings of the ASABE Annual International Meeting, Providence, RI, USA, 29 June–2 July 2008. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gunarathna, M.H.J.P.; Sakai, K.; Nakandakari, T.; Kazuro, M.; Onodera, T.; Kaneshiro, H.; Uehara, H.; Wakasugi, K. Optimized Subsurface Irrigation System (OPSIS): Beyond Traditional Subsurface Irrigation. Water 2017, 9, 599. https://doi.org/10.3390/w9080599

Gunarathna MHJP, Sakai K, Nakandakari T, Kazuro M, Onodera T, Kaneshiro H, Uehara H, Wakasugi K. Optimized Subsurface Irrigation System (OPSIS): Beyond Traditional Subsurface Irrigation. Water. 2017; 9(8):599. https://doi.org/10.3390/w9080599

Chicago/Turabian StyleGunarathna, M. H. J. P., Kazuhito Sakai, Tamotsu Nakandakari, Momii Kazuro, Tsuneo Onodera, Hiroyuki Kaneshiro, Hiroshi Uehara, and Kousuke Wakasugi. 2017. "Optimized Subsurface Irrigation System (OPSIS): Beyond Traditional Subsurface Irrigation" Water 9, no. 8: 599. https://doi.org/10.3390/w9080599