Abstract

The efficiency of cold rolling of steel strip in the main depends on the quality of technological lubricant and its cost. In this regard, it is important to develop new compositions of effective metalworking coolants that are low cost and provide maximum reduction in the friction coefficient. We developed and tested the new compositions of metalworking coolants on the basis of vegetable oil and chicken fat. The metalworking coolants were tested in Donbas State Engineering Academy (DSEA) on a laboratory rolling mill, 100 × 100, in cold rolling of 08Kp steel. The efficiency of the coolants was determined by the stretch ratio λ and the friction coefficient μ in the deformation zone, which was found by the forward slip method. We found the metalworking coolant with 100% concentration of boric acid esters of mono- and diglycerides is the most effective in the rolling of thin steel strips. Thus, the new metalworking coolants (MWC) on the basis of boric acid esters of mono- and diglycerides, synthesized on the basis of sunflower oil, can be recommended for use in the rolling of structural steels on account of its availability, high efficiency and low cost.

1. Introduction

The efficiency of cold rolling of steel sheets and strips in the main depends on the quality of the technological lubricant [1,2,3,4].

Technological fluid is a type of coolant and lubricant designed specifically for metalworking processes. There are various kinds of these fluids, which include oils, oil-water emulsions, pastes, gels, aerosols and air or other gases. They may be made from petroleum distillates, animal fats, plant oils, water and air, or other raw ingredients.

Metalworking coolants are usually water–soluble fluids designed to provide cooling and lubrication during metalworking operations. The use of coolant extends cutting tool life, improves part finish and tolerance and productivity. Coolants are generally grouped into three major categories: soluble oils, semi-synthetics and synthetics.

Soluble oils are metalworking fluid concentrates containing a high percentage of oil, usually greater than 50%. When mixed with water, they form an emulsion that has a milky appearance. The high oil content provides excellent physical lubricity for the cutting operation as well as protection for the machine tool.

Semi-synthetic coolants are metalworking fluid concentrates that contain a small amount of oil, usually less than 30%, as well as synthetic lubricants and other additives. When mixed with water, they form a translucent fluid. Semi-synthetics combine the physical lubricity of soluble oils with the chemical lubricity, cooling and cleanliness of synthetic coolants.

Synthetic coolants are metalworking fluid concentrates that contain no mineral oil. When mixed with water, they form a clear fluid. Synthetics have excellent cooling properties and run very clean providing long life in the sump.

The choice of metalworking coolant depends on a workpiece material.

Our investigations in the field of metal processing [5,6,7,8,9,10] have been shown the metalworking coolants can effectively reduce a friction level on the contact surfaces of metal and tool in metal forming. First of all, it relates to the production of cold-rolled plates and strips of ferrous and nonferrous metals, as well as the production of long products by rolling and pressing in a cold state.

Most of the liquid lubricants used at present all over the world are petroleum based mineral oils [3]. The present concept of being globally “green” puts additional demands on lubricants. The new lubricants should not only have good performance but should also be eco-friendly and eventually biodegradable. For example, synthetic ester lubricants are prepared from fatty acids, originating from vegetable oils. They have uniform molecular structures and therefore well defined properties that can be tailored to specific applications. The new biodegradable esters were synthesized using alcohols and fatty acids and their lubricity characteristics were studied in aluminium cold rolling [11]. Some synthetic esters were also reported as steel cold rolling oils [12,13].

However, the cost of lubricant is very important too. Therefore, the main problem is to find a balance between the high useful properties of the lubricant and its cost.

Earlier we found that both metalworking coolants, containing boric acid esters of mono- and diglycerides and metalworking coolant with chicken fat are effective enough in steel rolling [10]. But no detail studies were carried out. Boric acid esters of mono- and diglycerides were synthesized on basis of sunflower oil. Ukrainian producers in 2017 managed 5.21 million tons of sunflower oil that is a very high mark. Thus, vegetable oil is an inexpensive feedstock in Ukraine and can be the basis for the synthesis of inexpensive additives with high useful properties.

All metalworking coolants are formulated to work within a specific concentration range. These working concentration limits are determined and recommended by the manufacturer for optimal fluid performance. Finding the optimal composition and concentrations of components is a very important problem at development of metalworking coolant.

The goal of our study is to develop inexpensive metalworking coolant which can be used in cold rolling of thin steel strips.

2. Materials and Methods

The metalworking coolants used in our experiments were liquids with boric acid esters of mono- and diglycerides based on sunflower oil (MWC Nos. 1–6, Table 1), the new coolant compositions with chicken fat (MWC Nos. 9–12, Table 2), liquid with boric acid ethers of mono- and diglycerides based on waste sunflower oil (MWC No. 14), liquid with mono- and diglycerides based on waste sunflower oil (MWC No. 15), liquid with boric acid esters of mono- and diglycerides based on rapeseed oil (MWC No. 16), liquid with mono- and diglycerides based on rapeseed oil (MWC No. 17) and emulsions Nos. 18–23 (Table 3).

Table 1.

Compositions of new metalworking coolants (MWC) with boric acid esters of mono- and diglycerides.

Table 2.

Compositions of new metalworking coolants (MWC) with chicken fat.

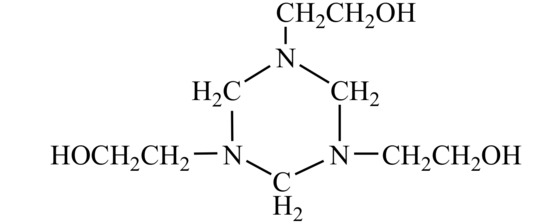

Figure 1.

The structure of antibacterial additive.

Table 3.

Compositions of emulsions.

To compare the results obtained in our experiments we also carried out steel rolling without MWC (dry sample, dry rolls) and tested.

- -

- the coolant «Universal-1TC» developed and used in Ilyich Iron and Steel Works, Mariupol, Ukraine, TU U23.2-31023384.002–2004 (No. 7) (see Table 1);

- -

- metalworking coolant with 100% concentration of mono- and diglycerides obtained from sunflower oil (No. 8) (see Table 1);

- -

- the lubricant SP-3, GOST 5702-75 (No. 13) (see Table 2).

All tests of MWC were carried out in industrial and laboratory rolling mill in Donbas State Engineering Academy (Figure 2) as well as in [10]. The strip material was annealed 08Kp steel. The samples were 1.88–1.91 mm thick and 39.90 mm wide. The tangential velocity of the rolls was 0.2 m/s. We studied two levels of reduction: 1st level with average reduction ratio εavg of 19.11% and 2nd level with εavg ≈ 45.53%.

Figure 2.

Industrial and laboratory rolling duo-mill, 260 × 200, DSEA.

The metalworking coolant was spread uniformly on the surface of the strip. The rolls were degreased with the solvent 646 before every pass.

The working rolls were made of 9X steel and had diameter of 260 mm. The hardness of forming surfaces of roll body was 80HS and the roughness was 0.63 μm.

The efficiency of MWC can be determined by value of a friction coefficient. MWC is more effective if the friction coefficient is lower with other conditions unchanged. Low coefficient of friction promotes the decrease of contact strain, rolling force, power consumption and roll wear.

To determine the friction coefficient μ we used the forward slip method [14]. The average value of a friction coefficient can be approximately determined if a forward slip ratio is known. The forward slip ratio S is determined from experimenting in stable rolling and it is an indicator of relative metal sliding on roller surface in the exit from deformation zone.

It is known that the speed of forward motion of the strip exiting from the rolls is higher than the surface speed of rolls. This phenomenon is named the forward slip [15].

The forward slip ratio S is defined as

where V1 is the entry strip speed and Vf is the surface speed of rolls.

S = (V1 − Vf)/Vf = V1/Vf − 1,

In practice, the forward slip ratio is determined by the roll kern method. The marks are notched on the body of roll at the distance lb along circular arc. During the rolling process, these marks left scratches on the strip. The distance l1 between these scratches was longer than lb. The forward slip ratio was defined as

where l1 was the distance between the scratches on the strip after pass and lb was the distance between the marks on the roll body.

S = (l1 − lb)/lb = l1/lb − 1,

Indeed, for a time t: lb = Vf·t and l1 = V1·t, so Vf = lb/t and V1 = l1/t.

Theoretically the forward slip ratio in symmetrical rolling can be determined considering the position of the neutral cross-section. In thin strip rolling, when the roll radius Rf is much higher than the strip thickness h1 in exit from deformation zone, the forward slip can be calculated as [15]

where γ is neutral angle.

The neutral angle γ is calculated as [14]

where Df is roll diameter.

For the same purpose the Formula (3) can be used in the form

The angle γ found in this way is substituted into formula [14]

which is used to find the friction angle β

The angle α is calculated as

where Δh is the difference between the strip thicknesses before pass h0 and after pass h1.

The friction coefficient is thus defined as

It should be taken into account that the Formulas (4)–(6) can be used only for uniform distribution of speeds along the cross-sections in a deformation zone because a hypothesis of “flat cross-sections” was used to derive these equations. But the speeds of metal particles are distributed non-uniformly in deformation zone. The complete alignment of speeds occurs only after exit of metal from the zone of contact with the rolls. In this regard, the neutral cross-section has a generally curved form [16]. This important fact is not taken into account in the Formulas (4)–(6). Therefore, the use of Formulas (4–6) gives satisfactory results only in rolling of relatively thin strips when l/havg > 3–4, that is, b0/l > 5, where l is the horizontal projection of the contact arc line of metal and rolls, havg is the average height of strip in the deformation zone, b0 is the initial width of the strip.

We studied rolling of thin strips and therefore, the use of these formulas is justified.

The efficiency of MWC can be also determined with help of the stretch ratios. The strip broadening after rolling is practically absent in rolling of thin flat-sample; that is less than 1%. Therefore, the ratio of the strip thicknesses before pass h0 to the strip thicknesses after pass h1 can be used to characterize the efficiency of MWC, when the initial roll gap S0, thickness h0 and width b0 of the sample are invariable. The stretch ratio increases with the use of more effective MWC [10,15], because the more effective MWC promotes the decrease of rolling force and elastic deformation of a stand.

The stretch ratio can be determined as λ = h0/h1. But measurement of small thickness gives a certain error. To improve the accuracy, we used the strip mark method. Before the pass we drew two marks on the strip at a distance of 200 mm (L0 = 200 mm). After the pass, we measured the distance between these marks (L1) and calculated the stretch ratio as λ = L1/L0 [10].

The efficiency of MWC was determined by comparing the stretch ratios in rolling of the tested MWC and in rolling of the same sample without MWC (dry).

To find the best additives with best properties we studied the MWC based on different vegetable oils and chicken fat with different concentrations of components.

In the first stage of our investigation we studied the MWC with the boric acid esters of mono- and diglycerides based on sunflower oil, MWC Nos. 1–6 and the coolant compositions with chicken fat, MWC Nos. 9–12 (see Table 4).

Table 4.

Experimental data of 08Kp steel cold rolling with various MWC. (L0 = 200 mm, lb = 150 mm, Df = 260 mm).

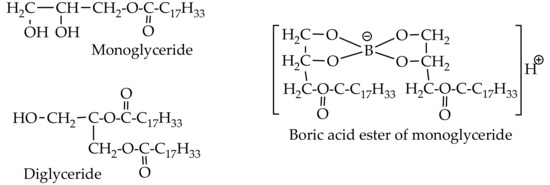

The feedstock in the synthesis of boric acid esters of mono- and diglycerides is a mixture of diglyceride and monoglyceride (Figure 3) obtained on the basis of vegetable oil.

Figure 3.

The structures of monoglyceride, diglyceride, and boric acid ester of monoglyceride.

Boric acid ester of monoglyceride (see Figure 3) is a stable compound unlike boric acid ester of diglyceride. In this regard, in the product named “boric acid esters of mono- and diglycerides based on a vegetable oil” the active components are the diglyceride and the boric acid ester of monoglyceride.

3. Results and Discussion

The friction coefficients in steel rolling with various MWC, calculated by the Formulas (4)–(9), are shown in Table 4.

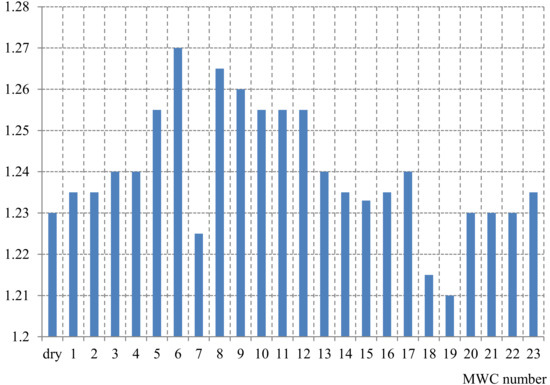

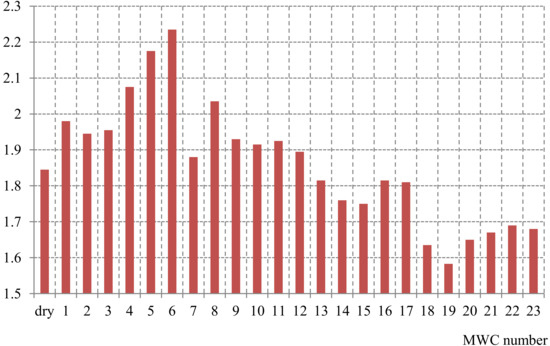

In our experiments, we studied rolling of thin steel strips and thickness measurements of them have certain errors. The use of the stretch ratio λ, calculated as λ = L1/L0, gives more visual results than the use of a friction coefficient. Therefore, to estimate the efficiency of MWC, we compared the stretch ratios λ in rolling with different MWC under other conditions unchanged (Figure 4 and Figure 5).

Figure 4.

The stretch ratios λ in rolling at 1st level of reduction.

Figure 5.

The stretch ratios λ in rolling at 2nd level of reduction.

The experiments have shown the use of boric acid esters of mono- and diglycerides as additives in compositions of MWC Nos. 1–6 leads to increase in the stretch ratios λ in comparison with dry rolling and rolling with the known coolant “Universal-1TC,” MWC No. 7.

MWC No. 6 is the most effective at both 1st and 2nd level of reduction (see Figure 4 and Figure 5). This coolant shows the highest efficiency at 2nd level of reduction: λ = 2.235, μ = 0.0450 and S = −0.79%. That indicates that in rolling with this reduction the reserve of friction forces in deformation zone is exhausted due to the high quality of MWC because the lag zone extends to all length of deformation zone.

The effective MWC reduces friction coefficient that promotes the decrease of rolling force and elastic deformation of a stand and leads to increase of quality of surface of steel strip in exit.

It should be noted the chlorinated paraffin wax XP-470 and calcium stearate are widely used in various compositions of MWC in steel rolling. But in our study, they showed negative influence on properties of MWC with boric acid esters of mono- and diglycerides. The MWC without these components is the most effective.

At 1st level of reduction the stretch ratio λ is high also at use of metalworking coolant with 100% concentration of mono- and diglycerides, MWC No. 8. The advantage of this coolant is an absence of the stage of synthesis of boric acid esters that reduces the cost of the additive. The feedstock can be used as additive.

MWC No. 8 shows relatively high results; therefore, both diglyceride and boric acid ester of monoglyceride raise the stretch ratio λ and reduce the friction coefficient μ in rolling of thin steel strips.

The compositions Nos. 9–12 with chicken fat are more effective than the lubricant SP-3, MWC No.13 but they are slightly worse than composition No. 6 based on boric esters. It should be noted the coolants Nos. 9–12 contain very important components: an emulsifier and an antibacterial additive, which provide high performance.

We also studied the efficiency of emulsions Nos. 18–23 and MWC with additives obtained from waste vegetable oils (MWC Nos. 14, 15) and from rapeseed oil (MWC Nos. 16, 17) (see Table 4, Figure 4 and Figure 5). An advantage of additives synthesized from waste vegetable oil is its very low cost.

At the first level of reduction (εavg ≈ 19.11%) the MWC No. 17 shows the best results among these compositions: the forward slip ratio and the friction coefficient are the smallest, S = 1.43%, μ = 0.0521 and the stretch ratio is the highest, λ = 1.240. But these results cannot be considered as positive. In the second level of reduction, εavg ≈ 45.53%, the results were worse than in rolling without MWC. That indicates the components of coolant have negative influence on properties of this MWC.

4. Conclusions

The metalworking coolant with 100% concentration of boric acid esters of mono- and diglycerides based on sunflower oil is the most effective in rolling of thin steel strips. The stretch ratio λ is maximal and the friction coefficient μ is minimal at use of this metalworking coolant, especially at 2nd level of reduction, εavg ≈ 45.53%. The mono- and diglycerides, which are the feedstock in the synthesis of boric acid esters, also show relatively high results.

It has been found that both diglyceride and boric acid ester of monoglyceride are active components reducing the friction coefficient in rolling of thin steel strips.

Thus, the metalworking coolant with boric acid esters of mono- and diglycerides is effective and inexpensive technological liquid for use in rolling of thin steel strips. The application of this metalworking coolant allows obtaining of a strip with a higher quality of surface.

Author Contributions

A.P.A. created the compositions of coolants, analysed the results and wrote the paper; V.A.F. designed a technique of experiments; P.V.D. analysed the results and wrote the paper; R.T. analysed the results; M.V.F. carried out the tests of metalworking coolants and analysed the results; S.A.K. created the compositions of coolants, analysed the data and wrote the paper; K.S.B. designed experiments and synthesized additives, analysed the results; N.V.T. synthesized additives, analysed the results.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lin, J.F.; Huang, T.K.; Hsu, C.T. Evaluation of lubricants for cold strip rolling. Wear 1991, 147, 79–91. [Google Scholar] [CrossRef]

- Lenard, J.G. The effect of lubricant additives on the coefficient of friction in cold rolling. J. Mater. Process. Technol. 1998, 80–81, 232–238. [Google Scholar] [CrossRef]

- McConnell, C.; Lenard, J.G. Friction in cold rolling of a low carbon steel with lubricants. J. Mater. Process. Technol. 2000, 99, 86–93. [Google Scholar] [CrossRef]

- Kosanov, J.; Lenard, J.G.; Uhrig, J.; Wallfarth, B. The effect of lubricant additives on the coefficient of friction in the flat-die test. Mater. Sci. Eng. A 2006, 427, 274–281. [Google Scholar] [CrossRef]

- Avdeenko, A.P.; Konovalova, S.A.; Avdeenko, E.A.; Fedorinov, M.V.; Gribkov, E.P. Application of greases and metalworking coolants in steel rolling: Report 1. In 14th International Conference Research and Development in Mechanical Industry RADMI 2014, Volume 1, Proceedings of the RADMI 2014, Tolopa, Serbia, 18–21 September 2014; Dašić, P.V., Ed.; SaTCIP Ltd.: Vrnjačka Banja, Serbia, 2014; pp. 155–161. ISBN 978-86-6075-047-3. [Google Scholar]

- Avdeenko, A.P.; Konovalova, S.A.; Avdeenko, E.A.; Fedorinov, M.V.; Gribkov, E.P. Application of greases and metalworking coolants in steel rolling: Report 2. In 14th International Conference Research and Development in Mechanical Industry RADMI 2014, Volume 1, Proceedings of the RADMI 2014, Tolopa, Serbia, 18–21 September 2014; Dašić, P.V., Ed.; SaTCIP Ltd.: Vrnjačka Banja, Serbia, 2014; pp. 162–165. ISBN 978-86-6075-047-3. [Google Scholar]

- Avdeenko, A.P.; Konovalova, S.A.; Avdeenko, E.A.; Fedorinov, M.V.; Gribkov, E.P. Application of greases and metalworking coolants in steel rolling: Report 3. In 14th International Conference Research and Development in Mechanical Industry RADMI 2014, Volume 1, Proceedings of the RADMI 2014, Tolopa, Serbia, 18–21 September 2014; Dašić, P.V., Ed.; SaTCIP Ltd.: Vrnjačka Banja, Serbia, 2014; pp. 166–168. ISBN 978-86-6075-047-3. [Google Scholar]

- Avdeenko, A.P.; Lutovac, M.; Konovalova, S.A.; Fedorynov, M.V. Investigation of Efficiency of use of High-Temperature Greases in Steel Rolling. Part 1. Appl. Mech. Mater. 2015, 806, 3–9. [Google Scholar] [CrossRef]

- Avdeenko, A.P.; Lutovac, M.; Konovalova, S.A.; Fedorynov, M.V. Investigation of Efficiency of use of High-Temperature Greases in Steel Rolling. Part 2. Appl. Mech. Mater. 2015, 806, 10–15. [Google Scholar] [CrossRef]

- Avdeenko, A.P.; Fedorinov, V.A.; Fedorinov, M.V.; Burmistrov, K.S.; Toropin, N.V.; Konovalova, S.A. New Compositions of Metalworking Coolants for Steel Rolling. J. Res. Dev. Mech. Ind. 2016, 8, 1–8. [Google Scholar]

- Nagendramma, P.; Shukla, B.M.; Adhikari, D.K. Synthesis, Characterization and Tribological Evaluation of New Generation Materials for Aluminum Cold Rolling Oils. Lubricants 2016, 4, 23. [Google Scholar] [CrossRef]

- Mahanti, S.; Bhatta, A.K.; Biswas, R.N.; Bhatia, J.; Singh, S.N. Development of a meta-stable semi-synthetic lubricant for cold rolling of steel. J. Synth. Lubr. 1990, 6, 285–298. [Google Scholar] [CrossRef]

- Okabe, H.; Kanno, T. Behaviour of polar compounds in lubricating oil films. ASLE Trans. 1981, 24, 459–466. [Google Scholar] [CrossRef]

- Grudev, A.P. Vneshnee Treniye Pri Prokatke; Metallurgiya: Moscow, Russia, 1973; p. 288. (In Russian) [Google Scholar]

- Wusatowski, Z. Fundamentals of rolling processes. In Fundamentals of Rolling; SLASK: Katowice, Poland, 1969; Chapter 3; pp. 69–202. [Google Scholar]

- Potapkin, V.F. Metod Poleyi Liniyi Skol’zheniya V Teorii Prokatki Shirokih Polos: Monograph; DDMA: Kramatorsk, Ukraine, 2005; p. 316. ISBN 966-379-019-9. (In Russian) [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).